wheel bolt torque SUZUKI JIMNY 2005 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 204 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-31

8) Press-fit spindle bushing (2) to wheel spindle (1) by using

special tool.

Set cut part (4) of spindle bushing (2) as shown in figure

(opposite side of the groove (3) of wheel spindle).

Special tool

(A) : 09922-55131

9) Press-fit spindle oil seal (1) until it becomes flush with wheel

spindle (2) surface by using special tool, and then apply

grease to its lip.

Special tool

(A) : 09944-66020

10) Apply grease to spindle oil seal lip.

“A” : Grease 99000-25010

11) Apply grease to spindle bushing inside surface and flange

(2).

“A” : Grease 99000-25010

12) Install wheel spindle to knuckle, coat their mating surface

with sealant.

“B” : Sealant 99000-31110 or 99000-31090

13) Install wheel spindle (1) and disc dust cover (2) to steering

knuckle. Tighten wheel spindle bolts to specified torque.

Tightening torque

Wheel spindle bolts

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

CAUTION:

As this hole is a part of the passage of the vacuum that

activates the air locking hub, if it is clogged with grease,

the air locking hub cannot be locked or unlocked.

Therefore, be careful not to apply too much grease to

avoid clogging the vacuum passage.

Page 215 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-42 FRONT SUSPENSION

9) Install right and left axle shafts to axle housing (for 4WD).

Install knuckle to axle housing (for 2WD).

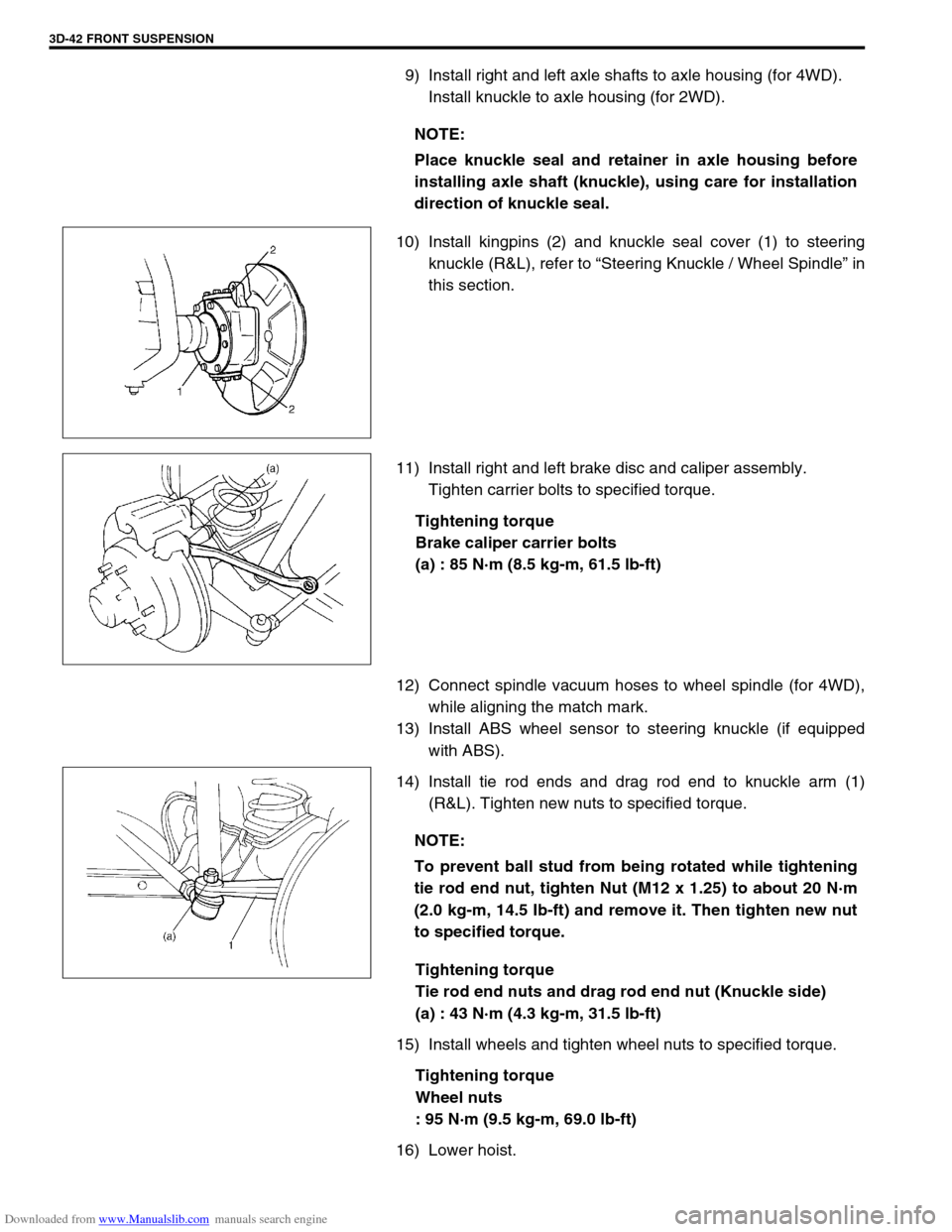

10) Install kingpins (2) and knuckle seal cover (1) to steering

knuckle (R&L), refer to “Steering Knuckle / Wheel Spindle” in

this section.

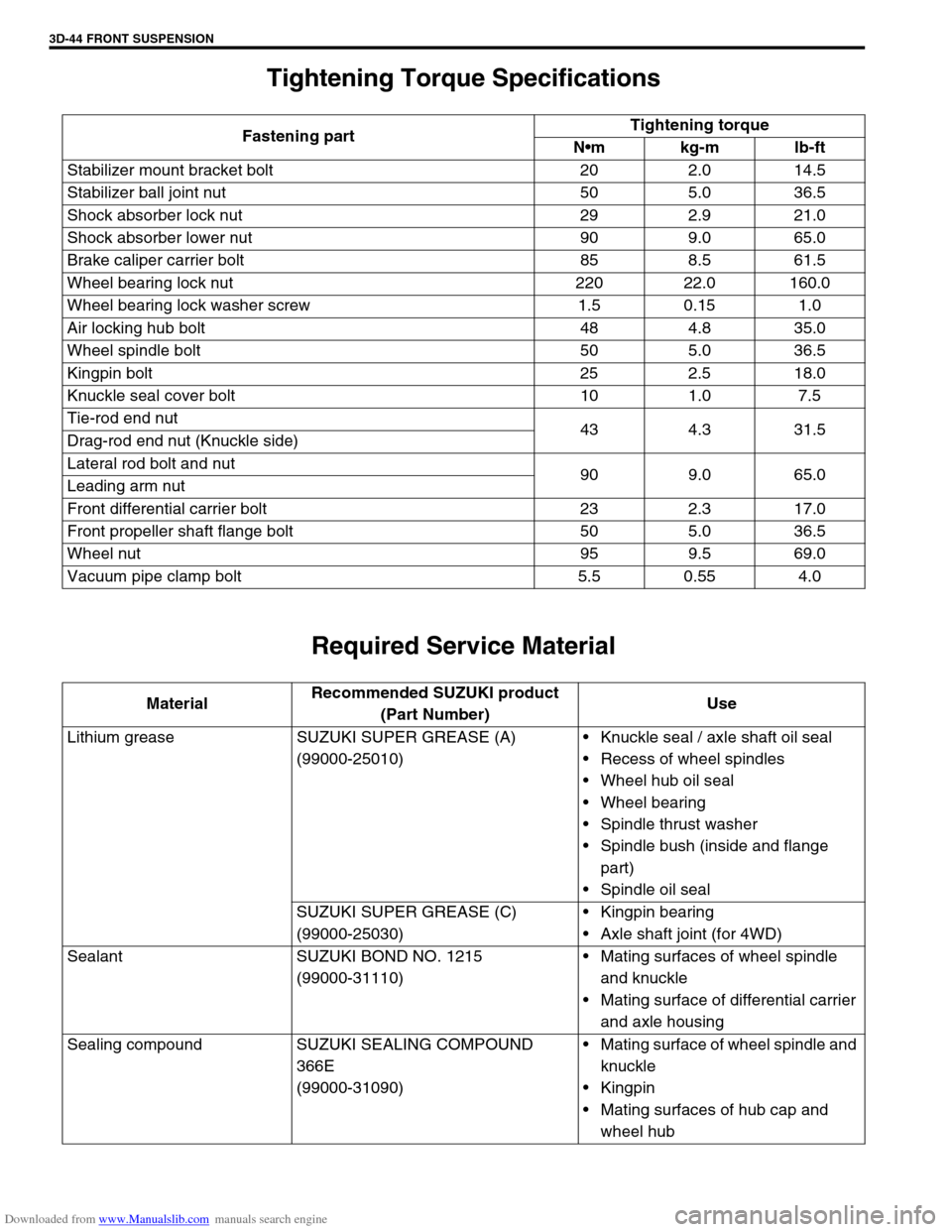

11) Install right and left brake disc and caliper assembly.

Tighten carrier bolts to specified torque.

Tightening torque

Brake caliper carrier bolts

(a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

12) Connect spindle vacuum hoses to wheel spindle (for 4WD),

while aligning the match mark.

13) Install ABS wheel sensor to steering knuckle (if equipped

with ABS).

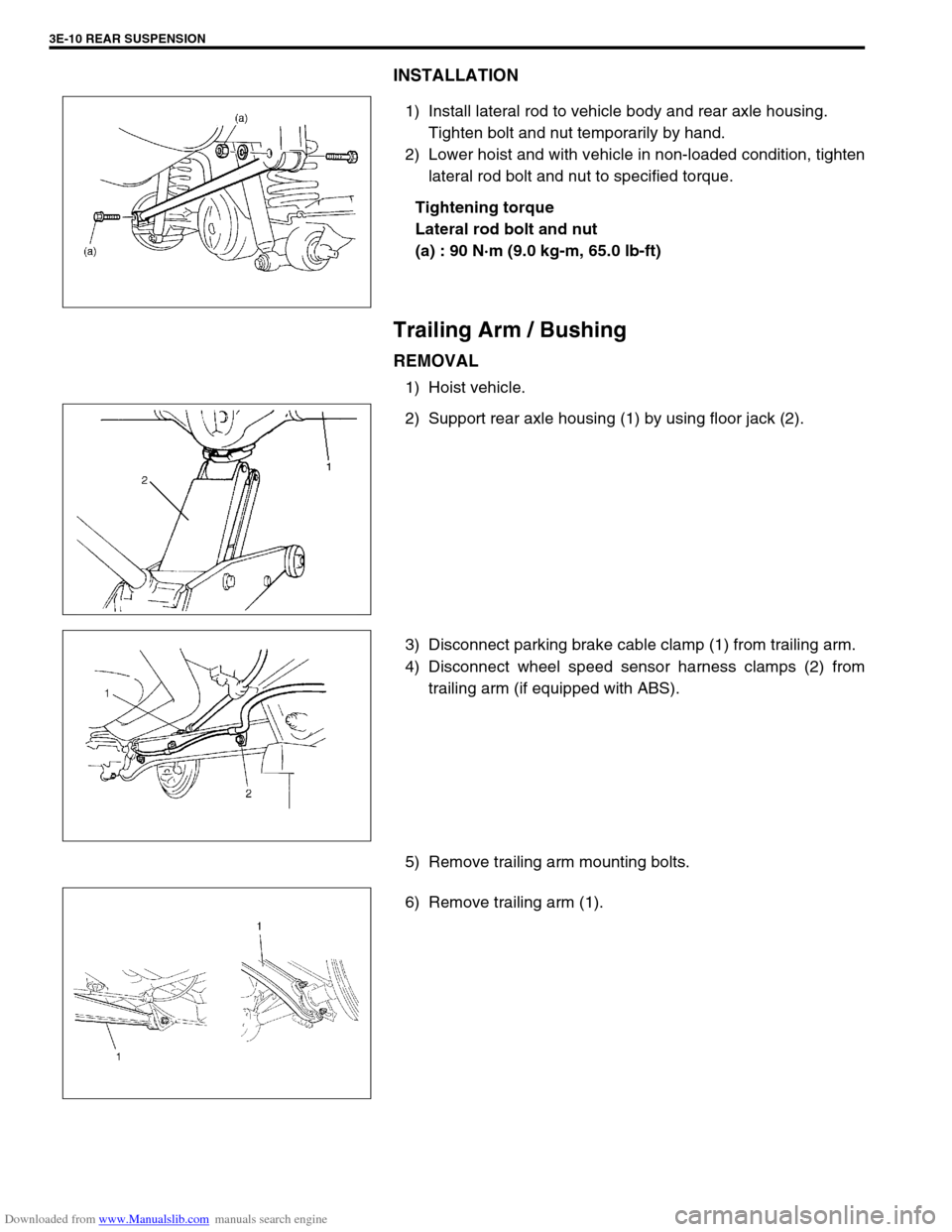

14) Install tie rod ends and drag rod end to knuckle arm (1)

(R&L). Tighten new nuts to specified torque.

Tightening torque

Tie rod end nuts and drag rod end nut (Knuckle side)

(a) : 43 N·m (4.3 kg-m, 31.5 lb-ft)

15) Install wheels and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts

: 95 N·m (9.5 kg-m, 69.0 lb-ft)

16) Lower hoist.NOTE:

Place knuckle seal and retainer in axle housing before

installing axle shaft (knuckle), using care for installation

direction of knuckle seal.

NOTE:

To prevent ball stud from being rotated while tightening

tie rod end nut, tighten Nut (M12 x 1.25) to about 20 N·m

(2.0 kg-m, 14.5 Ib-ft) and remove it. Then tighten new nut

to specified torque.

Page 216 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-43

17) Tighten lateral rod (1) mounting bolt and nut to specified

torque.

Tightening torque

Lateral rod bolt and nut

(a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

18) Tighten right and left shock absorber lower mounting nuts

and leading arm mounting nuts to specified torque.

Tightening torque

Shock absorber lower nuts and leading arm nuts

(a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

19) Refill front axle (differential) housing with new specified gear

oil. Refer to “Maintenance Service” in Section 7E for refill.

20) Confirm front end (wheel) alignment referring to “Preliminary

Checks Prior to Adjusting Front Alignment” in Section 3A. NOTE:

When tightening bolt and nut, be sure that vehicle is off

hoist and in non loaded condition.

NOTE:

When tightening these nuts, be sure that vehicle is off

hoist and in non loaded condition.

1. Shock absorber

2. Leading arm

Page 217 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-44 FRONT SUSPENSION

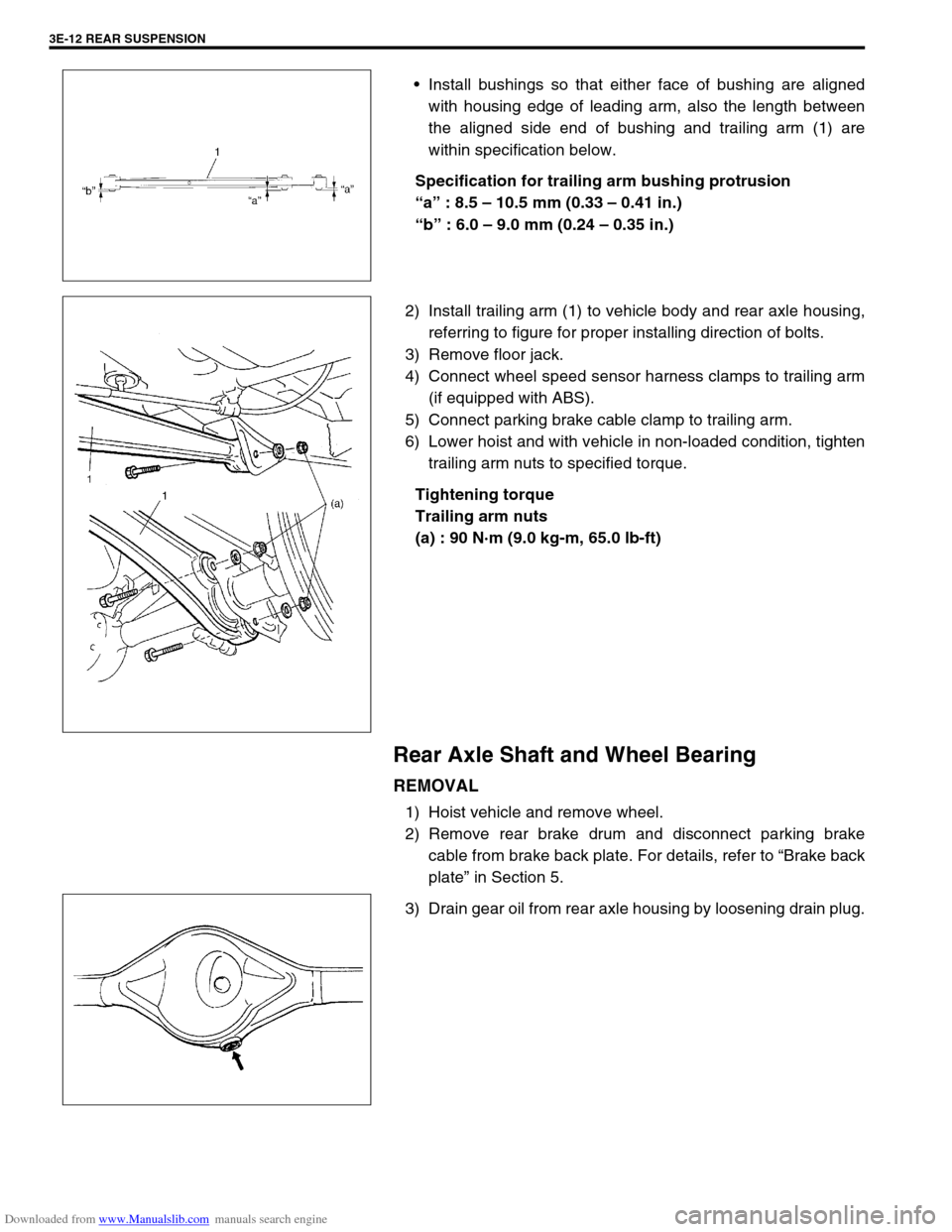

Tightening Torque Specifications

Required Service Material

Fastening partTightening torque

Nm kg-m lb-ft

Stabilizer mount bracket bolt 20 2.0 14.5

Stabilizer ball joint nut 50 5.0 36.5

Shock absorber lock nut 29 2.9 21.0

Shock absorber lower nut 90 9.0 65.0

Brake caliper carrier bolt 85 8.5 61.5

Wheel bearing lock nut 220 22.0 160.0

Wheel bearing lock washer screw 1.5 0.15 1.0

Air locking hub bolt 48 4.8 35.0

Wheel spindle bolt 50 5.0 36.5

Kingpin bolt 25 2.5 18.0

Knuckle seal cover bolt 10 1.0 7.5

Tie-rod end nut

43 4.3 31.5

Drag-rod end nut (Knuckle side)

Lateral rod bolt and nut

90 9.0 65.0

Leading arm nut

Front differential carrier bolt 23 2.3 17.0

Front propeller shaft flange bolt 50 5.0 36.5

Wheel nut 95 9.5 69.0

Vacuum pipe clamp bolt 5.5 0.55 4.0

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium grease SUZUKI SUPER GREASE (A)

(99000-25010)Knuckle seal / axle shaft oil seal

Recess of wheel spindles

Wheel hub oil seal

Wheel bearing

Spindle thrust washer

Spindle bush (inside and flange

part)

Spindle oil seal

SUZUKI SUPER GREASE (C)

(99000-25030)Kingpin bearing

Axle shaft joint (for 4WD)

Sealant SUZUKI BOND NO. 1215

(99000-31110)Mating surfaces of wheel spindle

and knuckle

Mating surface of differential carrier

and axle housing

Sealing compound SUZUKI SEALING COMPOUND

366E

(99000-31090)Mating surface of wheel spindle and

knuckle

Kingpin

Mating surfaces of hub cap and

wheel hub

Page 223 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-4 REAR SUSPENSION

Rear Suspension Fasteners

Check each bolt and nut fastening suspension parts for tightness.

Tighten loose one, if any, to specified torque, referring to “Tighten-

ing Torque Specifications” of this section.

Bearing Retainer and Axle Shaft Oil Seal

Check

When brake drum has been removed, check inside of brake

drum for gear oil leakage.

Also, check backside of brake back plate for oil leakage.If oil

leakage is found, replace defective oil seal.

Whenever it is possible to check oil seal during disassembly,

check its lip for wear.

If oil leakage or worn lip is found, replace defective oil seal.

Bump Stopper and Spring Rubber Seat Check

Inspect for wear and breakage. If found defective, replace.

Wheel Disc, Nut and Bearing Check

Inspect each wheel disc for dents, distortion and cracks. A

disc in badly damaged condition must be replaced.

Check wheel hub nuts for tightness and, as necessary,

retighten to specification.

Tightening torque

Wheel nuts

(a) : 95 N·m (9.5 kg-m, 69.0 lb-ft)

Page 225 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-6 REAR SUSPENSION

3) Remove upper mounting bolt (2).

4) Remove lower mounting bolt (3).

5) Remove shock absorber (1).

INSTALLATION

1) Install shock absorber (1), refer to figure for proper installing

direction of bush and washer (2).

Tighten bolts (3) temporarily by hand.

2) Remove floor jack.

3) Lower hoist.

4) Tighten shock absorber bolts (3) to specified torque.

Tightening torque

Shock absorber upper and lower bolts

(a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

Coil Spring

REMOVAL

1) Hoist vehicle and remove wheel.

2) Support rear axle housing (1) by using floor jack (2).

3) Remove brake flexible hose E-ring (2).

NOTE:

Tighten lower bolt with vehicle off hoist and in non-

loaded condition.

1. Brake flexible hose

Page 227 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-8 REAR SUSPENSION

INSTALLATION

1) Install spring rubber seat (1).

2) Install coil spring (2) on spring seat (1) of axle housing and

then raise axle housing.

3) Install shock absorber lower mounting bolt.

Tighten bolt temporarily by hand.

4) Install brake flexible hose E-ring.

5) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts

(a) : 95 N·m (9.5 kg-m, 69.0 lb-ft)

6) Lower hoist and tighten absorber lower bolt (2) to specified

torque.

Tightening torque

Shock absorber lower bolt

(a) : 85 N·m (8.5 kg-m, 61.5 lb-ft) NOTE:

Before installing spring rubber seat (1), apply soap water

on it.

NOTE:

Upper and lower diameters of coil spring (2) are differ-

ent.

Bring larger diameter end at bottom and set its open

end in place on spring seat (1).

When seating coil spring (2), mate spring end with

stepped part (3) of rear axle spring seat (1) as shown.

A : Upper side (small dia.)

B : Lower side (large dia.)

NOTE:

For tightening of lower bolt (2), refer to NOTE given under

“Shock Absorber” in this section.

Page 228 of 687

Downloaded from www.Manualslib.com manuals search engine REAR SUSPENSION 3E-9

Bump Stopper

REMOVAL

1) Hoist vehicle.

2) Remove wheel.

3) Remove bump stopper (1) by using special tool.

Special tool

(A) : 09941-66010

INSTALLATION

1) Tighten bump stopper (1) to specified torque by using spe-

cial tool.

Special tool

(A) : 09941-66010

Tightening torque

Bump stopper

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

2) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts

(a) : 95 N·m (9.5 kg-m, 69.0 lb-ft)

3) Lower hoist.

Lateral Rod

REMOVAL

1) Hoist vehicle.

2) Remove lateral rod mounting bolt (2) and nut (3).

3) Remove lateral rod (1).

Page 229 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-10 REAR SUSPENSION

INSTALLATION

1) Install lateral rod to vehicle body and rear axle housing.

Tighten bolt and nut temporarily by hand.

2) Lower hoist and with vehicle in non-loaded condition, tighten

lateral rod bolt and nut to specified torque.

Tightening torque

Lateral rod bolt and nut

(a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

Trailing Arm / Bushing

REMOVAL

1) Hoist vehicle.

2) Support rear axle housing (1) by using floor jack (2).

3) Disconnect parking brake cable clamp (1) from trailing arm.

4) Disconnect wheel speed sensor harness clamps (2) from

trailing arm (if equipped with ABS).

5) Remove trailing arm mounting bolts.

6) Remove trailing arm (1).

Page 231 of 687

Downloaded from www.Manualslib.com manuals search engine 3E-12 REAR SUSPENSION

Install bushings so that either face of bushing are aligned

with housing edge of leading arm, also the length between

the aligned side end of bushing and trailing arm (1) are

within specification below.

Specification for trailing arm bushing protrusion

“a” : 8.5 – 10.5 mm (0.33 – 0.41 in.)

“b” : 6.0 – 9.0 mm (0.24 – 0.35 in.)

2) Install trailing arm (1) to vehicle body and rear axle housing,

referring to figure for proper installing direction of bolts.

3) Remove floor jack.

4) Connect wheel speed sensor harness clamps to trailing arm

(if equipped with ABS).

5) Connect parking brake cable clamp to trailing arm.

6) Lower hoist and with vehicle in non-loaded condition, tighten

trailing arm nuts to specified torque.

Tightening torque

Trailing arm nuts

(a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

Rear Axle Shaft and Wheel Bearing

REMOVAL

1) Hoist vehicle and remove wheel.

2) Remove rear brake drum and disconnect parking brake

cable from brake back plate. For details, refer to “Brake back

plate” in Section 5.

3) Drain gear oil from rear axle housing by loosening drain plug.