No start SUZUKI JIMNY 2005 3.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 408 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-51

DTC P0110 (DTC No.18) Intake Air Temp. (IAT) Circuit Malfunction

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode no scan tool and check DTC.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

Low intake air temperature (High voltage-High resistance)

High intake air temperature (Low voltage-Low resistance)“Lg/R” circuit open or shorted to power.

“B/Bl” circuit open

IAT sensor malfunction

ECM malfunction

NOTE:

When DTC P0105 (No.11), P0110 (No.18), P046, P0115 (No.19) and P0120 (No.13) are indicated

together, it is possible that “B/Bl” circuit is open.

Before inspecting, be sure to check that ambient temperature is higher than –40 °C (–40 °F).

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check IAT Sensor and Its Circuit.

1) Connect scan tool to DLC with ignition

switch OFF. See Fig. 1.

2) Turn ignition switch ON.

3) Check intake air temp. displayed on scan

tool.

Is –40 °C (–40 °F) or 119 °C (246 °F) indicated?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.

Page 410 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-53

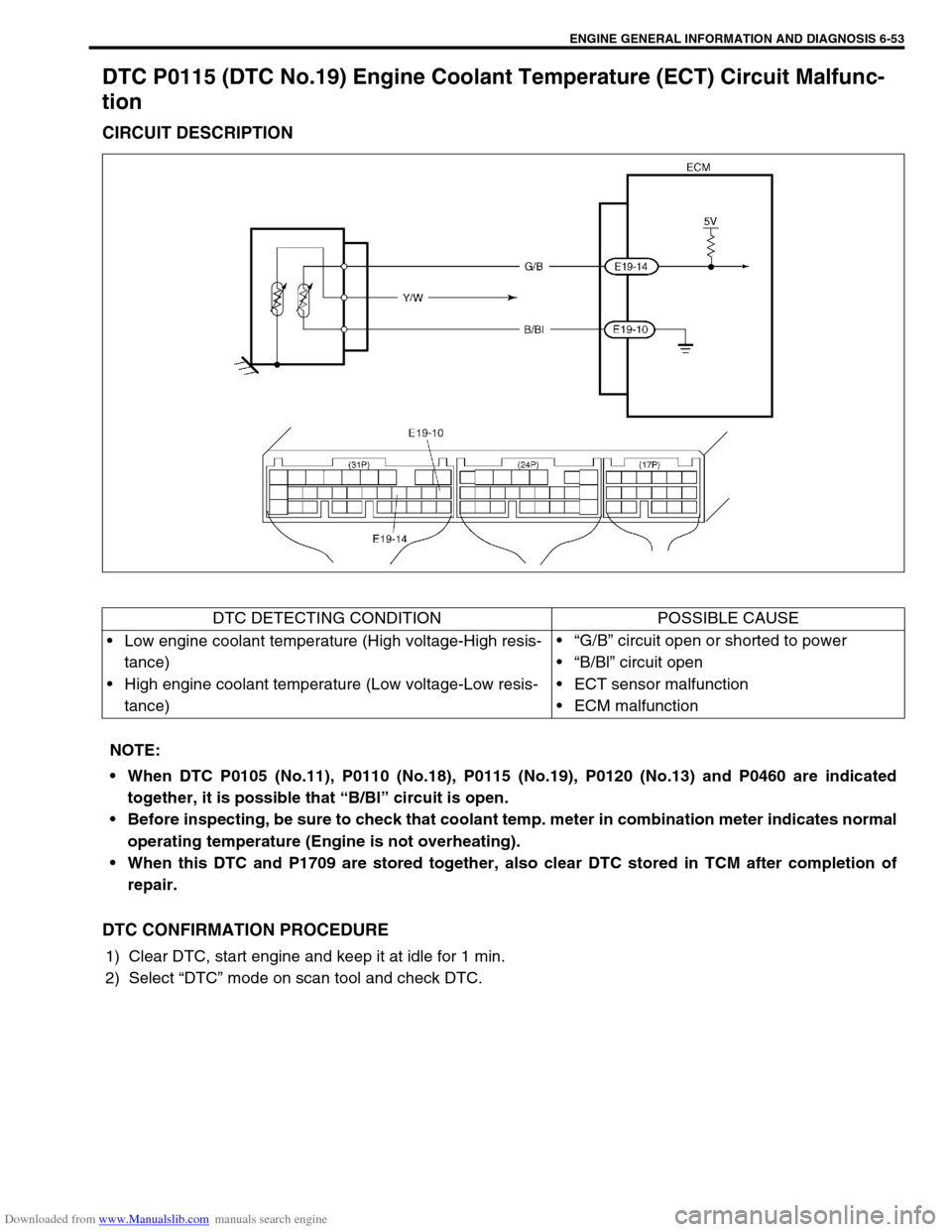

DTC P0115 (DTC No.19) Engine Coolant Temperature (ECT) Circuit Malfunc-

tion

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode on scan tool and check DTC.

DTC DETECTING CONDITION POSSIBLE CAUSE

Low engine coolant temperature (High voltage-High resis-

tance)

High engine coolant temperature (Low voltage-Low resis-

tance)“G/B” circuit open or shorted to power

“B/Bl” circuit open

ECT sensor malfunction

ECM malfunction

NOTE:

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19), P0120 (No.13) and P0460 are indicated

together, it is possible that “B/Bl” circuit is open.

Before inspecting, be sure to check that coolant temp. meter in combination meter indicates normal

operating temperature (Engine is not overheating).

When this DTC and P1709 are stored together, also clear DTC stored in TCM after completion of

repair.

Page 412 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-55

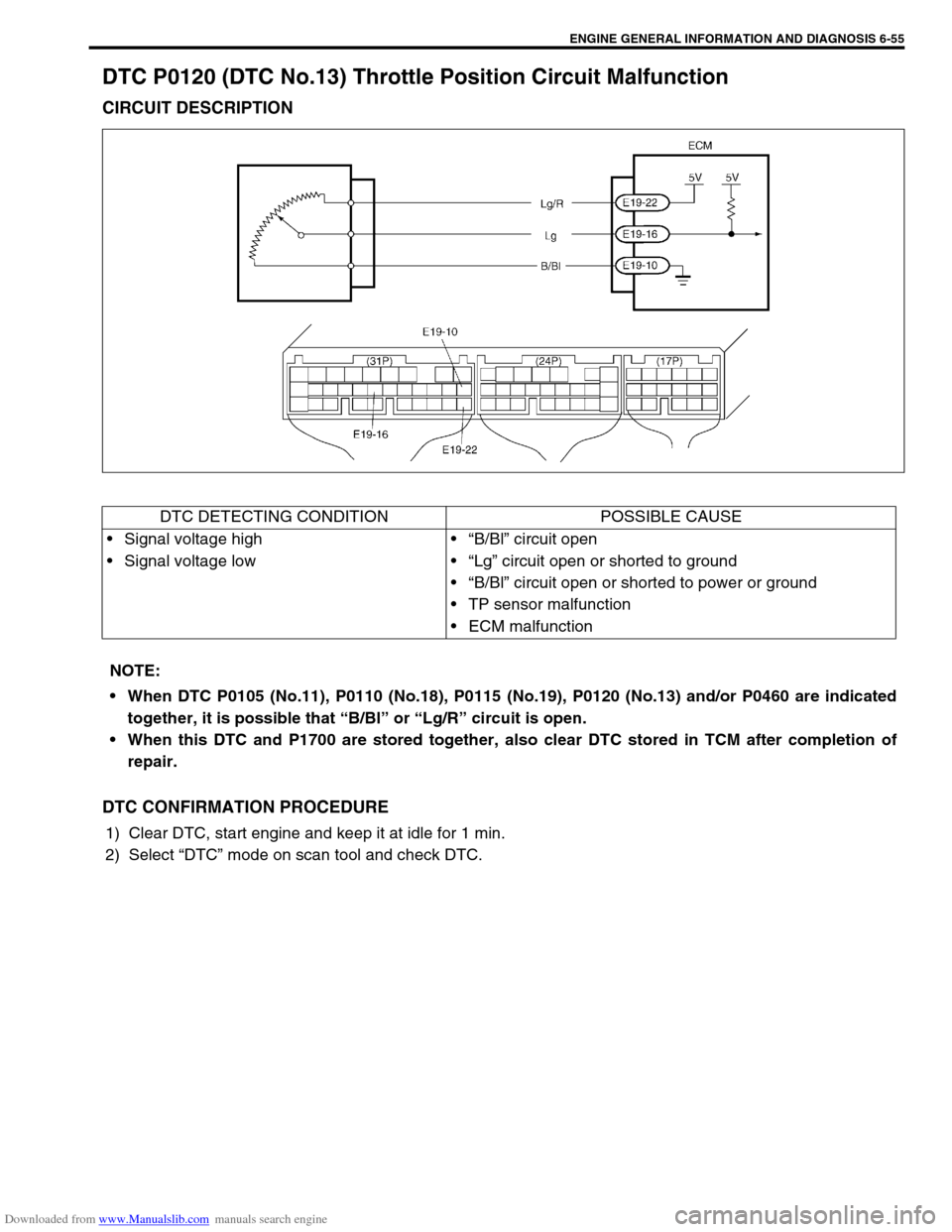

DTC P0120 (DTC No.13) Throttle Position Circuit Malfunction

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode on scan tool and check DTC. DTC DETECTING CONDITION POSSIBLE CAUSE

Signal voltage high

Signal voltage low“B/Bl” circuit open

“Lg” circuit open or shorted to ground

“B/Bl” circuit open or shorted to power or ground

TP sensor malfunction

ECM malfunction

NOTE:

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19), P0120 (No.13) and/or P0460 are indicated

together, it is possible that “B/Bl” or “Lg/R” circuit is open.

When this DTC and P1700 are stored together, also clear DTC stored in TCM after completion of

repair.

Page 419 of 687

Downloaded from www.Manualslib.com manuals search engine 6-62 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0135 (DTC No.14) Heated Oxygen Sensor (HO2S) Heater Circuit Mal-

function (Sensor-1)

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON, start engine and keep it at idle for 1 min.

3) Start vehicle and depress accelerator pedal fully for 5 sec. or longer.

4) Stop vehicle.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

1. Heated oxygen sensor-1 (HO2S-1) heater

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC will set when A or B condition is met.

A :

Low voltage at terminal E19-7 when engine is running

at high load.

B :

High voltage at terminal E19-7 when engine is running

under condition other than above.

✱

✱✱ ✱2 driving cycle detection logic, Continuous monitoring.HO2S-1 heater circuit open or shorted to ground

ECM malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

Page 420 of 687

![SUZUKI JIMNY 2005 3.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-63

INSPECTION

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3Step Action Yes No

1Was “Engine Diag. F SUZUKI JIMNY 2005 3.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-63

INSPECTION

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3Step Action Yes No

1Was “Engine Diag. F](/img/20/7588/w960_7588-419.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-63

INSPECTION

[A] Fig. 1 for Step 2 / [B] Fig. 2 for Step 3Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check Heater for Operation.

1) Check voltage at terminal E19-7. See Fig. 1.

2) Warm up engine to normal operating tem-

perature.

3) Stop engine.

4) Turn ignition switch ON and Check voltage

at terminal E19-7. See Fig. 1. Voltage

should be over 10 V.

5) Start engine, run it at idle and check voltage

at the same terminal. Voltage should be

below 1.9 V.

Are check results are specified?Intermittent trouble Check

for intermittent referring to

“Intermittent and Poor

Connection” in Section

0A.Go to Step 3.

3 Check Heater of Sensor-1.

1) Disconnect HO2S-1 coupler with ignition

switch OFF.

2) Check for proper connection to HO2S-1 at

“B/W” and “P/B” wire terminals.

3) If OK, then check heater resistance. See

Fig. 2.

Is it 5 – 6.4 Ω at 20 °C, 68 °F?“P/B” wire open or

shorted to ground or poor

connection at E19-7. If

wire and connection are

OK, substitute a known-

good ECM and recheck.Replace HO2S-1.

Page 423 of 687

Downloaded from www.Manualslib.com manuals search engine 6-66 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0141 Heated Oxygen Sensor (HO2S) Heater Circuit Malfunction (Sen-

sor-2)

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF once and then ON.

2) Clear DTC, start engine and warm up engine to normal operating temperature.

3) Keep it at 2000 r/min for 2 min.

4) Check pending DTC in “ON BOARD TEST” or “PENDING DTC” mode and DTC in “DTC” mode.

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC will set when A or B condition it met.

1) Low voltage at terminal E18-4 for specified time after

engine start or while engine running at high load.

2) High voltage at terminal E18-4 while engine running

under other than above condition.

✱

✱✱ ✱2 driving cycle detection logic, continuous monitoring.HO2S-2 heater circuit open or shorted to ground

ECM malfunction

Page 424 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-67

INSPECTION

Fig. 1 for Step 2Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 Check HO2S-2 Heater and Its Circuit.

1) Warm up engine to normal operating tem-

perature.

2) Stop engine.

3) Turn ignition switch ON and check voltage at

terminal E18-4. See Fig. 1. Voltage should

be over 10 V.

4) Start engine, run it at idle and check voltage

at the same terminal after 1 min. from

engine start.

Voltage should be below 1.9 V.

Are check result as specified?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.Go to Step 3.

3 Check Heater or Sensor-2.

1) Disconnect HO2S-2 coupler with ignition

switch OFF.

2) Check for proper connection to HO2S-2 at

“B/W” and “R/Bl” wire terminals.

3) If OK, then check heater for resistance.

Is it 11.7 – 14.3 Ω at 20 °C, 68 °F?“R/Bl” wire open or

shorted to ground or poor

connection at E18-4. If

wire and connection are

OK, substitute a known-

good ECM and recheck.Replace HO2S-2.

Page 426 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-69

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10 °C, 14 °F or higher

–Intake air temp. : 70 °C, 158 °F or lower

4) Start engine and drive vehicle under usual driving condition (described in DTC confirmation procedure of

DTC P0136) for 5 min. or longer and until engine is warmed up to normal operating temperature.

5) Keep vehicle speed at 30 – 40 mph, 50 – 60 km/h in 5th gear or “D” range for 5 min. or more.

6) Stop vehicle (do not turn ignition switch OFF).

7) Check pending DTC in “ON BOARD TEST” or “PENDING DTC” mode and DTC in “DTC” mode.

INSPECTION

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester on a level road.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag.

Flow Table”.

2 Is there DTC(s) other than fuel system

(DTC P0171 / P0172)?Go to applicable DTC

Diag. Flow Table.Go to Step 3.

3 Check HO2S-1 Output Voltage.

1) Connect scan tool to DLC with ignition switch

OFF. See Fig. 1.

2) Warm up engine to normal operating tempera-

ture and keep it at 2000 r/min. for 60 sec.

3) Repeat racing engine (Repeat depressing

accelerator pedal 5 to 6 times continuously and

take foot off from pedal to enrich and enlean

A/F mixture).

Does HO2S-1 output voltage deflect between

below 0.3 V and over 0.6 V repeatedly?Go to Step 4. Go to DTC P0130 Diag.

Flow Table (HO2S-1 cir-

cuit check).

4 Check Fuel Pressure (Refer to Section 6E for

details).

1) Release fuel pressure from fuel feed line.

2) Install fuel pressure gauge. See Fig. 2.

3) Check fuel pressure.

Fuel pressure specification

With fuel pump operating and engine at stop :

270 – 310 kPa, 2.7 – 3.1 kg/cm

2, 38.4 – 44.0 psi.

At specified idle speed :

210 – 260 kPa, 2.1 – 2.6 kg/cm

2, 29.8 – 37.0 psi.

Is measured value as specified?Go to Step 5. Go to Diag. Flow Table

B-3 Fuel Pressure

Check.

Page 430 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-73

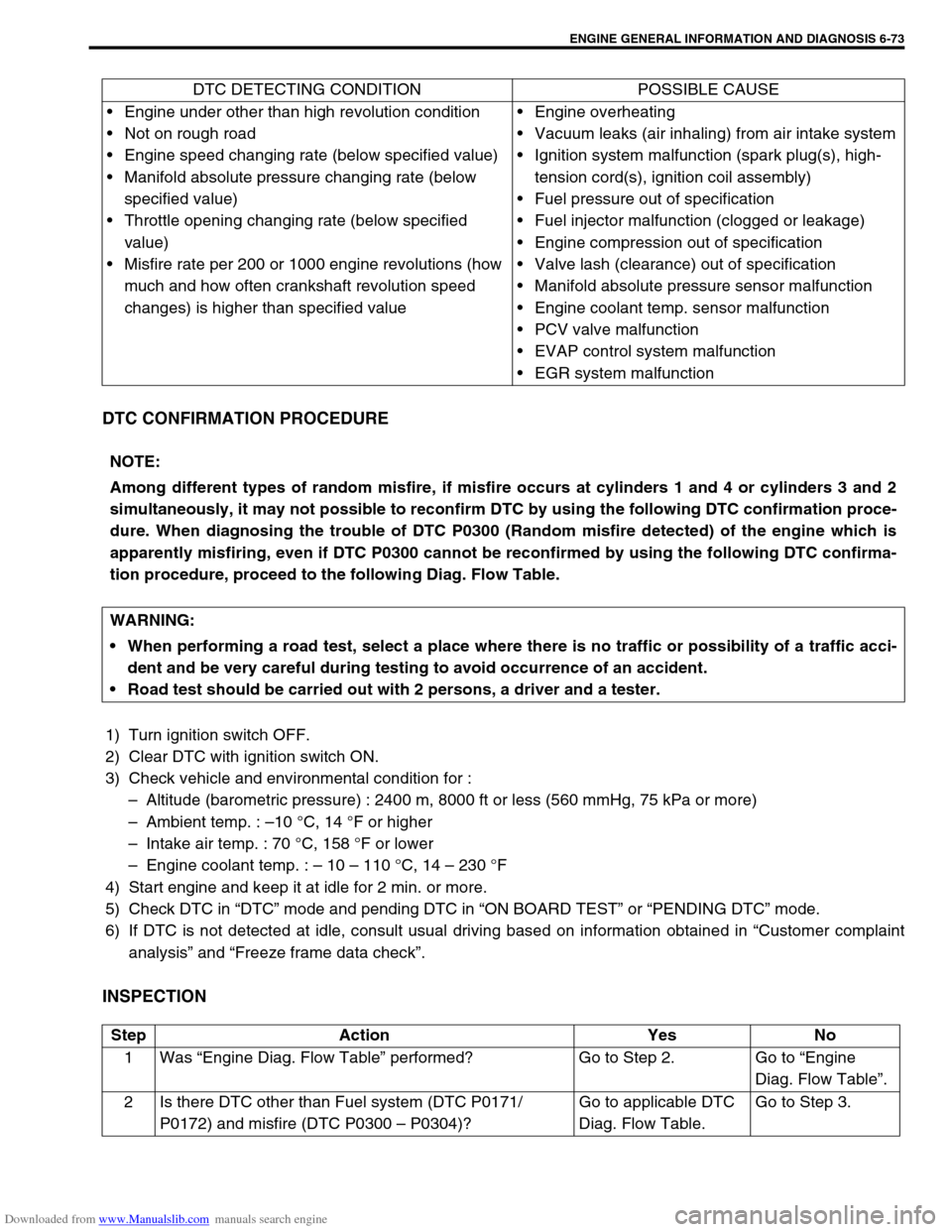

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON.

3) Check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10 °C, 14 °F or higher

–Intake air temp. : 70 °C, 158 °F or lower

–Engine coolant temp. : – 10 – 110 °C, 14 – 230 °F

4) Start engine and keep it at idle for 2 min. or more.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

6) If DTC is not detected at idle, consult usual driving based on information obtained in “Customer complaint

analysis” and “Freeze frame data check”.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

Engine under other than high revolution condition

Not on rough road

Engine speed changing rate (below specified value)

Manifold absolute pressure changing rate (below

specified value)

Throttle opening changing rate (below specified

value)

Misfire rate per 200 or 1000 engine revolutions (how

much and how often crankshaft revolution speed

changes) is higher than specified valueEngine overheating

Vacuum leaks (air inhaling) from air intake system

Ignition system malfunction (spark plug(s), high-

tension cord(s), ignition coil assembly)

Fuel pressure out of specification

Fuel injector malfunction (clogged or leakage)

Engine compression out of specification

Valve lash (clearance) out of specification

Manifold absolute pressure sensor malfunction

Engine coolant temp. sensor malfunction

PCV valve malfunction

EVAP control system malfunction

EGR system malfunction

NOTE:

Among different types of random misfire, if misfire occurs at cylinders 1 and 4 or cylinders 3 and 2

simultaneously, it may not possible to reconfirm DTC by using the following DTC confirmation proce-

dure. When diagnosing the trouble of DTC P0300 (Random misfire detected) of the engine which is

apparently misfiring, even if DTC P0300 cannot be reconfirmed by using the following DTC confirma-

tion procedure, proceed to the following Diag. Flow Table.

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine

Diag. Flow Table”.

2 Is there DTC other than Fuel system (DTC P0171/

P0172) and misfire (DTC P0300 – P0304)?Go to applicable DTC

Diag. Flow Table.Go to Step 3.

Page 434 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-77

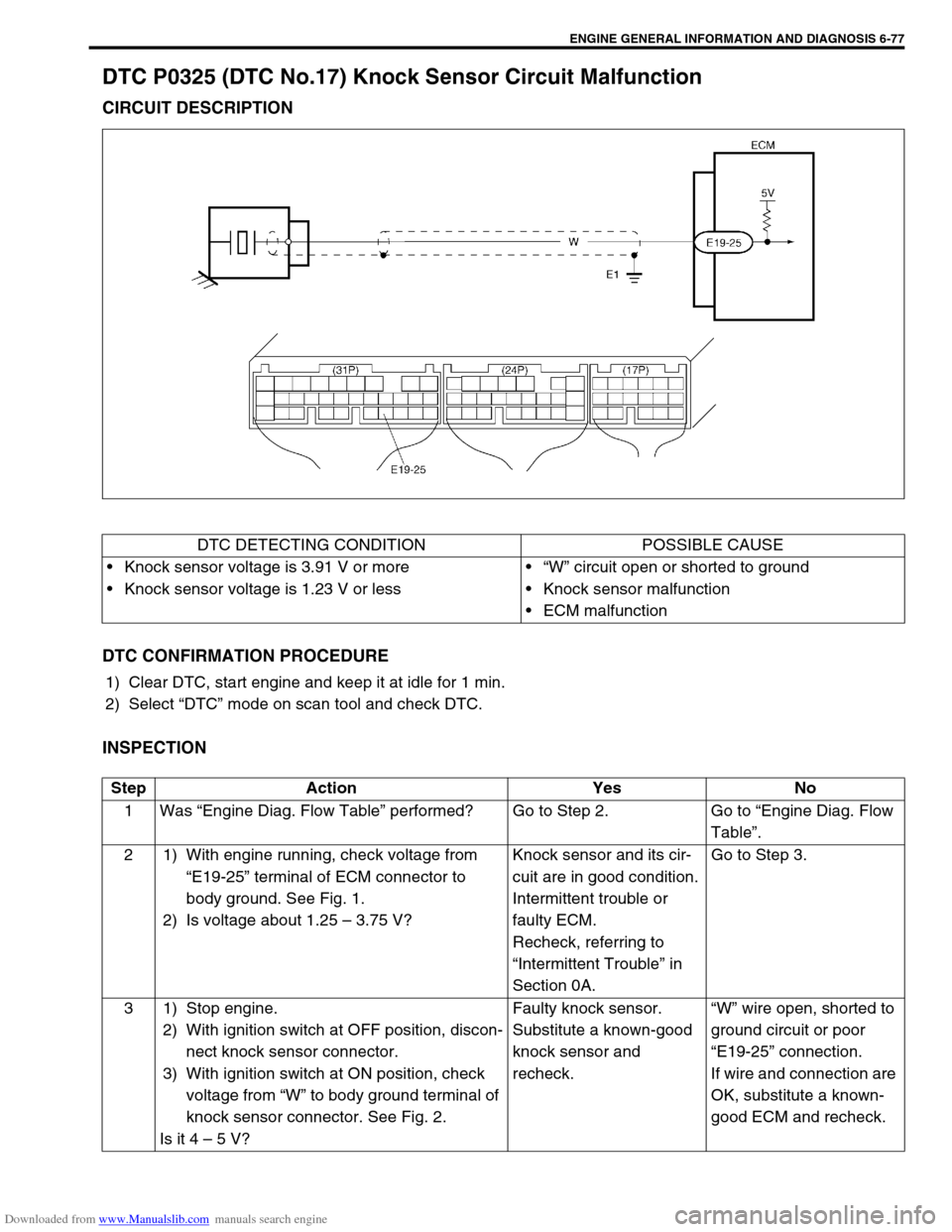

DTC P0325 (DTC No.17) Knock Sensor Circuit Malfunction

CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode on scan tool and check DTC.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

Knock sensor voltage is 3.91 V or more

Knock sensor voltage is 1.23 V or less“W” circuit open or shorted to ground

Knock sensor malfunction

ECM malfunction

Step Action Yes No

1Was “Engine Diag. Flow Table” performed? Go to Step 2. Go to “Engine Diag. Flow

Table”.

2 1) With engine running, check voltage from

“E19-25” terminal of ECM connector to

body ground. See Fig. 1.

2) Is voltage about 1.25 – 3.75 V?Knock sensor and its cir-

cuit are in good condition.

Intermittent trouble or

faulty ECM.

Recheck, referring to

“Intermittent Trouble” in

Section 0A.Go to Step 3.

3 1) Stop engine.

2) With ignition switch at OFF position, discon-

nect knock sensor connector.

3) With ignition switch at ON position, check

voltage from “W” to body ground terminal of

knock sensor connector. See Fig. 2.

Is it 4 – 5 V?Faulty knock sensor.

Substitute a known-good

knock sensor and

recheck.“W” wire open, shorted to

ground circuit or poor

“E19-25” connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.