No start SUZUKI JIMNY 2005 3.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 376 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-19

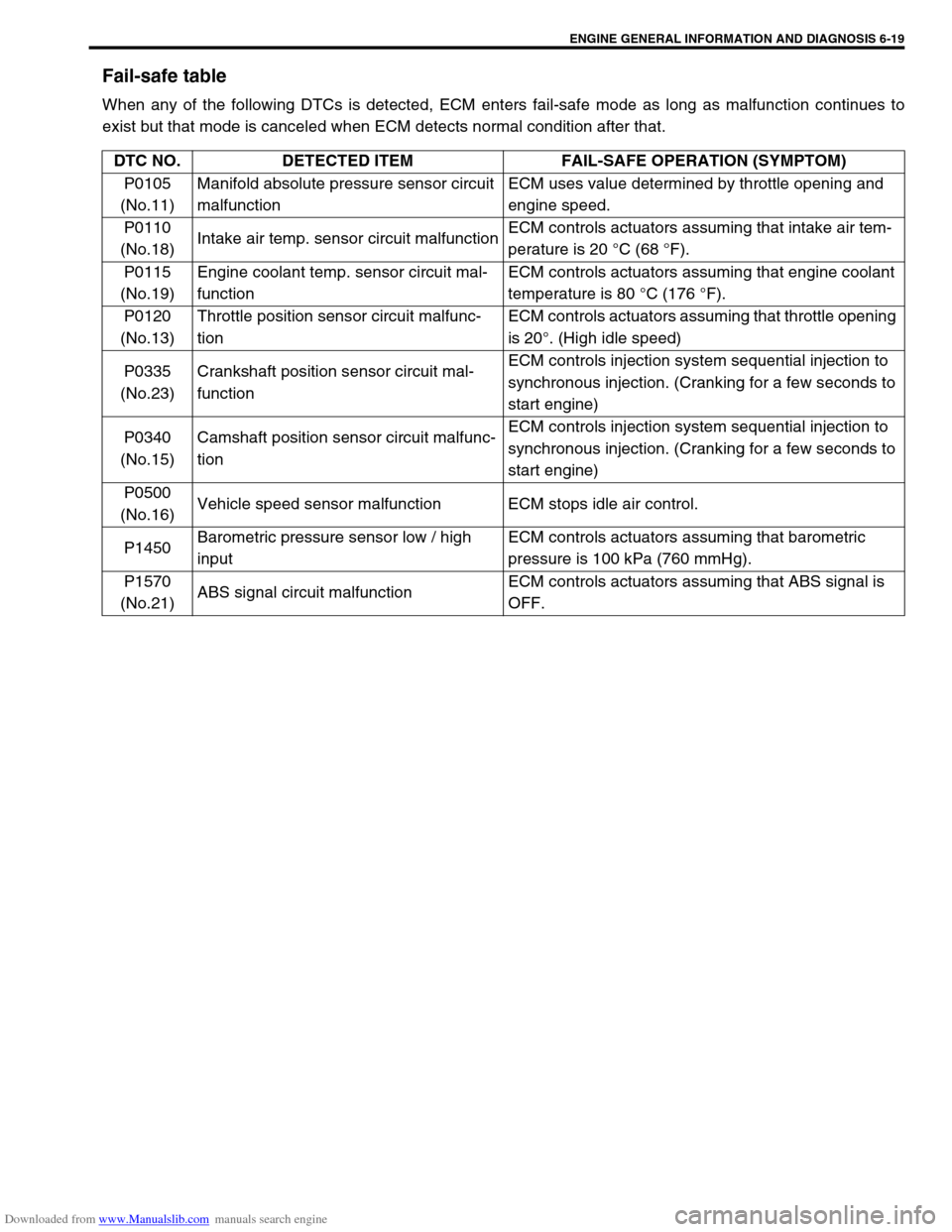

Fail-safe table

When any of the following DTCs is detected, ECM enters fail-safe mode as long as malfunction continues to

exist but that mode is canceled when ECM detects normal condition after that.

DTC NO. DETECTED ITEM FAIL-SAFE OPERATION (SYMPTOM)

P0105

(No.11)Manifold absolute pressure sensor circuit

malfunctionECM uses value determined by throttle opening and

engine speed.

P0110

(No.18)Intake air temp. sensor circuit malfunctionECM controls actuators assuming that intake air tem-

perature is 20 °C (68 °F).

P0115

(No.19)Engine coolant temp. sensor circuit mal-

functionECM controls actuators assuming that engine coolant

temperature is 80 °C (176 °F).

P0120

(No.13)Throttle position sensor circuit malfunc-

tionECM controls actuators assuming that throttle opening

is 20°. (High idle speed)

P0335

(No.23)Crankshaft position sensor circuit mal-

functionECM controls injection system sequential injection to

synchronous injection. (Cranking for a few seconds to

start engine)

P0340

(No.15)Camshaft position sensor circuit malfunc-

tionECM controls injection system sequential injection to

synchronous injection. (Cranking for a few seconds to

start engine)

P0500

(No.16)Vehicle speed sensor malfunction ECM stops idle air control.

P1450Barometric pressure sensor low / high

inputECM controls actuators assuming that barometric

pressure is 100 kPa (760 mmHg).

P1570

(No.21)ABS signal circuit malfunctionECM controls actuators assuming that ABS signal is

OFF.

Page 377 of 687

Downloaded from www.Manualslib.com manuals search engine 6-20 ENGINE GENERAL INFORMATION AND DIAGNOSIS

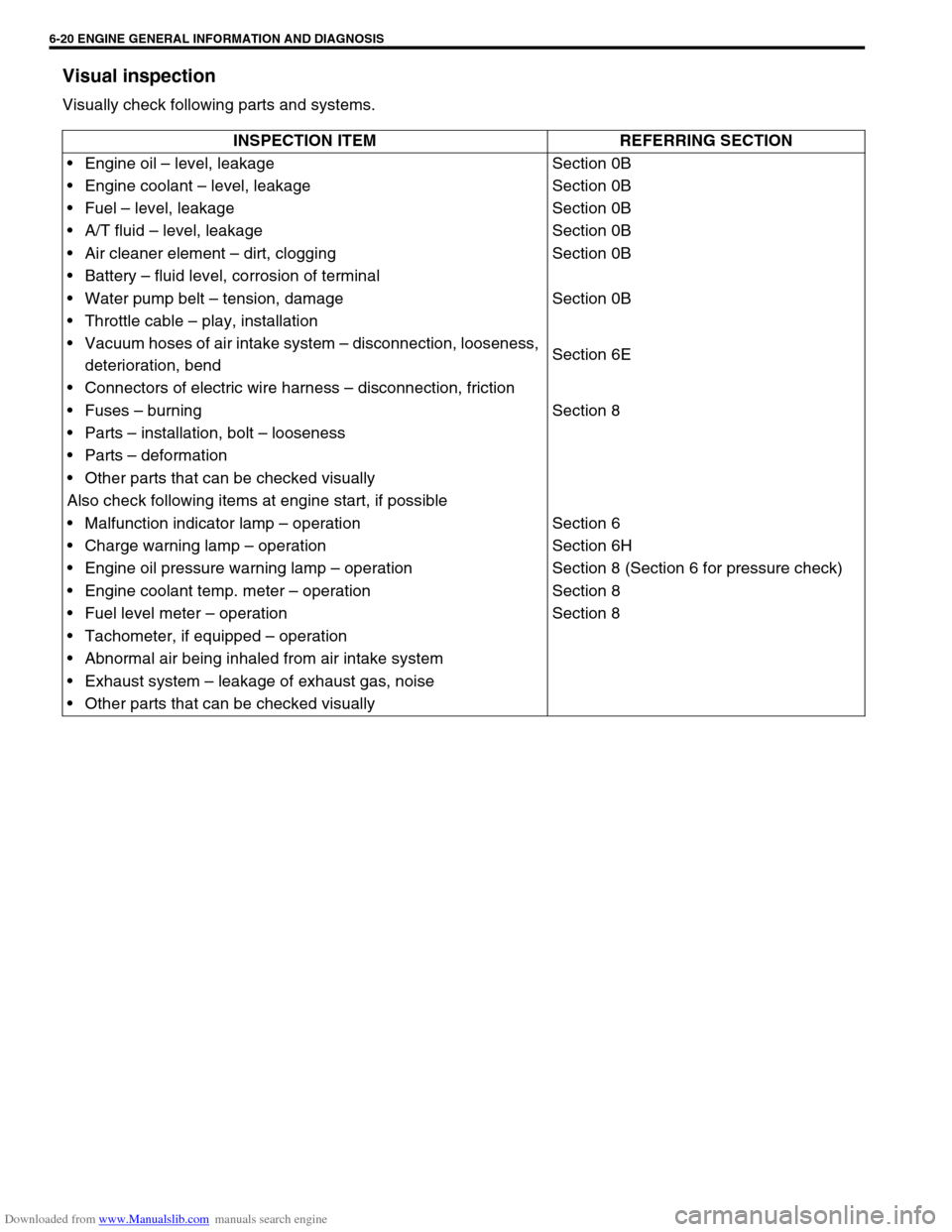

Visual inspection

Visually check following parts and systems.

INSPECTION ITEM REFERRING SECTION

Engine oil – level, leakage Section 0B

Engine coolant – level, leakage Section 0B

Fuel – level, leakage Section 0B

A/T fluid – level, leakage Section 0B

Air cleaner element – dirt, clogging Section 0B

Battery – fluid level, corrosion of terminal

Water pump belt – tension, damage Section 0B

Throttle cable – play, installation

Section 6E Vacuum hoses of air intake system – disconnection, looseness,

deterioration, bend

Connectors of electric wire harness – disconnection, friction

Fuses – burning Section 8

Parts – installation, bolt – looseness

Parts – deformation

Other parts that can be checked visually

Also check following items at engine start, if possible

Malfunction indicator lamp – operation Section 6

Charge warning lamp – operation Section 6H

Engine oil pressure warning lamp – operation Section 8 (Section 6 for pressure check)

Engine coolant temp. meter – operation Section 8

Fuel level meter – operation Section 8

Tachometer, if equipped – operation

Abnormal air being inhaled from air intake system

Exhaust system – leakage of exhaust gas, noise

Other parts that can be checked visually

Page 378 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-21

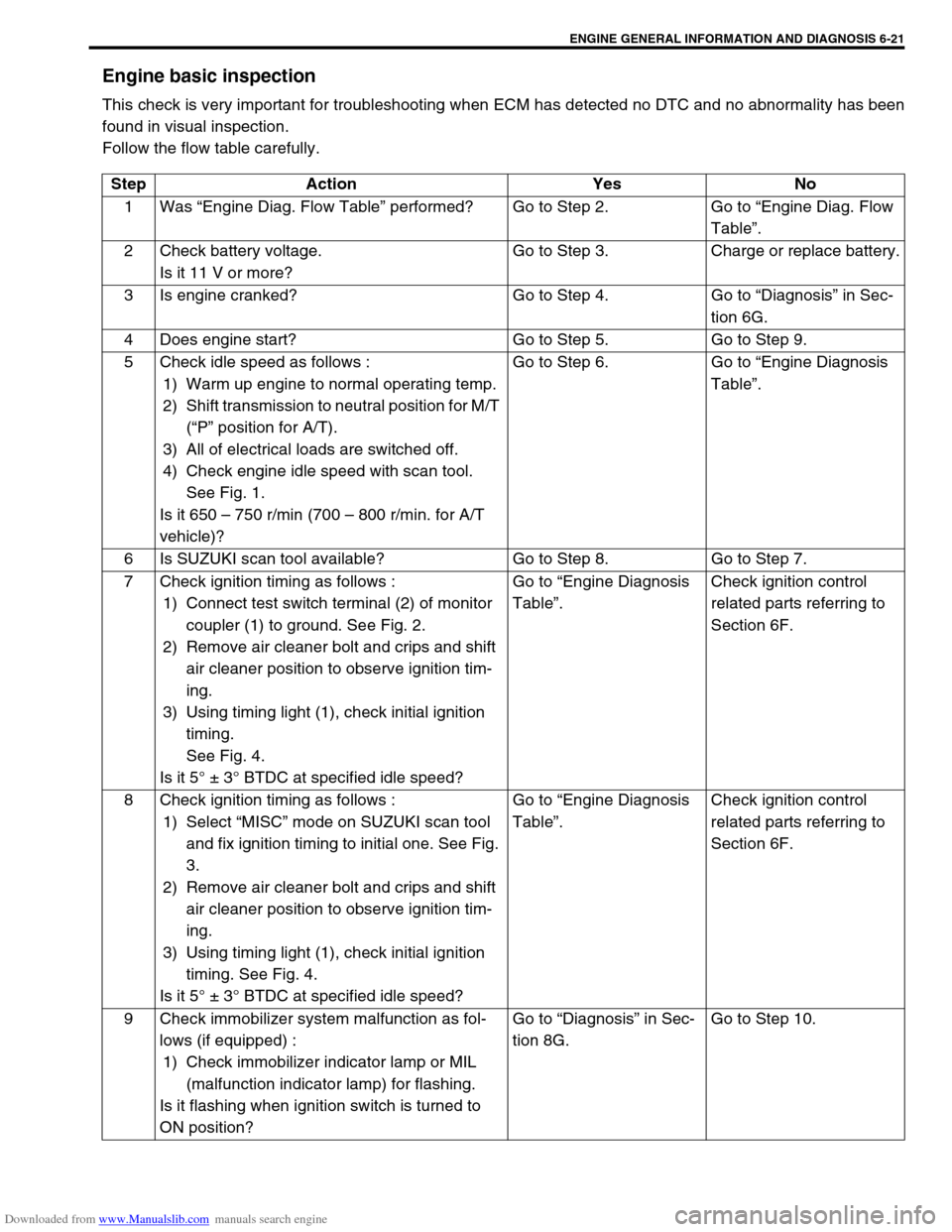

Engine basic inspection

This check is very important for troubleshooting when ECM has detected no DTC and no abnormality has been

found in visual inspection.

Follow the flow table carefully.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check battery voltage.

Is it 11 V or more?Go to Step 3. Charge or replace battery.

3 Is engine cranked? Go to Step 4. Go to “Diagnosis” in Sec-

tion 6G.

4 Does engine start? Go to Step 5. Go to Step 9.

5 Check idle speed as follows :

1) Warm up engine to normal operating temp.

2) Shift transmission to neutral position for M/T

(“P” position for A/T).

3) All of electrical loads are switched off.

4) Check engine idle speed with scan tool.

See Fig. 1.

Is it 650 – 750 r/min (700 – 800 r/min. for A/T

vehicle)?Go to Step 6. Go to “Engine Diagnosis

Table”.

6 Is SUZUKI scan tool available? Go to Step 8. Go to Step 7.

7 Check ignition timing as follows :

1) Connect test switch terminal (2) of monitor

coupler (1) to ground. See Fig. 2.

2) Remove air cleaner bolt and crips and shift

air cleaner position to observe ignition tim-

ing.

3) Using timing light (1), check initial ignition

timing.

See Fig. 4.

Is it 5° ± 3° BTDC at specified idle speed?Go to “Engine Diagnosis

Table”.Check ignition control

related parts referring to

Section 6F.

8 Check ignition timing as follows :

1) Select “MISC” mode on SUZUKI scan tool

and fix ignition timing to initial one. See Fig.

3.

2) Remove air cleaner bolt and crips and shift

air cleaner position to observe ignition tim-

ing.

3) Using timing light (1), check initial ignition

timing. See Fig. 4.

Is it 5° ± 3° BTDC at specified idle speed?Go to “Engine Diagnosis

Table”.Check ignition control

related parts referring to

Section 6F.

9 Check immobilizer system malfunction as fol-

lows (if equipped) :

1) Check immobilizer indicator lamp or MIL

(malfunction indicator lamp) for flashing.

Is it flashing when ignition switch is turned to

ON position?Go to “Diagnosis” in Sec-

tion 8G.Go to Step 10.

Page 380 of 687

![SUZUKI JIMNY 2005 3.G Service Service Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis tab SUZUKI JIMNY 2005 3.G Service Service Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis tab](/img/20/7588/w960_7588-379.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

[D] Fig. 4 for Step 7 or 8 / [E] Fig. 5 for Step 10 / [F] Fig. 6 for Step 13

Engine diagnosis table

Perform troubleshooting referring to following table when ECM has no DTC and no abnormality found in visual

inspection and engine basic inspection previously.

Condition Possible Cause Reference Item

Hard Starting

(Engine cranks OK)Faulty ignition coil Ignition coil assembly in Section 6F.

Faulty CMP sensing rotor or CKP sensing

rotorCMP sensing rotor or CKP sensing

rotor inspection in Section 6E.

Faulty idle air control system Diagnostic Flow Table B-4

Faulty ECT sensor, TP sensor, CKP sen-

sor, CMP sensor or MAP sensorECT sensor, TP sensor, CKP sensor,

CMP sensor or MAP sensor in Sec-

tion 6E.

Fuel pressure out of specification Diagnostic Flow Table B-3

Faulty fuel injector Diagnostic Flow Table B-1

Faulty ECM Inspection of ECM and its circuit in

this section.

Malfunctioning PCV system PCV system in Section 6E.

Low compression Compression check in Section 6A1.

Improper valve lash Valve lash in Section 6A1.

Improper valve timing Timing chain and chain tensioner in

Section 6A1.

Compression leak from valve seat Valves and cylinder head in Section

6A1.

Sticky valve stem Valves and cylinder head in Section

6A1.

Weak or damaged valve springs Valves and cylinder head in Section

6A1.

Compression leak at cylinder head gasket Valves and cylinder head in Section

6A1.

Sticking or damaged piston ring Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Worn piston, ring or cylinder Pistons, piston rings, connecting rods

and cylinders in Section 6A1.

Page 395 of 687

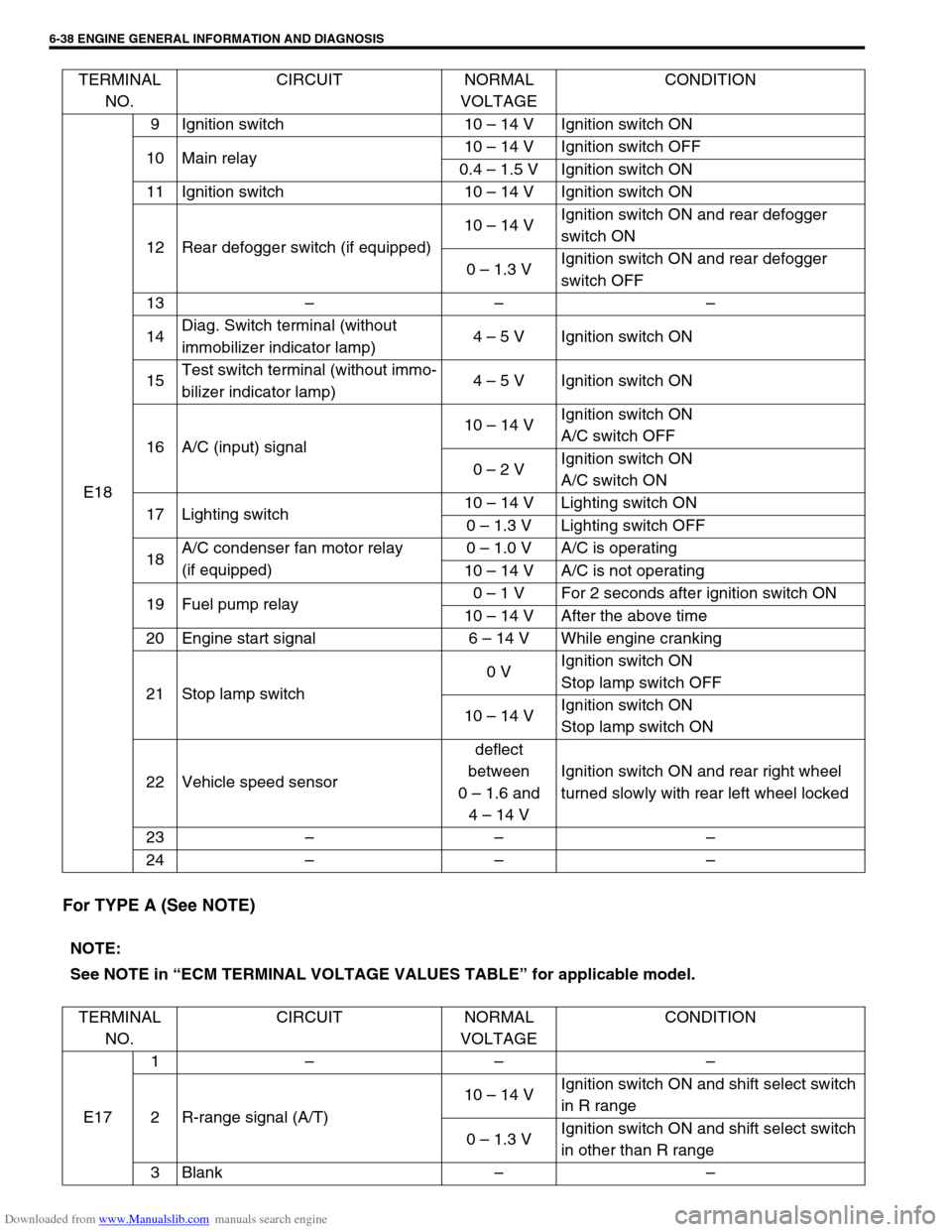

Downloaded from www.Manualslib.com manuals search engine 6-38 ENGINE GENERAL INFORMATION AND DIAGNOSIS

For TYPE A (See NOTE)

E189 Ignition switch 10 – 14 V Ignition switch ON

10 Main relay10 – 14 V Ignition switch OFF

0.4 – 1.5 V Ignition switch ON

11 Ignition switch 10 – 14 V Ignition switch ON

12 Rear defogger switch (if equipped)10 – 14 VIgnition switch ON and rear defogger

switch ON

0 – 1.3 VIgnition switch ON and rear defogger

switch OFF

13–– –

14Diag. Switch terminal (without

immobilizer indicator lamp)4 – 5 V Ignition switch ON

15Test switch terminal (without immo-

bilizer indicator lamp)4 – 5 V Ignition switch ON

16 A/C (input) signal10 – 14 VIgnition switch ON

A/C switch OFF

0 – 2 VIgnition switch ON

A/C switch ON

17 Lighting switch10 – 14 V Lighting switch ON

0 – 1.3 V Lighting switch OFF

18A/C condenser fan motor relay

(if equipped)0 – 1.0 V A/C is operating

10 – 14 V A/C is not operating

19 Fuel pump relay0 – 1 V For 2 seconds after ignition switch ON

10 – 14 V After the above time

20 Engine start signal 6 – 14 V While engine cranking

21 Stop lamp switch0 VIgnition switch ON

Stop lamp switch OFF

10 – 14 VIgnition switch ON

Stop lamp switch ON

22 Vehicle speed sensordeflect

between

0 – 1.6 and

4 – 14 VIgnition switch ON and rear right wheel

turned slowly with rear left wheel locked

23–– –

24–– – TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

NOTE:

See NOTE in “ECM TERMINAL VOLTAGE VALUES TABLE” for applicable model.

TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

E171–– –

2 R-range signal (A/T)10 – 14 VIgnition switch ON and shift select switch

in R range

0 – 1.3 VIgnition switch ON and shift select switch

in other than R range

3 Blank––

Page 396 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-39

For TYPE B (See NOTE)

E174Blank––

5 Overdrive cut signal (A/T)0 – 1.0 VIgnition switch ON and ECT less than

60 °C

10 – 14 VIgnition switch ON and ECT more than

60 °C

6 D-range idle up signal (A/T)10 – 14 VIgnition switch ON and shift select switch

in other than P and N range

0 – 1.6 VIgnition switch ON and shift select switch

in P and N range

7 Stop lamp switch0 VIgnition switch ON

Stop lamp switch OFF

10 – 14 VIgnition switch ON

Stop lamp switch ON

8–– –

9 Ignition switch 10 – 14 V Ignition switch ON

10–– –

11 Vehicle speed sensordeflect

between

0 – 1.6 and

4 – 14 VIgnition switch ON and rear right wheel

turned slowly with rear left wheel locked

12 ABS signal (if equipped) 10 – 14 V Ignition switch ON

13 Engine start signal 6 – 14 V While engine cranking

14–– –

15–– –

16 Rear defogger switch (if equipped)10 – 14 V Ignition switch ON and rear defogger

switch ON

0 – 1.3 V Ignition switch ON and rear defogger

switch OFF

17 A/T failure signal (with immobilizer

indicator lamp) (A/T)–– TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

NOTE:

See NOTE in “ECM TERMINAL VOLTAGE VALUES TABLE” for applicable model.

TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

E171 A/C evaporator temp. sensor 2.0 – 2.3 VIgnition switch ON

A/C evaporator temp. sensor at 25 °C

(77 °F)

2 R-range signal (A/T)10 – 14 VIgnition switch ON and shift select switch

in R range

0 – 1.3 VIgnition switch ON and shift select switch

in other than R range

3Blank––

4Blank––

Page 400 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-43

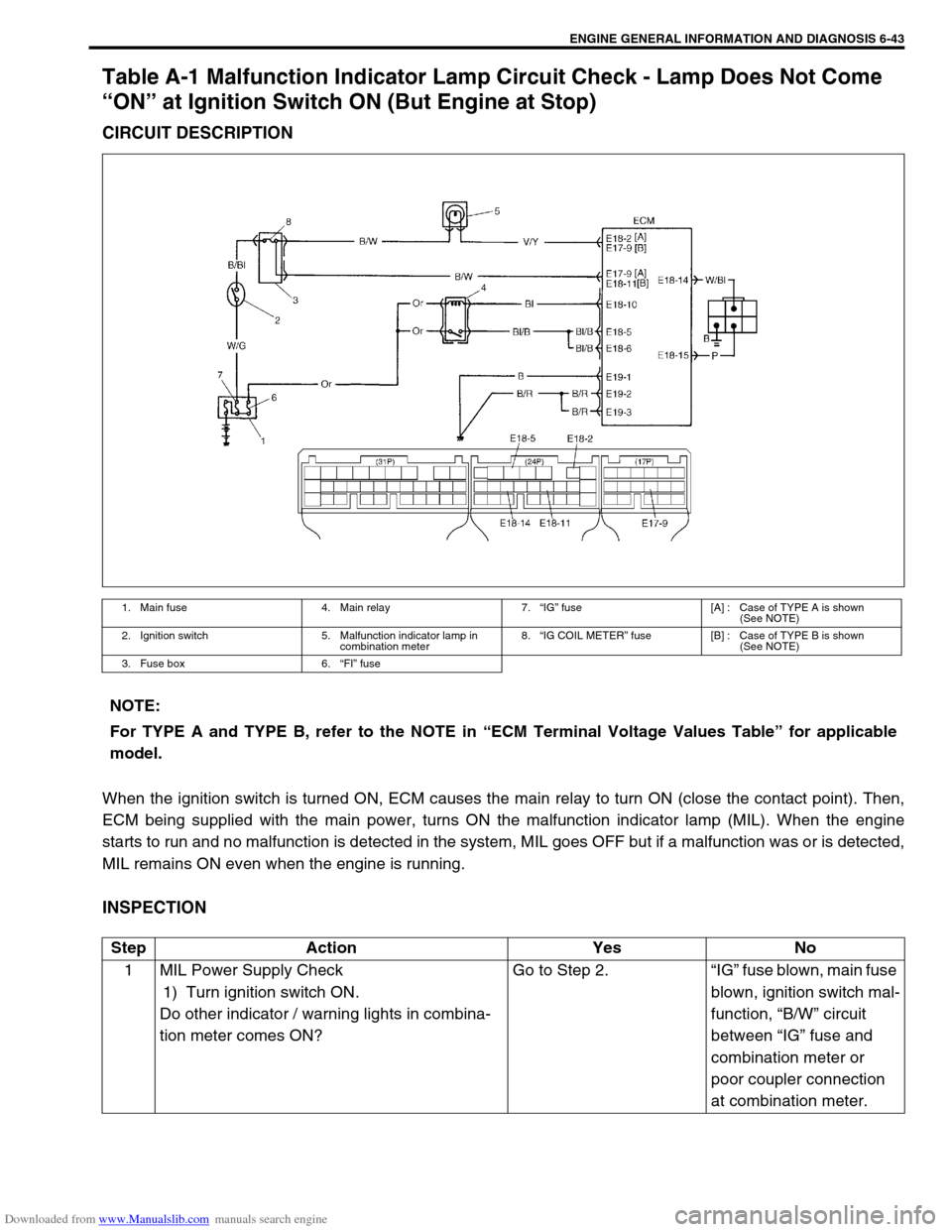

Table A-1 Malfunction Indicator Lamp Circuit Check - Lamp Does Not Come

“ON” at Ignition Switch ON (But Engine at Stop)

CIRCUIT DESCRIPTION

When the ignition switch is turned ON, ECM causes the main relay to turn ON (close the contact point). Then,

ECM being supplied with the main power, turns ON the malfunction indicator lamp (MIL). When the engine

starts to run and no malfunction is detected in the system, MIL goes OFF but if a malfunction was or is detected,

MIL remains ON even when the engine is running.

INSPECTION

1. Main fuse 4. Main relay 7.“IG” fuse [A] : Case of TYPE A is shown

(See NOTE)

2. Ignition switch 5. Malfunction indicator lamp in

combination meter8.“IG COIL METER” fuse [B] : Case of TYPE B is shown

(See NOTE)

3. Fuse box 6.“FI” fuse

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

Step Action Yes No

1 MIL Power Supply Check

1) Turn ignition switch ON.

Do other indicator / warning lights in combina-

tion meter comes ON?Go to Step 2.“IG” fuse blown, main fuse

blown, ignition switch mal-

function, “B/W” circuit

between “IG” fuse and

combination meter or

poor coupler connection

at combination meter.

Page 401 of 687

Downloaded from www.Manualslib.com manuals search engine 6-44 ENGINE GENERAL INFORMATION AND DIAGNOSIS

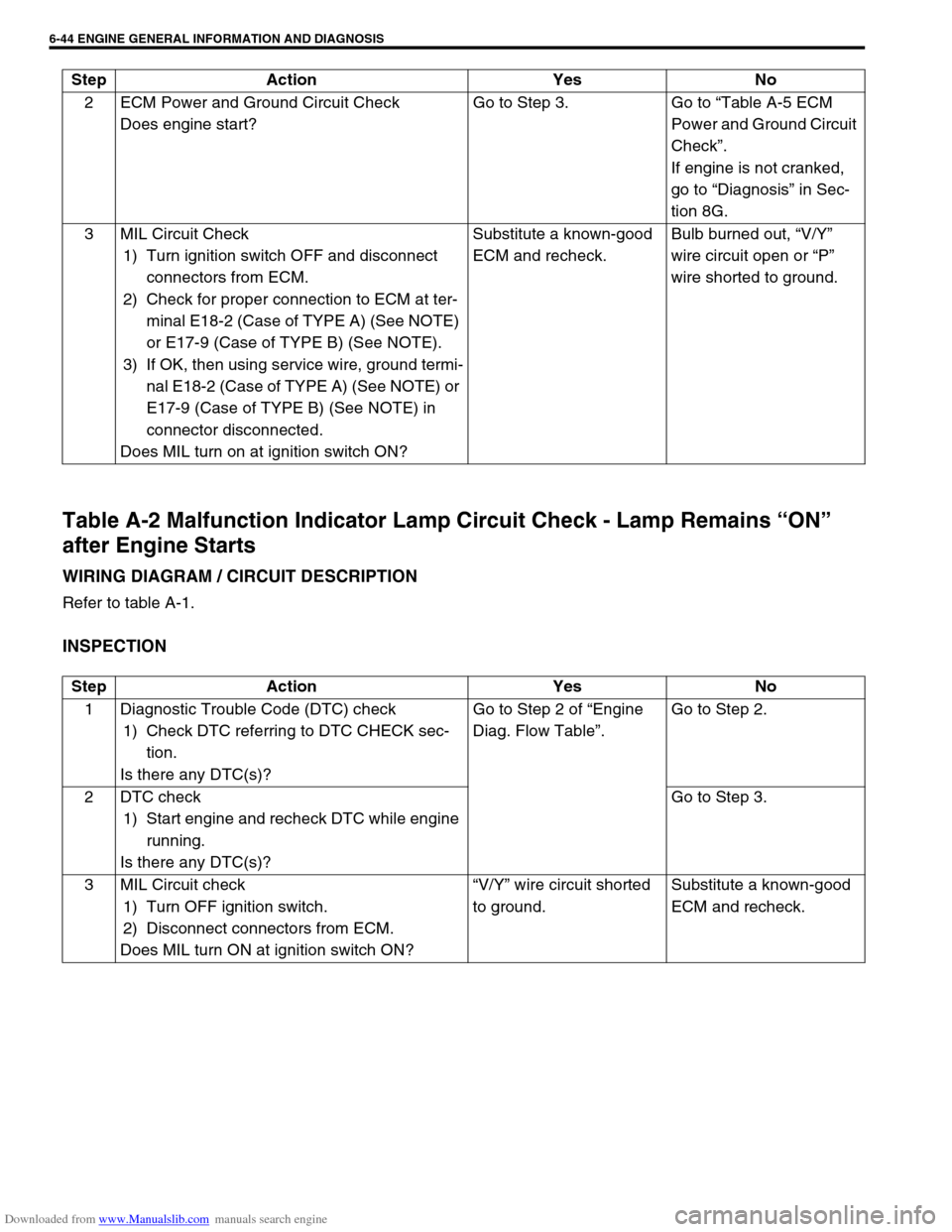

Table A-2 Malfunction Indicator Lamp Circuit Check - Lamp Remains “ON”

after Engine Starts

WIRING DIAGRAM / CIRCUIT DESCRIPTION

Refer to table A-1.

INSPECTION

2 ECM Power and Ground Circuit Check

Does engine start?Go to Step 3. Go to “Table A-5 ECM

Power and Ground Circuit

Check”.

If engine is not cranked,

go to “Diagnosis” in Sec-

tion 8G.

3 MIL Circuit Check

1) Turn ignition switch OFF and disconnect

connectors from ECM.

2) Check for proper connection to ECM at ter-

minal E18-2 (Case of TYPE A) (See NOTE)

or E17-9 (Case of TYPE B) (See NOTE).

3) If OK, then using service wire, ground termi-

nal E18-2 (Case of TYPE A) (See NOTE) or

E17-9 (Case of TYPE B) (See NOTE) in

connector disconnected.

Does MIL turn on at ignition switch ON?Substitute a known-good

ECM and recheck.Bulb burned out, “V/Y”

wire circuit open or “P”

wire shorted to ground. Step Action Yes No

Step Action Yes No

1 Diagnostic Trouble Code (DTC) check

1) Check DTC referring to DTC CHECK sec-

tion.

Is there any DTC(s)?Go to Step 2 of “Engine

Diag. Flow Table”.Go to Step 2.

2DTC check

1) Start engine and recheck DTC while engine

running.

Is there any DTC(s)?Go to Step 3.

3 MIL Circuit check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

Does MIL turn ON at ignition switch ON?“V/Y” wire circuit shorted

to ground.Substitute a known-good

ECM and recheck.

Page 403 of 687

Downloaded from www.Manualslib.com manuals search engine 6-46 ENGINE GENERAL INFORMATION AND DIAGNOSIS

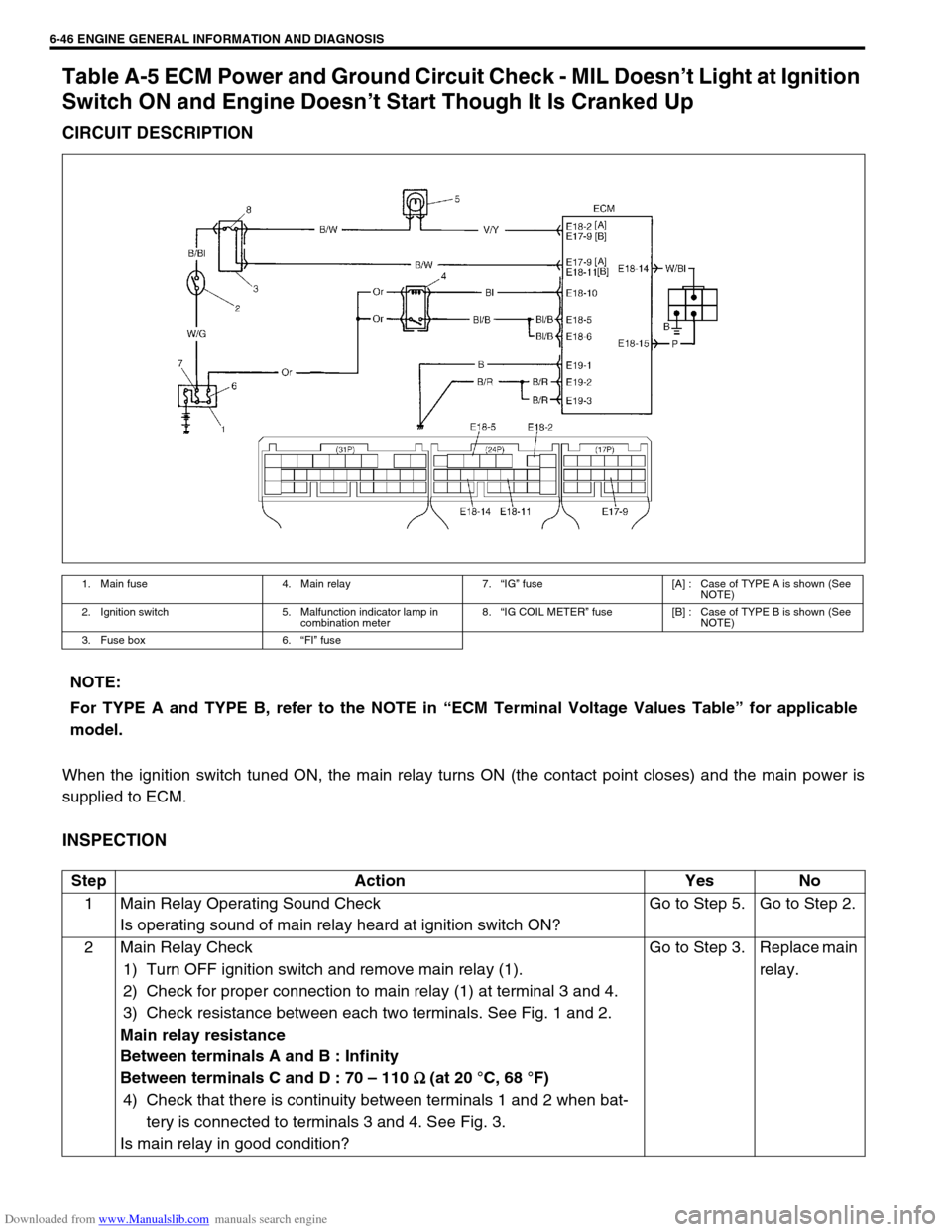

Table A-5 ECM Power and Ground Circuit Check - MIL Doesn’t Light at Ignition

Switch ON and Engine Doesn’t Start Though It Is Cranked Up

CIRCUIT DESCRIPTION

When the ignition switch tuned ON, the main relay turns ON (the contact point closes) and the main power is

supplied to ECM.

INSPECTION

1. Main fuse 4. Main relay 7.“IG” fuse [A] : Case of TYPE A is shown (See

NOTE)

2. Ignition switch 5. Malfunction indicator lamp in

combination meter8.“IG COIL METER” fuse [B] : Case of TYPE B is shown (See

NOTE)

3. Fuse box 6.“FI” fuse

NOTE:

For TYPE A and TYPE B, refer to the NOTE in “ECM Terminal Voltage Values Table” for applicable

model.

Step Action Yes No

1 Main Relay Operating Sound Check

Is operating sound of main relay heard at ignition switch ON?Go to Step 5. Go to Step 2.

2 Main Relay Check

1) Turn OFF ignition switch and remove main relay (1).

2) Check for proper connection to main relay (1) at terminal 3 and 4.

3) Check resistance between each two terminals. See Fig. 1 and 2.

Main relay resistance

Between terminals A and B : Infinity

Between terminals C and D : 70 – 110

Ω

Ω Ω Ω (at 20 °C, 68 °F)

4) Check that there is continuity between terminals 1 and 2 when bat-

tery is connected to terminals 3 and 4. See Fig. 3.

Is main relay in good condition?Go to Step 3. Replace main

relay.

Page 405 of 687

Downloaded from www.Manualslib.com manuals search engine 6-48 ENGINE GENERAL INFORMATION AND DIAGNOSIS

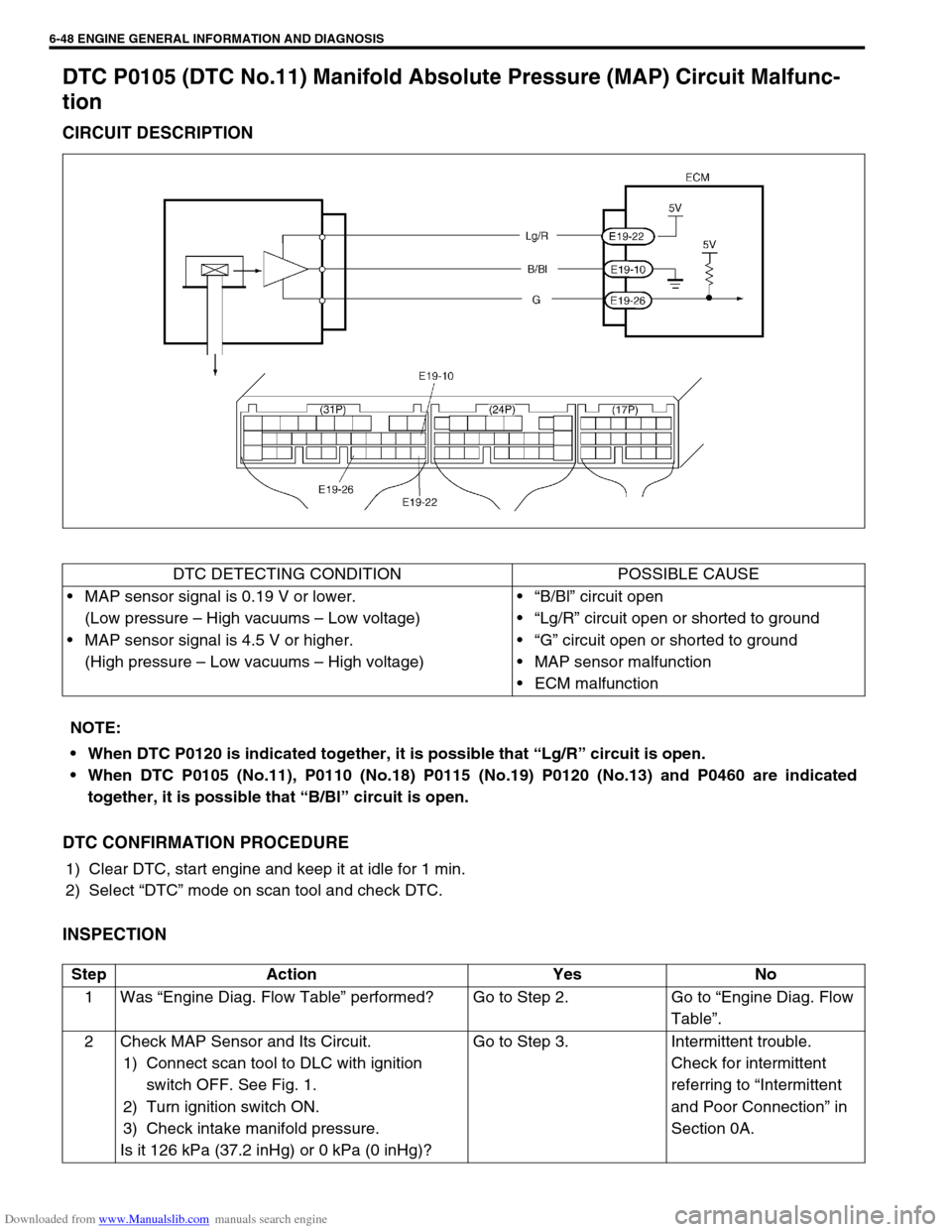

DTC P0105 (DTC No.11) Manifold Absolute Pressure (MAP) Circuit Malfunc-

tion

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode on scan tool and check DTC.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

MAP sensor signal is 0.19 V or lower.

(Low pressure – High vacuums – Low voltage)

MAP sensor signal is 4.5 V or higher.

(High pressure – Low vacuums – High voltage)“B/Bl” circuit open

“Lg/R” circuit open or shorted to ground

“G” circuit open or shorted to ground

MAP sensor malfunction

ECM malfunction

NOTE:

When DTC P0120 is indicated together, it is possible that “Lg/R” circuit is open.

When DTC P0105 (No.11), P0110 (No.18) P0115 (No.19) P0120 (No.13) and P0460 are indicated

together, it is possible that “B/Bl” circuit is open.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check MAP Sensor and Its Circuit.

1) Connect scan tool to DLC with ignition

switch OFF. See Fig. 1.

2) Turn ignition switch ON.

3) Check intake manifold pressure.

Is it 126 kPa (37.2 inHg) or 0 kPa (0 inHg)?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.