air suspension SUZUKI SWIFT 2000 1.G RG413 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 277 of 698

5-4 BRAKES

DIAGNOSIS

ROAD TESTING BRAKES

Brakes should be tested on dry, clean, smooth and reasonably level roadway which is not crowned. Road test

brakes by making brake applications with both light and heavy pedal forces at various speeds to determine if the

vehicle stops evenly and effectively. Also drive vehicle to see if it leads to one side or the other without brake

application. If it does, check the tire pressure, front end alignment and front suspension attachments for loose-

ness. See diagnosis table for other causes.

BRAKE FLUID LEAKS

Check the master cylinder fluid levels. While a slight drop in reservoir level does result from normal lining wear,

an abnormally low level indicates a leak in the system. In such a case, check the entire brake system for leak-

age. If even a slight evidence of leakage is noted, the cause should be corrected or defective parts should be

replaced.

SUBSTANDARD OR CONTAMINATED BRAKE FLUID

Improper brake fluid, mineral oil or water in the fluid may cause the brake fluid to boil or the rubber components

in the hydraulic system to deteriorate.

If primary piston cups are swollen, then rubber parts have deteriorated. This deterioration may also be evi-

denced by swollen wheel cylinder piston cups on the drum brake wheels.

If deterioration of rubber is evident, disassemble all hydraulic parts and wash with alcohol. Dry these parts with

compressed air before assembly to keep alcohol out of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads.

If master cylinder piston seals are satisfactory, check for leakage or excessive heat conditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed system.

The system must be flushed if there is any doubt as to the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to contaminated fluid.

Page 278 of 698

BRAKES 5-5

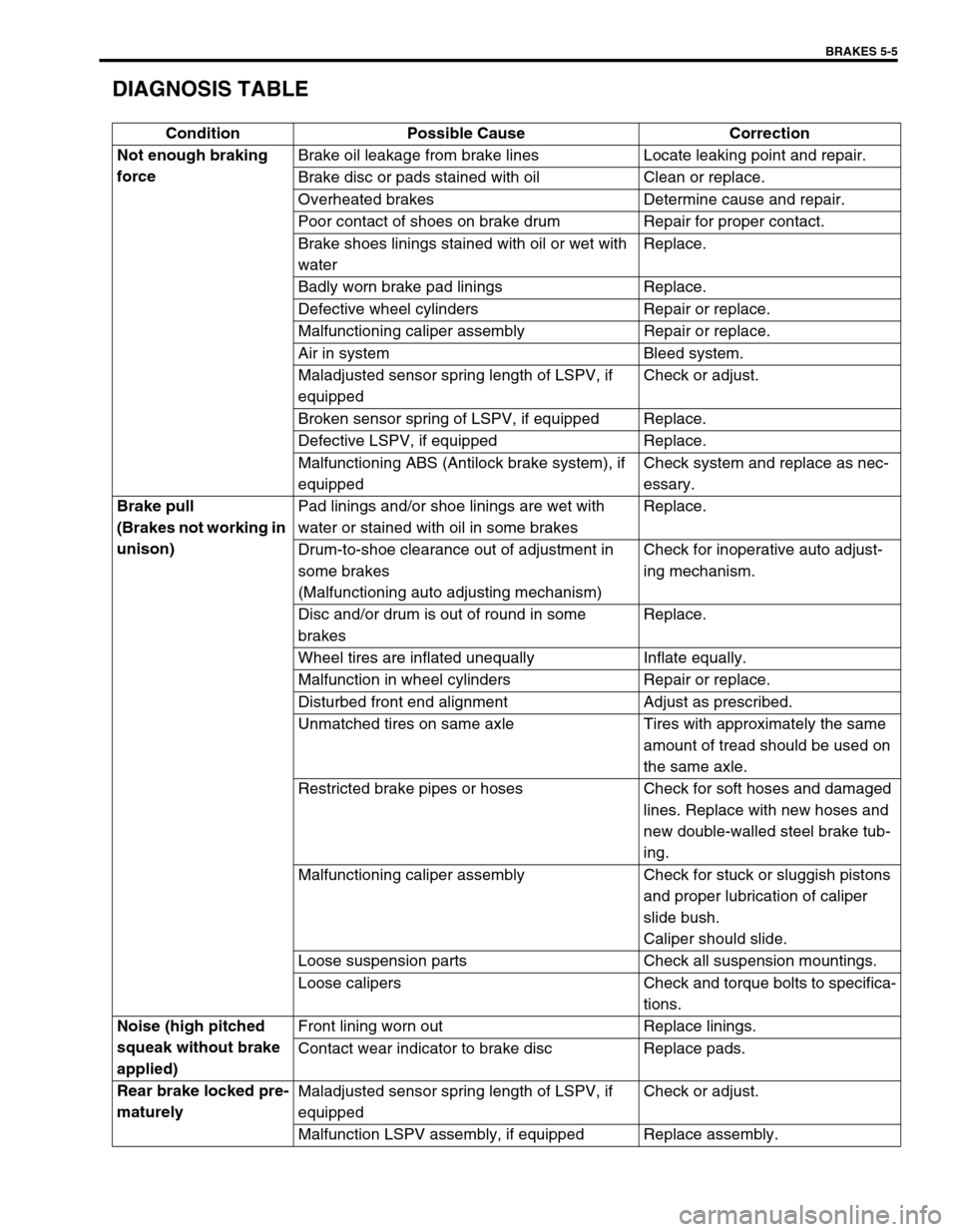

DIAGNOSIS TABLE

Condition Possible Cause Correction

Not enough braking

forceBrake oil leakage from brake lines Locate leaking point and repair.

Brake disc or pads stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Poor contact of shoes on brake drum Repair for proper contact.

Brake shoes linings stained with oil or wet with

waterReplace.

Badly worn brake pad linings Replace.

Defective wheel cylinders Repair or replace.

Malfunctioning caliper assembly Repair or replace.

Air in system Bleed system.

Maladjusted sensor spring length of LSPV, if

equippedCheck or adjust.

Broken sensor spring of LSPV, if equipped Replace.

Defective LSPV, if equipped Replace.

Malfunctioning ABS (Antilock brake system), if

equippedCheck system and replace as nec-

essary.

Brake pull

(Brakes not working in

unison)Pad linings and/or shoe linings are wet with

water or stained with oil in some brakesReplace.

Drum-to-shoe clearance out of adjustment in

some brakes

(Malfunctioning auto adjusting mechanism)Check for inoperative auto adjust-

ing mechanism.

Disc and/or drum is out of round in some

brakesReplace.

Wheel tires are inflated unequally Inflate equally.

Malfunction in wheel cylinders Repair or replace.

Disturbed front end alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same

amount of tread should be used on

the same axle.

Restricted brake pipes or hoses Check for soft hoses and damaged

lines. Replace with new hoses and

new double-walled steel brake tub-

ing.

Malfunctioning caliper assembly Check for stuck or sluggish pistons

and proper lubrication of caliper

slide bush.

Caliper should slide.

Loose suspension parts Check all suspension mountings.

Loose calipers Check and torque bolts to specifica-

tions.

Noise (high pitched

squeak without brake

applied)Front lining worn out Replace linings.

Contact wear indicator to brake disc Replace pads.

Rear brake locked pre-

maturelyMaladjusted sensor spring length of LSPV, if

equippedCheck or adjust.

Malfunction LSPV assembly, if equipped Replace assembly.

Page 314 of 698

BRAKES 5-41

BRAKE HOSE/PIPE

FRONT BRAKE HOSE/PIPE

REMOVAL

1) Raise and support vehicle properly. Remove tire and wheel.

2) Clean dirt and foreign material from both flexible hose end and pipe end fittings.

3) Remove brake flexible hose or pipe.

INSTALLATION

Reverse brake flexible hose installation procedure, noting the followings.

Make sure that steering wheel is in straight-forward position and flexible hose has not twist or kink.

Check to make sure that flexible hose doesn’t contact any part of suspension, both in extreme right and

extreme left turn conditions. If it does at any point, remove and correct. Fill and maintain brake fluid level in

reservoir.

Bleed brake system. Refer to “AIR BLEEDING OF BRAKE SYSTEM”.

Perform brake test and check installed part for fluid leakage. NOTE:

This operation is not necessary when removing pipes connecting master cylinder.