suspension SUZUKI JIMNY 2005 3.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 196 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-23

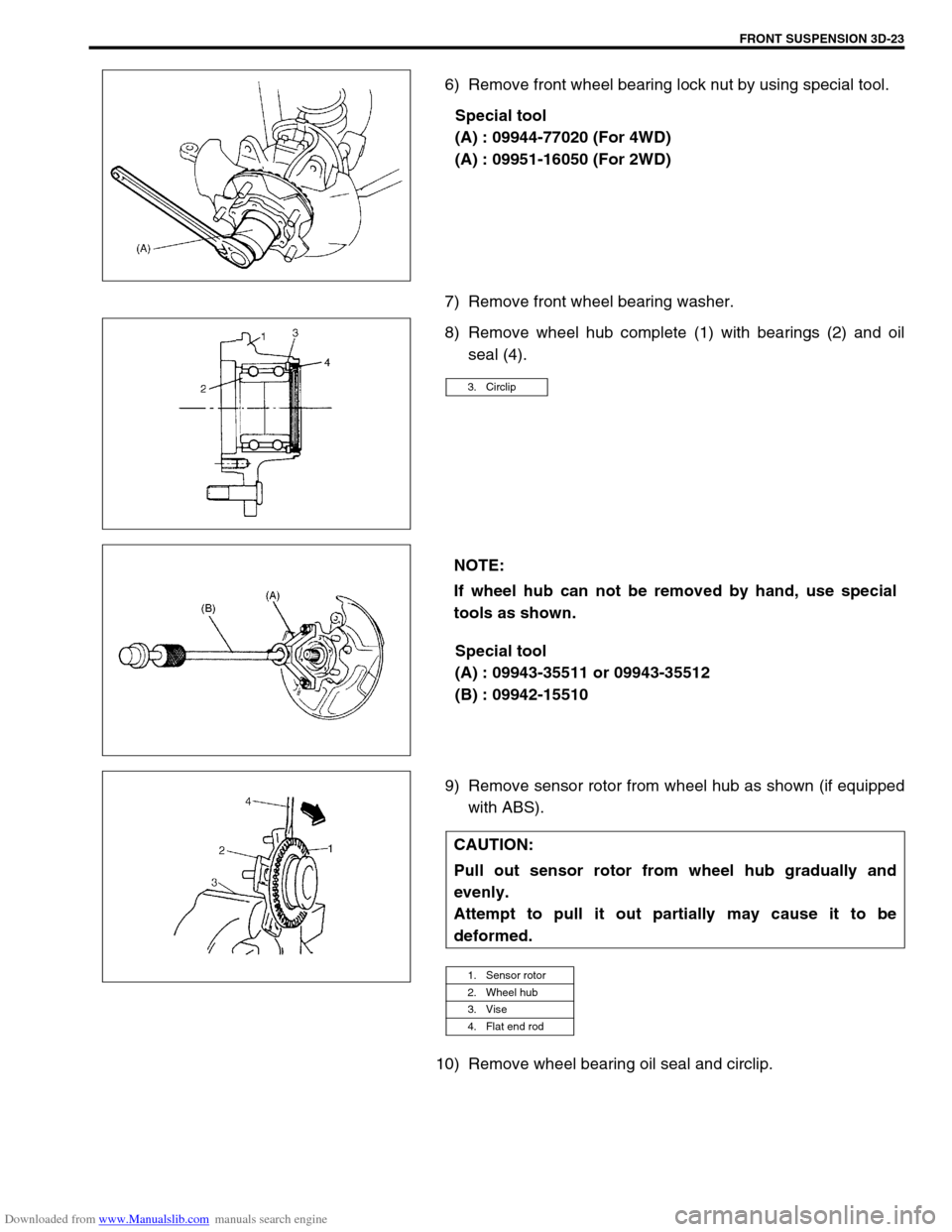

6) Remove front wheel bearing lock nut by using special tool.

Special tool

(A) : 09944-77020 (For 4WD)

(A) : 09951-16050 (For 2WD)

7) Remove front wheel bearing washer.

8) Remove wheel hub complete (1) with bearings (2) and oil

seal (4).

Special tool

(A) : 09943-35511 or 09943-35512

(B) : 09942-15510

9) Remove sensor rotor from wheel hub as shown (if equipped

with ABS).

10) Remove wheel bearing oil seal and circlip.

3. Circlip

NOTE:

If wheel hub can not be removed by hand, use special

tools as shown.

CAUTION:

Pull out sensor rotor from wheel hub gradually and

evenly.

Attempt to pull it out partially may cause it to be

deformed.

1. Sensor rotor

2. Wheel hub

3. Vise

4. Flat end rod

Page 197 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-24 FRONT SUSPENSION

11) Using hydraulic press (1) and special tool remove wheel

bearing (2).

Special tool

(A) : 09913-75520

12) Remove hub bolts from hub.

INSTALLATION

1) Insert new stud in hub hole. Rotate stud slowly to assure ser-

rations are aligned with those made by original bolt.

2) Using special tool, press-fit wheel bearing (3) until its end

contacts stepped surface of wheel hub (4).

Special tool

(A) : 09944-78210

3) Install bearing circlip.

4) Drive in wheel bearing oil seal (1) by using special tools.

Special tool

(B) : 09944-66010

(C) : 09924-74510

1. Oil hydraulic press

2. Hub bolt

CAUTION:

Press-fit wheel bearing (3) vertically to hub (4).

1. Oil hydraulic press

2. Steel plate

Page 198 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-25

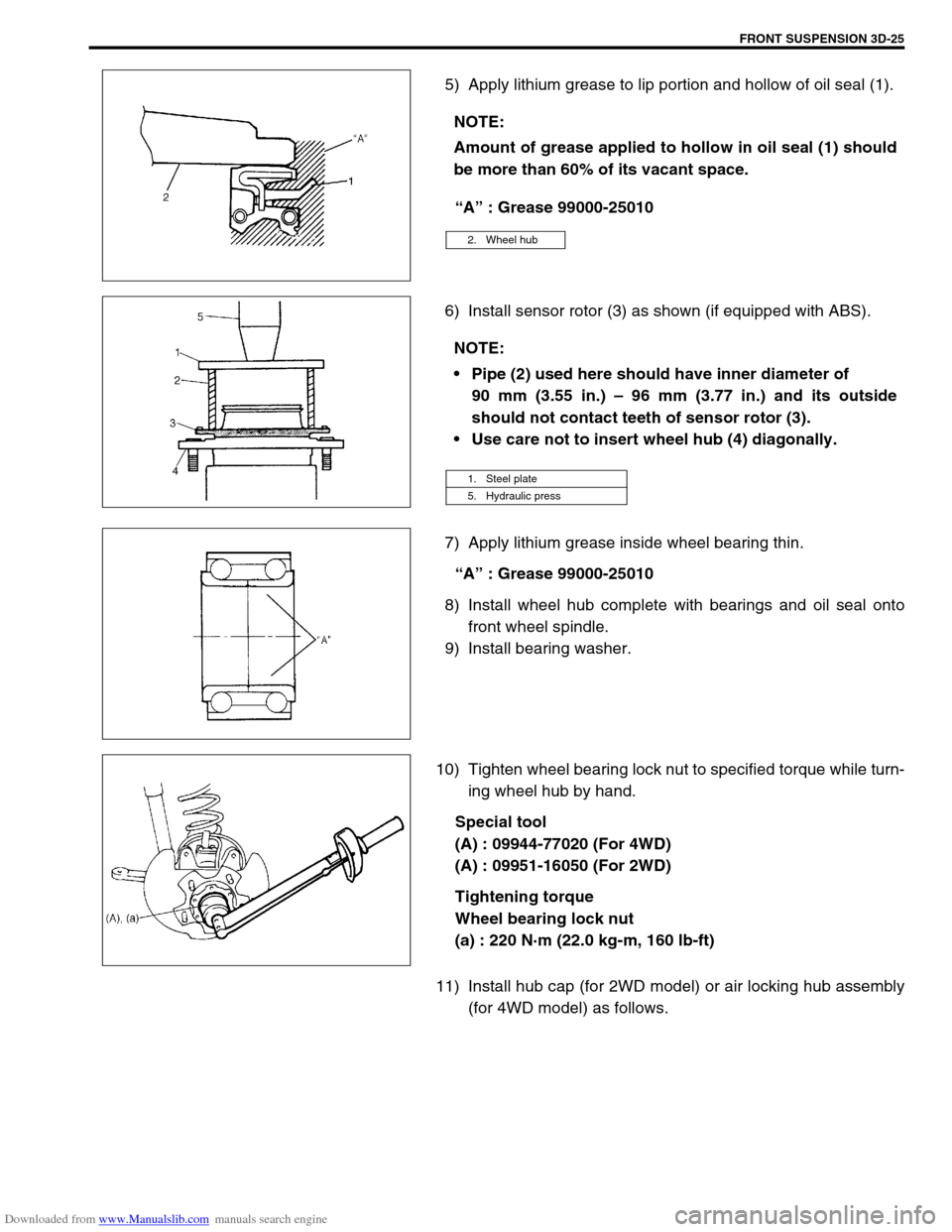

5) Apply lithium grease to lip portion and hollow of oil seal (1).

“A” : Grease 99000-25010

6) Install sensor rotor (3) as shown (if equipped with ABS).

7) Apply lithium grease inside wheel bearing thin.

“A” : Grease 99000-25010

8) Install wheel hub complete with bearings and oil seal onto

front wheel spindle.

9) Install bearing washer.

10) Tighten wheel bearing lock nut to specified torque while turn-

ing wheel hub by hand.

Special tool

(A) : 09944-77020 (For 4WD)

(A) : 09951-16050 (For 2WD)

Tightening torque

Wheel bearing lock nut

(a) : 220 N·m (22.0 kg-m, 160 lb-ft)

11) Install hub cap (for 2WD model) or air locking hub assembly

(for 4WD model) as follows. NOTE:

Amount of grease applied to hollow in oil seal (1) should

be more than 60% of its vacant space.

2. Wheel hub

NOTE:

Pipe (2) used here should have inner diameter of

90 mm (3.55 in.) – 96 mm (3.77 in.) and its outside

should not contact teeth of sensor rotor (3).

Use care not to insert wheel hub (4) diagonally.

1. Steel plate

5. Hydraulic press

Page 199 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-26 FRONT SUSPENSION

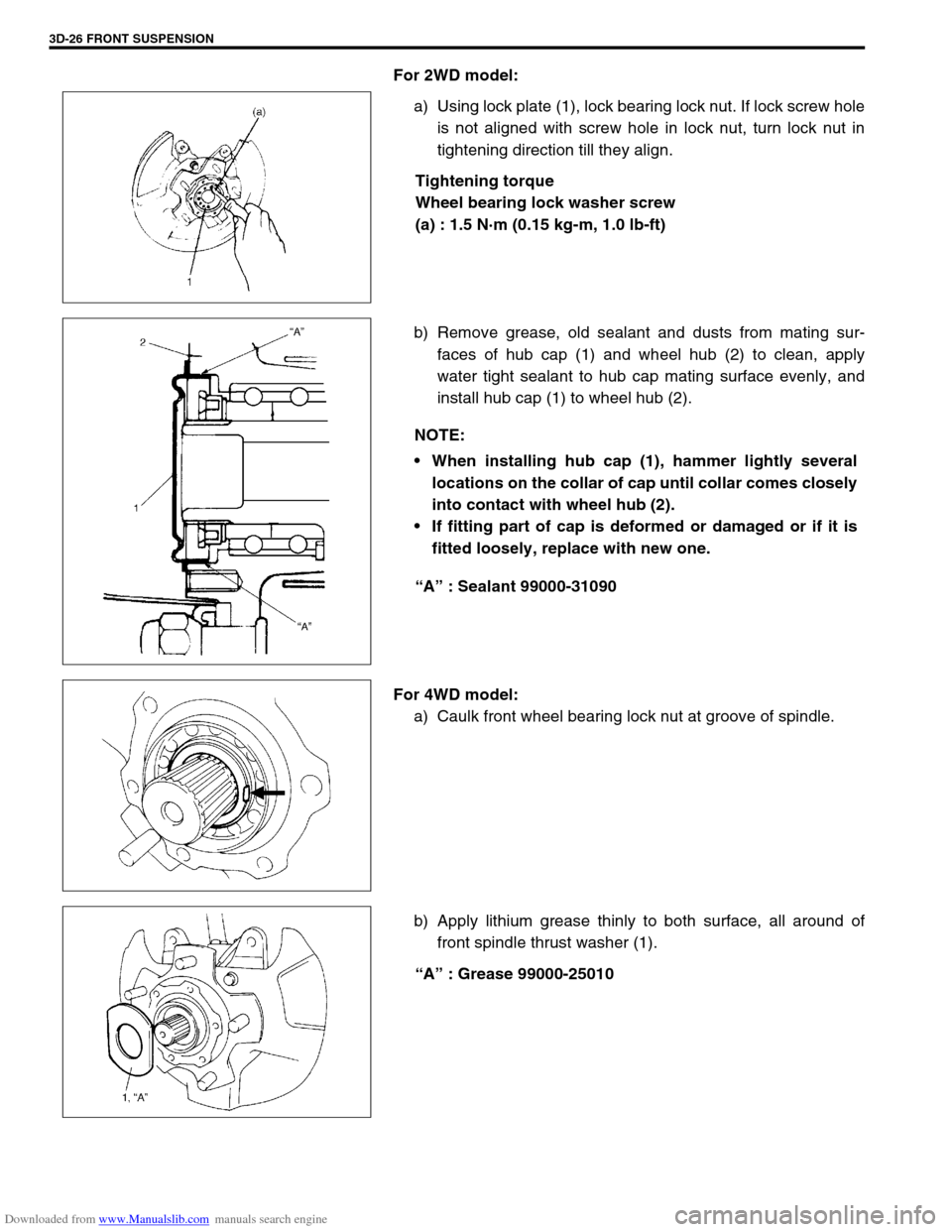

For 2WD model:

a) Using lock plate (1), lock bearing lock nut. If lock screw hole

is not aligned with screw hole in lock nut, turn lock nut in

tightening direction till they align.

Tightening torque

Wheel bearing lock washer screw

(a) : 1.5 N·m (0.15 kg-m, 1.0 lb-ft)

b) Remove grease, old sealant and dusts from mating sur-

faces of hub cap (1) and wheel hub (2) to clean, apply

water tight sealant to hub cap mating surface evenly, and

install hub cap (1) to wheel hub (2).

“A” : Sealant 99000-31090

For 4WD model:

a) Caulk front wheel bearing lock nut at groove of spindle.

b) Apply lithium grease thinly to both surface, all around of

front spindle thrust washer (1).

“A” : Grease 99000-25010

NOTE:

When installing hub cap (1), hammer lightly several

locations on the collar of cap until collar comes closely

into contact with wheel hub (2).

If fitting part of cap is deformed or damaged or if it is

fitted loosely, replace with new one.

Page 200 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-27

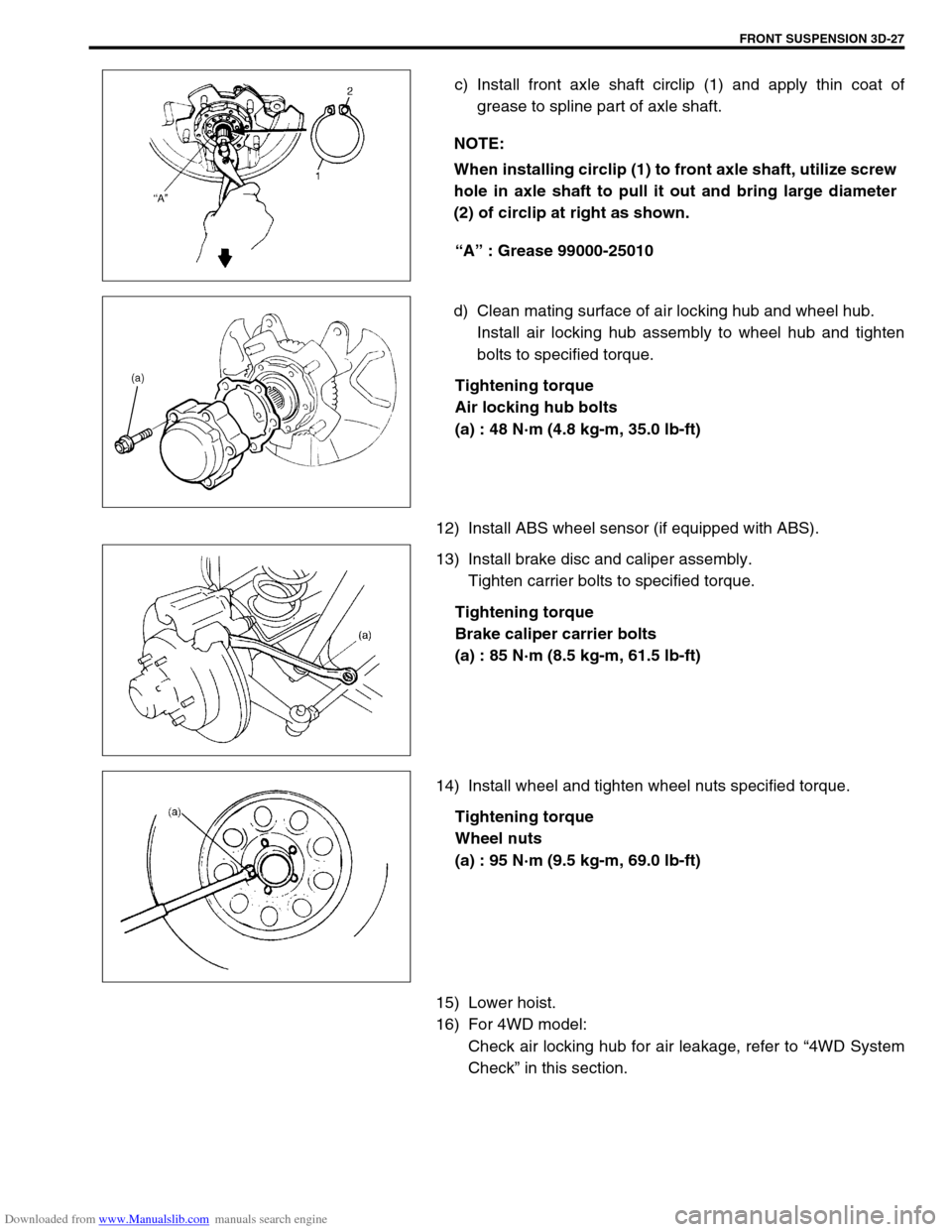

c) Install front axle shaft circlip (1) and apply thin coat of

grease to spline part of axle shaft.

“A” : Grease 99000-25010

d) Clean mating surface of air locking hub and wheel hub.

Install air locking hub assembly to wheel hub and tighten

bolts to specified torque.

Tightening torque

Air locking hub bolts

(a) : 48 N·m (4.8 kg-m, 35.0 lb-ft)

12) Install ABS wheel sensor (if equipped with ABS).

13) Install brake disc and caliper assembly.

Tighten carrier bolts to specified torque.

Tightening torque

Brake caliper carrier bolts

(a) : 85 N·m (8.5 kg-m, 61.5 lb-ft)

14) Install wheel and tighten wheel nuts specified torque.

Tightening torque

Wheel nuts

(a) : 95 N·m (9.5 kg-m, 69.0 lb-ft)

15) Lower hoist.

16) For 4WD model:

Check air locking hub for air leakage, refer to “4WD System

Check” in this section. NOTE:

When installing circlip (1) to front axle shaft, utilize screw

hole in axle shaft to pull it out and bring large diameter

(2) of circlip at right as shown.

Page 201 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-28 FRONT SUSPENSION

Steering Knuckle / Wheel Spindle

REMOVAL

1) Hoist vehicle and remove wheel.

2) Remove wheel hub assembly, refer to “Wheel Hub / Bearing /

Oil Seal” in this section.

3) Disconnect spindle vacuum hoses (1) from wheel spindle (for

4WD).

4) Remove disc dust cover (1) and wheel spindle (2).

5) Remove tie rod end (and drag rod end) nut(s) and discon-

nect tie rod end (and drag rod end) (2) from steering knuckle

(1) with special tool.

Special tool

(A) : 09913-65210

6) Remove knuckle seal cover bolts. Then remove knuckle seal

cover (1), knuckle seal and knuckle seal retainer from

knuckle. CAUTION:

Give match mark to each spindle vacuum hoses before

removing hose.

Page 202 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-29

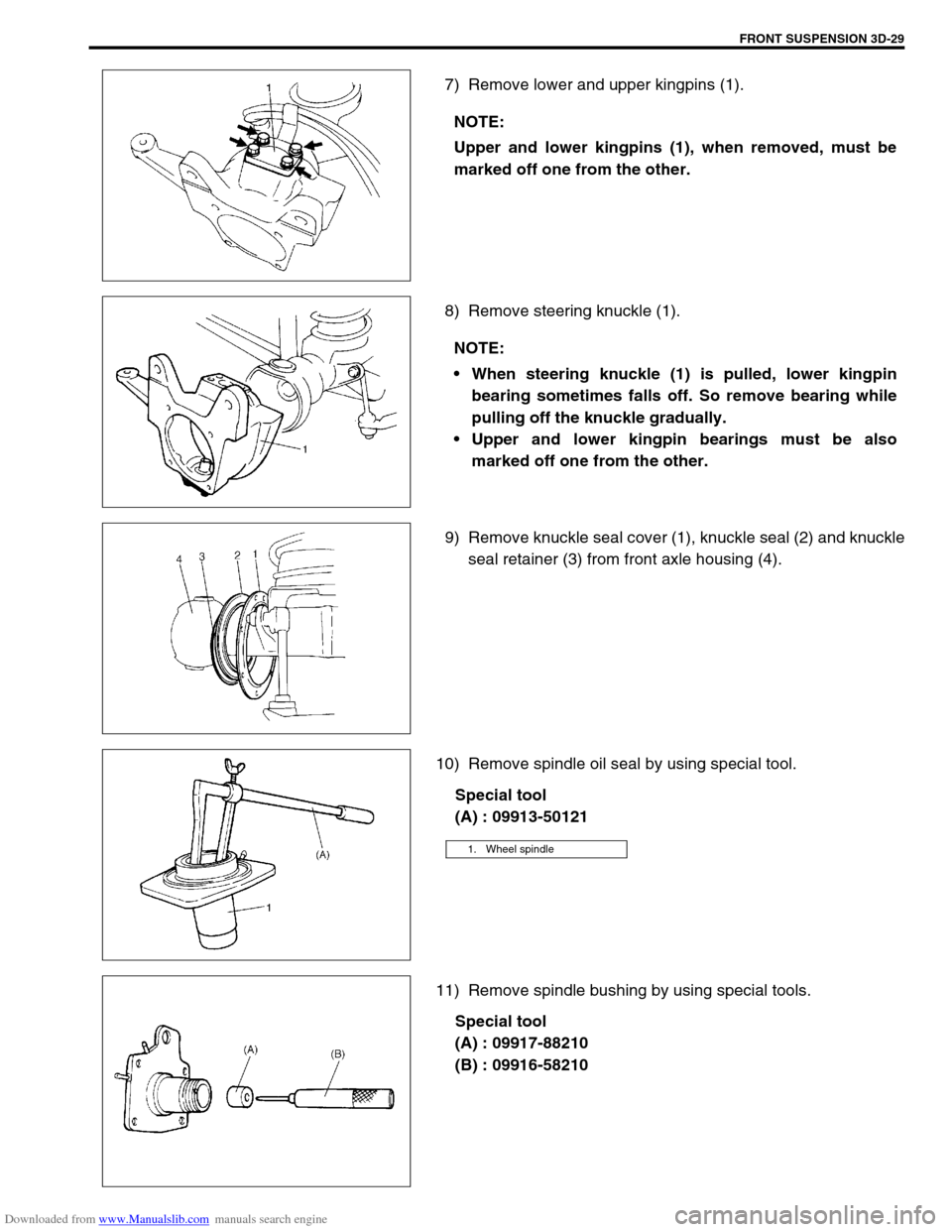

7) Remove lower and upper kingpins (1).

8) Remove steering knuckle (1).

9) Remove knuckle seal cover (1), knuckle seal (2) and knuckle

seal retainer (3) from front axle housing (4).

10) Remove spindle oil seal by using special tool.

Special tool

(A) : 09913-50121

11) Remove spindle bushing by using special tools.

Special tool

(A) : 09917-88210

(B) : 09916-58210 NOTE:

Upper and lower kingpins (1), when removed, must be

marked off one from the other.

NOTE:

When steering knuckle (1) is pulled, lower kingpin

bearing sometimes falls off. So remove bearing while

pulling off the knuckle gradually.

Upper and lower kingpin bearings must be also

marked off one from the other.

1. Wheel spindle

Page 203 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-30 FRONT SUSPENSION

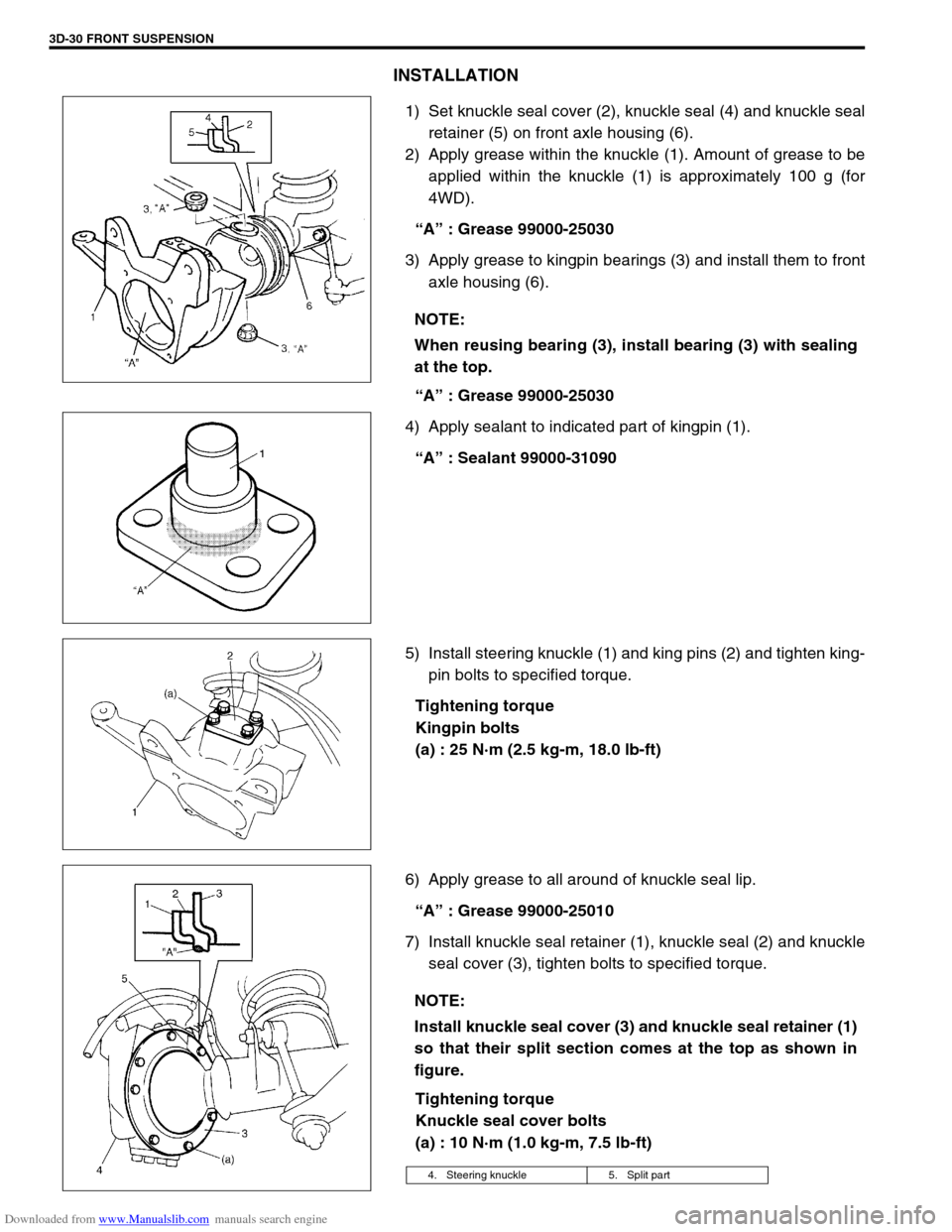

INSTALLATION

1) Set knuckle seal cover (2), knuckle seal (4) and knuckle seal

retainer (5) on front axle housing (6).

2) Apply grease within the knuckle (1). Amount of grease to be

applied within the knuckle (1) is approximately 100 g (for

4WD).

“A” : Grease 99000-25030

3) Apply grease to kingpin bearings (3) and install them to front

axle housing (6).

“A” : Grease 99000-25030

4) Apply sealant to indicated part of kingpin (1).

“A” : Sealant 99000-31090

5) Install steering knuckle (1) and king pins (2) and tighten king-

pin bolts to specified torque.

Tightening torque

Kingpin bolts

(a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

6) Apply grease to all around of knuckle seal lip.

“A” : Grease 99000-25010

7) Install knuckle seal retainer (1), knuckle seal (2) and knuckle

seal cover (3), tighten bolts to specified torque.

Tightening torque

Knuckle seal cover bolts

(a) : 10 N·m (1.0 kg-m, 7.5 lb-ft) NOTE:

When reusing bearing (3), install bearing (3) with sealing

at the top.

NOTE:

Install knuckle seal cover (3) and knuckle seal retainer (1)

so that their split section comes at the top as shown in

figure.

4. Steering knuckle 5. Split part

Page 204 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT SUSPENSION 3D-31

8) Press-fit spindle bushing (2) to wheel spindle (1) by using

special tool.

Set cut part (4) of spindle bushing (2) as shown in figure

(opposite side of the groove (3) of wheel spindle).

Special tool

(A) : 09922-55131

9) Press-fit spindle oil seal (1) until it becomes flush with wheel

spindle (2) surface by using special tool, and then apply

grease to its lip.

Special tool

(A) : 09944-66020

10) Apply grease to spindle oil seal lip.

“A” : Grease 99000-25010

11) Apply grease to spindle bushing inside surface and flange

(2).

“A” : Grease 99000-25010

12) Install wheel spindle to knuckle, coat their mating surface

with sealant.

“B” : Sealant 99000-31110 or 99000-31090

13) Install wheel spindle (1) and disc dust cover (2) to steering

knuckle. Tighten wheel spindle bolts to specified torque.

Tightening torque

Wheel spindle bolts

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

CAUTION:

As this hole is a part of the passage of the vacuum that

activates the air locking hub, if it is clogged with grease,

the air locking hub cannot be locked or unlocked.

Therefore, be careful not to apply too much grease to

avoid clogging the vacuum passage.

Page 205 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-32 FRONT SUSPENSION

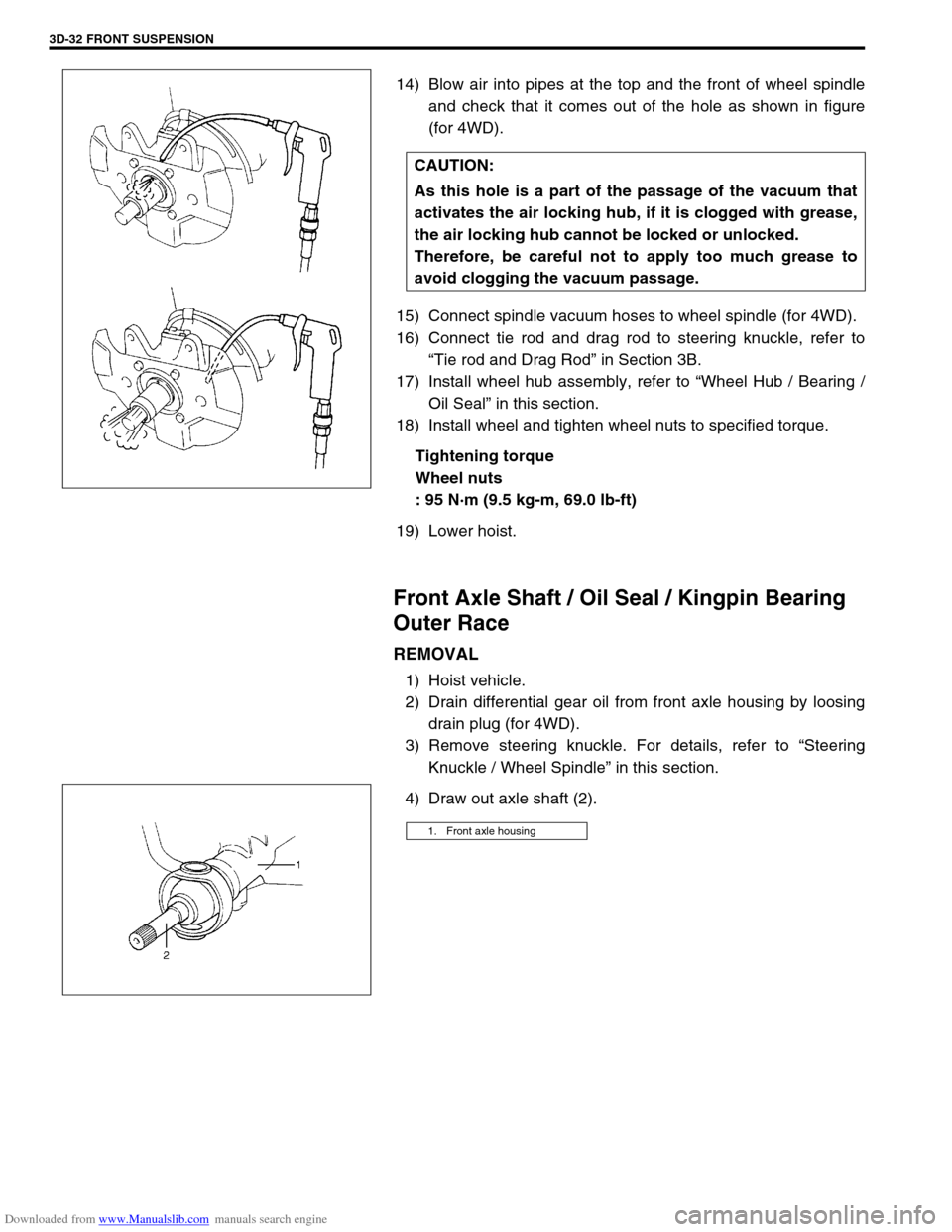

14) Blow air into pipes at the top and the front of wheel spindle

and check that it comes out of the hole as shown in figure

(for 4WD).

15) Connect spindle vacuum hoses to wheel spindle (for 4WD).

16) Connect tie rod and drag rod to steering knuckle, refer to

“Tie rod and Drag Rod” in Section 3B.

17) Install wheel hub assembly, refer to “Wheel Hub / Bearing /

Oil Seal” in this section.

18) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts

: 95 N·m (9.5 kg-m, 69.0 lb-ft)

19) Lower hoist.

Front Axle Shaft / Oil Seal / Kingpin Bearing

Outer Race

REMOVAL

1) Hoist vehicle.

2) Drain differential gear oil from front axle housing by loosing

drain plug (for 4WD).

3) Remove steering knuckle. For details, refer to “Steering

Knuckle / Wheel Spindle” in this section.

4) Draw out axle shaft (2).CAUTION:

As this hole is a part of the passage of the vacuum that

activates the air locking hub, if it is clogged with grease,

the air locking hub cannot be locked or unlocked.

Therefore, be careful not to apply too much grease to

avoid clogging the vacuum passage.

1. Front axle housing