engine SUZUKI JIMNY 2005 3.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 41 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-10 MAINTENANCE AND LUBRICATION

REPLACEMENT

Replace air cleaner filter with new one according to steps 1), 2)

and 5), 6) of inspection procedure.

Fuel Lines and Connections

INSPECTION

1) Visually inspect fuel lines and connections for evidence of

fuel leakage, hose cracking and damage. Make sure all

clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being cracked.

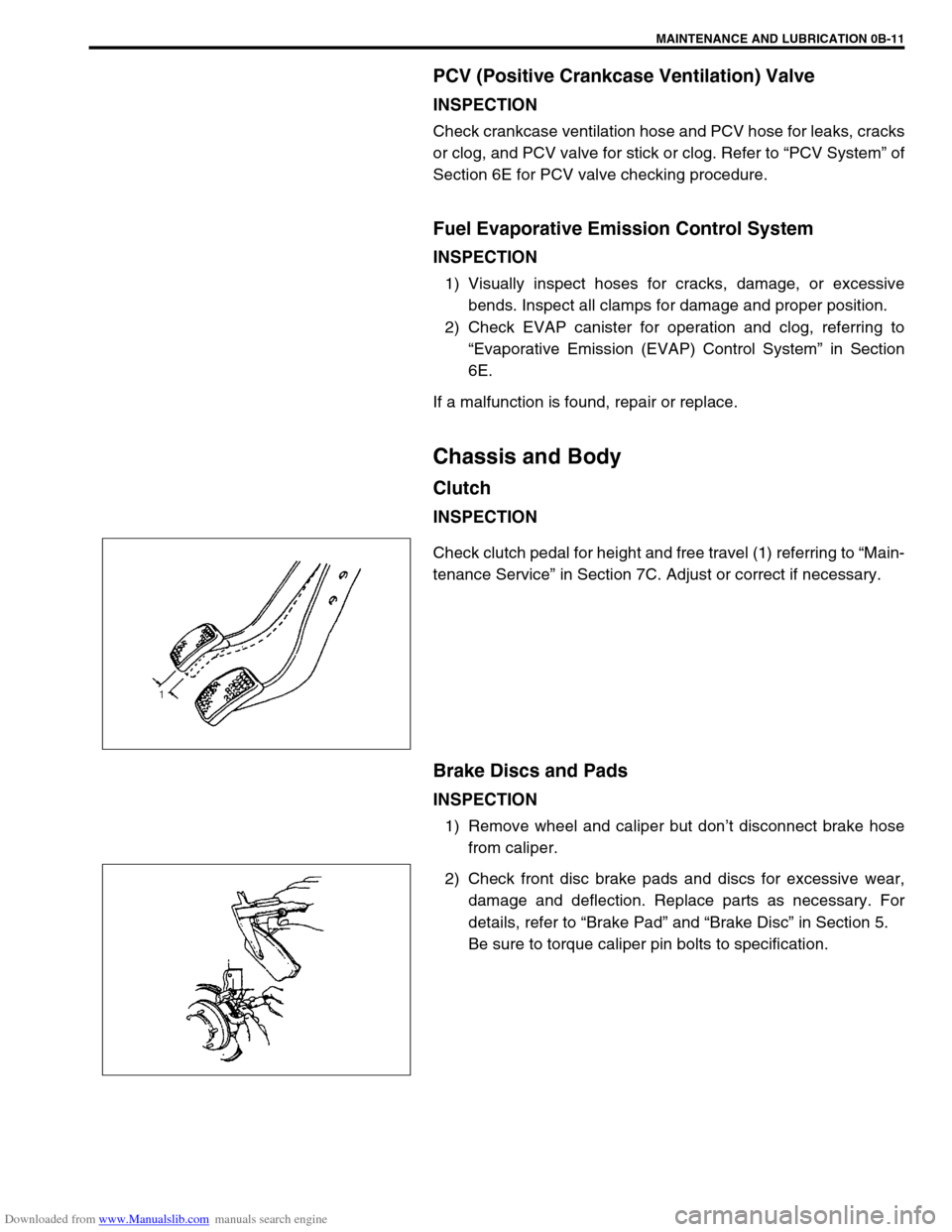

Fuel Filter

REPLACEMENT

Fuel filter (1) is a part of fuel pump assembly (2) which is installed

in fuel tank. Replace fuel filter with new one periodically, referring

to “Fuel Pump Assembly (with Fuel Filter, Fuel Level Gauge and

Fuel Cut Valve)” in Section 6C for proper procedure.

Fuel Tank

INSPECTION

Check fuel tank for damage, cracks, fuel leakage, corrosion and

tank bolts looseness.

If a problem is found, repair or replace.

Emission Control System

Crankcase Ventilation Hoses and Connections

INSPECTION

Refer to “PCV (Positive Crankcase Ventilation) Valve” in this sec-

tion.

WARNING:

This work must be performed in a well ventilated area

and away from any open flames (such as gas hot water

heaters).

Page 42 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-11

PCV (Positive Crankcase Ventilation) Valve

INSPECTION

Check crankcase ventilation hose and PCV hose for leaks, cracks

or clog, and PCV valve for stick or clog. Refer to “PCV System” of

Section 6E for PCV valve checking procedure.

Fuel Evaporative Emission Control System

INSPECTION

1) Visually inspect hoses for cracks, damage, or excessive

bends. Inspect all clamps for damage and proper position.

2) Check EVAP canister for operation and clog, referring to

“Evaporative Emission (EVAP) Control System” in Section

6E.

If a malfunction is found, repair or replace.

Chassis and Body

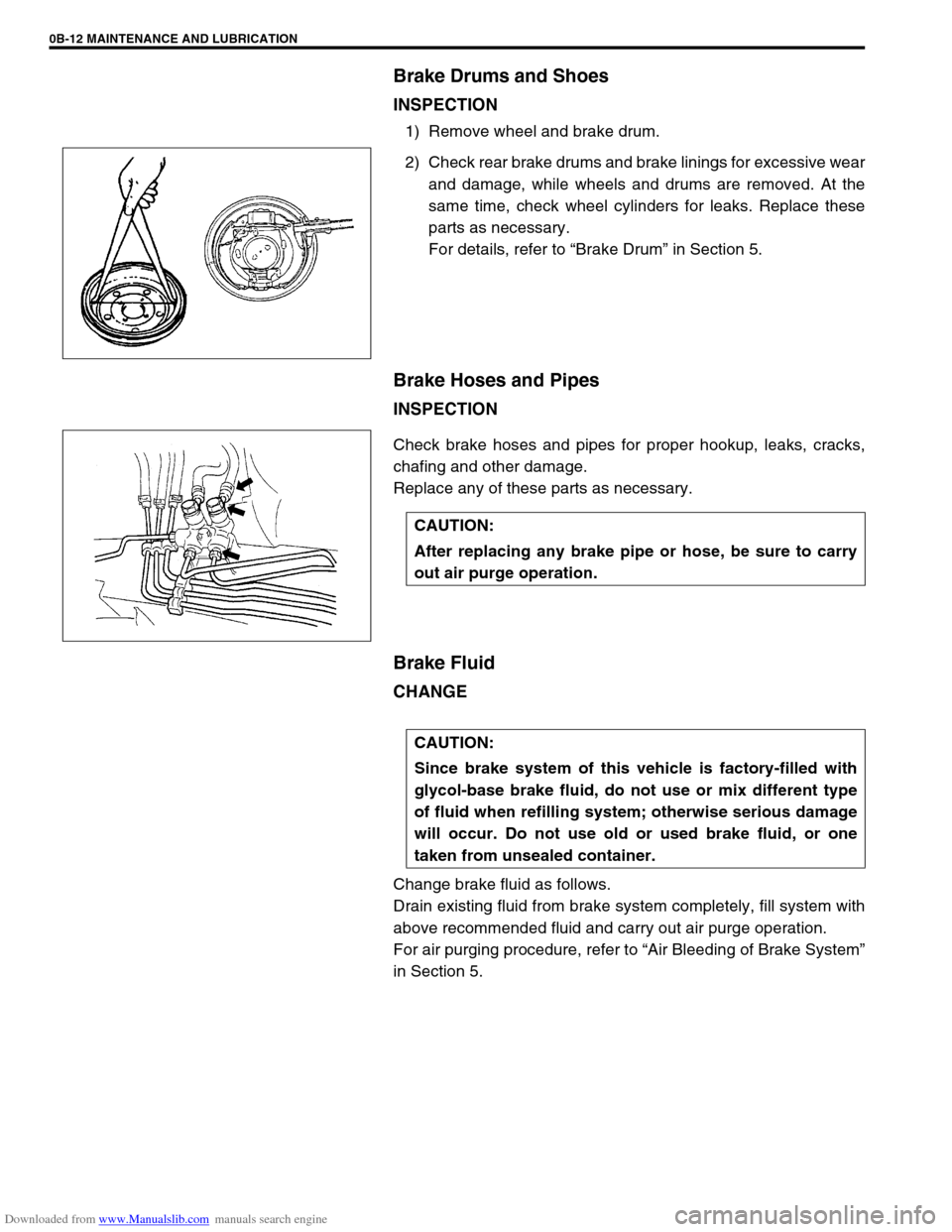

Clutch

INSPECTION

Check clutch pedal for height and free travel (1) referring to “Main-

tenance Service” in Section 7C. Adjust or correct if necessary.

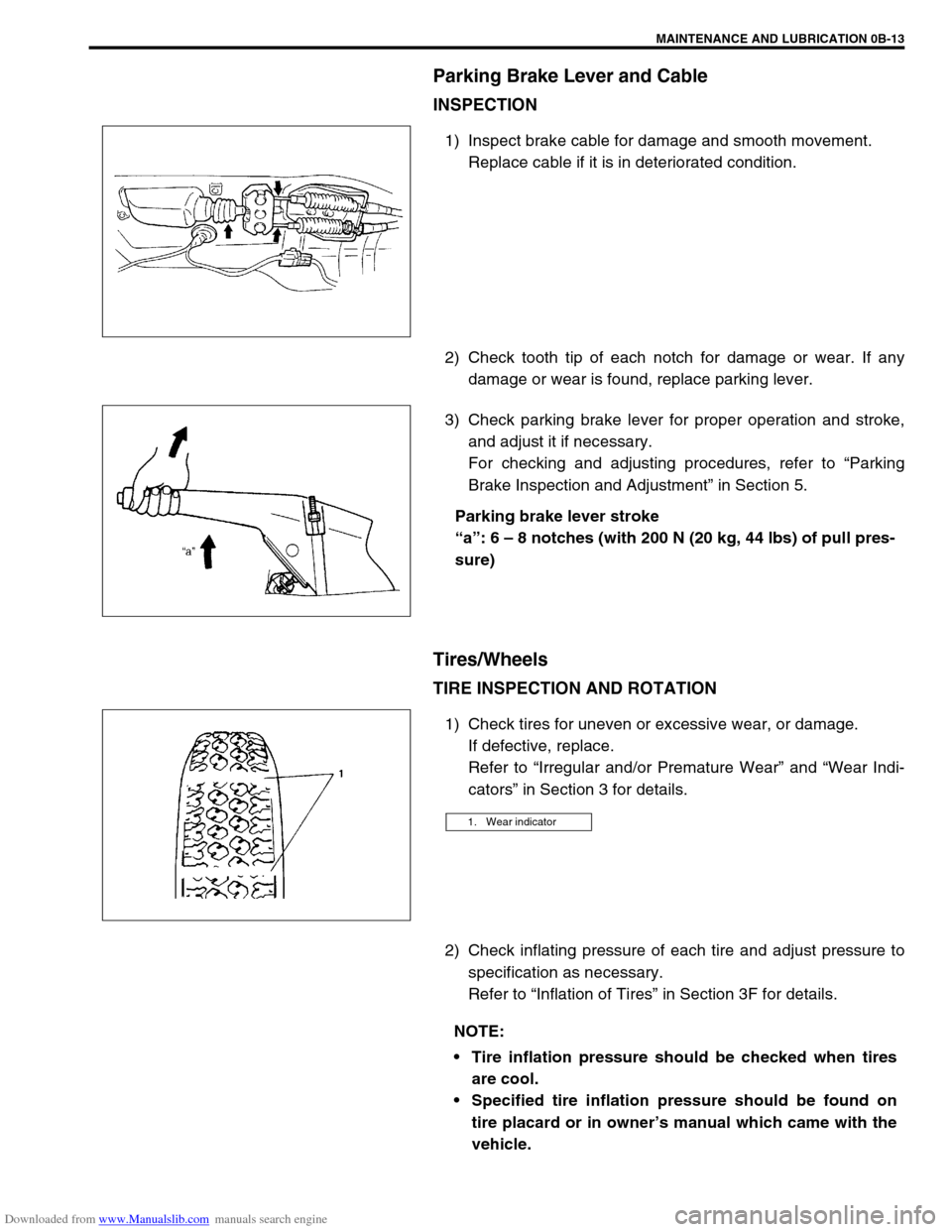

Brake Discs and Pads

INSPECTION

1) Remove wheel and caliper but don’t disconnect brake hose

from caliper.

2) Check front disc brake pads and discs for excessive wear,

damage and deflection. Replace parts as necessary. For

details, refer to “Brake Pad” and “Brake Disc” in Section 5.

Be sure to torque caliper pin bolts to specification.

Page 43 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-12 MAINTENANCE AND LUBRICATION

Brake Drums and Shoes

INSPECTION

1) Remove wheel and brake drum.

2) Check rear brake drums and brake linings for excessive wear

and damage, while wheels and drums are removed. At the

same time, check wheel cylinders for leaks. Replace these

parts as necessary.

For details, refer to “Brake Drum” in Section 5.

Brake Hoses and Pipes

INSPECTION

Check brake hoses and pipes for proper hookup, leaks, cracks,

chafing and other damage.

Replace any of these parts as necessary.

Brake Fluid

CHANGE

Change brake fluid as follows.

Drain existing fluid from brake system completely, fill system with

above recommended fluid and carry out air purge operation.

For air purging procedure, refer to “Air Bleeding of Brake System”

in Section 5.

CAUTION:

After replacing any brake pipe or hose, be sure to carry

out air purge operation.

CAUTION:

Since brake system of this vehicle is factory-filled with

glycol-base brake fluid, do not use or mix different type

of fluid when refilling system; otherwise serious damage

will occur. Do not use old or used brake fluid, or one

taken from unsealed container.

Page 44 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-13

Parking Brake Lever and Cable

INSPECTION

1) Inspect brake cable for damage and smooth movement.

Replace cable if it is in deteriorated condition.

2) Check tooth tip of each notch for damage or wear. If any

damage or wear is found, replace parking lever.

3) Check parking brake lever for proper operation and stroke,

and adjust it if necessary.

For checking and adjusting procedures, refer to “Parking

Brake Inspection and Adjustment” in Section 5.

Parking brake lever stroke

“a”: 6 – 8 notches (with 200 N (20 kg, 44 lbs) of pull pres-

sure)

Tires/Wheels

TIRE INSPECTION AND ROTATION

1) Check tires for uneven or excessive wear, or damage.

If defective, replace.

Refer to “Irregular and/or Premature Wear” and “Wear Indi-

cators” in Section 3 for details.

2) Check inflating pressure of each tire and adjust pressure to

specification as necessary.

Refer to “Inflation of Tires” in Section 3F for details.

1. Wear indicator

NOTE:

Tire inflation pressure should be checked when tires

are cool.

Specified tire inflation pressure should be found on

tire placard or in owner’s manual which came with the

vehicle.

Page 45 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-14 MAINTENANCE AND LUBRICATION

3) Rotate tires.

For details, refer to “Tire Rotation” in Section 3F.

WHEEL DISCS INSPECTION

Inspect each wheel disc for dents, distortion and cracks. A disc in

badly damaged condition must be replaced.

WHEEL BEARING INSPECTION

1) Check front wheel bearing for wear, damage, abnormal

noise or rattles. For details, refer to “Wheel Disc, Nut and

Bearing Check” in Section 3D.

2) Check rear wheel bearing for wear, damage, abnormal noise

or rattles. For details, refer to “Wheel Disc, Nut and Bearing

Check” in Section 3E.

Suspension System

INSPECTION

Check suspension bolts and nuts for tightness and retighten them

as necessary.

Repair or replace defective parts, if any.

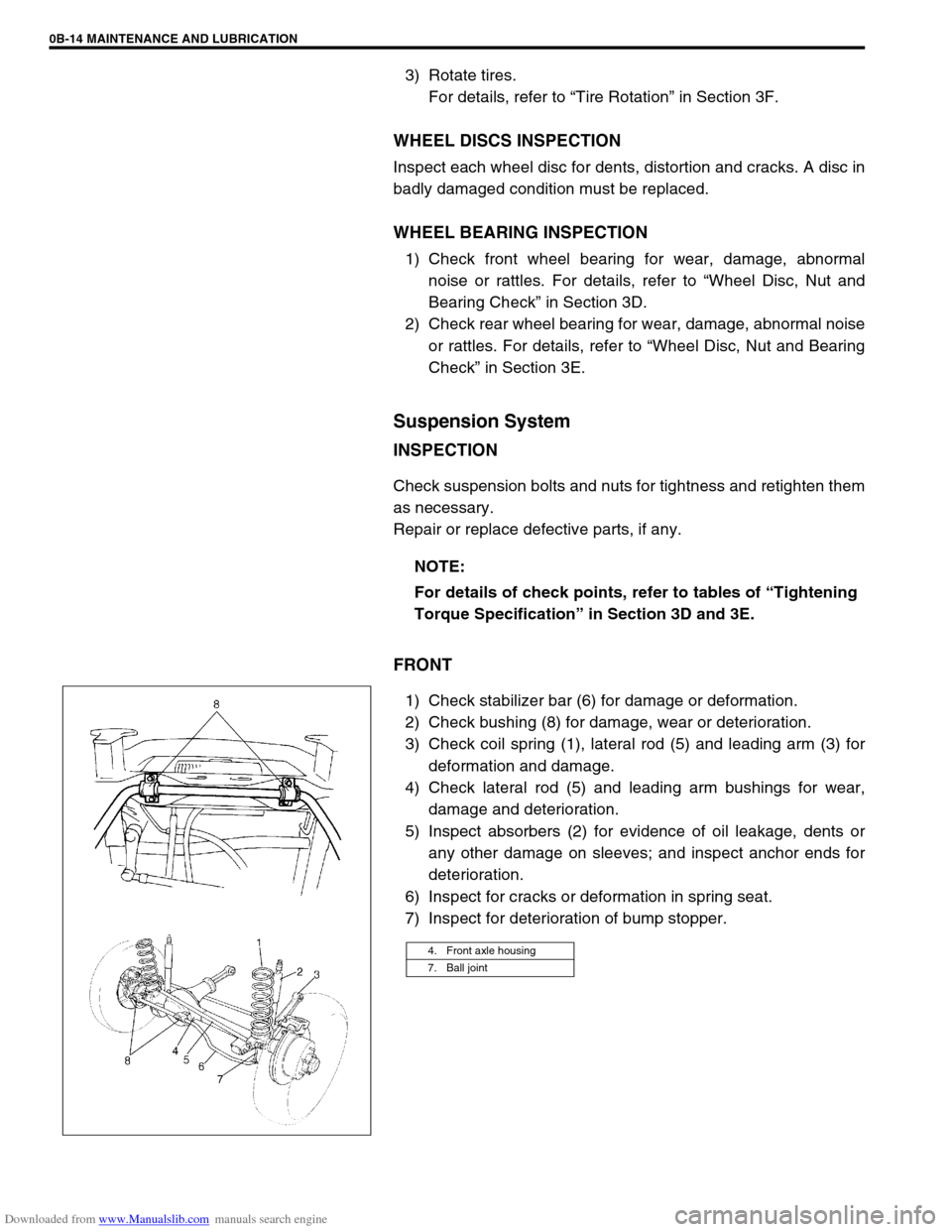

FRONT

1) Check stabilizer bar (6) for damage or deformation.

2) Check bushing (8) for damage, wear or deterioration.

3) Check coil spring (1), lateral rod (5) and leading arm (3) for

deformation and damage.

4) Check lateral rod (5) and leading arm bushings for wear,

damage and deterioration.

5) Inspect absorbers (2) for evidence of oil leakage, dents or

any other damage on sleeves; and inspect anchor ends for

deterioration.

6) Inspect for cracks or deformation in spring seat.

7) Inspect for deterioration of bump stopper.NOTE:

For details of check points, refer to tables of “Tightening

Torque Specification” in Section 3D and 3E.

4. Front axle housing

7. Ball joint

Page 46 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-15

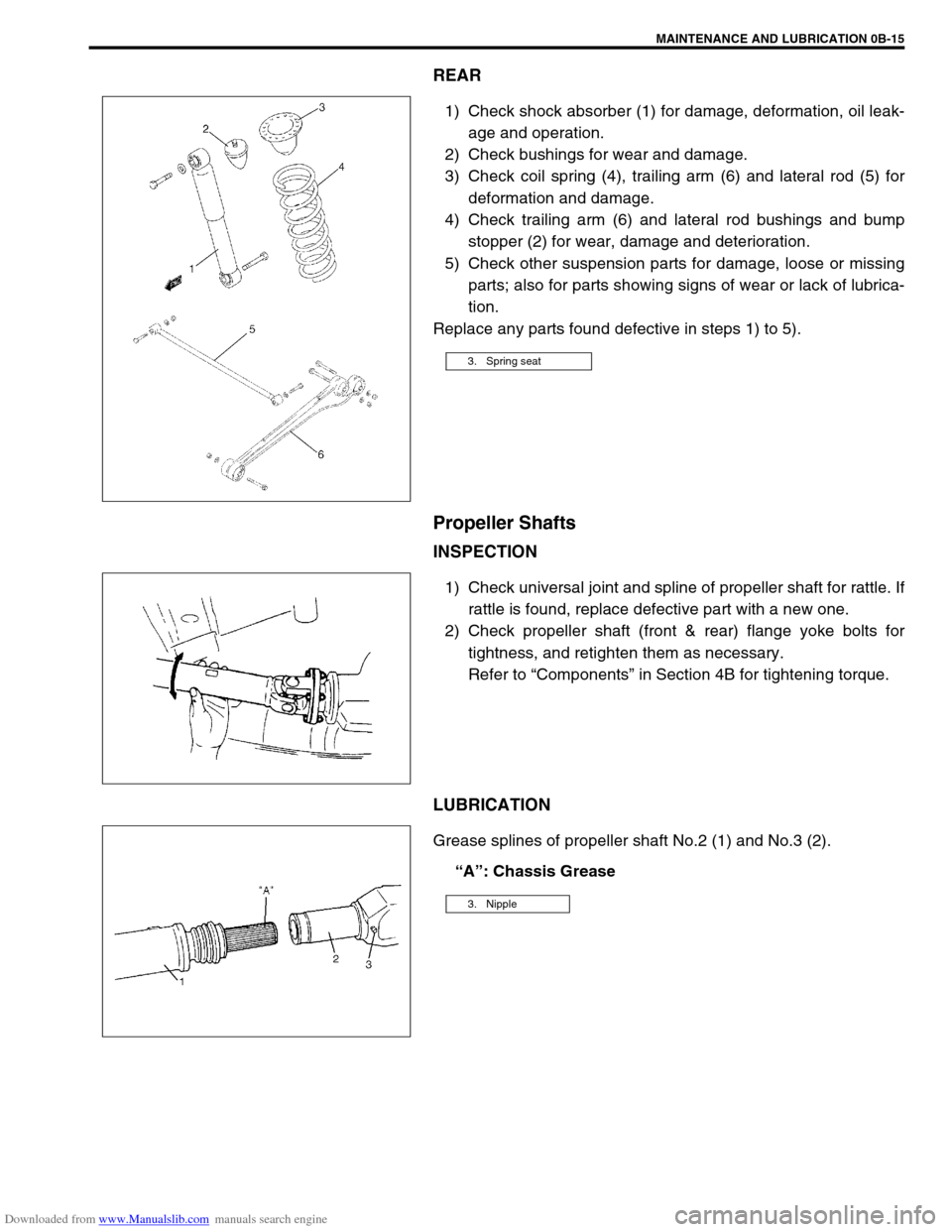

REAR

1) Check shock absorber (1) for damage, deformation, oil leak-

age and operation.

2) Check bushings for wear and damage.

3) Check coil spring (4), trailing arm (6) and lateral rod (5) for

deformation and damage.

4) Check trailing arm (6) and lateral rod bushings and bump

stopper (2) for wear, damage and deterioration.

5) Check other suspension parts for damage, loose or missing

parts; also for parts showing signs of wear or lack of lubrica-

tion.

Replace any parts found defective in steps 1) to 5).

Propeller Shafts

INSPECTION

1) Check universal joint and spline of propeller shaft for rattle. If

rattle is found, replace defective part with a new one.

2) Check propeller shaft (front & rear) flange yoke bolts for

tightness, and retighten them as necessary.

Refer to “Components” in Section 4B for tightening torque.

LUBRICATION

Grease splines of propeller shaft No.2 (1) and No.3 (2).

“A”: Chassis Grease

3. Spring seat

3. Nipple

Page 47 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-16 MAINTENANCE AND LUBRICATION

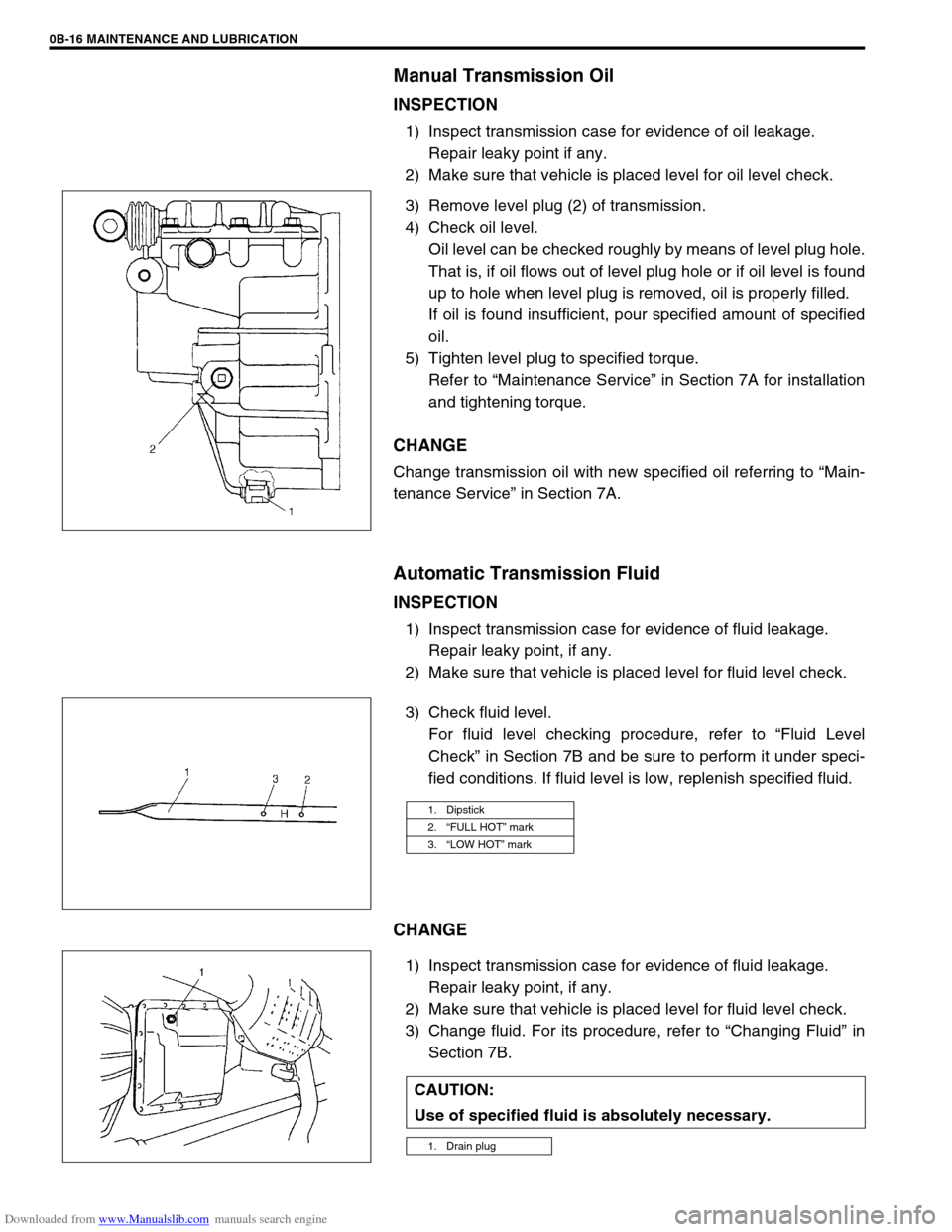

Manual Transmission Oil

INSPECTION

1) Inspect transmission case for evidence of oil leakage.

Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level check.

3) Remove level plug (2) of transmission.

4) Check oil level.

Oil level can be checked roughly by means of level plug hole.

That is, if oil flows out of level plug hole or if oil level is found

up to hole when level plug is removed, oil is properly filled.

If oil is found insufficient, pour specified amount of specified

oil.

5) Tighten level plug to specified torque.

Refer to “Maintenance Service” in Section 7A for installation

and tightening torque.

CHANGE

Change transmission oil with new specified oil referring to “Main-

tenance Service” in Section 7A.

Automatic Transmission Fluid

INSPECTION

1) Inspect transmission case for evidence of fluid leakage.

Repair leaky point, if any.

2) Make sure that vehicle is placed level for fluid level check.

3) Check fluid level.

For fluid level checking procedure, refer to “Fluid Level

Check” in Section 7B and be sure to perform it under speci-

fied conditions. If fluid level is low, replenish specified fluid.

CHANGE

1) Inspect transmission case for evidence of fluid leakage.

Repair leaky point, if any.

2) Make sure that vehicle is placed level for fluid level check.

3) Change fluid. For its procedure, refer to “Changing Fluid” in

Section 7B.

1. Dipstick

2.“FULL HOT” mark

3.“LOW HOT” mark

CAUTION:

Use of specified fluid is absolutely necessary.

1. Drain plug

Page 48 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-17

FLUID COOLER HOSE CHANGE

Replace inlet and outlet hoses of cooler hose and their clamps.

For replacement procedure, refer to “Oil Cooler Hoses” in Section

7B.

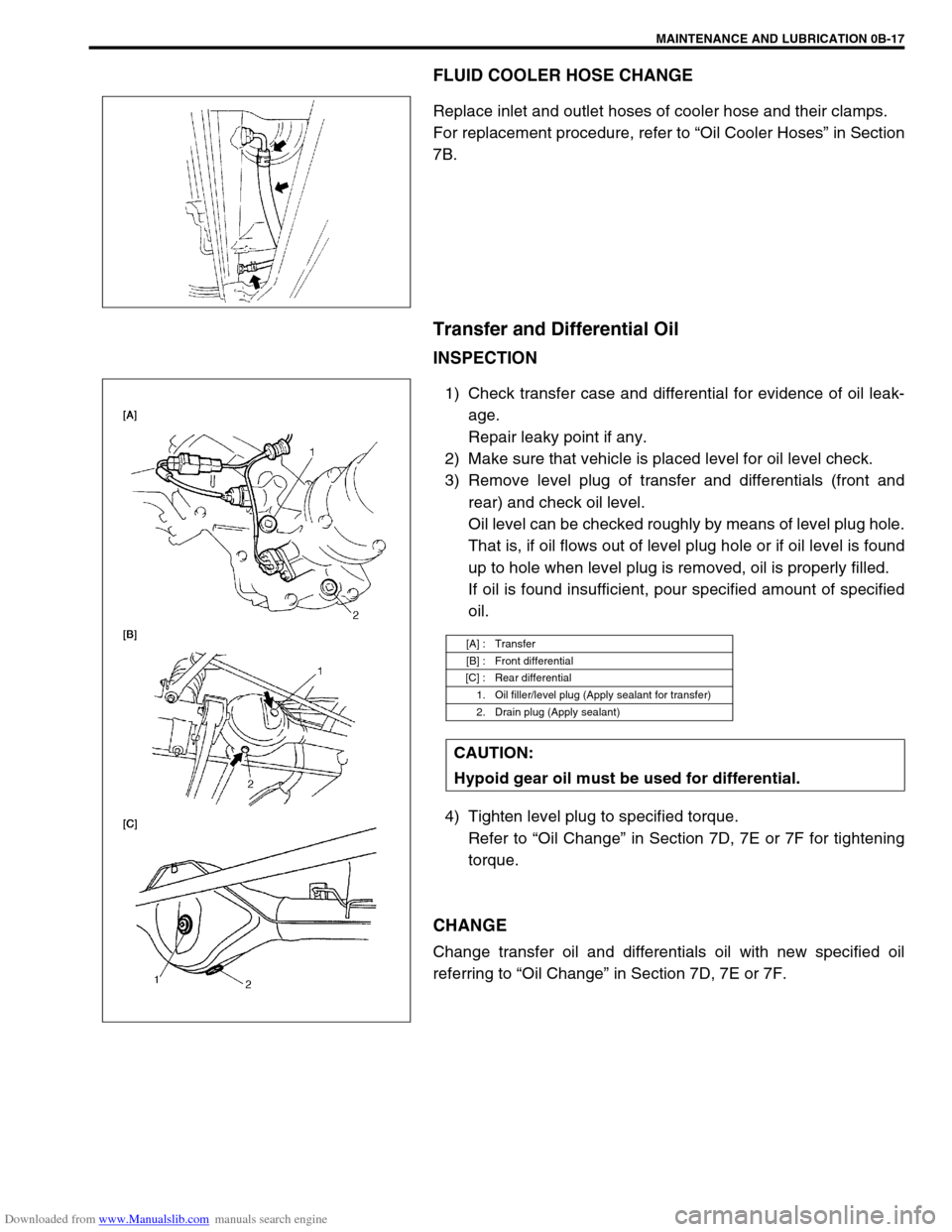

Transfer and Differential Oil

INSPECTION

1) Check transfer case and differential for evidence of oil leak-

age.

Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level check.

3) Remove level plug of transfer and differentials (front and

rear) and check oil level.

Oil level can be checked roughly by means of level plug hole.

That is, if oil flows out of level plug hole or if oil level is found

up to hole when level plug is removed, oil is properly filled.

If oil is found insufficient, pour specified amount of specified

oil.

4) Tighten level plug to specified torque.

Refer to “Oil Change” in Section 7D, 7E or 7F for tightening

torque.

CHANGE

Change transfer oil and differentials oil with new specified oil

referring to “Oil Change” in Section 7D, 7E or 7F.

[A] : Transfer

[B] : Front differential

[C] : Rear differential

1. Oil filler/level plug (Apply sealant for transfer)

2. Drain plug (Apply sealant)

CAUTION:

Hypoid gear oil must be used for differential.

Page 49 of 687

Downloaded from www.Manualslib.com manuals search engine 0B-18 MAINTENANCE AND LUBRICATION

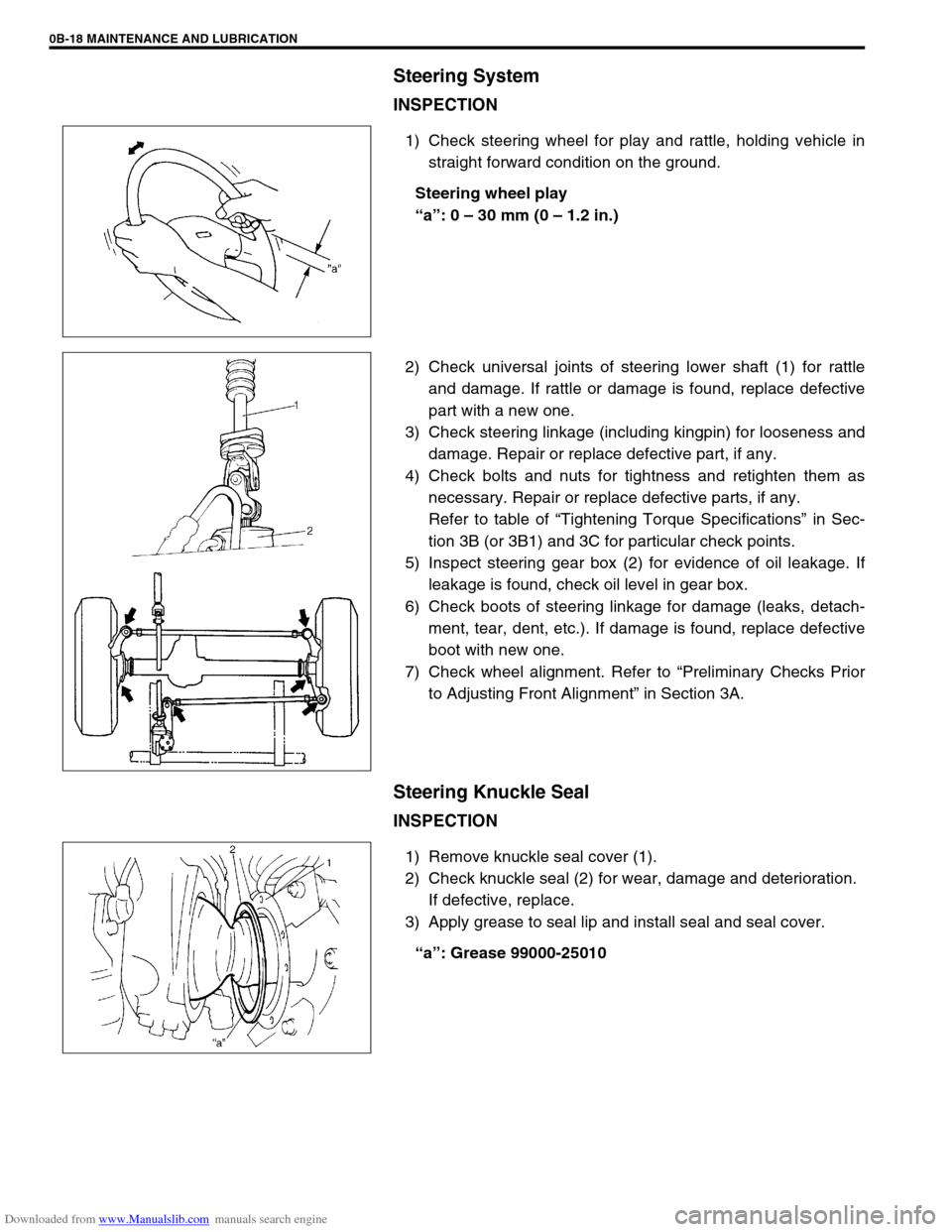

Steering System

INSPECTION

1) Check steering wheel for play and rattle, holding vehicle in

straight forward condition on the ground.

Steering wheel play

“a”: 0 – 30 mm (0 – 1.2 in.)

2) Check universal joints of steering lower shaft (1) for rattle

and damage. If rattle or damage is found, replace defective

part with a new one.

3) Check steering linkage (including kingpin) for looseness and

damage. Repair or replace defective part, if any.

4) Check bolts and nuts for tightness and retighten them as

necessary. Repair or replace defective parts, if any.

Refer to table of “Tightening Torque Specifications” in Sec-

tion 3B (or 3B1) and 3C for particular check points.

5) Inspect steering gear box (2) for evidence of oil leakage. If

leakage is found, check oil level in gear box.

6) Check boots of steering linkage for damage (leaks, detach-

ment, tear, dent, etc.). If damage is found, replace defective

boot with new one.

7) Check wheel alignment. Refer to “Preliminary Checks Prior

to Adjusting Front Alignment” in Section 3A.

Steering Knuckle Seal

INSPECTION

1) Remove knuckle seal cover (1).

2) Check knuckle seal (2) for wear, damage and deterioration.

If defective, replace.

3) Apply grease to seal lip and install seal and seal cover.

“a”: Grease 99000-25010

Page 50 of 687

Downloaded from www.Manualslib.com manuals search engine MAINTENANCE AND LUBRICATION 0B-19

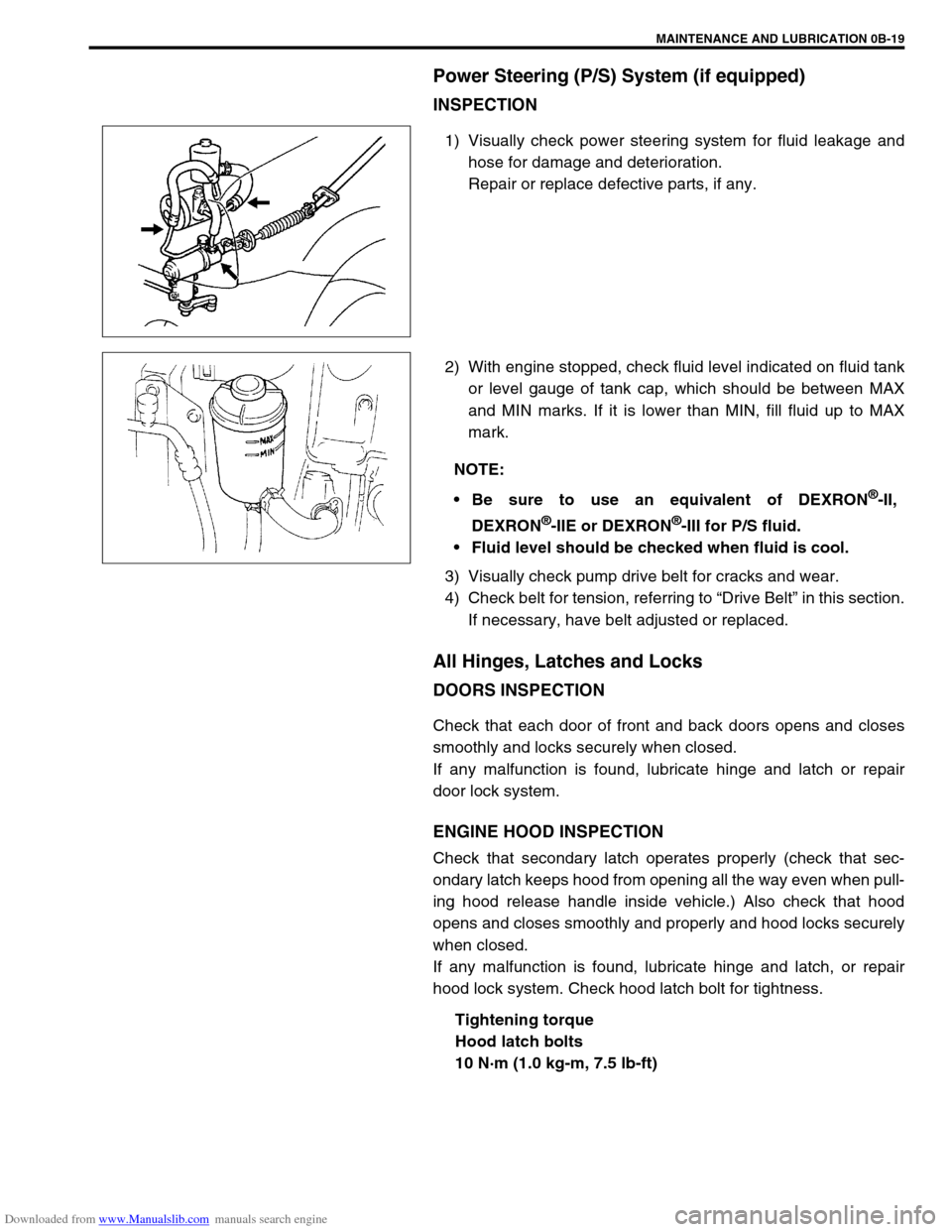

Power Steering (P/S) System (if equipped)

INSPECTION

1) Visually check power steering system for fluid leakage and

hose for damage and deterioration.

Repair or replace defective parts, if any.

2) With engine stopped, check fluid level indicated on fluid tank

or level gauge of tank cap, which should be between MAX

and MIN marks. If it is lower than MIN, fill fluid up to MAX

mark.

3) Visually check pump drive belt for cracks and wear.

4) Check belt for tension, referring to “Drive Belt” in this section.

If necessary, have belt adjusted or replaced.

All Hinges, Latches and Locks

DOORS INSPECTION

Check that each door of front and back doors opens and closes

smoothly and locks securely when closed.

If any malfunction is found, lubricate hinge and latch or repair

door lock system.

ENGINE HOOD INSPECTION

Check that secondary latch operates properly (check that sec-

ondary latch keeps hood from opening all the way even when pull-

ing hood release handle inside vehicle.) Also check that hood

opens and closes smoothly and properly and hood locks securely

when closed.

If any malfunction is found, lubricate hinge and latch, or repair

hood lock system. Check hood latch bolt for tightness.

Tightening torque

Hood latch bolts

10 N·m (1.0 kg-m, 7.5 lb-ft)

NOTE:

Be sure to use an equivalent of DEXRON

®-II,

DEXRON

®-IIE or DEXRON®-III for P/S fluid.

Fluid level should be checked when fluid is cool.