transmission oil SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 651 of 687

Downloaded from www.Manualslib.com manuals search engine 6F-2 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

General Description

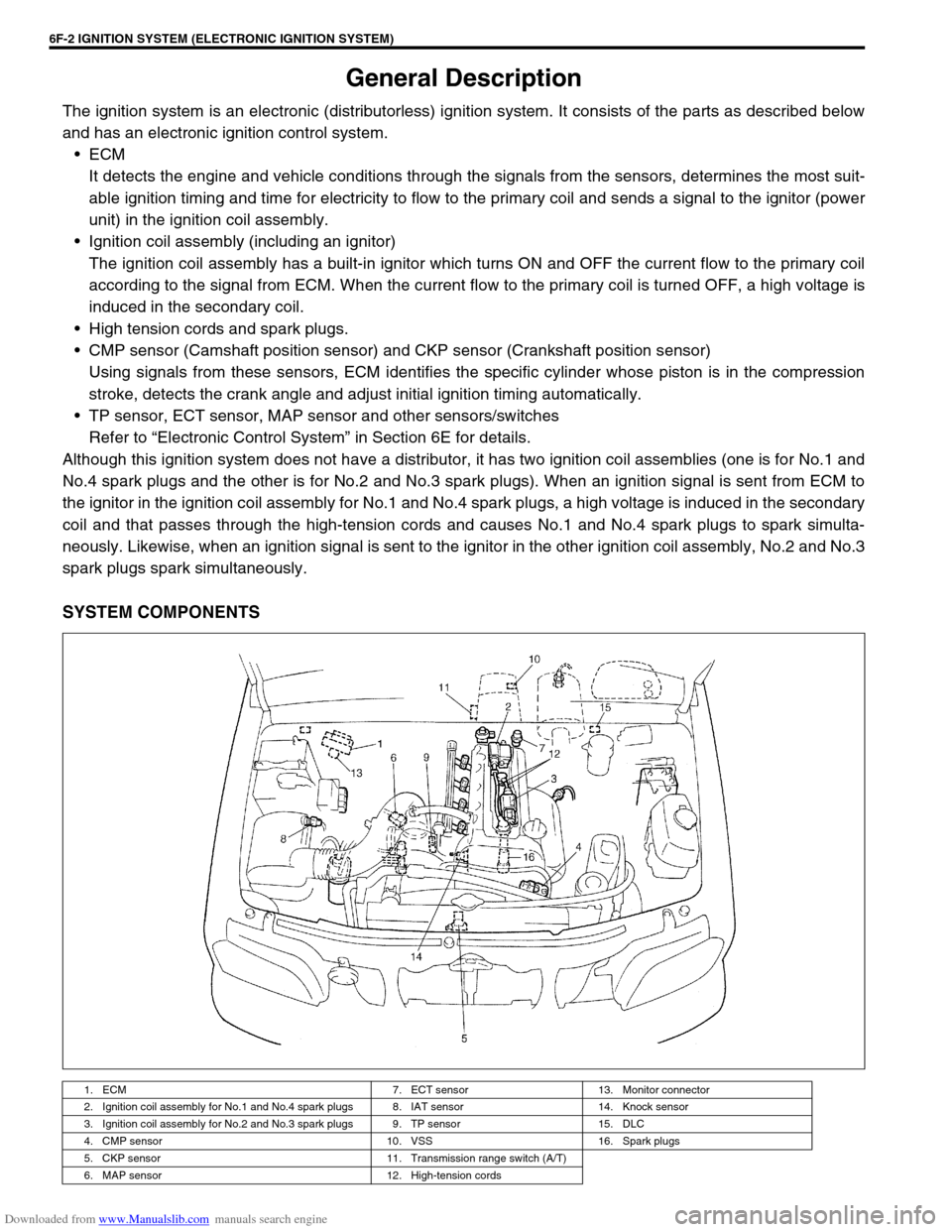

The ignition system is an electronic (distributorless) ignition system. It consists of the parts as described below

and has an electronic ignition control system.

ECM

It detects the engine and vehicle conditions through the signals from the sensors, determines the most suit-

able ignition timing and time for electricity to flow to the primary coil and sends a signal to the ignitor (power

unit) in the ignition coil assembly.

Ignition coil assembly (including an ignitor)

The ignition coil assembly has a built-in ignitor which turns ON and OFF the current flow to the primary coil

according to the signal from ECM. When the current flow to the primary coil is turned OFF, a high voltage is

induced in the secondary coil.

High tension cords and spark plugs.

CMP sensor (Camshaft position sensor) and CKP sensor (Crankshaft position sensor)

Using signals from these sensors, ECM identifies the specific cylinder whose piston is in the compression

stroke, detects the crank angle and adjust initial ignition timing automatically.

TP sensor, ECT sensor, MAP sensor and other sensors/switches

Refer to “Electronic Control System” in Section 6E for details.

Although this ignition system does not have a distributor, it has two ignition coil assemblies (one is for No.1 and

No.4 spark plugs and the other is for No.2 and No.3 spark plugs). When an ignition signal is sent from ECM to

the ignitor in the ignition coil assembly for No.1 and No.4 spark plugs, a high voltage is induced in the secondary

coil and that passes through the high-tension cords and causes No.1 and No.4 spark plugs to spark simulta-

neously. Likewise, when an ignition signal is sent to the ignitor in the other ignition coil assembly, No.2 and No.3

spark plugs spark simultaneously.

SYSTEM COMPONENTS

1. ECM 7. ECT sensor 13. Monitor connector

2. Ignition coil assembly for No.1 and No.4 spark plugs 8. IAT sensor 14. Knock sensor

3. Ignition coil assembly for No.2 and No.3 spark plugs 9. TP sensor 15. DLC

4. CMP sensor 10. VSS 16. Spark plugs

5. CKP sensor 11. Transmission range switch (A/T)

6. MAP sensor 12. High-tension cords

Page 657 of 687

Downloaded from www.Manualslib.com manuals search engine 6F-8 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

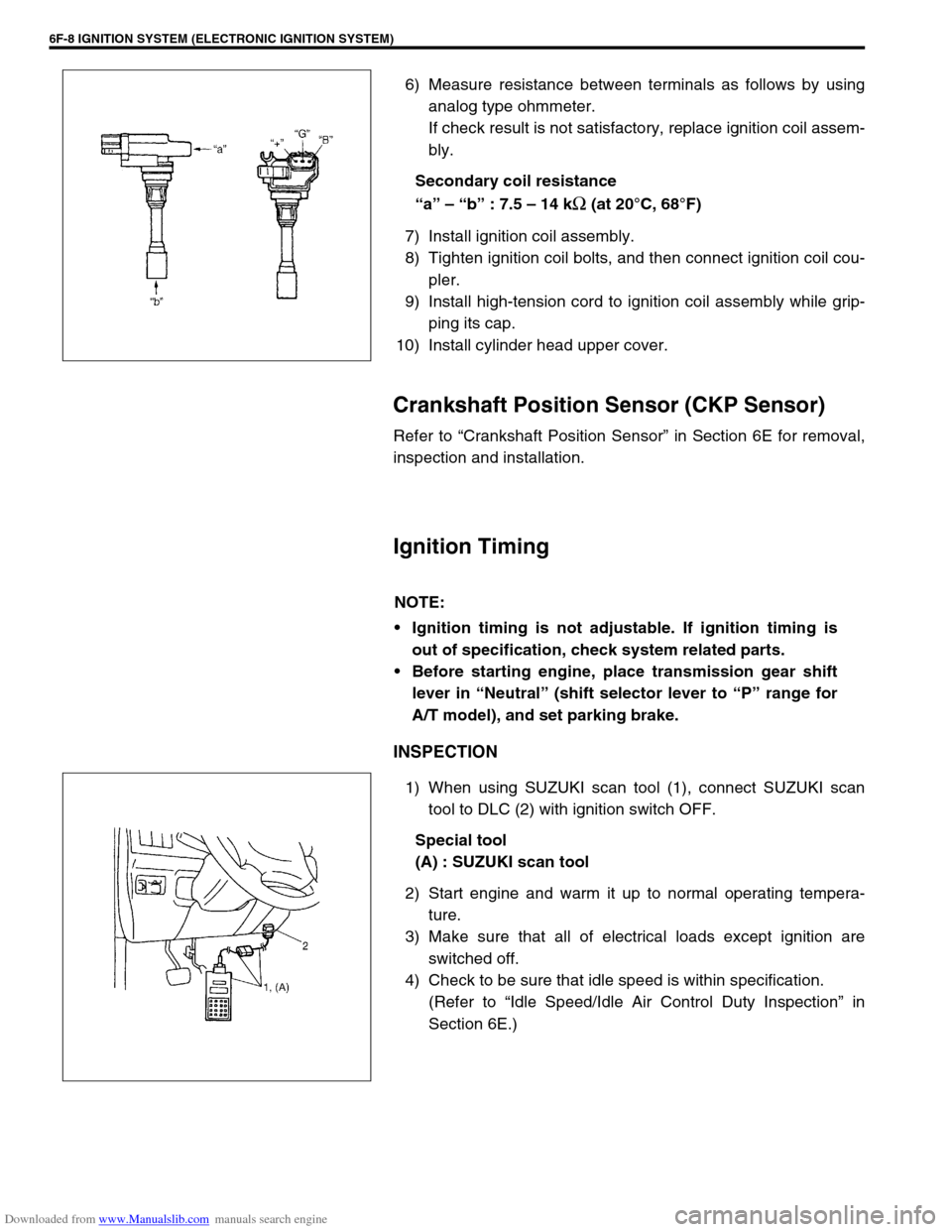

6) Measure resistance between terminals as follows by using

analog type ohmmeter.

If check result is not satisfactory, replace ignition coil assem-

bly.

Secondary coil resistance

“a” – “b” : 7.5 – 14 k

Ω (at 20°C, 68°F)

7) Install ignition coil assembly.

8) Tighten ignition coil bolts, and then connect ignition coil cou-

pler.

9) Install high-tension cord to ignition coil assembly while grip-

ping its cap.

10) Install cylinder head upper cover.

Crankshaft Position Sensor (CKP Sensor)

Refer to “Crankshaft Position Sensor” in Section 6E for removal,

inspection and installation.

Ignition Timing

INSPECTION

1) When using SUZUKI scan tool (1), connect SUZUKI scan

tool to DLC (2) with ignition switch OFF.

Special tool

(A) : SUZUKI scan tool

2) Start engine and warm it up to normal operating tempera-

ture.

3) Make sure that all of electrical loads except ignition are

switched off.

4) Check to be sure that idle speed is within specification.

(Refer to “Idle Speed/Idle Air Control Duty Inspection” in

Section 6E.)

NOTE:

Ignition timing is not adjustable. If ignition timing is

out of specification, check system related parts.

Before starting engine, place transmission gear shift

lever in “Neutral” (shift selector lever to “P” range for

A/T model), and set parking brake.

Page 661 of 687

Downloaded from www.Manualslib.com manuals search engine 6G-2 CRANKING SYSTEM

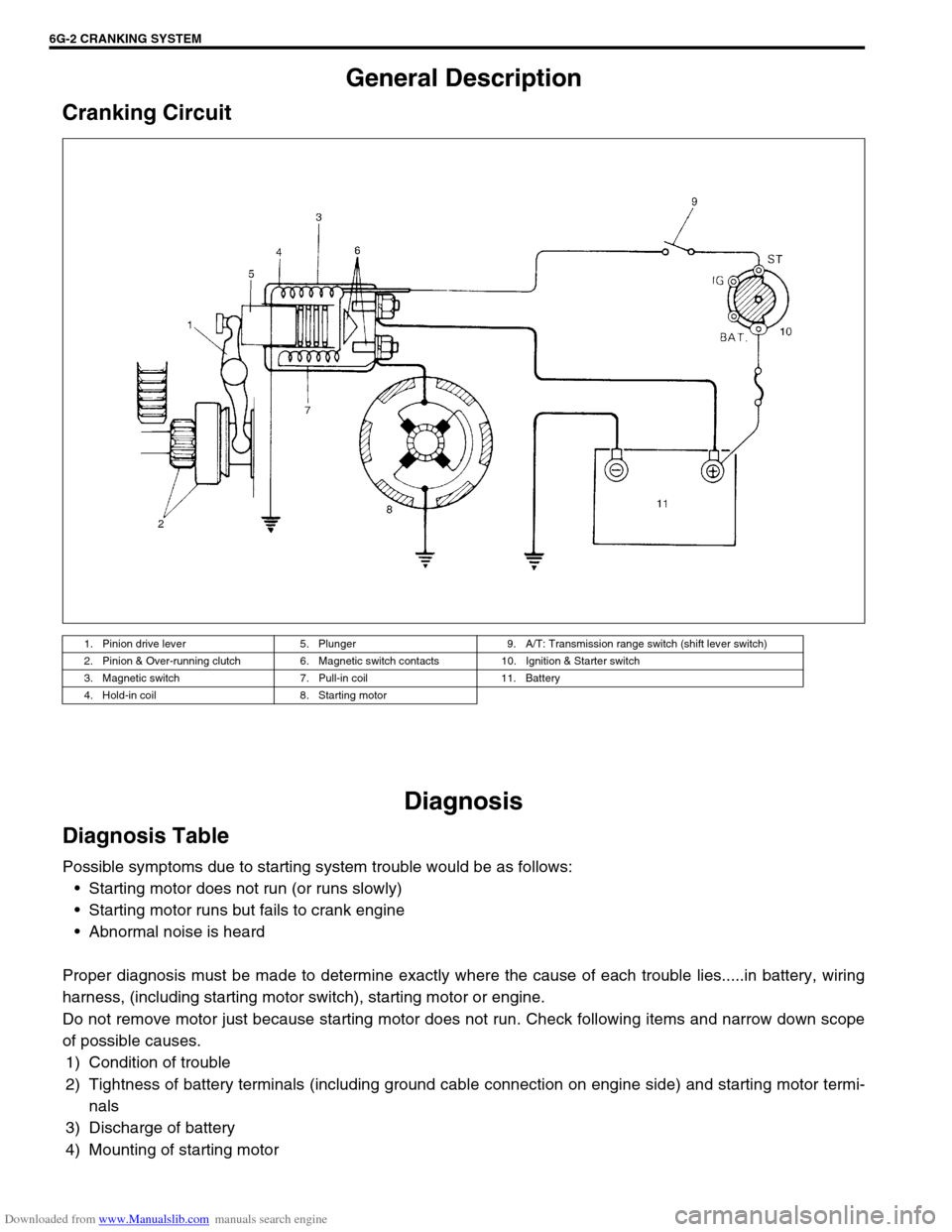

General Description

Cranking Circuit

Diagnosis

Diagnosis Table

Possible symptoms due to starting system trouble would be as follows:

Starting motor does not run (or runs slowly)

Starting motor runs but fails to crank engine

Abnormal noise is heard

Proper diagnosis must be made to determine exactly where the cause of each trouble lies.....in battery, wiring

harness, (including starting motor switch), starting motor or engine.

Do not remove motor just because starting motor does not run. Check following items and narrow down scope

of possible causes.

1) Condition of trouble

2) Tightness of battery terminals (including ground cable connection on engine side) and starting motor termi-

nals

3) Discharge of battery

4) Mounting of starting motor

1. Pinion drive lever 5. Plunger 9. A/T: Transmission range switch (shift lever switch)

2. Pinion & Over-running clutch 6. Magnetic switch contacts 10. Ignition & Starter switch

3. Magnetic switch 7. Pull-in coil 11. Battery

4. Hold-in coil 8. Starting motor

Page 676 of 687

Downloaded from www.Manualslib.com manuals search engine CHARGING SYSTEM 6H-9

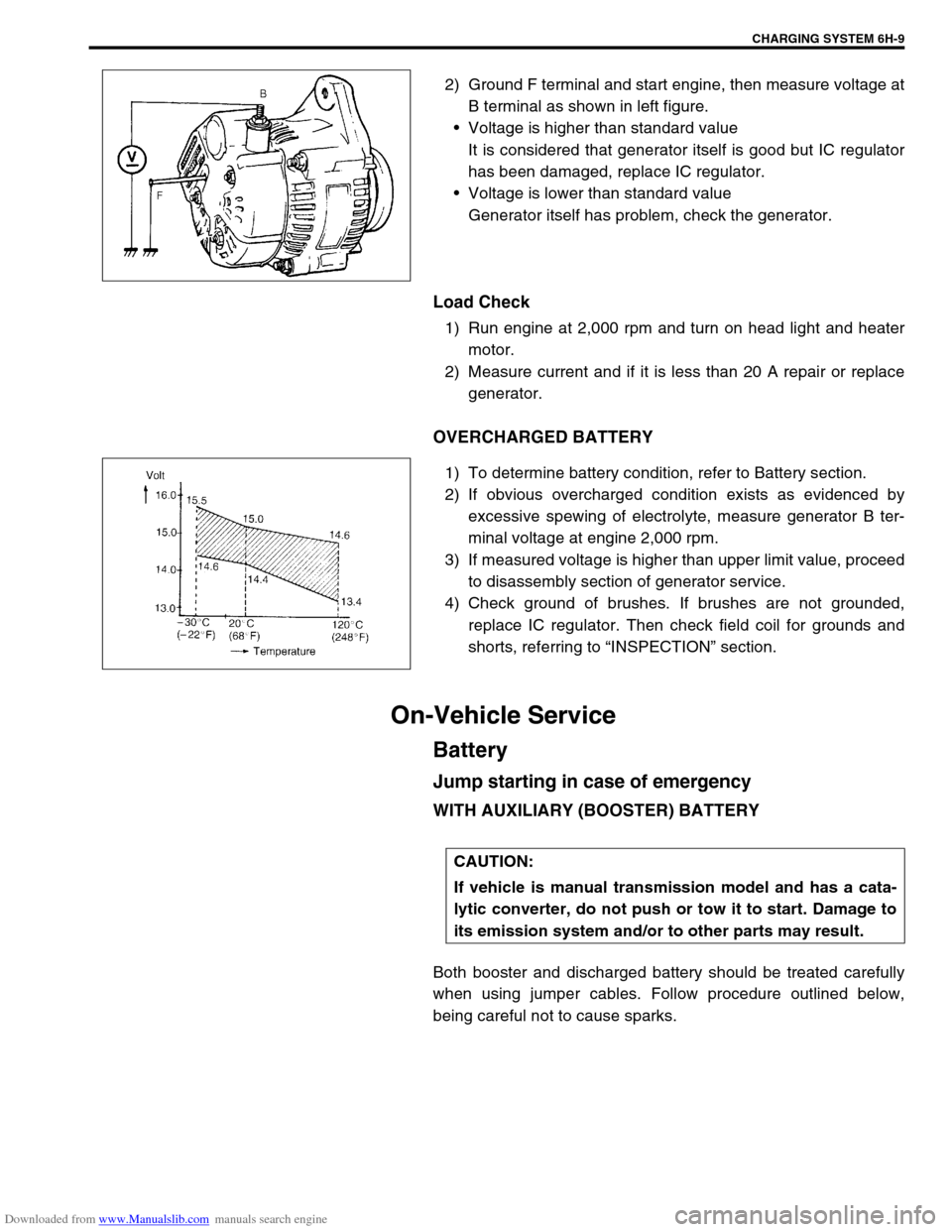

2) Ground F terminal and start engine, then measure voltage at

B terminal as shown in left figure.

Voltage is higher than standard value

It is considered that generator itself is good but IC regulator

has been damaged, replace IC regulator.

Voltage is lower than standard value

Generator itself has problem, check the generator.

Load Check

1) Run engine at 2,000 rpm and turn on head light and heater

motor.

2) Measure current and if it is less than 20 A repair or replace

generator.

OVERCHARGED BATTERY

1) To determine battery condition, refer to Battery section.

2) If obvious overcharged condition exists as evidenced by

excessive spewing of electrolyte, measure generator B ter-

minal voltage at engine 2,000 rpm.

3) If measured voltage is higher than upper limit value, proceed

to disassembly section of generator service.

4) Check ground of brushes. If brushes are not grounded,

replace IC regulator. Then check field coil for grounds and

shorts, referring to “INSPECTION” section.

On-Vehicle Service

Battery

Jump starting in case of emergency

WITH AUXILIARY (BOOSTER) BATTERY

Both booster and discharged battery should be treated carefully

when using jumper cables. Follow procedure outlined below,

being careful not to cause sparks.

CAUTION:

If vehicle is manual transmission model and has a cata-

lytic converter, do not push or tow it to start. Damage to

its emission system and/or to other parts may result.