differential SUZUKI SWIFT 2000 1.G RG413 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 239 of 698

3E-26 REAR SUSPENSION

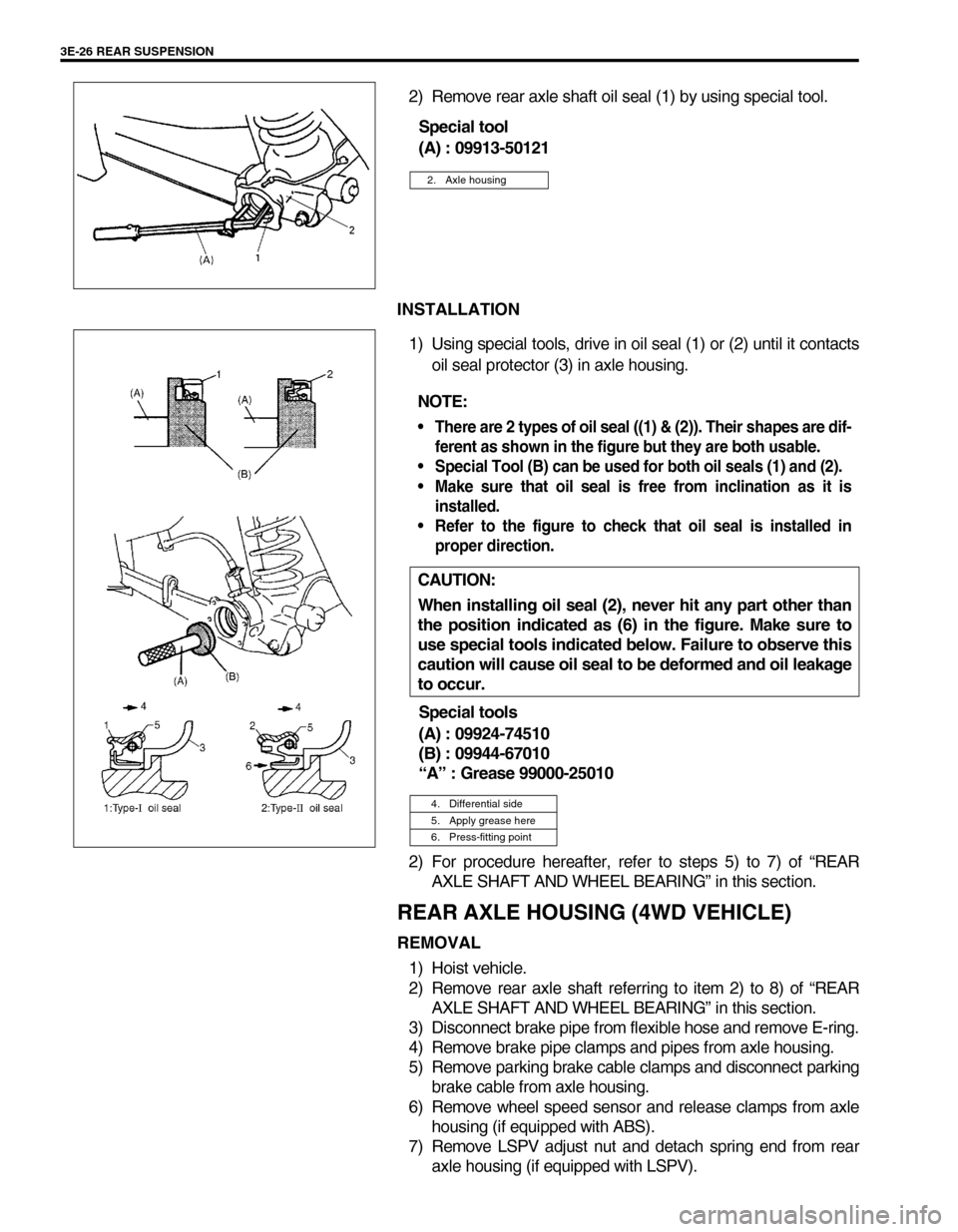

2) Remove rear axle shaft oil seal (1) by using special tool.

Special tool

(A) : 09913-50121

INSTALLATION

1) Using special tools, drive in oil seal (1) or (2) until it contacts

oil seal protector (3) in axle housing.

Special tools

(A) : 09924-74510

(B) : 09944-67010

“A” : Grease 99000-25010

2) For procedure hereafter, refer to steps 5) to 7) of “REAR

AXLE SHAFT AND WHEEL BEARING” in this section.

REAR AXLE HOUSING (4WD VEHICLE)

REMOVAL

1) Hoist vehicle.

2) Remove rear axle shaft referring to item 2) to 8) of “REAR

AXLE SHAFT AND WHEEL BEARING” in this section.

3) Disconnect brake pipe from flexible hose and remove E-ring.

4) Remove brake pipe clamps and pipes from axle housing.

5) Remove parking brake cable clamps and disconnect parking

brake cable from axle housing.

6) Remove wheel speed sensor and release clamps from axle

housing (if equipped with ABS).

7) Remove LSPV adjust nut and detach spring end from rear

axle housing (if equipped with LSPV).

2. Axle housing

NOTE:

There are 2 types of oil seal ((1) & (2)). Their shapes are dif-

ferent as shown in the figure but they are both usable.

Special Tool (B) can be used for both oil seals (1) and (2).

Make sure that oil seal is free from inclination as it is

installed.

Refer to the figure to check that oil seal is installed in

proper direction.

CAUTION:

When installing oil seal (2), never hit any part other than

the position indicated as (6) in the figure. Make sure to

use special tools indicated below. Failure to observe this

caution will cause oil seal to be deformed and oil leakage

to occur.

4. Differential side

5. Apply grease here

6. Press-fitting point

Page 240 of 698

REAR SUSPENSION 3E-27

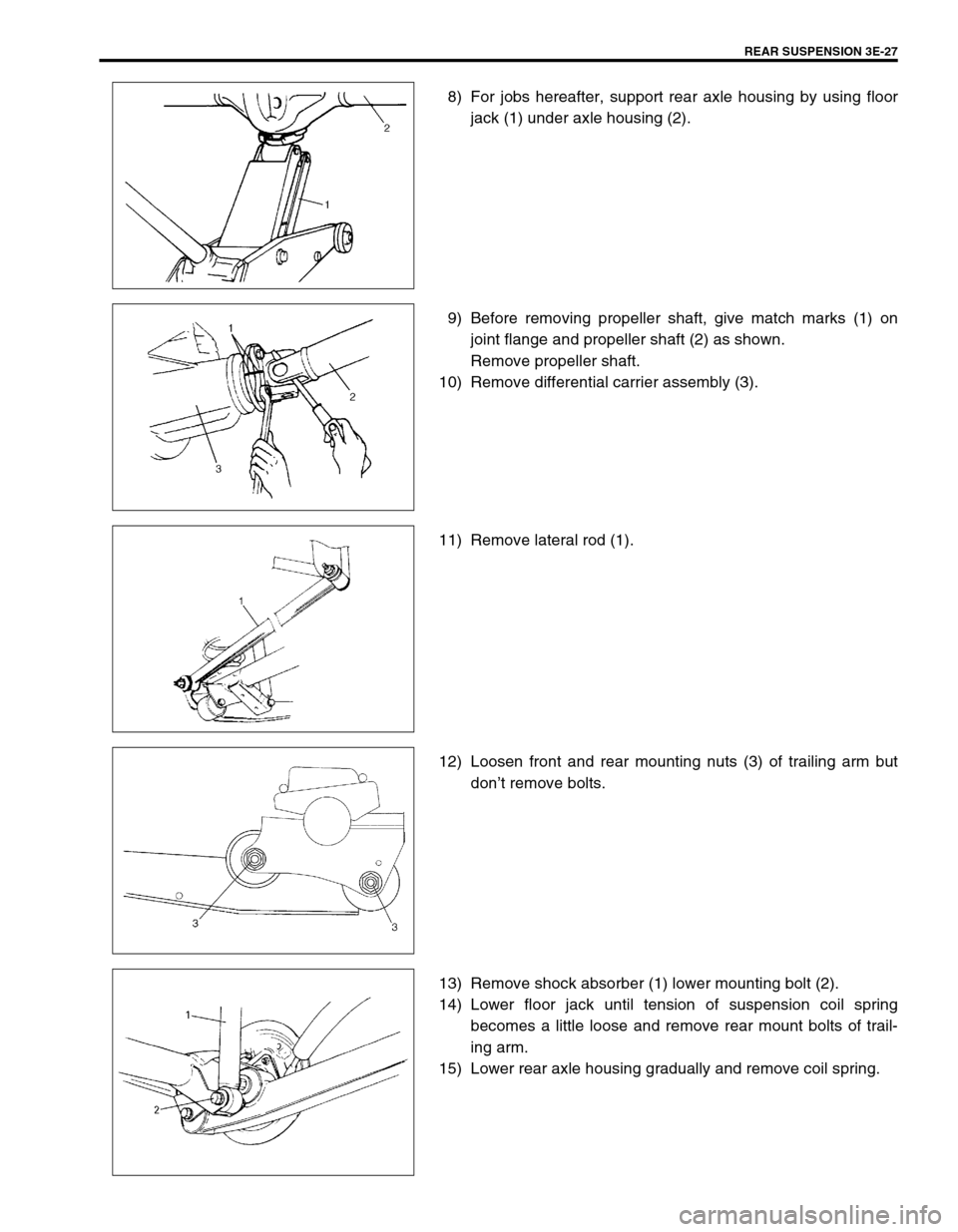

8) For jobs hereafter, support rear axle housing by using floor

jack (1) under axle housing (2).

9) Before removing propeller shaft, give match marks (1) on

joint flange and propeller shaft (2) as shown.

Remove propeller shaft.

10) Remove differential carrier assembly (3).

11) Remove lateral rod (1).

12) Loosen front and rear mounting nuts (3) of trailing arm but

don’t remove bolts.

13) Remove shock absorber (1) lower mounting bolt (2).

14) Lower floor jack until tension of suspension coil spring

becomes a little loose and remove rear mount bolts of trail-

ing arm.

15) Lower rear axle housing gradually and remove coil spring.

Page 242 of 698

REAR SUSPENSION 3E-29

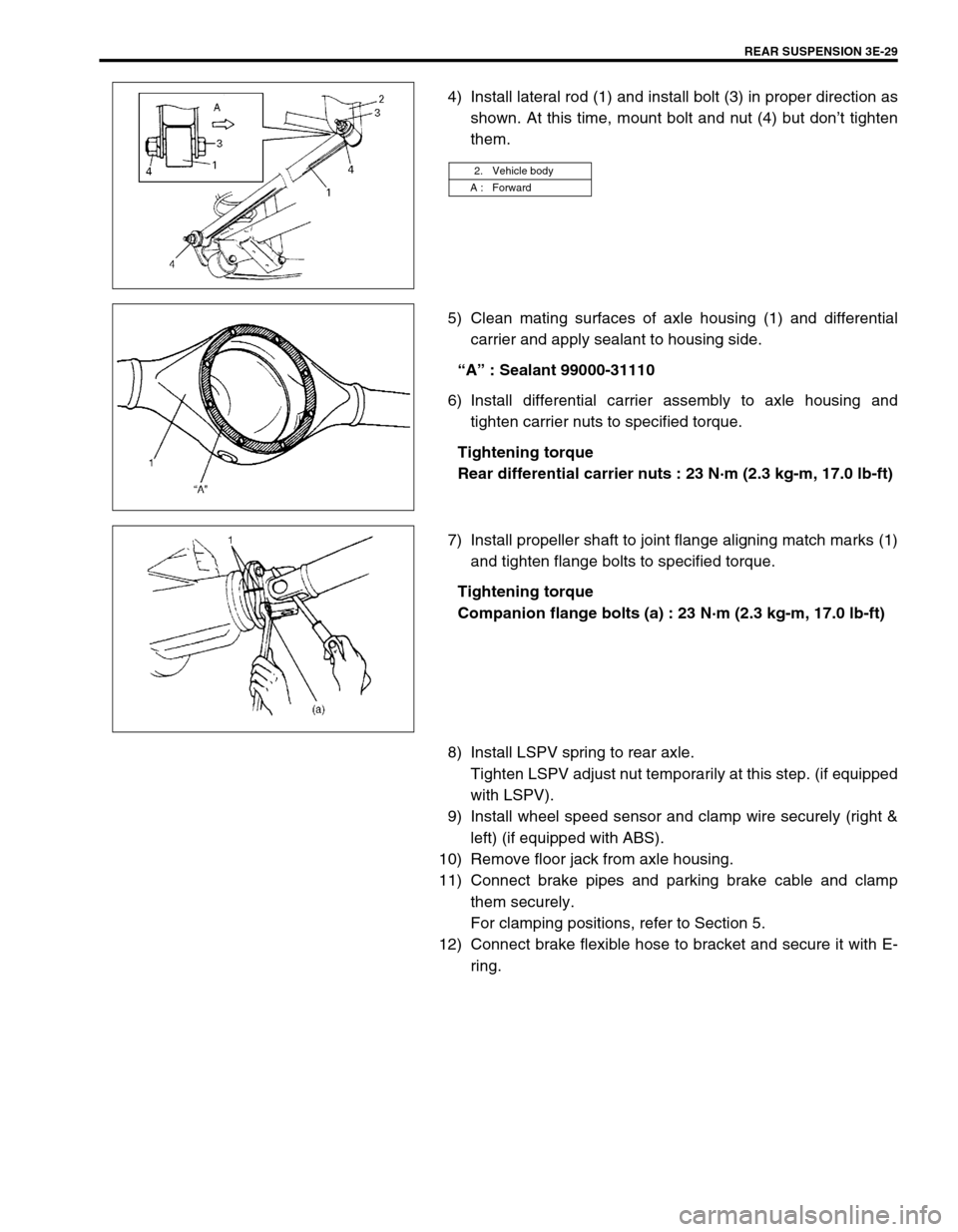

4) Install lateral rod (1) and install bolt (3) in proper direction as

shown. At this time, mount bolt and nut (4) but don’t tighten

them.

5) Clean mating surfaces of axle housing (1) and differential

carrier and apply sealant to housing side.

“A” : Sealant 99000-31110

6) Install differential carrier assembly to axle housing and

tighten carrier nuts to specified torque.

Tightening torque

Rear differential carrier nuts : 23 N·m (2.3 kg-m, 17.0 lb-ft)

7) Install propeller shaft to joint flange aligning match marks (1)

and tighten flange bolts to specified torque.

Tightening torque

Companion flange bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

8) Install LSPV spring to rear axle.

Tighten LSPV adjust nut temporarily at this step. (if equipped

with LSPV).

9) Install wheel speed sensor and clamp wire securely (right &

left) (if equipped with ABS).

10) Remove floor jack from axle housing.

11) Connect brake pipes and parking brake cable and clamp

them securely.

For clamping positions, refer to Section 5.

12) Connect brake flexible hose to bracket and secure it with E-

ring.

2. Vehicle body

A : Forward

Page 243 of 698

3E-30 REAR SUSPENSION

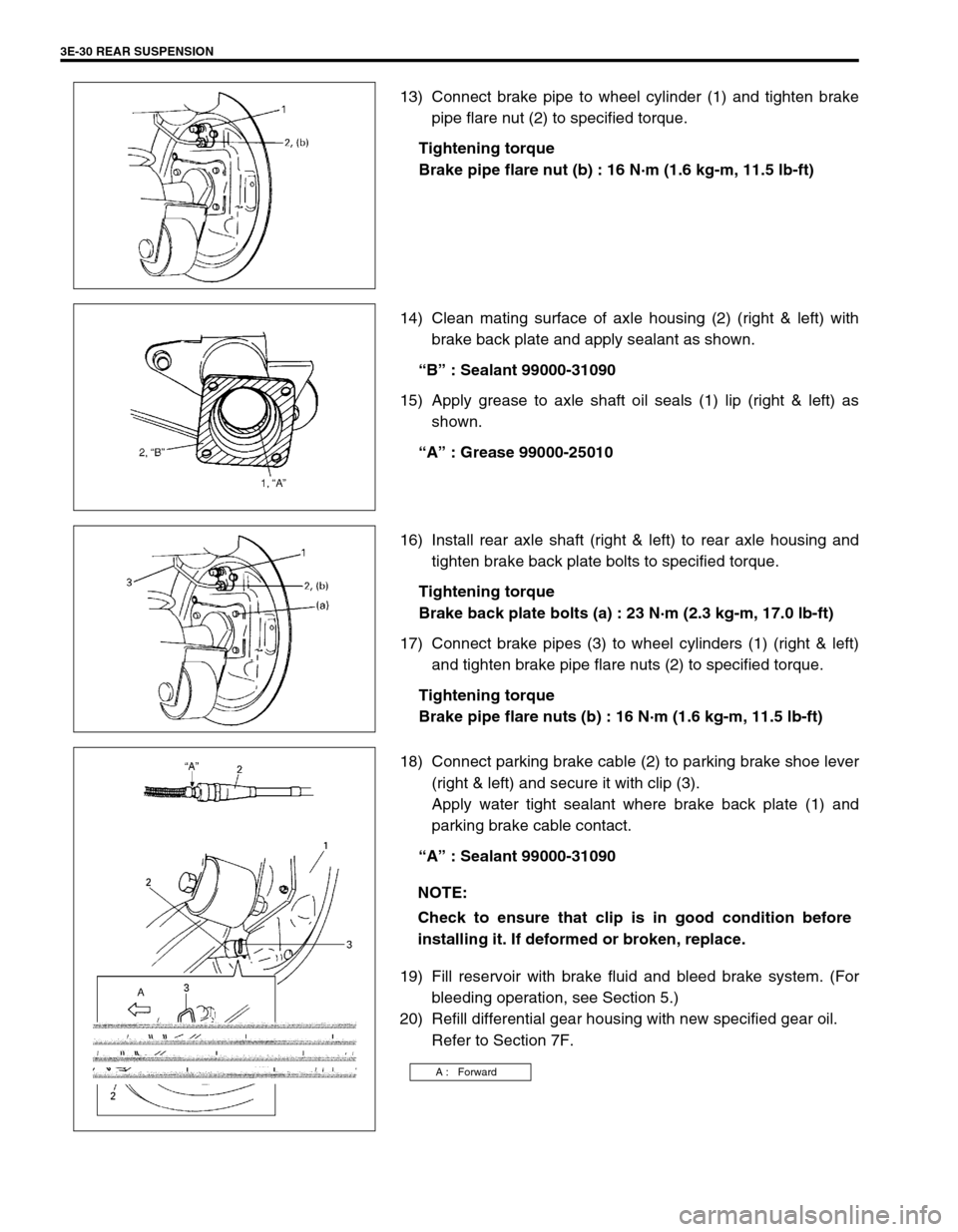

13) Connect brake pipe to wheel cylinder (1) and tighten brake

pipe flare nut (2) to specified torque.

Tightening torque

Brake pipe flare nut (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

14) Clean mating surface of axle housing (2) (right & left) with

brake back plate and apply sealant as shown.

“B” : Sealant 99000-31090

15) Apply grease to axle shaft oil seals (1) lip (right & left) as

shown.

“A” : Grease 99000-25010

16) Install rear axle shaft (right & left) to rear axle housing and

tighten brake back plate bolts to specified torque.

Tightening torque

Brake back plate bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

17) Connect brake pipes (3) to wheel cylinders (1) (right & left)

and tighten brake pipe flare nuts (2) to specified torque.

Tightening torque

Brake pipe flare nuts (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

18) Connect parking brake cable (2) to parking brake shoe lever

(right & left) and secure it with clip (3).

Apply water tight sealant where brake back plate (1) and

parking brake cable contact.

“A” : Sealant 99000-31090

19) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation, see Section 5.)

20) Refill differential gear housing with new specified gear oil.

Refer to Section 7F.

NOTE:

Check to ensure that clip is in good condition before

installing it. If deformed or broken, replace.

A : Forward

Page 249 of 698

3F-4 WHEELS AND TIRES

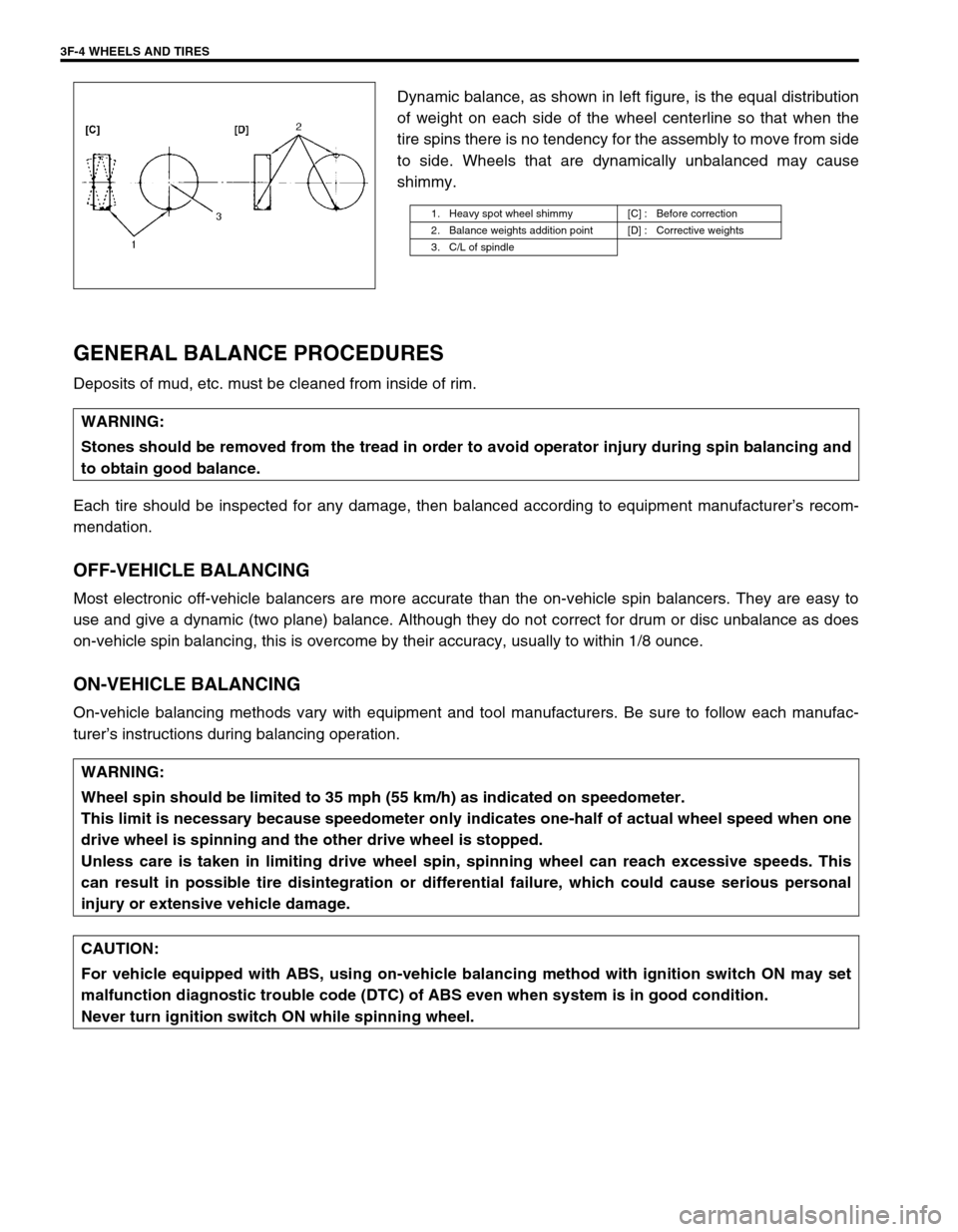

Dynamic balance, as shown in left figure, is the equal distribution

of weight on each side of the wheel centerline so that when the

tire spins there is no tendency for the assembly to move from side

to side. Wheels that are dynamically unbalanced may cause

shimmy.

GENERAL BALANCE PROCEDURES

Deposits of mud, etc. must be cleaned from inside of rim.

Each tire should be inspected for any damage, then balanced according to equipment manufacturer’s recom-

mendation.

OFF-VEHICLE BALANCING

Most electronic off-vehicle balancers are more accurate than the on-vehicle spin balancers. They are easy to

use and give a dynamic (two plane) balance. Although they do not correct for drum or disc unbalance as does

on-vehicle spin balancing, this is overcome by their accuracy, usually to within 1/8 ounce.

ON-VEHICLE BALANCING

On-vehicle balancing methods vary with equipment and tool manufacturers. Be sure to follow each manufac-

turer’s instructions during balancing operation.

1. Heavy spot wheel shimmy [C] : Before correction

2. Balance weights addition point [D] : Corrective weights

3. C/L of spindle

WARNING:

Stones should be removed from the tread in order to avoid operator injury during spin balancing and

to obtain good balance.

WARNING:

Wheel spin should be limited to 35 mph (55 km/h) as indicated on speedometer.

This limit is necessary because speedometer only indicates one-half of actual wheel speed when one

drive wheel is spinning and the other drive wheel is stopped.

Unless care is taken in limiting drive wheel spin, spinning wheel can reach excessive speeds. This

can result in possible tire disintegration or differential failure, which could cause serious personal

injury or extensive vehicle damage.

CAUTION:

For vehicle equipped with ABS, using on-vehicle balancing method with ignition switch ON may set

malfunction diagnostic trouble code (DTC) of ABS even when system is in good condition.

Never turn ignition switch ON while spinning wheel.

Page 255 of 698

4A-2 FRONT DRIVE SHAFT

GENERAL DESCRIPTION

COMPONENT

A constant velocity ball joint is used on the wheel side of front drive shaft. For right side drive shaft of 2WD vehi-

cle, a constant velocity tripod joint on the differential side. For left side drive shaft of every type vehicles and

right side drive shaft of 4WD vehicle, a constant velocity double offset joint is used on the differential or transfer

side. The drive shaft can slide through the tripod joint or the double offset joint in the extension/contraction direc-

tion.

DIAGNOSIS

DIAGNOSIS TABLE

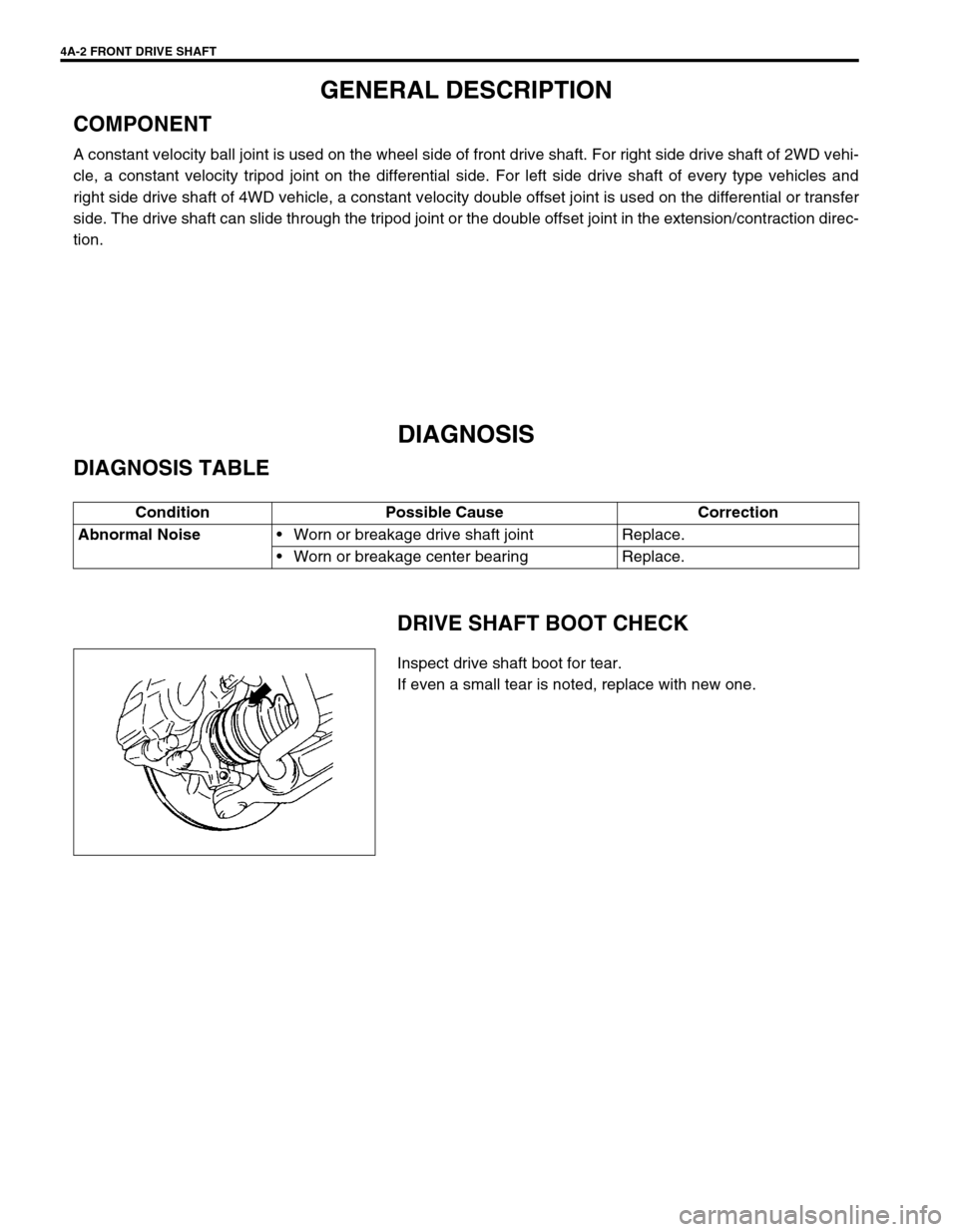

DRIVE SHAFT BOOT CHECK

Inspect drive shaft boot for tear.

If even a small tear is noted, replace with new one. Condition Possible Cause Correction

Abnormal Noise

Worn or breakage drive shaft joint Replace.

Worn or breakage center bearing Replace.

Page 256 of 698

FRONT DRIVE SHAFT 4A-3

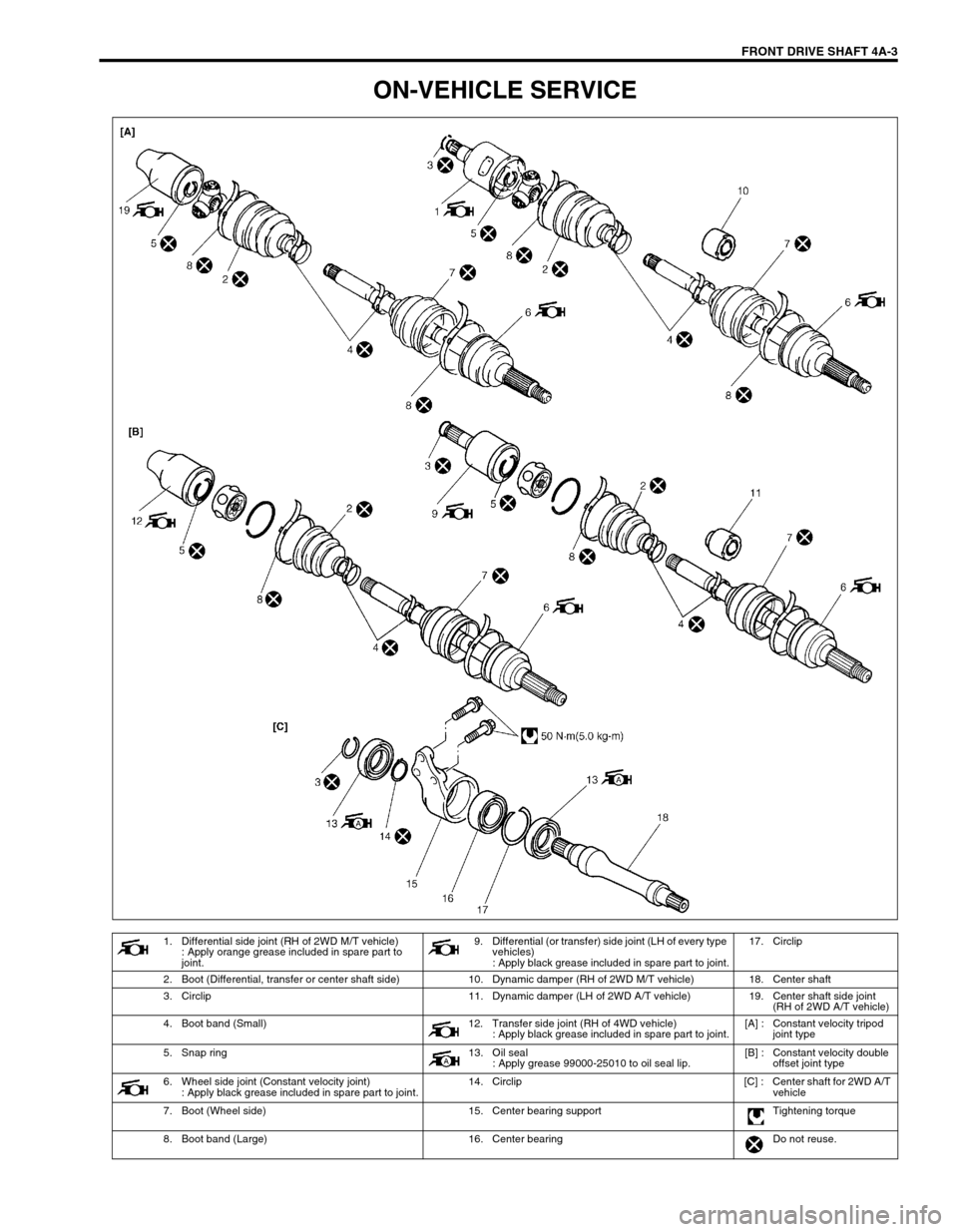

ON-VEHICLE SERVICE

1. Differential side joint (RH of 2WD M/T vehicle)

: Apply orange grease included in spare part to

joint.9. Differential (or transfer) side joint (LH of every type

vehicles)

: Apply black grease included in spare part to joint.17. Circlip

2. Boot (Differential, transfer or center shaft side) 10. Dynamic damper (RH of 2WD M/T vehicle) 18. Center shaft

3. Circlip 11. Dynamic damper (LH of 2WD A/T vehicle) 19. Center shaft side joint

(RH of 2WD A/T vehicle)

4. Boot band (Small) 12. Transfer side joint (RH of 4WD vehicle)

: Apply black grease included in spare part to joint.[A] : Constant velocity tripod

joint type

5. Snap ring 13. Oil seal

: Apply grease 99000-25010 to oil seal lip.[B] : Constant velocity double

offset joint type

6. Wheel side joint (Constant velocity joint)

: Apply black grease included in spare part to joint.14. Circlip [C] : Center shaft for 2WD A/T

vehicle

7. Boot (Wheel side) 15. Center bearing support Tightening torque

8. Boot band (Large) 16. Center bearing Do not reuse.

Page 257 of 698

4A-4 FRONT DRIVE SHAFT

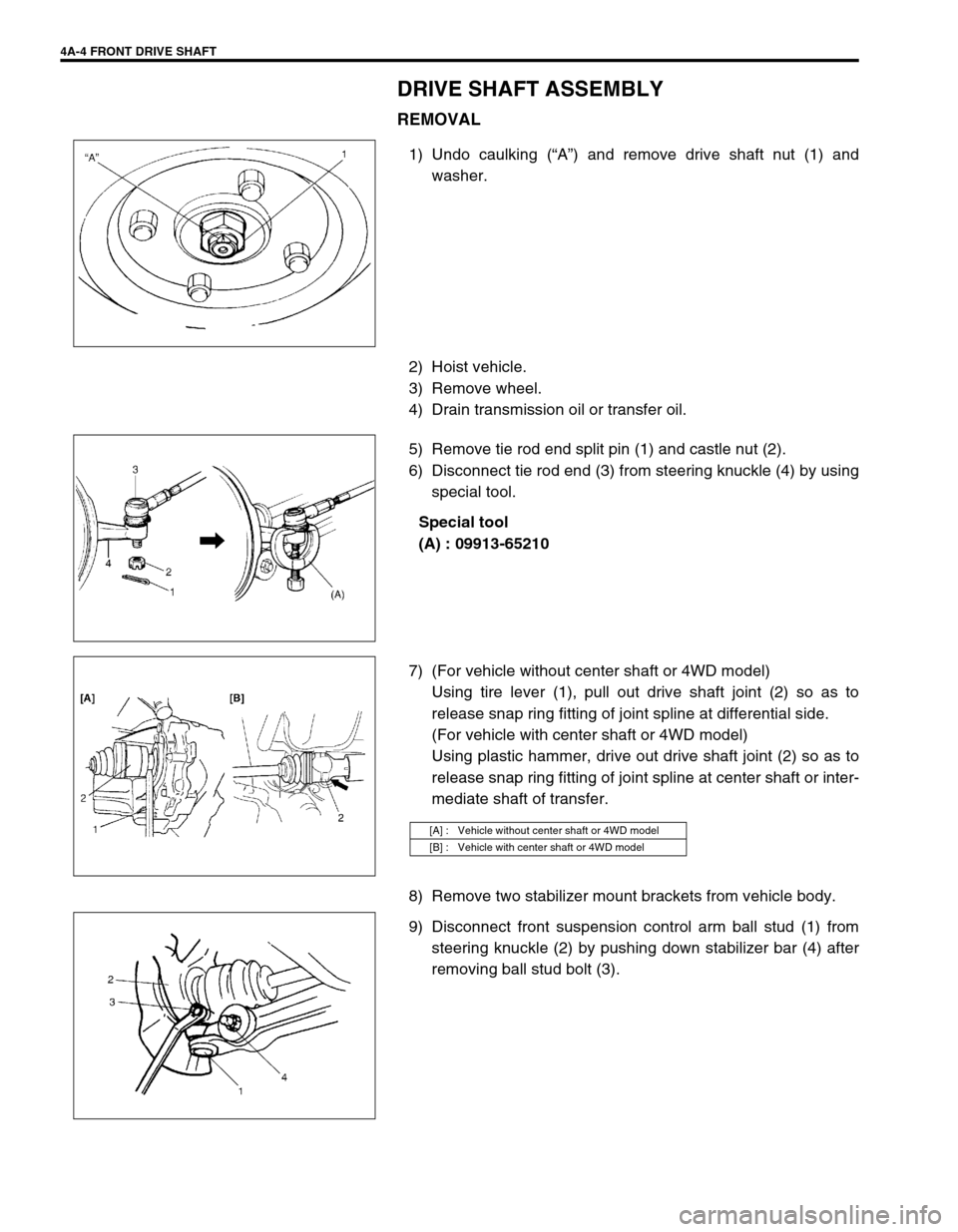

DRIVE SHAFT ASSEMBLY

REMOVAL

1) Undo caulking (“A”) and remove drive shaft nut (1) and

washer.

2) Hoist vehicle.

3) Remove wheel.

4) Drain transmission oil or transfer oil.

5) Remove tie rod end split pin (1) and castle nut (2).

6) Disconnect tie rod end (3) from steering knuckle (4) by using

special tool.

Special tool

(A) : 09913-65210

7) (For vehicle without center shaft or 4WD model)

Using tire lever (1), pull out drive shaft joint (2) so as to

release snap ring fitting of joint spline at differential side.

(For vehicle with center shaft or 4WD model)

Using plastic hammer, drive out drive shaft joint (2) so as to

release snap ring fitting of joint spline at center shaft or inter-

mediate shaft of transfer.

8) Remove two stabilizer mount brackets from vehicle body.

9) Disconnect front suspension control arm ball stud (1) from

steering knuckle (2) by pushing down stabilizer bar (4) after

removing ball stud bolt (3).

[A] : Vehicle without center shaft or 4WD model

[B] : Vehicle with center shaft or 4WD model

Page 258 of 698

FRONT DRIVE SHAFT 4A-5

10) Remove drive shaft assembly.

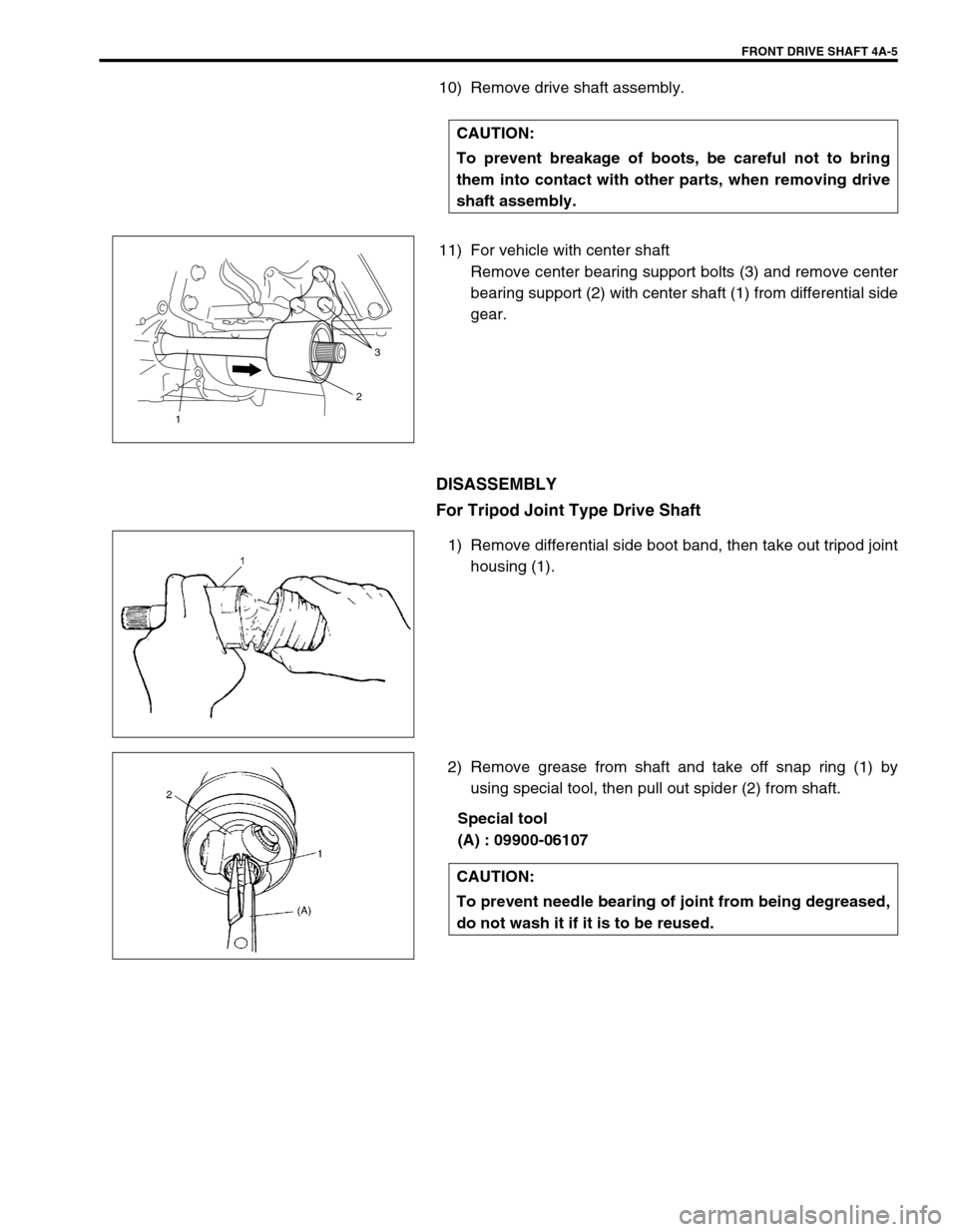

11) For vehicle with center shaft

Remove center bearing support bolts (3) and remove center

bearing support (2) with center shaft (1) from differential side

gear.

DISASSEMBLY

For Tripod Joint Type Drive Shaft

1) Remove differential side boot band, then take out tripod joint

housing (1).

2) Remove grease from shaft and take off snap ring (1) by

using special tool, then pull out spider (2) from shaft.

Special tool

(A) : 09900-06107 CAUTION:

To prevent breakage of boots, be careful not to bring

them into contact with other parts, when removing drive

shaft assembly.

3

2

1

CAUTION:

To prevent needle bearing of joint from being degreased,

do not wash it if it is to be reused.

Page 259 of 698

4A-6 FRONT DRIVE SHAFT

3) Remove boot band, then pull out differential side boot from

shaft.

4) Pull out damper through shaft. (if equipped)

5) Undo boot bands of wheel side joint boot, then pull out boot

through shaft.

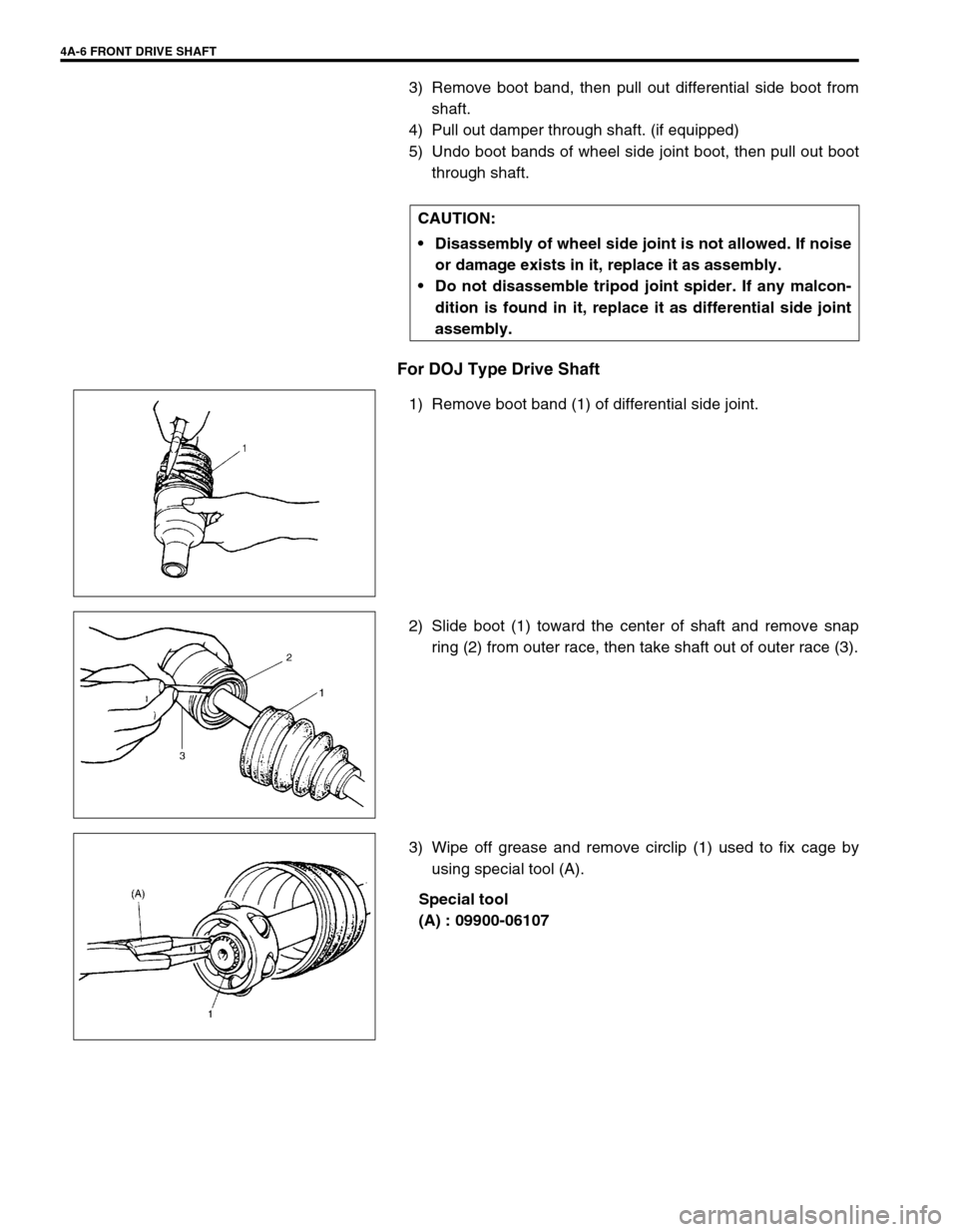

For DOJ Type Drive Shaft

1) Remove boot band (1) of differential side joint.

2) Slide boot (1) toward the center of shaft and remove snap

ring (2) from outer race, then take shaft out of outer race (3).

3) Wipe off grease and remove circlip (1) used to fix cage by

using special tool (A).

Special tool

(A) : 09900-06107 CAUTION:

Disassembly of wheel side joint is not allowed. If noise

or damage exists in it, replace it as assembly.

Do not disassemble tripod joint spider. If any malcon-

dition is found in it, replace it as differential side joint

assembly.