lock SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 653 of 698

6E1-32 ENGINE AND EMISSION CONTROL SYSTEM

CAMSHAFT POSITION SENSOR

INSPECTION

Check camshaft position sensor referring to DTC P0340 (No.15)

Diag. Flow Table in Section 6. If malfunction is found, replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Disconnect connector from camshaft position sensor.

3) Remove camshaft position sensor from cylinder head.

INSTALLATION

1) Check that O-ring is free from damage.

2) Check that camshaft position sensor and signal rotor teeth

are free from any metal particles and damage.

3) Install camshaft position sensor to cylinder head.

Tightening torque

Camshaft position sensor bolt

(a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

4) Connect connector to it securely.

5) Connect negative cable to battery.

CRANKSHAFT POSITION SENSOR

INSPECTION

Check crankshaft position sensor referring to step 1 and 2 of DTC

P0335 (No.23) Flow Table. If malfunction is found, replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Remove generator drive belt, loosen pivot bolt and move

generator outward.

3) Disconnect connector from crankshaft position sensor.

4) Remove crankshaft position sensor (1) from cylinder block.

INSTALLATION

1) Check to make sure that crankshaft position sensor and pul-

ley teeth are free from any metal particles and damage.

2) Install crankshaft position sensor to cylinder block.

3) Connect connector to it securely.

4) Adjust generator belt tension, refer to Section 6B.

5) Connect negative cable to battery.

Page 663 of 698

IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM) 6F1-1

6G

6F2

6G

6H

6K

6F1

7A

7A1

7A1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 6F1

IGNITION SYSTEM

(ELECTRONIC IGNITION SYSTEM)

CONTENTS

GENERAL DESCRIPTION ............................. 6F1-2

DIAGNOSIS .................................................... 6F1-3

ON-VEHICLE SERVICE ................................. 6F1-5

IGNITION SPARK TEST ............................. 6F1-5

HIGH-TENSION CORDS ............................ 6F1-5

SPARK PLUGS ........................................... 6F1-6IGNITION COIL ASSEMBLY

(INCLUDING IGNITOR) .............................. 6F1-7

CRANKSHAFT POSITION SENSOR

(CKP SENSOR) .......................................... 6F1-7

IGNITION TIMING ...................................... 6F1-8

SPECIAL TOOL ............................................. 6F1-9

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 673 of 698

CRANKING SYSTEM 6G-1

6F1

6F2

6H

6K

6G

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 6G

CRANKING SYSTEM

CONTENTS

GENERAL DESCRIPTION .............................. 6G-2

CRANKING CIRCUIT ................................... 6G-2

DIAGNOSIS ..................................................... 6G-2

DIAGNOSIS TABLE ..................................... 6G-2

PERFORMANCE TEST ............................... 6G-4

PULL-IN TEST ......................................... 6G-4

HOLD-IN TEST ........................................ 6G-4

PLUNGER AND PINION RETURN TEST 6G-4

NO-LOAD PERFORMANCE TEST .......... 6G-5ON-VEHICLE SERVICE ...................................6G-5

STARTING MOTOR .....................................6G-5

DISMOUNTING.........................................6G-5

REMOUNTING..........................................6G-5

DISASSEMBLY AND REASSEMBLY .......6G-6

SPECIFICATION ..............................................6G-8

1.0 kW TYPE.............................................6G-8

1.2 kW TYPE.............................................6G-8

REQUIRED SERVICE MATERIAL...................6G-8

WARNING:

For vehicles equipped with Supplement Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to AIR BAG SYSTEM COMPONENTS and WIRING LOCATION VIEW

under DIAGNOSIS in air bag system section in order to confirm whether you are performing service

on or near the air bag system components or wiring. Please observe all WARNINGS and SERVICE

PRECAUTIONS under PRECAUTIONS in air bag system section before performing service on or

around the air bag system components or wiring. Failure to follow WARNINGS could result in unin-

tentional activation of the system or could render the system inoperative. Either of these two condi-

tions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

Starting motor varies depending on specifications, etc. Therefore, be sure to check model and speci-

fication of the vehicle being serviced before replacing parts.

Page 680 of 698

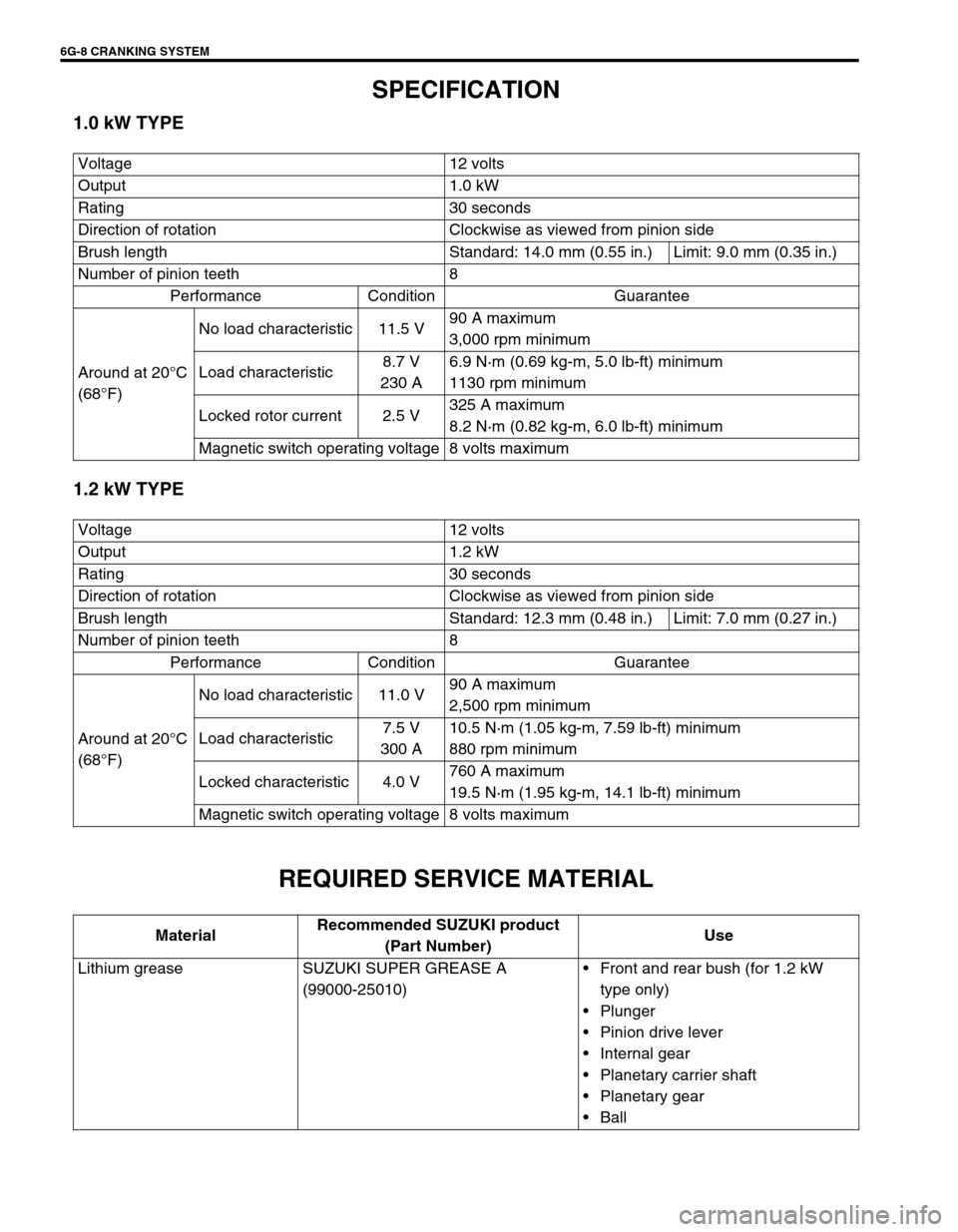

6G-8 CRANKING SYSTEM

SPECIFICATION

1.0 kW TYPE

1.2 kW TYPE

REQUIRED SERVICE MATERIAL

Voltage 12 volts

Output 1.0 kW

Rating 30 seconds

Direction of rotation Clockwise as viewed from pinion side

Brush length Standard: 14.0 mm (0.55 in.) Limit: 9.0 mm (0.35 in.)

Number of pinion teeth 8

Performance Condition Guarantee

Around at 20°C

(68°F)No load characteristic 11.5 V90 A maximum

3,000 rpm minimum

Load characteristic8.7 V

230 A6.9 N·m (0.69 kg-m, 5.0 lb-ft) minimum

1130 rpm minimum

Locked rotor current 2.5 V325 A maximum

8.2 N·m (0.82 kg-m, 6.0 lb-ft) minimum

Magnetic switch operating voltage 8 volts maximum

Voltage 12 volts

Output 1.2 kW

Rating 30 seconds

Direction of rotation Clockwise as viewed from pinion side

Brush length Standard: 12.3 mm (0.48 in.) Limit: 7.0 mm (0.27 in.)

Number of pinion teeth 8

Performance Condition Guarantee

Around at 20°C

(68°F)No load characteristic 11.0 V90 A maximum

2,500 rpm minimum

Load characteristic7.5 V

300 A10.5 N·m (1.05 kg-m, 7.59 lb-ft) minimum

880 rpm minimum

Locked characteristic 4.0 V760 A maximum

19.5 N·m (1.95 kg-m, 14.1 lb-ft) minimum

Magnetic switch operating voltage 8 volts maximum

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium grease SUZUKI SUPER GREASE A

(99000-25010)Front and rear bush (for 1.2 kW

type only)

Plunger

Pinion drive lever

Internal gear

Planetary carrier shaft

Planetary gear

Ball

Page 681 of 698

CHARGING SYSTEM 6H-1

6F1

6F2

6G

6K

7A

6H

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 6H

CHARGING SYSTEM

CONTENTS

GENERAL DESCRIPTION .............................. 6H-2

BATTERY ..................................................... 6H-2

CARRIER AND HOLD-DOWN ................. 6H-2

ELECTROLYTE FREEZING .................... 6H-2

SULFATION ............................................. 6H-2

BUILT-IN INDICATOR (IF EQUIPPED) ... 6H-2

CARE OF BATTERY ................................ 6H-3

GENERATOR .............................................. 6H-4

DIAGNOSIS ..................................................... 6H-5

BATTERY ..................................................... 6H-5

VISUAL INSPECTION.............................. 6H-5

HYDROMETER TEST.............................. 6H-5

GENERATOR .............................................. 6H-6

CHARGING INDICATOR LAMP

OPERATION ............................................ 6H-6

UNDERCHARGED BATTERY ................. 6H-7

OVERCHARGED BATTERY.................... 6H-8ON-VEHICLE SERVICE .................................. 6H-9

BATTERY .................................................... 6H-9

JUMP STARTING IN CASE OF

EMERGENCY .......................................... 6H-9

DISMOUNTING...................................... 6H-10

HANDLING............................................. 6H-10

REMOUNTING....................................... 6H-10

GENERATOR ............................................ 6H-10

GENERATOR BELT .............................. 6H-10

DISMOUNTING AND REMOUNTING ... 6H-11

DISASSEMBLY AND REASSEMBLY .... 6H-11

INSPECTION ......................................... 6H-12

SPECIFICATION ........................................... 6H-14

BATTERY .................................................. 6H-14

GENERATOR ............................................ 6H-14

TIGHTENING TORQUE SPECIFICATION.... 6H-14

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 694 of 698

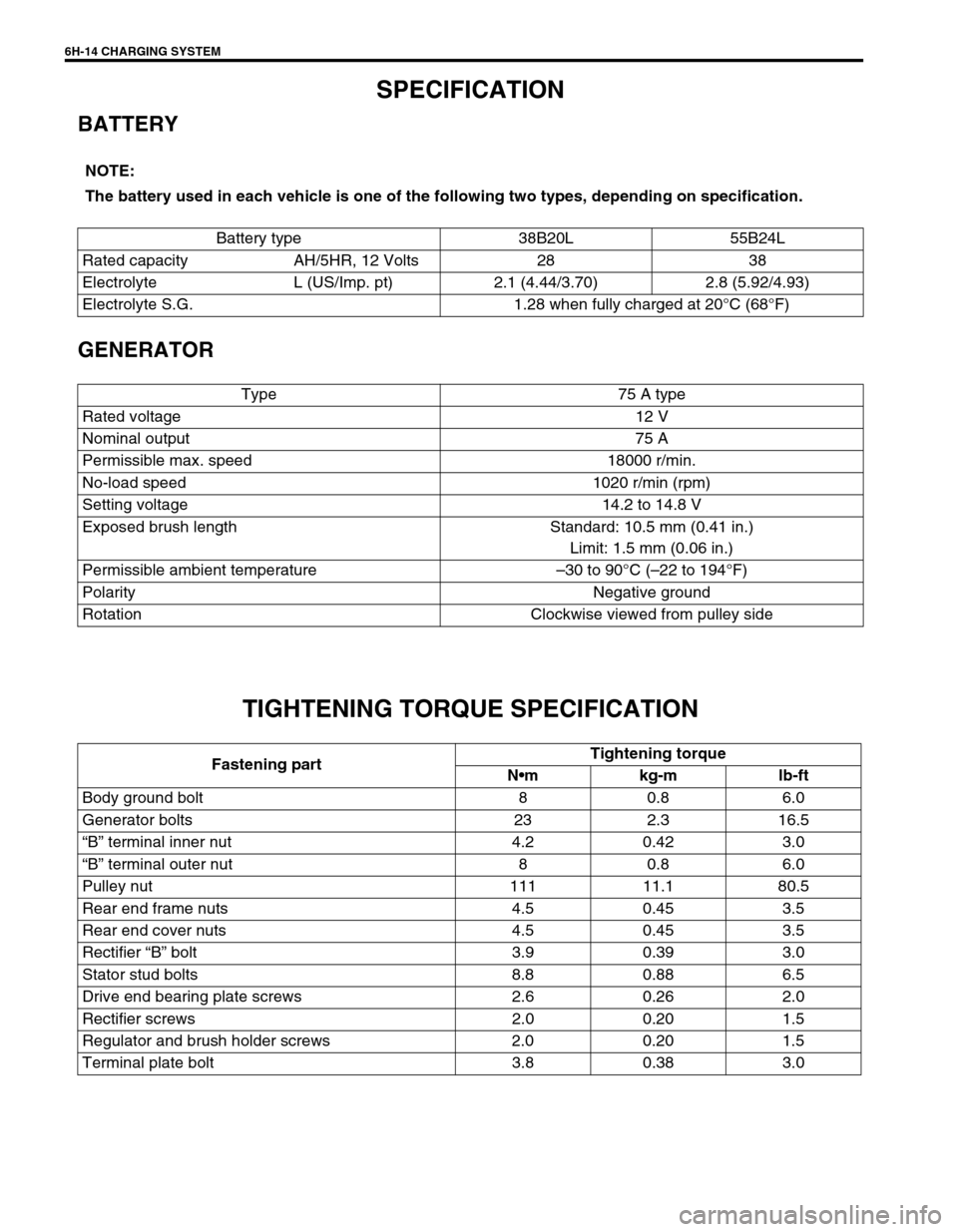

6H-14 CHARGING SYSTEM

SPECIFICATION

BATTERY

GENERATOR

TIGHTENING TORQUE SPECIFICATION

NOTE:

The battery used in each vehicle is one of the following two types, depending on specification.

Battery type 38B20L 55B24L

Rated capacity AH/5HR, 12 Volts 28 38

Electrolyte L (US/Imp. pt) 2.1 (4.44/3.70) 2.8 (5.92/4.93)

Electrolyte S.G. 1.28 when fully charged at 20°C (68°F)

Type 75 A type

Rated voltage 12 V

Nominal output 75 A

Permissible max. speed 18000 r/min.

No-load speed 1020 r/min (rpm)

Setting voltage 14.2 to 14.8 V

Exposed brush length Standard: 10.5 mm (0.41 in.)

Limit: 1.5 mm (0.06 in.)

Permissible ambient temperature–30 to 90°C (–22 to 194°F)

Polarity Negative ground

Rotation Clockwise viewed from pulley side

Fastening partTightening torque

Nm kg-m lb-ft

Body ground bolt 8 0.8 6.0

Generator bolts 23 2.3 16.5

“B” terminal inner nut 4.2 0.42 3.0

“B” terminal outer nut 8 0.8 6.0

Pulley nut 111 11.1 80.5

Rear end frame nuts 4.5 0.45 3.5

Rear end cover nuts 4.5 0.45 3.5

Rectifier “B” bolt 3.9 0.39 3.0

Stator stud bolts 8.8 0.88 6.5

Drive end bearing plate screws 2.6 0.26 2.0

Rectifier screws 2.0 0.20 1.5

Regulator and brush holder screws 2.0 0.20 1.5

Terminal plate bolt 3.8 0.38 3.0