check oil SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 103 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-42 AIR CONDITIONING (OPTIONAL)

INSPECTION

Check clutch plate and clutch pulley for leaks of compressor

oil.

Check clutch bearing of compressor pulley for noise, wear

and grease leakage.

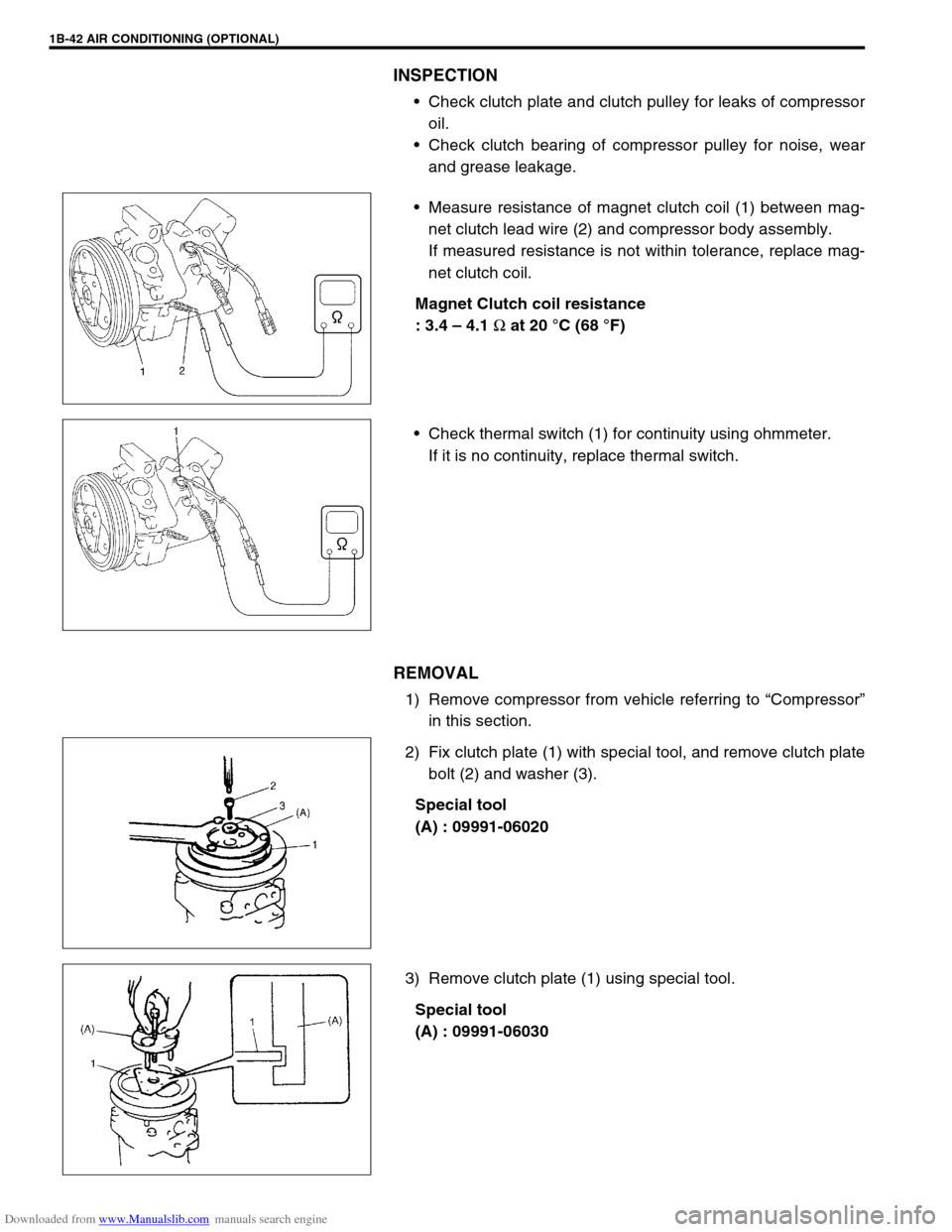

Measure resistance of magnet clutch coil (1) between mag-

net clutch lead wire (2) and compressor body assembly.

If measured resistance is not within tolerance, replace mag-

net clutch coil.

Magnet Clutch coil resistance

: 3.4 – 4.1

Ω at 20 °C (68 °F)

Check thermal switch (1) for continuity using ohmmeter.

If it is no continuity, replace thermal switch.

REMOVAL

1) Remove compressor from vehicle referring to “Compressor”

in this section.

2) Fix clutch plate (1) with special tool, and remove clutch plate

bolt (2) and washer (3).

Special tool

(A) : 09991-06020

3) Remove clutch plate (1) using special tool.

Special tool

(A) : 09991-06030

Page 112 of 687

Downloaded from www.Manualslib.com manuals search engine STEERING, SUSPENSION, WHEELS AND TIRES 3-3

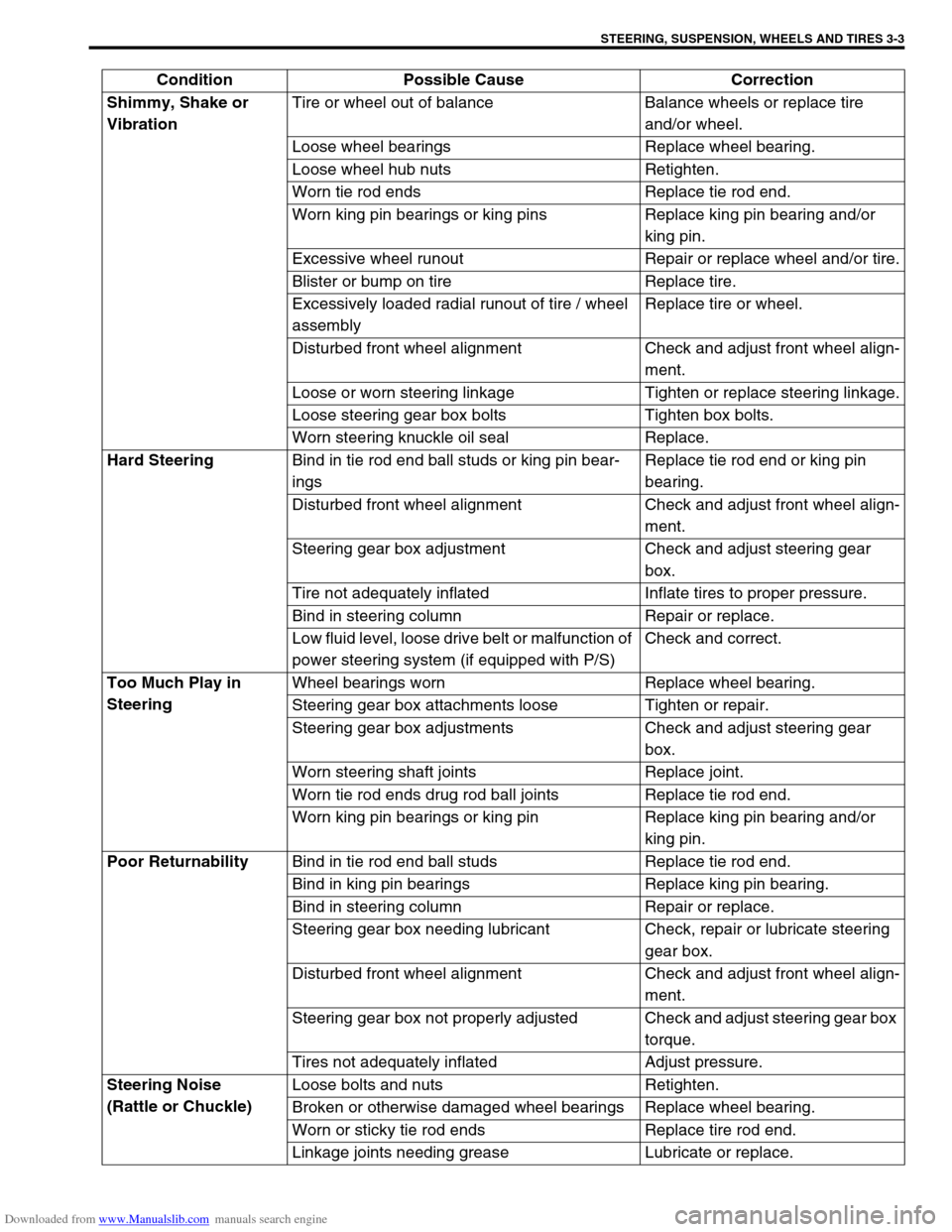

Shimmy, Shake or

VibrationTire or wheel out of balance Balance wheels or replace tire

and/or wheel.

Loose wheel bearings Replace wheel bearing.

Loose wheel hub nuts Retighten.

Worn tie rod ends Replace tie rod end.

Worn king pin bearings or king pins Replace king pin bearing and/or

king pin.

Excessive wheel runout Repair or replace wheel and/or tire.

Blister or bump on tire Replace tire.

Excessively loaded radial runout of tire / wheel

assemblyReplace tire or wheel.

Disturbed front wheel alignment Check and adjust front wheel align-

ment.

Loose or worn steering linkage Tighten or replace steering linkage.

Loose steering gear box bolts Tighten box bolts.

Worn steering knuckle oil seal Replace.

Hard Steering

Bind in tie rod end ball studs or king pin bear-

ingsReplace tie rod end or king pin

bearing.

Disturbed front wheel alignment Check and adjust front wheel align-

ment.

Steering gear box adjustment Check and adjust steering gear

box.

Tire not adequately inflated Inflate tires to proper pressure.

Bind in steering column Repair or replace.

Low fluid level, loose drive belt or malfunction of

power steering system (if equipped with P/S)Check and correct.

Too Much Play in

SteeringWheel bearings worn Replace wheel bearing.

Steering gear box attachments loose Tighten or repair.

Steering gear box adjustments Check and adjust steering gear

box.

Worn steering shaft joints Replace joint.

Worn tie rod ends drug rod ball joints Replace tie rod end.

Worn king pin bearings or king pin Replace king pin bearing and/or

king pin.

Poor Returnability

Bind in tie rod end ball studs Replace tie rod end.

Bind in king pin bearings Replace king pin bearing.

Bind in steering column Repair or replace.

Steering gear box needing lubricant Check, repair or lubricate steering

gear box.

Disturbed front wheel alignment Check and adjust front wheel align-

ment.

Steering gear box not properly adjusted Check and adjust steering gear box

torque.

Tires not adequately inflated Adjust pressure.

Steering Noise

(Rattle or Chuckle)Loose bolts and nuts Retighten.

Broken or otherwise damaged wheel bearings Replace wheel bearing.

Worn or sticky tie rod ends Replace tire rod end.

Linkage joints needing grease Lubricate or replace. Condition Possible Cause Correction

Page 122 of 687

Downloaded from www.Manualslib.com manuals search engine STEERING GEAR BOX (MANUAL TYPE) AND LINKAGE 3B-1

6F1

6F2

6G

6H

3B

7C1

7D

7E

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3B

STEERING GEAR BOX (MANUAL TYPE)

AND LINKAGE

CONTENTS

General Description ....................................... 3B-2

Diagnosis ........................................................ 3B-3

Diagnosis Table ........................................... 3B-3

Steering Wheel Play Check ......................... 3B-3

Tie Rod And Drag Rod Check ...................... 3B-3

Steering Gear Box Oil Level Check ............. 3B-4

Adjustment of Worm Shaft Starting Torque . 3B-4On-Vehicle Service ........................................ 3B-6

Steering Gear Box ....................................... 3B-6

Tie Rod And Drag Rod................................. 3B-8

Tightening Torque Specifications .............. 3B-10

Required Service Material ........................... 3B-10

Special Tools ................................................ 3B-10 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and negative cable is disconnected from the battery. Otherwise, the system may

be activated by reserve energy in the Sensing and Diagnostic Module (SDM)

NOTE:

All steering gear fasteners are important attaching parts in that they could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with one

of the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified dur-

ing reassembly to assure proper retention of these parts.

Page 125 of 687

Downloaded from www.Manualslib.com manuals search engine 3B-4 STEERING GEAR BOX (MANUAL TYPE) AND LINKAGE

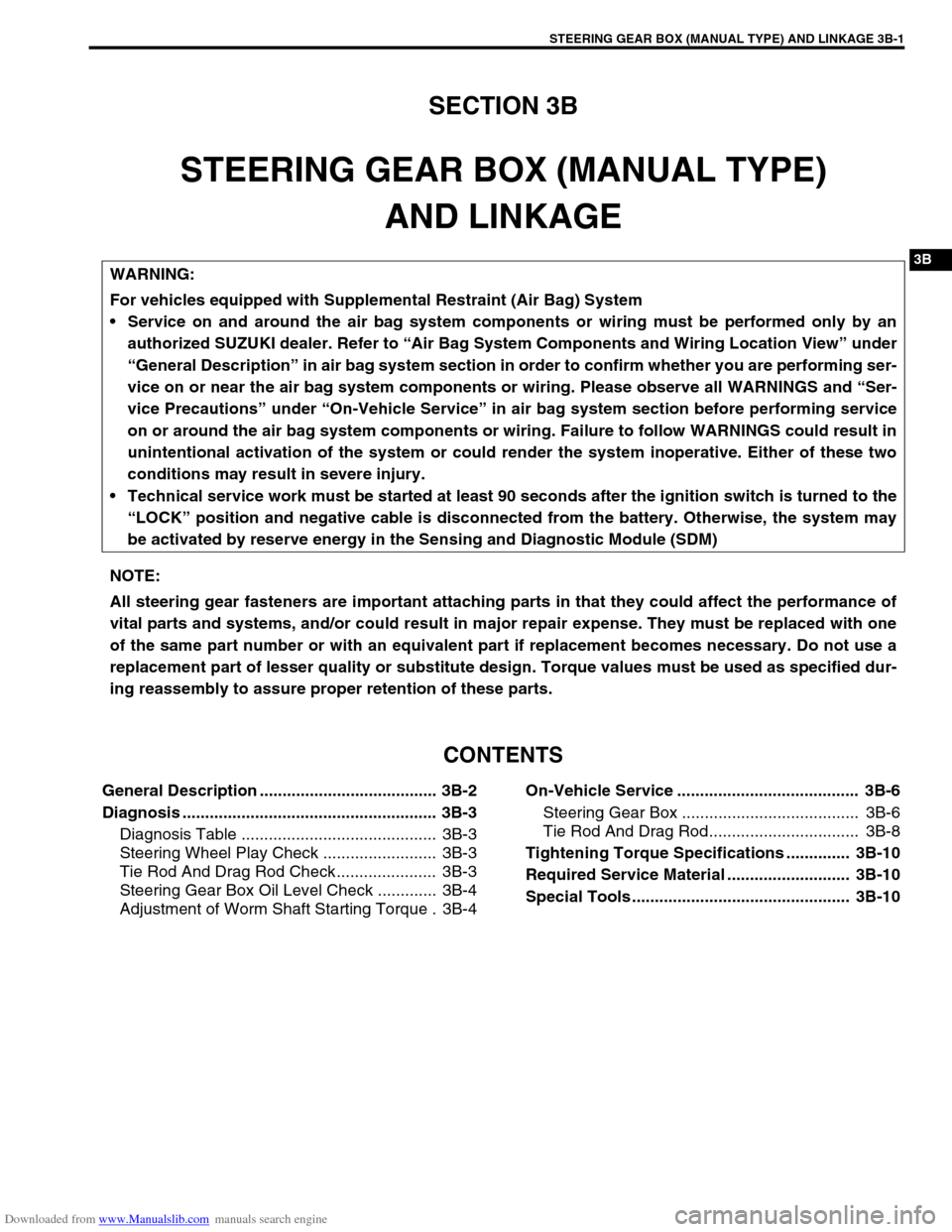

Steering Gear Box Oil Level Check

Oil surface should be up to the level as shown in figure. If not, add

prescribed gear oil, SAE 90.

Steering gear box oil level

“a” : 23 mm (0.91 in.)

Apply sealant to thread parts of breathing plug and tighten breath-

ing plug to specified torque.

(A) : Sealant 99000-31110

Tightening torque

Breathing plug

(a) : 4 N·m (0.4 kg-m, 3.0 lb-ft)

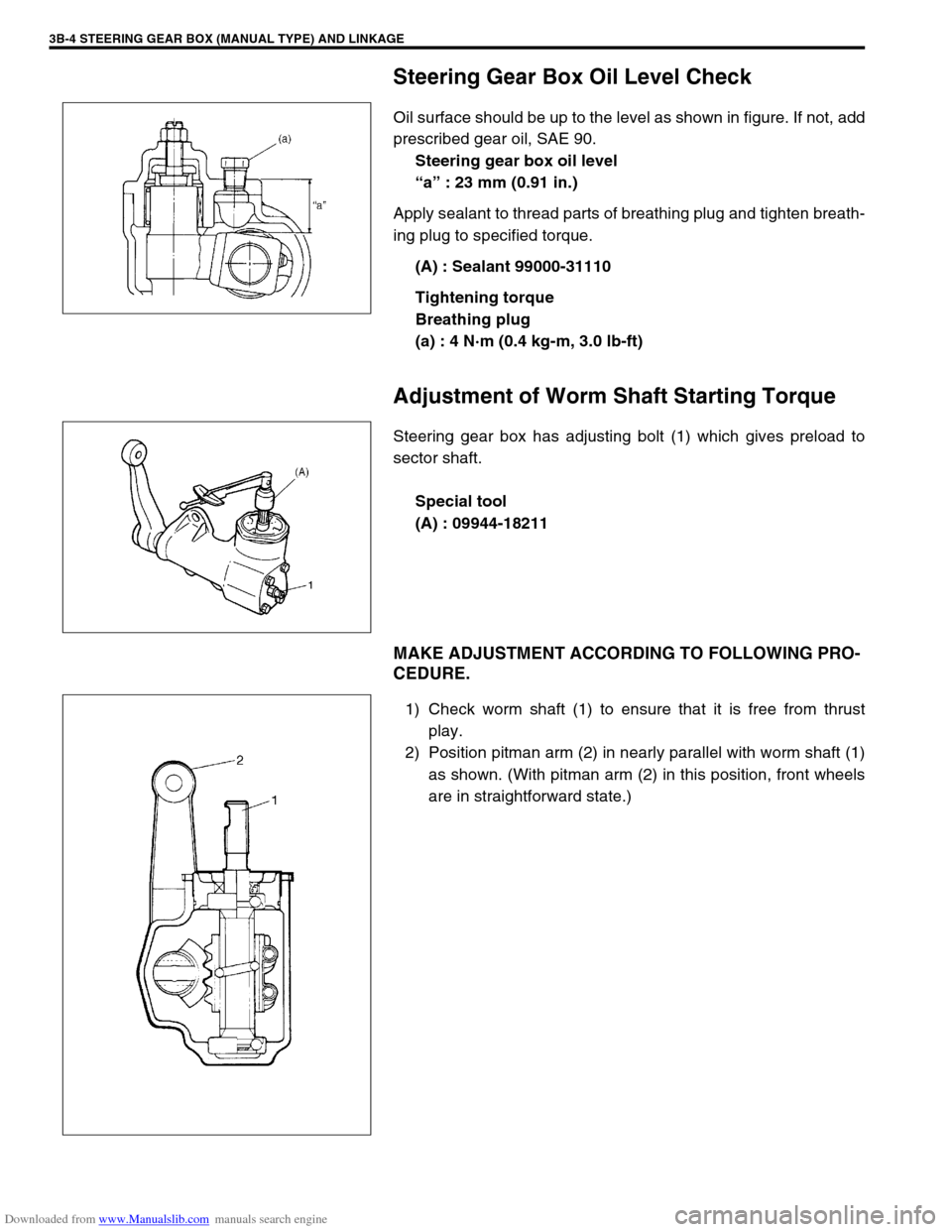

Adjustment of Worm Shaft Starting Torque

Steering gear box has adjusting bolt (1) which gives preload to

sector shaft.

Special tool

(A) : 09944-18211

MAKE ADJUSTMENT ACCORDING TO FOLLOWING PRO-

CEDURE.

1) Check worm shaft (1) to ensure that it is free from thrust

play.

2) Position pitman arm (2) in nearly parallel with worm shaft (1)

as shown. (With pitman arm (2) in this position, front wheels

are in straightforward state.)

Page 131 of 687

Downloaded from www.Manualslib.com manuals search engine 3B-10 STEERING GEAR BOX (MANUAL TYPE) AND LINKAGE

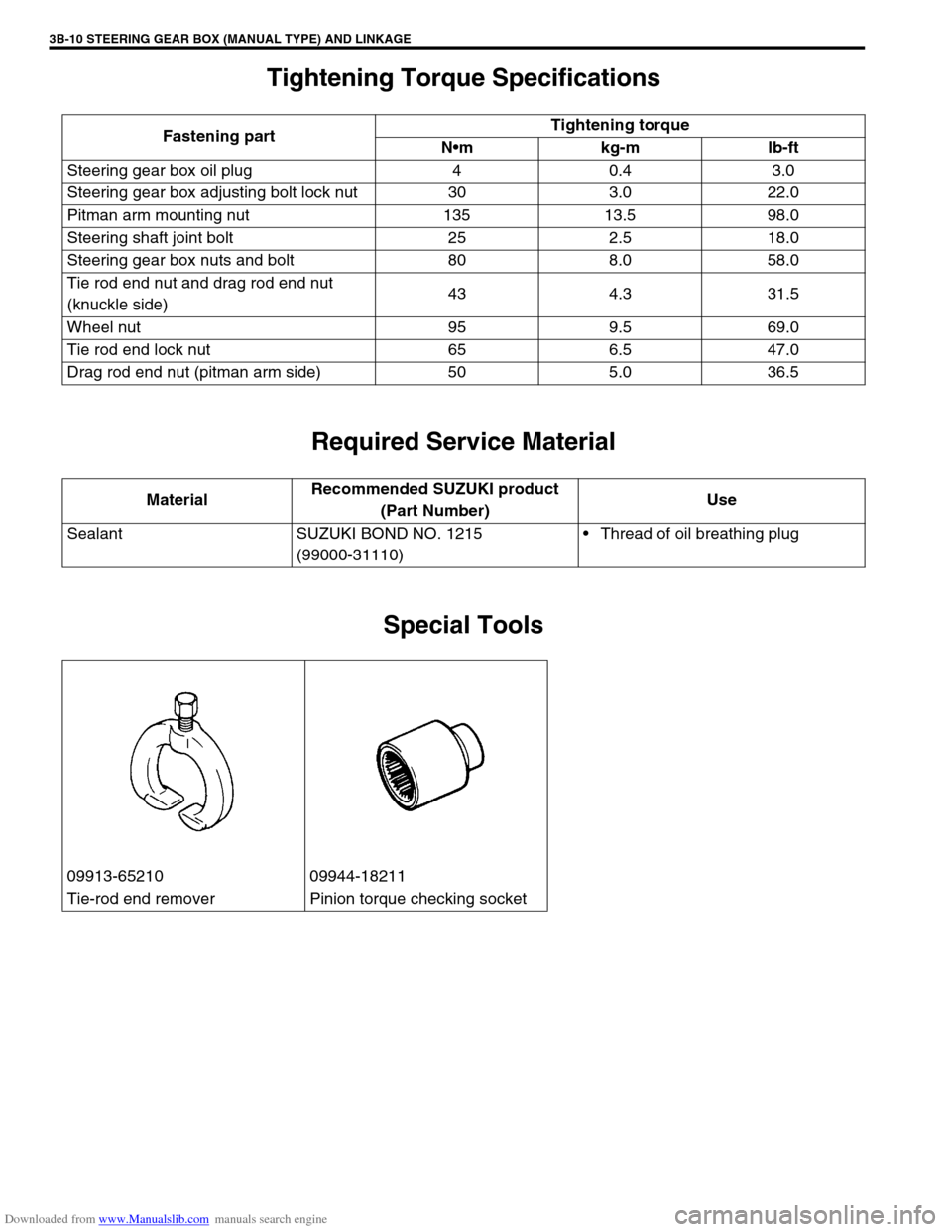

Tightening Torque Specifications

Required Service Material

Special Tools

Fastening partTightening torque

Nm kg-m lb-ft

Steering gear box oil plug 4 0.4 3.0

Steering gear box adjusting bolt lock nut 30 3.0 22.0

Pitman arm mounting nut 135 13.5 98.0

Steering shaft joint bolt 25 2.5 18.0

Steering gear box nuts and bolt 80 8.0 58.0

Tie rod end nut and drag rod end nut

(knuckle side)43 4.3 31.5

Wheel nut 95 9.5 69.0

Tie rod end lock nut 65 6.5 47.0

Drag rod end nut (pitman arm side) 50 5.0 36.5

MaterialRecommended SUZUKI product

(Part Number)Use

Sealant SUZUKI BOND NO. 1215

(99000-31110)Thread of oil breathing plug

09913-65210 09944-18211

Tie-rod end remover Pinion torque checking socket

Page 137 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-6 POWER STEERING (P/S) SYSTEM (If equipped)

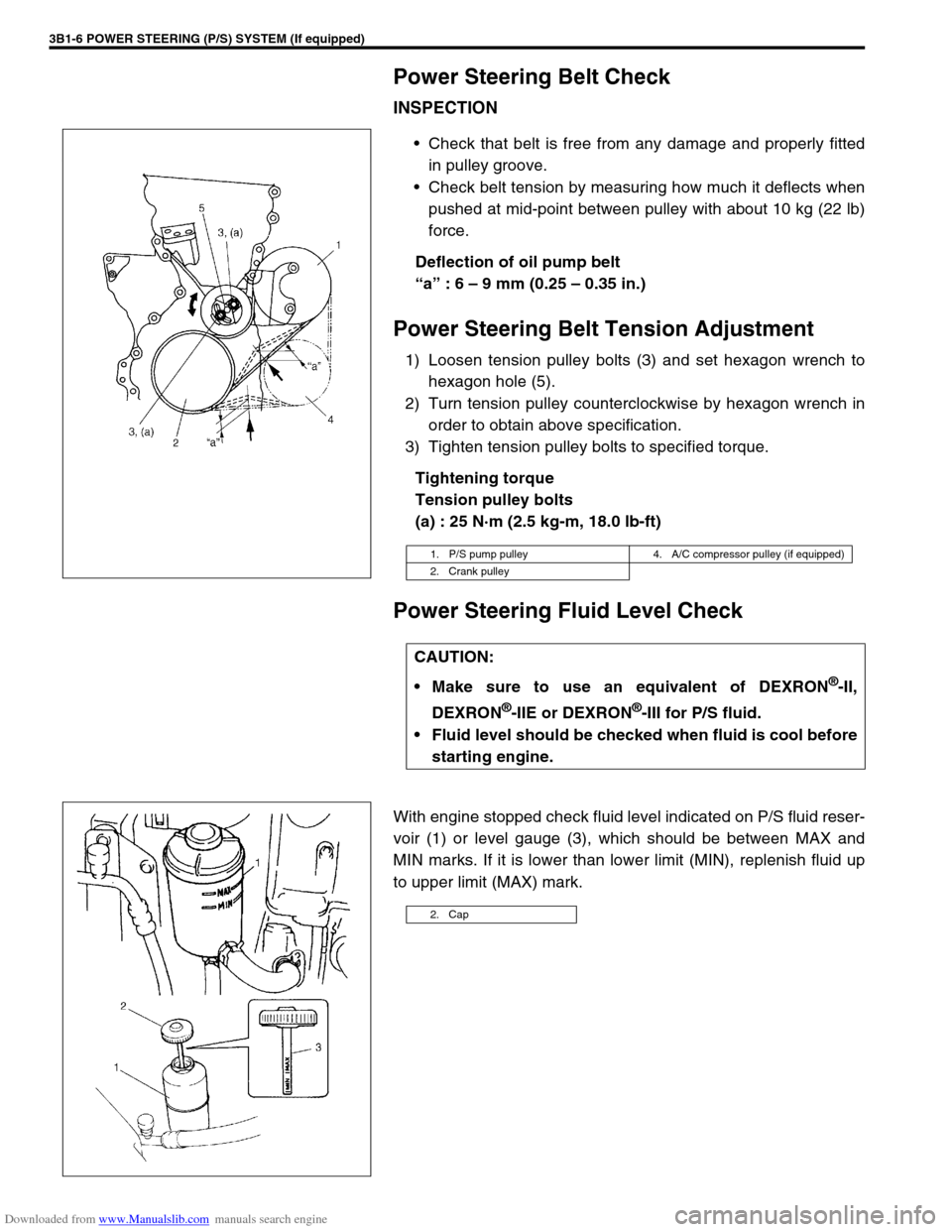

Power Steering Belt Check

INSPECTION

Check that belt is free from any damage and properly fitted

in pulley groove.

Check belt tension by measuring how much it deflects when

pushed at mid-point between pulley with about 10 kg (22 lb)

force.

Deflection of oil pump belt

“a” : 6 – 9 mm (0.25 – 0.35 in.)

Power Steering Belt Tension Adjustment

1) Loosen tension pulley bolts (3) and set hexagon wrench to

hexagon hole (5).

2) Turn tension pulley counterclockwise by hexagon wrench in

order to obtain above specification.

3) Tighten tension pulley bolts to specified torque.

Tightening torque

Tension pulley bolts

(a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

Power Steering Fluid Level Check

With engine stopped check fluid level indicated on P/S fluid reser-

voir (1) or level gauge (3), which should be between MAX and

MIN marks. If it is lower than lower limit (MIN), replenish fluid up

to upper limit (MAX) mark.

1. P/S pump pulley 4. A/C compressor pulley (if equipped)

2. Crank pulley

CAUTION:

Make sure to use an equivalent of DEXRON

®-II,

DEXRON

®-IIE or DEXRON®-III for P/S fluid.

Fluid level should be checked when fluid is cool before

starting engine.

2. Cap

Page 141 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-10 POWER STEERING (P/S) SYSTEM (If equipped)

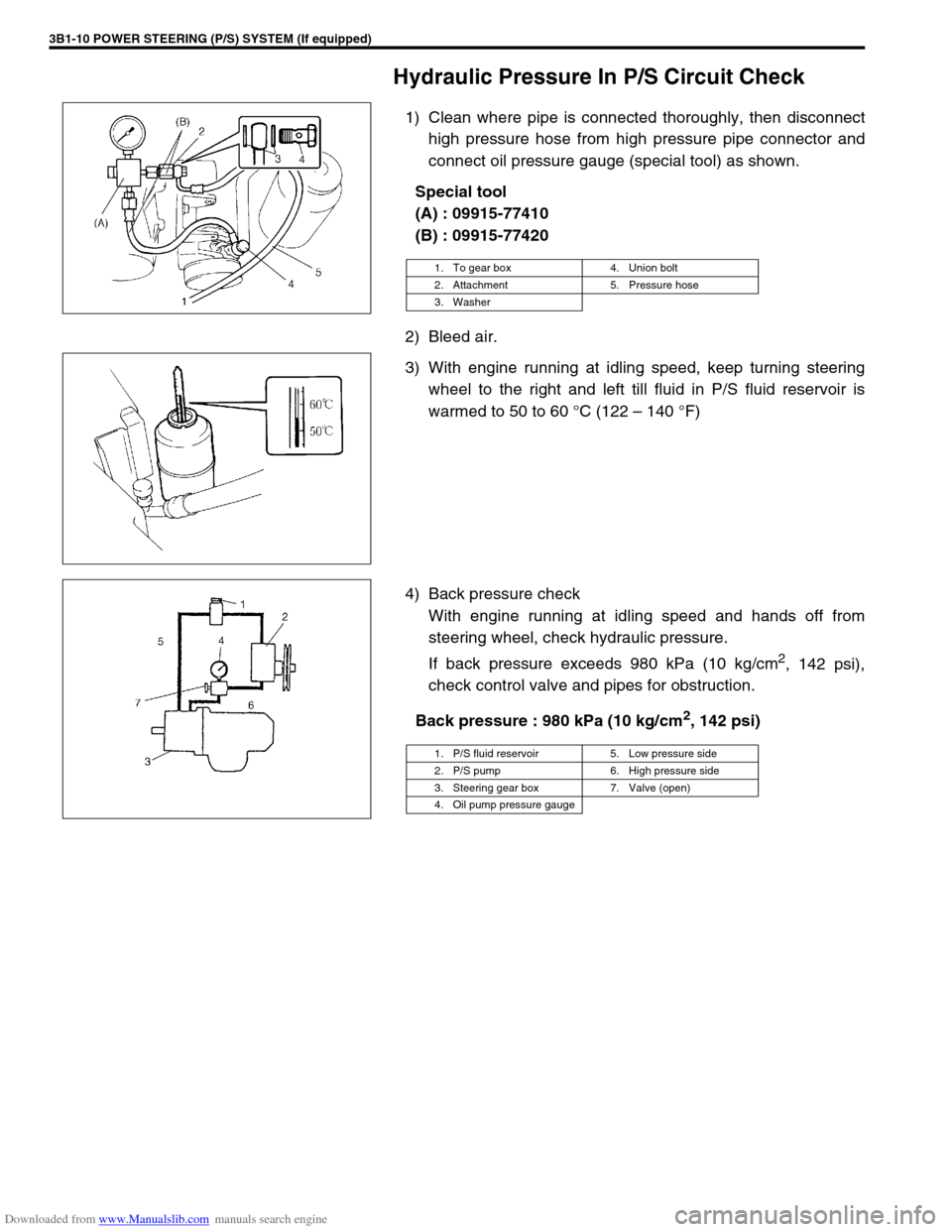

Hydraulic Pressure In P/S Circuit Check

1) Clean where pipe is connected thoroughly, then disconnect

high pressure hose from high pressure pipe connector and

connect oil pressure gauge (special tool) as shown.

Special tool

(A) : 09915-77410

(B) : 09915-77420

2) Bleed air.

3) With engine running at idling speed, keep turning steering

wheel to the right and left till fluid in P/S fluid reservoir is

warmed to 50 to 60 °C (122 – 140 °F)

4) Back pressure check

With engine running at idling speed and hands off from

steering wheel, check hydraulic pressure.

If back pressure exceeds 980 kPa (10 kg/cm

2, 142 psi),

check control valve and pipes for obstruction.

Back pressure : 980 kPa (10 kg/cm

2, 142 psi)

1. To gear box 4. Union bolt

2. Attachment 5. Pressure hose

3. Washer

1. P/S fluid reservoir 5. Low pressure side

2. P/S pump 6. High pressure side

3. Steering gear box 7. Valve (open)

4. Oil pump pressure gauge

Page 142 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-11

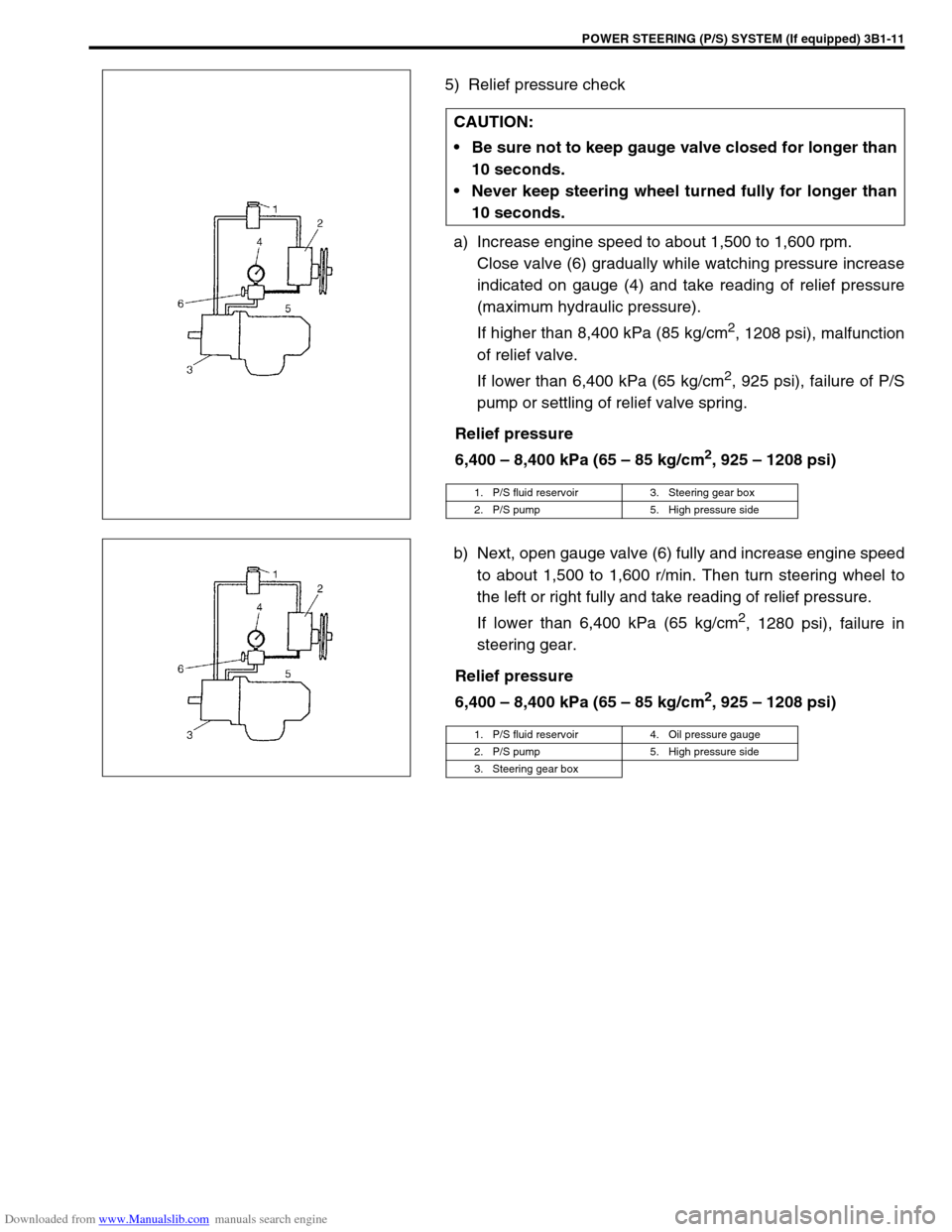

5) Relief pressure check

a) Increase engine speed to about 1,500 to 1,600 rpm.

Close valve (6) gradually while watching pressure increase

indicated on gauge (4) and take reading of relief pressure

(maximum hydraulic pressure).

If higher than 8,400 kPa (85 kg/cm

2, 1208 psi), malfunction

of relief valve.

If lower than 6,400 kPa (65 kg/cm

2, 925 psi), failure of P/S

pump or settling of relief valve spring.

Relief pressure

6,400 – 8,400 kPa (65 – 85 kg/cm

2, 925 – 1208 psi)

b) Next, open gauge valve (6) fully and increase engine speed

to about 1,500 to 1,600 r/min. Then turn steering wheel to

the left or right fully and take reading of relief pressure.

If lower than 6,400 kPa (65 kg/cm

2, 1280 psi), failure in

steering gear.

Relief pressure

6,400 – 8,400 kPa (65 – 85 kg/cm

2, 925 – 1208 psi) CAUTION:

Be sure not to keep gauge valve closed for longer than

10 seconds.

Never keep steering wheel turned fully for longer than

10 seconds.

1. P/S fluid reservoir 3. Steering gear box

2. P/S pump 5. High pressure side

1. P/S fluid reservoir 4. Oil pressure gauge

2. P/S pump 5. High pressure side

3. Steering gear box

Page 144 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-13

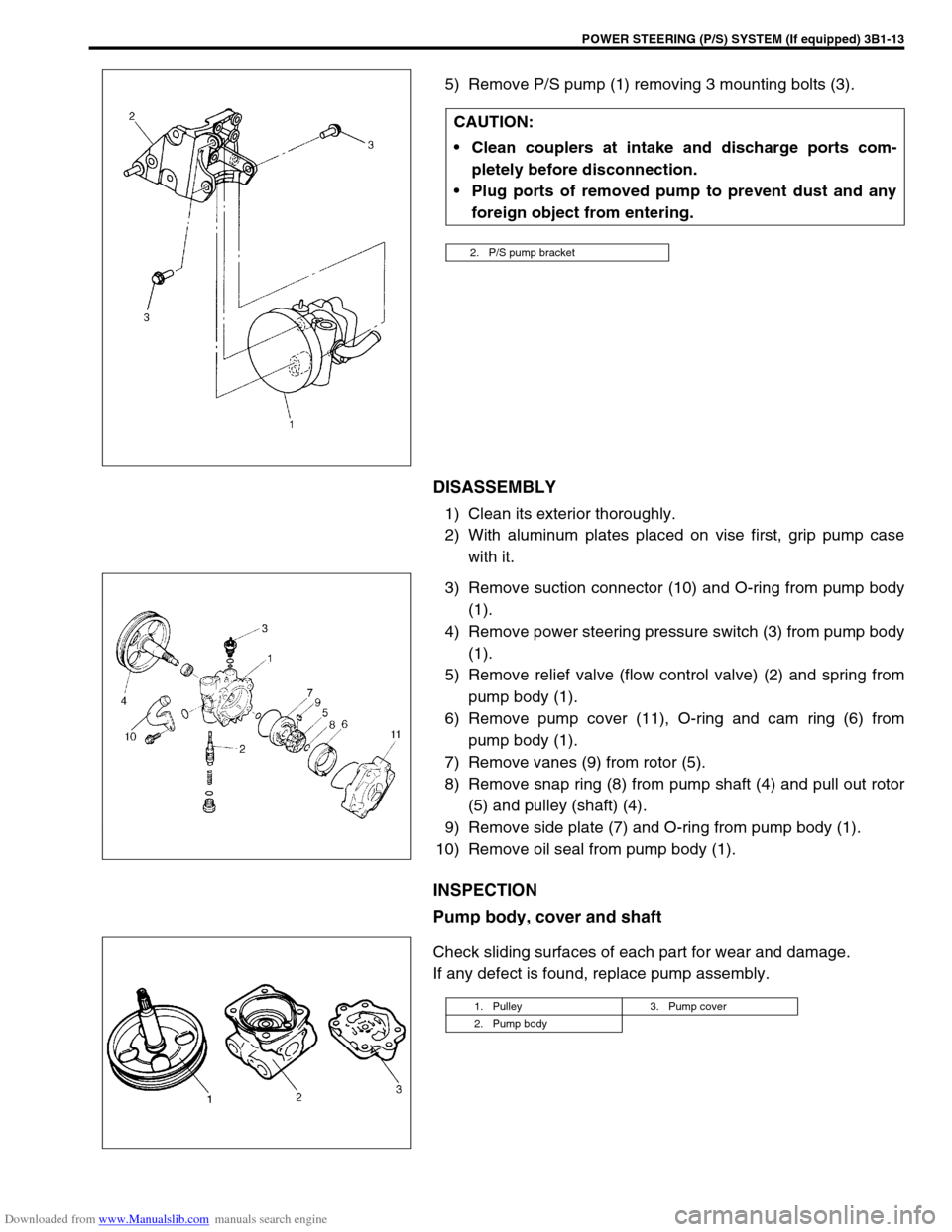

5) Remove P/S pump (1) removing 3 mounting bolts (3).

DISASSEMBLY

1) Clean its exterior thoroughly.

2) With aluminum plates placed on vise first, grip pump case

with it.

3) Remove suction connector (10) and O-ring from pump body

(1).

4) Remove power steering pressure switch (3) from pump body

(1).

5) Remove relief valve (flow control valve) (2) and spring from

pump body (1).

6) Remove pump cover (11), O-ring and cam ring (6) from

pump body (1).

7) Remove vanes (9) from rotor (5).

8) Remove snap ring (8) from pump shaft (4) and pull out rotor

(5) and pulley (shaft) (4).

9) Remove side plate (7) and O-ring from pump body (1).

10) Remove oil seal from pump body (1).

INSPECTION

Pump body, cover and shaft

Check sliding surfaces of each part for wear and damage.

If any defect is found, replace pump assembly.CAUTION:

Clean couplers at intake and discharge ports com-

pletely before disconnection.

Plug ports of removed pump to prevent dust and any

foreign object from entering.

2. P/S pump bracket

1. Pulley 3. Pump cover

2. Pump body

Page 146 of 687

Downloaded from www.Manualslib.com manuals search engine POWER STEERING (P/S) SYSTEM (If equipped) 3B1-15

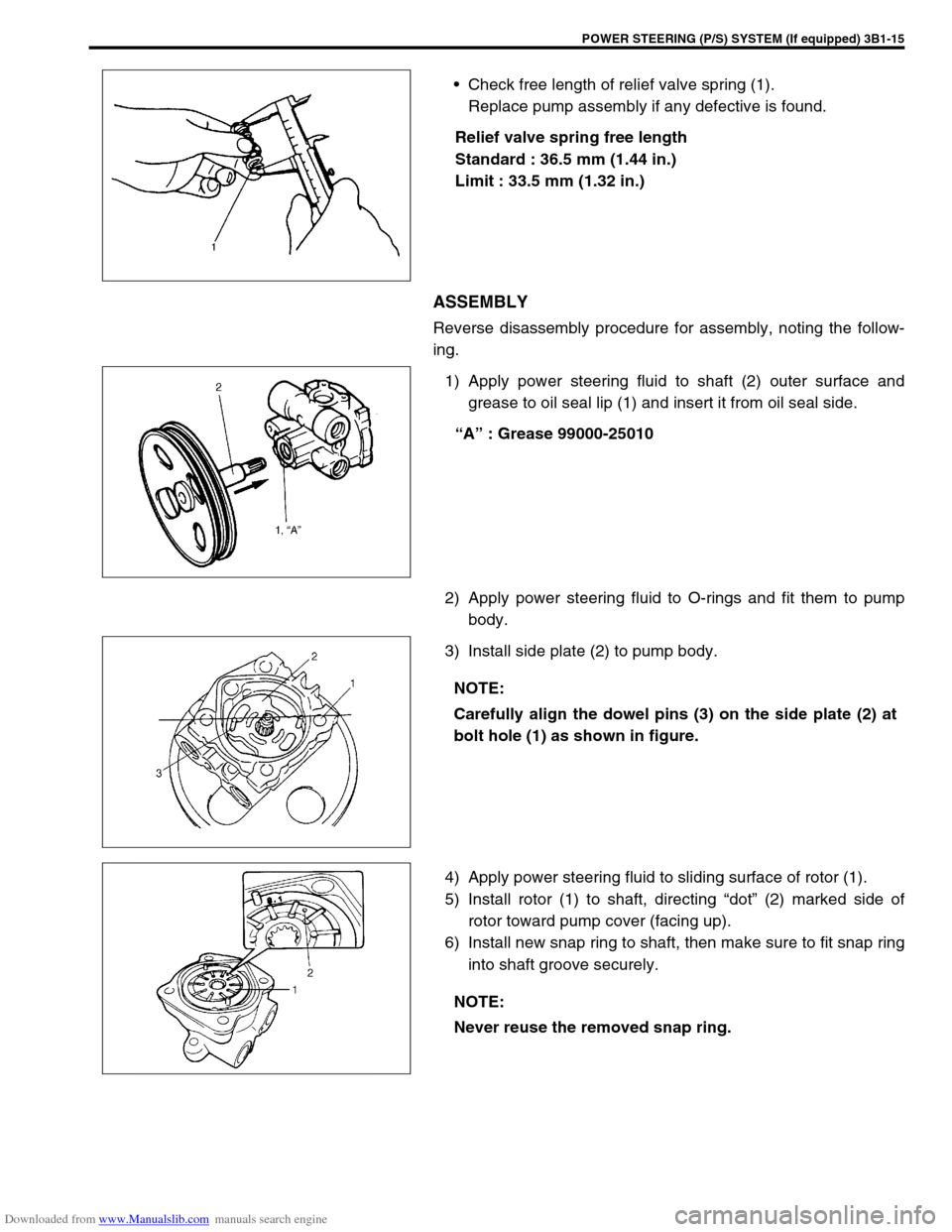

Check free length of relief valve spring (1).

Replace pump assembly if any defective is found.

Relief valve spring free length

Standard : 36.5 mm (1.44 in.)

Limit : 33.5 mm (1.32 in.)

ASSEMBLY

Reverse disassembly procedure for assembly, noting the follow-

ing.

1) Apply power steering fluid to shaft (2) outer surface and

grease to oil seal lip (1) and insert it from oil seal side.

“A” : Grease 99000-25010

2) Apply power steering fluid to O-rings and fit them to pump

body.

3) Install side plate (2) to pump body.

4) Apply power steering fluid to sliding surface of rotor (1).

5) Install rotor (1) to shaft, directing “dot” (2) marked side of

rotor toward pump cover (facing up).

6) Install new snap ring to shaft, then make sure to fit snap ring

into shaft groove securely.

NOTE:

Carefully align the dowel pins (3) on the side plate (2) at

bolt hole (1) as shown in figure.

NOTE:

Never reuse the removed snap ring.