SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 691 of 698

CHARGING SYSTEM 6H-11

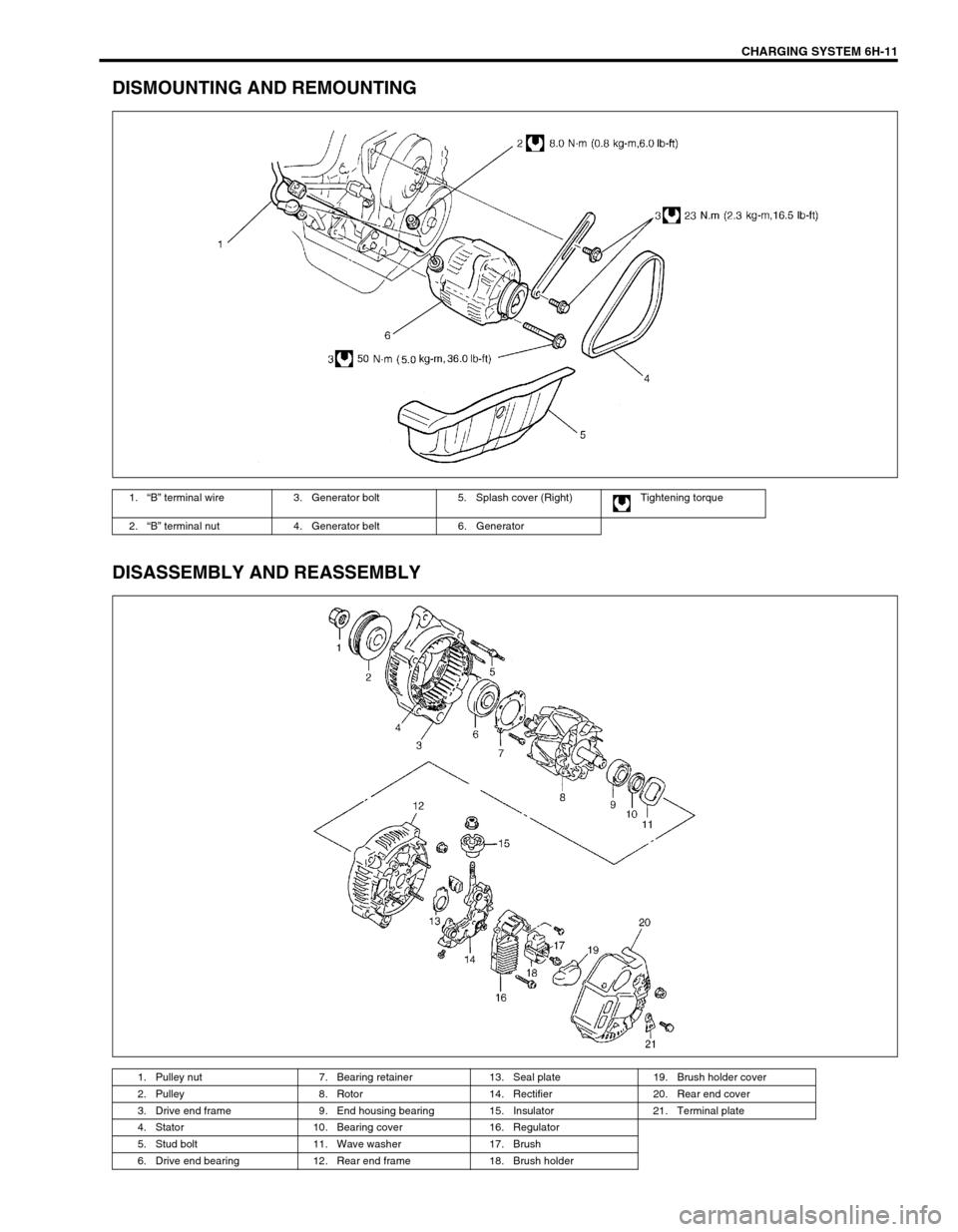

DISMOUNTING AND REMOUNTING

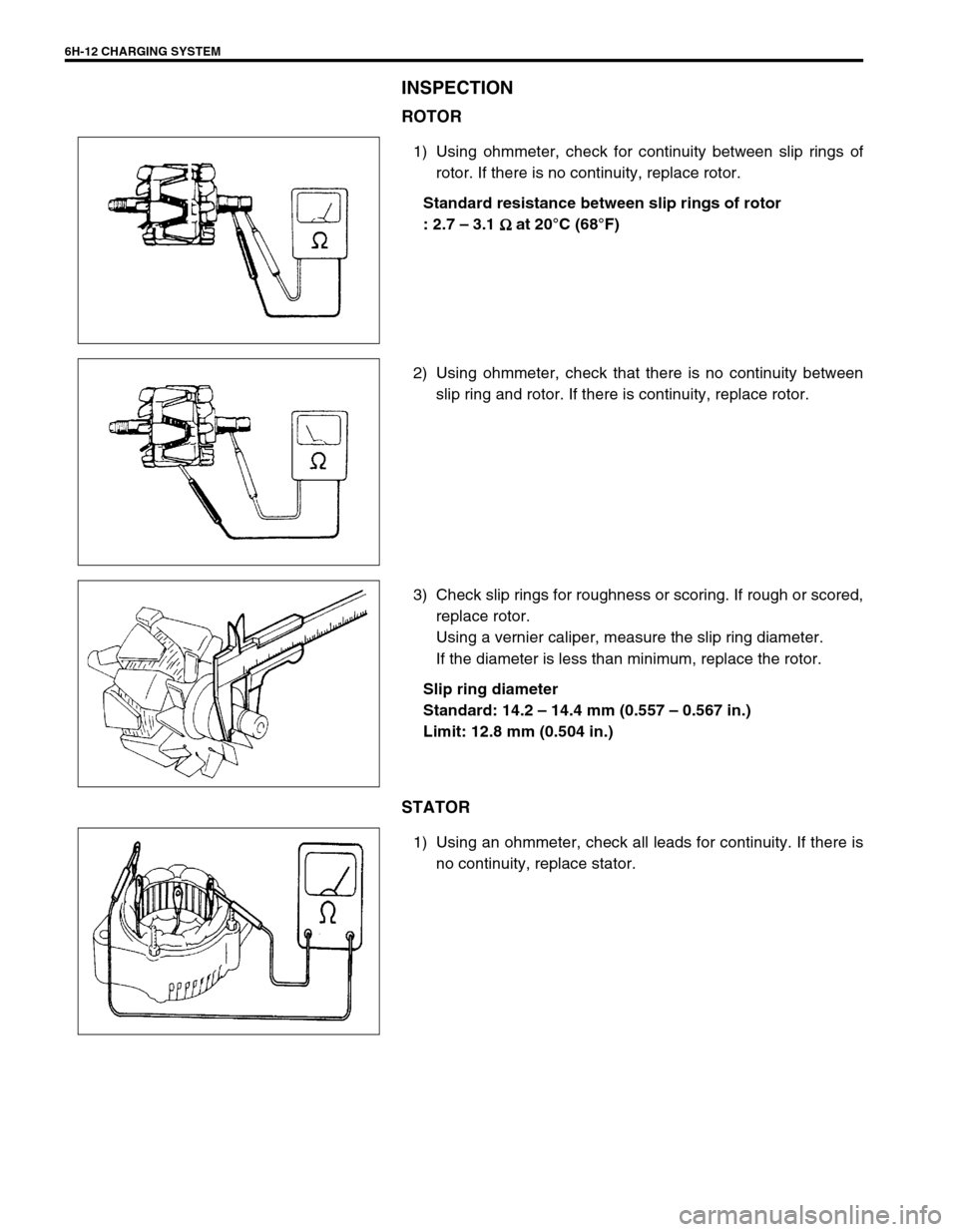

DISASSEMBLY AND REASSEMBLY

1.“B” terminal wire 3. Generator bolt 5. Splash cover (Right) Tightening torque

2.“B” terminal nut 4. Generator belt 6. Generator

1. Pulley nut 7. Bearing retainer 13. Seal plate 19. Brush holder cover

2. Pulley 8. Rotor 14. Rectifier 20. Rear end cover

3. Drive end frame 9. End housing bearing 15. Insulator 21. Terminal plate

4. Stator 10. Bearing cover 16. Regulator

5. Stud bolt 11. Wave washer 17. Brush

6. Drive end bearing 12. Rear end frame 18. Brush holder

Page 692 of 698

6H-12 CHARGING SYSTEM

INSPECTION

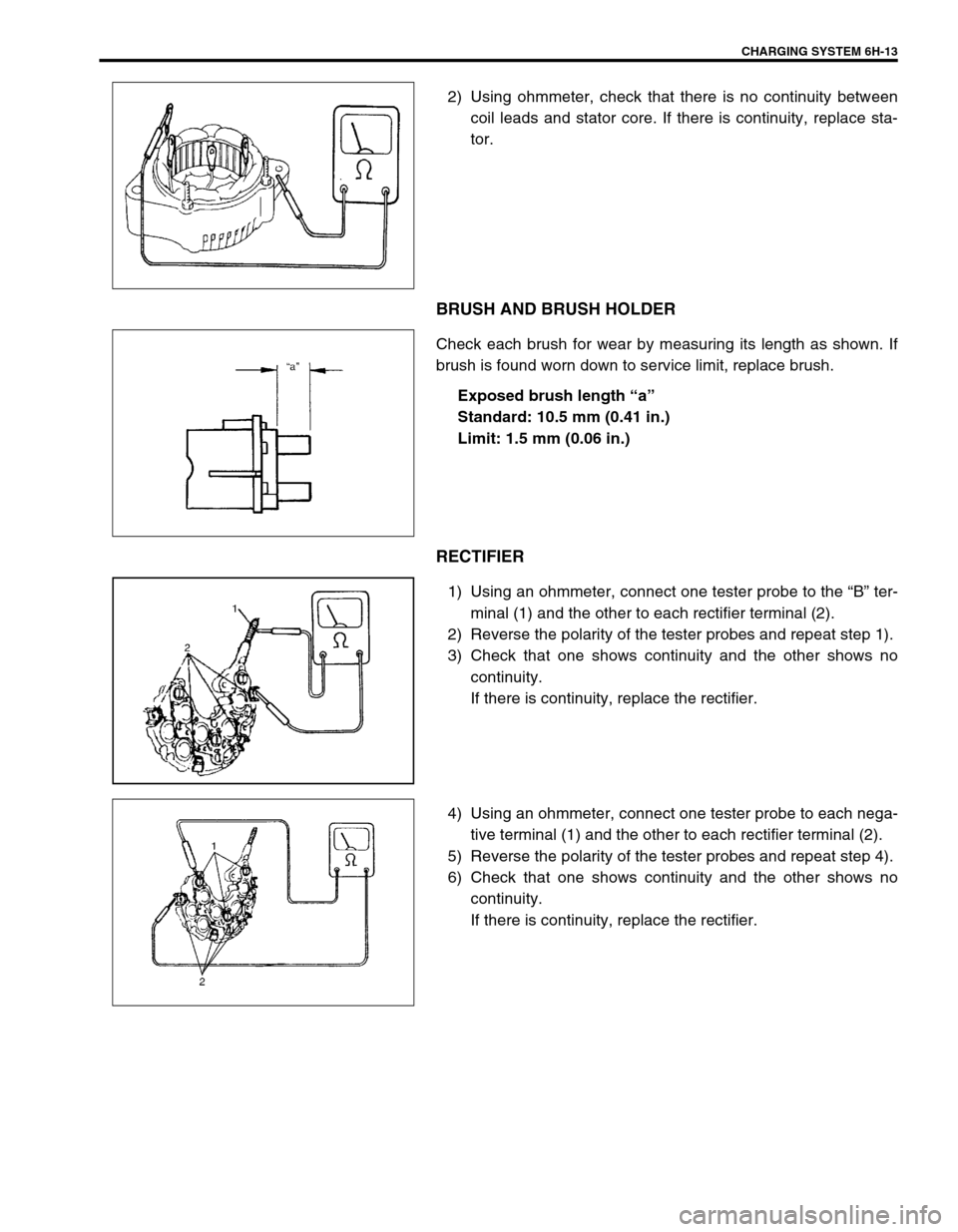

ROTOR

1) Using ohmmeter, check for continuity between slip rings of

rotor. If there is no continuity, replace rotor.

Standard resistance between slip rings of rotor

: 2.7 – 3.1

Ω

ΩΩ Ω at 20°C (68°F)

2) Using ohmmeter, check that there is no continuity between

slip ring and rotor. If there is continuity, replace rotor.

3) Check slip rings for roughness or scoring. If rough or scored,

replace rotor.

Using a vernier caliper, measure the slip ring diameter.

If the diameter is less than minimum, replace the rotor.

Slip ring diameter

Standard: 14.2 – 14.4 mm (0.557 – 0.567 in.)

Limit: 12.8 mm (0.504 in.)

STATOR

1) Using an ohmmeter, check all leads for continuity. If there is

no continuity, replace stator.

Page 693 of 698

CHARGING SYSTEM 6H-13

2) Using ohmmeter, check that there is no continuity between

coil leads and stator core. If there is continuity, replace sta-

tor.

BRUSH AND BRUSH HOLDER

Check each brush for wear by measuring its length as shown. If

brush is found worn down to service limit, replace brush.

Exposed brush length “a”

Standard: 10.5 mm (0.41 in.)

Limit: 1.5 mm (0.06 in.)

RECTIFIER

1) Using an ohmmeter, connect one tester probe to the “B” ter-

minal (1) and the other to each rectifier terminal (2).

2) Reverse the polarity of the tester probes and repeat step 1).

3) Check that one shows continuity and the other shows no

continuity.

If there is continuity, replace the rectifier.

4) Using an ohmmeter, connect one tester probe to each nega-

tive terminal (1) and the other to each rectifier terminal (2).

5) Reverse the polarity of the tester probes and repeat step 4).

6) Check that one shows continuity and the other shows no

continuity.

If there is continuity, replace the rectifier.

Page 694 of 698

6H-14 CHARGING SYSTEM

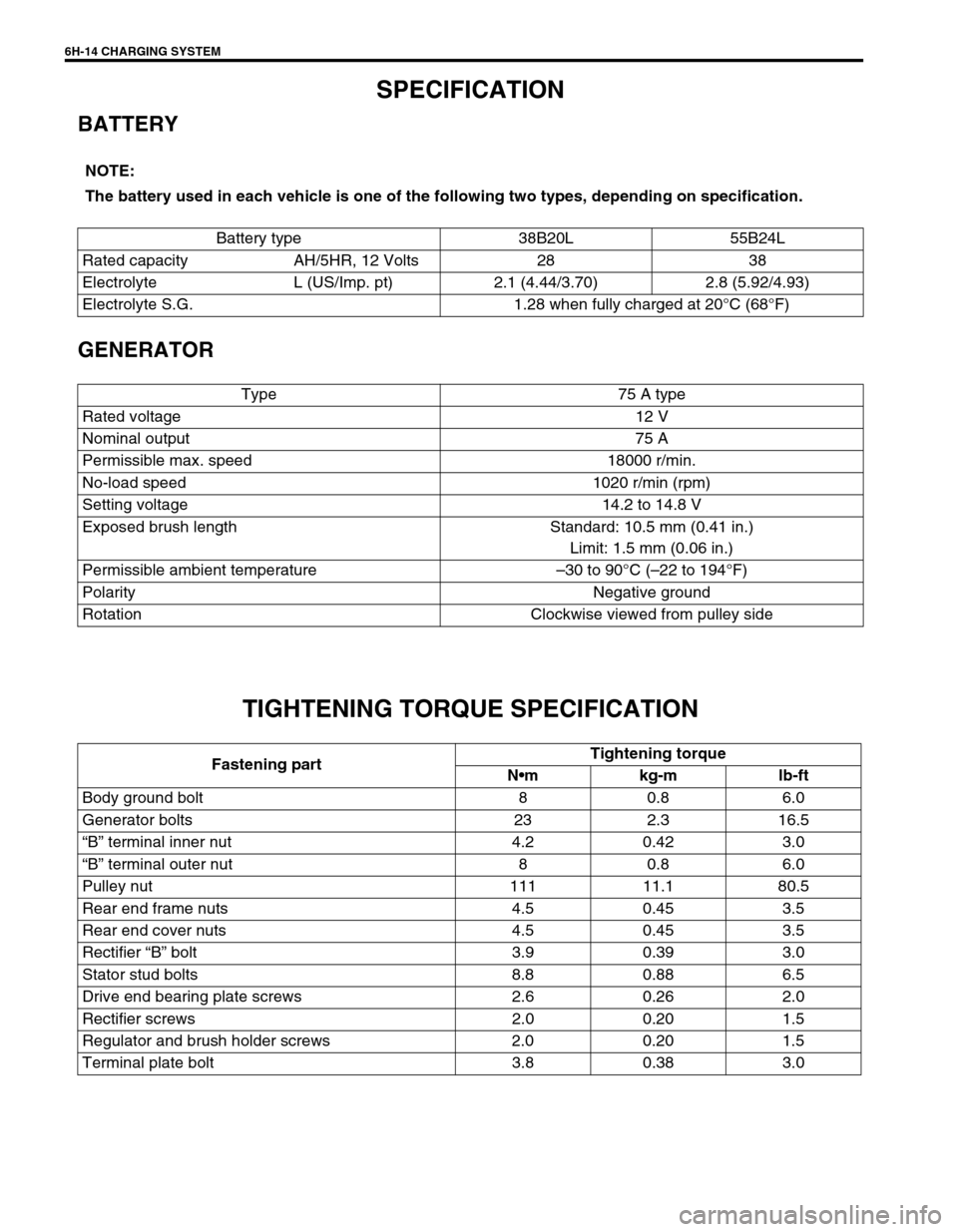

SPECIFICATION

BATTERY

GENERATOR

TIGHTENING TORQUE SPECIFICATION

NOTE:

The battery used in each vehicle is one of the following two types, depending on specification.

Battery type 38B20L 55B24L

Rated capacity AH/5HR, 12 Volts 28 38

Electrolyte L (US/Imp. pt) 2.1 (4.44/3.70) 2.8 (5.92/4.93)

Electrolyte S.G. 1.28 when fully charged at 20°C (68°F)

Type 75 A type

Rated voltage 12 V

Nominal output 75 A

Permissible max. speed 18000 r/min.

No-load speed 1020 r/min (rpm)

Setting voltage 14.2 to 14.8 V

Exposed brush length Standard: 10.5 mm (0.41 in.)

Limit: 1.5 mm (0.06 in.)

Permissible ambient temperature–30 to 90°C (–22 to 194°F)

Polarity Negative ground

Rotation Clockwise viewed from pulley side

Fastening partTightening torque

Nm kg-m lb-ft

Body ground bolt 8 0.8 6.0

Generator bolts 23 2.3 16.5

“B” terminal inner nut 4.2 0.42 3.0

“B” terminal outer nut 8 0.8 6.0

Pulley nut 111 11.1 80.5

Rear end frame nuts 4.5 0.45 3.5

Rear end cover nuts 4.5 0.45 3.5

Rectifier “B” bolt 3.9 0.39 3.0

Stator stud bolts 8.8 0.88 6.5

Drive end bearing plate screws 2.6 0.26 2.0

Rectifier screws 2.0 0.20 1.5

Regulator and brush holder screws 2.0 0.20 1.5

Terminal plate bolt 3.8 0.38 3.0

Page 695 of 698

EXHAUST SYSTEM 6K-1

6F1

6F2

6G

6H

7A

7A1

6K

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 6K

EXHAUST SYSTEM

CONTENTS

GENERAL DESCRIPTION ...............................6K-2

MAINTENANCE................................................6K-2

ON-VEHICLE SERVICE ...................................6K-3EXHAUST MANIFOLD ................................. 6K-4

EXHAUST PIPE ............................................ 6K-4

Page 696 of 698

6K-2 EXHAUST SYSTEM

GENERAL DESCRIPTION

The exhaust system consists of an exhaust manifold, three-way catalytic converter (TWC) in catalyst case,

exhaust pipes, a muffler and seals, gasket and etc.

The three-way catalytic converter is an emission control device added to the exhaust system to lower the levels

of Hydrocarbon (HC), Carbon Monoxide (CO), and Oxides of Nitrogen (NOx) pollutants in the exhaust gas.

MAINTENANCE

At every interval of periodic maintenance service, and when vehi-

cle is raised for other service, check exhaust system as follows:

Check rubber mountings for damage, deterioration, and out

of position.

Check exhaust system for leakage, loose connection, dent

and damage.

If bolts or nuts are loosened, tighten them to specified

torque.

Refer to “GENERAL DESCRIPTION”.

Check nearby body areas damaged, missing, or misposi-

tioned part, open seam, hole connection or any other defect

which could permit exhaust fumes to seep into vehicle.

Make sure that exhaust system components have enough

clearance from underbody to avoid overheating and possible

damage to passenger compartment carpet.

Any defect should be fixed at once. WARNING:

To avoid the danger of being burned, do not touch the

exhaust system when the system is hot. Any service on

the exhaust system should be performed when the sys-

tem is cool.

Page 697 of 698

EXHAUST SYSTEM 6K-3

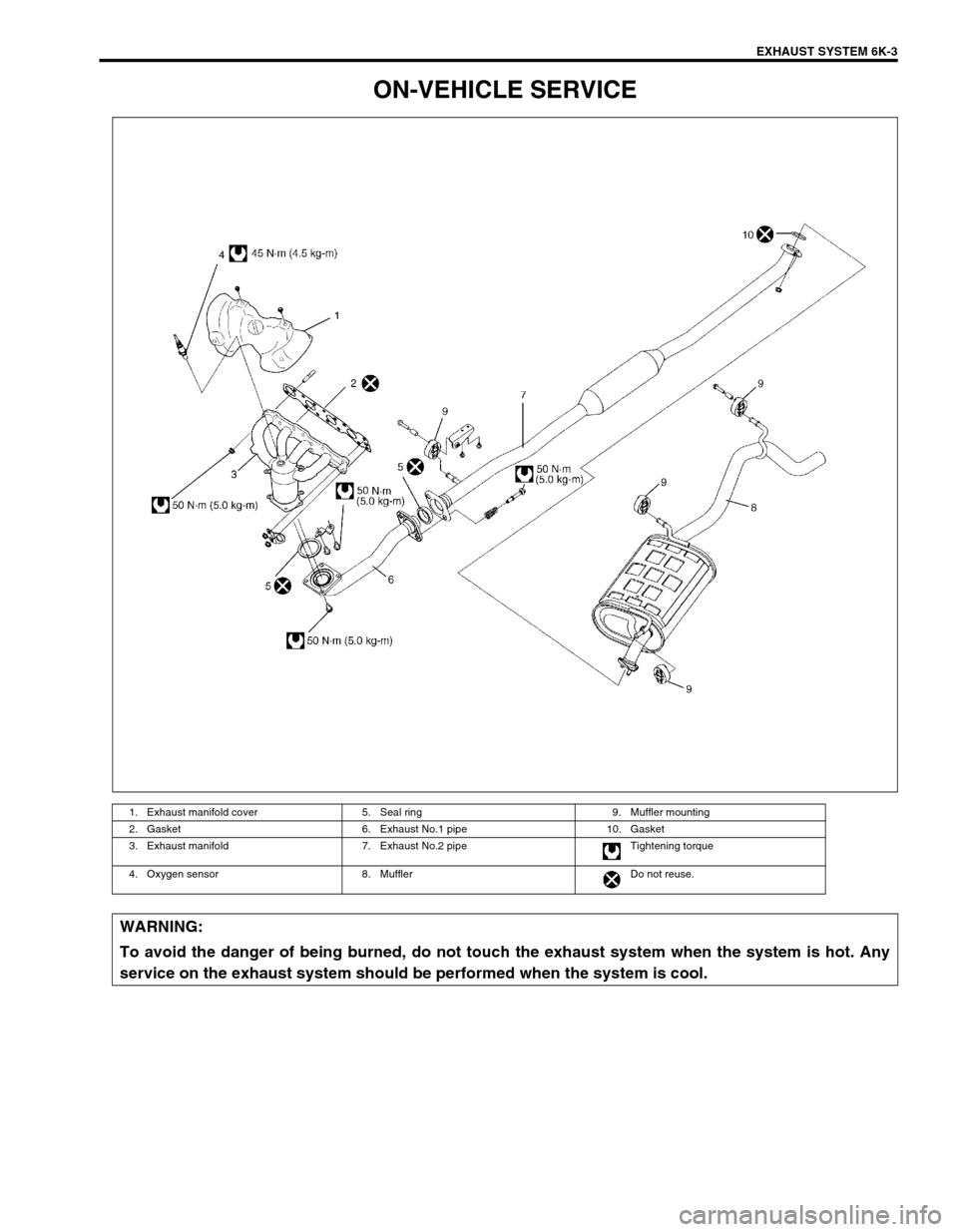

ON-VEHICLE SERVICE

1. Exhaust manifold cover 5. Seal ring 9. Muffler mounting

2. Gasket 6. Exhaust No.1 pipe 10. Gasket

3. Exhaust manifold 7. Exhaust No.2 pipe Tightening torque

4. Oxygen sensor 8. Muffler Do not reuse.

WARNING:

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

Page 698 of 698

6K-4 EXHAUST SYSTEM

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION

Refer to Section 6A1 for removal and installation procedures of exhaust manifold.

INSPECTION

Check gasket and seal for deterioration or damage.

Replace them as necessary.

EXHAUST PIPE

REMOVAL AND INSTALLATION

For replacement of exhaust pipe, be sure to hoist vehicle and observe WARNING under “MAINTENANCE” and

the following.

Tighten bolts and nuts to specified torque when reassembling. Refer to “GENERAL DESCRIPTION” for

location of bolts and nuts.

After installation, start engine and check each joint of exhaust system for leakage. CAUTION:

Exhaust pipe have three way catalytic converter in it, it should not be exposed to any impulse.

Be careful not to drop it or hit it against something.