diagram SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 438 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-69

DTC P0134 HEATED OXYGEN SENSOR (HO2S) CIRCUIT NO ACTIVITY

DETECTED (SENSOR-1)

WIRING DIAGRAM / CIRCUIT DESCRIPTION

Refer to DTC P0130 section.

DTC CONFIRMATION PROCEDURE

Refer to DTC P0131 section.

INSPECTION

Fig. 1 for Step 3DTC DETECTING CONDITION POSSIBLE CAUSE

Engine warmed up.

While running under other than high load and high engine speed

conditions or at specified idle speed (engine is in closed loop con-

dition), HO2S-1 output voltage is high or low continuously.

✱2 driving cycle detection logic, Continuous monitoring.“WHT” or “ORN” circuit open or short

Heated oxygen sensor malfunction

Fuel system malfunction

Exhaust gas leakage

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Is there DTC(s) other than Fuel system

(DTC P0171/P0172) and HO2S-1 (DTC

P0134)?Go to applicable DTC

Diag. Flow Table.Go to Step 3.

3 Check HO2S-1 and Its Circuit.

1) Connect scan tool to DLC with ignition

switch OFF.

2) Warm up engine to normal operating tem-

perature and keep it at 2000 r/min. for 60

sec.

3) Repeat racing engine (Repeat depressing

accelerator pedal 5 to 6 times continuously

and take foot off from pedal to enrich and

enlean A/F mixture). See Fig. 1.

Does HO2S-1 output voltage deflect between

0.3V and over 0.6V repeatedly?Go to DTC P0171 and

P0172 Diag. Flow Table

(Fuel System Check).Check “WHT” and “ORN”

wires for open and short,

and connections for poor

connection. If wires and

connections are OK,

replace HO2S-1.

Page 439 of 698

6-70 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0135 (DTC NO.14) HEATED OXYGEN SENSOR (HO2S) HEATER CIRCUIT

MALFUNCTION (SENSOR-1)

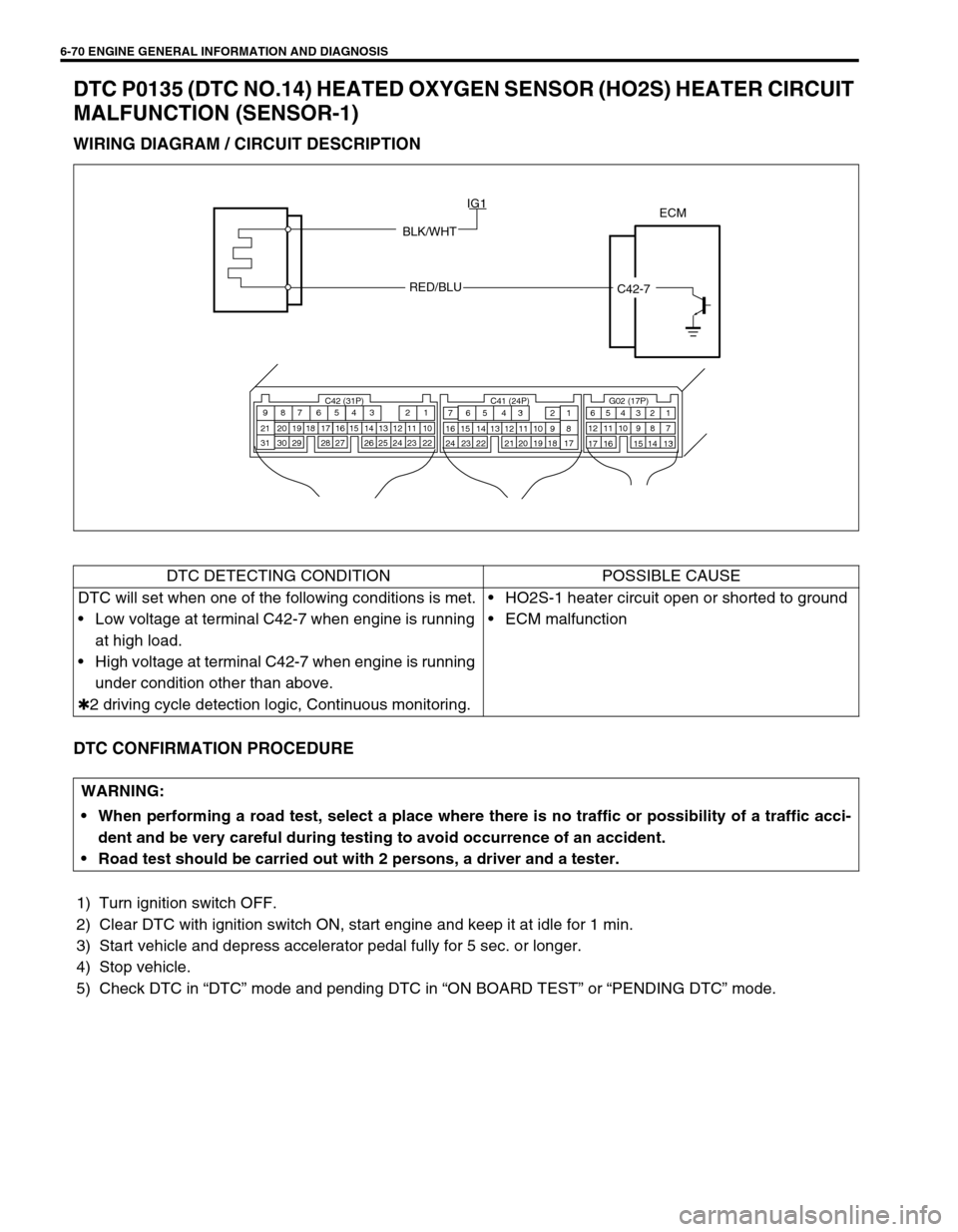

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

2) Clear DTC with ignition switch ON, start engine and keep it at idle for 1 min.

3) Start vehicle and depress accelerator pedal fully for 5 sec. or longer.

4) Stop vehicle.

5) Check DTC in “DTC” mode and pending DTC in “ON BOARD TEST” or “PENDING DTC” mode.

ECM

BLK/WHT

RED/BLU

C42-7 IG1

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC will set when one of the following conditions is met.

Low voltage at terminal C42-7 when engine is running

at high load.

High voltage at terminal C42-7 when engine is running

under condition other than above.

✱2 driving cycle detection logic, Continuous monitoring.HO2S-1 heater circuit open or shorted to ground

ECM malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester.

Page 441 of 698

6-72 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0136 HEATED OXYGEN SENSOR (HO2S) CIRCUIT MALFUNCTION

(SENSOR-2)

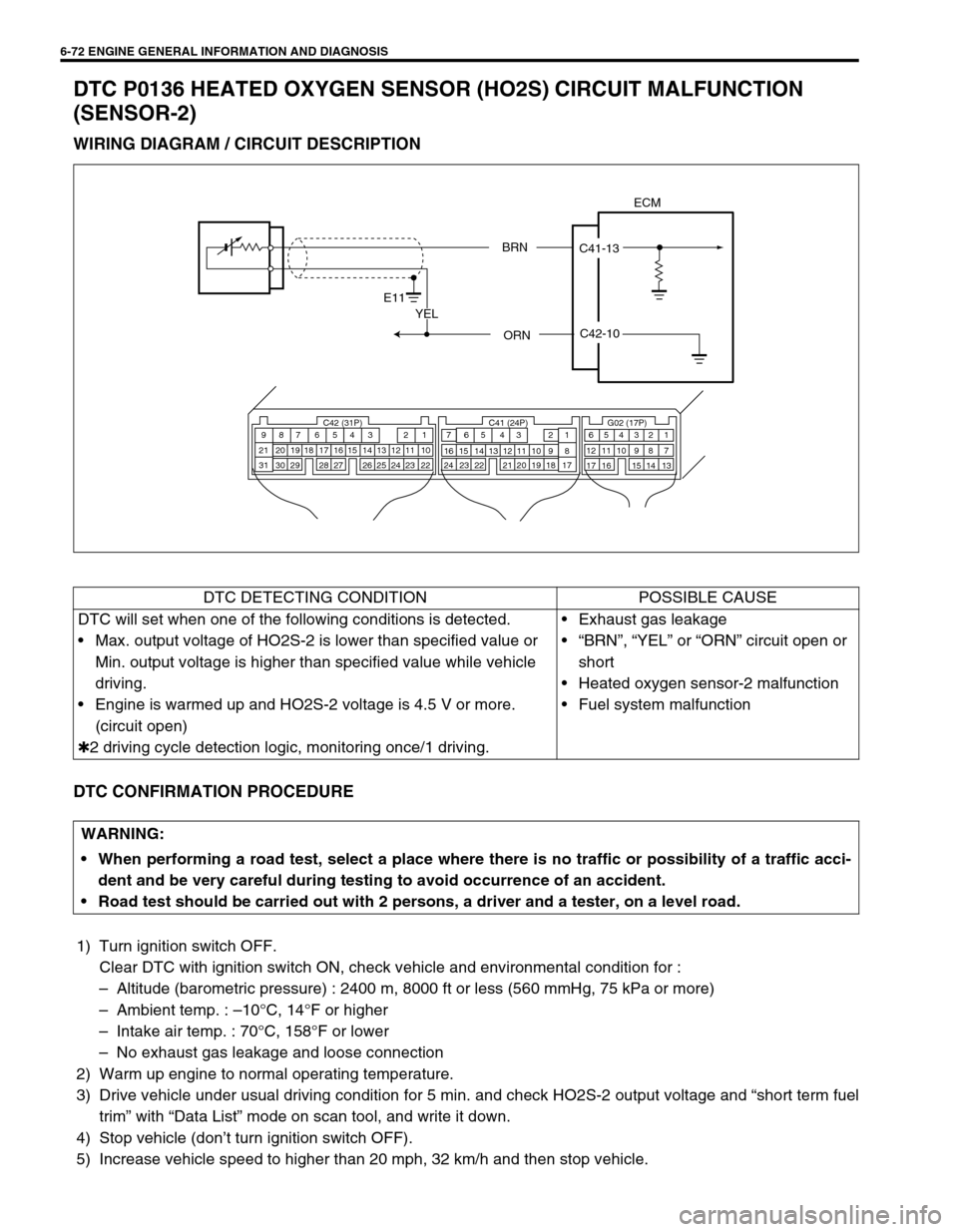

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

Clear DTC with ignition switch ON, check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10°C, 14°F or higher

–Intake air temp. : 70°C, 158°F or lower

–No exhaust gas leakage and loose connection

2) Warm up engine to normal operating temperature.

3) Drive vehicle under usual driving condition for 5 min. and check HO2S-2 output voltage and “short term fuel

trim” with “Data List” mode on scan tool, and write it down.

4) Stop vehicle (don’t turn ignition switch OFF).

5) Increase vehicle speed to higher than 20 mph, 32 km/h and then stop vehicle.

ECM

E11BRN

ORNC42-10 C41-13

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

YEL

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC will set when one of the following conditions is detected.

Max. output voltage of HO2S-2 is lower than specified value or

Min. output voltage is higher than specified value while vehicle

driving.

Engine is warmed up and HO2S-2 voltage is 4.5 V or more.

(circuit open)

✱2 driving cycle detection logic, monitoring once/1 driving.Exhaust gas leakage

“BRN”, “YEL” or “ORN” circuit open or

short

Heated oxygen sensor-2 malfunction

Fuel system malfunction

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.

Page 443 of 698

6-74 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0141 HEATED OXYGEN SENSOR (HO2S) HEATER CIRCUIT MALFUNC-

TION (SENSOR-2)

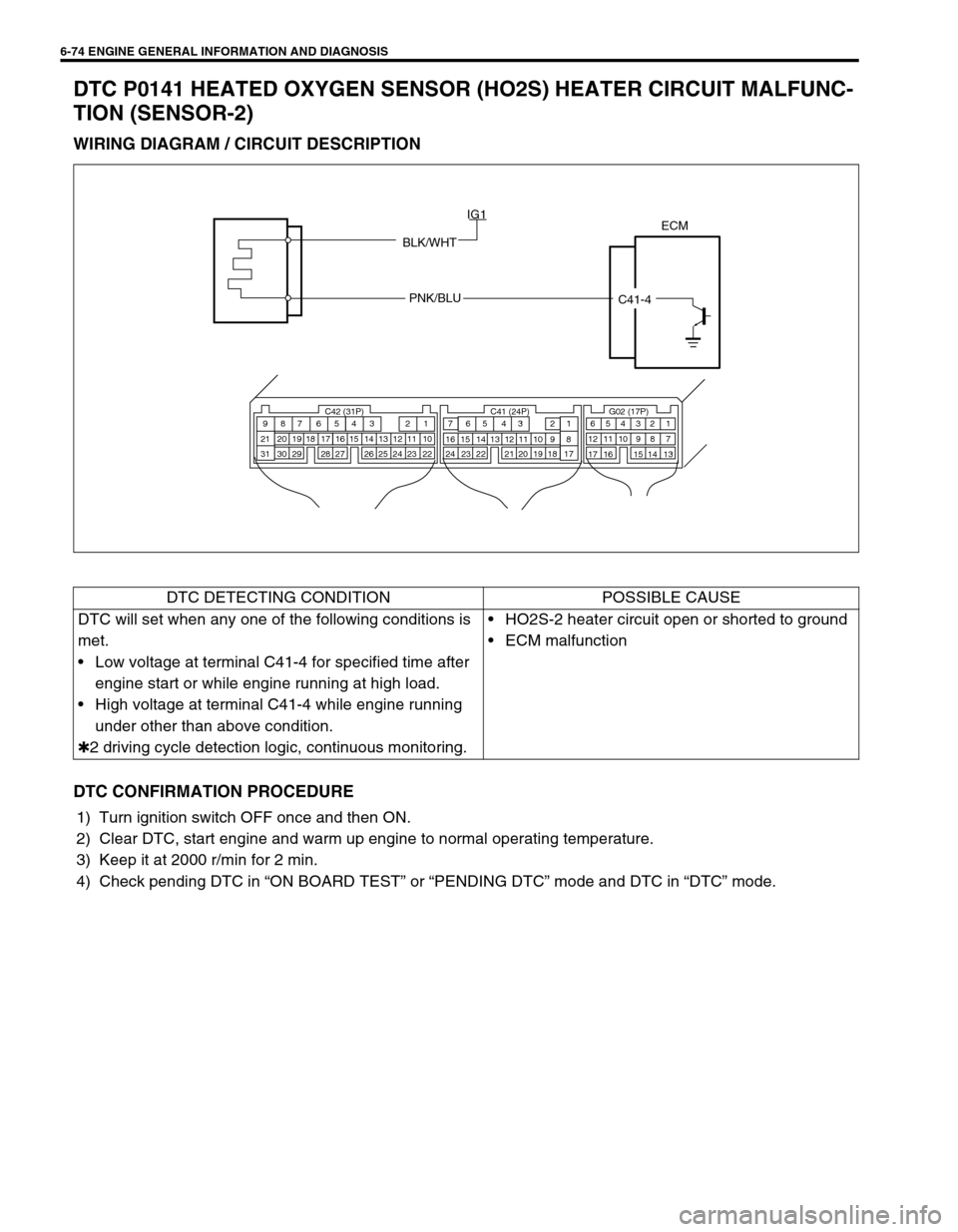

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF once and then ON.

2) Clear DTC, start engine and warm up engine to normal operating temperature.

3) Keep it at 2000 r/min for 2 min.

4) Check pending DTC in “ON BOARD TEST” or “PENDING DTC” mode and DTC in “DTC” mode.

ECM

BLK/WHT

PNK/BLU

C41-4 IG1

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

DTC will set when any one of the following conditions is

met.

Low voltage at terminal C41-4 for specified time after

engine start or while engine running at high load.

High voltage at terminal C41-4 while engine running

under other than above condition.

✱2 driving cycle detection logic, continuous monitoring.HO2S-2 heater circuit open or shorted to ground

ECM malfunction

Page 445 of 698

![SUZUKI SWIFT 2000 1.G RG413 Service Owners Manual 6-76 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0171 FUEL SYSTEM TOO LEAN

DTC P0172 FUEL SYSTEM TOO RICH

WIRING DIAGRAM / CIRCUIT DESCRIPTION

1. Injector [a] : Signal to decrease amount of fuel inj SUZUKI SWIFT 2000 1.G RG413 Service Owners Manual 6-76 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0171 FUEL SYSTEM TOO LEAN

DTC P0172 FUEL SYSTEM TOO RICH

WIRING DIAGRAM / CIRCUIT DESCRIPTION

1. Injector [a] : Signal to decrease amount of fuel inj](/img/20/7606/w960_7606-444.png)

6-76 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0171 FUEL SYSTEM TOO LEAN

DTC P0172 FUEL SYSTEM TOO RICH

WIRING DIAGRAM / CIRCUIT DESCRIPTION

1. Injector [a] : Signal to decrease amount of fuel injection [f] : A/F mixture becomes leaner

2. HO2S-1 [b] : Signal to increase amount of fuel injection [g] : Oxygen concentration decreases

3. WU-TWC (Warm up-three way catalytic convec-

tor)[c] : High voltage [h] : Oxygen concentration increases

4. Sensed information [d] : Low voltage

5. ECM [e] : A/F mixture becomes richer

[a]

[b]

[f] [e] [g][d]

[h][c]

1

2 5

1

2

2

3

54

+BECM

C42-9

C42-21

C42-8 C42-31

C42-1

BLU/YEL

BLU/WHT

BLU/RED

BLK/ORN

C42-3

BLK/ORN BLU/ORN

WHT

ORNC42-10C42-13

E111

DTC DETECTING CONDITION POSSIBLE CAUSE

When one of the following conditions occurs while

engine running under closed loop condition.

Air/fuel ratio too lean

(Total fuel trim (short and long terms added) is more

than 30%)

Air/fuel ratio too rich

(Total fuel trim is less than – 30%)

✱2 driving cycle detection logic, continuous monitoring.Vacuum leaks (air drawn in).

Exhaust gas leakage.

Heated oxygen sensor-1 circuit malfunction.

Fuel pressure out of specification.

Fuel injector malfunction (clogged or leakage).

MAP sensor poor performance.

ECT sensor poor performance.

IAT sensor poor performance.

TP sensor poor performance.

EVAP control system malfunction.

PCV valve malfunction.

Page 450 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-81

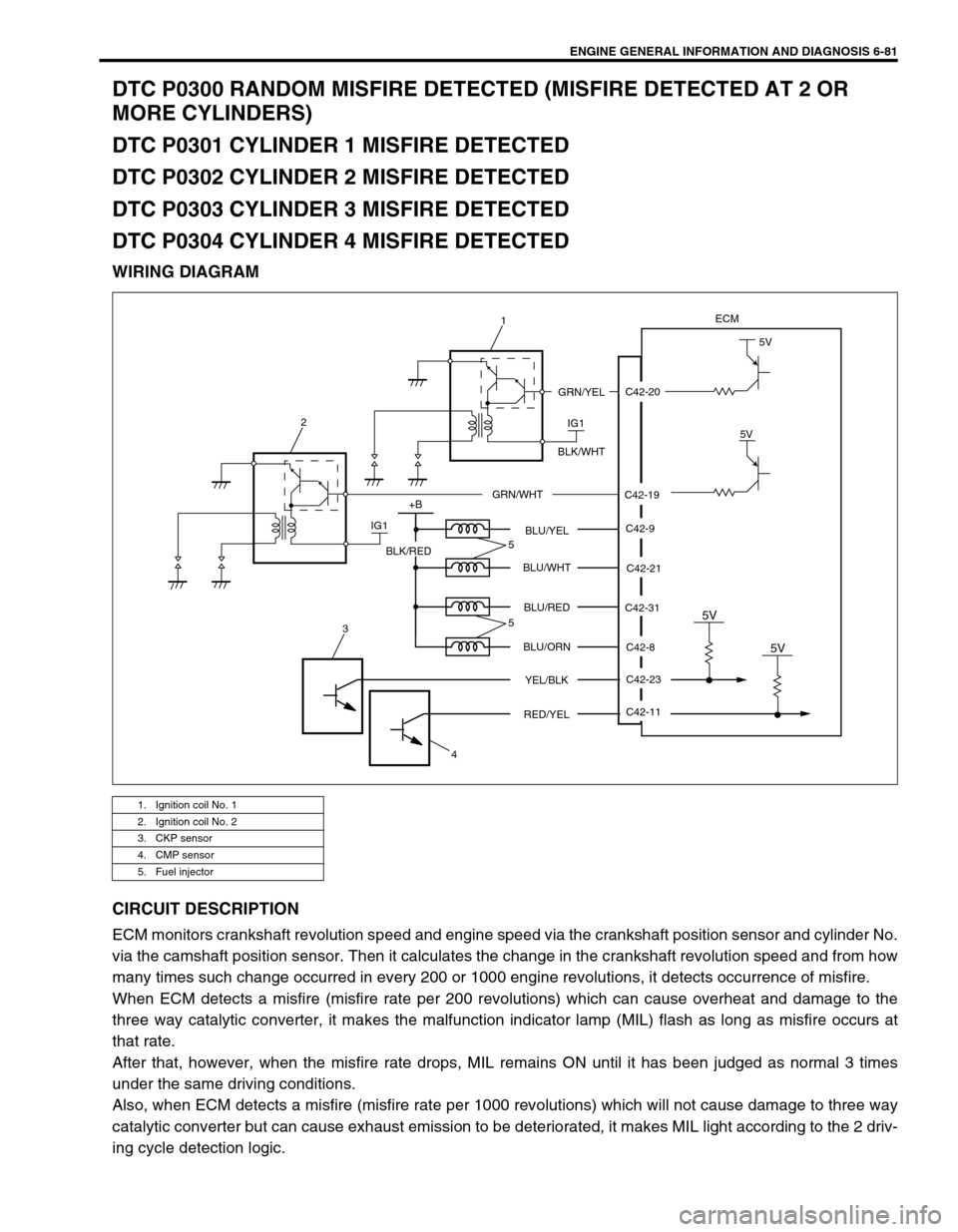

DTC P0300 RANDOM MISFIRE DETECTED (MISFIRE DETECTED AT 2 OR

MORE CYLINDERS)

DTC P0301 CYLINDER 1 MISFIRE DETECTED

DTC P0302 CYLINDER 2 MISFIRE DETECTED

DTC P0303 CYLINDER 3 MISFIRE DETECTED

DTC P0304 CYLINDER 4 MISFIRE DETECTED

WIRING DIAGRAM

CIRCUIT DESCRIPTION

ECM monitors crankshaft revolution speed and engine speed via the crankshaft position sensor and cylinder No.

via the camshaft position sensor. Then it calculates the change in the crankshaft revolution speed and from how

many times such change occurred in every 200 or 1000 engine revolutions, it detects occurrence of misfire.

When ECM detects a misfire (misfire rate per 200 revolutions) which can cause overheat and damage to the

three way catalytic converter, it makes the malfunction indicator lamp (MIL) flash as long as misfire occurs at

that rate.

After that, however, when the misfire rate drops, MIL remains ON until it has been judged as normal 3 times

under the same driving conditions.

Also, when ECM detects a misfire (misfire rate per 1000 revolutions) which will not cause damage to three way

catalytic converter but can cause exhaust emission to be deteriorated, it makes MIL light according to the 2 driv-

ing cycle detection logic.

1. Ignition coil No. 1

2. Ignition coil No. 2

3. CKP sensor

4. CMP sensor

5. Fuel injector

C42-20

C42-19

ECM

IG1

5V

5V

GRN/YEL

BLK/WHT

GRN/WHT

IG1 2

+B

C42-9

C42-21

C42-8

C42-23 C42-31 BLU/YEL

BLU/WHT

BLU/RED

BLU/ORN

YEL/BLK

5V

C42-11

RED/YEL

5V

BLK/RED

3

45

5

1

Page 455 of 698

6-86 ENGINE GENERAL INFORMATION AND DIAGNOSIS

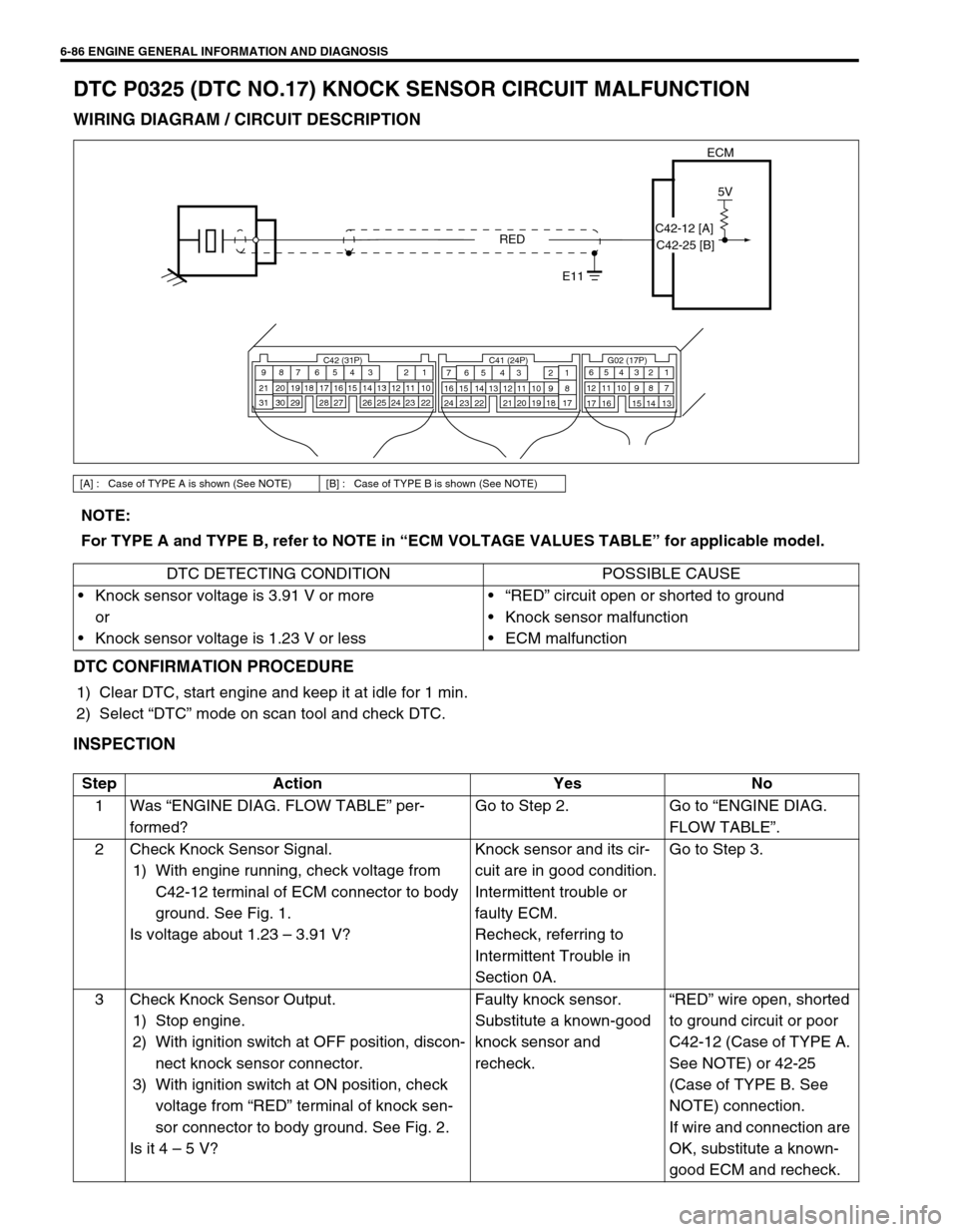

DTC P0325 (DTC NO.17) KNOCK SENSOR CIRCUIT MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Clear DTC, start engine and keep it at idle for 1 min.

2) Select “DTC” mode on scan tool and check DTC.

INSPECTION

[A] : Case of TYPE A is shown (See NOTE) [B] : Case of TYPE B is shown (See NOTE)

ECM

5V

RED

E11

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

C42-12 [A]

C42-25 [B]

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

DTC DETECTING CONDITION POSSIBLE CAUSE

Knock sensor voltage is 3.91 V or more

or

Knock sensor voltage is 1.23 V or less“RED” circuit open or shorted to ground

Knock sensor malfunction

ECM malfunction

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check Knock Sensor Signal.

1) With engine running, check voltage from

C42-12 terminal of ECM connector to body

ground. See Fig. 1.

Is voltage about 1.23 – 3.91 V?Knock sensor and its cir-

cuit are in good condition.

Intermittent trouble or

faulty ECM.

Recheck, referring to

Intermittent Trouble in

Section 0A.Go to Step 3.

3 Check Knock Sensor Output.

1) Stop engine.

2) With ignition switch at OFF position, discon-

nect knock sensor connector.

3) With ignition switch at ON position, check

voltage from “RED” terminal of knock sen-

sor connector to body ground. See Fig. 2.

Is it 4 – 5 V?Faulty knock sensor.

Substitute a known-good

knock sensor and

recheck.“RED” wire open, shorted

to ground circuit or poor

C42-12 (Case of TYPE A.

See NOTE) or 42-25

(Case of TYPE B. See

NOTE) connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.

Page 457 of 698

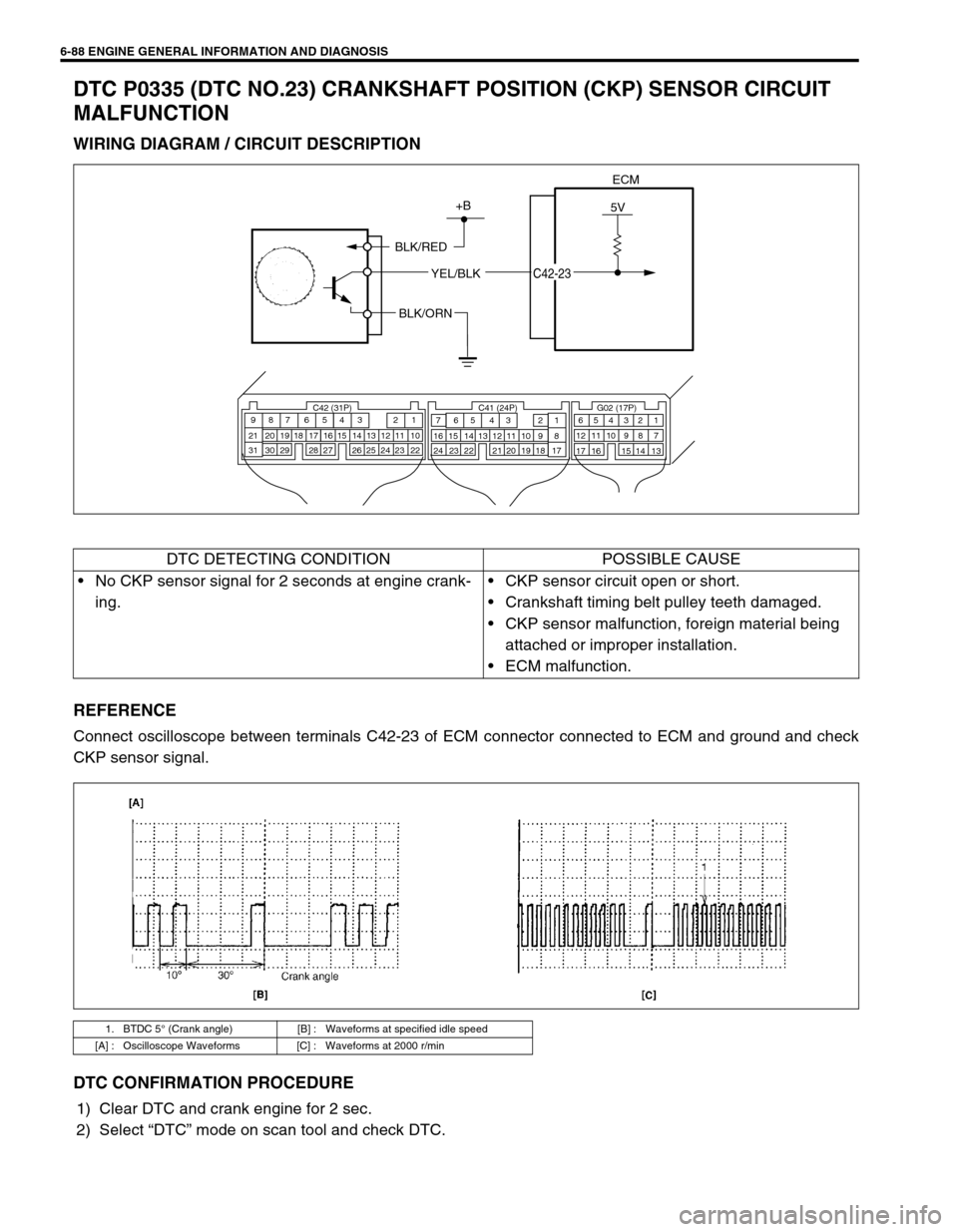

6-88 ENGINE GENERAL INFORMATION AND DIAGNOSIS

DTC P0335 (DTC NO.23) CRANKSHAFT POSITION (CKP) SENSOR CIRCUIT

MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

REFERENCE

Connect oscilloscope between terminals C42-23 of ECM connector connected to ECM and ground and check

CKP sensor signal.

DTC CONFIRMATION PROCEDURE

1) Clear DTC and crank engine for 2 sec.

2) Select “DTC” mode on scan tool and check DTC.

ECM

5V+B

BLK/RED

YEL/BLK

C42-23

BLK/ORN

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

DTC DETECTING CONDITION POSSIBLE CAUSE

No CKP sensor signal for 2 seconds at engine crank-

ing.CKP sensor circuit open or short.

Crankshaft timing belt pulley teeth damaged.

CKP sensor malfunction, foreign material being

attached or improper installation.

ECM malfunction.

1. BTDC 5° (Crank angle) [B] : Waveforms at specified idle speed

[A] : Oscilloscope Waveforms [C] : Waveforms at 2000 r/min

Page 460 of 698

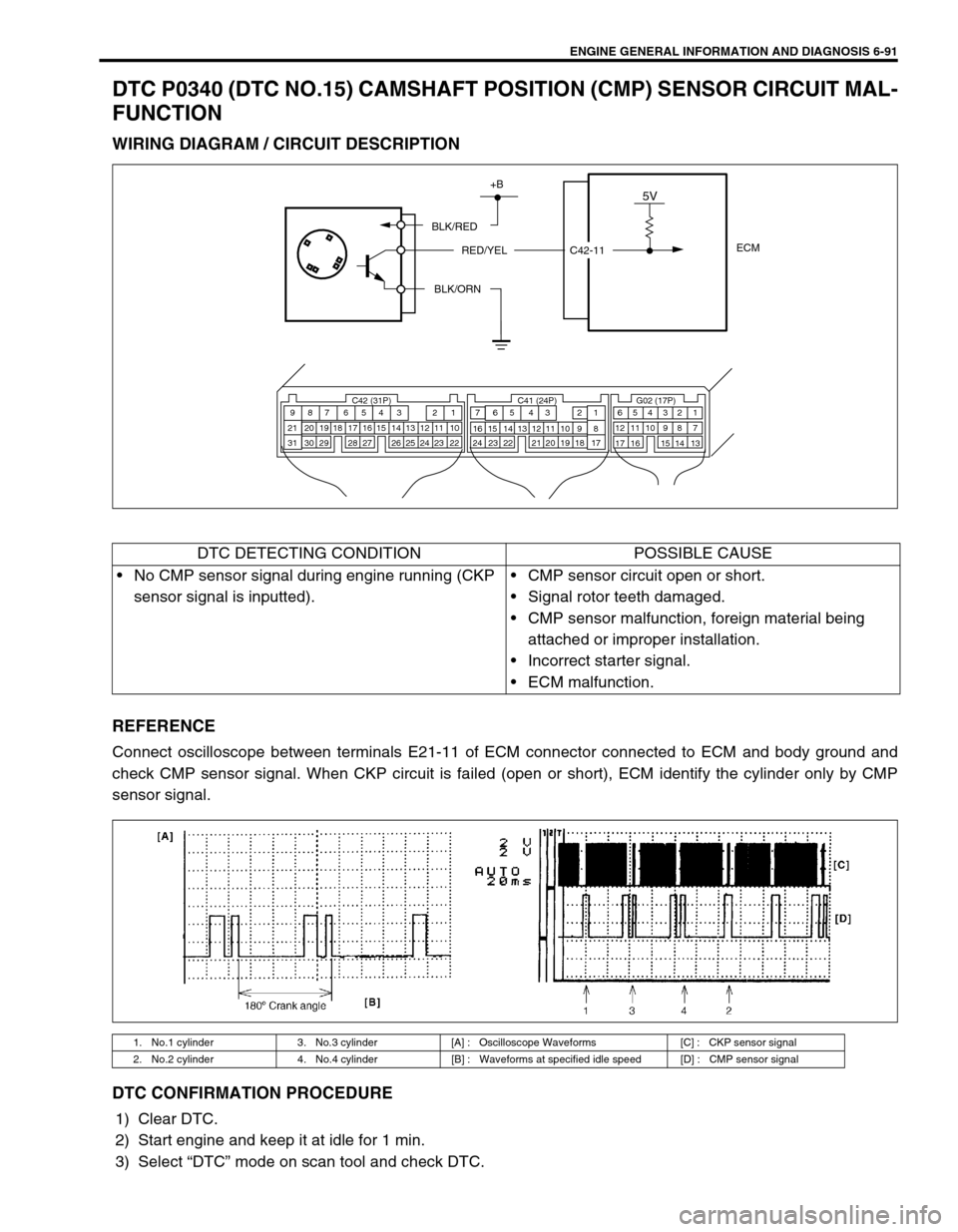

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-91

DTC P0340 (DTC NO.15) CAMSHAFT POSITION (CMP) SENSOR CIRCUIT MAL-

FUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

REFERENCE

Connect oscilloscope between terminals E21-11 of ECM connector connected to ECM and body ground and

check CMP sensor signal. When CKP circuit is failed (open or short), ECM identify the cylinder only by CMP

sensor signal.

DTC CONFIRMATION PROCEDURE

1) Clear DTC.

2) Start engine and keep it at idle for 1 min.

3) Select “DTC” mode on scan tool and check DTC.

ECM

5V+B

BLK/RED

RED/YEL

BLK/ORN

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

C42-11

DTC DETECTING CONDITION POSSIBLE CAUSE

No CMP sensor signal during engine running (CKP

sensor signal is inputted).CMP sensor circuit open or short.

Signal rotor teeth damaged.

CMP sensor malfunction, foreign material being

attached or improper installation.

Incorrect starter signal.

ECM malfunction.

1. No.1 cylinder 3. No.3 cylinder [A] : Oscilloscope Waveforms [C] : CKP sensor signal

2. No.2 cylinder 4. No.4 cylinder [B] : Waveforms at specified idle speed [D] : CMP sensor signal

Page 463 of 698

6-94 ENGINE GENERAL INFORMATION AND DIAGNOSIS

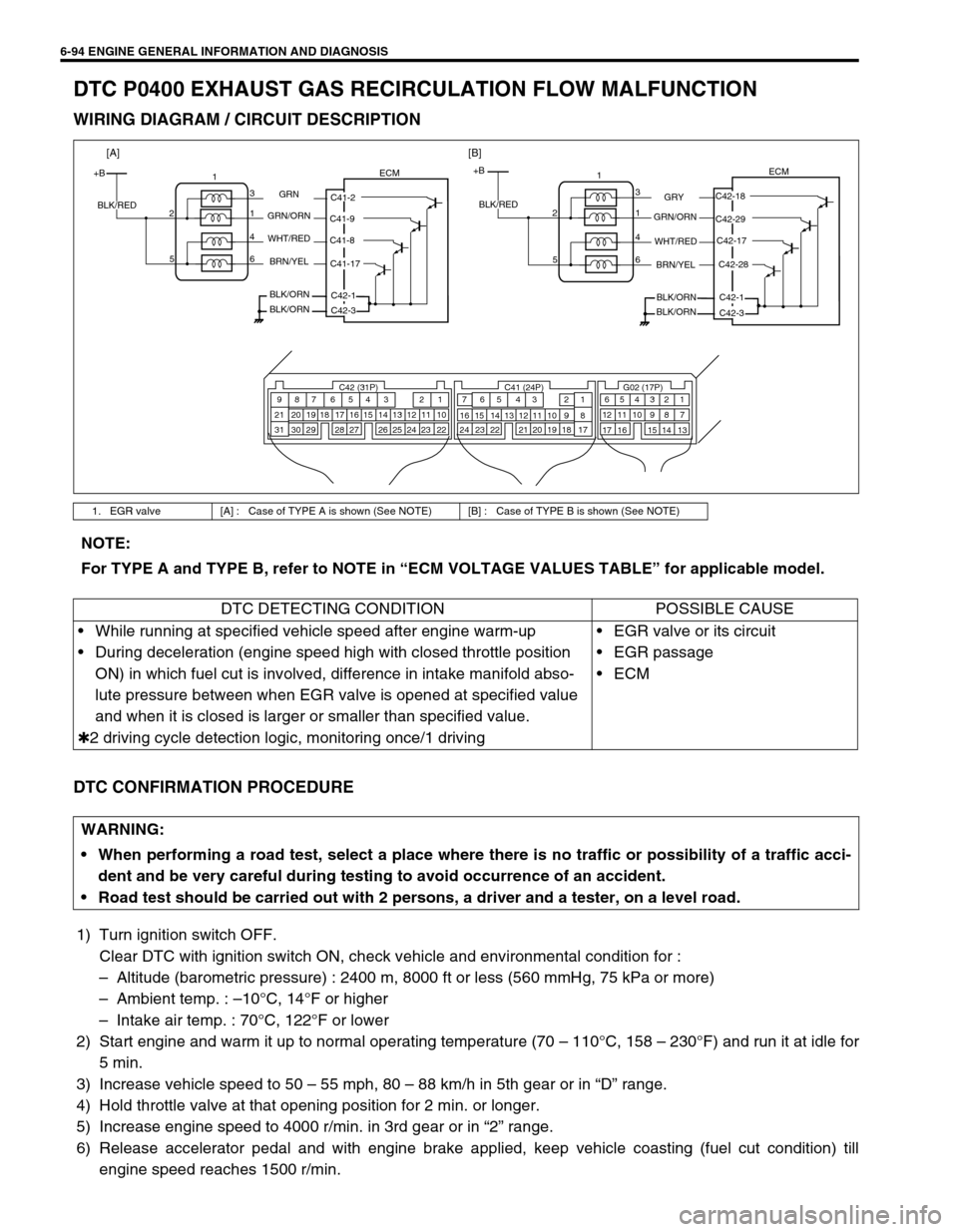

DTC P0400 EXHAUST GAS RECIRCULATION FLOW MALFUNCTION

WIRING DIAGRAM / CIRCUIT DESCRIPTION

DTC CONFIRMATION PROCEDURE

1) Turn ignition switch OFF.

Clear DTC with ignition switch ON, check vehicle and environmental condition for :

–Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

–Ambient temp. : –10°C, 14°F or higher

–Intake air temp. : 70°C, 122°F or lower

2) Start engine and warm it up to normal operating temperature (70 – 110°C, 158 – 230°F) and run it at idle for

5 min.

3) Increase vehicle speed to 50 – 55 mph, 80 – 88 km/h in 5th gear or in “D” range.

4) Hold throttle valve at that opening position for 2 min. or longer.

5) Increase engine speed to 4000 r/min. in 3rd gear or in “2” range.

6) Release accelerator pedal and with engine brake applied, keep vehicle coasting (fuel cut condition) till

engine speed reaches 1500 r/min.

1. EGR valve [A] : Case of TYPE A is shown (See NOTE) [B] : Case of TYPE B is shown (See NOTE)

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

+BECM

C42-18

C42-29

C42-28 C42-17

C42-1

GRY

GRN/ORN

WHT/RED

C42-3 BRN/YEL

BLK/ORN

BLK/ORN BLK/RED1

3

1 2

4

6 5

+BECM

C41-2

C41-9

C41-17 C41-8

C42-1

GRN

GRN/ORN

WHT/RED

C42-3 BRN/YEL

BLK/ORN

BLK/ORN BLK/RED1

3

1 2

4

6 5

[A][B]

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

DTC DETECTING CONDITION POSSIBLE CAUSE

While running at specified vehicle speed after engine warm-up

During deceleration (engine speed high with closed throttle position

ON) in which fuel cut is involved, difference in intake manifold abso-

lute pressure between when EGR valve is opened at specified value

and when it is closed is larger or smaller than specified value.

✱2 driving cycle detection logic, monitoring once/1 drivingEGR valve or its circuit

EGR passage

ECM

WARNING:

When performing a road test, select a place where there is no traffic or possibility of a traffic acci-

dent and be very careful during testing to avoid occurrence of an accident.

Road test should be carried out with 2 persons, a driver and a tester, on a level road.