height adjustment SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 120 of 687

Downloaded from www.Manualslib.com manuals search engine FRONT WHEEL ALIGNMENT 3A-3

Diagnosis

Diagnosis Table

For the details, refer to “Diagnosis Table” in Section 3.

Preliminary Checks Prior To Adjusting Front Wheel Alignment

Steering and vibration complaints are not always the result of improper alignment. An additional item to be

checked is the possibility of tire lead due to worn or improperly manufactured tires. “Lead” is the deviation of the

vehicle from a straight path on a level road without hand pressure on the steering wheel. Section 3 of this man-

ual contains a procedure for determining the presence of a tire lead problem. Before making any adjustment

affecting toe setting, the following checks and inspections should be made to ensure correctness of alignment

readings and alignment adjustments:

1) Check all tires for proper inflation pressures and approximately the same tread wear.

2) Check for loose of king pin bearings. Check tie rod ends; if excessive looseness is noted, it must be cor-

rected before adjusting.

3) Check for run-out of wheels and tires.

4) Check vehicle trim heights; if out of limits and a correction is to be made, it must be made before adjusting

toe.

5) Check for loose of suspension arms.

6) Check for loose or missing stabilizer bar attachments.

7) Consideration must be given to excess loads, such as tool boxes. If this excess load is normally carried in

vehicle, it should remain in vehicle during alignment checks.

8) Consider condition of equipment being used to check alignment and follow manufacturer's instructions.

9) Regardless of equipment used to check alignment, vehicle must be on a level surface both fore and aft and

transversely.

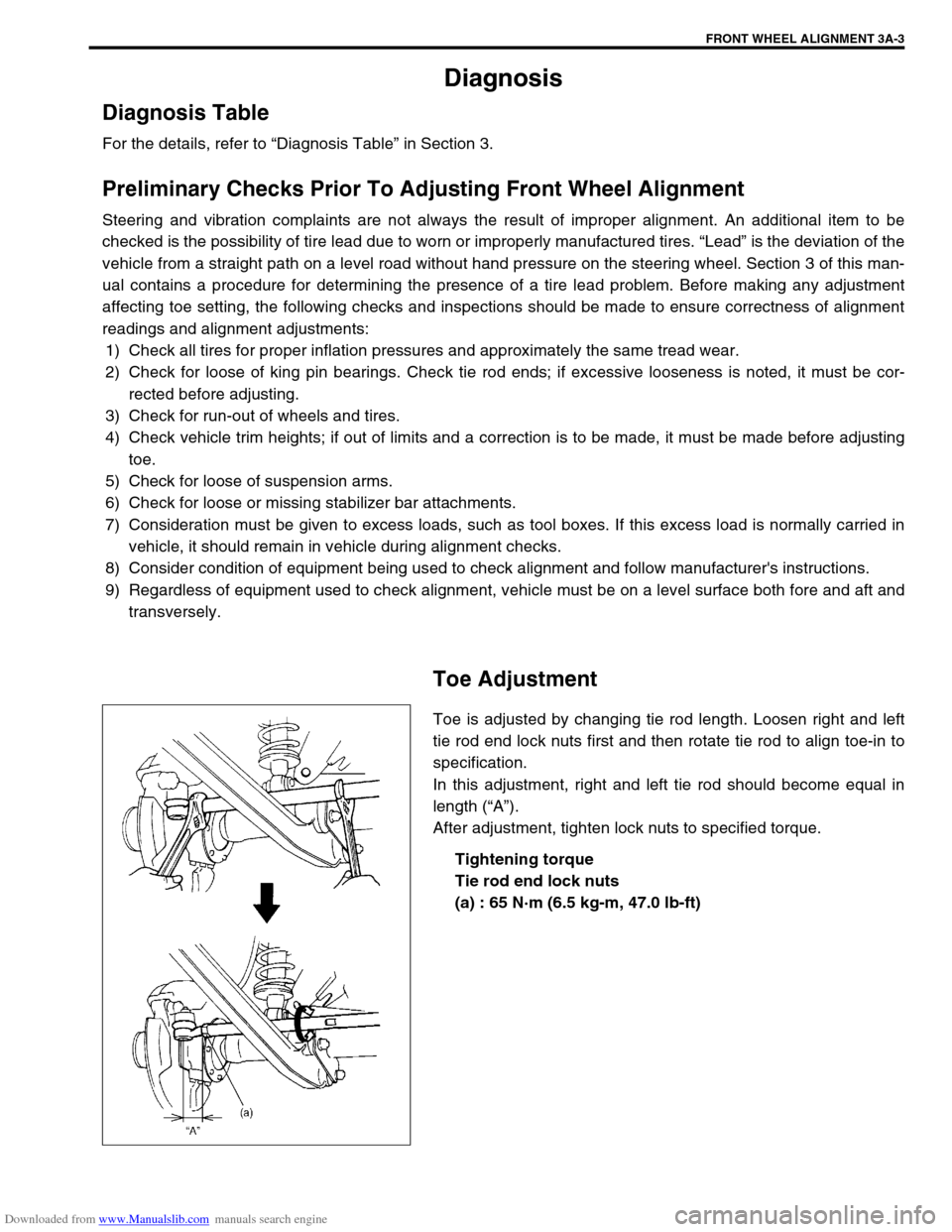

Toe Adjustment

Toe is adjusted by changing tie rod length. Loosen right and left

tie rod end lock nuts first and then rotate tie rod to align toe-in to

specification.

In this adjustment, right and left tie rod should become equal in

length (“A”).

After adjustment, tighten lock nuts to specified torque.

Tightening torque

Tie rod end lock nuts

(a) : 65 N·m (6.5 kg-m, 47.0 lb-ft)

Page 262 of 687

Downloaded from www.Manualslib.com manuals search engine BRAKES 5-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

5

9

10

10A

10B

9

10

10A

10B

SECTION 5

BRAKES

CONTENTS

General Description ......................................... 5-3

Diagnosis .......................................................... 5-4

Road Testing Brakes ...................................... 5-4

Brake Fluid Leaks .......................................... 5-4

Substandard or Contaminated Brake Fluid .... 5-4

Diagnosis Table ............................................. 5-5

Brake Pedal Free Height Adjustment ............. 5-8

Brake Pedal Play Check ................................ 5-8

Stop Light Switch Adjustment ........................ 5-8

Excessive Pedal Travel Check ....................... 5-9

Front Brake Disc Check ................................. 5-9

Front Brake Pad Check .................................. 5-9

Rear Brake Shoe Check .............................. 5-10

Master Cylinder and Brake Fluid Level

Check ........................................................... 5-10

Rear Drum Brake Shoe Adjustment ............. 5-11

Parking Brake Inspection and Adjustment ... 5-11

Booster Operation Check ............................. 5-12Fluid Pressure Test

(If Equipped with LSPV) ............................... 5-15

On-Vehicle Service ........................................ 5-17

Air Bleeding of Brake System ...................... 5-17

Brake Hose and Pipe Inspection.................. 5-18

Front Disc Brake .......................................... 5-19

Brake pad ................................................. 5-20

Caliper assembly...................................... 5-22

Brake Disc.................................................... 5-26

Rear Brake ................................................... 5-29

Brake drum............................................... 5-29

Brake shoe ............................................... 5-32

Wheel Cylinder............................................. 5-33

Brake back plate ...................................... 5-34

Master Cylinder .............................................. 5-36

Master Cylinder Reservoir ........................... 5-36

Master Cylinder Assembly ........................... 5-37 WARNING:

For lifting point of vehicle, refer to Section 0A.

WARNING:

For vehicles equipped with Supplement Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

When inspecting and servicing vehicle equipped with ABS, be sure to refer to section 5E first.

All brake fasteners are important attaching parts in that they could affect the performance of vital

parts and systems, and/or could result in major repair expense. They must be replaced with one of

same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified

during reassembly to assure proper retention of all parts. There is to be no welding as it may result

in extensive damage and weakening of the metal.

Page 269 of 687

Downloaded from www.Manualslib.com manuals search engine 5-8 BRAKES

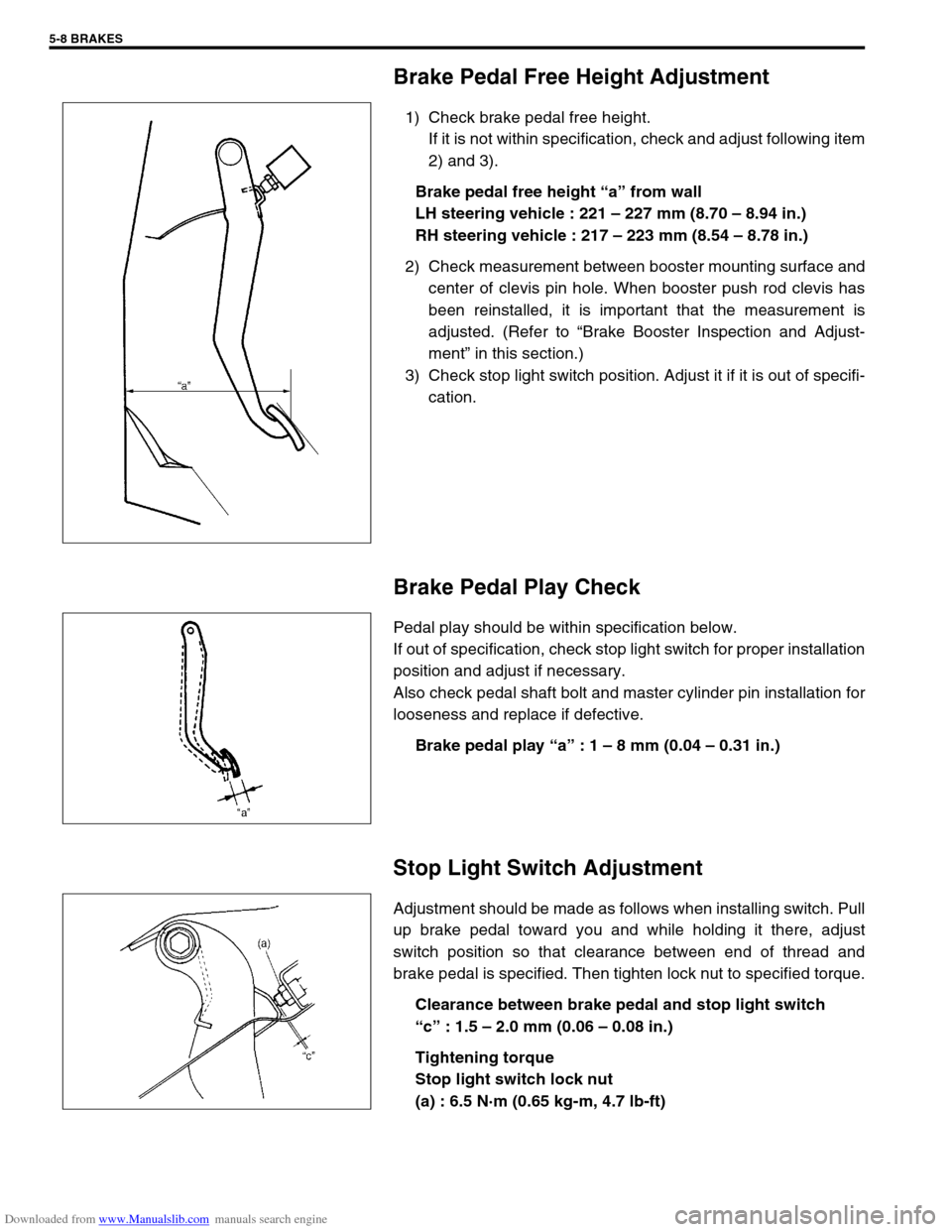

Brake Pedal Free Height Adjustment

1) Check brake pedal free height.

If it is not within specification, check and adjust following item

2) and 3).

Brake pedal free height “a” from wall

LH steering vehicle : 221 – 227 mm (8.70 – 8.94 in.)

RH steering vehicle : 217 – 223 mm (8.54 – 8.78 in.)

2) Check measurement between booster mounting surface and

center of clevis pin hole. When booster push rod clevis has

been reinstalled, it is important that the measurement is

adjusted. (Refer to “Brake Booster Inspection and Adjust-

ment” in this section.)

3) Check stop light switch position. Adjust it if it is out of specifi-

cation.

Brake Pedal Play Check

Pedal play should be within specification below.

If out of specification, check stop light switch for proper installation

position and adjust if necessary.

Also check pedal shaft bolt and master cylinder pin installation for

looseness and replace if defective.

Brake pedal play “a” : 1 – 8 mm (0.04 – 0.31 in.)

Stop Light Switch Adjustment

Adjustment should be made as follows when installing switch. Pull

up brake pedal toward you and while holding it there, adjust

switch position so that clearance between end of thread and

brake pedal is specified. Then tighten lock nut to specified torque.

Clearance between brake pedal and stop light switch

“c” : 1.5 – 2.0 mm (0.06 – 0.08 in.)

Tightening torque

Stop light switch lock nut

(a) : 6.5 N·m (0.65 kg-m, 4.7 lb-ft)

Page 620 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE AND EMISSION CONTROL SYSTEM 6E-15

On-Vehicle Service

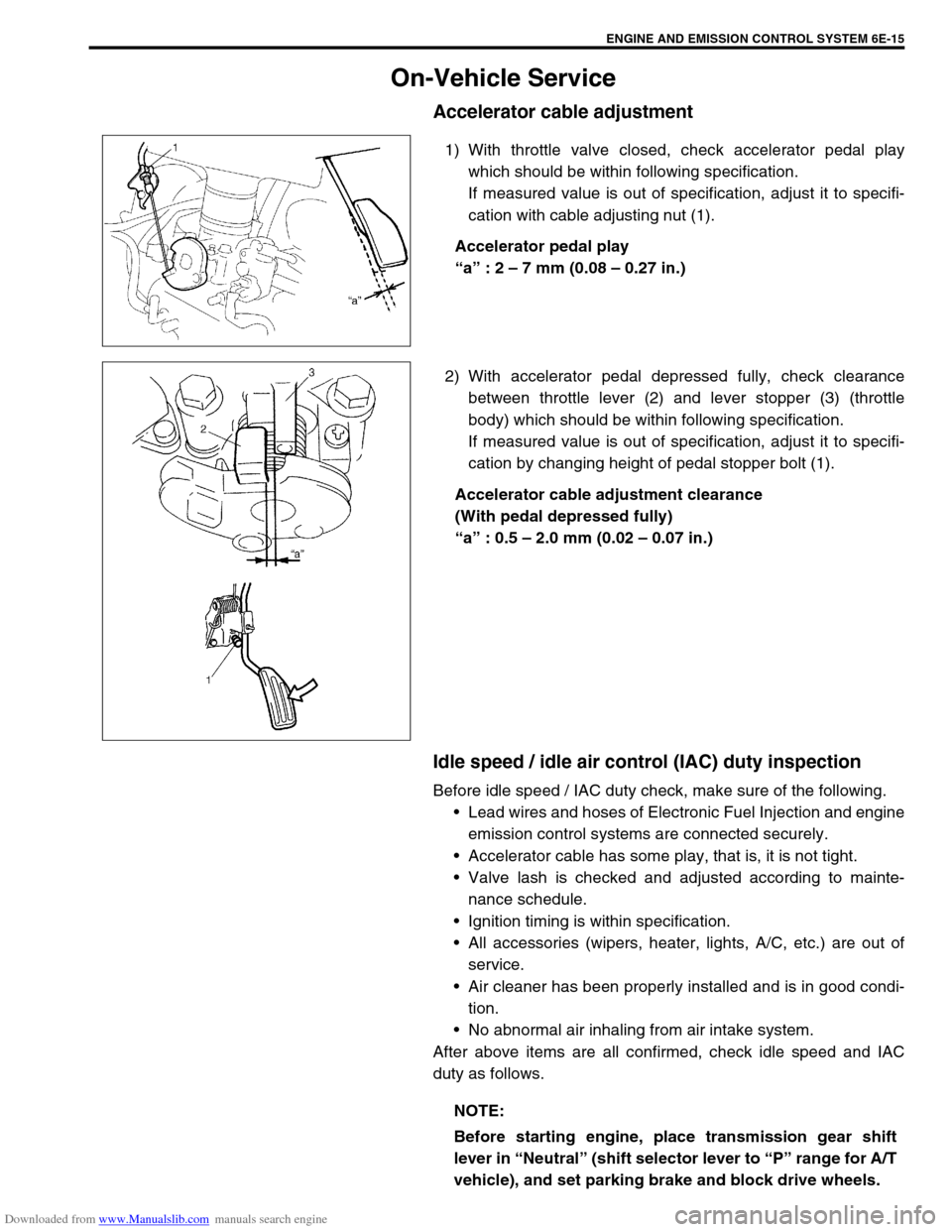

Accelerator cable adjustment

1) With throttle valve closed, check accelerator pedal play

which should be within following specification.

If measured value is out of specification, adjust it to specifi-

cation with cable adjusting nut (1).

Accelerator pedal play

“a” : 2 – 7 mm (0.08 – 0.27 in.)

2) With accelerator pedal depressed fully, check clearance

between throttle lever (2) and lever stopper (3) (throttle

body) which should be within following specification.

If measured value is out of specification, adjust it to specifi-

cation by changing height of pedal stopper bolt (1).

Accelerator cable adjustment clearance

(With pedal depressed fully)

“a” : 0.5 – 2.0 mm (0.02 – 0.07 in.)

Idle speed / idle air control (IAC) duty inspection

Before idle speed / IAC duty check, make sure of the following.

Lead wires and hoses of Electronic Fuel Injection and engine

emission control systems are connected securely.

Accelerator cable has some play, that is, it is not tight.

Valve lash is checked and adjusted according to mainte-

nance schedule.

Ignition timing is within specification.

All accessories (wipers, heater, lights, A/C, etc.) are out of

service.

Air cleaner has been properly installed and is in good condi-

tion.

No abnormal air inhaling from air intake system.

After above items are all confirmed, check idle speed and IAC

duty as follows.

NOTE:

Before starting engine, place transmission gear shift

lever in “Neutral” (shift selector lever to “P” range for A/T

vehicle), and set parking brake and block drive wheels.