service indicator SUZUKI JIMNY 2005 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: JIMNY, Model: SUZUKI JIMNY 2005 3.GPages: 687, PDF Size: 13.38 MB

Page 181 of 687

Downloaded from www.Manualslib.com manuals search engine 3D-8 FRONT SUSPENSION

Diagnosis

Diagnosis Table

For description not found in the table below, refer to “Diagnosis Table” in Section 3.

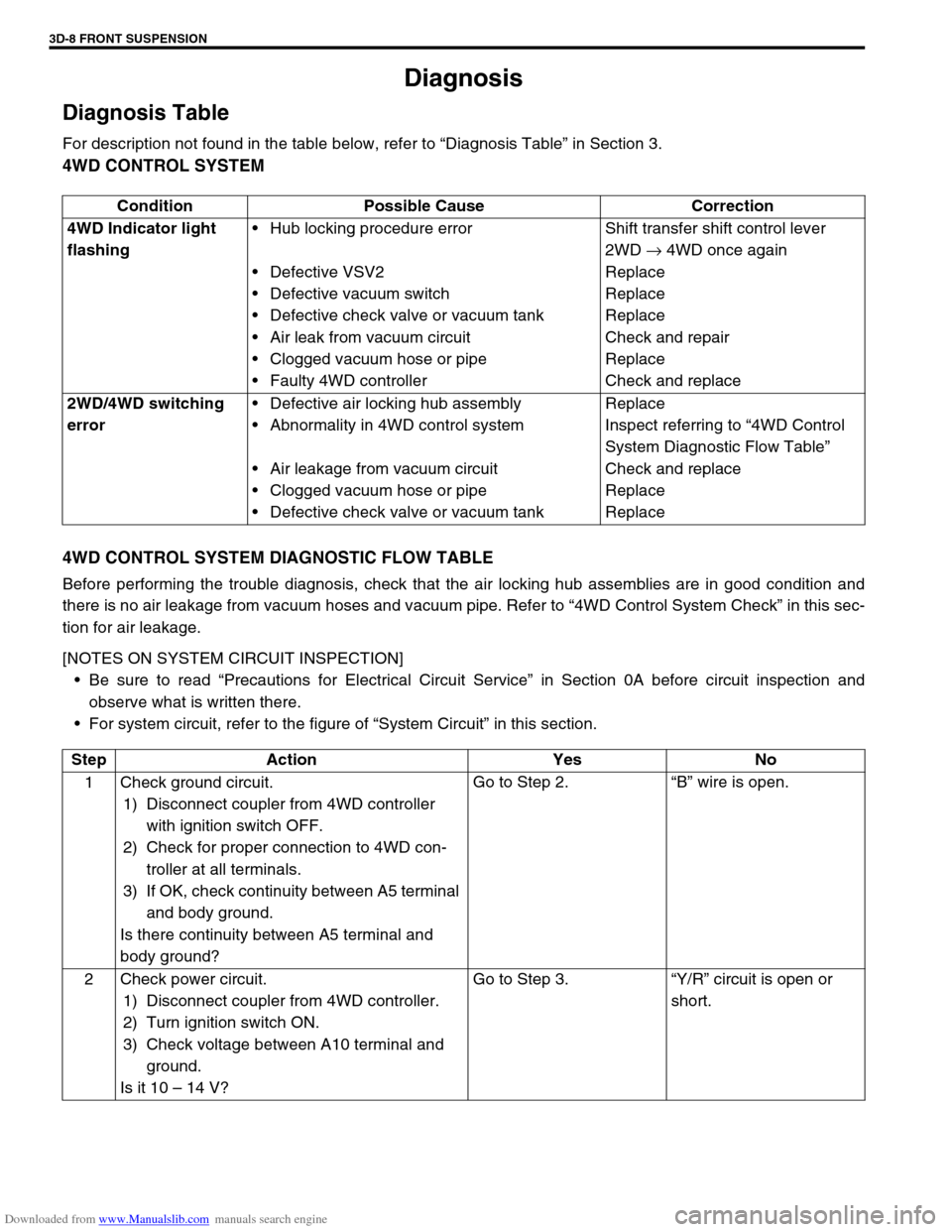

4WD CONTROL SYSTEM

4WD CONTROL SYSTEM DIAGNOSTIC FLOW TABLE

Before performing the trouble diagnosis, check that the air locking hub assemblies are in good condition and

there is no air leakage from vacuum hoses and vacuum pipe. Refer to “4WD Control System Check” in this sec-

tion for air leakage.

[NOTES ON SYSTEM CIRCUIT INSPECTION]

Be sure to read “Precautions for Electrical Circuit Service” in Section 0A before circuit inspection and

observe what is written there.

For system circuit, refer to the figure of “System Circuit” in this section. Condition Possible Cause Correction

4WD Indicator light

flashingHub locking procedure error

Defective VSV2

Defective vacuum switch

Defective check valve or vacuum tank

Air leak from vacuum circuit

Clogged vacuum hose or pipe

Faulty 4WD controllerShift transfer shift control lever

2WD → 4WD once again

Replace

Replace

Replace

Check and repair

Replace

Check and replace

2WD/4WD switching

errorDefective air locking hub assembly

Abnormality in 4WD control system

Air leakage from vacuum circuit

Clogged vacuum hose or pipe

Defective check valve or vacuum tankReplace

Inspect referring to “4WD Control

System Diagnostic Flow Table”

Check and replace

Replace

Replace

Step Action Yes No

1 Check ground circuit.

1) Disconnect coupler from 4WD controller

with ignition switch OFF.

2) Check for proper connection to 4WD con-

troller at all terminals.

3) If OK, check continuity between A5 terminal

and body ground.

Is there continuity between A5 terminal and

body ground?Go to Step 2.“B” wire is open.

2 Check power circuit.

1) Disconnect coupler from 4WD controller.

2) Turn ignition switch ON.

3) Check voltage between A10 terminal and

ground.

Is it 10 – 14 V?Go to Step 3.“Y/R” circuit is open or

short.

Page 358 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8B

6

8D

8E

8B

9

10A

10B

SECTION 6

ENGINE GENERAL INFORMATION AND

DIAGNOSIS

GENERAL INFORMATION AND ENGINE DIAGNOSIS ..............................................................................

6-1

ENGINE MECHANICAL ...........................................................................................................................

6A1-1

ENGINE COOLING.....................................................................................................................................

6B-1

ENGINE FUEL ............................................................................................................................................

6C-1

ENGINE AND EMISSION CONTROL SYSTEM ........................................................................................

6E-1

IGNITION SYSTEM ....................................................................................................................................

6F-1

CRANKING SYSTEM .................................................................................................................................

6G-1

CHARGING SYSTEM .................................................................................................................................

6H-1

EXHAUST SYSTEM ...................................................................................................................................

6K-1

CONTENTS

General Information .......................................... 6-3

Statement on Cleanliness and Care ............... 6-3

General Information on Engine Service .......... 6-3

Precaution on fuel system service............... 6-4

Fuel pressure relief procedure .................... 6-5

Fuel leakage check procedure .................... 6-5

Engine Diagnosis .............................................. 6-6

General Description ........................................ 6-6

On-Board Diagnostic System (Vehicle with

Immobilizer Indicator Lamp) ............................ 6-6On-Board Diagnostic System (Vehicle without

Immobilizer Indicator Lamp)............................ 6-9

Precaution in Diagnosing Trouble ................. 6-10

Engine Diagnostic Flow Table ...................... 6-11

Customer problem inspection form

(example) .................................................. 6-13

Malfunction indicator lamp (MIL) check..... 6-14

Diagnostic trouble code (DTC) check ....... 6-14

Diagnostic trouble code (DTC)

clearance................................................... 6-15 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Whether the following systems (parts) are used in the particular vehicle or not depends on vehicle

specifications. Be sure to bear this in mind when performing service work.

EGR valve

Heated oxygen sensor(s) or CO adjusting resistor

Three-way catalytic converter (TWC) and warm up three-way catalytic converter (WU-TWC)

Page 366 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-9

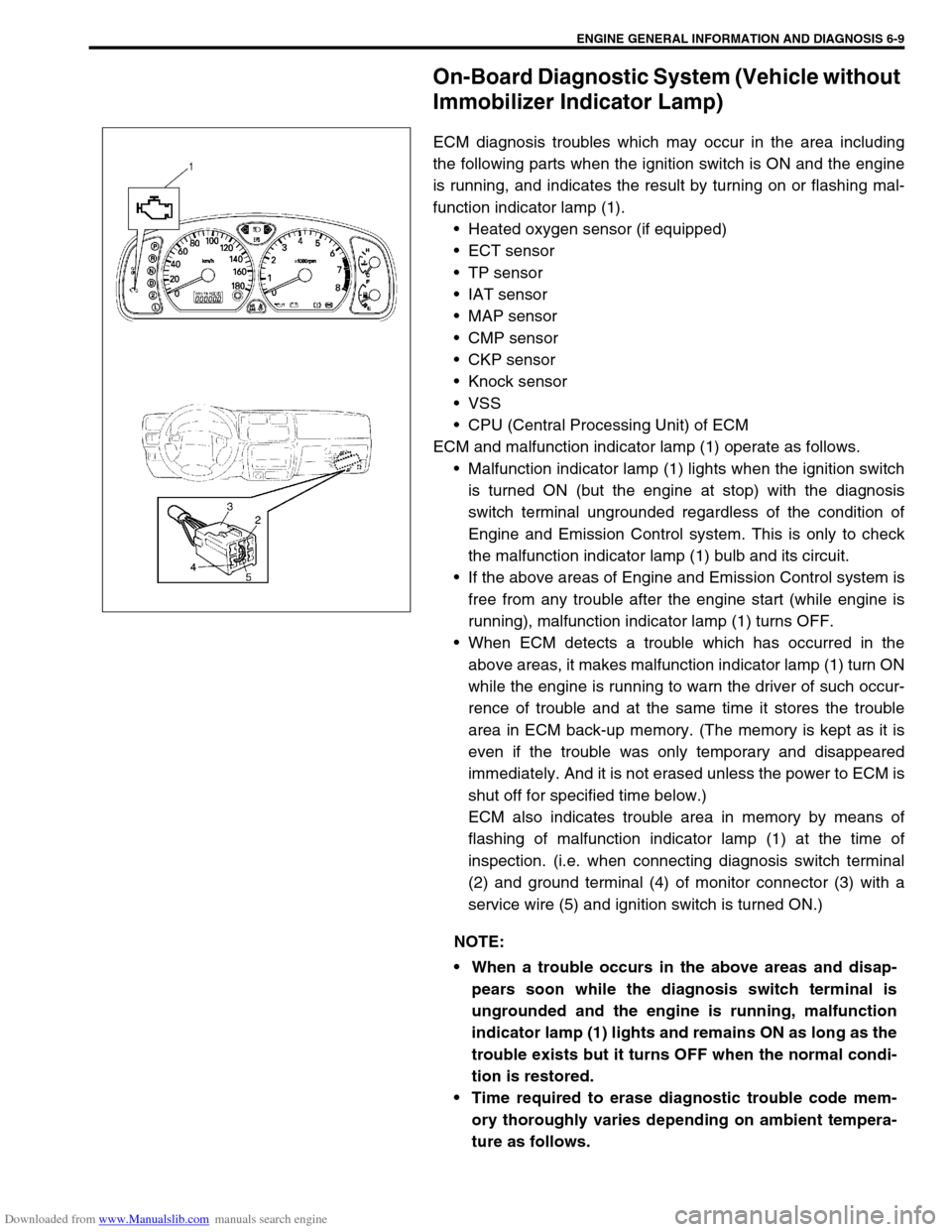

On-Board Diagnostic System (Vehicle without

Immobilizer Indicator Lamp)

ECM diagnosis troubles which may occur in the area including

the following parts when the ignition switch is ON and the engine

is running, and indicates the result by turning on or flashing mal-

function indicator lamp (1).

Heated oxygen sensor (if equipped)

ECT sensor

TP sensor

IAT sensor

MAP sensor

CMP sensor

CKP sensor

Knock sensor

VSS

CPU (Central Processing Unit) of ECM

ECM and malfunction indicator lamp (1) operate as follows.

Malfunction indicator lamp (1) lights when the ignition switch

is turned ON (but the engine at stop) with the diagnosis

switch terminal ungrounded regardless of the condition of

Engine and Emission Control system. This is only to check

the malfunction indicator lamp (1) bulb and its circuit.

If the above areas of Engine and Emission Control system is

free from any trouble after the engine start (while engine is

running), malfunction indicator lamp (1) turns OFF.

When ECM detects a trouble which has occurred in the

above areas, it makes malfunction indicator lamp (1) turn ON

while the engine is running to warn the driver of such occur-

rence of trouble and at the same time it stores the trouble

area in ECM back-up memory. (The memory is kept as it is

even if the trouble was only temporary and disappeared

immediately. And it is not erased unless the power to ECM is

shut off for specified time below.)

ECM also indicates trouble area in memory by means of

flashing of malfunction indicator lamp (1) at the time of

inspection. (i.e. when connecting diagnosis switch terminal

(2) and ground terminal (4) of monitor connector (3) with a

service wire (5) and ignition switch is turned ON.)

NOTE:

When a trouble occurs in the above areas and disap-

pears soon while the diagnosis switch terminal is

ungrounded and the engine is running, malfunction

indicator lamp (1) lights and remains ON as long as the

trouble exists but it turns OFF when the normal condi-

tion is restored.

Time required to erase diagnostic trouble code mem-

ory thoroughly varies depending on ambient tempera-

ture as follows.

Page 367 of 687

Downloaded from www.Manualslib.com manuals search engine 6-10 ENGINE GENERAL INFORMATION AND DIAGNOSIS

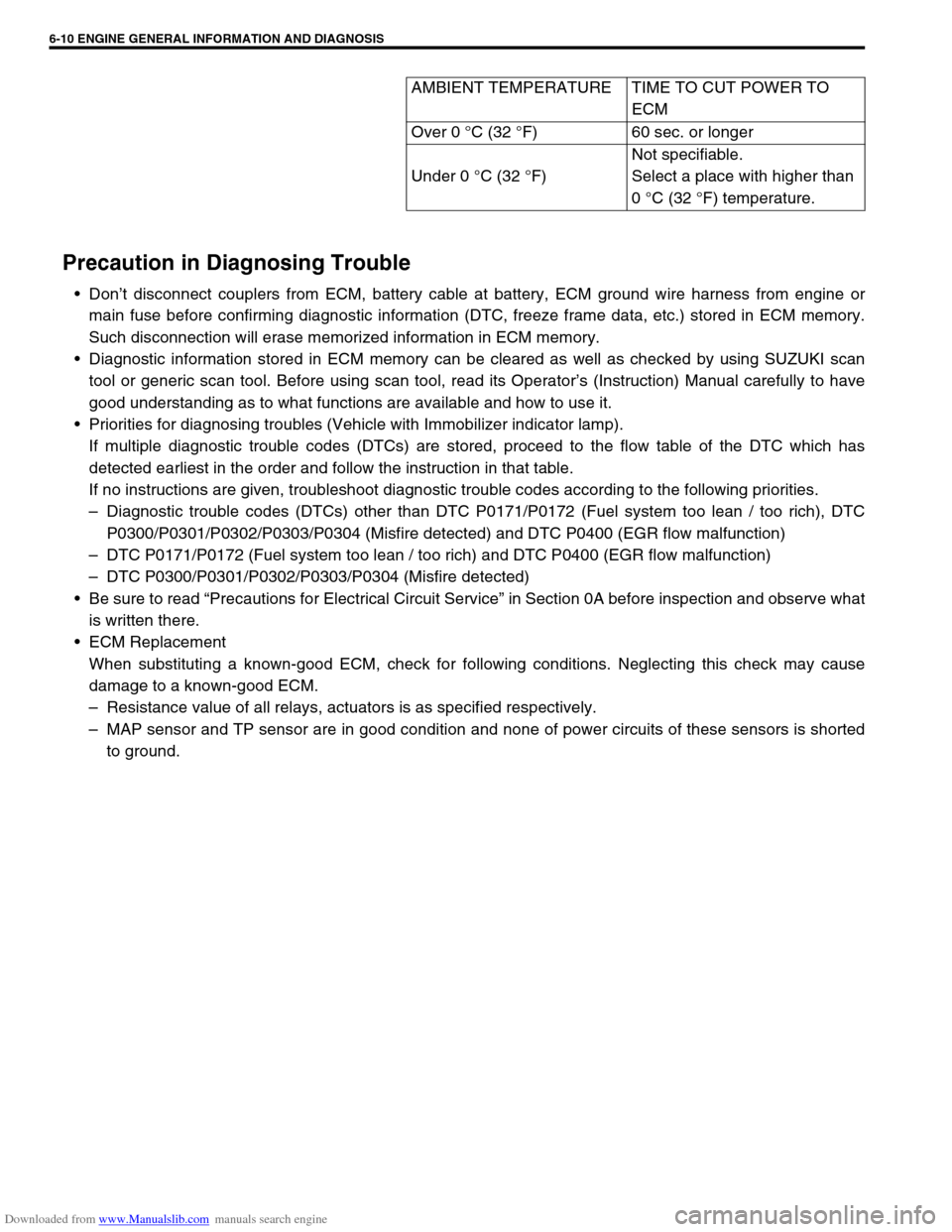

Precaution in Diagnosing Trouble

Don’t disconnect couplers from ECM, battery cable at battery, ECM ground wire harness from engine or

main fuse before confirming diagnostic information (DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information in ECM memory.

Diagnostic information stored in ECM memory can be cleared as well as checked by using SUZUKI scan

tool or generic scan tool. Before using scan tool, read its Operator’s (Instruction) Manual carefully to have

good understanding as to what functions are available and how to use it.

Priorities for diagnosing troubles (Vehicle with Immobilizer indicator lamp).

If multiple diagnostic trouble codes (DTCs) are stored, proceed to the flow table of the DTC which has

detected earliest in the order and follow the instruction in that table.

If no instructions are given, troubleshoot diagnostic trouble codes according to the following priorities.

–Diagnostic trouble codes (DTCs) other than DTC P0171/P0172 (Fuel system too lean / too rich), DTC

P0300/P0301/P0302/P0303/P0304 (Misfire detected) and DTC P0400 (EGR flow malfunction)

–DTC P0171/P0172 (Fuel system too lean / too rich) and DTC P0400 (EGR flow malfunction)

–DTC P0300/P0301/P0302/P0303/P0304 (Misfire detected)

Be sure to read “Precautions for Electrical Circuit Service” in Section 0A before inspection and observe what

is written there.

ECM Replacement

When substituting a known-good ECM, check for following conditions. Neglecting this check may cause

damage to a known-good ECM.

–Resistance value of all relays, actuators is as specified respectively.

–MAP sensor and TP sensor are in good condition and none of power circuits of these sensors is shorted

to ground.AMBIENT TEMPERATURE TIME TO CUT POWER TO

ECM

Over 0 °C (32 °F) 60 sec. or longer

Under 0 °C (32 °F)Not specifiable.

Select a place with higher than

0 °C (32 °F) temperature.

Page 371 of 687

Downloaded from www.Manualslib.com manuals search engine 6-14 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Malfunction indicator lamp (MIL) check

1) Turn ON ignition switch (but the engine at stop) and check

that MIL lights.

If MIL does not light up (or MIL dims), go to “Diagnostic Flow

Table A-1” for troubleshooting.

If MIL flushes, go to “Diagnostic Flow Table A-3” for trouble

shooting (vehicle without immobilizer indicator lamp).

2) Start engine and check that MIL turns OFF.

If MIL remains ON and no DTC is stored in ECM, go to

“Diagnostic Flow Table A-2” for troubleshooting.

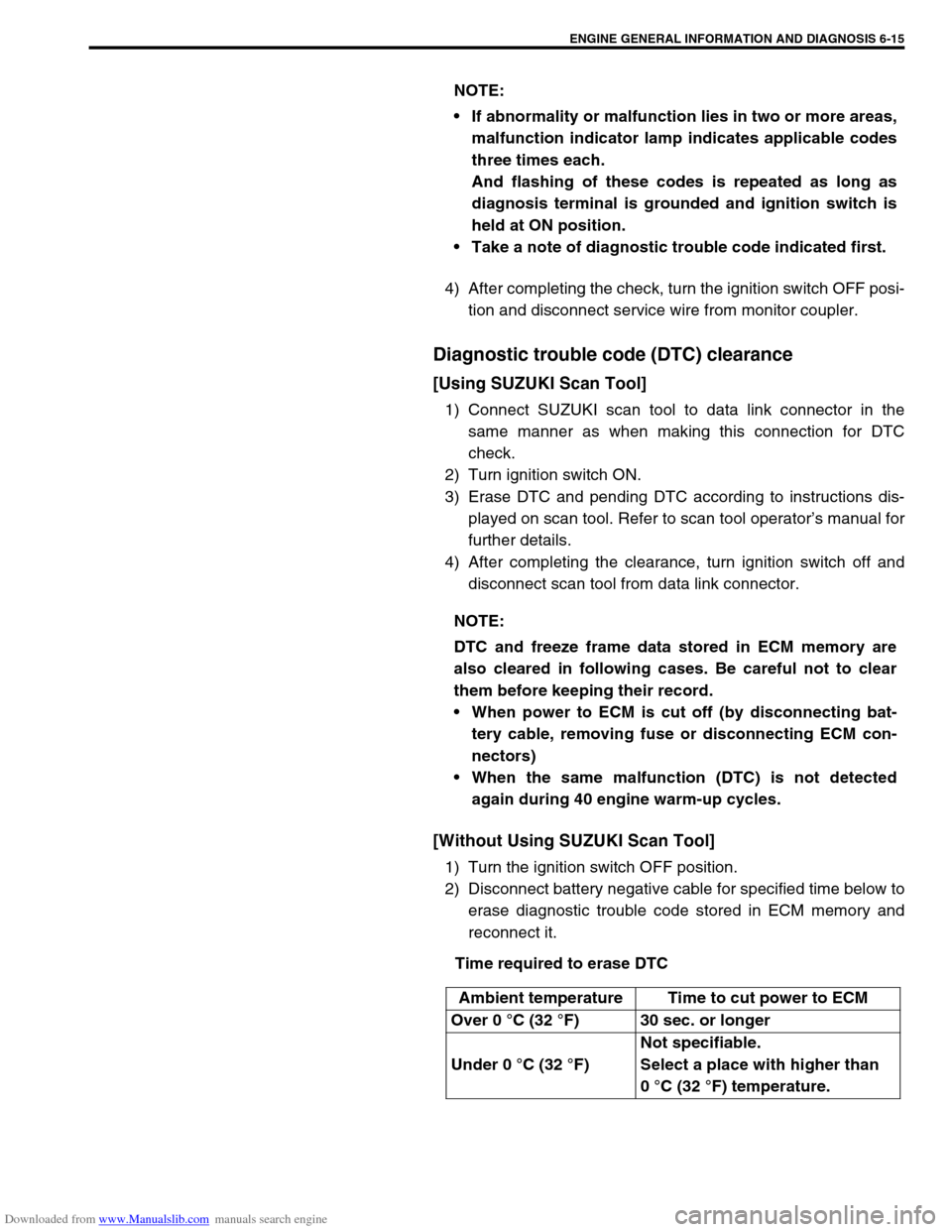

Diagnostic trouble code (DTC) check

[Using SUZUKI Scan Tool]

1) Prepare SUZUKI scan tool.

2) With ignition switch OFF, connect it to data link connector

(DLC) (1) located on underside of instrument panel at

driver’s seat side.

Special tool

(A) : SUZUKI scan tool

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC, pending DTC and freeze frame data according to

instructions displayed on scan tool and print it or write it

down.

Refer to scan tool operator’s manual for further details.

If communication between scan tool and ECM is not possi-

ble, check if scan tool is communicable by connecting it to

ECM in another vehicle. If communication is possible in this

case, scan tool is in good condition. Then check data link

connector and serial data line (circuit) in the vehicle with

which communication was not possible.

5) After completing the check, turn ignition switch off and dis-

connect scan tool from data link connector.

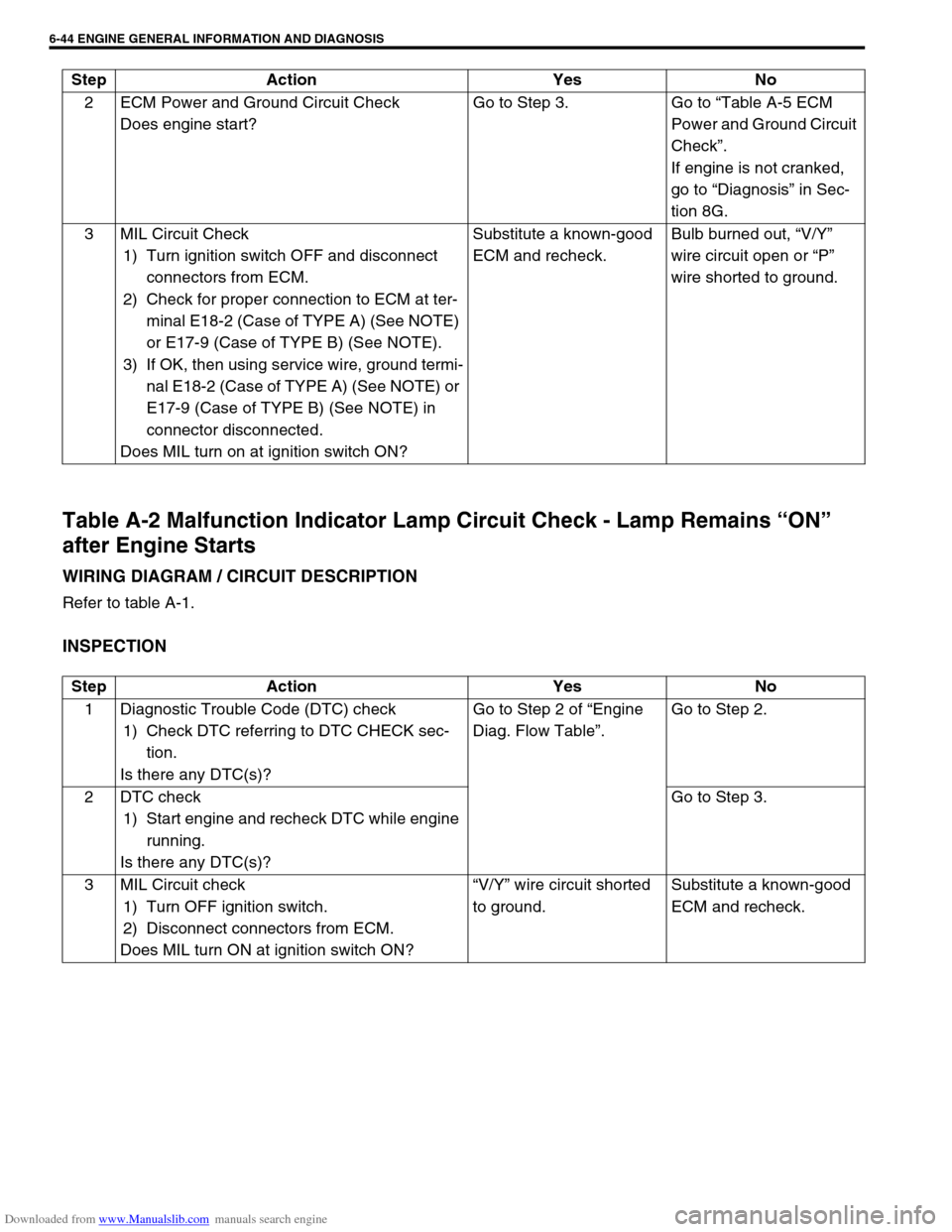

[Without Using SUZUKI Scan Tool] (Vehicle Without

Immobilizer Indicator Lamp)

1) Check malfunction indicator lamp referring to “Malfunction

Indicator Lamp Check” in this section.

2) With the ignition switch OFF position, connect diagnosis

switch terminal (3) and ground terminal (2) in monitor con-

nector (1) with service wire (4).

3) With the ignition switch ON position and leaving engine OFF,

read DTC from flashing pattern of malfunction indicator

lamp. Refer to “Diagnostic Trouble Code Table”.

If lamp does not flash or remains ON or OFF, go to “Diag-

nostic Flow Table A-4”.

Page 372 of 687

Downloaded from www.Manualslib.com manuals search engine ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-15

4) After completing the check, turn the ignition switch OFF posi-

tion and disconnect service wire from monitor coupler.

Diagnostic trouble code (DTC) clearance

[Using SUZUKI Scan Tool]

1) Connect SUZUKI scan tool to data link connector in the

same manner as when making this connection for DTC

check.

2) Turn ignition switch ON.

3) Erase DTC and pending DTC according to instructions dis-

played on scan tool. Refer to scan tool operator’s manual for

further details.

4) After completing the clearance, turn ignition switch off and

disconnect scan tool from data link connector.

[Without Using SUZUKI Scan Tool]

1) Turn the ignition switch OFF position.

2) Disconnect battery negative cable for specified time below to

erase diagnostic trouble code stored in ECM memory and

reconnect it.

Time required to erase DTC NOTE:

If abnormality or malfunction lies in two or more areas,

malfunction indicator lamp indicates applicable codes

three times each.

And flashing of these codes is repeated as long as

diagnosis terminal is grounded and ignition switch is

held at ON position.

Take a note of diagnostic trouble code indicated first.

NOTE:

DTC and freeze frame data stored in ECM memory are

also cleared in following cases. Be careful not to clear

them before keeping their record.

When power to ECM is cut off (by disconnecting bat-

tery cable, removing fuse or disconnecting ECM con-

nectors)

When the same malfunction (DTC) is not detected

again during 40 engine warm-up cycles.

Ambient temperature Time to cut power to ECM

Over 0 °C (32 °F) 30 sec. or longer

Under 0 °C (32 °F)Not specifiable.

Select a place with higher than

0 °C (32 °F) temperature.

Page 401 of 687

Downloaded from www.Manualslib.com manuals search engine 6-44 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Table A-2 Malfunction Indicator Lamp Circuit Check - Lamp Remains “ON”

after Engine Starts

WIRING DIAGRAM / CIRCUIT DESCRIPTION

Refer to table A-1.

INSPECTION

2 ECM Power and Ground Circuit Check

Does engine start?Go to Step 3. Go to “Table A-5 ECM

Power and Ground Circuit

Check”.

If engine is not cranked,

go to “Diagnosis” in Sec-

tion 8G.

3 MIL Circuit Check

1) Turn ignition switch OFF and disconnect

connectors from ECM.

2) Check for proper connection to ECM at ter-

minal E18-2 (Case of TYPE A) (See NOTE)

or E17-9 (Case of TYPE B) (See NOTE).

3) If OK, then using service wire, ground termi-

nal E18-2 (Case of TYPE A) (See NOTE) or

E17-9 (Case of TYPE B) (See NOTE) in

connector disconnected.

Does MIL turn on at ignition switch ON?Substitute a known-good

ECM and recheck.Bulb burned out, “V/Y”

wire circuit open or “P”

wire shorted to ground. Step Action Yes No

Step Action Yes No

1 Diagnostic Trouble Code (DTC) check

1) Check DTC referring to DTC CHECK sec-

tion.

Is there any DTC(s)?Go to Step 2 of “Engine

Diag. Flow Table”.Go to Step 2.

2DTC check

1) Start engine and recheck DTC while engine

running.

Is there any DTC(s)?Go to Step 3.

3 MIL Circuit check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

Does MIL turn ON at ignition switch ON?“V/Y” wire circuit shorted

to ground.Substitute a known-good

ECM and recheck.

Page 621 of 687

Downloaded from www.Manualslib.com manuals search engine 6E-16 ENGINE AND EMISSION CONTROL SYSTEM

1) Connect SUZUKI scan tool to DLC with ignition switch OFF,

if it is available.

2) Warm up engine to normal operating temperature.

3) Check engine idle speed and “IAC duty” as follows:

a) When using SUZUKI scan tool:

i) Select “Data List” mode on scan tool to check “IAC duty”.

(A) : SUZUKI scan tool

b) When using duty meter (3) (Vehicle without immobilizer

indicator lamp):

i) Set tachometer.

ii) Using service wire (2), ground “Diag. switch terminal” in

monitor connector (1) and connect duty meter between

“Duty output terminal (4)” and “Ground terminal (5)” of

monitor connector (1).

4) If duty and/or idle speed is out of specifications, inspect idle

air control system referring to “Diagnostic Flow Table B-4 Idle

Air Control System Check” in Section 6.

Engine idle speed and IAC duty

5) Remove service wire from monitor connector.

6) Check that specified engine idle speed is obtained with A/C

ON if vehicle is equipped with A/C.

If not, check A/C ON signal circuit and idle air control sys-

tem. NOTE:

IAC duty can be checked using monitor connector only

for vehicle not equipped with immobilizer indicator lamp.

[A] : When using SUZUKI scan tool

[B] : When using duty meter (Vehicle without immobilizer indicator lamp)

A/C OFF A/C ON

M/T vehicle700 ± 50 r/min (rpm)

5 – 25 %900 ± 50 r/min

(rpm)

A/T vehicle

at P/N range750 ± 50 r/min (rpm)

5 – 25 %900 ± 50 r/min

(rpm)

NOTE:

Above duty values are ON duty (low voltage rate) meter

indications.

Page 658 of 687

Downloaded from www.Manualslib.com manuals search engine IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F-9

5) Fix ignition timing to initial one as follows.

a) When using SUZUKI scan tool:

Select “MISC” mode on SUZUKI scan tool and fix ignition

timing to initial one.

b) Without using SUZUKI scan tool: (vehicle without immobi-

lizer indicator lamp)

Disconnect scan tool from DLC, and connect D and E ter-

minals of monitor connector (1) or E to body ground by

using service wire so that ignition timing is fixed on initial

one.

6) Using timing light (1), check that ignition timing is within

specification.

Initial ignition timing (test switch terminal grounded or

fixed with SUZUKI scan tool)

5

± 3° BTDC at idle speed

Ignition order

1-3-4-2

7) If ignition timing is out of specification, check the followings:

CKP sensor

CKP sensor plate

TP sensor

Test switch signal circuit

VSS

Timing chain cover installation

8) After checking Initial Ignition Timing, release ignition timing

fixation by using SUZUKI scan tool or disconnect service

wire from monitor connector.

9) With engine idling (test switch terminal ungrounded, throttle

opening at closed position and car stopped), check that igni-

tion timing is about 7°–17° BTDC. (Constant variation within

a few degrees from 7°–17° indicates no abnormality but

proves operation of electronic timing control system.) Also,

check that increasing engine speed advances ignition timing.

If above check results are not satisfactory, check CKP sen-

sor, test switch terminal circuit and ECM.