drive SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 80 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-19

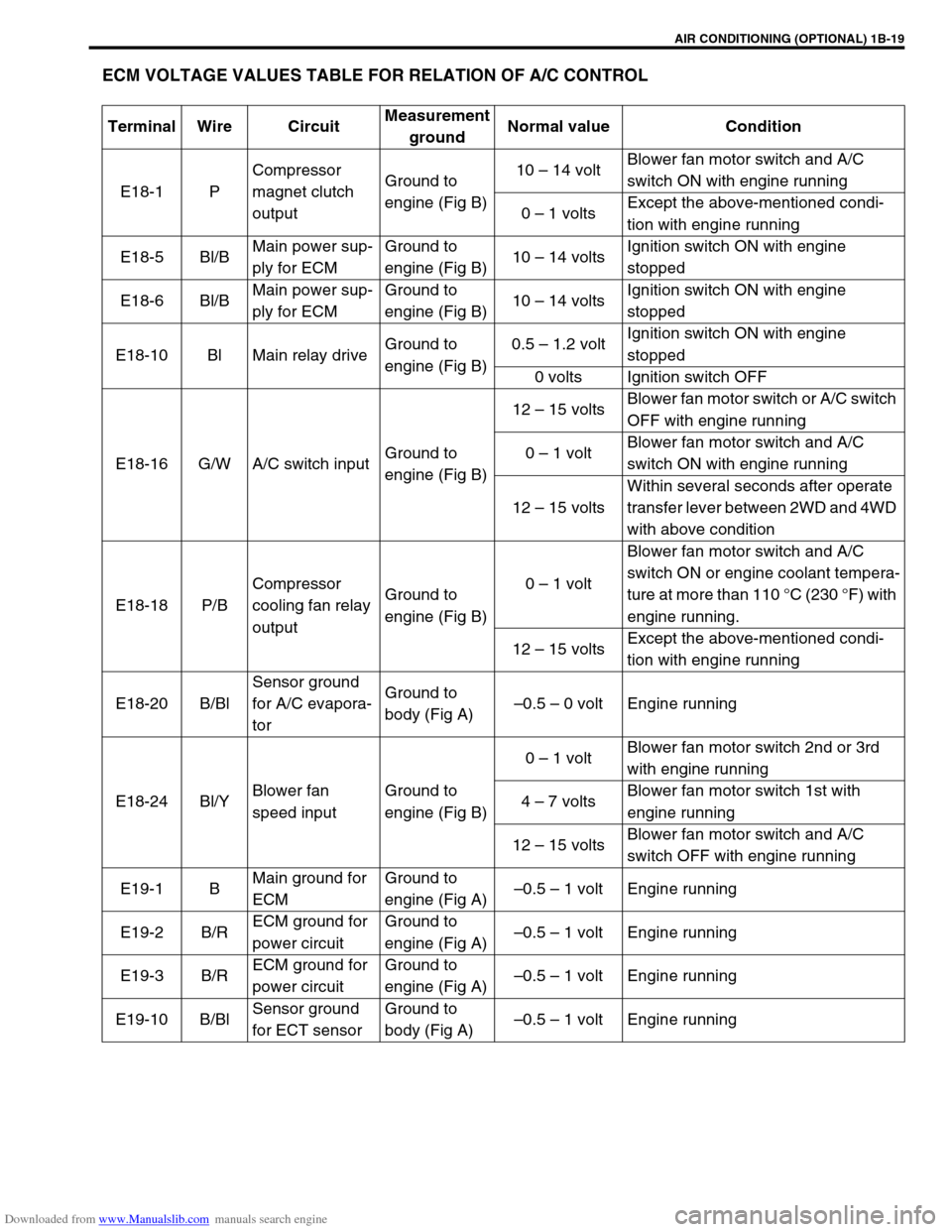

ECM VOLTAGE VALUES TABLE FOR RELATION OF A/C CONTROL

Terminal Wire CircuitMeasurement

groundNormal value Condition

E18-1 PCompressor

magnet clutch

outputGround to

engine (Fig B)10 – 14 voltBlower fan motor switch and A/C

switch ON with engine running

0 – 1 voltsExcept the above-mentioned condi-

tion with engine running

E18-5 Bl/BMain power sup-

ply for ECMGround to

engine (Fig B)10 – 14 voltsIgnition switch ON with engine

stopped

E18-6 Bl/BMain power sup-

ply for ECMGround to

engine (Fig B)10 – 14 voltsIgnition switch ON with engine

stopped

E18-10 Bl Main relay driveGround to

engine (Fig B)0.5 – 1.2 voltIgnition switch ON with engine

stopped

0 volts Ignition switch OFF

E18-16 G/W A/C switch inputGround to

engine (Fig B)12 – 15 voltsBlower fan motor switch or A/C switch

OFF with engine running

0 – 1 voltBlower fan motor switch and A/C

switch ON with engine running

12 – 15 voltsWithin several seconds after operate

transfer lever between 2WD and 4WD

with above condition

E18-18 P/BCompressor

cooling fan relay

outputGround to

engine (Fig B)0 – 1 voltBlower fan motor switch and A/C

switch ON or engine coolant tempera-

ture at more than 110 °C (230 °F) with

engine running.

12 – 15 voltsExcept the above-mentioned condi-

tion with engine running

E18-20 B/BlSensor ground

for A/C evapora-

torGround to

body (Fig A)–0.5 – 0 volt Engine running

E18-24 Bl/YBlower fan

speed inputGround to

engine (Fig B)0 – 1 voltBlower fan motor switch 2nd or 3rd

with engine running

4 – 7 voltsBlower fan motor switch 1st with

engine running

12 – 15 voltsBlower fan motor switch and A/C

switch OFF with engine running

E19-1 BMain ground for

ECMGround to

engine (Fig A)–0.5 – 1 volt Engine running

E19-2 B/RECM ground for

power circuitGround to

engine (Fig A)–0.5 – 1 volt Engine running

E19-3 B/RECM ground for

power circuitGround to

engine (Fig A)–0.5 – 1 volt Engine running

E19-10 B/BlSensor ground

for ECT sensorGround to

body (Fig A)–0.5 – 1 volt Engine running

Page 92 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-31

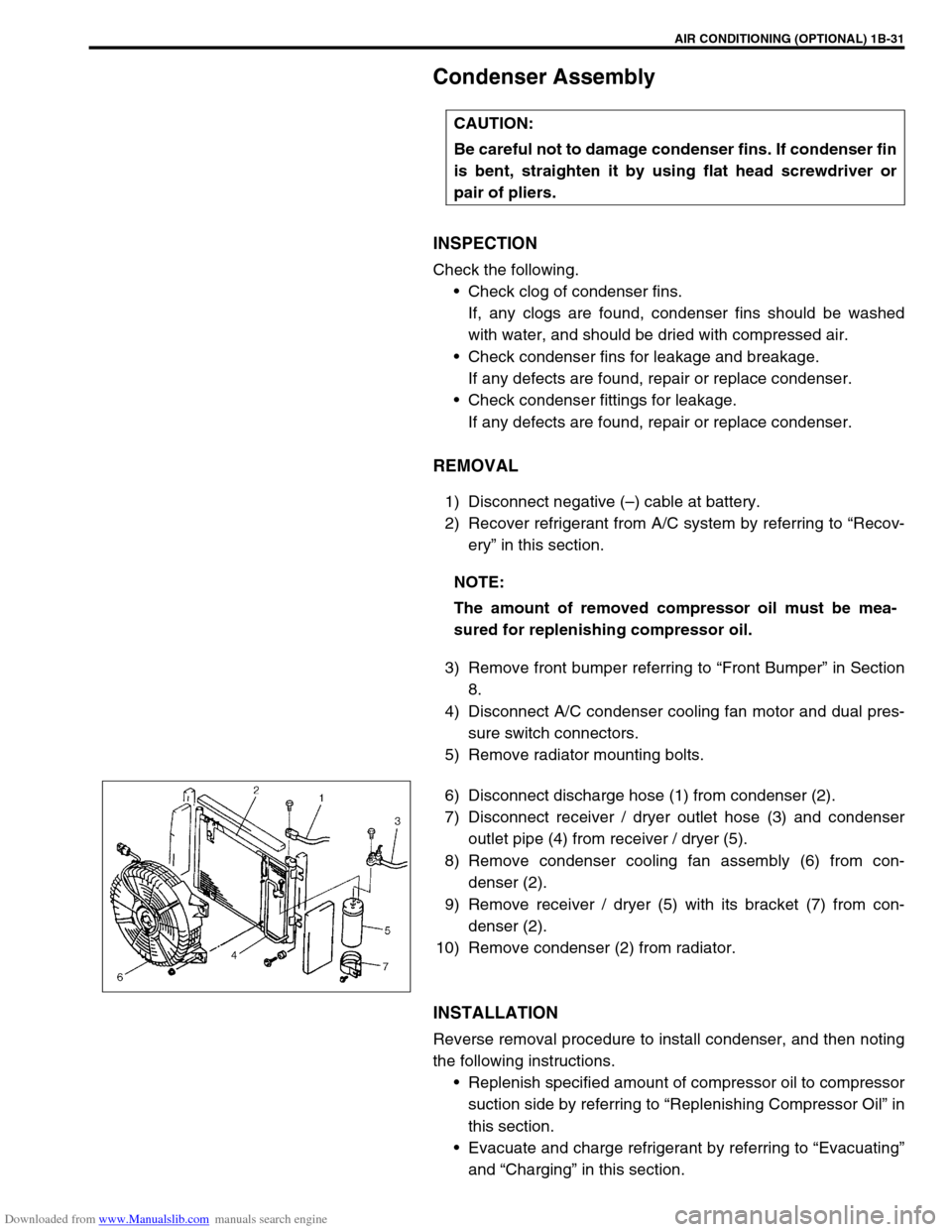

Condenser Assembly

INSPECTION

Check the following.

Check clog of condenser fins.

If, any clogs are found, condenser fins should be washed

with water, and should be dried with compressed air.

Check condenser fins for leakage and breakage.

If any defects are found, repair or replace condenser.

Check condenser fittings for leakage.

If any defects are found, repair or replace condenser.

REMOVAL

1) Disconnect negative (–) cable at battery.

2) Recover refrigerant from A/C system by referring to “Recov-

ery” in this section.

3) Remove front bumper referring to “Front Bumper” in Section

8.

4) Disconnect A/C condenser cooling fan motor and dual pres-

sure switch connectors.

5) Remove radiator mounting bolts.

6) Disconnect discharge hose (1) from condenser (2).

7) Disconnect receiver / dryer outlet hose (3) and condenser

outlet pipe (4) from receiver / dryer (5).

8) Remove condenser cooling fan assembly (6) from con-

denser (2).

9) Remove receiver / dryer (5) with its bracket (7) from con-

denser (2).

10) Remove condenser (2) from radiator.

INSTALLATION

Reverse removal procedure to install condenser, and then noting

the following instructions.

Replenish specified amount of compressor oil to compressor

suction side by referring to “Replenishing Compressor Oil” in

this section.

Evacuate and charge refrigerant by referring to “Evacuating”

and “Charging” in this section. CAUTION:

Be careful not to damage condenser fins. If condenser fin

is bent, straighten it by using flat head screwdriver or

pair of pliers.

NOTE:

The amount of removed compressor oil must be mea-

sured for replenishing compressor oil.

Page 94 of 687

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING (OPTIONAL) 1B-33

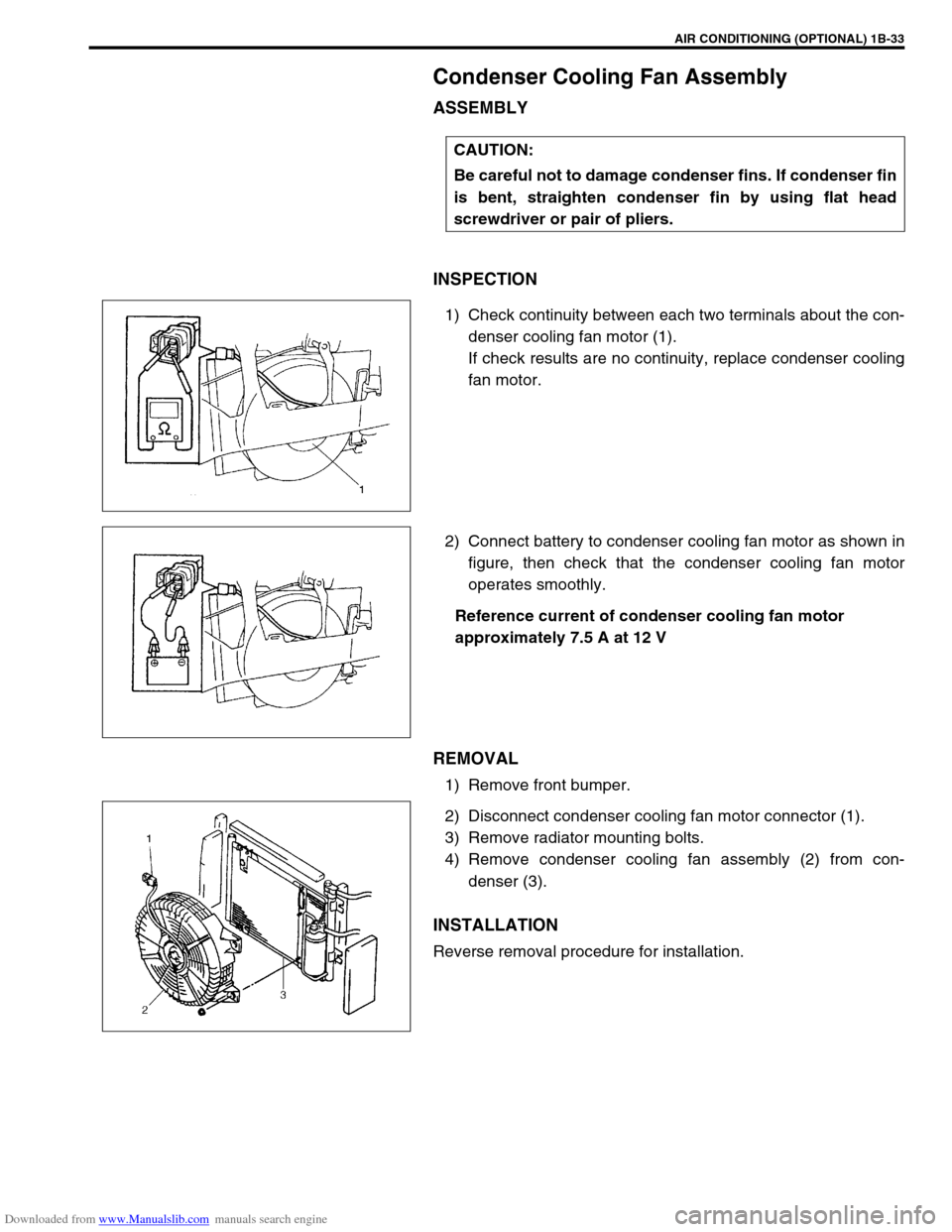

Condenser Cooling Fan Assembly

ASSEMBLY

INSPECTION

1) Check continuity between each two terminals about the con-

denser cooling fan motor (1).

If check results are no continuity, replace condenser cooling

fan motor.

2) Connect battery to condenser cooling fan motor as shown in

figure, then check that the condenser cooling fan motor

operates smoothly.

Reference current of condenser cooling fan motor

approximately 7.5 A at 12 V

REMOVAL

1) Remove front bumper.

2) Disconnect condenser cooling fan motor connector (1).

3) Remove radiator mounting bolts.

4) Remove condenser cooling fan assembly (2) from con-

denser (3).

INSTALLATION

Reverse removal procedure for installation.CAUTION:

Be careful not to damage condenser fins. If condenser fin

is bent, straighten condenser fin by using flat head

screwdriver or pair of pliers.

Page 95 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-34 AIR CONDITIONING (OPTIONAL)

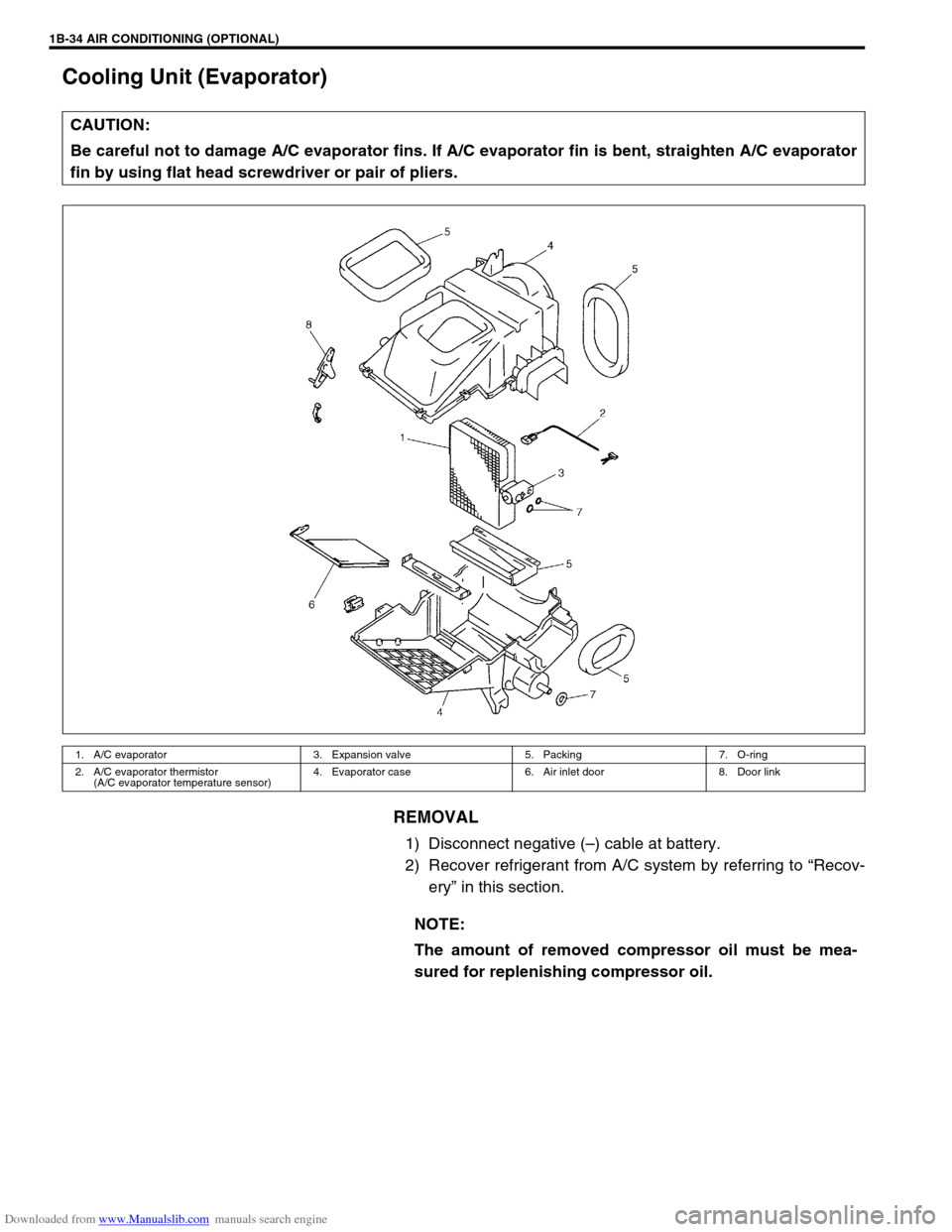

Cooling Unit (Evaporator)

REMOVAL

1) Disconnect negative (–) cable at battery.

2) Recover refrigerant from A/C system by referring to “Recov-

ery” in this section. CAUTION:

Be careful not to damage A/C evaporator fins. If A/C evaporator fin is bent, straighten A/C evaporator

fin by using flat head screwdriver or pair of pliers.

1. A/C evaporator 3. Expansion valve 5. Packing 7. O-ring

2. A/C evaporator thermistor

(A/C evaporator temperature sensor)4. Evaporator case 6. Air inlet door 8. Door link

NOTE:

The amount of removed compressor oil must be mea-

sured for replenishing compressor oil.

Page 101 of 687

Downloaded from www.Manualslib.com manuals search engine 1B-40 AIR CONDITIONING (OPTIONAL)

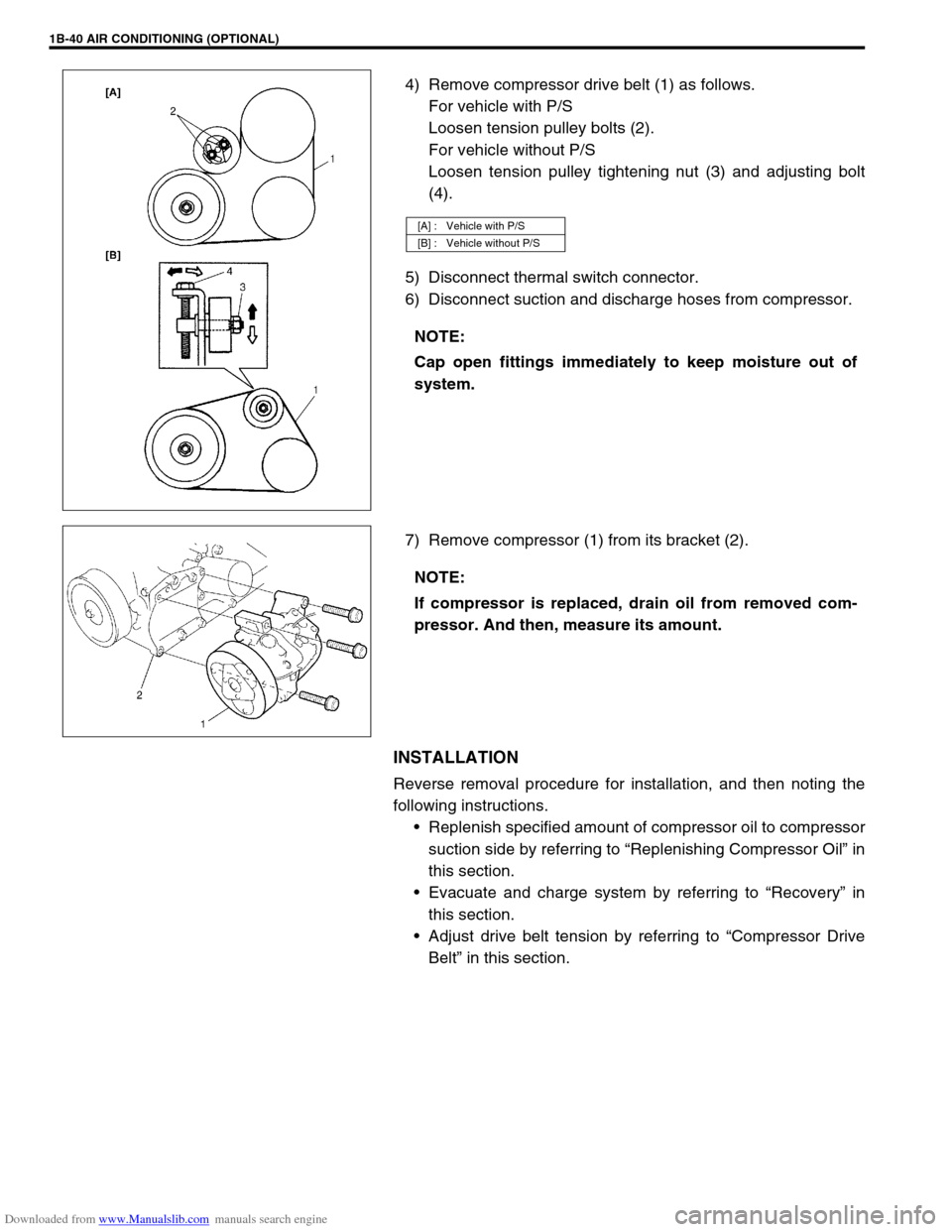

4) Remove compressor drive belt (1) as follows.

For vehicle with P/S

Loosen tension pulley bolts (2).

For vehicle without P/S

Loosen tension pulley tightening nut (3) and adjusting bolt

(4).

5) Disconnect thermal switch connector.

6) Disconnect suction and discharge hoses from compressor.

7) Remove compressor (1) from its bracket (2).

INSTALLATION

Reverse removal procedure for installation, and then noting the

following instructions.

Replenish specified amount of compressor oil to compressor

suction side by referring to “Replenishing Compressor Oil” in

this section.

Evacuate and charge system by referring to “Recovery” in

this section.

Adjust drive belt tension by referring to “Compressor Drive

Belt” in this section.

[A] : Vehicle with P/S

[B] : Vehicle without P/S

NOTE:

Cap open fittings immediately to keep moisture out of

system.

NOTE:

If compressor is replaced, drain oil from removed com-

pressor. And then, measure its amount.

Page 112 of 687

Downloaded from www.Manualslib.com manuals search engine STEERING, SUSPENSION, WHEELS AND TIRES 3-3

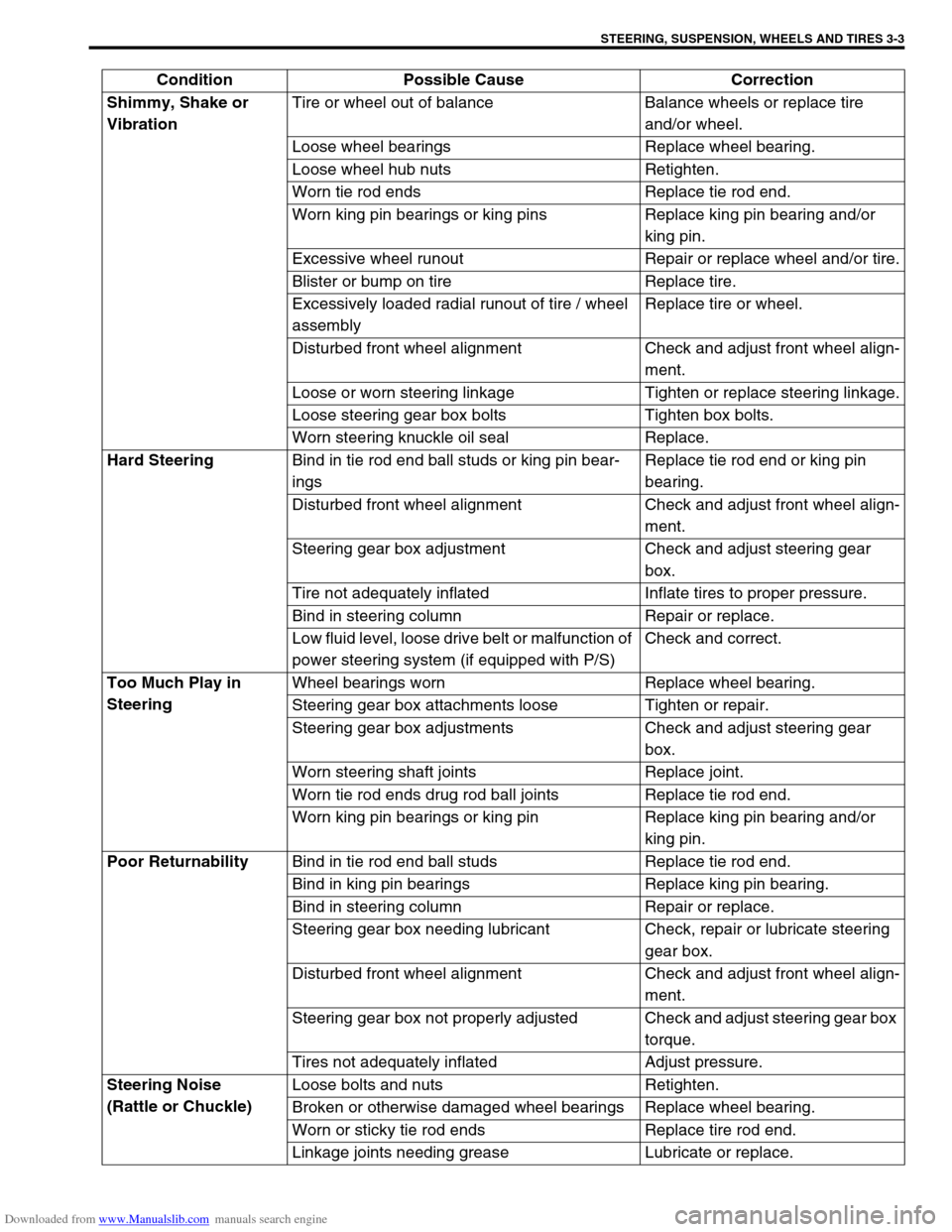

Shimmy, Shake or

VibrationTire or wheel out of balance Balance wheels or replace tire

and/or wheel.

Loose wheel bearings Replace wheel bearing.

Loose wheel hub nuts Retighten.

Worn tie rod ends Replace tie rod end.

Worn king pin bearings or king pins Replace king pin bearing and/or

king pin.

Excessive wheel runout Repair or replace wheel and/or tire.

Blister or bump on tire Replace tire.

Excessively loaded radial runout of tire / wheel

assemblyReplace tire or wheel.

Disturbed front wheel alignment Check and adjust front wheel align-

ment.

Loose or worn steering linkage Tighten or replace steering linkage.

Loose steering gear box bolts Tighten box bolts.

Worn steering knuckle oil seal Replace.

Hard Steering

Bind in tie rod end ball studs or king pin bear-

ingsReplace tie rod end or king pin

bearing.

Disturbed front wheel alignment Check and adjust front wheel align-

ment.

Steering gear box adjustment Check and adjust steering gear

box.

Tire not adequately inflated Inflate tires to proper pressure.

Bind in steering column Repair or replace.

Low fluid level, loose drive belt or malfunction of

power steering system (if equipped with P/S)Check and correct.

Too Much Play in

SteeringWheel bearings worn Replace wheel bearing.

Steering gear box attachments loose Tighten or repair.

Steering gear box adjustments Check and adjust steering gear

box.

Worn steering shaft joints Replace joint.

Worn tie rod ends drug rod ball joints Replace tie rod end.

Worn king pin bearings or king pin Replace king pin bearing and/or

king pin.

Poor Returnability

Bind in tie rod end ball studs Replace tie rod end.

Bind in king pin bearings Replace king pin bearing.

Bind in steering column Repair or replace.

Steering gear box needing lubricant Check, repair or lubricate steering

gear box.

Disturbed front wheel alignment Check and adjust front wheel align-

ment.

Steering gear box not properly adjusted Check and adjust steering gear box

torque.

Tires not adequately inflated Adjust pressure.

Steering Noise

(Rattle or Chuckle)Loose bolts and nuts Retighten.

Broken or otherwise damaged wheel bearings Replace wheel bearing.

Worn or sticky tie rod ends Replace tire rod end.

Linkage joints needing grease Lubricate or replace. Condition Possible Cause Correction

Page 114 of 687

Downloaded from www.Manualslib.com manuals search engine STEERING, SUSPENSION, WHEELS AND TIRES 3-5

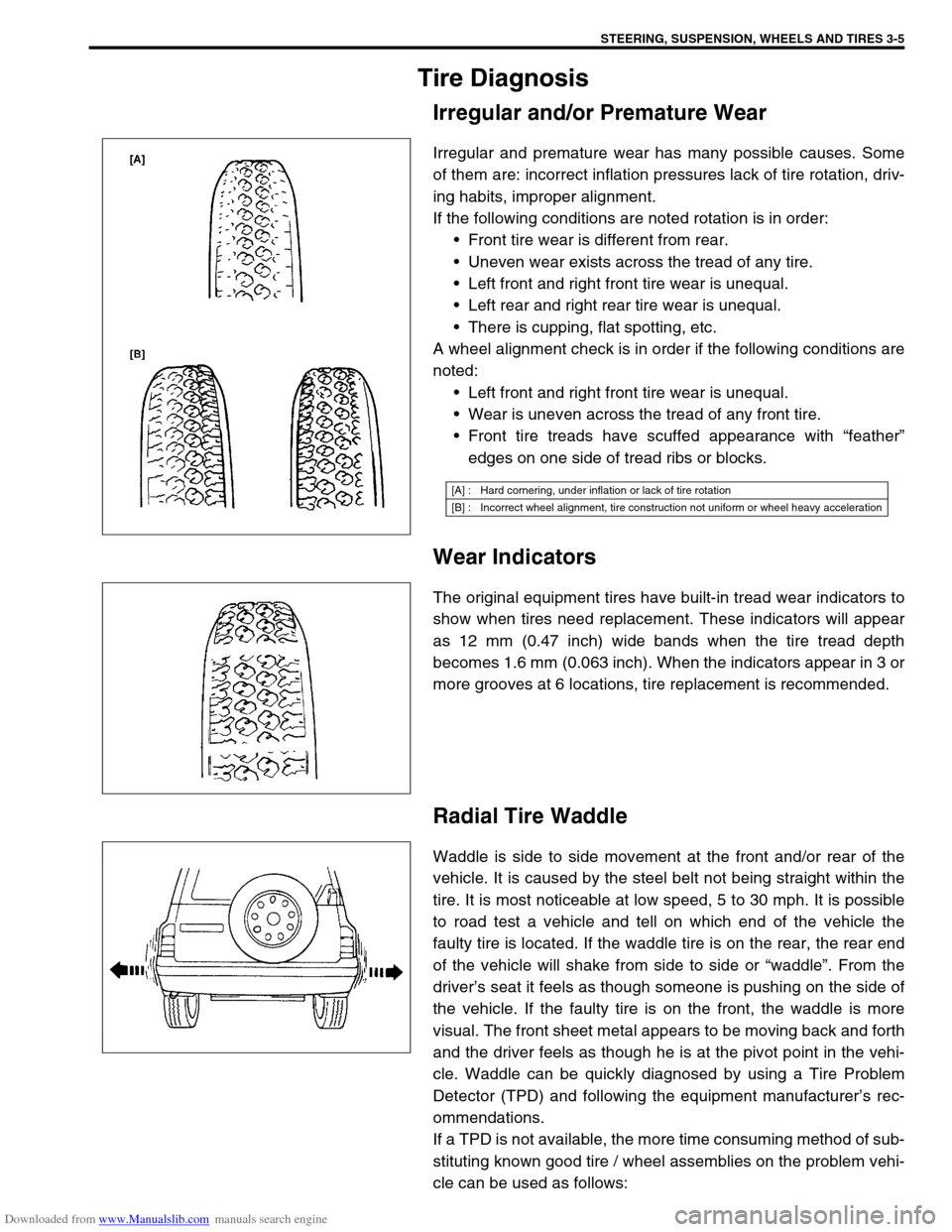

Tire Diagnosis

Irregular and/or Premature Wear

Irregular and premature wear has many possible causes. Some

of them are: incorrect inflation pressures lack of tire rotation, driv-

ing habits, improper alignment.

If the following conditions are noted rotation is in order:

Front tire wear is different from rear.

Uneven wear exists across the tread of any tire.

Left front and right front tire wear is unequal.

Left rear and right rear tire wear is unequal.

There is cupping, flat spotting, etc.

A wheel alignment check is in order if the following conditions are

noted:

Left front and right front tire wear is unequal.

Wear is uneven across the tread of any front tire.

Front tire treads have scuffed appearance with “feather”

edges on one side of tread ribs or blocks.

Wear Indicators

The original equipment tires have built-in tread wear indicators to

show when tires need replacement. These indicators will appear

as 12 mm (0.47 inch) wide bands when the tire tread depth

becomes 1.6 mm (0.063 inch). When the indicators appear in 3 or

more grooves at 6 locations, tire replacement is recommended.

Radial Tire Waddle

Waddle is side to side movement at the front and/or rear of the

vehicle. It is caused by the steel belt not being straight within the

tire. It is most noticeable at low speed, 5 to 30 mph. It is possible

to road test a vehicle and tell on which end of the vehicle the

faulty tire is located. If the waddle tire is on the rear, the rear end

of the vehicle will shake from side to side or “waddle”. From the

driver’s seat it feels as though someone is pushing on the side of

the vehicle. If the faulty tire is on the front, the waddle is more

visual. The front sheet metal appears to be moving back and forth

and the driver feels as though he is at the pivot point in the vehi-

cle. Waddle can be quickly diagnosed by using a Tire Problem

Detector (TPD) and following the equipment manufacturer’s rec-

ommendations.

If a TPD is not available, the more time consuming method of sub-

stituting known good tire / wheel assemblies on the problem vehi-

cle can be used as follows:

[A] : Hard cornering, under inflation or lack of tire rotation

[B] : Incorrect wheel alignment, tire construction not uniform or wheel heavy acceleration

Page 133 of 687

Downloaded from www.Manualslib.com manuals search engine 3B1-2 POWER STEERING (P/S) SYSTEM (If equipped)

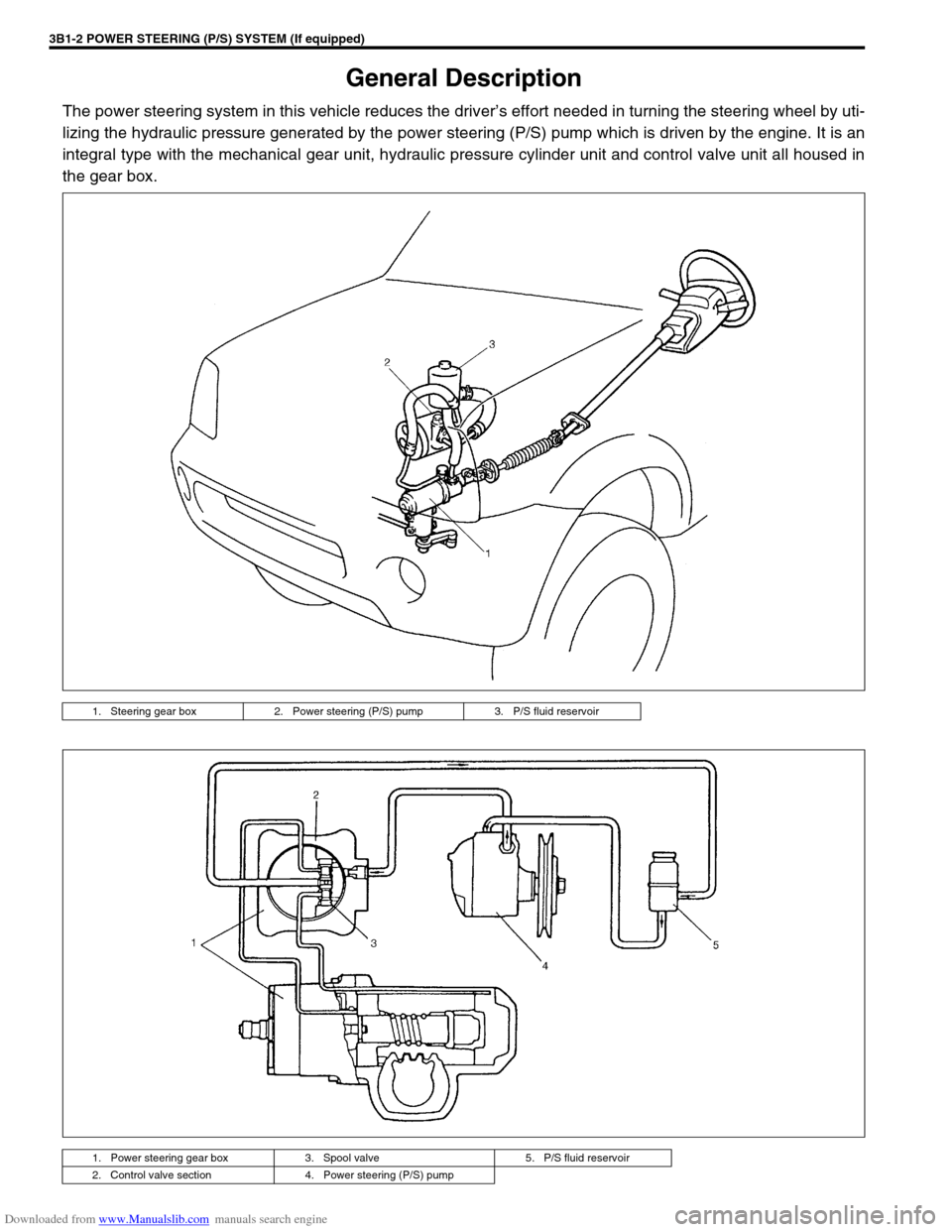

General Description

The power steering system in this vehicle reduces the driver’s effort needed in turning the steering wheel by uti-

lizing the hydraulic pressure generated by the power steering (P/S) pump which is driven by the engine. It is an

integral type with the mechanical gear unit, hydraulic pressure cylinder unit and control valve unit all housed in

the gear box.

1. Steering gear box 2. Power steering (P/S) pump 3. P/S fluid reservoir

1. Power steering gear box 3. Spool valve 5. P/S fluid reservoir

2. Control valve section 4. Power steering (P/S) pump

Page 154 of 687

Downloaded from www.Manualslib.com manuals search engine STEERING WHEEL AND COLUMN 3C-1

6F1

6F2

6G

6H

6K

7A

3C

7E

7F

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3C

STEERING WHEEL AND COLUMN

CONTENTS

General Description ....................................... 3C-2

Diagnosis ........................................................ 3C-3

Inspection and Repair Required

After Accident ............................................... 3C-3

On-Vehicle Service......................................... 3C-3

Service Precautions (For Vehicle with

Air Bag System) ........................................... 3C-3

Diagnosis and servicing ........................... 3C-3

Disabling air bag system .......................... 3C-3

Enabling air bag system ........................... 3C-3

Handling and storage ............................... 3C-3

Disposal.................................................... 3C-3

Drive Air Bag (Inflator) Module (For Vehicle

with Air Bag System) .................................... 3C-4

Steering Wheel ............................................. 3C-5Centering contact coil (for vehicle with

air bag system)......................................... 3C-8

Combination Switch (For Vehicle without

Air Bag System)/Contact Coil and

Combination Switch Assembly (For Vehicle

with Air Bag System).................................... 3C-9

Steering Column Assembly........................ 3C-11

Steering Lock Assembly

(Ignition Switch) ......................................... 3C-15

Steering Lower Shaft ................................. 3C-16

Checking Steering Column for Accident

Damage ......................................................... 3C-18

Tightening Torque Specifications .............. 3C-19

Required Service Material ........................... 3C-19

Special Tool .................................................. 3C-19

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Please observe all WARNINGS and “Service Precautions” under “On-

Vehicle Service” in air bag system section before performing service on or around the air bag sys-

tem components or wiring. Failure to follow WARNINGS could result in unintentional activation of

the system or could render the system inoperative. Either of these two conditions may result in

severe injury.

The procedures in this section must be followed in the order listed to temporarily disable the air

bag system and prevent false diagnostic codes from setting. Failure to follow procedures could

result in possible air bag system activation, personal injury or otherwise unneeded air bag system

repairs.

CAUTION:

When fasteners are removed, always reinstall them at the same location from which they were

removed. If a fastener needs to be replaced, use the correct part number fastener for that application.

If the correct part number fastener is not available, a fastener of equal size and strength (or stronger)

may be used. Fasteners that are not reused, and those requiring thread-locking compound, will be

called out. The correct torque value must be used when installing fasteners that require it. If the above

procedures are not followed, parts or system damage could result.

Page 155 of 687

Downloaded from www.Manualslib.com manuals search engine 3C-2 STEERING WHEEL AND COLUMN

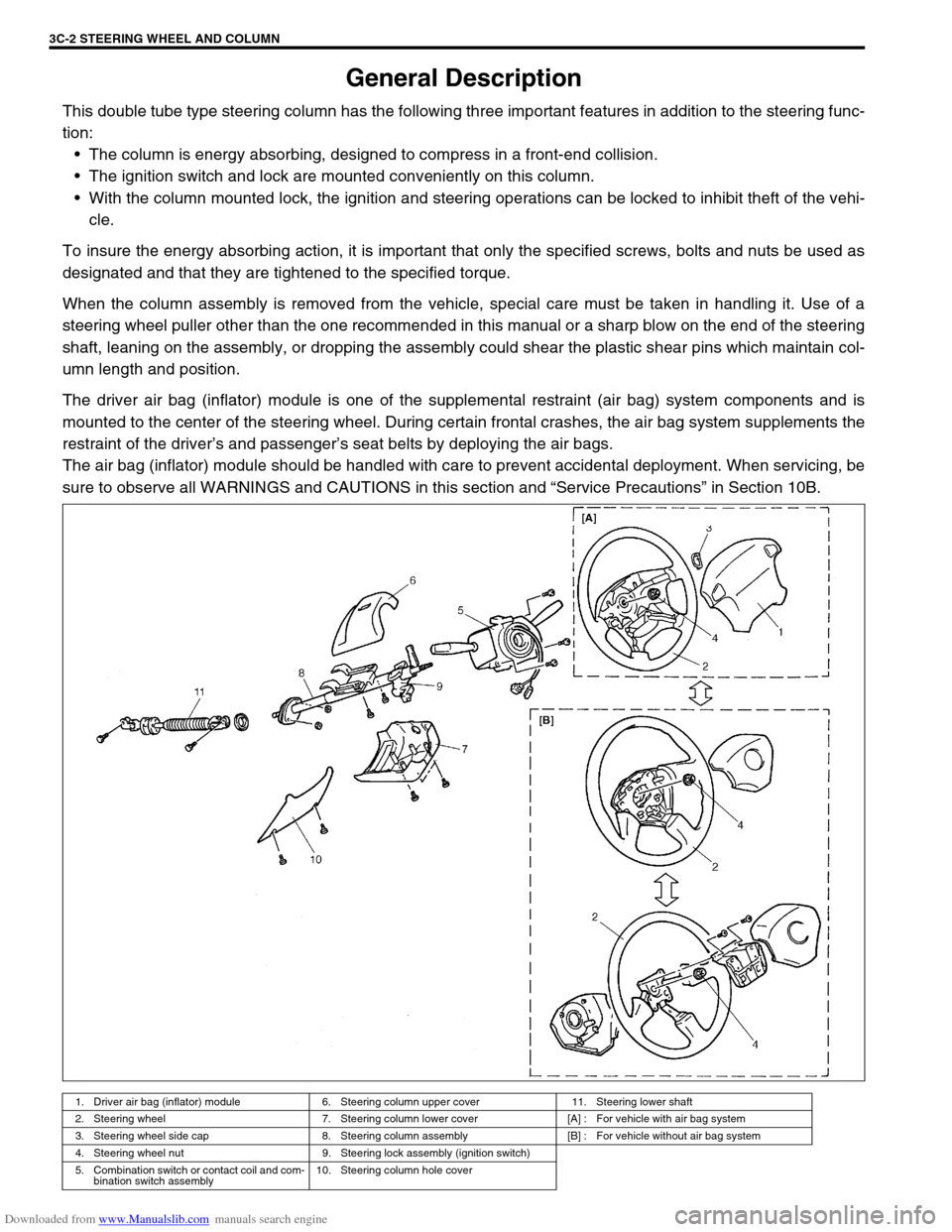

General Description

This double tube type steering column has the following three important features in addition to the steering func-

tion:

The column is energy absorbing, designed to compress in a front-end collision.

The ignition switch and lock are mounted conveniently on this column.

With the column mounted lock, the ignition and steering operations can be locked to inhibit theft of the vehi-

cle.

To insure the energy absorbing action, it is important that only the specified screws, bolts and nuts be used as

designated and that they are tightened to the specified torque.

When the column assembly is removed from the vehicle, special care must be taken in handling it. Use of a

steering wheel puller other than the one recommended in this manual or a sharp blow on the end of the steering

shaft, leaning on the assembly, or dropping the assembly could shear the plastic shear pins which maintain col-

umn length and position.

The driver air bag (inflator) module is one of the supplemental restraint (air bag) system components and is

mounted to the center of the steering wheel. During certain frontal crashes, the air bag system supplements the

restraint of the driver’s and passenger’s seat belts by deploying the air bags.

The air bag (inflator) module should be handled with care to prevent accidental deployment. When servicing, be

sure to observe all WARNINGS and CAUTIONS in this section and “Service Precautions” in Section 10B.

1. Driver air bag (inflator) module 6. Steering column upper cover 11. Steering lower shaft

2. Steering wheel 7. Steering column lower cover [A] : For vehicle with air bag system

3. Steering wheel side cap 8. Steering column assembly [B] : For vehicle without air bag system

4. Steering wheel nut 9. Steering lock assembly (ignition switch)

5. Combination switch or contact coil and com-

bination switch assembly10. Steering column hole cover