Brake line SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 362 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-5

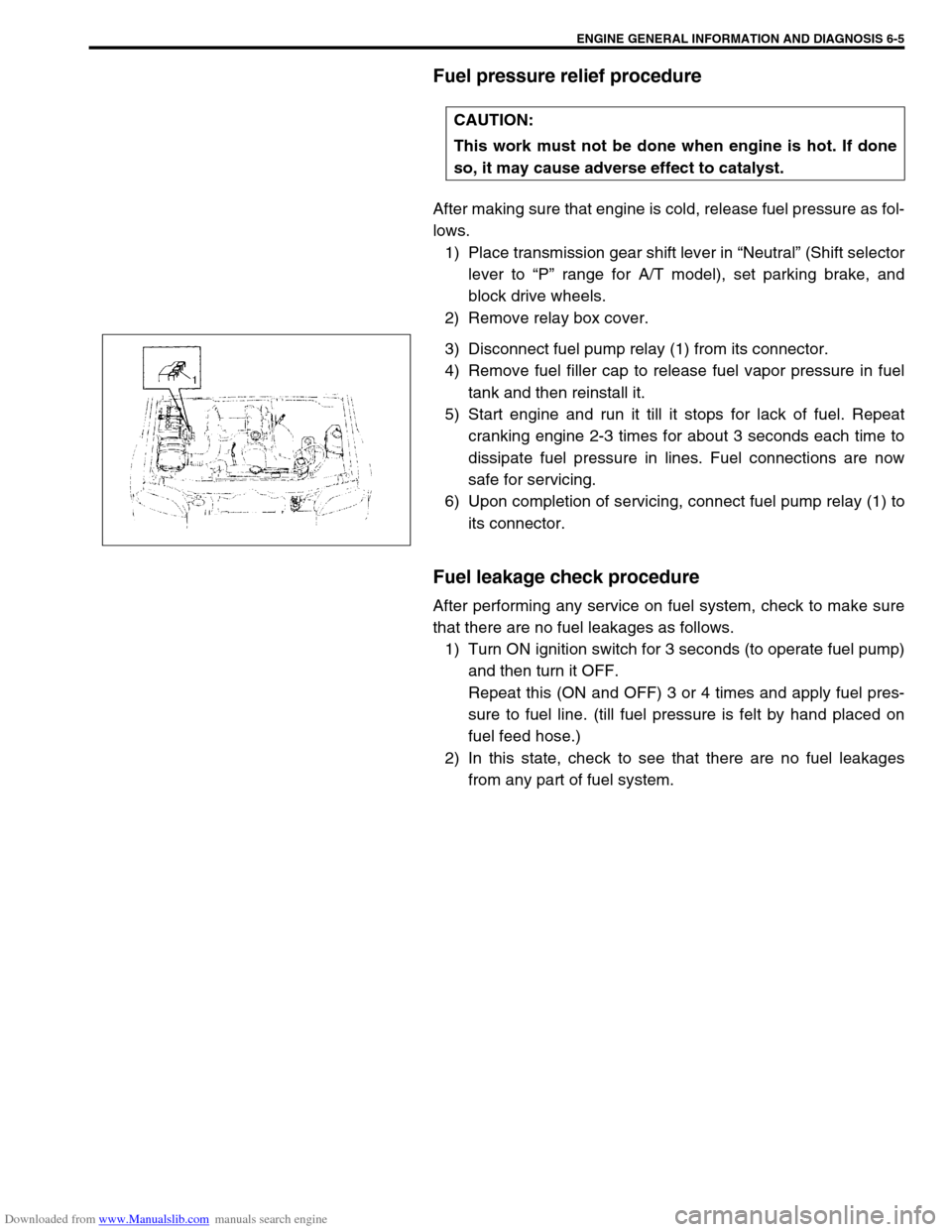

Fuel pressure relief procedure

After making sure that engine is cold, release fuel pressure as fol-

lows.

1) Place transmission gear shift lever in “Neutral” (Shift selector

lever to “P” range for A/T model), set parking brake, and

block drive wheels.

2) Remove relay box cover.

3) Disconnect fuel pump relay (1) from its connector.

4) Remove fuel filler cap to release fuel vapor pressure in fuel

tank and then reinstall it.

5) Start engine and run it till it stops for lack of fuel. Repeat

cranking engine 2-3 times for about 3 seconds each time to

dissipate fuel pressure in lines. Fuel connections are now

safe for servicing.

6) Upon completion of servicing, connect fuel pump relay (1) to

its connector.

Fuel leakage check procedure

After performing any service on fuel system, check to make sure

that there are no fuel leakages as follows.

1) Turn ON ignition switch for 3 seconds (to operate fuel pump)

and then turn it OFF.

Repeat this (ON and OFF) 3 or 4 times and apply fuel pres-

sure to fuel line. (till fuel pressure is felt by hand placed on

fuel feed hose.)

2) In this state, check to see that there are no fuel leakages

from any part of fuel system. CAUTION:

This work must not be done when engine is hot. If done

so, it may cause adverse effect to catalyst.

Page 381 of 687

Downloaded from www.Manualslib.com manuals search engine 6-24 ENGINE GENERAL INFORMATION AND DIAGNOSIS

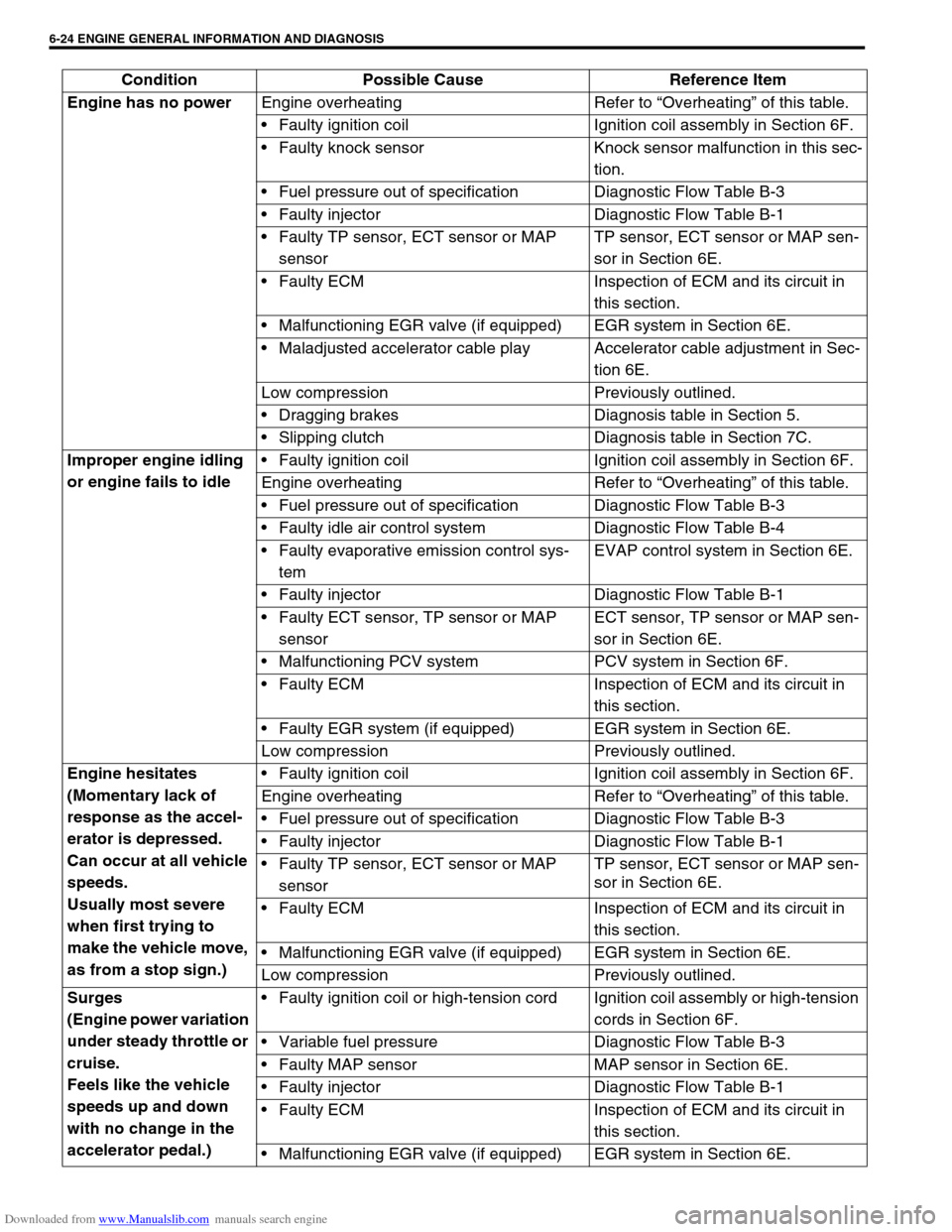

Engine has no power

Engine overheating Refer to “Overheating” of this table.

Faulty ignition coil Ignition coil assembly in Section 6F.

Faulty knock sensor Knock sensor malfunction in this sec-

tion.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty injector Diagnostic Flow Table B-1

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Maladjusted accelerator cable play Accelerator cable adjustment in Sec-

tion 6E.

Low compression Previously outlined.

Dragging brakes Diagnosis table in Section 5.

Slipping clutch Diagnosis table in Section 7C.

Improper engine idling

or engine fails to idleFaulty ignition coil Ignition coil assembly in Section 6F.

Engine overheating Refer to “Overheating” of this table.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty idle air control system Diagnostic Flow Table B-4

Faulty evaporative emission control sys-

temEVAP control system in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECT sensor, TP sensor or MAP

sensorECT sensor, TP sensor or MAP sen-

sor in Section 6E.

Malfunctioning PCV system PCV system in Section 6F.

Faulty ECM Inspection of ECM and its circuit in

this section.

Faulty EGR system (if equipped) EGR system in Section 6E.

Low compression Previously outlined.

Engine hesitates

(Momentary lack of

response as the accel-

erator is depressed.

Can occur at all vehicle

speeds.

Usually most severe

when first trying to

make the vehicle move,

as from a stop sign.)Faulty ignition coil Ignition coil assembly in Section 6F.

Engine overheating Refer to “Overheating” of this table.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty injector Diagnostic Flow Table B-1

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Low compression Previously outlined.

Surges

(Engine power variation

under steady throttle or

cruise.

Feels like the vehicle

speeds up and down

with no change in the

accelerator pedal.)Faulty ignition coil or high-tension cord Ignition coil assembly or high-tension

cords in Section 6F.

Variable fuel pressure Diagnostic Flow Table B-3

Faulty MAP sensor MAP sensor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E. Condition Possible Cause Reference Item

Page 382 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-25

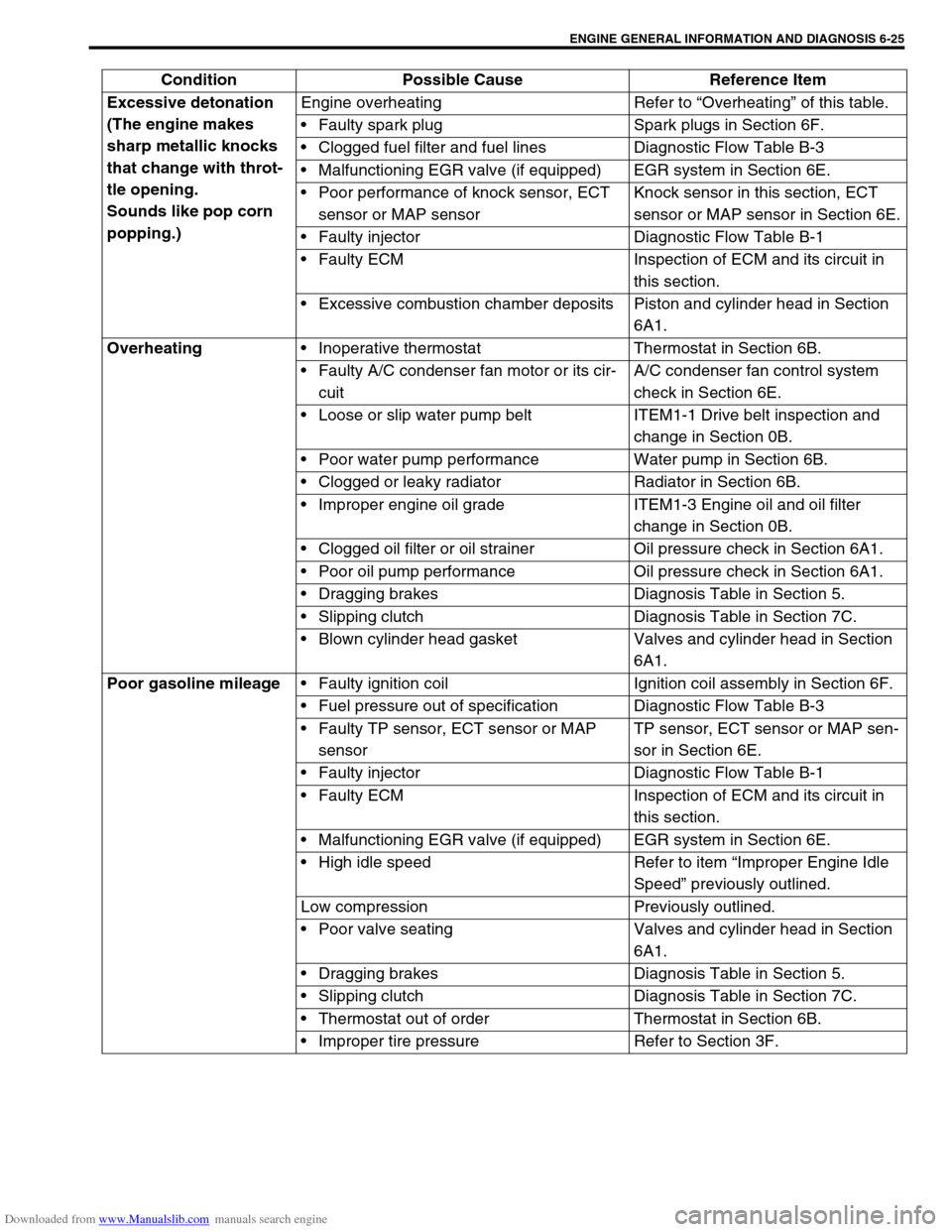

Excessive detonation

(The engine makes

sharp metallic knocks

that change with throt-

tle opening.

Sounds like pop corn

popping.)Engine overheating Refer to “Overheating” of this table.

Faulty spark plug Spark plugs in Section 6F.

Clogged fuel filter and fuel lines Diagnostic Flow Table B-3

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

Poor performance of knock sensor, ECT

sensor or MAP sensorKnock sensor in this section, ECT

sensor or MAP sensor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Excessive combustion chamber deposits Piston and cylinder head in Section

6A1.

Overheating

Inoperative thermostat Thermostat in Section 6B.

Faulty A/C condenser fan motor or its cir-

cuitA/C condenser fan control system

check in Section 6E.

Loose or slip water pump belt ITEM1-1 Drive belt inspection and

change in Section 0B.

Poor water pump performance Water pump in Section 6B.

Clogged or leaky radiator Radiator in Section 6B.

Improper engine oil grade ITEM1-3 Engine oil and oil filter

change in Section 0B.

Clogged oil filter or oil strainer Oil pressure check in Section 6A1.

Poor oil pump performance Oil pressure check in Section 6A1.

Dragging brakes Diagnosis Table in Section 5.

Slipping clutch Diagnosis Table in Section 7C.

Blown cylinder head gasket Valves and cylinder head in Section

6A1.

Poor gasoline mileage

Faulty ignition coil Ignition coil assembly in Section 6F.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty TP sensor, ECT sensor or MAP

sensorTP sensor, ECT sensor or MAP sen-

sor in Section 6E.

Faulty injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E.

High idle speed Refer to item “Improper Engine Idle

Speed” previously outlined.

Low compression Previously outlined.

Poor valve seating Valves and cylinder head in Section

6A1.

Dragging brakes Diagnosis Table in Section 5.

Slipping clutch Diagnosis Table in Section 7C.

Thermostat out of order Thermostat in Section 6B.

Improper tire pressure Refer to Section 3F. Condition Possible Cause Reference Item

Page 487 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-6 ENGINE MECHANICAL (M13 ENGINE)

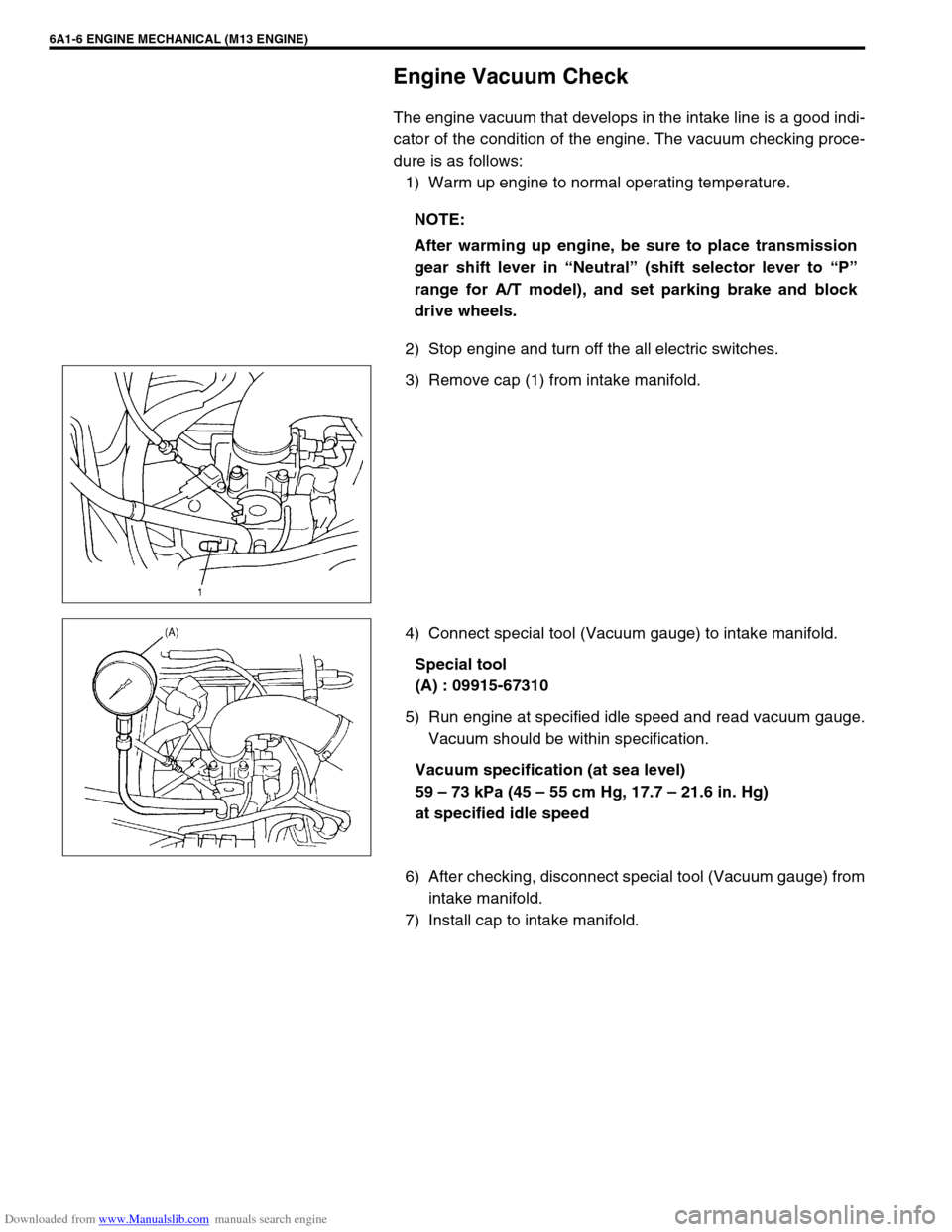

Engine Vacuum Check

The engine vacuum that develops in the intake line is a good indi-

cator of the condition of the engine. The vacuum checking proce-

dure is as follows:

1) Warm up engine to normal operating temperature.

2) Stop engine and turn off the all electric switches.

3) Remove cap (1) from intake manifold.

4) Connect special tool (Vacuum gauge) to intake manifold.

Special tool

(A) : 09915-67310

5) Run engine at specified idle speed and read vacuum gauge.

Vacuum should be within specification.

Vacuum specification (at sea level)

59 – 73 kPa (45 – 55 cm Hg, 17.7 – 21.6 in. Hg)

at specified idle speed

6) After checking, disconnect special tool (Vacuum gauge) from

intake manifold.

7) Install cap to intake manifold.NOTE:

After warming up engine, be sure to place transmission

gear shift lever in “Neutral” (shift selector lever to “P”

range for A/T model), and set parking brake and block

drive wheels.

Page 677 of 687

Downloaded from www.Manualslib.com manuals search engine 6H-10 CHARGING SYSTEM

1) Set parking brake and place automatic transmission in

PARK (NEUTRAL on manual transmission). Turn off ignition,

turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add dis-

tilled water.

3) Attach end of one jumper cable to positive terminal of

booster battery and the other end of the same cable to posi-

tive terminal of discharged battery. (Use 12-volt battery only

to jump start engine).

4) Attach one end of the remaining negative cable to negative

terminal of booster battery, and the other end to a solid

engine ground (such as exhaust manifold) at least 45 cm (18

in.) away from battery of vehicle being started.

5) Start engine of vehicle with booster battery and turn off elec-

trical accessories. Then start engine of the vehicle with dis-

charged battery.

6) Disconnect jumper cables in the exact reverse order.

WITH CHARGING EQUIPMENT

WARNING:

Departure from these conditions or procedure

described below could result in:

–Serious personal injury (particularly to eyes) or

property damage from such causes as battery explo-

sion, battery acid, or electrical burns.

–Damage to electronic components of either vehicle.

Remove rings, watches, and other jewelry. Wear

approved eye protection.

Be careful so that metal tools or jumper cables do not

contact positive battery terminal (or metal in contact

with it) and any other metal on vehicle, because a short

circuit could occur.

WARNING:

Do not connect negative cable directly to negative termi-

nal of dead battery.

CAUTION:

When jump starting engine with charging equipment, be

sure equipment used is 12-volt and negative ground. Do

not use 24-volt charging equipment. Using such equip-

ment can cause serious damage to electrical system or

electronic parts.