diagram SUZUKI SWIFT 2000 1.G RG413 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 416 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-47

TABLE A-2 MALFUNCTION INDICATOR LAMP CIRCUIT CHECK - LAMP

REMAINS “ON” AFTER ENGINE STARTS

WIRING DIAGRAM / CIRCUIT DESCRIPTION

Refer to table A-1.

INSPECTION

3 MIL Circuit Check

1) Turn ignition switch OFF and disconnect

connectors from ECM.

2) Check for proper connection to ECM at ter-

minal G02-1 (Case of TYPE A. See NOTE)

or G02-9 (Case of TYPE B. See NOTE).

3) If OK, then using service wire, ground termi-

nal G02-1 (Case of TYPE A. See NOTE) or

G02-9 (Case of TYPE B. See NOTE) in con-

nector disconnected.

Does MIL turn on at ignition switch ON?Substitute a known-good

ECM and recheck.Bulb burned out or “PPL/

YEL” (Case of TYPE A.

See NOTE) or “PPL/

WHT” (Case of TYPE B.

See NOTE) wire circuit

open.

Test switch terminal cir-

cuit grounded (vehicle

without immobilizer indi-

cator lamp) Step Action Yes No

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

Step Action Yes No

1 Diagnostic Trouble Code (DTC) Check

1) Check DTC referring to DTC CHECK

section.

Is there any DTC(s)?Go to Step 2 of ENGINE DIAG.

FLOW TABLE.Go to Step 2.

2DTC Check

1) Start engine and recheck DTC while

engine running.

Is there any DTC(s)?Go to Step 3.

3 MIL Circuit Check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

Does MIL turn ON at ignition switch ON?“PPL/YEL” (Case of TYPE A.

See NOTE) or “PPL/WHT”

(Case of TYPE B. See NOTE)

wire circuit shorted to ground.Substitute a known-good

ECM and recheck.

Page 417 of 698

6-48 ENGINE GENERAL INFORMATION AND DIAGNOSIS

TABLE A-3 MIL CHECK - MIL FLASHES AT IGNITION SWITCH ON (VEHICLE

WITHOUT IMMOBILIZER INDICATOR LAMP)

WIRING DIAGRAM / CIRCUIT DESCRIPTION

Refer to TABLE A-1.

INSPECTION

TABLE A-4 MIL CHECK - MIL DOES NOT FLASH OR JUST REMAINS ON EVEN

WITH GROUNDING DIAGNOSIS SWITCH TERMINAL (VEHICLE WITHOUT

IMMOBILIZER INDICATOR LAMP)

WIRING DIAGRAM / CIRCUIT DESCRIPTION

Refer to TABLE A-1.

INSPECTION

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

Step Action Yes No

1 MIL Flashing Pattern Check

1) Turn ignition switch ON.

Does lamp flashing pattern indicate diag-

nostic trouble code?Go to Step 2. Substitute a known-good ECM

and recheck.

2 Diag. Switch Circuit Check

Is diag. switch terminal connected to

ground via service wire?System is in good condi-

tion.“PPL/WHT” circuit for monitor

connector shorted to ground. If

circuit is OK substitute a known-

good ECM and recheck.

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

Step Action Yes No

1 MIL Circuit Check

1) Turn ignition switch OFF and disconnect connec-

tors from ECM.

Does MIL turn ON at ignition switch ON?“PPL/YEL” (Case of TYPE A.

See NOTE) or “PPL/WHT”

(Case of TYPE B. See NOTE)

circuit shorted to ground.Go to Step 2.

2 ECM/PCM Connection Check

1) Turn ignition switch OFF.

Is connector (C42-27 (Case of TYPE A. See NOTE)

or C41-14 (Case of TYPE B. See NOTE) connection)

connected to ECM/PCM properly?Go to Step 3. Poor connector connec-

tion.

3 Diag. Switch Terminal Circuit Check

1) Connect connectors to ECM.

2) Using service wire, ground C42-27 (Case of

TYPE A. See NOTE) or C41-14 (Case of TYPE

B. See NOTE) connection) terminal with connec-

tors connected to ECM.

3) Turn ignition switch ON.

Does MIL flash?“PPL/WHT” or “BLK” circuit in

monitor connector is open.Substitute a known-good

ECM and recheck.

Page 418 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-49

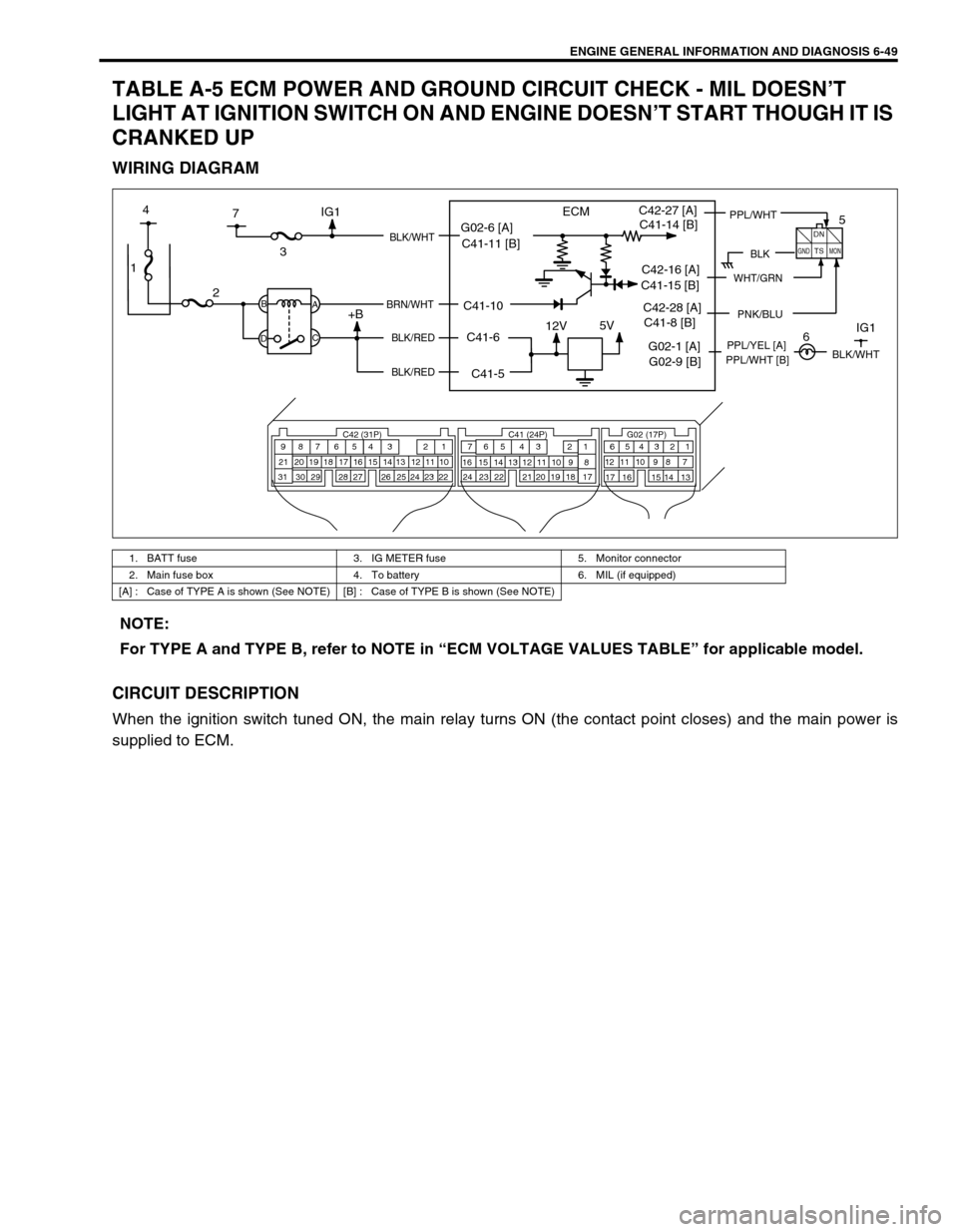

TABLE A-5 ECM POWER AND GROUND CIRCUIT CHECK - MIL DOESN’T

LIGHT AT IGNITION SWITCH ON AND ENGINE DOESN’T START THOUGH IT IS

CRANKED UP

WIRING DIAGRAM

CIRCUIT DESCRIPTION

When the ignition switch tuned ON, the main relay turns ON (the contact point closes) and the main power is

supplied to ECM.

1. BATT fuse 3. IG METER fuse 5. Monitor connector

2. Main fuse box 4. To battery 6. MIL (if equipped)

[A] : Case of TYPE A is shown (See NOTE) [B] : Case of TYPE B is shown (See NOTE)

1

12V5V

ECM

23

+BB

DA

C

BLK/WHT

BRN/WHT

BLK/RED

BLK/RED

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

BLK

DN

TS

GNDMON

PPL/WHTC42-27 [A]

C42-16 [A]

PNK/BLUC42-28 [A]

7 4

G02-1 [A]IG1PPL/YEL [A]

5

6IG1

WHT/GRN

BLK/WHT

G02-6 [A]

C41-5 C41-6 C41-10 C41-11 [B]C41-14 [B]

C41-15 [B]

C41-8 [B]

G02-9 [B]PPL/WHT [B]

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

Page 421 of 698

6-52 ENGINE GENERAL INFORMATION AND DIAGNOSIS

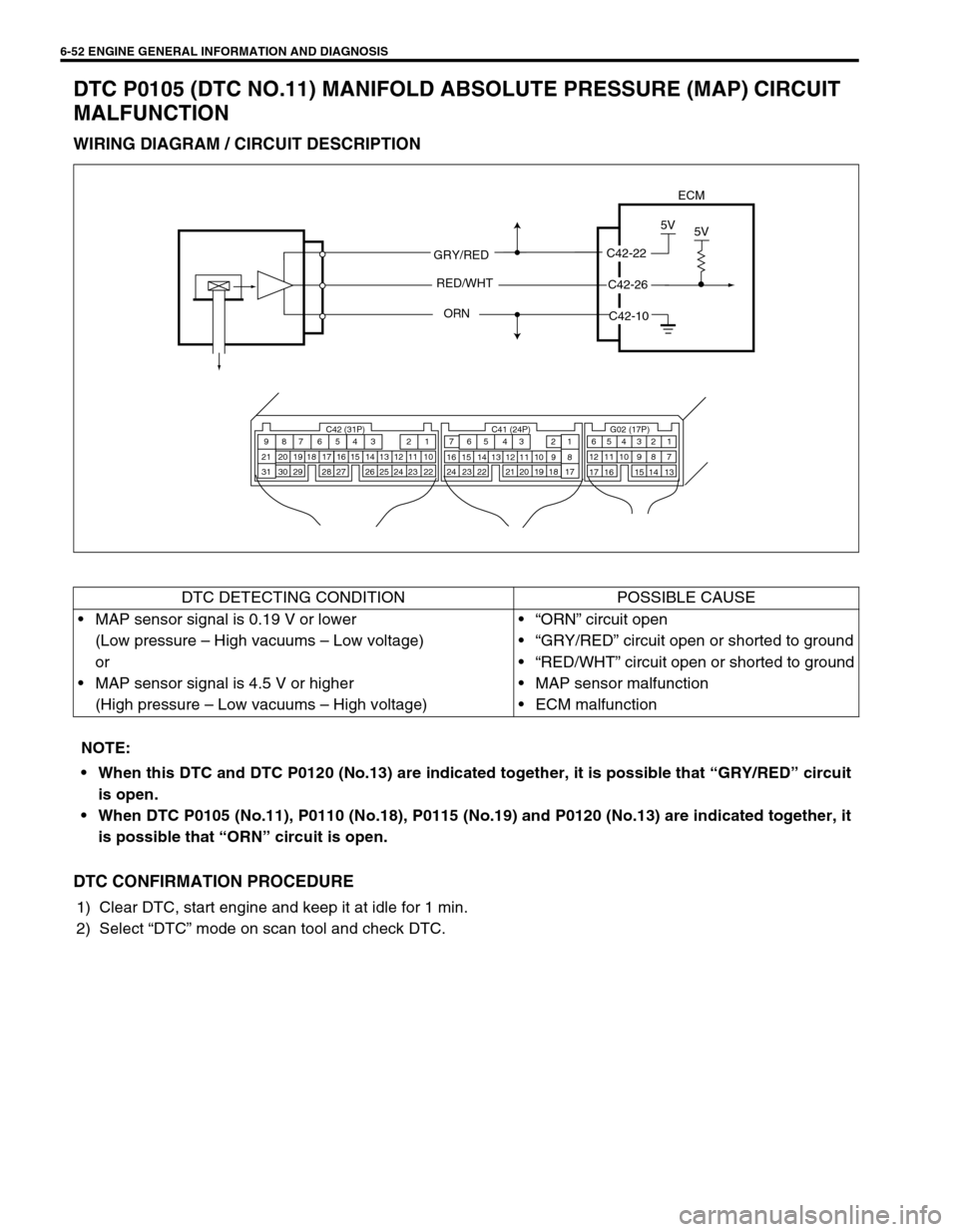

DTC P0105 (DTC NO.11) MANIFOLD ABSOLUTE PRESSURE (MAP) CIRCUIT

MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode on scan tool and check DTC.

ECM

GRY/RED

ORN

C42-22

5V

AMPC42-26

5V

RED/WHT

C42-10

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

MAP sensor signal is 0.19 V or lower

(Low pressure – High vacuums – Low voltage)

or

MAP sensor signal is 4.5 V or higher

(High pressure – Low vacuums – High voltage)“ORN” circuit open

“GRY/RED” circuit open or shorted to ground

“RED/WHT” circuit open or shorted to ground

MAP sensor malfunction

ECM malfunction

NOTE:

When this DTC and DTC P0120 (No.13) are indicated together, it is possible that “GRY/RED” circuit

is open.

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19) and P0120 (No.13) are indicated together, it

is possible that “ORN” circuit is open.

Page 424 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-55

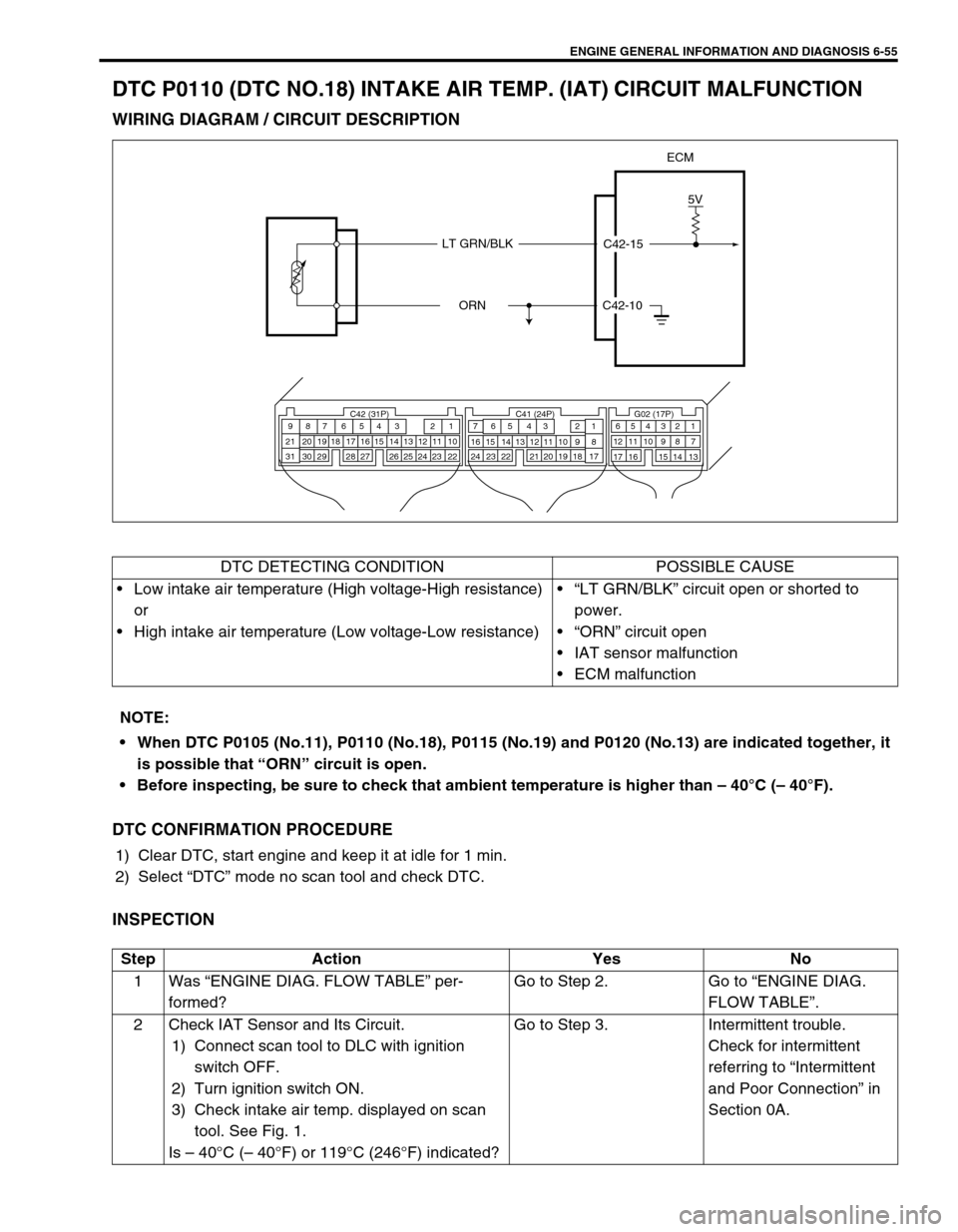

DTC P0110 (DTC NO.18) INTAKE AIR TEMP. (IAT) CIRCUIT MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode no scan tool and check DTC.

INSPECTION

C42-10

C42-15

5V

ECM

LT GRN/BLK

ORN

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

Low intake air temperature (High voltage-High resistance)

or

High intake air temperature (Low voltage-Low resistance)“LT GRN/BLK” circuit open or shorted to

power.

“ORN” circuit open

IAT sensor malfunction

ECM malfunction

NOTE:

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19) and P0120 (No.13) are indicated together, it

is possible that “ORN” circuit is open.

Before inspecting, be sure to check that ambient temperature is higher than – 40°C (– 40°F).

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check IAT Sensor and Its Circuit.

1) Connect scan tool to DLC with ignition

switch OFF.

2) Turn ignition switch ON.

3) Check intake air temp. displayed on scan

tool. See Fig. 1.

Is – 40°C (– 40°F) or 119°C (246°F) indicated?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection” in

Section 0A.

Page 426 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-57

Fig. 3 for Step 4

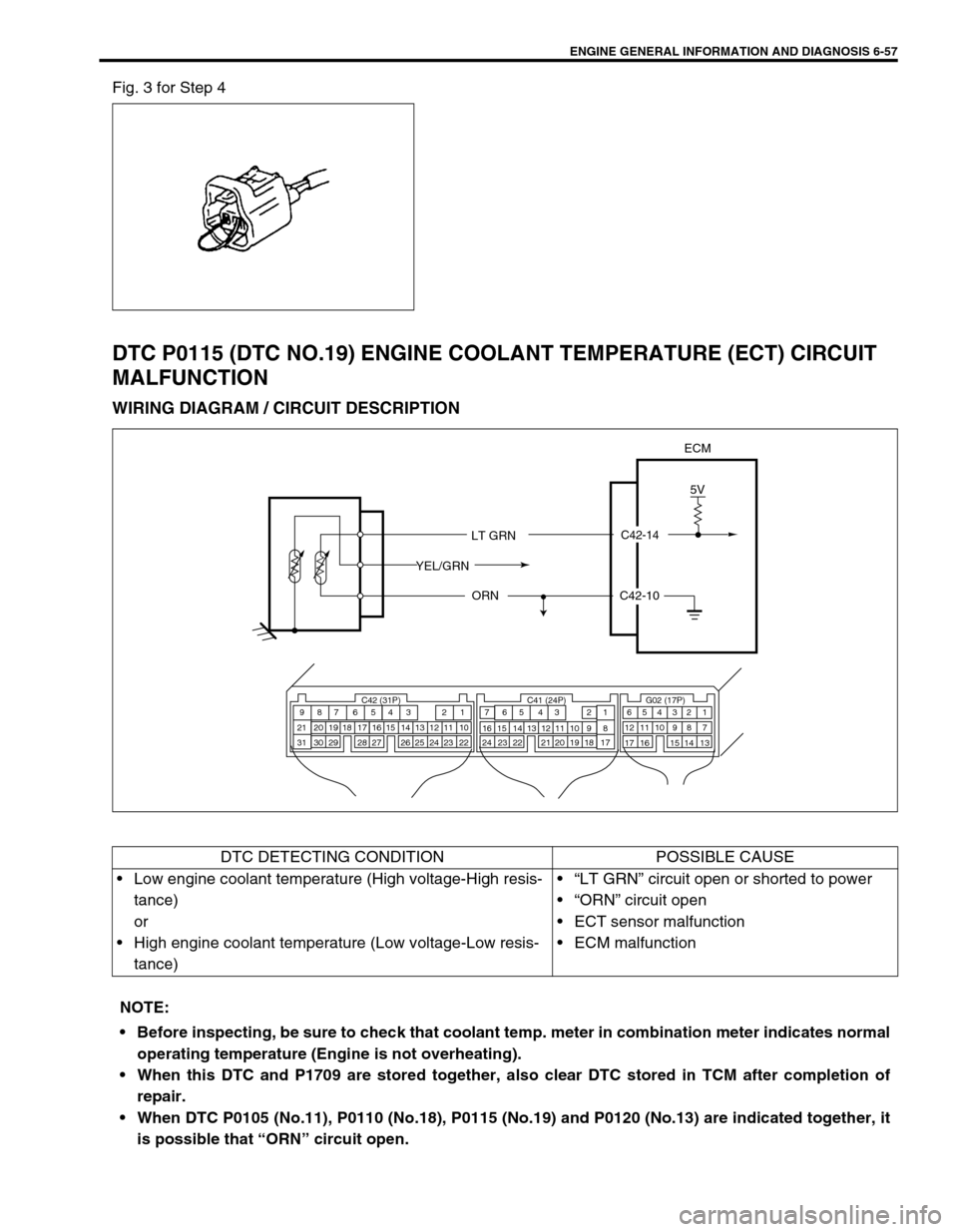

DTC P0115 (DTC NO.19) ENGINE COOLANT TEMPERATURE (ECT) CIRCUIT

MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

C42-14

5V

ECM

LT GRN

ORN

YEL/GRN

C42-10

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

Low engine coolant temperature (High voltage-High resis-

tance)

or

High engine coolant temperature (Low voltage-Low resis-

tance)“LT GRN” circuit open or shorted to power

“ORN” circuit open

ECT sensor malfunction

ECM malfunction

NOTE:

Before inspecting, be sure to check that coolant temp. meter in combination meter indicates normal

operating temperature (Engine is not overheating).

When this DTC and P1709 are stored together, also clear DTC stored in TCM after completion of

repair.

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19) and P0120 (No.13) are indicated together, it

is possible that “ORN” circuit open.

Page 429 of 698

6-60 ENGINE GENERAL INFORMATION AND DIAGNOSIS

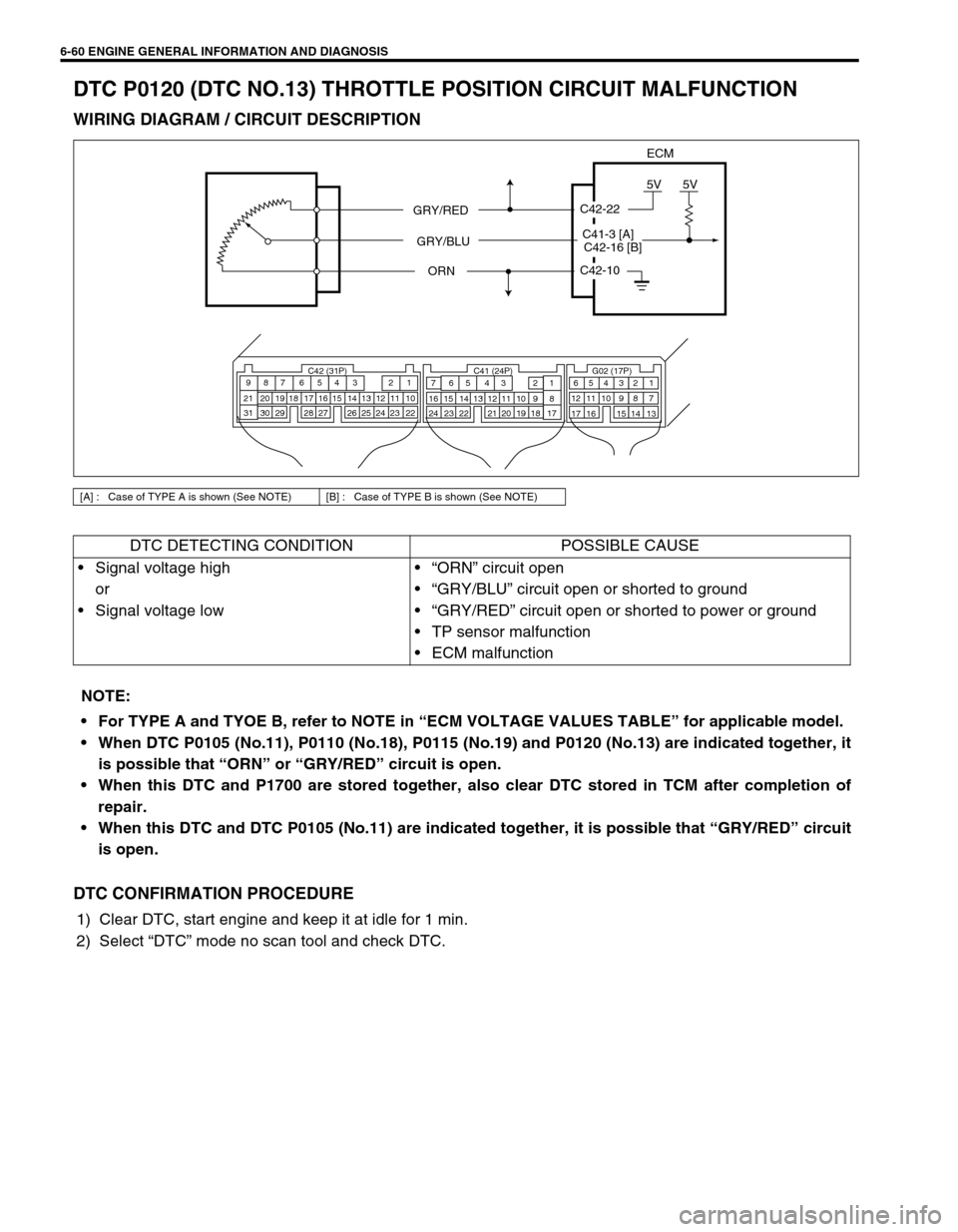

DTC P0120 (DTC NO.13) THROTTLE POSITION CIRCUIT MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode no scan tool and check DTC.

[A] : Case of TYPE A is shown (See NOTE) [B] : Case of TYPE B is shown (See NOTE)

DTC DETECTING CONDITION POSSIBLE CAUSE

Signal voltage high

or

Signal voltage low“ORN” circuit open

“GRY/BLU” circuit open or shorted to ground

“GRY/RED” circuit open or shorted to power or ground

TP sensor malfunction

ECM malfunction

C42-10

C42-22

5V5V

ECM

GRY/RED

GRY/BLU

ORN

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

C42-16 [B] C41-3 [A]

NOTE:

For TYPE A and TYOE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

When DTC P0105 (No.11), P0110 (No.18), P0115 (No.19) and P0120 (No.13) are indicated together, it

is possible that “ORN” or “GRY/RED” circuit is open.

When this DTC and P1700 are stored together, also clear DTC stored in TCM after completion of

repair.

When this DTC and DTC P0105 (No.11) are indicated together, it is possible that “GRY/RED” circuit

is open.

Page 432 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-63

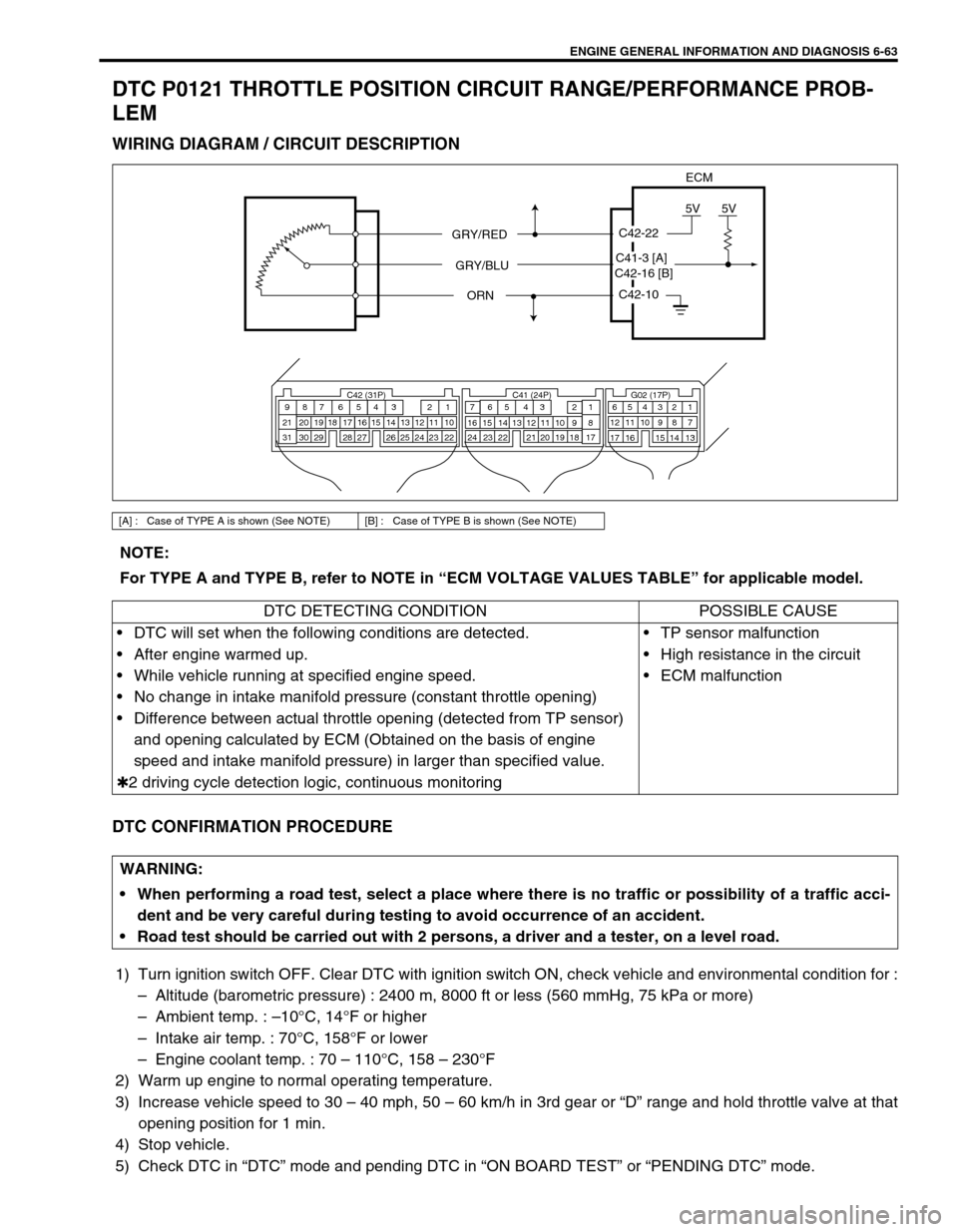

DTC P0121 THROTTLE POSITION CIRCUIT RANGE/PERFORMANCE PROB-

LEM

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF. Clear DTC with ignition switch ON, check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10°C, 14°F or higher

–Intake air temp. : 70°C, 158°F or lower

–Engine coolant temp. : 70 – 110°C, 158 – 230°F

2) Warm up engine to normal operating temperature.

3) Increase vehicle speed to 30 – 40 mph, 50 – 60 km/h in 3rd gear or “D” range and hold throttle valve at that

opening position for 1 min.

4) Stop vehicle.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

[A] : Case of TYPE A is shown (See NOTE) [B] : Case of TYPE B is shown (See NOTE)

C42-10

C42-22

5V5V

ECM

GRY/RED

GRY/BLU

ORN

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

C42-16 [B]C41-3 [A]

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC will set when the following conditions are detected.

After engine warmed up.

While vehicle running at specified engine speed.

No change in intake manifold pressure (constant throttle opening)

Difference between actual throttle opening (detected from TP sensor)

and opening calculated by ECM (Obtained on the basis of engine

speed and intake manifold pressure) in larger than specified value.

✱2 driving cycle detection logic, continuous monitoringTP sensor malfunction

High resistance in the circuit

ECM malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Page 435 of 698

6-66 ENGINE GENERAL INFORMATION AND DIAGNOSIS

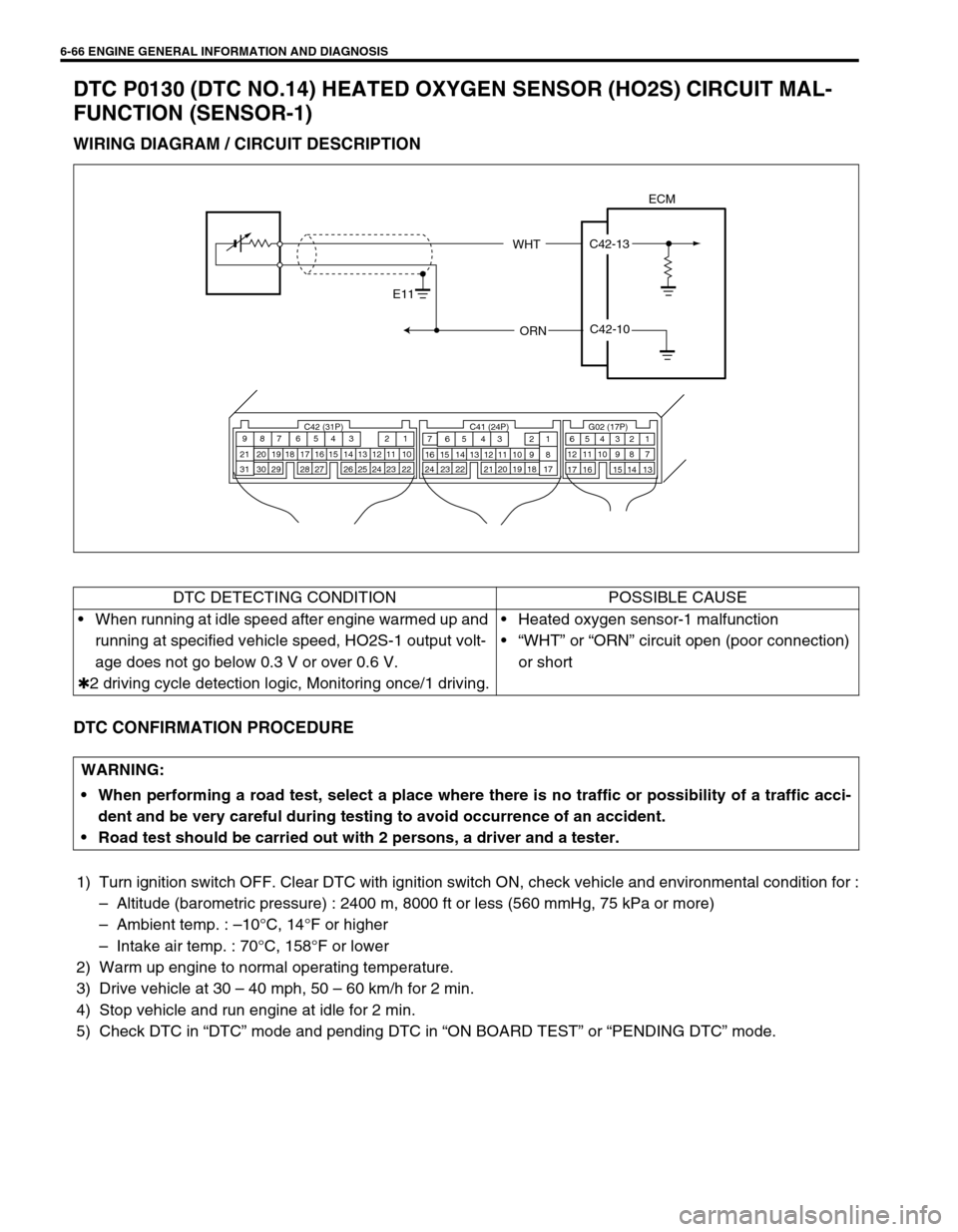

DTC P0130 (DTC NO.14) HEATED OXYGEN SENSOR (HO2S) CIRCUIT MAL-

FUNCTION (SENSOR-1)

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF. Clear DTC with ignition switch ON, check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10°C, 14°F or higher

–Intake air temp. : 70°C, 158°F or lower

2) Warm up engine to normal operating temperature.

3) Drive vehicle at 30 – 40 mph, 50 – 60 km/h for 2 min.

4) Stop vehicle and run engine at idle for 2 min.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

ECM

WHT

ORNC42-10 C42-13

E11

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

When running at idle speed after engine warmed up and

running at specified vehicle speed, HO2S-1 output volt-

age does not go below 0.3 V or over 0.6 V.

✱2 driving cycle detection logic, Monitoring once/1 driving.Heated oxygen sensor-1 malfunction

“WHT” or “ORN” circuit open (poor connection)

or short

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

Page 437 of 698

6-68 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0133 HEATED OXYGEN SENSOR (HO2S) CIRCUIT SLOW RESPONSE

(SENSOR-1)

WIRING DIAGRAM / CIRCUIT DESCRIPTION

Refer to DTC P0130 section.

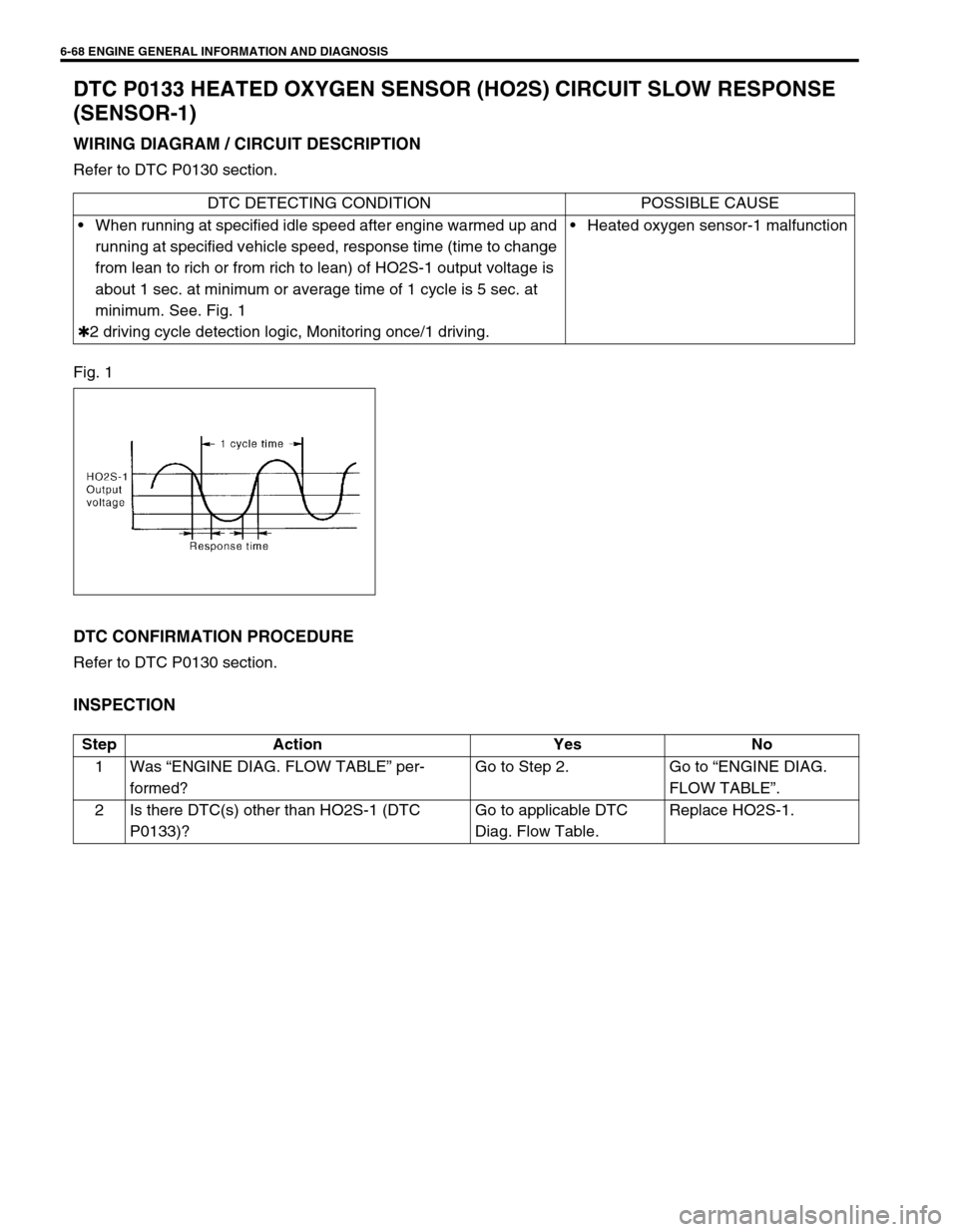

Fig. 1

DTC CONFIRMATION PROCEDURE

Refer to DTC P0130 section.

INSPECTION

DTC DETECTING CONDITION POSSIBLE CAUSE

When running at specified idle speed after engine warmed up and

running at specified vehicle speed, response time (time to change

from lean to rich or from rich to lean) of HO2S-1 output voltage is

about 1 sec. at minimum or average time of 1 cycle is 5 sec. at

minimum. See. Fig. 1

✱2 driving cycle detection logic, Monitoring once/1 driving.Heated oxygen sensor-1 malfunction

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Is there DTC(s) other than HO2S-1 (DTC

P0133)?Go to applicable DTC

Diag. Flow Table.Replace HO2S-1.