suspension SUZUKI SWIFT 2000 1.G RG413 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 115 of 698

3-6 STEERING, SUSPENSION, WHEELS AND TIRES

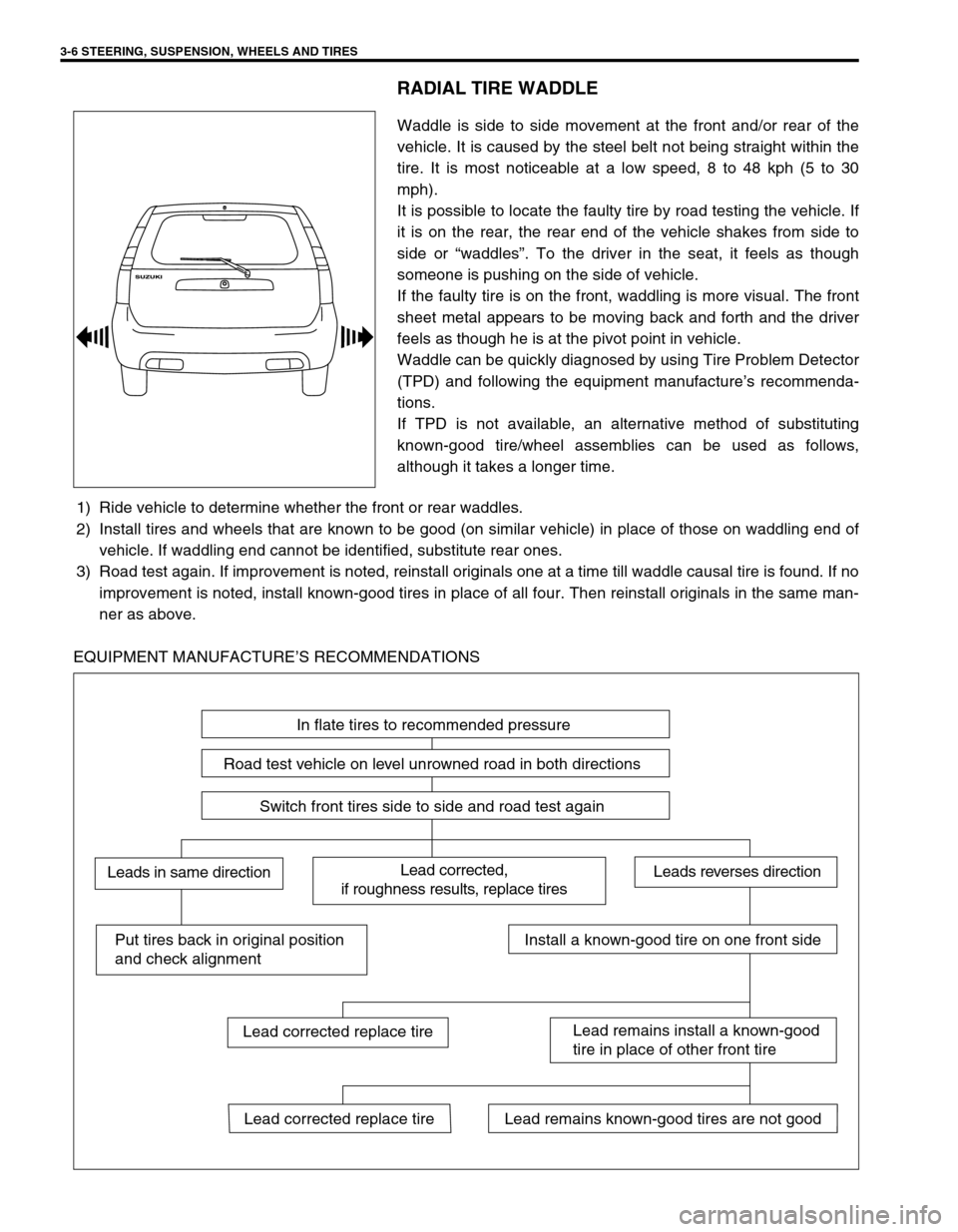

RADIAL TIRE WADDLE

Waddle is side to side movement at the front and/or rear of the

vehicle. It is caused by the steel belt not being straight within the

tire. It is most noticeable at a low speed, 8 to 48 kph (5 to 30

mph).

It is possible to locate the faulty tire by road testing the vehicle. If

it is on the rear, the rear end of the vehicle shakes from side to

side or “waddles”. To the driver in the seat, it feels as though

someone is pushing on the side of vehicle.

If the faulty tire is on the front, waddling is more visual. The front

sheet metal appears to be moving back and forth and the driver

feels as though he is at the pivot point in vehicle.

Waddle can be quickly diagnosed by using Tire Problem Detector

(TPD) and following the equipment manufacture’s recommenda-

tions.

If TPD is not available, an alternative method of substituting

known-good tire/wheel assemblies can be used as follows,

although it takes a longer time.

1) Ride vehicle to determine whether the front or rear waddles.

2) Install tires and wheels that are known to be good (on similar vehicle) in place of those on waddling end of

vehicle. If waddling end cannot be identified, substitute rear ones.

3) Road test again. If improvement is noted, reinstall originals one at a time till waddle causal tire is found. If no

improvement is noted, install known-good tires in place of all four. Then reinstall originals in the same man-

ner as above.

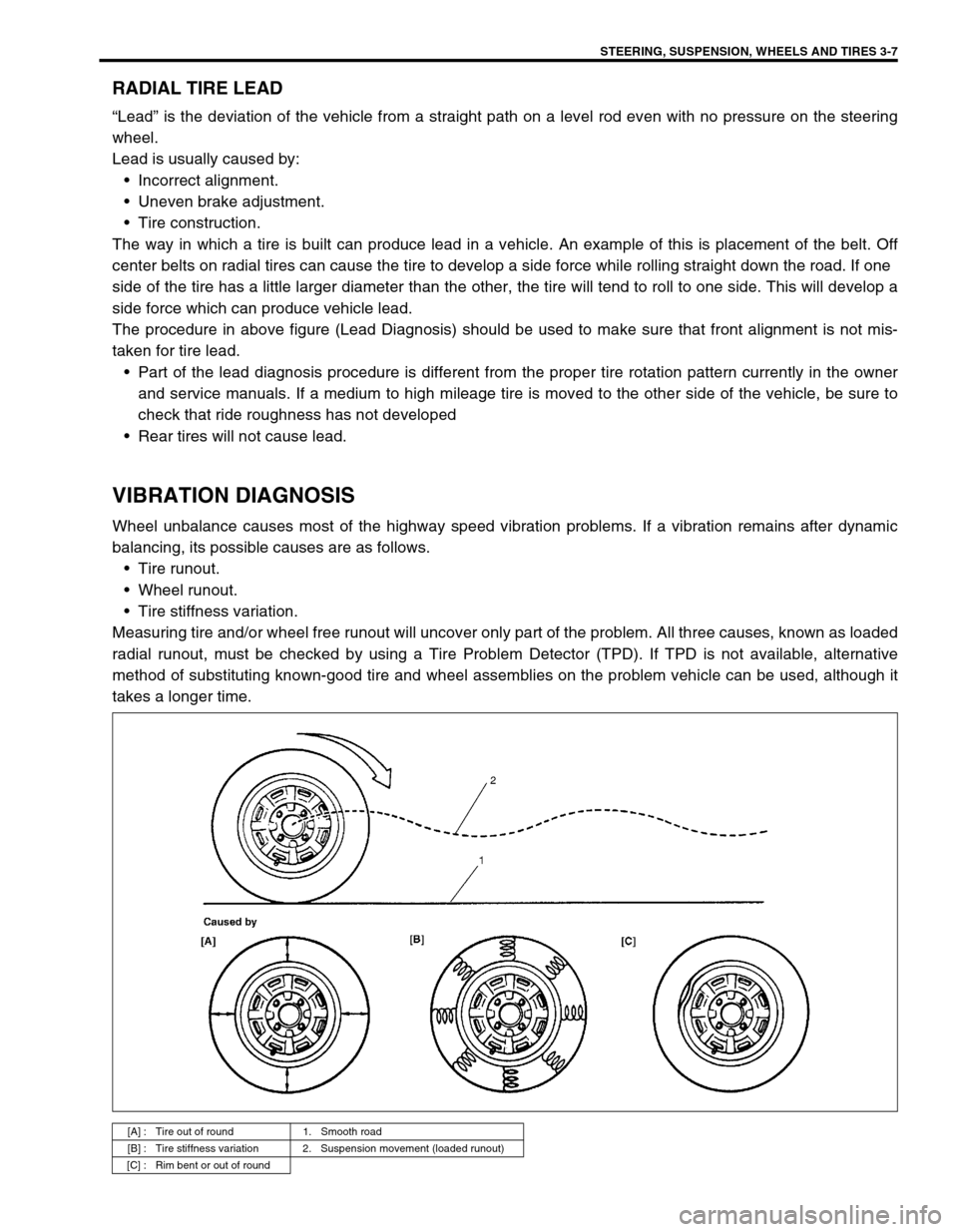

EQUIPMENT MANUFACTURE’S RECOMMENDATIONS

In flate tires to recommended pressure

Road test vehicle on level unrowned road in both directions

Switch front tires side to side and road test again

Lead corrected,

if roughness results, replace tiresLeads in same directionLeads reverses direction

Put tires back in original position

and check alignmentInstall a known-good tire on one front side

Lead remains install a known-good

tire in place of other front tire

Lead remains known-good tires are not goodLead corrected replace tire

Lead corrected replace tire

Page 116 of 698

STEERING, SUSPENSION, WHEELS AND TIRES 3-7

RADIAL TIRE LEAD

“Lead” is the deviation of the vehicle from a straight path on a level rod even with no pressure on the steering

wheel.

Lead is usually caused by:

Incorrect alignment.

Uneven brake adjustment.

Tire construction.

The way in which a tire is built can produce lead in a vehicle. An example of this is placement of the belt. Off

center belts on radial tires can cause the tire to develop a side force while rolling straight down the road. If one

side of the tire has a little larger diameter than the other, the tire will tend to roll to one side. This will develop a

side force which can produce vehicle lead.

The procedure in above figure (Lead Diagnosis) should be used to make sure that front alignment is not mis-

taken for tire lead.

Part of the lead diagnosis procedure is different from the proper tire rotation pattern currently in the owner

and service manuals. If a medium to high mileage tire is moved to the other side of the vehicle, be sure to

check that ride roughness has not developed

Rear tires will not cause lead.

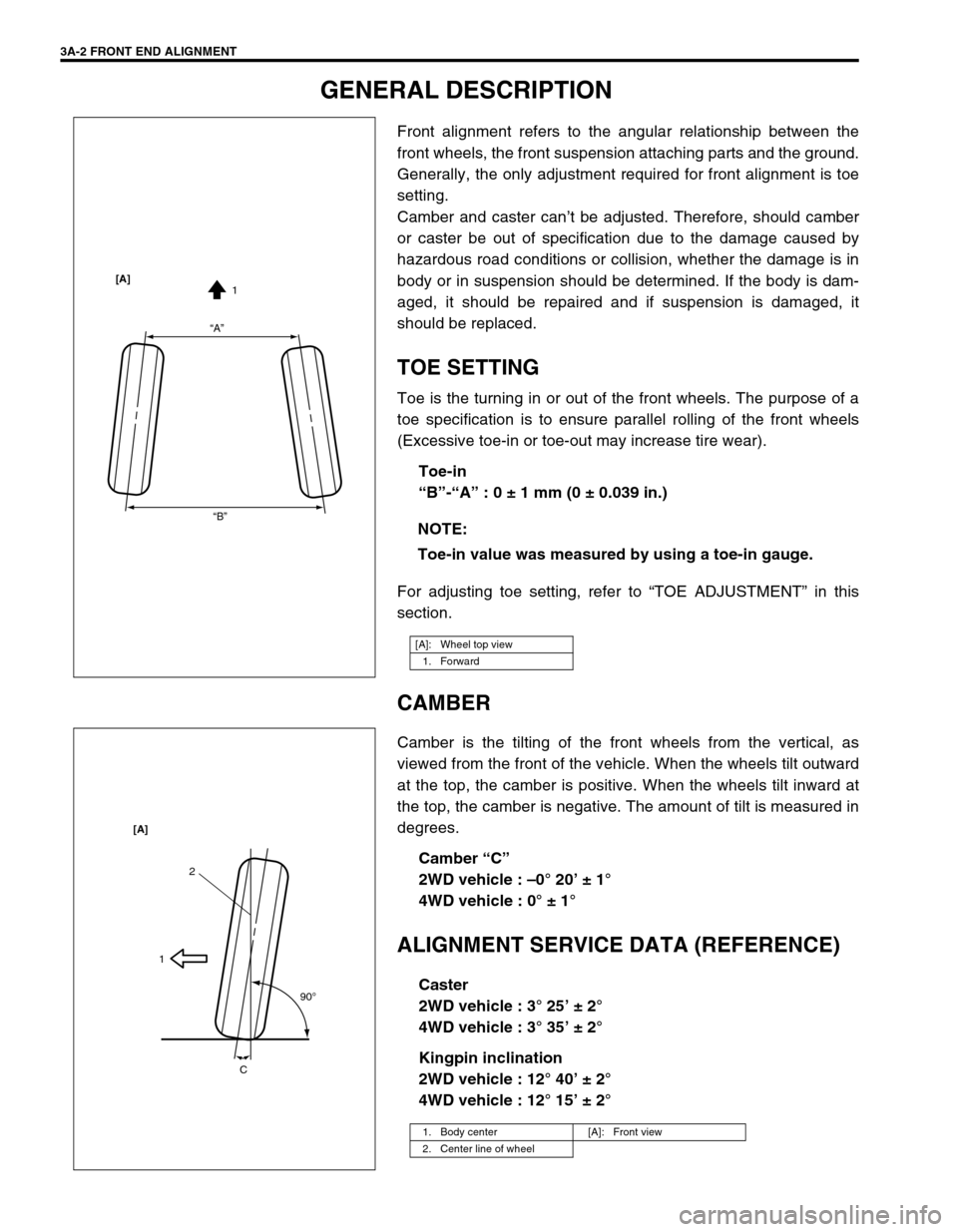

VIBRATION DIAGNOSIS

Wheel unbalance causes most of the highway speed vibration problems. If a vibration remains after dynamic

balancing, its possible causes are as follows.

Tire runout.

Wheel runout.

Tire stiffness variation.

Measuring tire and/or wheel free runout will uncover only part of the problem. All three causes, known as loaded

radial runout, must be checked by using a Tire Problem Detector (TPD). If TPD is not available, alternative

method of substituting known-good tire and wheel assemblies on the problem vehicle can be used, although it

takes a longer time.

[A] : Tire out of round 1. Smooth road

[B] : Tire stiffness variation 2. Suspension movement (loaded runout)

[C] : Rim bent or out of round

Page 117 of 698

3-8 STEERING, SUSPENSION, WHEELS AND TIRES

Page 119 of 698

3A-2 FRONT END ALIGNMENT

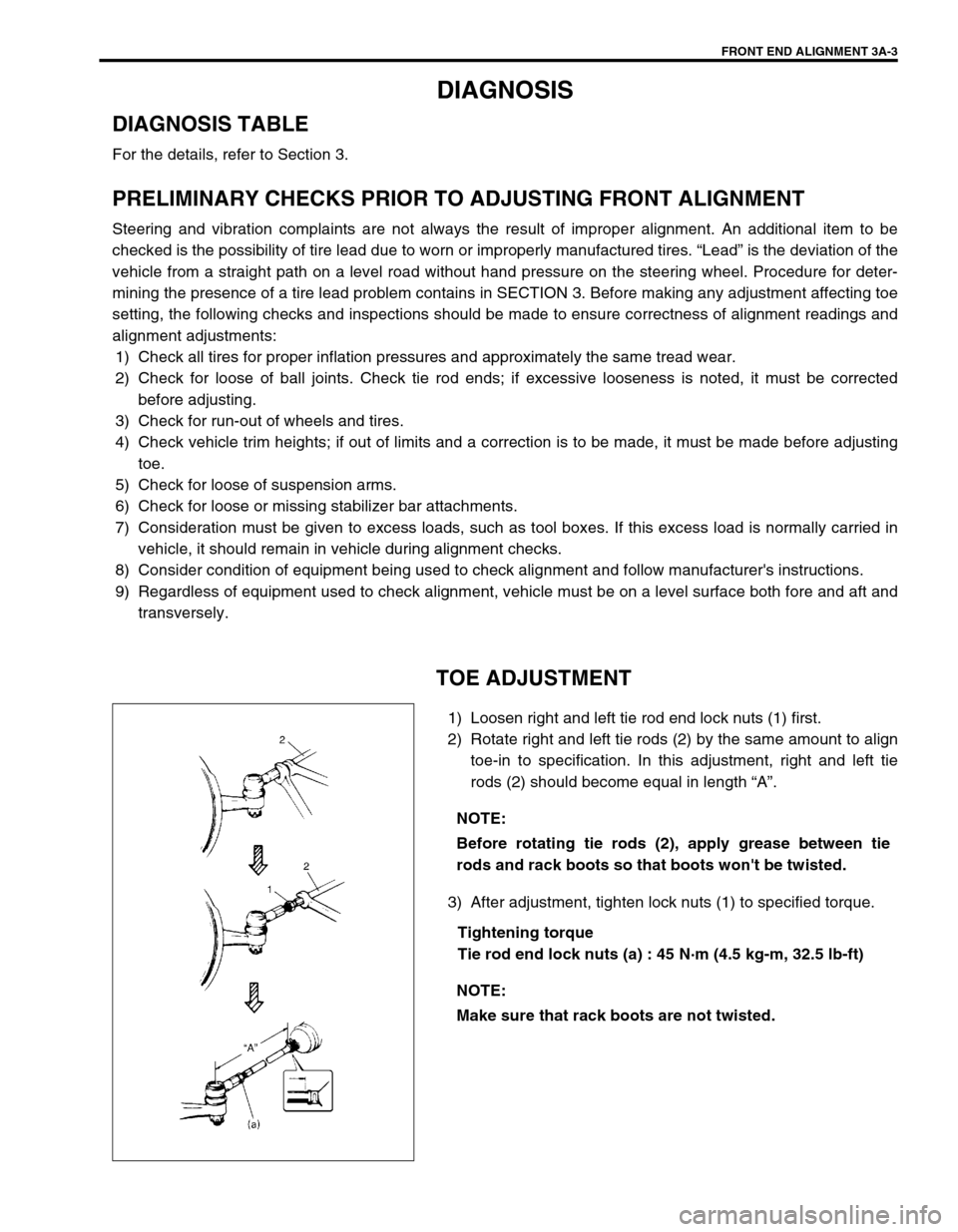

GENERAL DESCRIPTION

Front alignment refers to the angular relationship between the

front wheels, the front suspension attaching parts and the ground.

Generally, the only adjustment required for front alignment is toe

setting.

Camber and caster can’t be adjusted. Therefore, should camber

or caster be out of specification due to the damage caused by

hazardous road conditions or collision, whether the damage is in

body or in suspension should be determined. If the body is dam-

aged, it should be repaired and if suspension is damaged, it

should be replaced.

TOE SETTING

Toe is the turning in or out of the front wheels. The purpose of a

toe specification is to ensure parallel rolling of the front wheels

(Excessive toe-in or toe-out may increase tire wear).

Toe-in

“B”-“A” : 0 ± 1 mm (0 ± 0.039 in.)

For adjusting toe setting, refer to “TOE ADJUSTMENT” in this

section.

CAMBER

Camber is the tilting of the front wheels from the vertical, as

viewed from the front of the vehicle. When the wheels tilt outward

at the top, the camber is positive. When the wheels tilt inward at

the top, the camber is negative. The amount of tilt is measured in

degrees.

Camber “C”

2WD vehicle : –0° 20’ ± 1°

4WD vehicle : 0° ± 1°

ALIGNMENT SERVICE DATA (REFERENCE)

Caster

2WD vehicle : 3° 25’ ± 2°

4WD vehicle : 3° 35’ ± 2°

Kingpin inclination

2WD vehicle : 12° 40’ ± 2°

4WD vehicle : 12° 15’ ± 2° NOTE:

Toe-in value was measured by using a toe-in gauge.

[A]: Wheel top view

1. Forward

“A”

“B”1 [A]

1. Body center [A]: Front view

2. Center line of wheel

2

1

90

o

C [A]

Page 120 of 698

FRONT END ALIGNMENT 3A-3

DIAGNOSIS

DIAGNOSIS TABLE

For the details, refer to Section 3.

PRELIMINARY CHECKS PRIOR TO ADJUSTING FRONT ALIGNMENT

Steering and vibration complaints are not always the result of improper alignment. An additional item to be

checked is the possibility of tire lead due to worn or improperly manufactured tires. “Lead” is the deviation of the

vehicle from a straight path on a level road without hand pressure on the steering wheel. Procedure for deter-

mining the presence of a tire lead problem contains in SECTION 3. Before making any adjustment affecting toe

setting, the following checks and inspections should be made to ensure correctness of alignment readings and

alignment adjustments:

1) Check all tires for proper inflation pressures and approximately the same tread wear.

2) Check for loose of ball joints. Check tie rod ends; if excessive looseness is noted, it must be corrected

before adjusting.

3) Check for run-out of wheels and tires.

4) Check vehicle trim heights; if out of limits and a correction is to be made, it must be made before adjusting

toe.

5) Check for loose of suspension arms.

6) Check for loose or missing stabilizer bar attachments.

7) Consideration must be given to excess loads, such as tool boxes. If this excess load is normally carried in

vehicle, it should remain in vehicle during alignment checks.

8) Consider condition of equipment being used to check alignment and follow manufacturer's instructions.

9) Regardless of equipment used to check alignment, vehicle must be on a level surface both fore and aft and

transversely.

TOE ADJUSTMENT

1) Loosen right and left tie rod end lock nuts (1) first.

2) Rotate right and left tie rods (2) by the same amount to align

toe-in to specification. In this adjustment, right and left tie

rods (2) should become equal in length “A”.

3) After adjustment, tighten lock nuts (1) to specified torque.

Tightening torque

Tie rod end lock nuts (a) : 45 N·m (4.5 kg-m, 32.5 lb-ft) NOTE:

Before rotating tie rods (2), apply grease between tie

rods and rack boots so that boots won't be twisted.

NOTE:

Make sure that rack boots are not twisted.

Page 121 of 698

3A-4 FRONT END ALIGNMENT

CAMBER AND CASTER CHECK AND

ADJUSTMENT

Should camber or caster be found out of specifications upon

inspection, locate its cause first.

If it is in damaged, loose, bent, dented or worn suspension parts,

they should be replaced.

If it is in vehicle body, repair it so as to attain specifications.

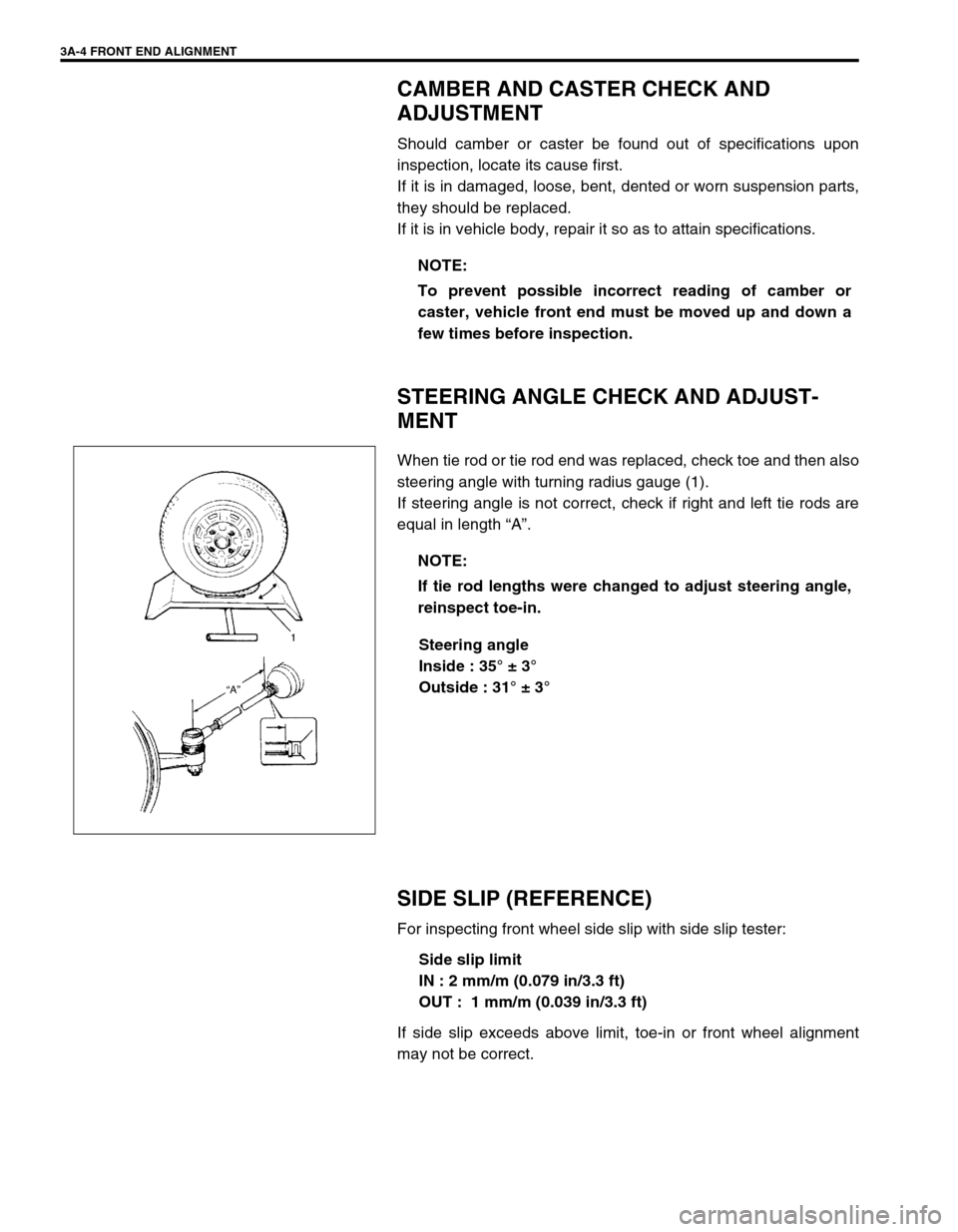

STEERING ANGLE CHECK AND ADJUST-

MENT

When tie rod or tie rod end was replaced, check toe and then also

steering angle with turning radius gauge (1).

If steering angle is not correct, check if right and left tie rods are

equal in length “A”.

Steering angle

Inside : 35° ± 3°

Outside : 31° ± 3°

SIDE SLIP (REFERENCE)

For inspecting front wheel side slip with side slip tester:

Side slip limit

IN : 2 mm/m (0.079 in/3.3 ft)

OUT : 1 mm/m (0.039 in/3.3 ft)

If side slip exceeds above limit, toe-in or front wheel alignment

may not be correct.NOTE:

To prevent possible incorrect reading of camber or

caster, vehicle front end must be moved up and down a

few times before inspection.

NOTE:

If tie rod lengths were changed to adjust steering angle,

reinspect toe-in.

Page 194 of 698

FRONT SUSPENSION 3D-1

6F1

6F2

6G

1A

6K

7A

7A1

7B1

7C1

3D

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3D

FRONT SUSPENSION

CONTENTS

GENERAL DESCRIPTION .............................. 3D-1

DIAGNOSIS ..................................................... 3D-3

STABILIZER BAR AND/OR BUSHING

CHECK ......................................................... 3D-3

STRUT ASSEMBLY CHECK ....................... 3D-3

SUSPENSION CONTROL ARM / STEERING

KNUCKLE CHECK ....................................... 3D-4

SUSPENSION CONTROL ARM BUSHING

CHECK ......................................................... 3D-4

SUSPENSION CONTROL ARM JOINT

CHECK ......................................................... 3D-4

FRONT SUSPENSION FASTENERS

CHECK ......................................................... 3D-5WHEEL DISC, NUT AND BEARING

CHECK ........................................................ 3D-5

ON-VEHICLE SERVICE .................................. 3D-6

STRUT ASSEMBLY..................................... 3D-6

STABILIZER BAR AND/OR BUSHINGS ..... 3D-9

WHEEL HUB AND STEERING

KNUCKLE .................................................. 3D-11

SUSPENSION CONTROL ARM /

BUSHING................................................... 3D-16

REQUIRED SERVICE MATERIAL................ 3D-19

SPECIAL TOOL ............................................ 3D-19

GENERAL DESCRIPTION

The front suspension is the strut type independent suspension. The upper end of a strut is anchored to the vehi-

cle body by a strut support. The strut and strut support are isolated by a rubber mount. A strut bearing is also

installed a little lower to the rubber mount.

The lower end of the strut is connected to the upper end of a steering knuckle and lower end of knuckle is

attached to the stud of a ball joint which is incorporated in a unit with a suspension control arm. And connected

to this steering knuckle is the tie rod end.

Thus, movement of the steering wheel is transmitted to the tie rod end and then to the knuckle, eventually caus-

ing the wheel-and-tire to move. In this operation, with the movement of the knuckle, the strut also rotates by

means of the strut bearing and lower ball joint.NOTE:

All front suspension fasteners are an important attaching part in that it could affect the perfor-

mance of vital parts and systems, and/or could result in major repair expense. They must be

replaced with one of the same part number or with an equivalent part if replacement becomes nec-

essary. Do not use a replacement part of lesser quality or substitute design. Torque values must be

used as specified during reassembly to assure proper retention of this part.

Never attempt to heat, quench or straighten any front suspension part. Replace it with a new part or

damage to the part may result.

Page 195 of 698

![SUZUKI SWIFT 2000 1.G RG413 Service User Guide 3D-2 FRONT SUSPENSION

1. Strut assembly 4. Wheel 7. Drive shaft [A] : FORWARD

2. Stabilizer bar 5. Suspension control arm 8. Tie rod Tightening torque

3. Steering knuckle 6. Vehicle body 9. Brake disc SUZUKI SWIFT 2000 1.G RG413 Service User Guide 3D-2 FRONT SUSPENSION

1. Strut assembly 4. Wheel 7. Drive shaft [A] : FORWARD

2. Stabilizer bar 5. Suspension control arm 8. Tie rod Tightening torque

3. Steering knuckle 6. Vehicle body 9. Brake disc](/img/20/7606/w960_7606-194.png)

3D-2 FRONT SUSPENSION

1. Strut assembly 4. Wheel 7. Drive shaft [A] : FORWARD

2. Stabilizer bar 5. Suspension control arm 8. Tie rod Tightening torque

3. Steering knuckle 6. Vehicle body 9. Brake disc Do not reuse.

[A]

4

92

35

8

660 N·m(6.0 kg-m) 175 N·m(17.5 kg-m)

60 N·m(6.0 kg-m)

85 N·m(8.5 kg-m)

85 N·m(8.5 kg-m)

43 N·m(4.3 kg-m)

65 N·m(6.5 kg-m)

65 N·m(6.5 kg-m)

23 N·m(2.3 kg-m)

50 N·m(5.0 kg-m)

175 N·m(17.5 kg-m)

105 N·m(10.5 kg-m)

1

8

45 N·m (4.5kg-m) 7

5

4

9

Page 196 of 698

FRONT SUSPENSION 3D-3

DIAGNOSIS

STABILIZER BAR AND/OR BUSHING CHECK

Bar

Inspect for damage or deformation.

If defective, replace.

Bushing

Inspect for damage, wear or deterioration.

If defective, replace.

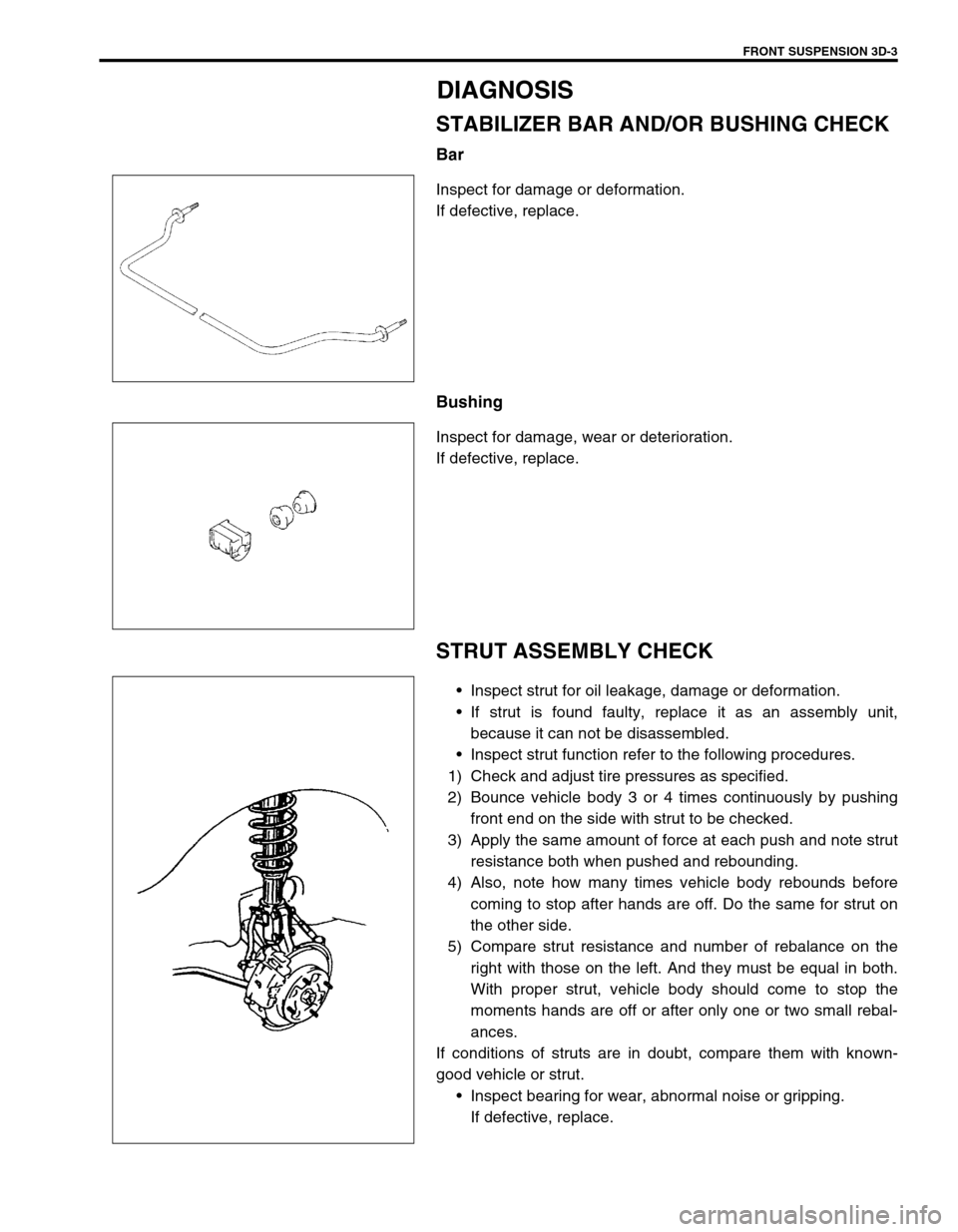

STRUT ASSEMBLY CHECK

Inspect strut for oil leakage, damage or deformation.

If strut is found faulty, replace it as an assembly unit,

because it can not be disassembled.

Inspect strut function refer to the following procedures.

1) Check and adjust tire pressures as specified.

2) Bounce vehicle body 3 or 4 times continuously by pushing

front end on the side with strut to be checked.

3) Apply the same amount of force at each push and note strut

resistance both when pushed and rebounding.

4) Also, note how many times vehicle body rebounds before

coming to stop after hands are off. Do the same for strut on

the other side.

5) Compare strut resistance and number of rebalance on the

right with those on the left. And they must be equal in both.

With proper strut, vehicle body should come to stop the

moments hands are off or after only one or two small rebal-

ances.

If conditions of struts are in doubt, compare them with known-

good vehicle or strut.

Inspect bearing for wear, abnormal noise or gripping.

If defective, replace.

Page 197 of 698

3D-4 FRONT SUSPENSION

Inspect spring seat for cracks or deformation.

If defective, replace.

Inspect bump stopper for deterioration.

If defective, replace.

Inspect rebound stopper and strut mount for wear, cracks or

deformation.

If defective, replace.

SUSPENSION CONTROL ARM / STEERING

KNUCKLE CHECK

Inspect for cracks, deformation or damage.

If defective, replace.

SUSPENSION CONTROL ARM BUSHING

CHECK

Inspect for damage, wear or deterioration.

If defective, replace.

SUSPENSION CONTROL ARM JOINT CHECK

Check for smooth rotation.

Inspect ball stud for damage.

Inspect dust cover for damage.

If there is any damage to either, control arm assembly must be

replaced as a complete unit.

NOTE:

Suspension control arm and arm joint cannot be sepa-

rated.