ATE SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 559 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-78 ENGINE MECHANICAL (M13 ENGINE)

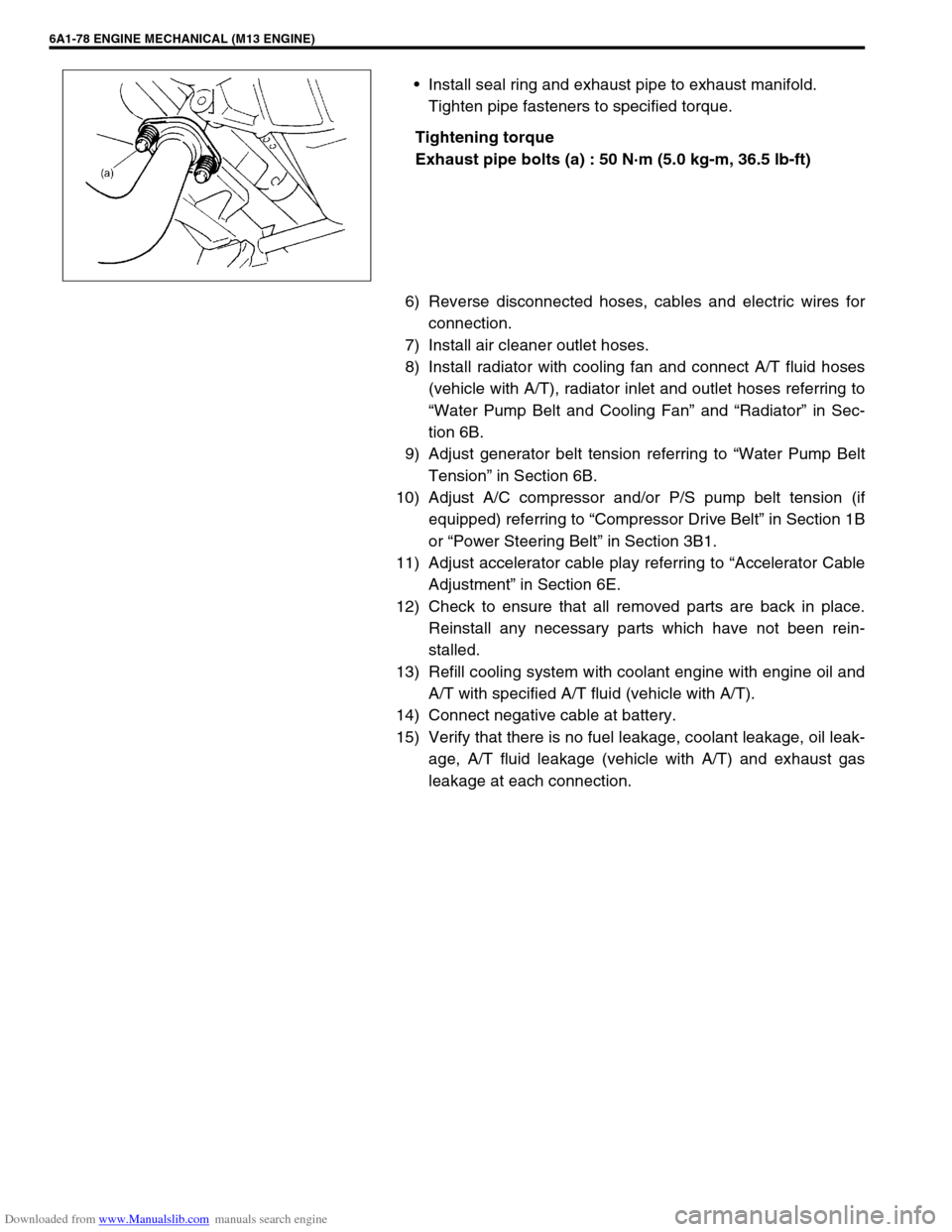

Install seal ring and exhaust pipe to exhaust manifold.

Tighten pipe fasteners to specified torque.

Tightening torque

Exhaust pipe bolts (a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

6) Reverse disconnected hoses, cables and electric wires for

connection.

7) Install air cleaner outlet hoses.

8) Install radiator with cooling fan and connect A/T fluid hoses

(vehicle with A/T), radiator inlet and outlet hoses referring to

“Water Pump Belt and Cooling Fan” and “Radiator” in Sec-

tion 6B.

9) Adjust generator belt tension referring to “Water Pump Belt

Tension” in Section 6B.

10) Adjust A/C compressor and/or P/S pump belt tension (if

equipped) referring to “Compressor Drive Belt” in Section 1B

or “Power Steering Belt” in Section 3B1.

11) Adjust accelerator cable play referring to “Accelerator Cable

Adjustment” in Section 6E.

12) Check to ensure that all removed parts are back in place.

Reinstall any necessary parts which have not been rein-

stalled.

13) Refill cooling system with coolant engine with engine oil and

A/T with specified A/T fluid (vehicle with A/T).

14) Connect negative cable at battery.

15) Verify that there is no fuel leakage, coolant leakage, oil leak-

age, A/T fluid leakage (vehicle with A/T) and exhaust gas

leakage at each connection.

Page 560 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-79

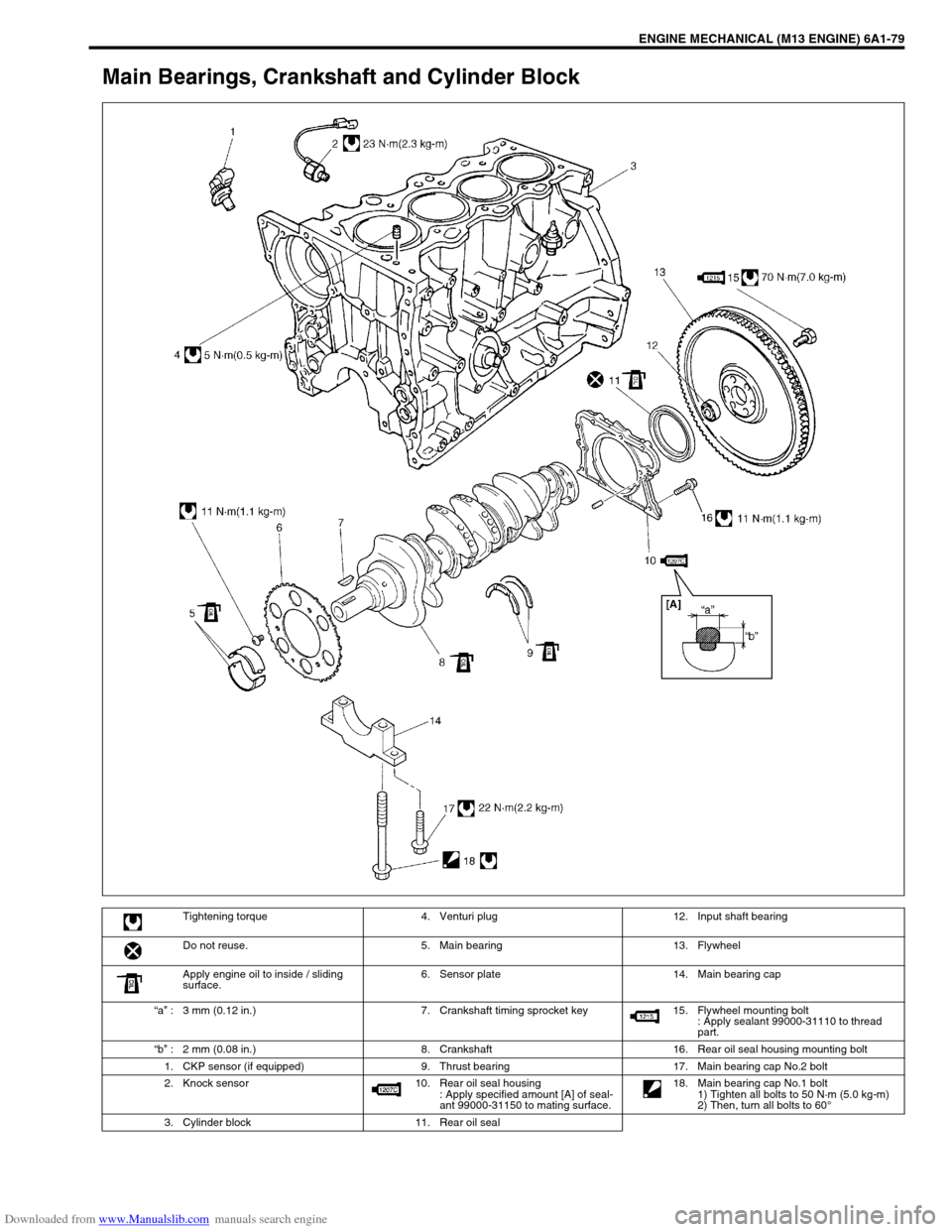

Main Bearings, Crankshaft and Cylinder Block

Tightening torque 4. Venturi plug 12. Input shaft bearing

Do not reuse. 5. Main bearing 13. Flywheel

Apply engine oil to inside / sliding

surface.6. Sensor plate 14. Main bearing cap

“a” : 3 mm (0.12 in.) 7. Crankshaft timing sprocket key 15. Flywheel mounting bolt

: Apply sealant 99000-31110 to thread

part.

“b” : 2 mm (0.08 in.) 8. Crankshaft 16. Rear oil seal housing mounting bolt

1. CKP sensor (if equipped) 9. Thrust bearing 17. Main bearing cap No.2 bolt

2. Knock sensor 10. Rear oil seal housing

: Apply specified amount [A] of seal-

ant 99000-31150 to mating surface. 18. Main bearing cap No.1 bolt

1) Tighten all bolts to 50 N·m (5.0 kg-m)

2) Then, turn all bolts to 60°

3. Cylinder block 11. Rear oil seal

Page 561 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-80 ENGINE MECHANICAL (M13 ENGINE)

REMOVAL

1) Remove engine assembly from vehicle as previously out-

lined.

2) Remove clutch cover, clutch disc and flywheel (drive plate

for A/T) by using special tool.

Special tool

(A) : 09924-17810

3) Remove the following parts from engine as previously out-

lined.

Oil pan and oil pump strainer

Intake manifold and exhaust manifold

Cylinder head cover

Timing chain cover

Timing chain guide, chain tensioner adjuster, chain ten-

sioner, timing chain and crankshaft timing sprocket

Camshaft, tappet and shim

Cylinder head assembly

Piston and connecting rod

4) Remove rear oil seal housing (1).

5) Loosen bearing cap No.1 and No.2 bolts in such order as

indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

Page 562 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-81

INSPECTION

Main bearing cap No.1 bolt

Measure each thread diameter of bearing cap No.1 bolts (1) at

“A” on 60 mm (2.36 in.) from seat side of flange bolt and “B” on 90

mm (3.54 in.) from seat side of flange bolt by using a micrometer

(2).

Calculate difference in diameters (“A” – “B”).

If it exceeds limit, replace with new one.

Bearing cap No.1 bolt diameter measurement points

“a” : 60 mm (2.36 in.)

“b” : 90 mm (3.54 in.)

Bearing cap No.1 bolt diameter difference

Limit (“A” – “B”) : 0.2 mm (0.008 in.)

Crankshaft

Crankshaft runout

Using a dial gauge, measure runout at center journal. Rotate

crankshaft slowly. If runout exceeds its limit, replace crankshaft.

Crankshaft runout

Limit : 0.04 mm (0.0016 in.)

Crankshaft thrust play

Measure this play with crankshaft set in cylinder block in the nor-

mal manner, that is with thrust bearing (1) and journal bearing

caps installed.

Thickness of crankshaft thrust bearing

Standard : 2.500 mm (0.0984 in.)

Oversize (0.125 mm (0.0049 in.)) : 2.563 mm (0.1009 in.)

“A”

“a”

“b”“B”

1

1

2

Page 564 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-83

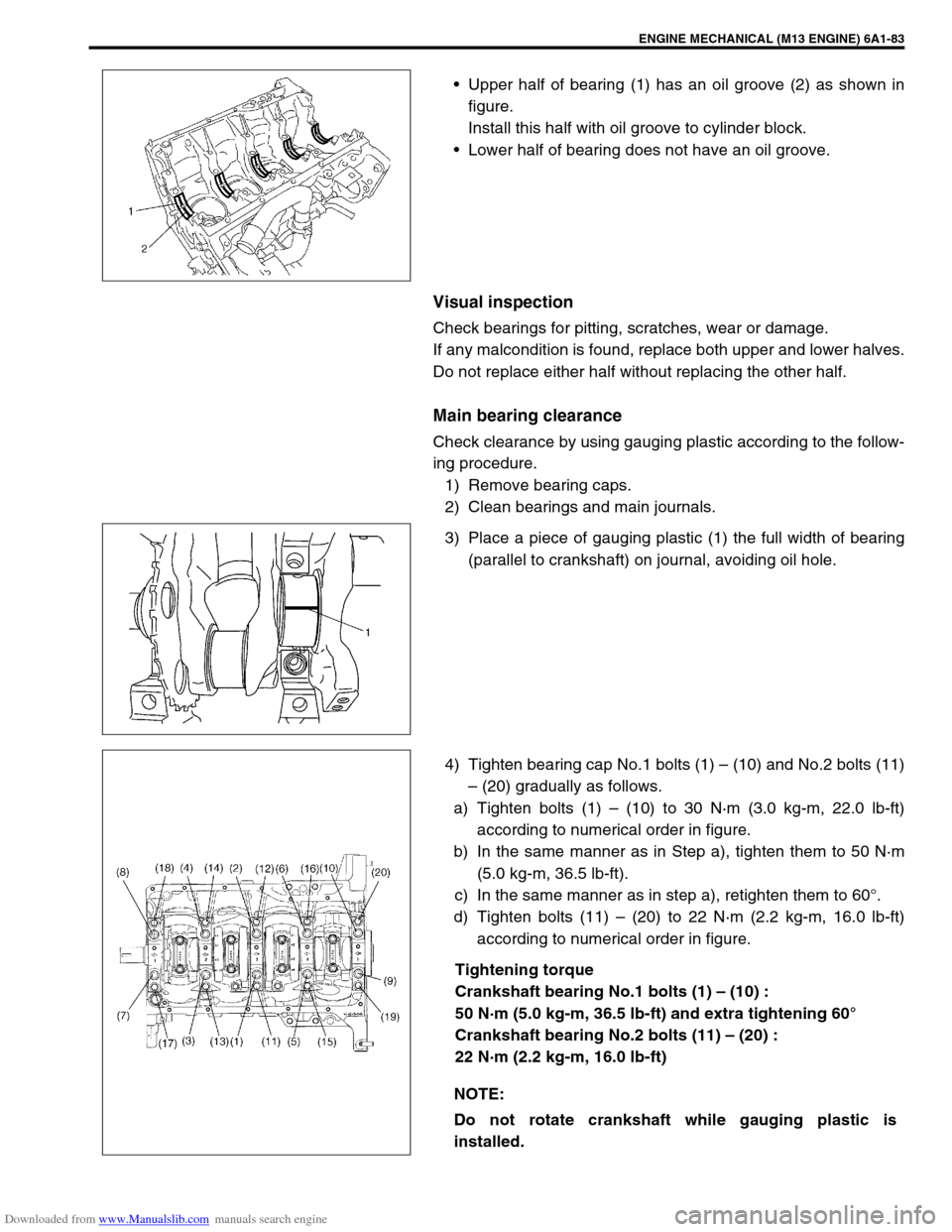

Upper half of bearing (1) has an oil groove (2) as shown in

figure.

Install this half with oil groove to cylinder block.

Lower half of bearing does not have an oil groove.

Visual inspection

Check bearings for pitting, scratches, wear or damage.

If any malcondition is found, replace both upper and lower halves.

Do not replace either half without replacing the other half.

Main bearing clearance

Check clearance by using gauging plastic according to the follow-

ing procedure.

1) Remove bearing caps.

2) Clean bearings and main journals.

3) Place a piece of gauging plastic (1) the full width of bearing

(parallel to crankshaft) on journal, avoiding oil hole.

4) Tighten bearing cap No.1 bolts (1) – (10) and No.2 bolts (11)

– (20) gradually as follows.

a) Tighten bolts (1) – (10) to 30 N·m (3.0 kg-m, 22.0 lb-ft)

according to numerical order in figure.

b) In the same manner as in Step a), tighten them to 50 N·m

(5.0 kg-m, 36.5 lb-ft).

c) In the same manner as in step a), retighten them to 60°.

d) Tighten bolts (11) – (20) to 22 N·m (2.2 kg-m, 16.0 lb-ft)

according to numerical order in figure.

Tightening torque

Crankshaft bearing No.1 bolts (1) – (10) :

50 N·m (5.0 kg-m, 36.5 lb-ft) and extra tightening 60°

Crankshaft bearing No.2 bolts (11) – (20) :

22 N·m (2.2 kg-m, 16.0 lb-ft)

NOTE:

Do not rotate crankshaft while gauging plastic is

installed.

Page 565 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-84 ENGINE MECHANICAL (M13 ENGINE)

5) Remove bearing caps and using scale (1) on gauging plastic

(2) envelop, measure gauging plastic width at its widest

point. If clearance exceeds its limit, replace bearing. Always

replace both upper and lower inserts as a unit.

A new standard bearing may produce proper clearance. If

not, it will be necessary to regrind crankshaft journal for use

of 0.25 mm undersize bearing.

After selecting new bearing, recheck clearance.

Main bearing clearance

Standard : 0.025 – 0.045 mm (0.0010 – 0.0018 in.)

Limit : 0.065 mm (0.0026 in.)

Selection of main bearings

STANDARD BEARING:

If bearing is in malcondition, or bearing clearance is out of specifi-

cation, select a new standard bearing according to the following

procedure and install it.

1) First check journal diameter. As shown in figure, crank web

No.2 has stamped numbers.

Three kinds of numbers (“1”, “2” and “3”) represent the fol-

lowing journal diameters.

Stamped numbers on crank web No.2 represent journal

diameters marked with an arrow in figure respectively.

For example, stamped number “1” indicates that correspond-

ing journal diameter is 44.994 – 45.000 mm (1.7714 –

1.7717 in.).

Crankshaft journal diameter NOTE:

After checking the bearing clearance, check for thread

deformation of each bearing cap No.1 bolt according to

previous mentioned Step 4) once again.

Stamped numbers Journal diameter

144.994 – 45.000 mm

(1.7714 – 1.7717 in.)

244.988 – 44.994 mm

(1.7712 – 1.7714 in.)

344.982 – 44.988 mm

(1.7709 – 1.7712 in.)

Page 566 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-85

2) Next, check bearing cap bore diameter without bearing. On

mating surface of cylinder block, five alphabets are stamped

as shown in figure.

Three kinds of alphabets (“A”, “B” and “C”) represent the fol-

lowing cap bore diameters.

Stamped alphabets on cylinder block represent bearing cap

bore diameter marked with an arrow in figure respectively.

For example, stamped “A” indicates that corresponding

bearing cap bore diameter is 49.000 – 49.006 mm (1.9291 –

1.9294 in.).

Crankshaft bearing cap bore

3) There are five kinds of standard bearings differing in thick-

ness. To distinguish them, they are painted in the following

colors at the center of bearings.

Each color indicates the following thickness.

Standard size of crankshaft main bearingStamped alphabetBearing cap bore diameter

(without bearing)

A49.000 – 49.006 mm

(1.9291 – 1.9294 in.)

B49.006 – 49.012 mm

(1.9294 – 1.9296 in.)

C49.012 – 49.018 mm

(1.9296 – 1.9298 in.)

Color painted Bearing thickness

Pink1.990 – 1.994 mm

(0.0783 – 0.0785 in.)

Purple1.993 – 1.997 mm

(0.0785 – 0.0786 in.)

Brown1.996 – 2.000 mm

(0.0786 – 0.0787 in.)

Green1.999 – 2.003 mm

(0.0787 – 0.0789 in.)

Black2.002 – 2.006 mm

(0.0788 – 0.0790 in.)

1. Paint

Page 569 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-88 ENGINE MECHANICAL (M13 ENGINE)

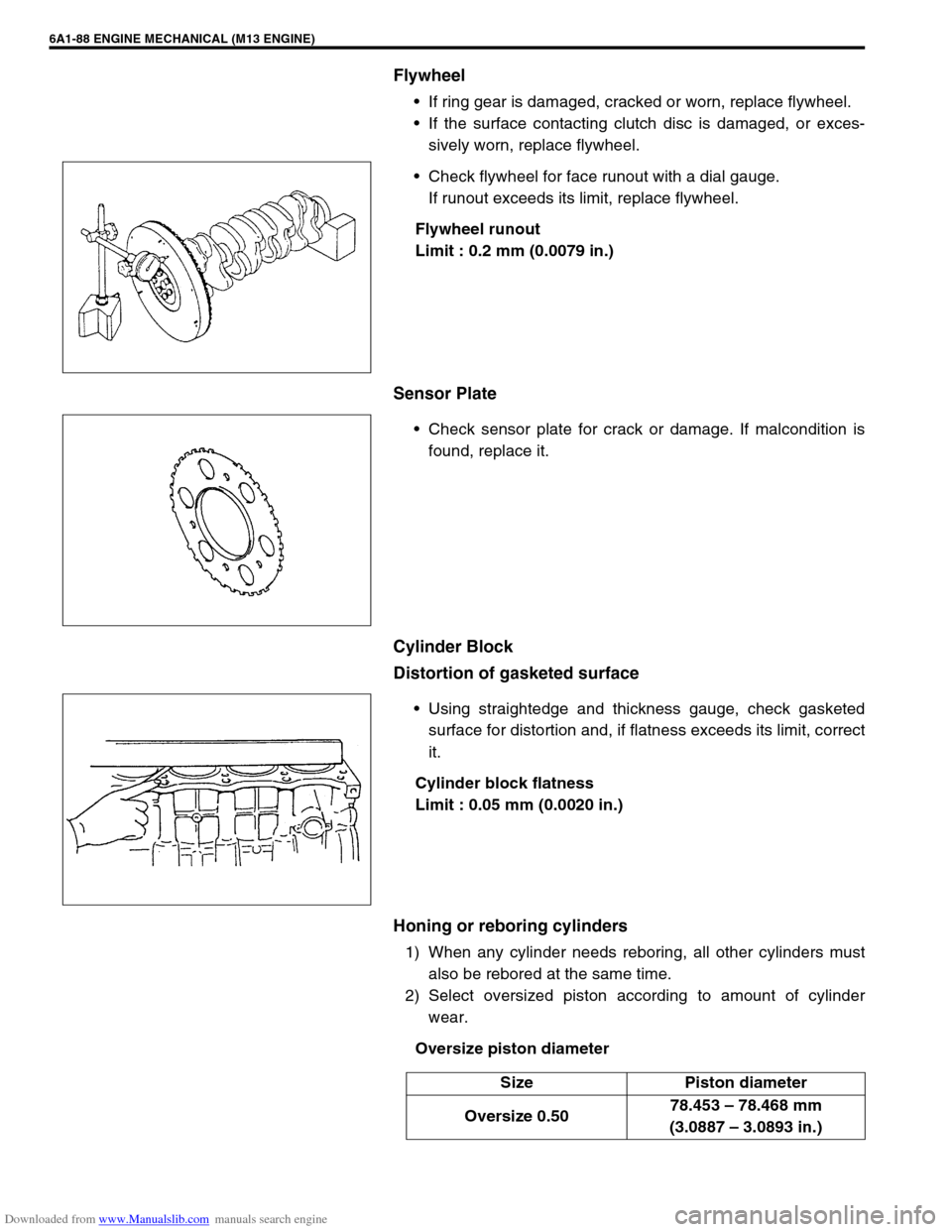

Flywheel

If ring gear is damaged, cracked or worn, replace flywheel.

If the surface contacting clutch disc is damaged, or exces-

sively worn, replace flywheel.

Check flywheel for face runout with a dial gauge.

If runout exceeds its limit, replace flywheel.

Flywheel runout

Limit : 0.2 mm (0.0079 in.)

Sensor Plate

Check sensor plate for crack or damage. If malcondition is

found, replace it.

Cylinder Block

Distortion of gasketed surface

Using straightedge and thickness gauge, check gasketed

surface for distortion and, if flatness exceeds its limit, correct

it.

Cylinder block flatness

Limit : 0.05 mm (0.0020 in.)

Honing or reboring cylinders

1) When any cylinder needs reboring, all other cylinders must

also be rebored at the same time.

2) Select oversized piston according to amount of cylinder

wear.

Oversize piston diameter

Size Piston diameter

Oversize 0.5078.453 – 78.468 mm

(3.0887 – 3.0893 in.)

Page 570 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE MECHANICAL (M13 ENGINE) 6A1-89

3) Using micrometer, measure piston diameter.

Measurement position for piston diameter

“a” : 19.5 mm (0.77 in.)

4) Calculate cylinder bore diameter to be rebored as follows.

D = A + B – C

D : Cylinder bore diameter to be rebored.

A : Piston diameter as measured.

B : Piston clearance = 0.02 –0.04 mm (0.0008 – 0.0016 in.)

C : Allowance for honing = 0.02 mm (0.0008 in.)

5) Rebore and hone cylinder to calculated dimension.

6) Measure piston clearance after honing.

NOTE:

Before reboring, install all main bearing caps in place

and tighten to specification to avoid distortion of bearing

bores.

Page 571 of 687

Downloaded from www.Manualslib.com manuals search engine 6A1-90 ENGINE MECHANICAL (M13 ENGINE)

INSTALLATION

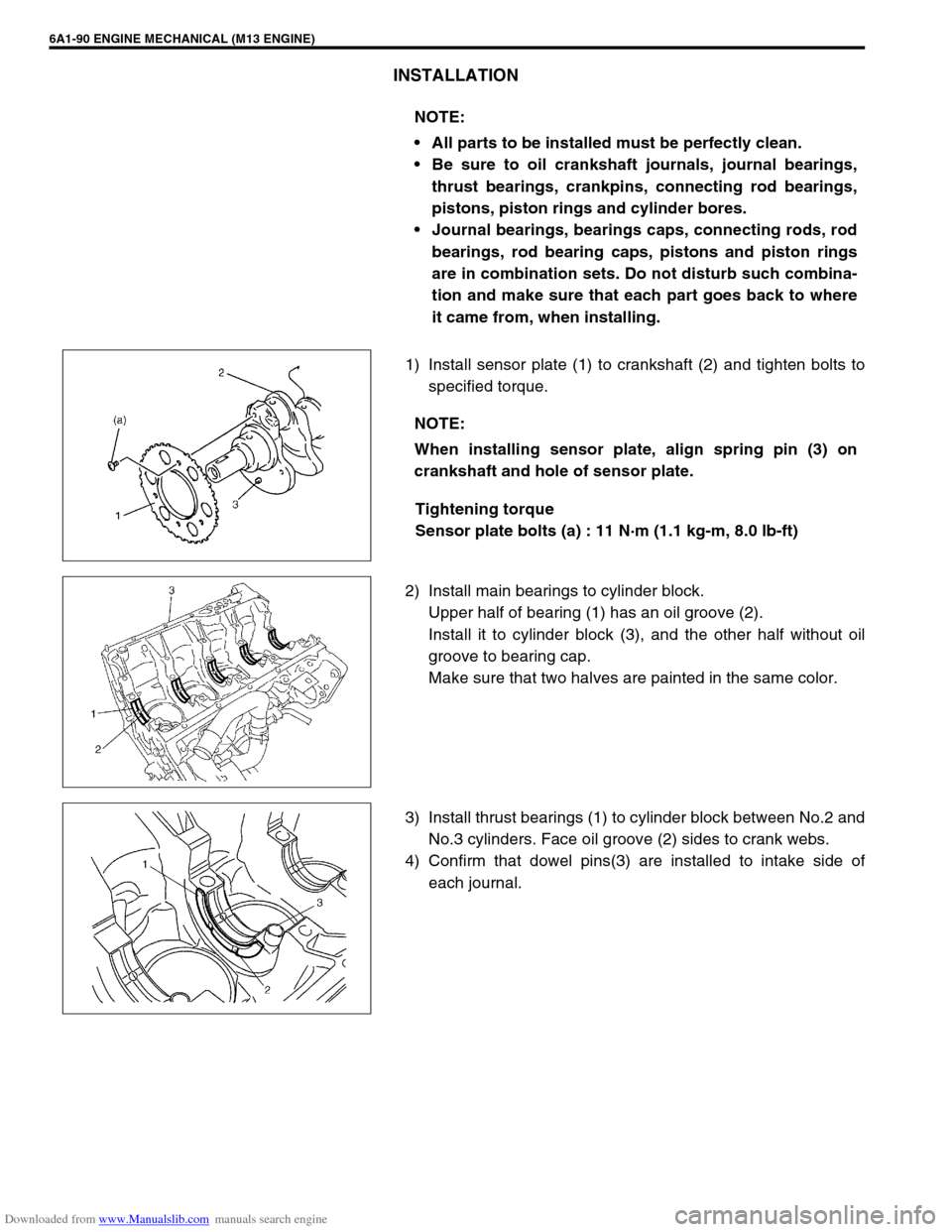

1) Install sensor plate (1) to crankshaft (2) and tighten bolts to

specified torque.

Tightening torque

Sensor plate bolts (a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

2) Install main bearings to cylinder block.

Upper half of bearing (1) has an oil groove (2).

Install it to cylinder block (3), and the other half without oil

groove to bearing cap.

Make sure that two halves are painted in the same color.

3) Install thrust bearings (1) to cylinder block between No.2 and

No.3 cylinders. Face oil groove (2) sides to crank webs.

4) Confirm that dowel pins(3) are installed to intake side of

each journal. NOTE:

All parts to be installed must be perfectly clean.

Be sure to oil crankshaft journals, journal bearings,

thrust bearings, crankpins, connecting rod bearings,

pistons, piston rings and cylinder bores.

Journal bearings, bearings caps, connecting rods, rod

bearings, rod bearing caps, pistons and piston rings

are in combination sets. Do not disturb such combina-

tion and make sure that each part goes back to where

it came from, when installing.

NOTE:

When installing sensor plate, align spring pin (3) on

crankshaft and hole of sensor plate.