fuse SUZUKI SWIFT 2000 1.G RG413 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 155 of 698

3B1-14 ELECTRICAL POWER STEERING (P/S) SYSTEM

INSPECTION

Step Action Yes No

1 1) Set parking brake.

2) Note combination meter when ignition

switch is turned to ON position.

Does the “BRAKE” indicator (warning lamp)

come ON?Go to Step 2.“BLK/YEL”, “BLK/WHT”

wire circuit or “IG METER”

fuse open or short to

ground.

2 1) Ignition switch OFF.

2) Remove and inspect “P/S” fuse.

Is fuse in good condition?Go to Step 3. Check “BLK/RED” wire

circuit for short to ground.

If OK, replace “P/S” fuse.

3 1) With ignition switch OFF, reinstall fuse and

disconnect P/S control module connector

(“G24”).

2) Check proper connection to P/S control

module at “G24-1” terminal.

3) If OK, check voltage between “G24-1”

(“BLK/RED” wire) terminal and body ground

with ignition switch ON.

Is it 10 – 14 V?Go to Step 4.“BLK/RED” wire circuit

open or short to ground.

4 1) Check proper connection to P/S control

module at “G24-8” terminal.

2) If OK, check voltage between “G24-8”

(“BLK/WHT” wire) terminal and body ground

with ignition switch ON.

Is it 10 – 14 V?Go to Step 5.“BLK/WHT” wire circuit

open or short to ground.

5 1) Check proper connection to P/S control

module at “G24-5” terminal.

2) If OK, check voltage between “G24-5”

(“YEL” wire) terminal and body ground with

ignition switch ON.

Is it 10 – 14 V?Substitute a known-good

P/S control module and

recheck.Go to Step 6.

6 1) Remove combination meter. Refer to “COM-

BINATION METER” in Section 8.

2) Remove and inspect “EPS” light bulb.

Is bulb in good condition?“YEL”, “BLK/WHT” wire

circuit or inside of combi-

nation meter open or

short to other circuit.Check “YEL” wire circuit

for short to ground.

If OK, replace “EPS” light

bulb.

Page 157 of 698

3B1-16 ELECTRICAL POWER STEERING (P/S) SYSTEM

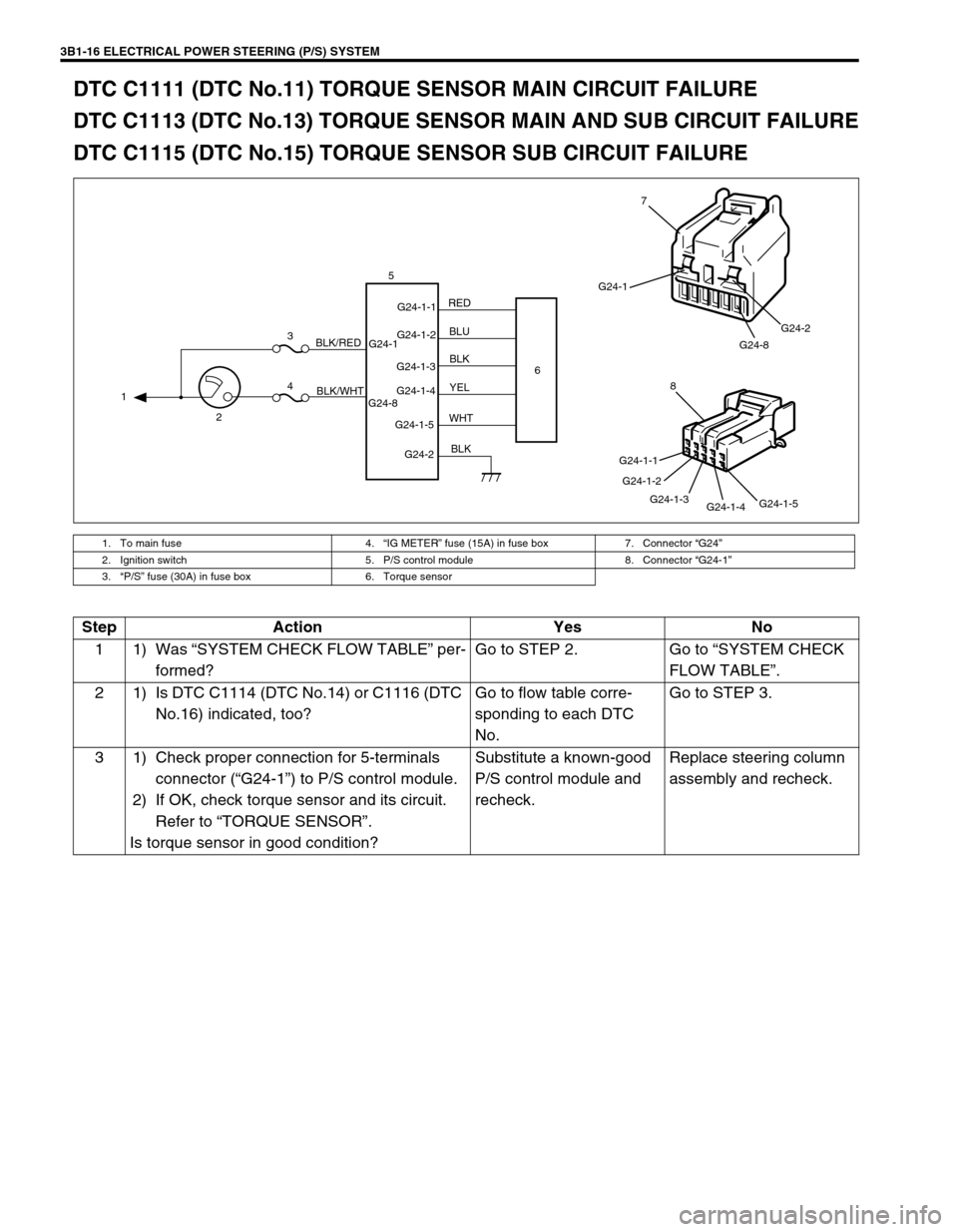

DTC C1111 (DTC No.11) TORQUE SENSOR MAIN CIRCUIT FAILURE

DTC C1113 (DTC No.13) TORQUE SENSOR MAIN AND SUB CIRCUIT FAILURE

DTC C1115 (DTC No.15) TORQUE SENSOR SUB CIRCUIT FAILURE

1. To main fuse 4.“IG METER” fuse (15A) in fuse box 7. Connector “G24”

2. Ignition switch 5. P/S control module 8. Connector “G24-1”

3.“P/S” fuse (30A) in fuse box 6. Torque sensor

G24-2 G24-1

G24-8G24-1-4 G24-1-3

G24-1-5G24-1-2G24-1-1

1

23

45

6

BLK/WHT BLK/RED

BLK WHTYEL BLK BLU RED

G24-1

G24-8G24-2

7

G24-1-5

G24-1-4 G24-1-3 G24-1-2 G24-1-18

Step Action Yes No

11)Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to STEP 2. Go to “SYSTEM CHECK

FLOW TABLE”.

2 1) Is DTC C1114 (DTC No.14) or C1116 (DTC

No.16) indicated, too?Go to flow table corre-

sponding to each DTC

No.Go to STEP 3.

3 1) Check proper connection for 5-terminals

connector (“G24-1”) to P/S control module.

2) If OK, check torque sensor and its circuit.

Refer to “TORQUE SENSOR”.

Is torque sensor in good condition?Substitute a known-good

P/S control module and

recheck.Replace steering column

assembly and recheck.

Page 158 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-17

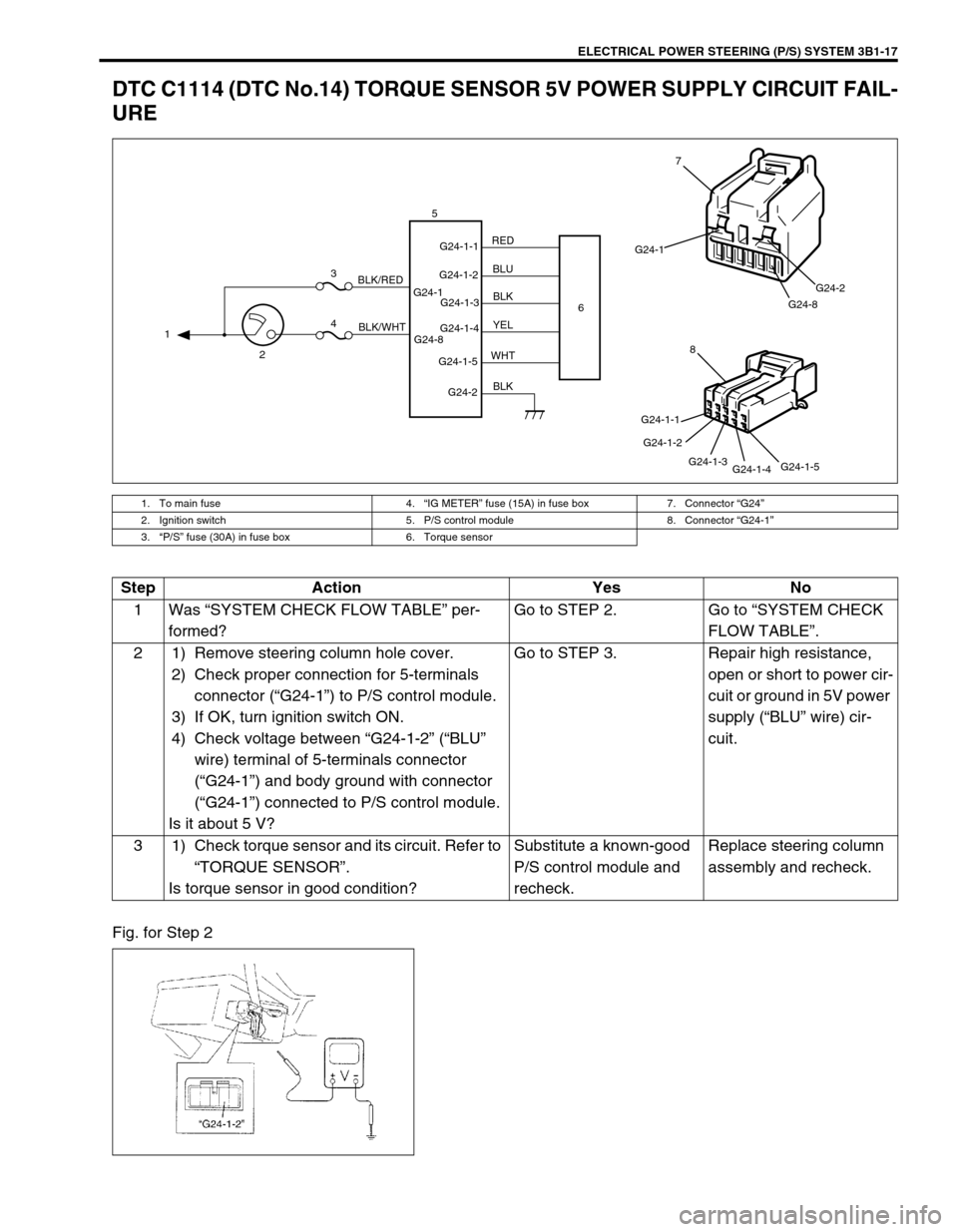

DTC C1114 (DTC No.14) TORQUE SENSOR 5V POWER SUPPLY CIRCUIT FAIL-

URE

Fig. for Step 2

1. To main fuse 4.“IG METER” fuse (15A) in fuse box 7. Connector “G24”

2. Ignition switch 5. P/S control module 8. Connector “G24-1”

3.“P/S” fuse (30A) in fuse box 6. Torque sensor

G24-1

G24-8G24-2

7

G24-1-5

G24-1-4 G24-1-3 G24-1-2 G24-1-18

G24-2 G24-1

G24-8G24-1-4G24-1-3

G24-1-5G24-1-2G24-1-1

1

23

45

6

BLK/WHT BLK/RED

BLK WHTYEL BLK BLU RED

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to STEP 2. Go to “SYSTEM CHECK

FLOW TABLE”.

2 1) Remove steering column hole cover.

2) Check proper connection for 5-terminals

connector (“G24-1”) to P/S control module.

3) If OK, turn ignition switch ON.

4) Check voltage between “G24-1-2” (“BLU”

wire) terminal of 5-terminals connector

(“G24-1”) and body ground with connector

(“G24-1”) connected to P/S control module.

Is it about 5 V?Go to STEP 3. Repair high resistance,

open or short to power cir-

cuit or ground in 5V power

supply (“BLU” wire) cir-

cuit.

3 1) Check torque sensor and its circuit. Refer to

“TORQUE SENSOR”.

Is torque sensor in good condition?Substitute a known-good

P/S control module and

recheck.Replace steering column

assembly and recheck.

Page 159 of 698

3B1-18 ELECTRICAL POWER STEERING (P/S) SYSTEM

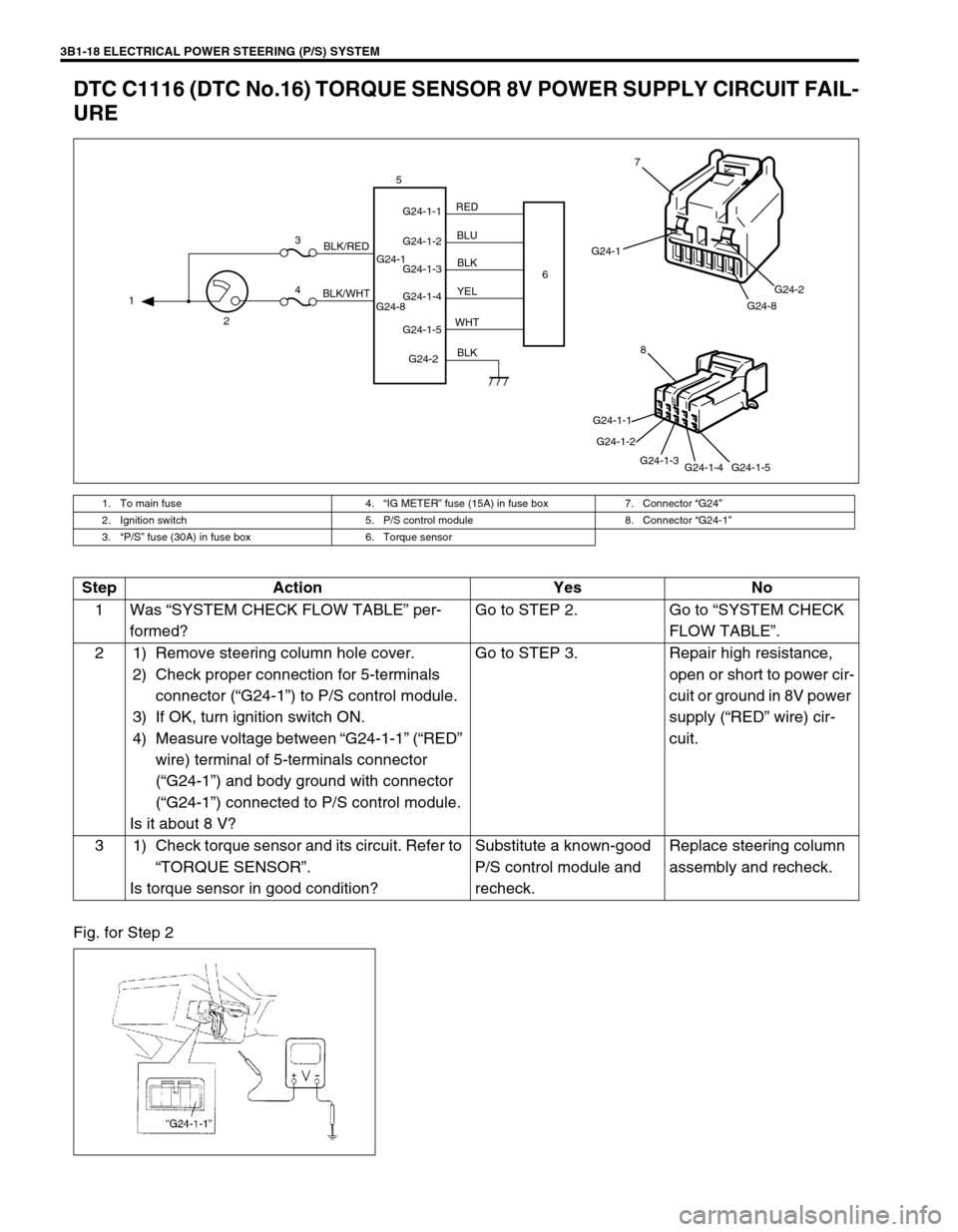

DTC C1116 (DTC No.16) TORQUE SENSOR 8V POWER SUPPLY CIRCUIT FAIL-

URE

Fig. for Step 2

1. To main fuse 4.“IG METER” fuse (15A) in fuse box 7. Connector “G24”

2. Ignition switch 5. P/S control module 8. Connector “G24-1”

3.“P/S” fuse (30A) in fuse box 6. Torque sensor

G24-1

G24-8G24-2

7

G24-1-5

G24-1-4 G24-1-3 G24-1-2 G24-1-18

G24-2 G24-1

G24-8G24-1-4 G24-1-3

G24-1-5 G24-1-2 G24-1-1

1

23

45

6

BLK/WHTBLK/RED

BLK WHTYEL BLK BLU RED

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to STEP 2. Go to “SYSTEM CHECK

FLOW TABLE”.

2 1) Remove steering column hole cover.

2) Check proper connection for 5-terminals

connector (“G24-1”) to P/S control module.

3) If OK, turn ignition switch ON.

4) Measure voltage between “G24-1-1” (“RED”

wire) terminal of 5-terminals connector

(“G24-1”) and body ground with connector

(“G24-1”) connected to P/S control module.

Is it about 8 V?Go to STEP 3. Repair high resistance,

open or short to power cir-

cuit or ground in 8V power

supply (“RED” wire) cir-

cuit.

3 1) Check torque sensor and its circuit. Refer to

“TORQUE SENSOR”.

Is torque sensor in good condition?Substitute a known-good

P/S control module and

recheck.Replace steering column

assembly and recheck.

Page 160 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-19

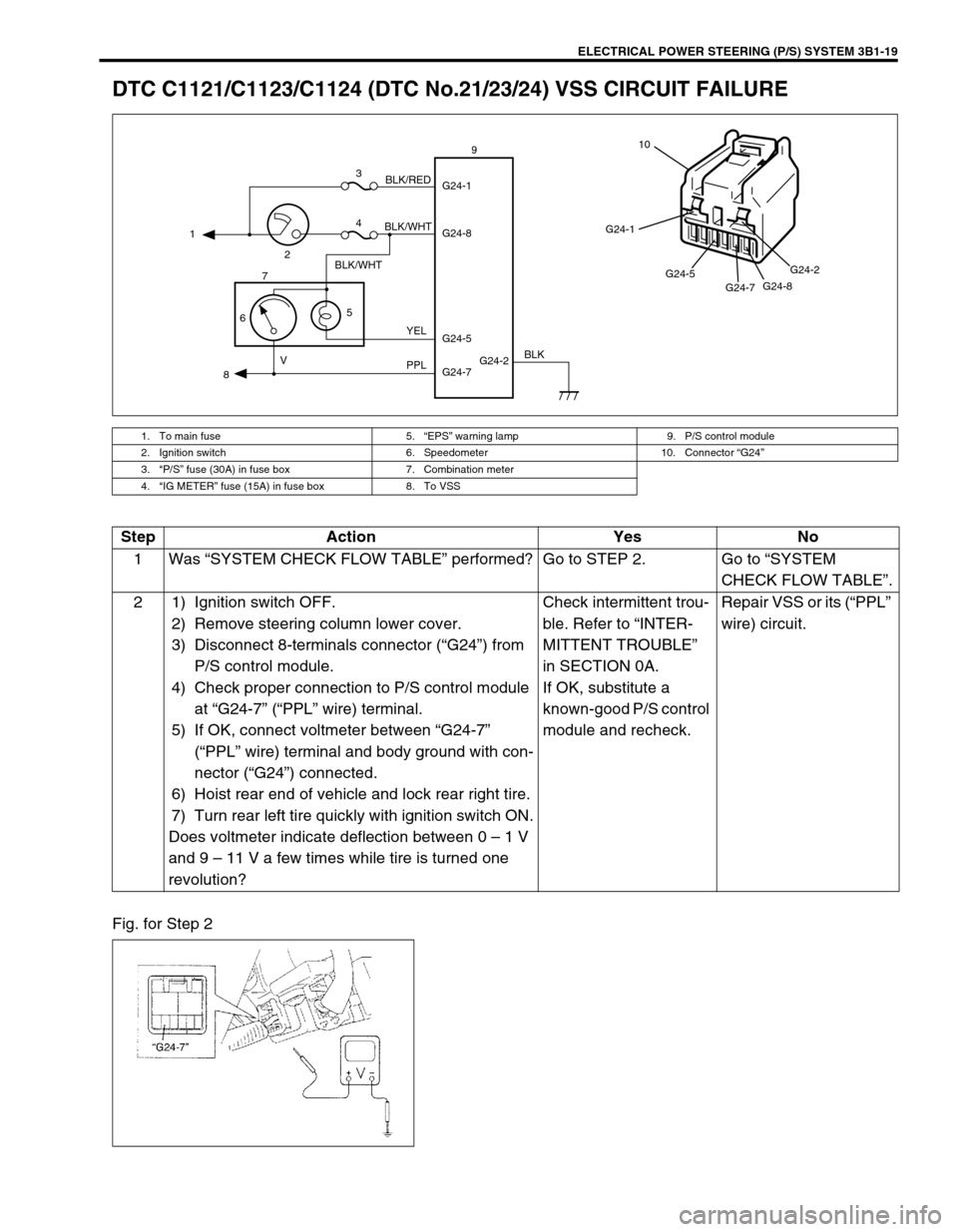

DTC C1121/C1123/C1124 (DTC No.21/23/24) VSS CIRCUIT FAILURE

Fig. for Step 2

1. To main fuse 5.“EPS” warning lamp 9. P/S control module

2. Ignition switch 6. Speedometer 10. Connector “G24”

3.“P/S” fuse (30A) in fuse box 7. Combination meter

4.“IG METER” fuse (15A) in fuse box 8. To VSS

G24-2 G24-1

G24-8

G24-7 G24-5 1

23

4

5

67

89

BLK/WHT

BLK/WHTBLK/RED

YEL

PPL VBLK

G24-1

G24-5

G24-7G24-8G24-2

10

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” performed? Go to STEP 2. Go to “SYSTEM

CHECK FLOW TABLE”.

2 1) Ignition switch OFF.

2) Remove steering column lower cover.

3) Disconnect 8-terminals connector (“G24”) from

P/S control module.

4) Check proper connection to P/S control module

at “G24-7” (“PPL” wire) terminal.

5) If OK, connect voltmeter between “G24-7”

(“PPL” wire) terminal and body ground with con-

nector (“G24”) connected.

6) Hoist rear end of vehicle and lock rear right tire.

7) Turn rear left tire quickly with ignition switch ON.

Does voltmeter indicate deflection between 0 – 1 V

and 9 – 11 V a few times while tire is turned one

revolution?Check intermittent trou-

ble. Refer to “INTER-

MITTENT TROUBLE”

in SECTION 0A.

If OK, substitute a

known-good P/S control

module and recheck.Repair VSS or its (“PPL”

wire) circuit.

Page 161 of 698

3B1-20 ELECTRICAL POWER STEERING (P/S) SYSTEM

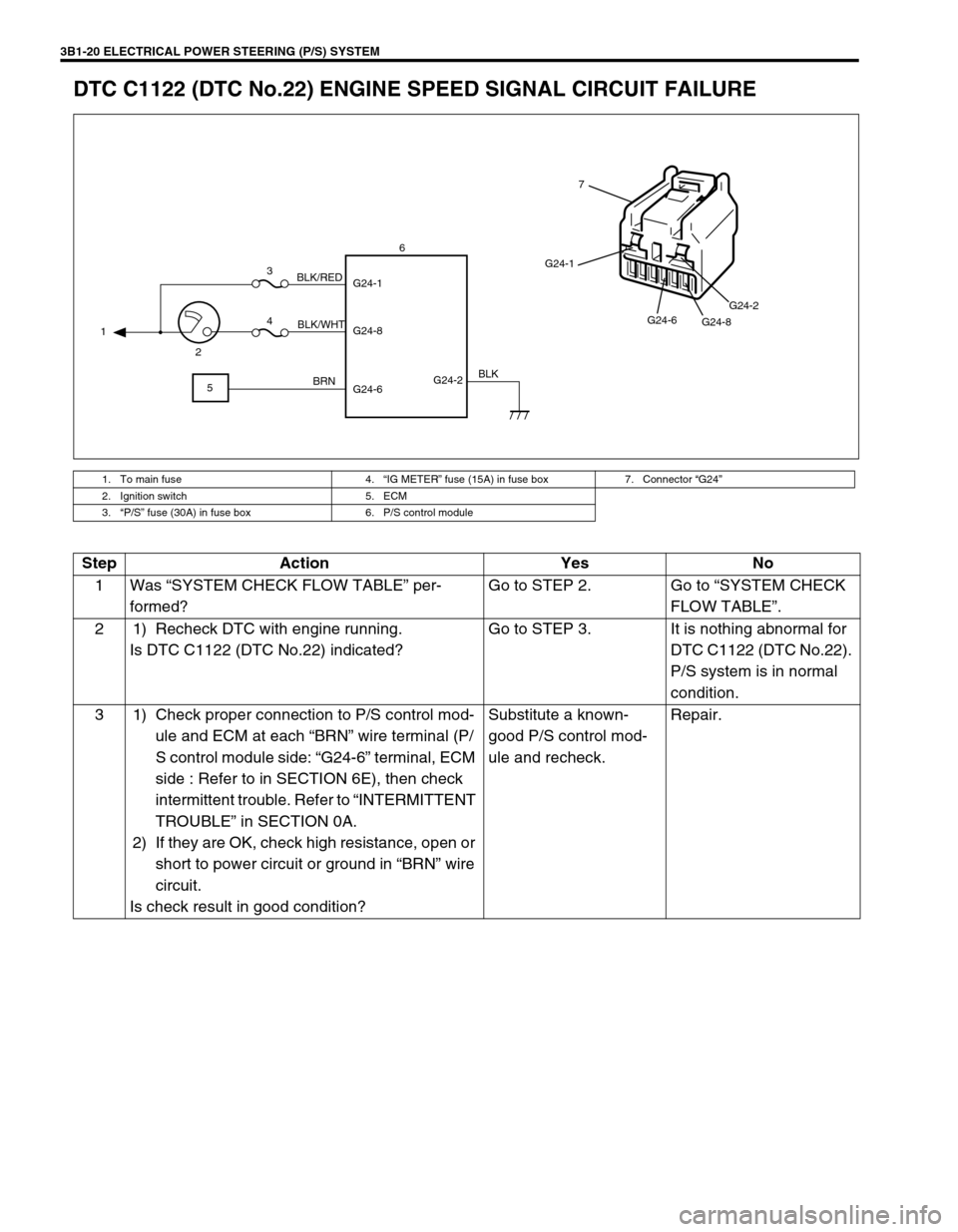

DTC C1122 (DTC No.22) ENGINE SPEED SIGNAL CIRCUIT FAILURE

1. To main fuse 4.“IG METER” fuse (15A) in fuse box 7. Connector “G24”

2. Ignition switch 5. ECM

3.“P/S” fuse (30A) in fuse box 6. P/S control module

G24-2 G24-1

G24-8

G24-6 1

23

4

56

BLK/WHT BLK/RED

BRNBLK

G24-1

G24-6

G24-8G24-2

7

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to STEP 2. Go to “SYSTEM CHECK

FLOW TABLE”.

2 1) Recheck DTC with engine running.

Is DTC C1122 (DTC No.22) indicated?Go to STEP 3. It is nothing abnormal for

DTC C1122 (DTC No.22).

P/S system is in normal

condition.

3 1) Check proper connection to P/S control mod-

ule and ECM at each “BRN” wire terminal (P/

S control module side: “G24-6” terminal, ECM

side : Refer to in SECTION 6E), then check

intermittent trouble. Refer to “INTERMITTENT

TROUBLE” in SECTION 0A.

2) If they are OK, check high resistance, open or

short to power circuit or ground in “BRN” wire

circuit.

Is check result in good condition?Substitute a known-

good P/S control mod-

ule and recheck.Repair.

Page 162 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-21

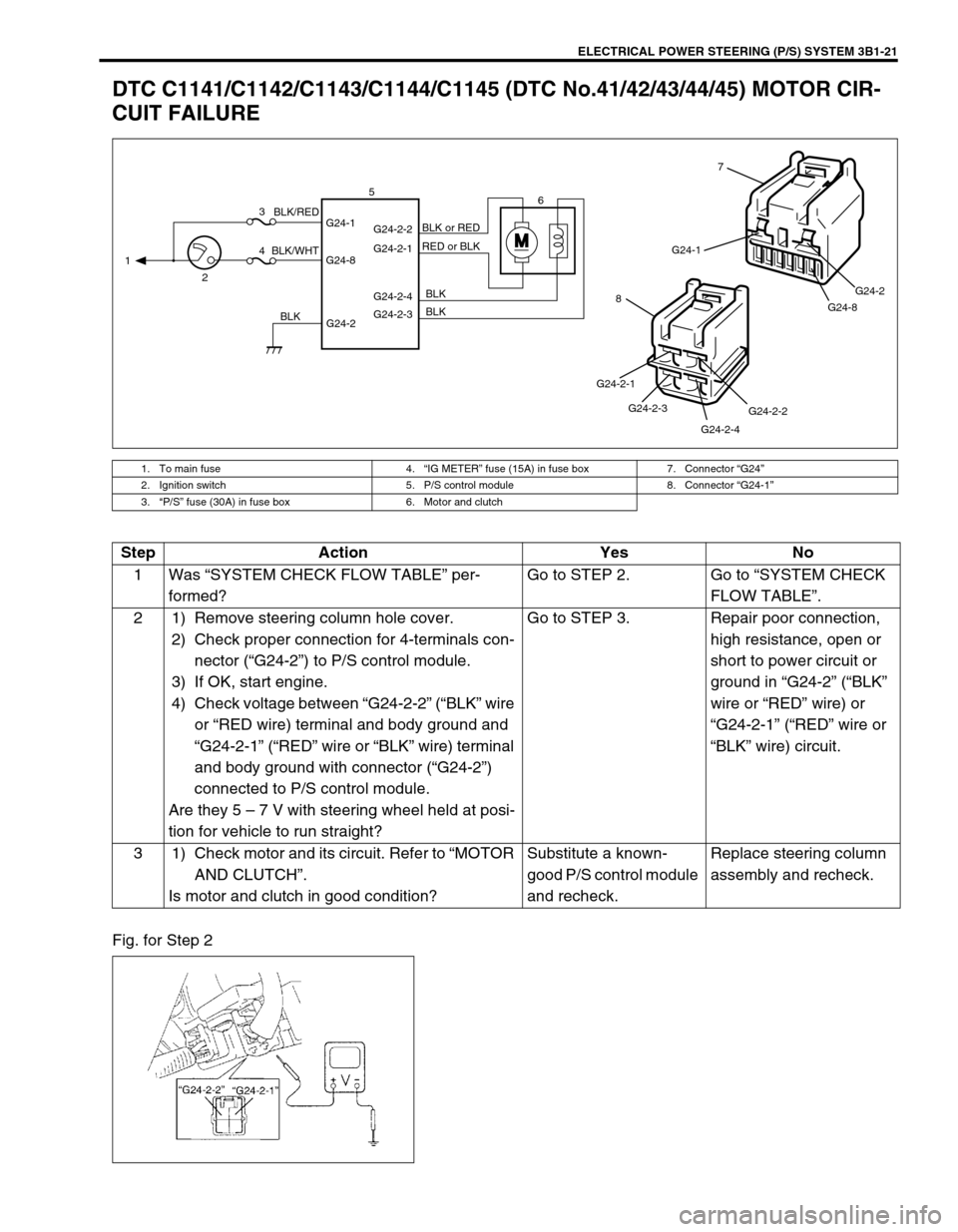

DTC C1141/C1142/C1143/C1144/C1145 (DTC No.41/42/43/44/45) MOTOR CIR-

CUIT FAILURE

Fig. for Step 2

1. To main fuse 4.“IG METER” fuse (15A) in fuse box 7. Connector “G24”

2. Ignition switch 5. P/S control module 8. Connector “G24-1”

3.“P/S” fuse (30A) in fuse box 6. Motor and clutch

MG24-1

G24-8G24-2

7

G24-2-2

G24-2-4 G24-2-3 G24-2-1

8

G24-2 G24-1

G24-8G24-2-2

G24-2-1

G24-2-4

G24-2-3 1

23

46 5

BLK/WHTBLK/RED

BLKBLK BLK RED or BLK BLK or RED

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to STEP 2. Go to “SYSTEM CHECK

FLOW TABLE”.

2 1) Remove steering column hole cover.

2) Check proper connection for 4-terminals con-

nector (“G24-2”) to P/S control module.

3) If OK, start engine.

4) Check voltage between “G24-2-2” (“BLK” wire

or “RED wire) terminal and body ground and

“G24-2-1” (“RED” wire or “BLK” wire) terminal

and body ground with connector (“G24-2”)

connected to P/S control module.

Are they 5 – 7 V with steering wheel held at posi-

tion for vehicle to run straight?Go to STEP 3. Repair poor connection,

high resistance, open or

short to power circuit or

ground in “G24-2” (“BLK”

wire or “RED” wire) or

“G24-2-1” (“RED” wire or

“BLK” wire) circuit.

3 1) Check motor and its circuit. Refer to “MOTOR

AND CLUTCH”.

Is motor and clutch in good condition?Substitute a known-

good P/S control module

and recheck.Replace steering column

assembly and recheck.

Page 163 of 698

3B1-22 ELECTRICAL POWER STEERING (P/S) SYSTEM

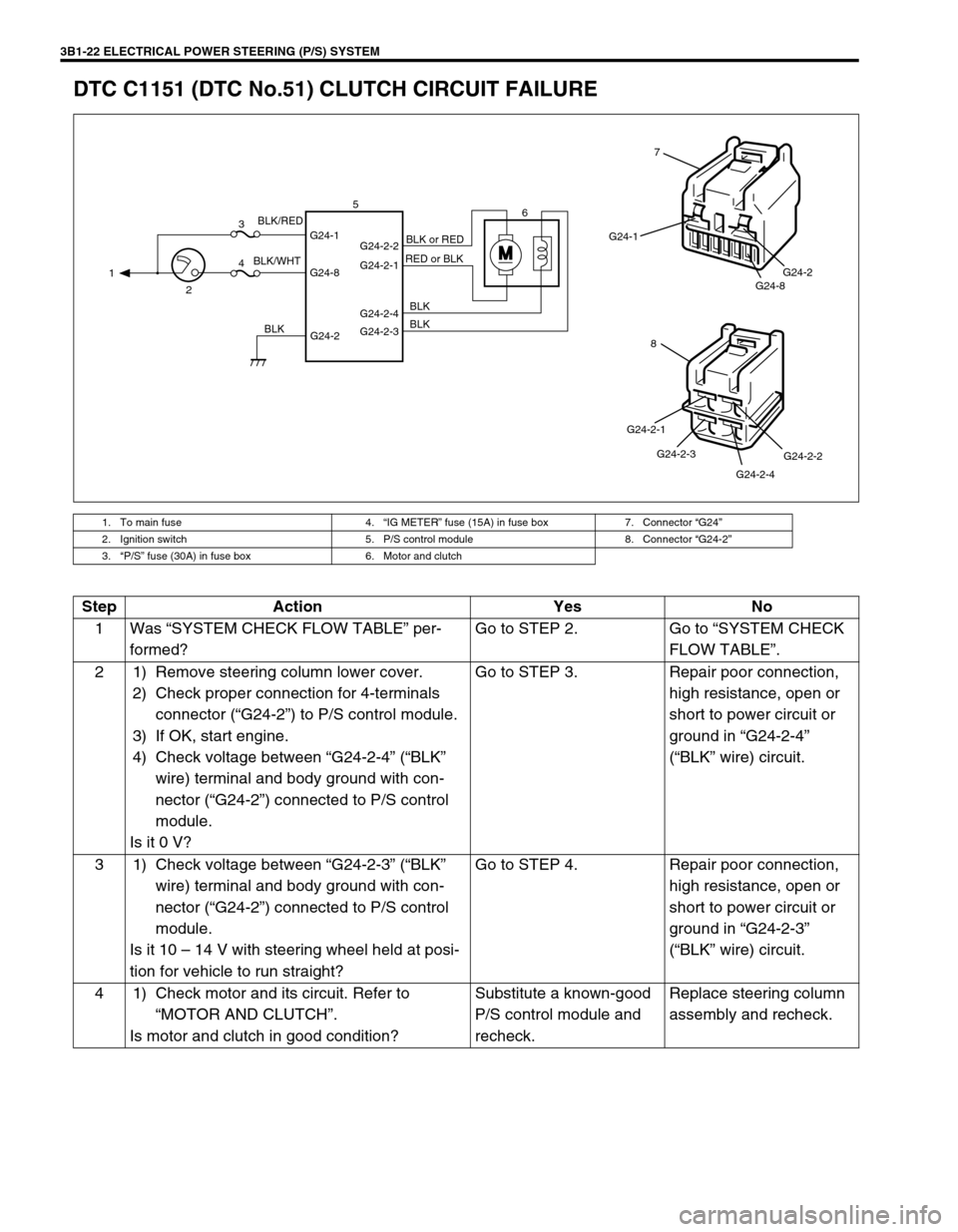

DTC C1151 (DTC No.51) CLUTCH CIRCUIT FAILURE

1. To main fuse 4.“IG METER” fuse (15A) in fuse box 7. Connector “G24”

2. Ignition switch 5. P/S control module 8. Connector “G24-2”

3.“P/S” fuse (30A) in fuse box 6. Motor and clutch

M

G24-2 G24-1

G24-8G24-2-2

G24-2-1

G24-2-4

G24-2-3 1

23

46 5

BLK/WHTBLK/RED

BLKBLK BLK RED or BLKBLK or RED

G24-1

G24-8G24-2

7

G24-2-2

G24-2-4 G24-2-3 G24-2-1

8

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to STEP 2. Go to “SYSTEM CHECK

FLOW TABLE”.

2 1) Remove steering column lower cover.

2) Check proper connection for 4-terminals

connector (“G24-2”) to P/S control module.

3) If OK, start engine.

4) Check voltage between “G24-2-4” (“BLK”

wire) terminal and body ground with con-

nector (“G24-2”) connected to P/S control

module.

Is it 0 V?Go to STEP 3. Repair poor connection,

high resistance, open or

short to power circuit or

ground in “G24-2-4”

(“BLK” wire) circuit.

3 1) Check voltage between “G24-2-3” (“BLK”

wire) terminal and body ground with con-

nector (“G24-2”) connected to P/S control

module.

Is it 10 – 14 V with steering wheel held at posi-

tion for vehicle to run straight?Go to STEP 4. Repair poor connection,

high resistance, open or

short to power circuit or

ground in “G24-2-3”

(“BLK” wire) circuit.

4 1) Check motor and its circuit. Refer to

“MOTOR AND CLUTCH”.

Is motor and clutch in good condition?Substitute a known-good

P/S control module and

recheck.Replace steering column

assembly and recheck.

Page 165 of 698

3B1-24 ELECTRICAL POWER STEERING (P/S) SYSTEM

DTC C1153(DTC No.53) P/S CONTROL MODULE POWER SUPPLY CIRCUIT

FAILURE

Fig. for Step 2

DTC C1152/C1154/C1155 (DTC No.52/54/55) P/S CONTROL MODULE FAILURE

Substitute a known-good P/S control module and recheck.

1. To main fuse 3.“P/S” fuse (30A) in fuse box 5. P/S control module

2. Ignition switch 4.“IG METER” fuse (15A) in fuse box 6. Connector “G24”

G24-2 G24-1

G24-8 13

45

BLK/WHT BLK/RED

BLK

G24-1

G24-8G24-2

6

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to STEP 2. Go to “SYSTEM CHECK

FLOW TABLE”.

2 1) Remove steering column lower cover.

2) Check “P/S” fuse and proper connection to

P/S control module at “G24-1” (“BLK/WHT”

wire) terminal.

3) If OK, check voltage between “G24-1” termi-

nal and body ground with connector (“G24”)

connected to P/S control module.

Is it 10 – 14 V?Check intermittent trou-

ble. Refer to “INTERMIT-

TENT TROUBLE” in

SECTION 0A.

If OK, substitute a known-

good P/S control module

and recheck.Repair poor connection or

high resistance in “G24-1”

(“BLK/RED” wire) circuit.

Page 332 of 698

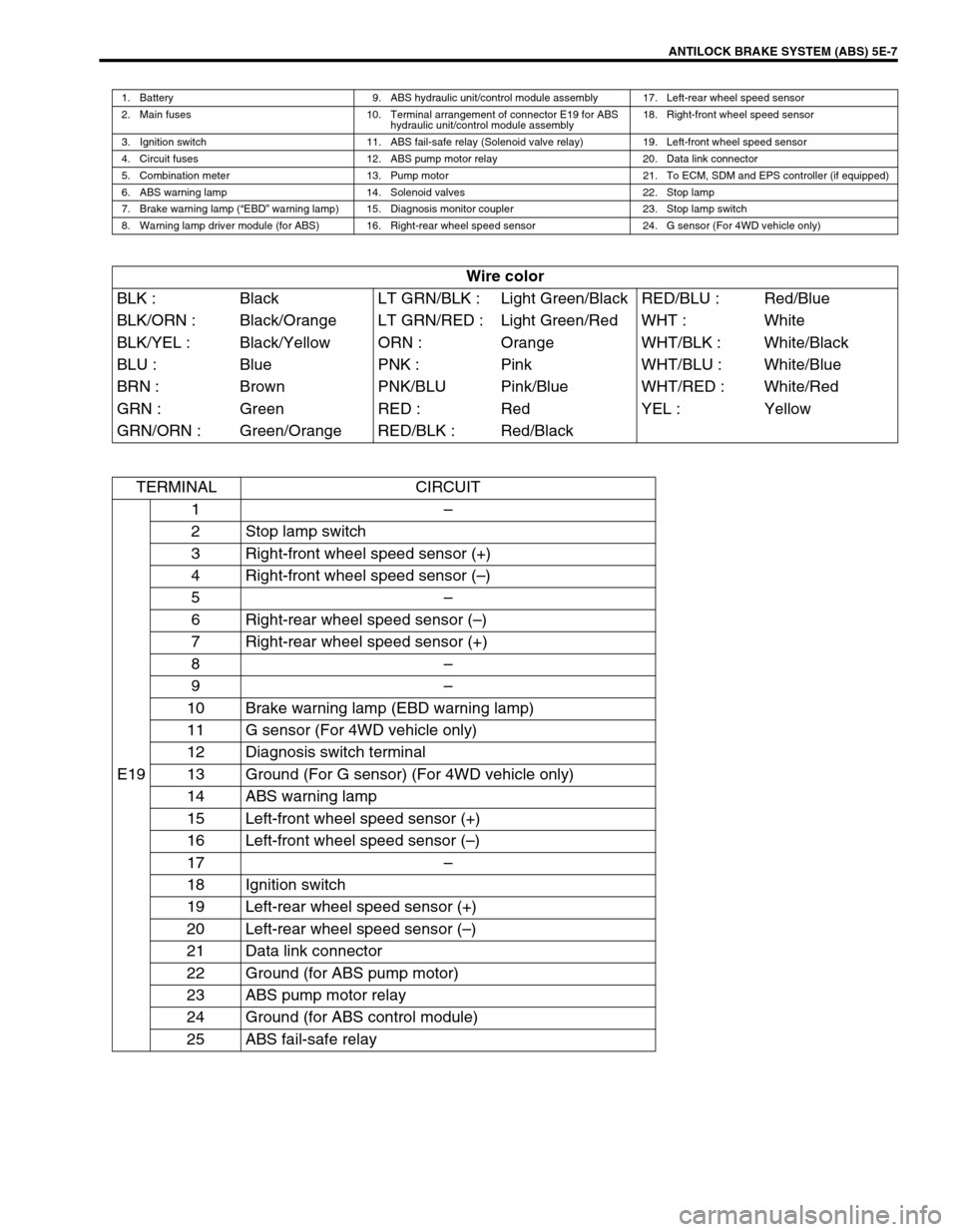

ANTILOCK BRAKE SYSTEM (ABS) 5E-7

1. Battery 9. ABS hydraulic unit/control module assembly 17. Left-rear wheel speed sensor

2. Main fuses 10. Terminal arrangement of connector E19 for ABS

hydraulic unit/control module assembly18. Right-front wheel speed sensor

3. Ignition switch 11. ABS fail-safe relay (Solenoid valve relay) 19. Left-front wheel speed sensor

4. Circuit fuses 12. ABS pump motor relay 20. Data link connector

5. Combination meter 13. Pump motor 21. To ECM, SDM and EPS controller (if equipped)

6. ABS warning lamp 14. Solenoid valves 22. Stop lamp

7. Brake warning lamp (“EBD” warning lamp) 15. Diagnosis monitor coupler 23. Stop lamp switch

8. Warning lamp driver module (for ABS) 16. Right-rear wheel speed sensor 24. G sensor (For 4WD vehicle only)

Wire color

BLK : Black LT GRN/BLK : Light Green/Black RED/BLU : Red/Blue

BLK/ORN : Black/Orange LT GRN/RED : Light Green/Red WHT : White

BLK/YEL : Black/Yellow ORN : Orange WHT/BLK : White/Black

BLU : Blue PNK : Pink WHT/BLU : White/Blue

BRN : Brown PNK/BLU Pink/Blue WHT/RED : White/Red

GRN : Green RED : Red YEL : Yellow

GRN/ORN : Green/Orange RED/BLK : Red/Black

TERMINAL CIRCUIT

E191–

2 Stop lamp switch

3 Right-front wheel speed sensor (+)

4 Right-front wheel speed sensor (–)

5–

6 Right-rear wheel speed sensor (–)

7 Right-rear wheel speed sensor (+)

8–

9–

10 Brake warning lamp (EBD warning lamp)

11 G sensor (For 4WD vehicle only)

12 Diagnosis switch terminal

13 Ground (For G sensor) (For 4WD vehicle only)

14 ABS warning lamp

15 Left-front wheel speed sensor (+)

16 Left-front wheel speed sensor (–)

17–

18 Ignition switch

19 Left-rear wheel speed sensor (+)

20 Left-rear wheel speed sensor (–)

21 Data link connector

22 Ground (for ABS pump motor)

23 ABS pump motor relay

24 Ground (for ABS control module)

25 ABS fail-safe relay