steering SUZUKI RENO 2008 1.G Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: RENO, Model: SUZUKI RENO 2008 1.GPages: 226, PDF Size: 4.98 MB

Page 174 of 226

5-30

SERVICE AND APPEARANCE CARE

85Z14-03E

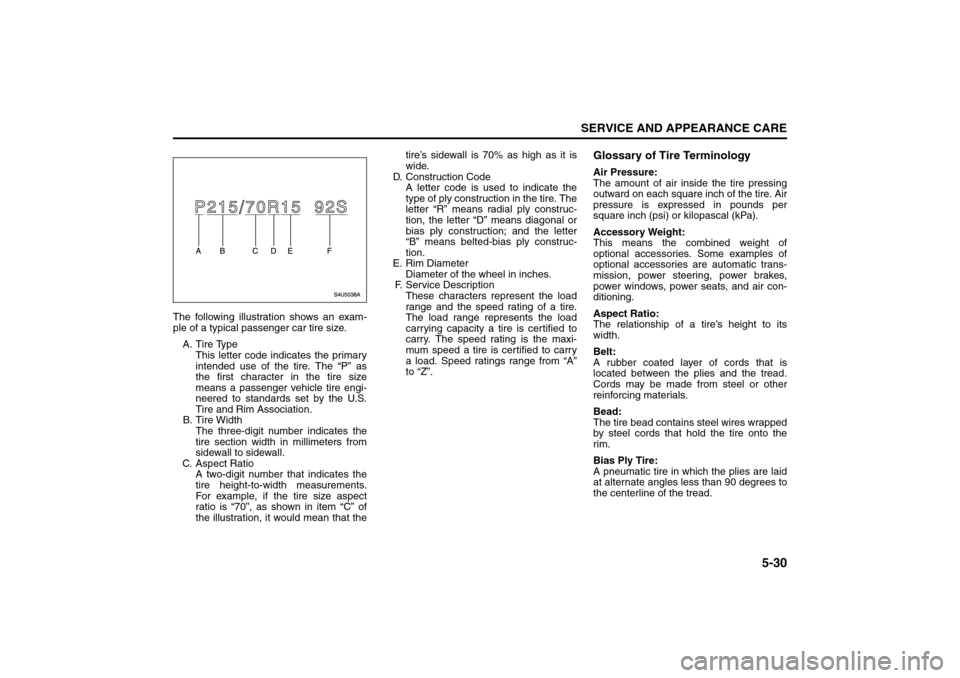

The following illustration shows an exam-

ple of a typical passenger car tire size.

A. Tire Type

This letter code indicates the primary

intended use of the tire. The “P” as

the first character in the tire size

means a passenger vehicle tire engi-

neered to standards set by the U.S.

Tire and Rim Association.

B. Tire Width

The three-digit number indicates the

tire section width in millimeters from

sidewall to sidewall.

C. Aspect Ratio

A two-digit number that indicates the

tire height-to-width measurements.

For example, if the tire size aspect

ratio is “70”, as shown in item “C” of

the illustration, it would mean that thetire’s sidewall is 70% as high as it is

wide.

D. Construction Code

A letter code is used to indicate the

type of ply construction in the tire. The

letter “R” means radial ply construc-

tion, the letter “D” means diagonal or

bias ply construction; and the letter

“B” means belted-bias ply construc-

tion.

E. Rim Diameter

Diameter of the wheel in inches.

F. Service Description

These characters represent the load

range and the speed rating of a tire.

The load range represents the load

carrying capacity a tire is certified to

carry. The speed rating is the maxi-

mum speed a tire is certified to carry

a load. Speed ratings range from “A”

to “Z”.

Glossary of Tire TerminologyAir Pressure:

The amount of air inside the tire pressing

outward on each square inch of the tire. Air

pressure is expressed in pounds per

square inch (psi) or kilopascal (kPa).

Accessory Weight:

This means the combined weight of

optional accessories. Some examples of

optional accessories are automatic trans-

mission, power steering, power brakes,

power windows, power seats, and air con-

ditioning.

Aspect Ratio:

The relationship of a tire’s height to its

width.

Belt:

A rubber coated layer of cords that is

located between the plies and the tread.

Cords may be made from steel or other

reinforcing materials.

Bead:

The tire bead contains steel wires wrapped

by steel cords that hold the tire onto the

rim.

Bias Ply Tire:

A pneumatic tire in which the plies are laid

at alternate angles less than 90 degrees to

the centerline of the tread.

Tires:

Page 177 of 226

5-33SERVICE AND APPEARANCE CARE

85Z14-03E

The tire pressure warning light can come

on due to normal causes such as natural

air leaks and pressure changes caused by

changes in temperature or atmospheric

pressure. Adjusting the air pressure in the

tires to the pressure shown on the tire and

loading information label should cause the

tire pressure warning light to turn off.

If you use new wheels with new tire infla-

tion pressure sensors, their ID codes must

be programmed into the tire pressure mon-itoring system. Have tire and wheel

replacement performed by an authorized

service facility to avoid the risk of damag-

ing the tire pressure monitor sensors.

The tire pressure monitoring system may

not work normally in the following circum-

stances:

Wheels other than genuine wheels are

being used.

Wheels whose ID codes are not memo-

rized by the vehicle are used. The moni-

toring system should be set up by an

authorized service facility.

Wheels that are not fitted with tire pres-

sure sensors are being used.

The tire inflation pressure sensors’ bat-

tery is exhausted.

A wireless facility or device using the

same frequency is near the vehicle.

Snow or ice is stuck inside the fenders

and/or on the wheels.

The tire pressure monitoring system oper-

ates on a radio frequency subject to Fed-

WARNING

If the tire pressure warning light

comes on and stays on, reduce your

speed and avoid abrupt steering and

braking. Stop in a safe place as soon

as possible and check your tires.

If you have a flat tire, replace it with

a spare tire. Refer to “Changing a

Flat Tire” in section 5.

If one or more of your tires is

under-inflated, adjust the inflation

pressure in all of your tires to the

recommended inflation pressure as

soon as possible.

Be aware that driving on a signifi-

cantly under-inflated tire can cause

the tire to overheat and can lead to

tire failure, and may affect steering

control and brake effectiveness. This

could lead to an accident, resulting in

severe injury or death.

CAUTION

Do not use liquid sealants for a flat

tire as air pressure sensors can be

damaged.

In case of tire a bursting or sudden

pressure drops, the tire pressure

monitoring system warning light

may not come on immediately.

The inflation pressures vary with

the ambient temperature. If the

vehicle is subjected to large varia-

tions in ambient temperature, the

tire

inflation pressure may be

under-inflated when the ambient

temperature is relatively low. If the

warning light comes on, adjust the

tire inflation pressure.

The tire pressure sensors can be

damaged by the installation or

removal of tires. When tires must

be repaired or replaced, we highly

recommend that you have them

repaired or replaced by your

SUZUKI dealer.

If the tire pressure warning light

comes on or blinks frequently,

there may be something wrong

with one of the tires or with the

monitoring system. Have your vehi-

cle inspected by your SUZUKI

dealer.

WARNING

Only use tires and wheels recom-

mended by us as standard or

optional equipment for your vehicle.

Use of tires or wheels not recom-

mended by us can result in TPMS fail-

ure. Refer to “Tires” in the “SERVICE

AND APPEARANCE CARE” section

for additional information.

Tires:

Page 180 of 226

5-36

SERVICE AND APPEARANCE CARE

85Z14-03E

molded into the tire sidewall typically

shown as “Max. Load”. Use of replacement

tires with a lower load-carrying capacity

than the original tires, or failure to keep the

tires inflated to the recommended tire pres-

sure, may reduce the GVWR or GAWR

limit of your vehicle.

NOTE:

Use of replacement tires with a higher

load-carrying capacity than the original

tires, or using a tire inflation pressure

higher than the recommended tire inflation

pressure, will not increase the GVWR or

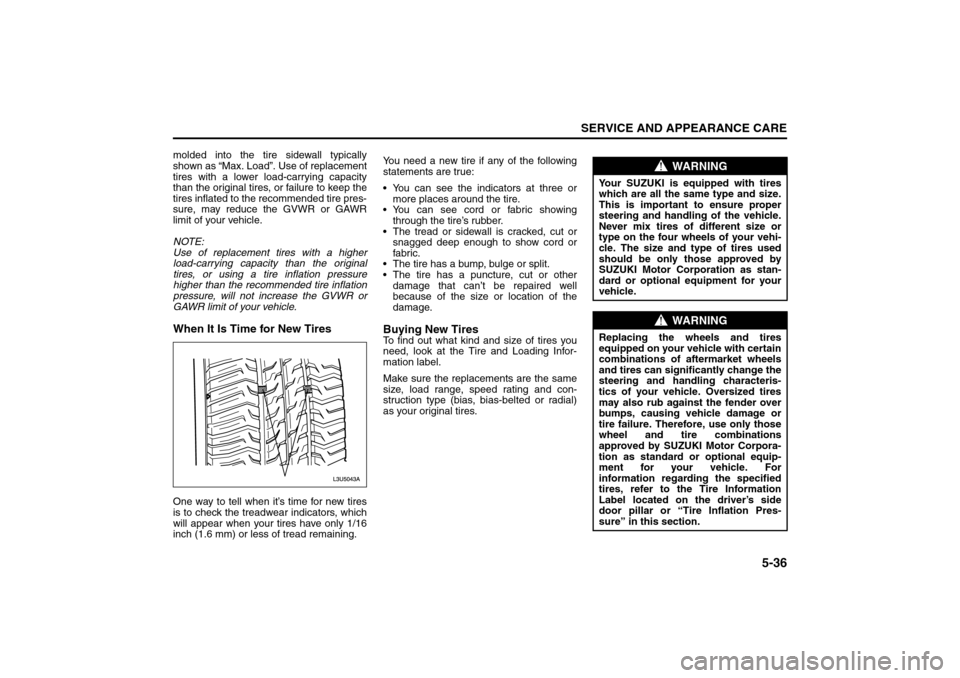

GAWR limit of your vehicle.When It Is Time for New TiresOne way to tell when it’s time for new tires

is to check the treadwear indicators, which

will appear when your tires have only 1/16

inch (1.6 mm) or less of tread remaining.You need a new tire if any of the following

statements are true:

You can see the indicators at three or

more places around the tire.

You can see cord or fabric showing

through the tire’s rubber.

The tread or sidewall is cracked, cut or

snagged deep enough to show cord or

fabric.

The tire has a bump, bulge or split.

The tire has a puncture, cut or other

damage that can’t be repaired well

because of the size or location of the

damage.

Buying New TiresTo find out what kind and size of tires you

need, look at the Tire and Loading Infor-

mation label.

Make sure the replacements are the same

size, load range, speed rating and con-

struction type (bias, bias-belted or radial)

as your original tires.

WARNING

Your SUZUKI is equipped with tires

which are all the same type and size.

This is important to ensure proper

steering and handling of the vehicle.

Never mix tires of different size or

type on the four wheels of your vehi-

cle. The size and type of tires used

should be only those approved by

SUZUKI Motor Corporation as stan-

dard or optional equipment for your

vehicle.

WARNING

Replacing the wheels and tires

equipped on your vehicle with certain

combinations of aftermarket wheels

and tires can significantly change the

steering and handling characteris-

tics of your vehicle. Oversized tires

may also rub against the fender over

bumps, causing vehicle damage or

tire failure. Therefore, use only those

wheel and tire combinations

approved by SUZUKI Motor Corpora-

tion as standard or optional equip-

ment for your vehicle. For

information regarding the specified

tires, refer to the Tire Information

Label located on the driver’s side

door pillar or “Tire Inflation Pres-

sure” in this section.

Tires:

Page 183 of 226

5-39SERVICE AND APPEARANCE CARE

85Z14-03E

it’s much more likely to leak out slowly. But

if you should ever have a “blowout”, here

are a few tips about what to expect and

what to do:

If a front tire fails, the flat tire will create a

drag that pulls the vehicle toward that side.

Take your foot off the accelerator pedal

and grip the steering wheel firmly. Steer to

maintain lane position, and then gently

brake to a stop well out of the traffic lane.

A rear blowout, particularly on a curve,

acts much like a skid and may require the

same correction you’d use in a skid. In any

rear blowout, remove your foot from the

accelerator pedal. Get the vehicle under

control by steering the way you want the

vehicle to go. It may be very bumpy and

noisy, but you can still steer. Gently brake

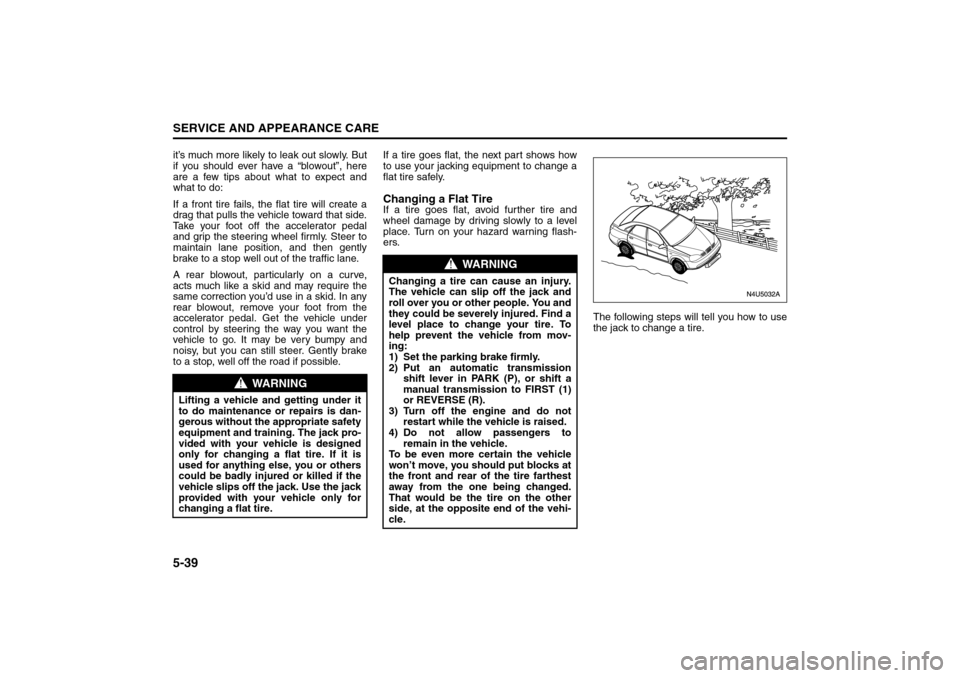

to a stop, well off the road if possible.If a tire goes flat, the next part shows how

to use your jacking equipment to change a

flat tire safely.

Changing a Flat TireIf a tire goes flat, avoid further tire and

wheel damage by driving slowly to a level

place. Turn on your hazard warning flash-

ers.

The following steps will tell you how to use

the jack to change a tire.

WARNING

Lifting a vehicle and getting under it

to do maintenance or repairs is dan-

gerous without the appropriate safety

equipment and training. The jack pro-

vided with your vehicle is designed

only for changing a flat tire. If it is

used for anything else, you or others

could be badly injured or killed if the

vehicle slips off the jack. Use the jack

provided with your vehicle only for

changing a flat tire.

WARNING

Changing a tire can cause an injury.

The vehicle can slip off the jack and

roll over you or other people. You and

they could be severely injured. Find a

level place to change your tire. To

help prevent the vehicle from mov-

ing:

1) Set the parking brake firmly.

2) Put an automatic transmission

shift lever in PARK (P), or shift a

manual transmission to FIRST (1)

or REVERSE (R).

3) Turn off the engine and do not

restart while the vehicle is raised.

4) Do not allow passengers to

remain in the vehicle.

To be even more certain the vehicle

won’t move, you should put blocks at

the front and rear of the tire farthest

away from the one being changed.

That would be the tire on the other

side, at the opposite end of the vehi-

cle.

Tires:

Page 197 of 226

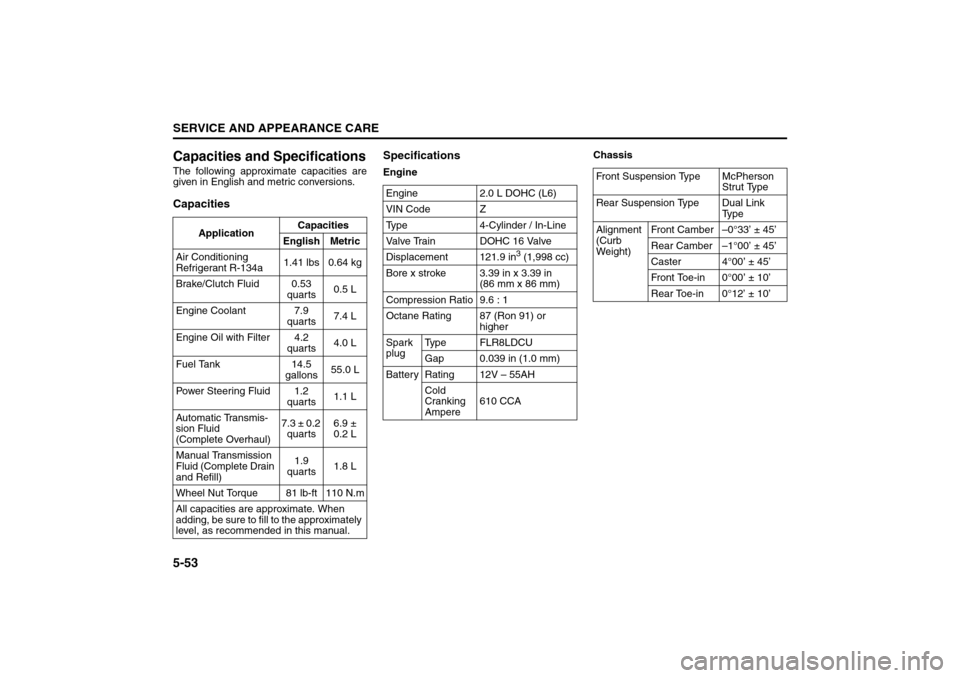

5-53SERVICE AND APPEARANCE CARE

85Z14-03E

Capacities and SpecificationsThe following approximate capacities are

given in English and metric conversions. CapacitiesSpecifications

EngineChassis

ApplicationCapacities

English Metric

Air Conditioning

Refrigerant R-134a1.41 lbs 0.64 kg

Brake/Clutch Fluid 0.53

quarts0.5 L

Engine Coolant 7.9

quarts7.4 L

Engine Oil with Filter 4.2

quarts4.0 L

Fuel Tank 14.5

gallons55.0 L

Power Steering Fluid 1.2

quarts1.1 L

Automatic Transmis-

sion Fluid

(Complete Overhaul)7.3 ± 0.2

quarts6.9 ±

0.2 L

Manual Transmission

Fluid (Complete Drain

and Refill)1.9

quarts1.8 L

Wheel Nut Torque 81 lb-ft 110 N.m

All capacities are approximate. When

adding, be sure to fill to the approximately

level, as recommended in this manual. Engine 2.0 L DOHC (L6)

VIN Code Z

Type 4-Cylinder / In-Line

Valve Train DOHC 16 Valve

Displacement 121.9 in

3 (1,998 cc)

Bore x stroke 3.39 in x 3.39 in

(86 mm x 86 mm)

Compression Ratio 9.6 : 1

Octane Rating 87 (Ron 91) or

higher

Spark

plugType FLR8LDCU

Gap 0.039 in (1.0 mm)

Battery Rating 12V – 55AH

Cold

Cranking

Ampere610 CCA

Front Suspension Type McPherson

Strut Type

Rear Suspension Type Dual Link

Ty p e

Alignment

(Curb

Weight)Front Camber –0°33’ ± 45’

Rear Camber –1°00’ ± 45’

Caster 4°00’ ± 45’

Front Toe-in 0°00’ ± 10’

Rear Toe-in 0°12’ ± 10’

Page 202 of 226

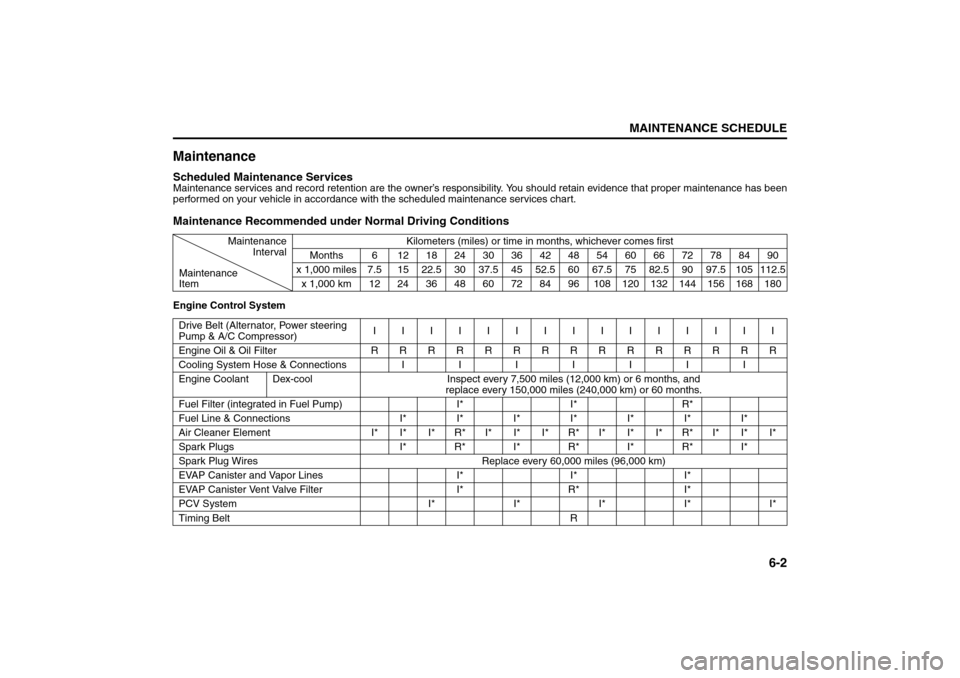

6-2

MAINTENANCE SCHEDULE

85Z14-03E

MaintenanceScheduled Maintenance ServicesMaintenance services and record retention are the owner’s responsibility. You should retain evidence that proper maintenance has been

performed on your vehicle in accordance with the scheduled maintenance services chart.Maintenance Recommended under Normal Driving ConditionsEngine Control SystemMaintenance

IntervalKilometers (miles) or time in months, whichever comes first

Months 6 1218243036424854606672788490

Maintenance

Itemx 1,000 miles 7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5

x 1,000 km 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180

Drive Belt (Alternator, Power steering

Pump & A/C Compressor)IIIIIIIIIIIIIII

Engine Oil & Oil Filter RRRRRRRRRRRRRRR

Cooling System Hose & Connections I I I I I I I

Engine Coolant Dex-cool Inspect every 7,500 miles (12,000 km) or 6 months, and

replace every 150,000 miles (240,000 km) or 60 months.

Fuel Filter (integrated in Fuel Pump) I* I* R*

Fuel Line & Connections I* I* I* I* I* I* I*

Air Cleaner Element I* I* I* R* I* I* I* R* I* I* I* R* I* I* I*

Spark Plugs I*R*I*R*I*R*I*

Spark Plug Wires Replace every 60,000 miles (96,000 km)

EVAP Canister and Vapor Lines I* I* I*

EVAP Canister Vent Valve Filter I* R* I*

PCV System I* I* I* I* I*

Timing BeltR

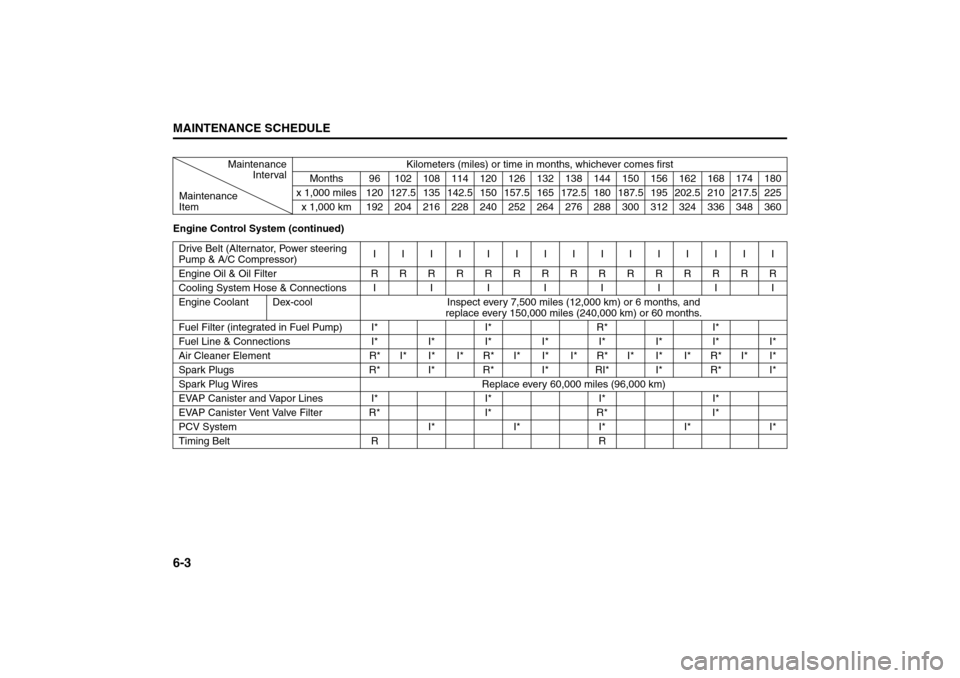

Page 203 of 226

6-3MAINTENANCE SCHEDULE

85Z14-03E

Engine Control System (continued)Maintenance

IntervalKilometers (miles) or time in months, whichever comes first

Months 96 102 108 114 120 126 132 138 144 150 156 162 168 174 180

Maintenance

Itemx 1,000 miles 120 127.5 135 142.5 150 157.5 165 172.5 180 187.5 195 202.5 210 217.5 225

x 1,000 km 192 204 216 228 240 252 264 276 288 300 312 324 336 348 360

Drive Belt (Alternator, Power steering

Pump & A/C Compressor)IIIIIIIIIIIIIII

Engine Oil & Oil Filter RRRRRRRRRRRRRRR

Cooling System Hose & Connections I I I I I I I I

Engine Coolant Dex-cool Inspect every 7,500 miles (12,000 km) or 6 months, and

replace every 150,000 miles (240,000 km) or 60 months.

Fuel Filter (integrated in Fuel Pump) I* I* R* I*

Fuel Line & Connections I* I* I* I* I* I* I* I*

Air Cleaner Element R* I* I* I* R* I* I* I* R* I* I* I* R* I* I*

Spark Plugs R* I* R* I* RI* I* R* I*

Spark Plug Wires Replace every 60,000 miles (96,000 km)

EVAP Canister and Vapor Lines I* I* I* I*

EVAP Canister Vent Valve Filter R* I* R* I*

PCV System I* I* I* I* I*

Timing Belt R R

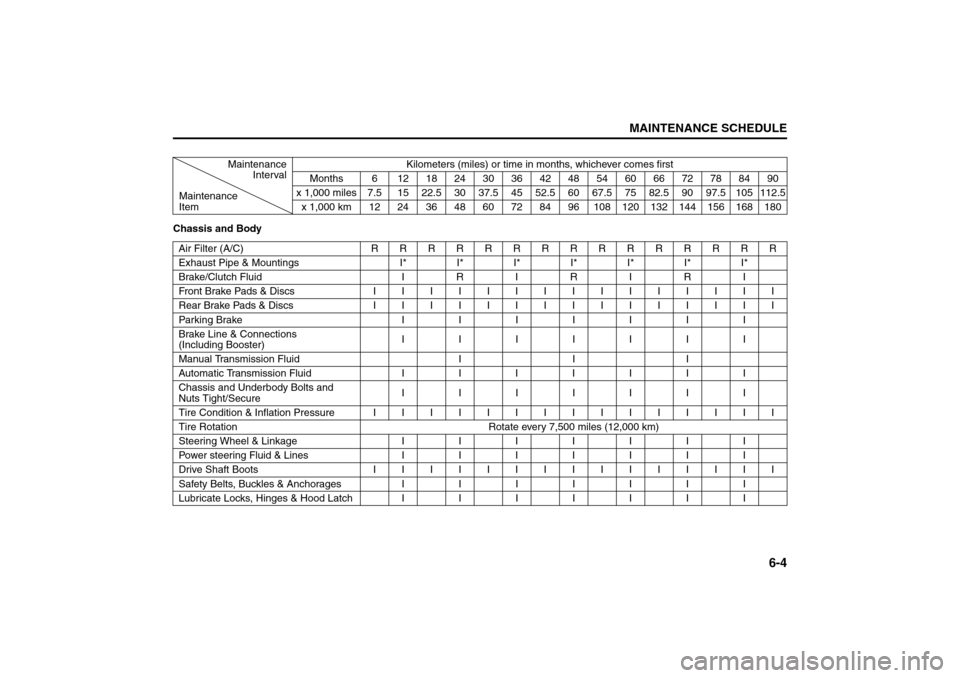

Page 204 of 226

6-4

MAINTENANCE SCHEDULE

85Z14-03E

Chassis and BodyMaintenance

IntervalKilometers (miles) or time in months, whichever comes first

Months 6 1218243036424854606672788490

Maintenance

Itemx 1,000 miles 7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5

x 1,000 km 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180

Air Filter (A/C) RRRRRRRRRRRRRRR

Exhaust Pipe & Mountings I* I* I* I* I* I* I*

Brake/Clutch Fluid I R I R I R I

Front Brake Pads & Discs IIIIIIIIIIIIIII

Rear Brake Pads & Discs IIIIIIIIIIIIIII

Parking Brake IIIIIII

Brake Line & Connections

(Including Booster)IIIIIII

Manual Transmission Fluid I I I

Automatic Transmission Fluid IIIIIII

Chassis and Underbody Bolts and

Nuts Tight/SecureIIIIIII

Tire Condition & Inflation Pressure IIIIIIIIIIIIIII

Tire Rotation Rotate every 7,500 miles (12,000 km)

Steering Wheel & Linkage I I I I I I I

Power steering Fluid & Lines I I I I I I I

Drive Shaft Boots IIIIIIIIIIIIIII

Safety Belts, Buckles & Anchorages I I I I I I I

Lubricate Locks, Hinges & Hood Latch I I I I I I I

Page 205 of 226

6-5MAINTENANCE SCHEDULE

85Z14-03E

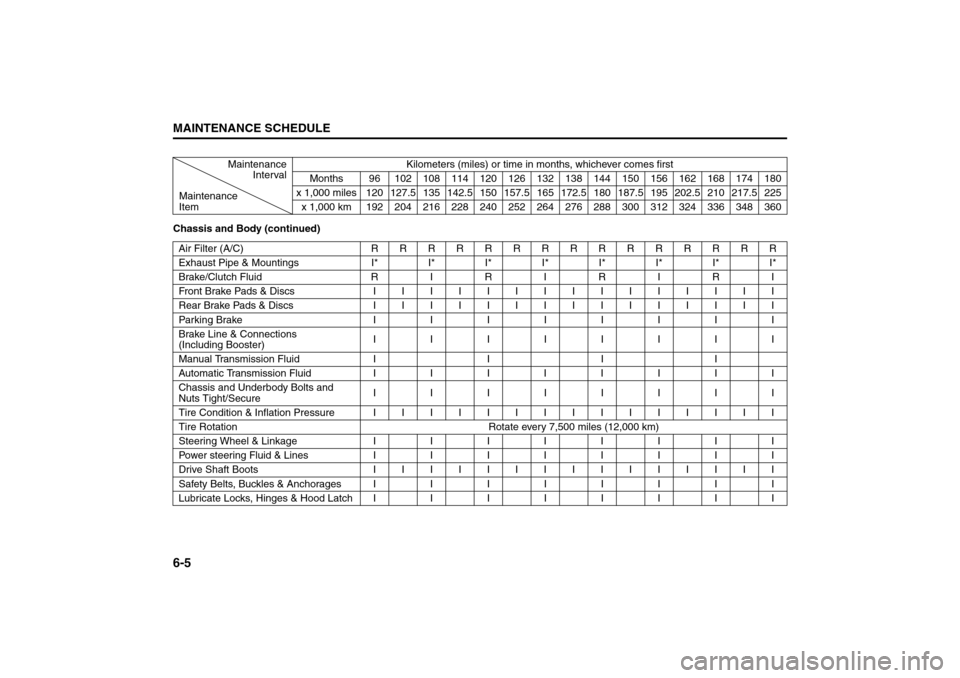

Chassis and Body (continued)Maintenance

IntervalKilometers (miles) or time in months, whichever comes first

Months 96 102 108 114 120 126 132 138 144 150 156 162 168 174 180

Maintenance

Itemx 1,000 miles 120 127.5 135 142.5 150 157.5 165 172.5 180 187.5 195 202.5 210 217.5 225

x 1,000 km 192 204 216 228 240 252 264 276 288 300 312 324 336 348 360

Air Filter (A/C) RRRRRRRRRRRRRRR

Exhaust Pipe & Mountings I* I* I* I* I* I* I* I*

Brake/Clutch Fluid R I R I R I R I

Front Brake Pads & Discs IIIIIIIIIIIIIII

Rear Brake Pads & Discs IIIIIIIIIIIIIII

Parking Brake IIIIIIII

Brake Line & Connections

(Including Booster)IIIIIIII

Manual Transmission Fluid I I I I

Automatic Transmission Fluid IIIIIIII

Chassis and Underbody Bolts and

Nuts Tight/SecureIIIIIIII

Tire Condition & Inflation Pressure IIIIIIIIIIIIIII

Tire Rotation Rotate every 7,500 miles (12,000 km)

Steering Wheel & Linkage I I I I I I I I

Power steering Fluid & Lines I I I I I I I I

Drive Shaft Boots IIIIIIIIIIIIIII

Safety Belts, Buckles & Anchorages I I I I I I I I

Lubricate Locks, Hinges & Hood Latch I I I I I I I I

Page 206 of 226

6-6

MAINTENANCE SCHEDULE

85Z14-03E

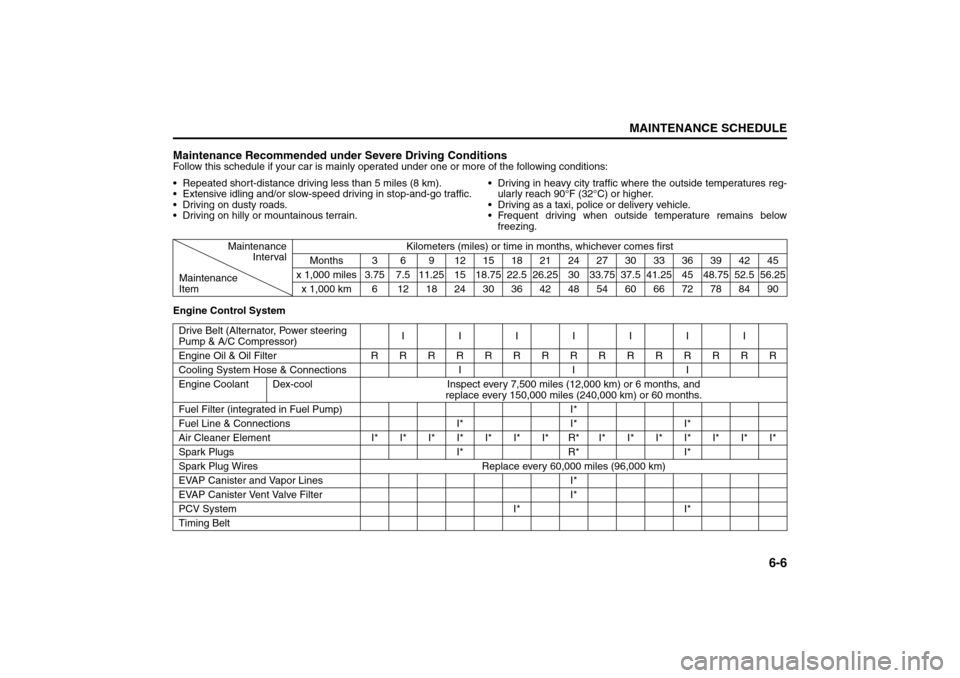

Maintenance Recommended under Severe Driving ConditionsFollow this schedule if your car is mainly operated under one or more of the following conditions:

Engine Control System Repeated short-distance driving less than 5 miles (8 km).

Extensive idling and/or slow-speed driving in stop-and-go traffic.

Driving on dusty roads.

Driving on hilly or mountainous terrain. Driving in heavy city traffic where the outside temperatures reg-

ularly reach 90°F (32°C) or higher.

Driving as a taxi, police or delivery vehicle.

Frequent driving when outside temperature remains below

freezing.

Maintenance

IntervalKilometers (miles) or time in months, whichever comes first

Months 3 6 9 121518212427303336394245

Maintenance

Itemx 1,000 miles 3.75 7.5 11.25 15 18.75 22.526.25 30 33.75 37.5 41.25 45 48.75 52.5 56.25

x 1,000 km 6 1218243036424854606672788490

Drive Belt (Alternator, Power steering

Pump & A/C Compressor)IIIIIII

Engine Oil & Oil Filter RRRRRRRRRRRRRRR

Cooling System Hose & Connections I I I

Engine Coolant Dex-cool Inspect every 7,500 miles (12,000 km) or 6 months, and

replace every 150,000 miles (240,000 km) or 60 months.

Fuel Filter (integrated in Fuel Pump) I*

Fuel Line & Connections I* I* I*

Air Cleaner Element I* I* I* I* I* I* I* R* I* I* I* I* I* I* I*

Spark Plugs I* R* I*

Spark Plug Wires Replace every 60,000 miles (96,000 km)

EVAP Canister and Vapor Lines I*

EVAP Canister Vent Valve Filter I*

PCV System I* I*

Timing Belt