SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 21 of 698

0A-18 GENERAL INFORMATION

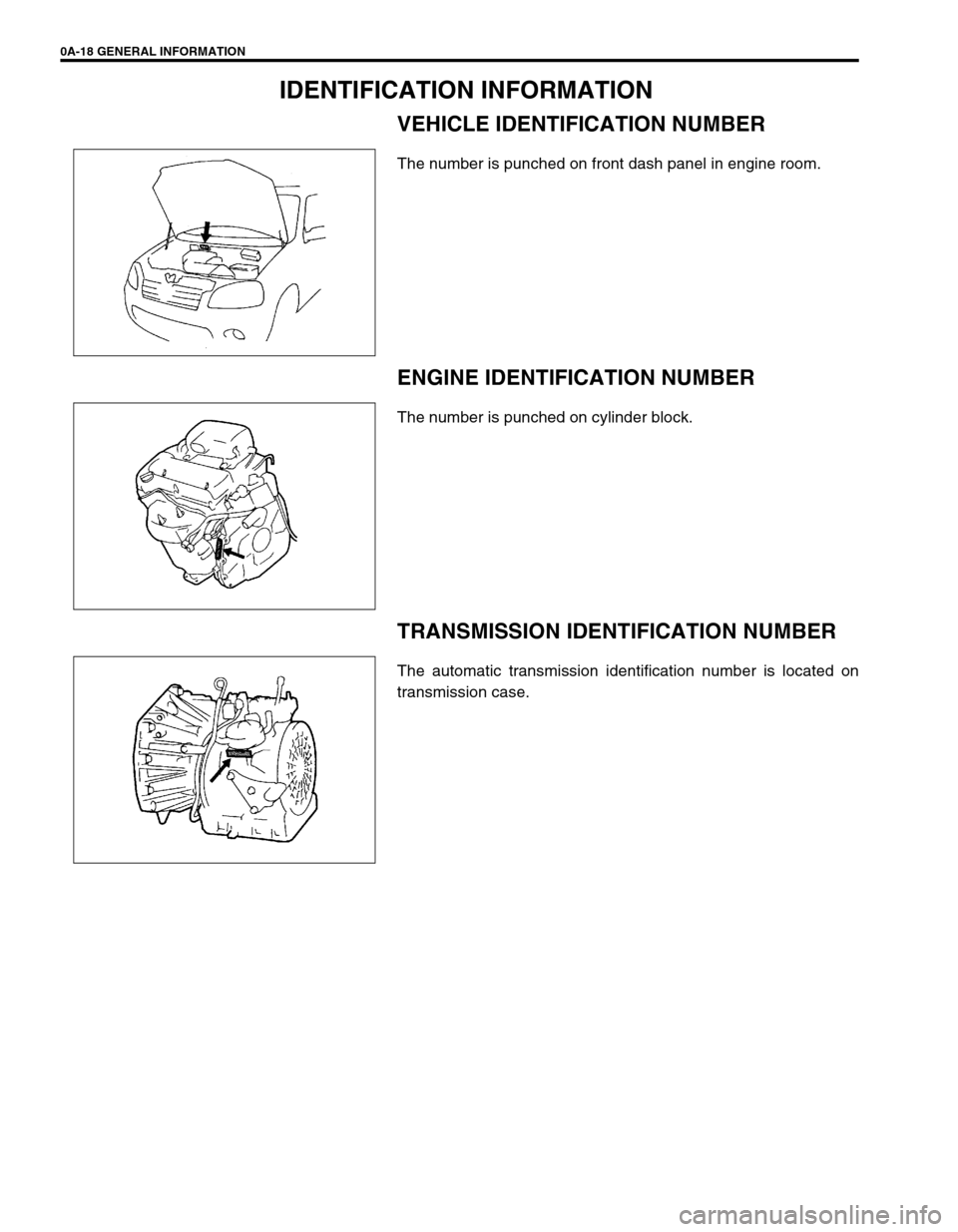

IDENTIFICATION INFORMATION

VEHICLE IDENTIFICATION NUMBER

The number is punched on front dash panel in engine room.

ENGINE IDENTIFICATION NUMBER

The number is punched on cylinder block.

TRANSMISSION IDENTIFICATION NUMBER

The automatic transmission identification number is located on

transmission case.

Page 22 of 698

GENERAL INFORMATION 0A-19

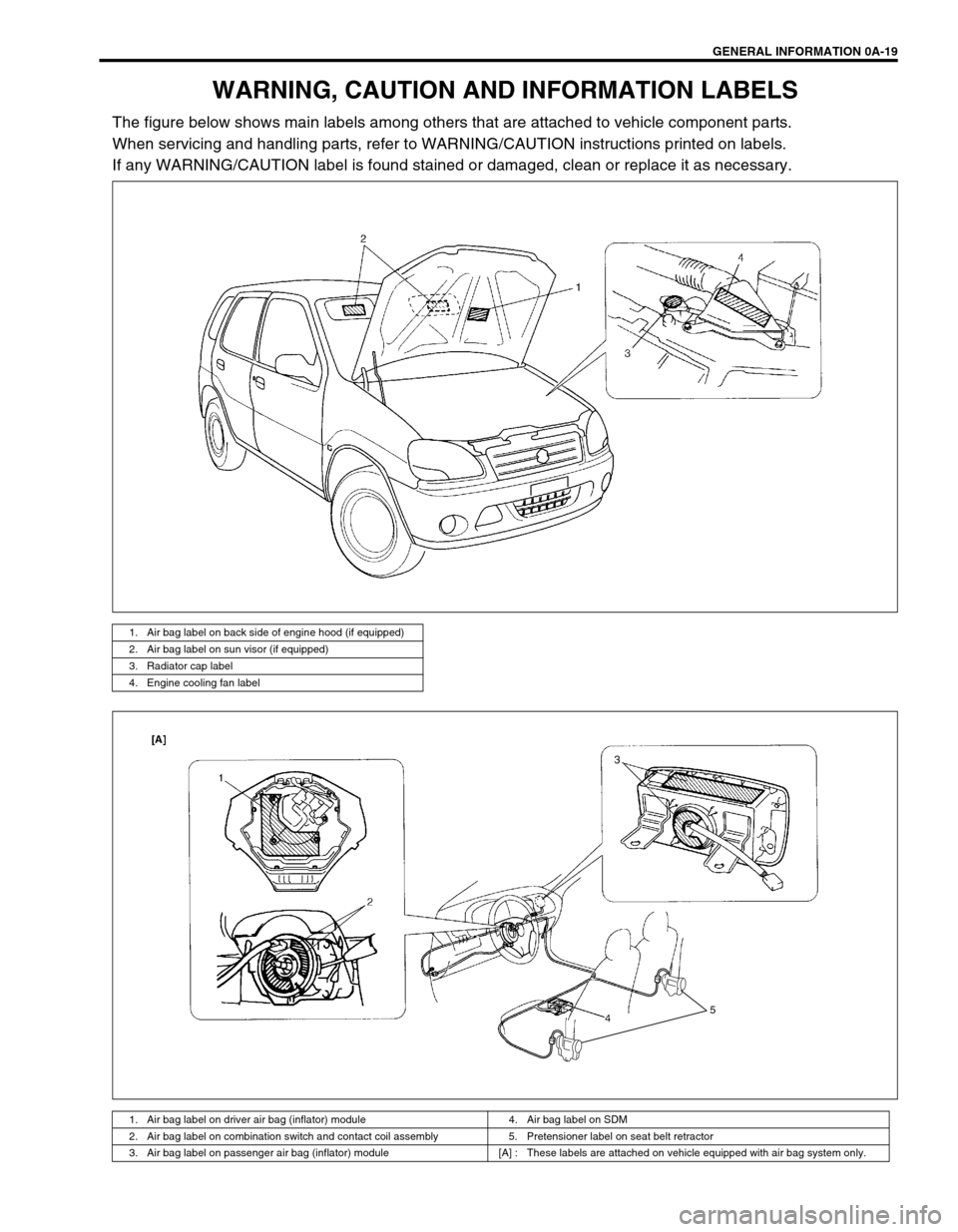

WARNING, CAUTION AND INFORMATION LABELS

The figure below shows main labels among others that are attached to vehicle component parts.

When servicing and handling parts, refer to WARNING/CAUTION instructions printed on labels.

If any WARNING/CAUTION label is found stained or damaged, clean or replace it as necessary.

1. Air bag label on back side of engine hood (if equipped)

2. Air bag label on sun visor (if equipped)

3. Radiator cap label

4. Engine cooling fan label

1. Air bag label on driver air bag (inflator) module 4. Air bag label on SDM

2. Air bag label on combination switch and contact coil assembly 5. Pretensioner label on seat belt retractor

3. Air bag label on passenger air bag (inflator) module [A] : These labels are attached on vehicle equipped with air bag system only.

5

Page 23 of 698

0A-20 GENERAL INFORMATION

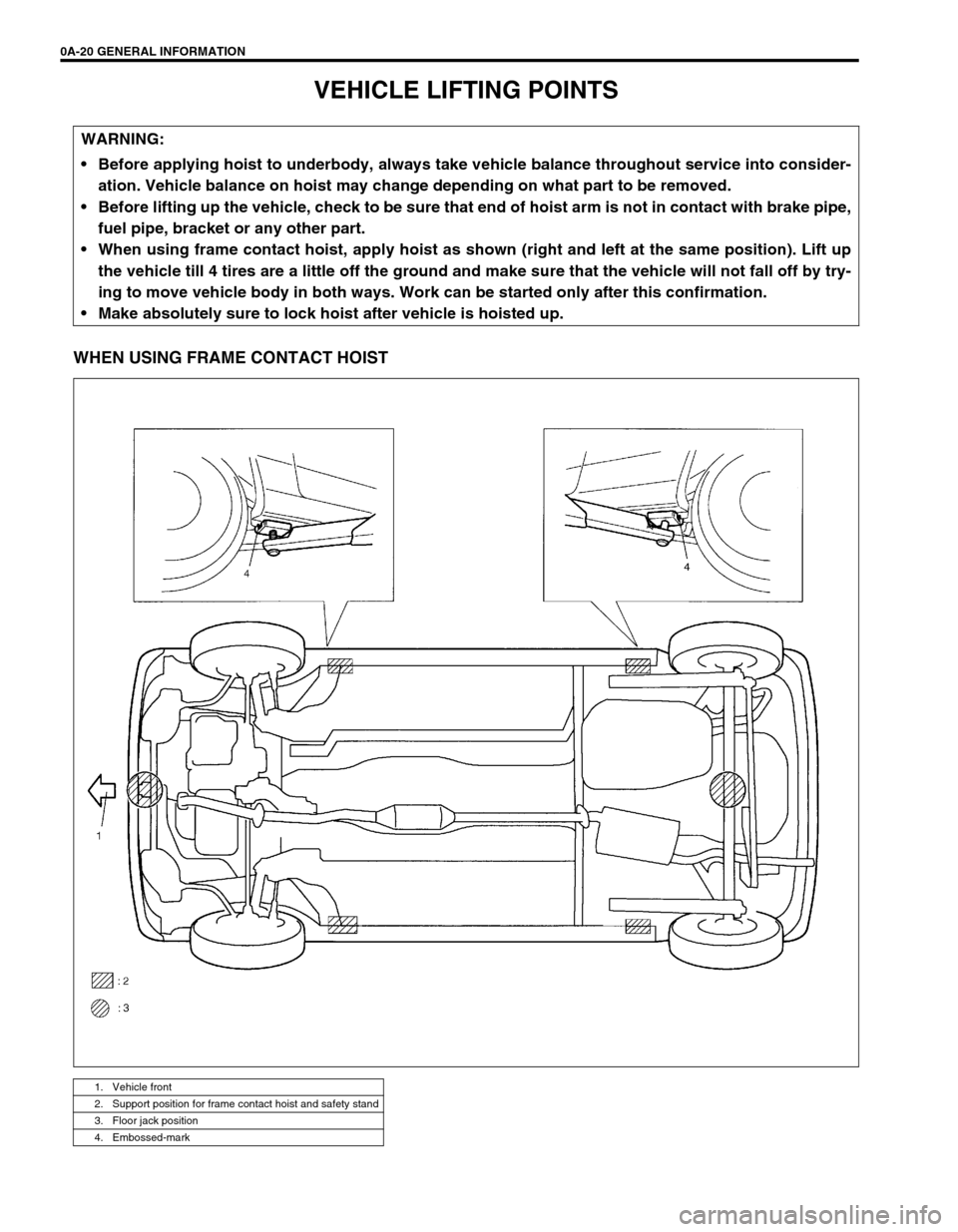

VEHICLE LIFTING POINTS

WHEN USING FRAME CONTACT HOIST

WARNING:

Before applying hoist to underbody, always take vehicle balance throughout service into consider-

ation. Vehicle balance on hoist may change depending on what part to be removed.

Before lifting up the vehicle, check to be sure that end of hoist arm is not in contact with brake pipe,

fuel pipe, bracket or any other part.

When using frame contact hoist, apply hoist as shown (right and left at the same position). Lift up

the vehicle till 4 tires are a little off the ground and make sure that the vehicle will not fall off by try-

ing to move vehicle body in both ways. Work can be started only after this confirmation.

Make absolutely sure to lock hoist after vehicle is hoisted up.

1. Vehicle front

2. Support position for frame contact hoist and safety stand

3. Floor jack position

4. Embossed-mark

Page 24 of 698

GENERAL INFORMATION 0A-21

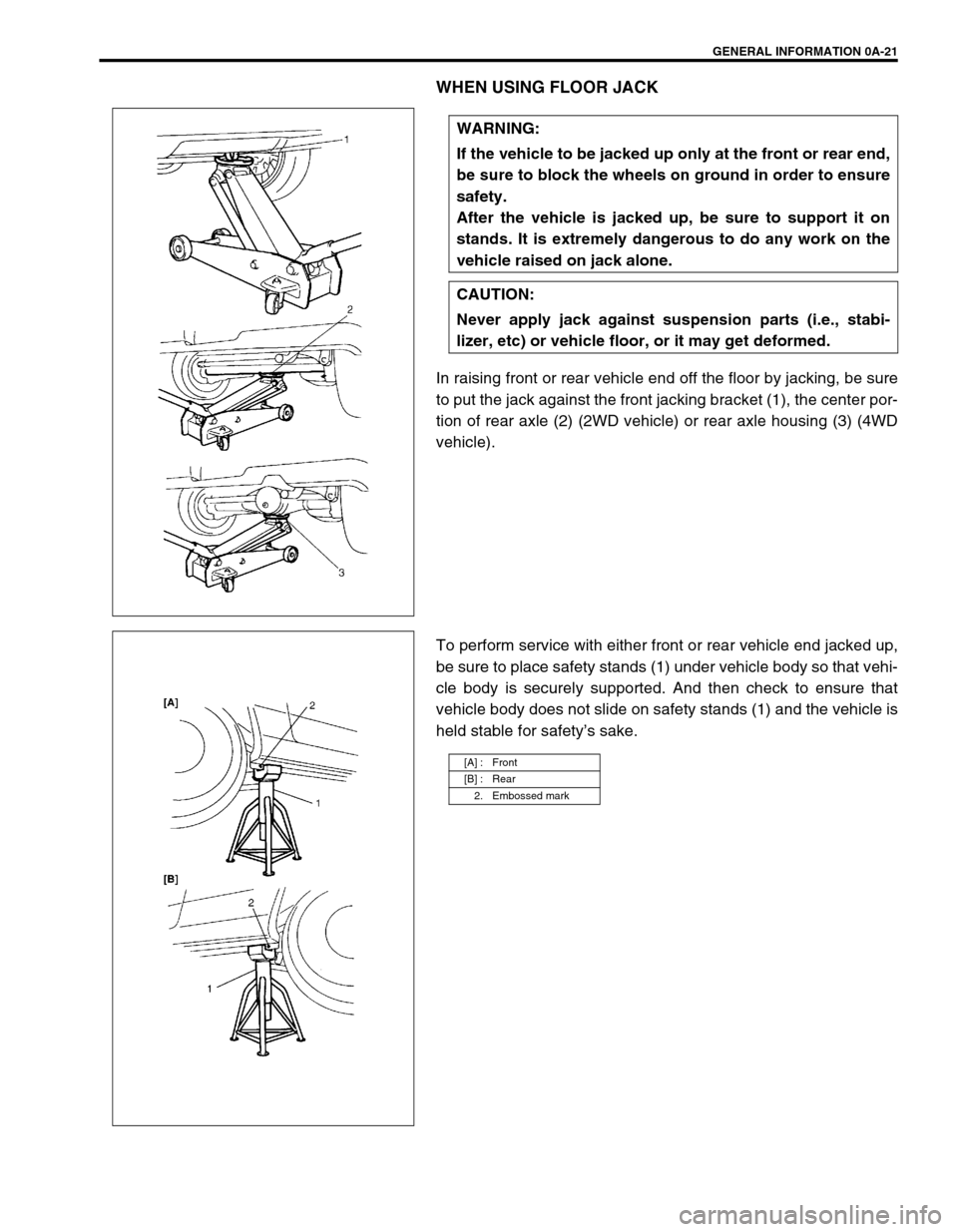

WHEN USING FLOOR JACK

In raising front or rear vehicle end off the floor by jacking, be sure

to put the jack against the front jacking bracket (1), the center por-

tion of rear axle (2) (2WD vehicle) or rear axle housing (3) (4WD

vehicle).

To perform service with either front or rear vehicle end jacked up,

be sure to place safety stands (1) under vehicle body so that vehi-

cle body is securely supported. And then check to ensure that

vehicle body does not slide on safety stands (1) and the vehicle is

held stable for safety’s sake. WARNING:

If the vehicle to be jacked up only at the front or rear end,

be sure to block the wheels on ground in order to ensure

safety.

After the vehicle is jacked up, be sure to support it on

stands. It is extremely dangerous to do any work on the

vehicle raised on jack alone.

CAUTION:

Never apply jack against suspension parts (i.e., stabi-

lizer, etc) or vehicle floor, or it may get deformed.

[A] : Front

[B] : Rear

2. Embossed mark

Page 25 of 698

0A-22 GENERAL INFORMATION

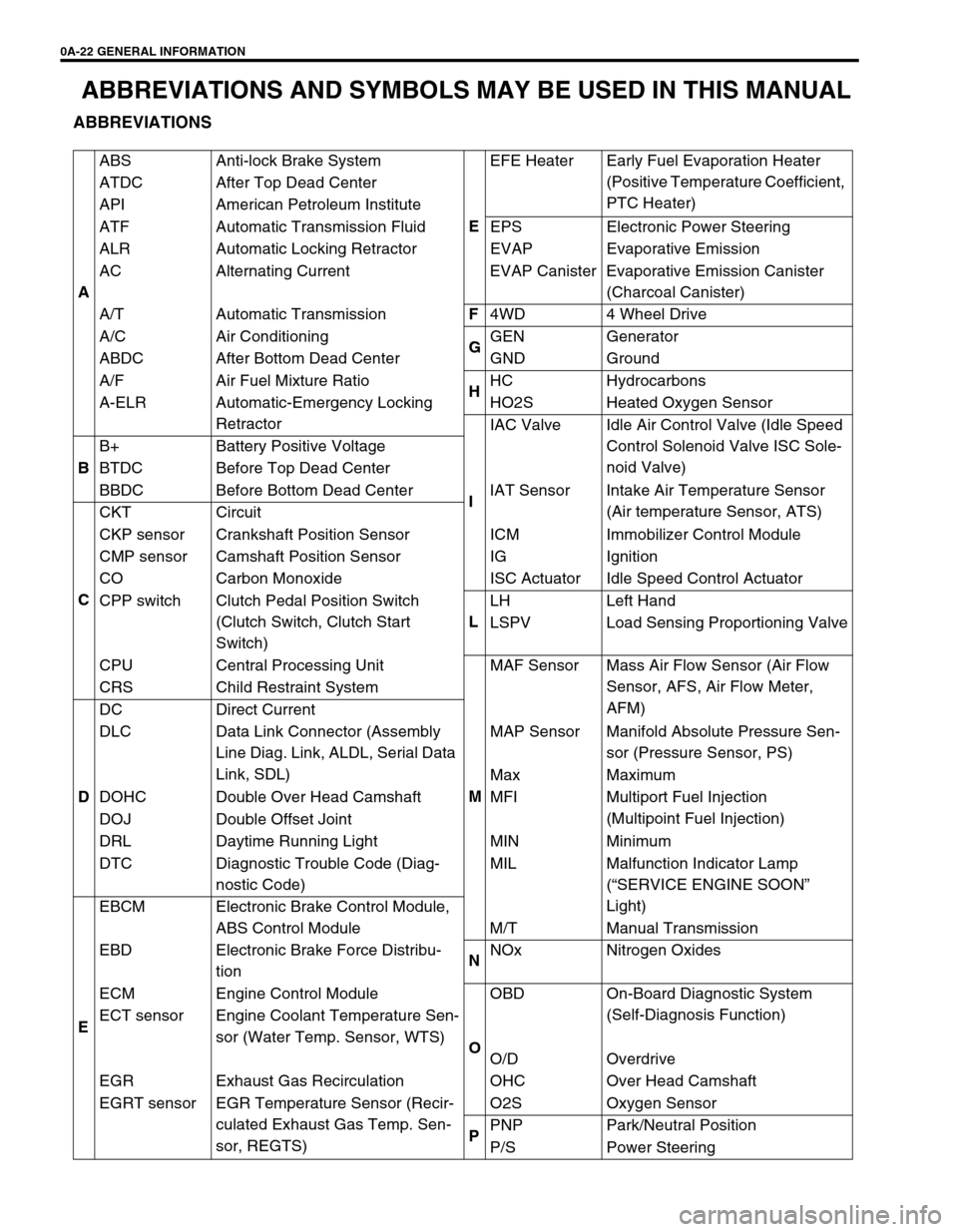

ABBREVIATIONS AND SYMBOLS MAY BE USED IN THIS MANUAL

ABBREVIATIONS

AABS Anti-lock Brake System

EEFE Heater Early Fuel Evaporation Heater

(Positive Temperature Coefficient,

PTC Heater) ATDC After Top Dead Center

API American Petroleum Institute

ATF Automatic Transmission Fluid EPS Electronic Power Steering

ALR Automatic Locking Retractor EVAP Evaporative Emission

AC Alternating Current EVAP Canister Evaporative Emission Canister

(Charcoal Canister)

A/T Automatic TransmissionF

4WD 4 Wheel Drive

A/C Air Conditioning

GGEN Generator

ABDC After Bottom Dead Center GND Ground

A/F Air Fuel Mixture Ratio

HHC Hydrocarbons

A-ELR Automatic-Emergency Locking

RetractorHO2S Heated Oxygen Sensor

IIAC Valve Idle Air Control Valve (Idle Speed

Control Solenoid Valve ISC Sole-

noid Valve)

BB+ Battery Positive Voltage

BTDC Before Top Dead Center

BBDC Before Bottom Dead Center IAT Sensor Intake Air Temperature Sensor

(Air temperature Sensor, ATS)

CCKT Circuit

CKP sensor Crankshaft Position Sensor ICM Immobilizer Control Module

CMP sensor Camshaft Position Sensor IG Ignition

CO Carbon Monoxide ISC Actuator Idle Speed Control Actuator

CPP switch Clutch Pedal Position Switch

(Clutch Switch, Clutch Start

Switch)LLH Left Hand

LSPV Load Sensing Proportioning Valve

CPU Central Processing Unit

MMAF Sensor Mass Air Flow Sensor (Air Flow

Sensor, AFS, Air Flow Meter,

AFM) CRS Child Restraint System

DDC Direct Current

DLC Data Link Connector (Assembly

Line Diag. Link, ALDL, Serial Data

Link, SDL)MAP Sensor Manifold Absolute Pressure Sen-

sor (Pressure Sensor, PS)

Max Maximum

DOHC Double Over Head Camshaft MFI Multiport Fuel Injection

(Multipoint Fuel Injection)

DOJ Double Offset Joint

DRL Daytime Running Light MIN Minimum

DTC Diagnostic Trouble Code (Diag-

nostic Code)MIL Malfunction Indicator Lamp

(“SERVICE ENGINE SOON”

Light)

EEBCM Electronic Brake Control Module,

ABS Control Module M/T Manual Transmission

EBD Electronic Brake Force Distribu-

tionNNOx Nitrogen Oxides

ECM Engine Control Module

OOBD On-Board Diagnostic System

(Self-Diagnosis Function)

ECT sensor Engine Coolant Temperature Sen-

sor (Water Temp. Sensor, WTS)

O/D Overdrive

EGR Exhaust Gas Recirculation OHC Over Head Camshaft

EGRT sensor EGR Temperature Sensor (Recir-

culated Exhaust Gas Temp. Sen-

sor, REGTS)O2S Oxygen Sensor

PPNP Park/Neutral Position

P/S Power Steering

Page 26 of 698

GENERAL INFORMATION 0A-23

PPSP Switch Power Steering Pressure Switch

(P/S Pressure Switch)

PCM Powertrain Control Module

PCV Positive Crankcase Ventilation

R

RH Right Hand

SSAE Society of Automotive Engineers

SDM Sensing and Diagnostic Module

(Air bag controller, Air bag con-

trol module)

SFI Sequential Multiport Fuel Injec-

tion

SOHC Single over Head Camshaft

TTBI Throttle Body Fuel Injection

(Single-Point Fuel Injection, SPI)

TCC Torque Converter Clutch

TCM Transmission Control Module

(A/T Controller, A/T Control

Module)

TP Sensor Throttle Position Sensor

TVV Thermal Vacuum Valve (Ther-

mal Vacuum Switching Valve,

TVSV, Bimetal Vacuum Switch-

ing Valve, BVSV)

TWC Three Way Catalytic Converter

(Three Way Catalyst)

2WD 2 Wheel Drive

VVIN Vehicle Identification Number

VSS Vehicle Speed Sensor

WWU-OC Warm Up Oxidation Catalytic

Converter

WU-TWC Warm Up Three Way Catalytic

Converter

Page 27 of 698

0A-24 GENERAL INFORMATION

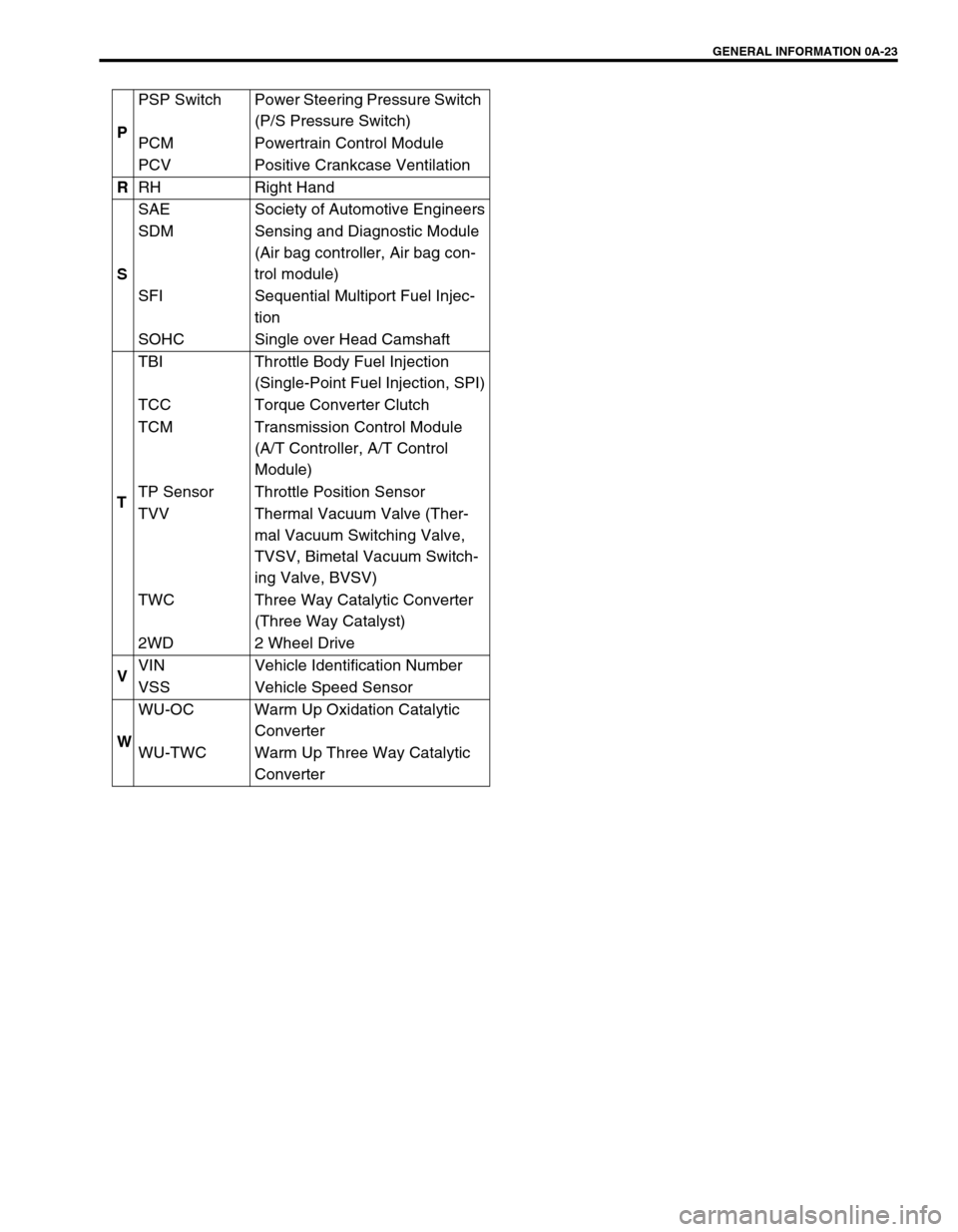

SYMBOLS

WIRE COLOR SYMBOLS

There are two kinds of colored wire used in this vehicle. One is

single-colored wire and the other is dual-colored (striped) wire.

The single-colored wire uses only one color symbol (i.e. “GRN”).

The dual-colored wire uses two color symbols (i.e. “GRN/YEL”).

The first symbol represents the base color of the wire (“GRN” in

the figure) and the second symbol represents the color of the

stripe (“YEL” in the figure). SYMBOL DEFINITION SYMBOL DEFINITION

Tightening torque Apply SUZUKI BOND NO. 1216

99000-31160

Apply oil (engine, transmission, trans-

fer, differential)Apply SILICONE SEALANT

99000-31120

Apply fluid (brake, power steering or

automatic transmission fluid)Apply SEALING COMPOUND 366E

99000-31090

Apply SUZUKI SUPER GREASE A

99000-25010

Apply SUZUKI SUPER GREASE C

99000-25030Apply THREAD LOCK 1322

99000-32110

Apply SUZUKI SUPER GREASE E

99000-25050Apply THREAD LOCK 1333B

99000-32020

Apply SUZUKI SUPER GREASE H

99000-25120Apply THREAD LOCK 1342

99000-32050

Apply SUZUKI SUPER GREASE I

99000-25210

Apply SUZUKI BOND NO. 1215

99000-31110Do not reuse

Apply SUZUKI BOND NO. 1207C

99000-31150Note on reassembly

Symbol Wire Color Symbol Wire Color

B BLK Black O, Or ORN Orange

Bl BLU Blue R RED Red

Br BRN Brown W WHT White

GGRN Green Y YEL Yellow

Gr GRY Gray P PNK Pink

Lbl LT BLU Light blue V PPL Violet

Lg LT GRN Light green

Page 28 of 698

GENERAL INFORMATION 0A-25

FASTENER INFORMATION

METRIC FASTENERS

Most of the fasteners used for this vehicle are metric. When replacing any fasteners, it is most important that

replacement fasteners be the correct diameter, thread pitch and strength.

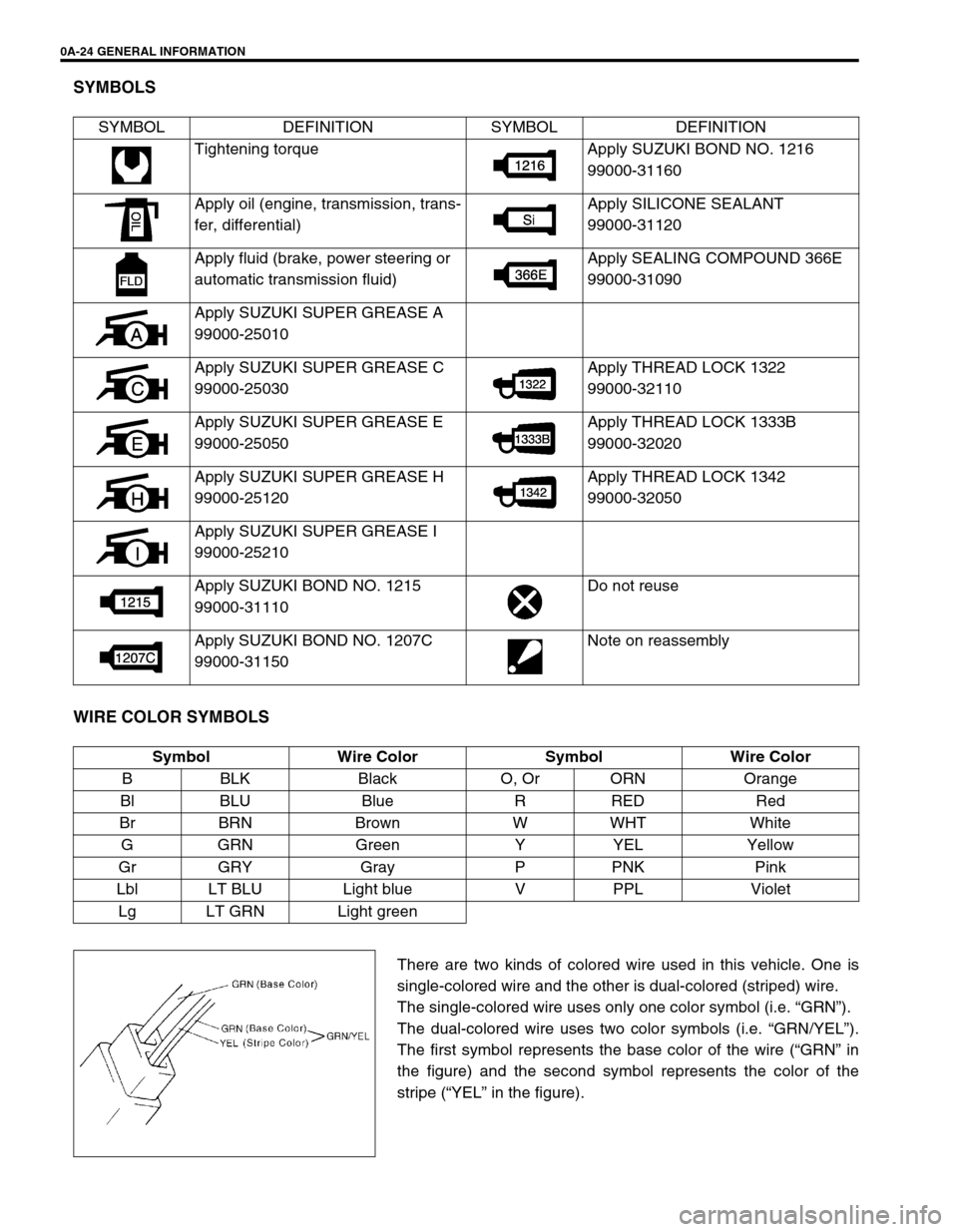

FASTENER STRENGTH IDENTIFICATION

Most commonly used metric fastener strength property classes are 4T, 6.8, 7T, 8.8 and radial line with the class

identification embossed on the head of each bolt. Some metric nuts will be marked with punch, 6 or 8 mark

strength identification on the nut face. Figure shows the different strength markings.

When replacing metric fasteners, be careful to use bolts and nuts of the same strength or greater than the origi-

nal fasteners (the same number marking or higher). It is likewise important to select replacement fasteners of

the correct diameter and thread pitch. Correct replacement bolts and nuts are available through the parts divi-

sion.

Metric bolts : Identification class numbers or marks correspond to bolt strength (increasing numbers represent

increasing strength).

STANDARD TIGHTENING TORQUE

Each fastener should be tightened to the torque specified in each section of this manual. If no description or

specification is provided, refer to the following tightening torque chart for the applicable torque for each fastener.

When a fastener of greater strength than the original one is used, however, use the torque specified for the orig-

inal fastener.

1. Nut strength identification

NOTE:

For the flanged bolt, flanged nut and self-lock nut of 4T and 7T strength, add 10% to the tightening

torque given in the chart below.

The chart below is applicable only where the fastened parts are made of steel light alloy.

Page 29 of 698

0A-26 GENERAL INFORMATION

Tightening torque chart :

Thread Diameter (Nominal Diameter) (mm)

4 5 6 8 10 12 14 16 18

StrengthA equivalent of 4T strength

fastenerN·m 1.5 3.0 5.5 13 29 45 65 105 160

kg-m 0.15 0.30 0.55 1.3 2.9 4.5 6.5 10.5 16

lb-ft 1.0 2.5 4.0 9.5 21.0 32.5 47.0 76.0 116.0

A equivalent of 6.8 strength

fastener without flangeN·m 2.4 4.7 8.4 20 42 80 125 193 280

kg-m 0.24 0.47 0.84 2.0 4.2 8.0 12.5 19.3 28

lb-ft 2.0 3.5 6.0 14.5 30.5 58.0 90.5 139.5 202.5

A equivalent of 6.8 strength

fastener with flangeN·m 2.4 4.9 8.8 21 44 84 133 203 298

kg-m 0.24 0.49 0.88 2.1 4.4 8.4 13.3 20.3 29.8

lb-ft 2.0 3.5 6.5 15.5 32.0 61.0 96.5 147.0 215.5

A equivalent of 7T strength

fastenerN·m 2.3 4.5 10 23 50 85 135 210 240

kg-m 0.23 0.45 1.0 2.3 5.0 8.5 13.5 21 24

lb-ft 2.0 3.5 7.5 17.0 36.5 61.5 98.0 152.0 174.0

A equivalent of 8.8 strength

fastener without flangeN·m 3.1 6.3 11 27 56 105 168 258 373

kg-m 0.31 0.63 1.1 2.7 5.6 10.5 16.8 25.8 37.3

lb-ft 2.5 4.5 8.0 19.5 40.5 76.0 121.5 187.0 270.0

A equivalent of 8.8 strength

fastener with flangeN·m 3.2 6.5 12 29 59 113 175 270 395

kg-m 0.32 0.65 1.2 2.9 5.9 11.3 17.5 27 39.5

lb-ft 2.5 5.0 9.0 21.0 43.0 82.0 126.5 195.5 286.0

✱: Self-lock nut

Page 30 of 698

MAINTENANCE AND LUBRICATION 0B-1

0A 6F1

0B

0B

6G

1A 6H

1B 6K

37A

3A 7A1

3B1 7B1

3C1 7C1

3D 7D

3E 7E

3F 7F

4A2 8A

4B 8B

8C

58D

5A 8E

5B

5C 9

5E

5E1 10

10A

610B

6-1

6A1

6A2

6A4

6B

6C

6E1

6E2

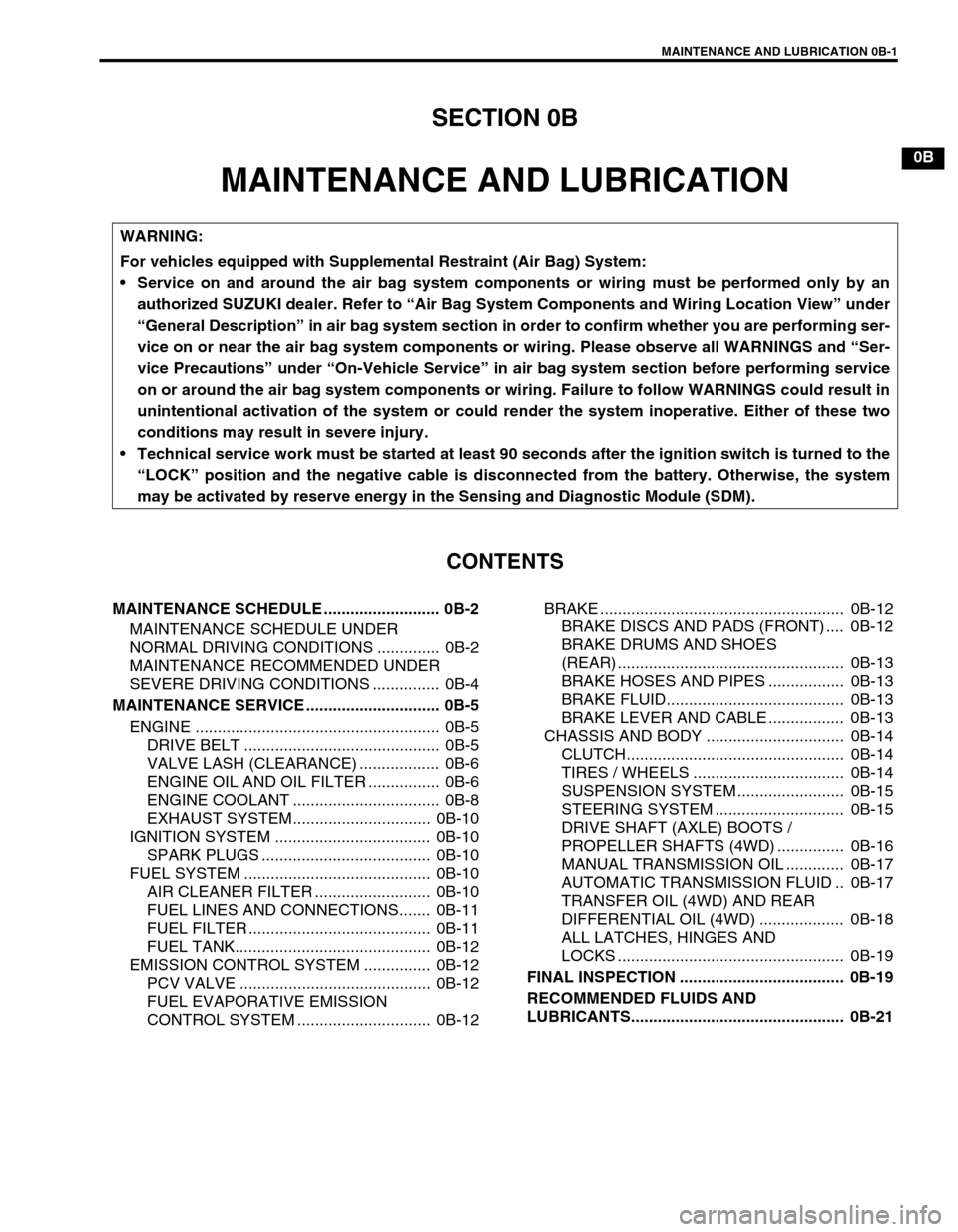

SECTION 0B

MAINTENANCE AND LUBRICATION

CONTENTS

MAINTENANCE SCHEDULE .......................... 0B-2

MAINTENANCE SCHEDULE UNDER

NORMAL DRIVING CONDITIONS .............. 0B-2

MAINTENANCE RECOMMENDED UNDER

SEVERE DRIVING CONDITIONS ............... 0B-4

MAINTENANCE SERVICE .............................. 0B-5

ENGINE ....................................................... 0B-5

DRIVE BELT ............................................ 0B-5

VALVE LASH (CLEARANCE) .................. 0B-6

ENGINE OIL AND OIL FILTER ................ 0B-6

ENGINE COOLANT ................................. 0B-8

EXHAUST SYSTEM............................... 0B-10

IGNITION SYSTEM ................................... 0B-10

SPARK PLUGS ...................................... 0B-10

FUEL SYSTEM .......................................... 0B-10

AIR CLEANER FILTER .......................... 0B-10

FUEL LINES AND CONNECTIONS....... 0B-11

FUEL FILTER ......................................... 0B-11

FUEL TANK............................................ 0B-12

EMISSION CONTROL SYSTEM ............... 0B-12

PCV VALVE ........................................... 0B-12

FUEL EVAPORATIVE EMISSION

CONTROL SYSTEM .............................. 0B-12BRAKE ....................................................... 0B-12

BRAKE DISCS AND PADS (FRONT) .... 0B-12

BRAKE DRUMS AND SHOES

(REAR) ................................................... 0B-13

BRAKE HOSES AND PIPES ................. 0B-13

BRAKE FLUID........................................ 0B-13

BRAKE LEVER AND CABLE ................. 0B-13

CHASSIS AND BODY ............................... 0B-14

CLUTCH................................................. 0B-14

TIRES / WHEELS .................................. 0B-14

SUSPENSION SYSTEM ........................ 0B-15

STEERING SYSTEM ............................. 0B-15

DRIVE SHAFT (AXLE) BOOTS /

PROPELLER SHAFTS (4WD) ............... 0B-16

MANUAL TRANSMISSION OIL ............. 0B-17

AUTOMATIC TRANSMISSION FLUID .. 0B-17

TRANSFER OIL (4WD) AND REAR

DIFFERENTIAL OIL (4WD) ................... 0B-18

ALL LATCHES, HINGES AND

LOCKS ................................................... 0B-19

FINAL INSPECTION ..................................... 0B-19

RECOMMENDED FLUIDS AND

LUBRICANTS................................................ 0B-21

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).