check oil SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 113 of 698

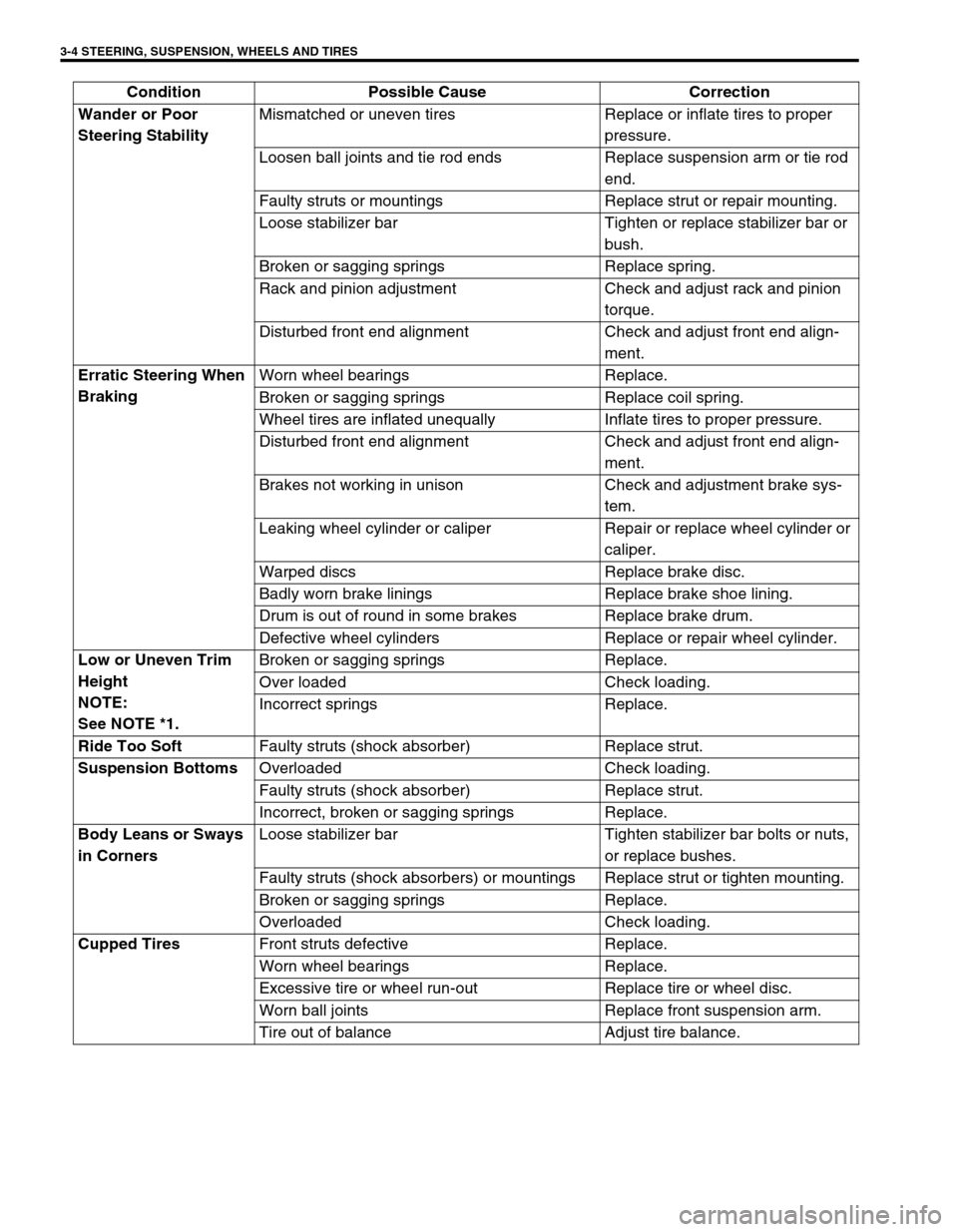

3-4 STEERING, SUSPENSION, WHEELS AND TIRES

Wander or Poor

Steering StabilityMismatched or uneven tires Replace or inflate tires to proper

pressure.

Loosen ball joints and tie rod ends Replace suspension arm or tie rod

end.

Faulty struts or mountings Replace strut or repair mounting.

Loose stabilizer bar Tighten or replace stabilizer bar or

bush.

Broken or sagging springs Replace spring.

Rack and pinion adjustment Check and adjust rack and pinion

torque.

Disturbed front end alignment Check and adjust front end align-

ment.

Erratic Steering When

BrakingWorn wheel bearings Replace.

Broken or sagging springs Replace coil spring.

Wheel tires are inflated unequally Inflate tires to proper pressure.

Disturbed front end alignment Check and adjust front end align-

ment.

Brakes not working in unison Check and adjustment brake sys-

tem.

Leaking wheel cylinder or caliper Repair or replace wheel cylinder or

caliper.

Warped discs Replace brake disc.

Badly worn brake linings Replace brake shoe lining.

Drum is out of round in some brakes Replace brake drum.

Defective wheel cylinders Replace or repair wheel cylinder.

Low or Uneven Trim

Height

NOTE:

See NOTE *1.Broken or sagging springs Replace.

Over loaded Check loading.

Incorrect springs Replace.

Ride Too Soft

Faulty struts (shock absorber) Replace strut.

Suspension Bottoms

Overloaded Check loading.

Faulty struts (shock absorber) Replace strut.

Incorrect, broken or sagging springs Replace.

Body Leans or Sways

in CornersLoose stabilizer bar Tighten stabilizer bar bolts or nuts,

or replace bushes.

Faulty struts (shock absorbers) or mountings Replace strut or tighten mounting.

Broken or sagging springs Replace.

Overloaded Check loading.

Cupped Tires

Front struts defective Replace.

Worn wheel bearings Replace.

Excessive tire or wheel run-out Replace tire or wheel disc.

Worn ball joints Replace front suspension arm.

Tire out of balance Adjust tire balance. Condition Possible Cause Correction

Page 135 of 698

3B-14 MANUAL RACK AND PINION

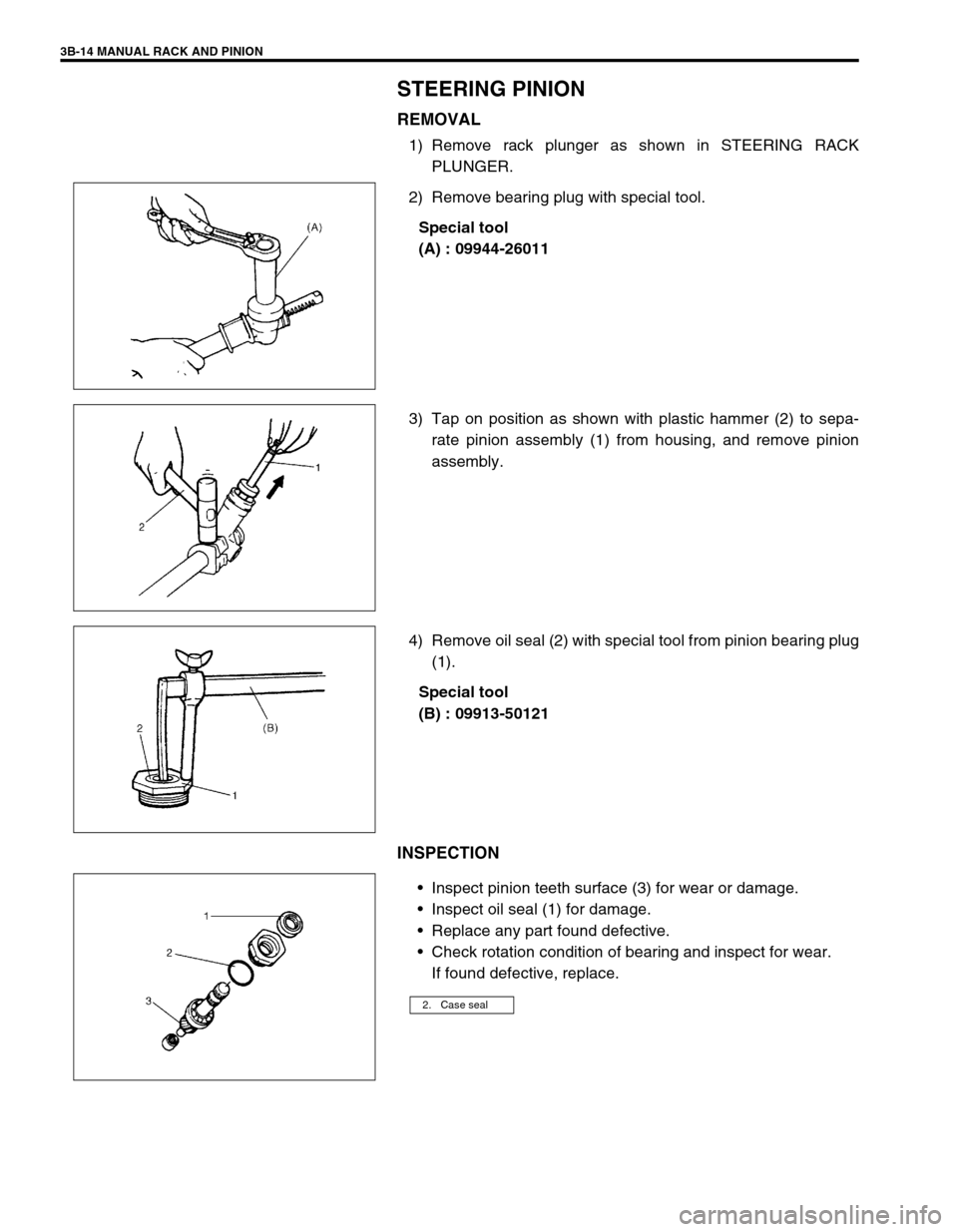

STEERING PINION

REMOVAL

1) Remove rack plunger as shown in STEERING RACK

PLUNGER.

2) Remove bearing plug with special tool.

Special tool

(A) : 09944-26011

3) Tap on position as shown with plastic hammer (2) to sepa-

rate pinion assembly (1) from housing, and remove pinion

assembly.

4) Remove oil seal (2) with special tool from pinion bearing plug

(1).

Special tool

(B) : 09913-50121

INSPECTION

Inspect pinion teeth surface (3) for wear or damage.

Inspect oil seal (1) for damage.

Replace any part found defective.

Check rotation condition of bearing and inspect for wear.

If found defective, replace.

2. Case seal

Page 141 of 698

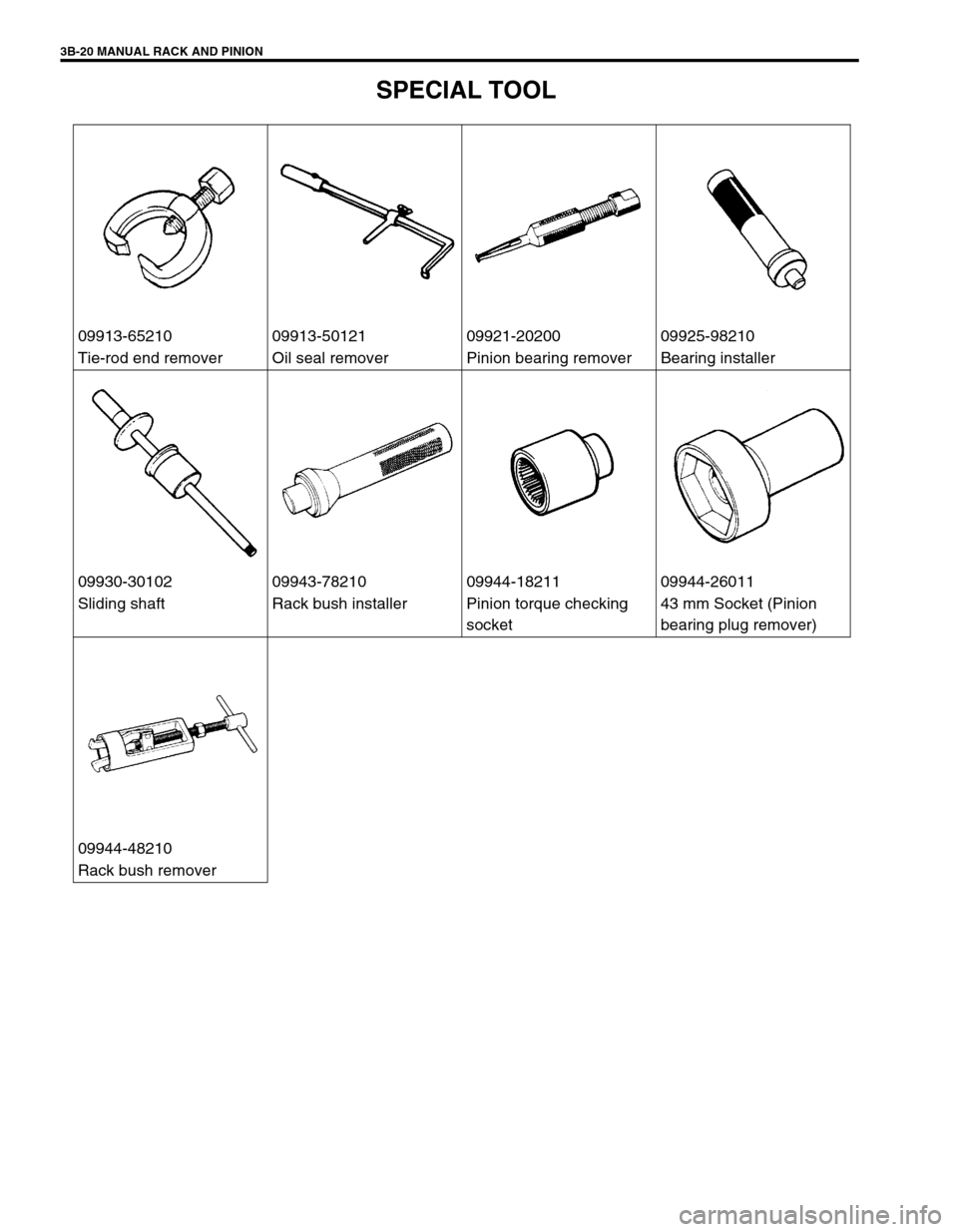

3B-20 MANUAL RACK AND PINION

SPECIAL TOOL

09913-65210 09913-50121 09921-20200 09925-98210

Tie-rod end remover Oil seal remover Pinion bearing remover Bearing installer

09930-30102 09943-78210 09944-18211 09944-26011

Sliding shaft Rack bush installer Pinion torque checking

socket43 mm Socket (Pinion

bearing plug remover)

09944-48210

Rack bush remover

Page 151 of 698

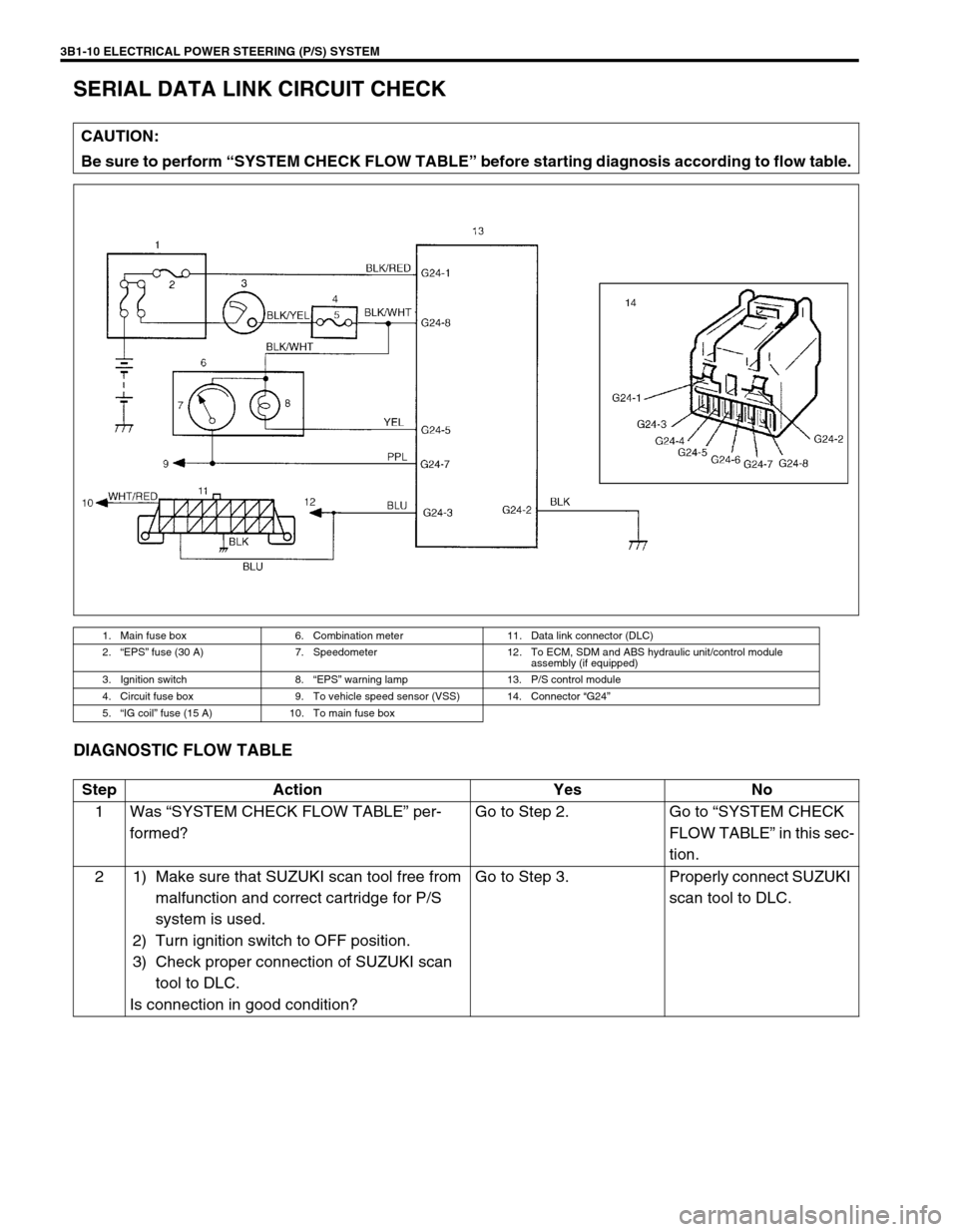

3B1-10 ELECTRICAL POWER STEERING (P/S) SYSTEM

SERIAL DATA LINK CIRCUIT CHECK

DIAGNOSTIC FLOW TABLE

CAUTION:

Be sure to perform “SYSTEM CHECK FLOW TABLE” before starting diagnosis according to flow table.

1. Main fuse box 6. Combination meter 11. Data link connector (DLC)

2.“EPS” fuse (30 A) 7. Speedometer 12. To ECM, SDM and ABS hydraulic unit/control module

assembly (if equipped)

3. Ignition switch 8.“EPS” warning lamp 13. P/S control module

4. Circuit fuse box 9. To vehicle speed sensor (VSS) 14. Connector “G24”

5.“IG coil” fuse (15 A) 10. To main fuse box

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to Step 2. Go to “SYSTEM CHECK

FLOW TABLE” in this sec-

tion.

2 1) Make sure that SUZUKI scan tool free from

malfunction and correct cartridge for P/S

system is used.

2) Turn ignition switch to OFF position.

3) Check proper connection of SUZUKI scan

tool to DLC.

Is connection in good condition?Go to Step 3. Properly connect SUZUKI

scan tool to DLC.

Page 174 of 698

STEERING WHEEL AND COLUMN 3C-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

3C1

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3C

STEERING WHEEL AND COLUMN

CONTENTS

GENERAL DESCRIPTION .............................. 3C-2

STEERING COLUMN .................................. 3C-2

STEERING WHEEL AND DRIVER AIR

BAG (INFLATOR) MODULE ........................ 3C-2

DIAGNOSIS ..................................................... 3C-2

INSPECTION AND REPAIR REQUIRED

AFTER ACCIDENT ...................................... 3C-2

ON-VEHICLE SERVICE .................................. 3C-3

SERVICE PRECAUTIONS........................... 3C-3

SERVICE AND DIAGNOSIS .................... 3C-3

DISABLING AIR BAG SYSTEM ............... 3C-3

ENABLING AIR BAG SYSTEM ................ 3C-3

HANDLING AND STORAGE.................... 3C-4

DISPOSAL ............................................... 3C-4DRIVER AIR BAG (INFLATOR) MODULE .. 3C-4

STEERING WHEEL ..................................... 3C-6

CENTERING CONTACT COIL .................... 3C-7

CONTACT COIL AND COMBINATION

SWITCH ASSEMBLY .................................. 3C-8

STEERING COLUMN ASSEMBLY............ 3C-10

STEERING LOCK ASSEMBLY

(IGNITION SWITCH) ................................. 3C-16

STEERING LOWER SHAFT...................... 3C-17

CHECKING STEERING COLUMN

ASSEMBLY AND LOWER SHAFT FOR

ACCIDENT DAMAGE ................................... 3C-18

SPECIAL TOOL ............................................ 3C-19

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Please observe all WARNINGS and “Service Precautions” under “On-

Vehicle Service” in air bag system section before performing service on or around the air bag sys-

tem components or wiring. Failure to follow WARNINGS could result in unintentional activation of

the system or could render the system inoperative. Either of these two conditions may result in

severe injury.

The procedures in this section must be followed in the order listed to temporarily disable the air

bag system and prevent false diagnostic codes from setting. Failure to follow procedures could

result in possible air bag system activation, personal injury or otherwise unneeded air bag system

repairs.

CAUTION:

When fasteners are removed, always reinstall them at the same location from which they were

removed. If a fastener needs to be replaced, use the correct part number fastener for that application.

If the correct part number fastener is not available, a fastener of equal size and strength (or stronger)

may be used. Fasteners that are not reused, and those requiring thread-locking compound, will be

called out. The correct torque value must be used when installing fasteners that require it. If the above

procedures are not followed, parts or system damage could result.

Page 180 of 698

STEERING WHEEL AND COLUMN 3C-7

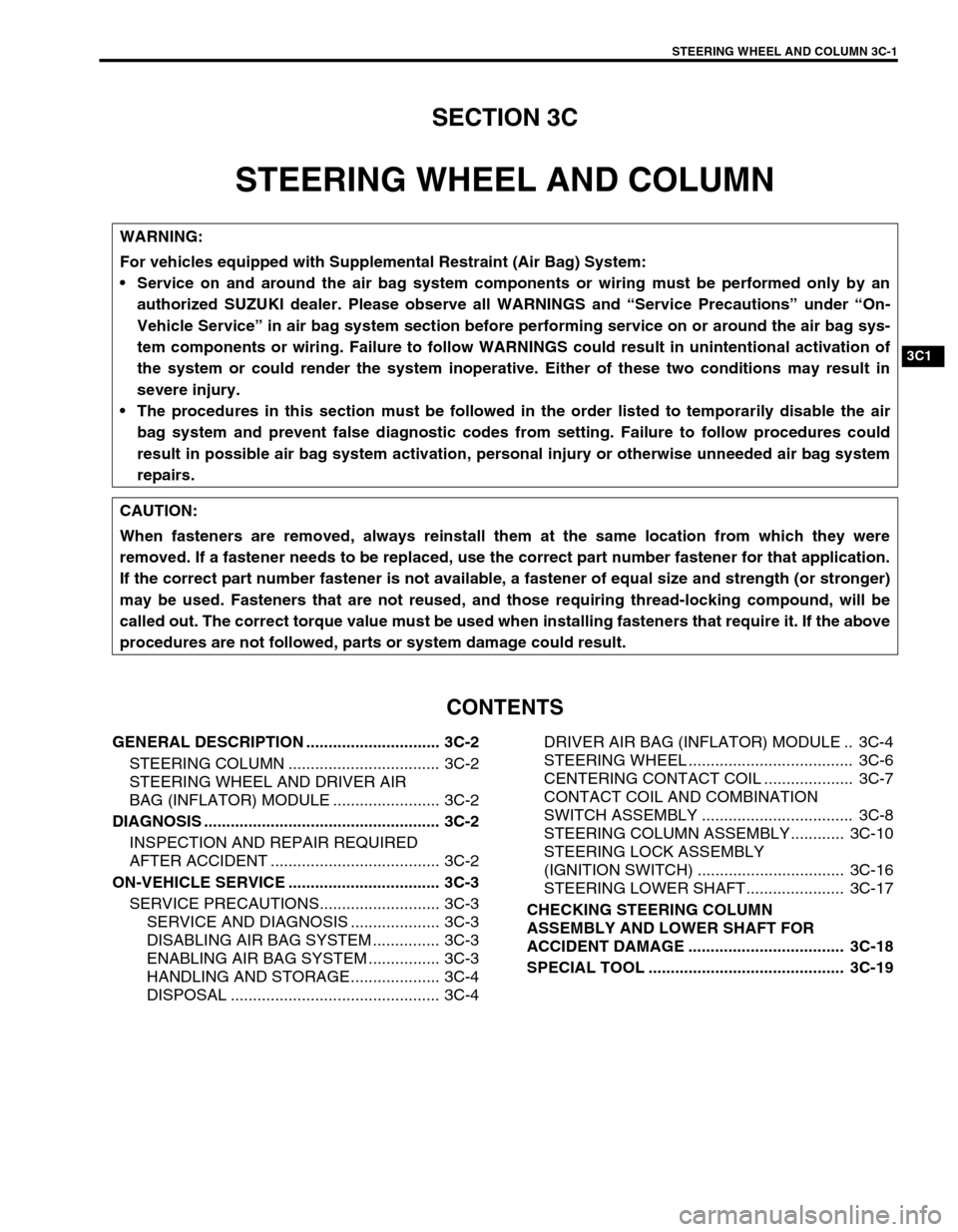

INSTALLATION

1) Check that vehicle’s front tires are at straight-ahead position

and contact coil is centered. Refer to “CENTERING CON-

TACT COIL”.

2) Install steering wheel (1) to steering shaft with 2 lugs (2) on

contact coil fitted in two grooves (3) in the back of steering

wheel and also aligning marks (4) on steering wheel and

steering shaft.

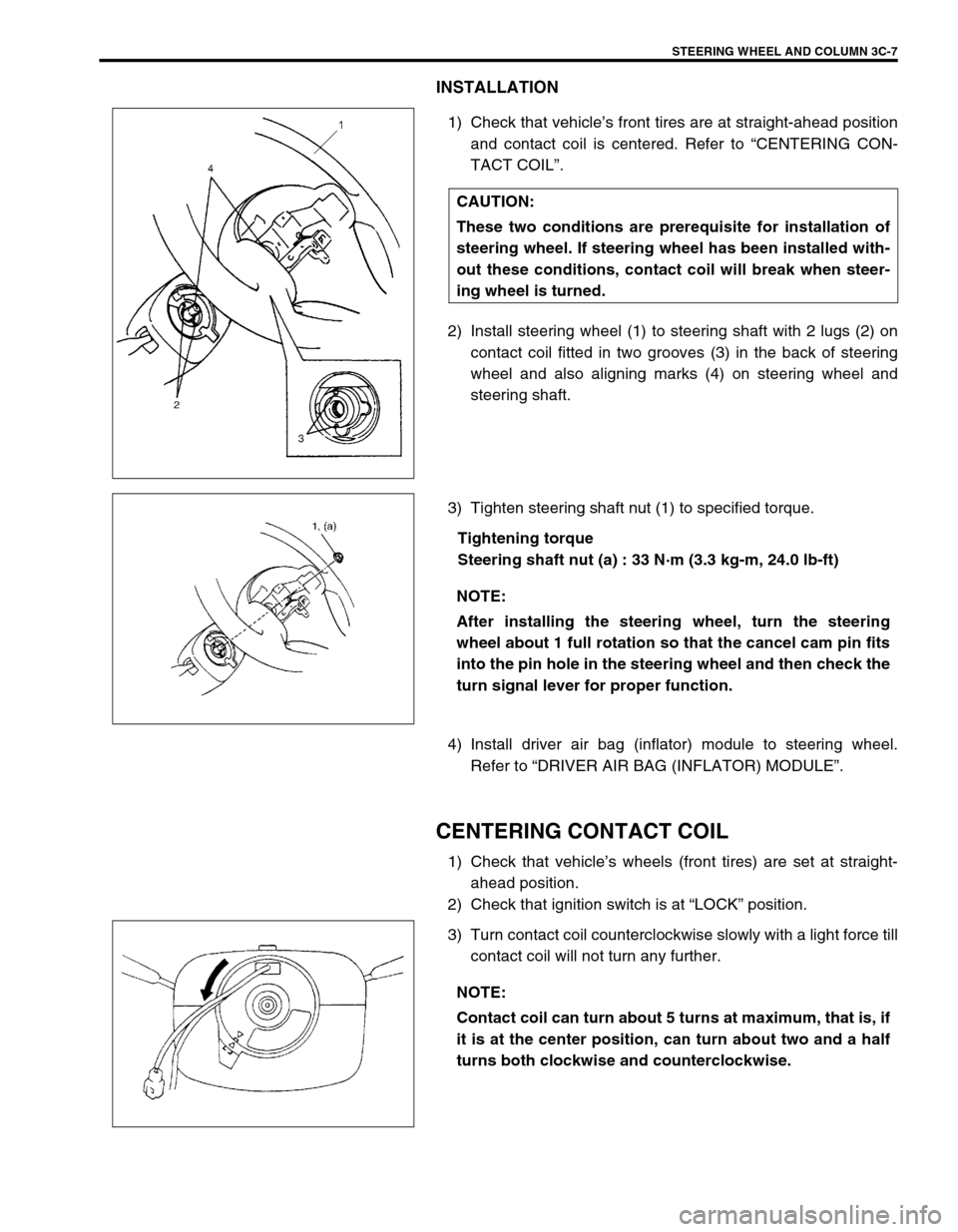

3) Tighten steering shaft nut (1) to specified torque.

Tightening torque

Steering shaft nut (a) : 33 N·m (3.3 kg-m, 24.0 lb-ft)

4) Install driver air bag (inflator) module to steering wheel.

Refer to “DRIVER AIR BAG (INFLATOR) MODULE”.

CENTERING CONTACT COIL

1) Check that vehicle’s wheels (front tires) are set at straight-

ahead position.

2) Check that ignition switch is at “LOCK” position.

3) Turn contact coil counterclockwise slowly with a light force till

contact coil will not turn any further. CAUTION:

These two conditions are prerequisite for installation of

steering wheel. If steering wheel has been installed with-

out these conditions, contact coil will break when steer-

ing wheel is turned.

NOTE:

After installing the steering wheel, turn the steering

wheel about 1 full rotation so that the cancel cam pin fits

into the pin hole in the steering wheel and then check the

turn signal lever for proper function.

NOTE:

Contact coil can turn about 5 turns at maximum, that is, if

it is at the center position, can turn about two and a half

turns both clockwise and counterclockwise.

Page 182 of 698

STEERING WHEEL AND COLUMN 3C-9

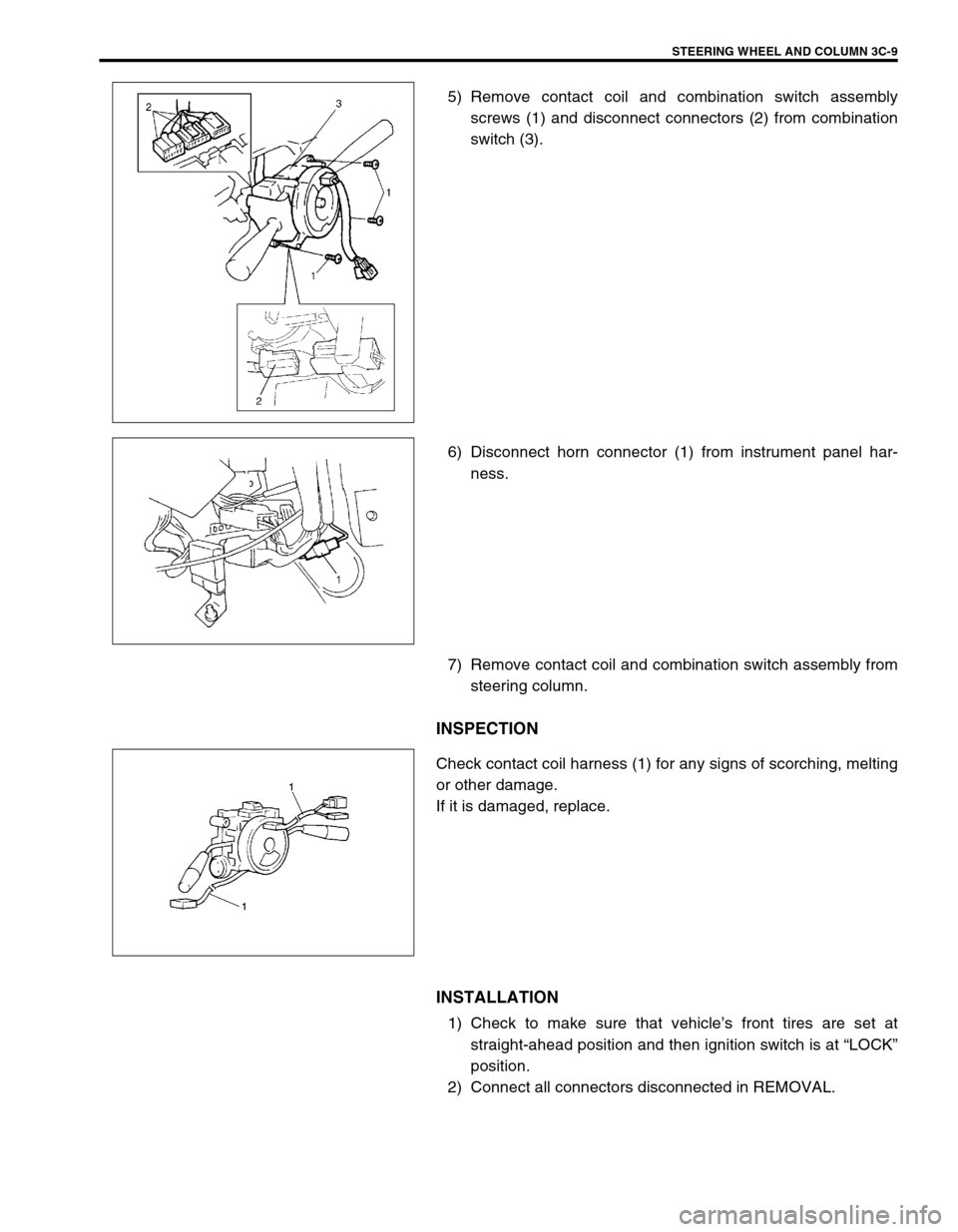

5) Remove contact coil and combination switch assembly

screws (1) and disconnect connectors (2) from combination

switch (3).

6) Disconnect horn connector (1) from instrument panel har-

ness.

7) Remove contact coil and combination switch assembly from

steering column.

INSPECTION

Check contact coil harness (1) for any signs of scorching, melting

or other damage.

If it is damaged, replace.

INSTALLATION

1) Check to make sure that vehicle’s front tires are set at

straight-ahead position and then ignition switch is at “LOCK”

position.

2) Connect all connectors disconnected in REMOVAL.

Page 190 of 698

STEERING WHEEL AND COLUMN 3C-17

5) Tighten new bolts (1) until head of each bolt is broken off.

6) Turn ignition key to “ACC” or “ON” position and check to be

sure that steering shaft (2) rotates smoothly. Also check for

lock operation.

7) Install steering column. Refer to “STEERING COLUMN”.

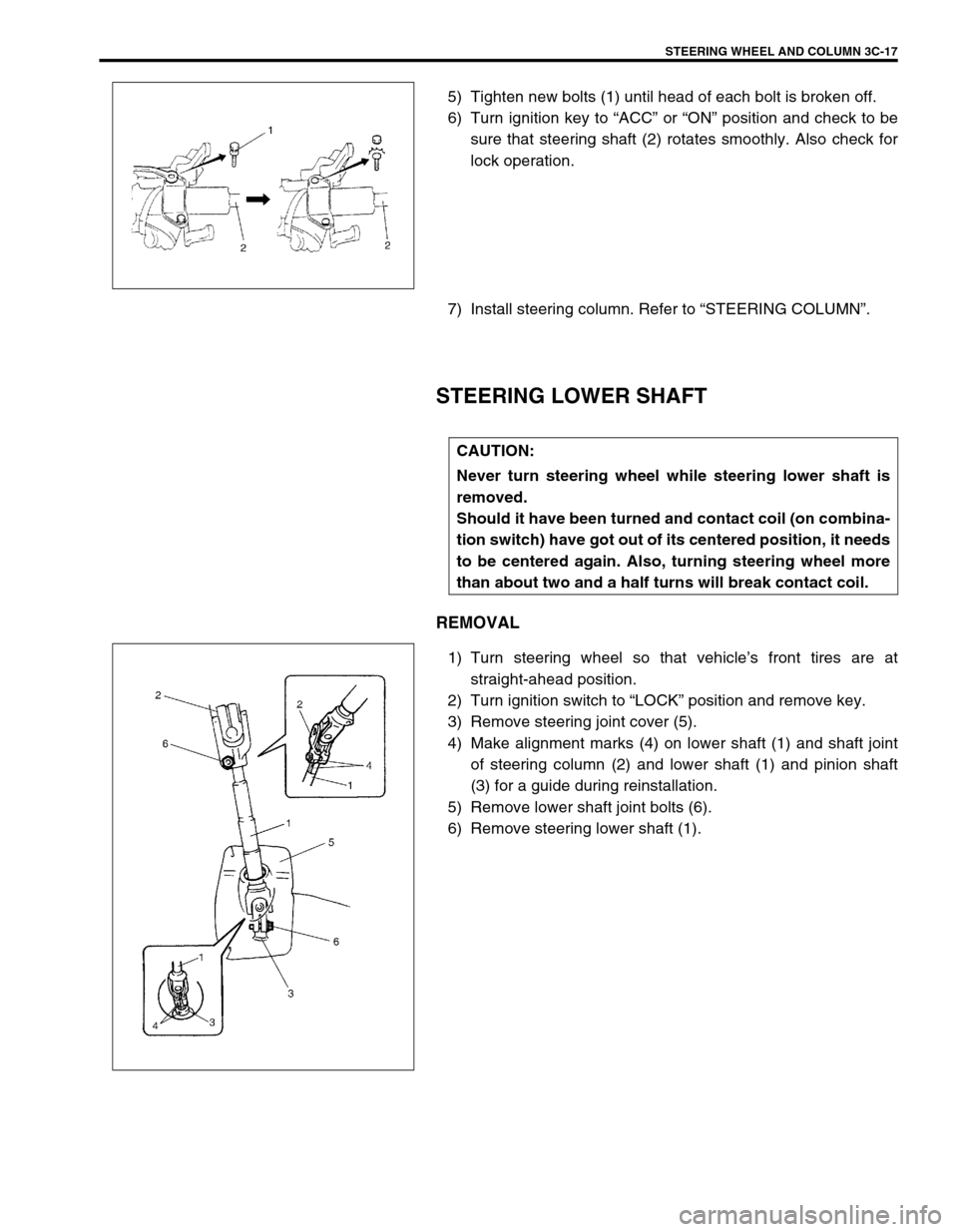

STEERING LOWER SHAFT

REMOVAL

1) Turn steering wheel so that vehicle’s front tires are at

straight-ahead position.

2) Turn ignition switch to “LOCK” position and remove key.

3) Remove steering joint cover (5).

4) Make alignment marks (4) on lower shaft (1) and shaft joint

of steering column (2) and lower shaft (1) and pinion shaft

(3) for a guide during reinstallation.

5) Remove lower shaft joint bolts (6).

6) Remove steering lower shaft (1).

CAUTION:

Never turn steering wheel while steering lower shaft is

removed.

Should it have been turned and contact coil (on combina-

tion switch) have got out of its centered position, it needs

to be centered again. Also, turning steering wheel more

than about two and a half turns will break contact coil.

Page 196 of 698

FRONT SUSPENSION 3D-3

DIAGNOSIS

STABILIZER BAR AND/OR BUSHING CHECK

Bar

Inspect for damage or deformation.

If defective, replace.

Bushing

Inspect for damage, wear or deterioration.

If defective, replace.

STRUT ASSEMBLY CHECK

Inspect strut for oil leakage, damage or deformation.

If strut is found faulty, replace it as an assembly unit,

because it can not be disassembled.

Inspect strut function refer to the following procedures.

1) Check and adjust tire pressures as specified.

2) Bounce vehicle body 3 or 4 times continuously by pushing

front end on the side with strut to be checked.

3) Apply the same amount of force at each push and note strut

resistance both when pushed and rebounding.

4) Also, note how many times vehicle body rebounds before

coming to stop after hands are off. Do the same for strut on

the other side.

5) Compare strut resistance and number of rebalance on the

right with those on the left. And they must be equal in both.

With proper strut, vehicle body should come to stop the

moments hands are off or after only one or two small rebal-

ances.

If conditions of struts are in doubt, compare them with known-

good vehicle or strut.

Inspect bearing for wear, abnormal noise or gripping.

If defective, replace.

Page 214 of 698

REAR SUSPENSION 3E-1

6F1

6F2

6G

1A

6K

7A

7A1

7B1

7C1

3E

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3E

REAR SUSPENSION

CONTENTS

GENERAL DESCRIPTION .............................. 3E-2

DIAGNOSIS ..................................................... 3E-4

REAR SHOCK ABSORBER CHECK ........... 3E-4

TRAILING ARM, LATERAL ROD, REAR

AXLE, PEAR AXLE HOUSING AND COIL

SPRING CHECK .......................................... 3E-4

BUMP STOPPER/SPRING UPPER SEAT

CHECK ......................................................... 3E-5

REAR SUSPENSION FASTENERS ............ 3E-5

WHEEL DISC, NUT AND BEARING

CHECK ......................................................... 3E-5

ON-VEHICLE SERVICE .................................. 3E-6

LATERAL ROD ............................................ 3E-6

REAR SHOCK ABSORBER......................... 3E-7

COIL SPRING .............................................. 3E-7BUMP STOPPER ...................................... 3E-10

SPRING UPPER SEAT ............................. 3E-11

TRAILING ARM ......................................... 3E-11

REAR AXLE (2WD VEHICLE) ................... 3E-14

WHEEL BEARING AND WHEEL STUD

(2WD VEHICLE) ........................................ 3E-19

REAR AXLE SHAFT AND WHEEL

BEARING (4WD VEHICLE) ....................... 3E-21

REAR AXLE SHAFT OIL SEAL (4WD

VEHICLE) .................................................. 3E-25

REAR AXLE HOUSING (4WD

VEHICLE) .................................................. 3E-26

REQUIRED SERVICE MATERIAL................ 3E-32

SPECIAL TOOL ............................................ 3E-32

NOTE:

All suspension fasteners are an important attaching part in that it could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number or with an equivalent part if replacement becomes necessary. Do not

use a replacement part of lesser quality or substitute design. Torque values must be used as speci-

fied during reassembly to assure proper retention of this part.

Never attempt to heat, quench or straighten any front suspension part. Replace it with a new part, or

damage to the part may result.