warning light SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 339 of 698

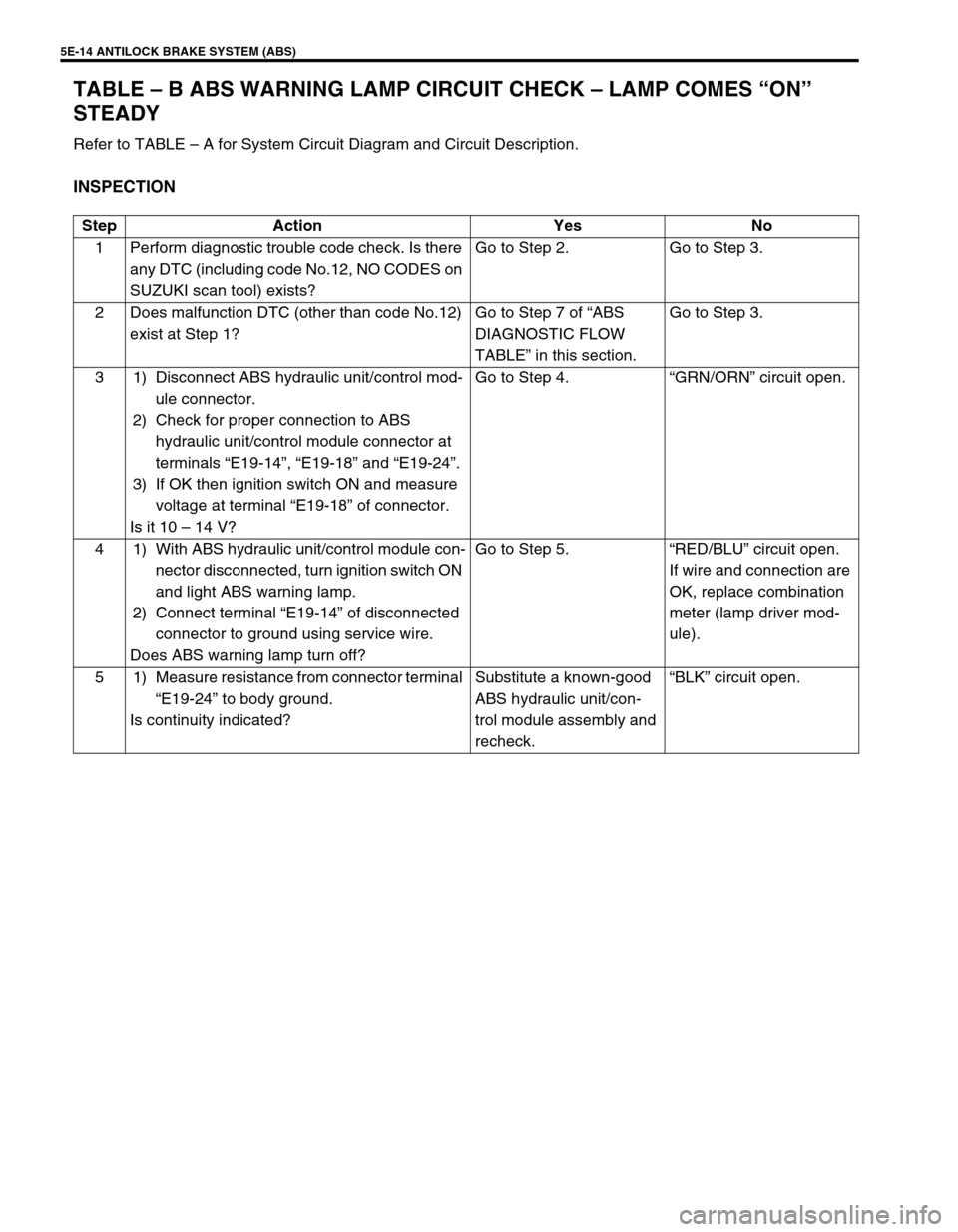

5E-14 ANTILOCK BRAKE SYSTEM (ABS)

TABLE – B ABS WARNING LAMP CIRCUIT CHECK – LAMP COMES “ON”

STEADY

Refer to TABLE – A for System Circuit Diagram and Circuit Description.

INSPECTION

Step Action Yes No

1 Perform diagnostic trouble code check. Is there

any DTC (including code No.12, NO CODES on

SUZUKI scan tool) exists?Go to Step 2. Go to Step 3.

2 Does malfunction DTC (other than code No.12)

exist at Step 1?Go to Step 7 of “ABS

DIAGNOSTIC FLOW

TABLE” in this section.Go to Step 3.

3 1) Disconnect ABS hydraulic unit/control mod-

ule connector.

2) Check for proper connection to ABS

hydraulic unit/control module connector at

terminals “E19-14”, “E19-18” and “E19-24”.

3) If OK then ignition switch ON and measure

voltage at terminal “E19-18” of connector.

Is it 10 – 14 V?Go to Step 4.“GRN/ORN” circuit open.

4 1) With ABS hydraulic unit/control module con-

nector disconnected, turn ignition switch ON

and light ABS warning lamp.

2) Connect terminal “E19-14” of disconnected

connector to ground using service wire.

Does ABS warning lamp turn off?Go to Step 5.“RED/BLU” circuit open.

If wire and connection are

OK, replace combination

meter (lamp driver mod-

ule).

5 1) Measure resistance from connector terminal

“E19-24” to body ground.

Is continuity indicated?Substitute a known-good

ABS hydraulic unit/con-

trol module assembly and

recheck.“BLK” circuit open.

Page 401 of 698

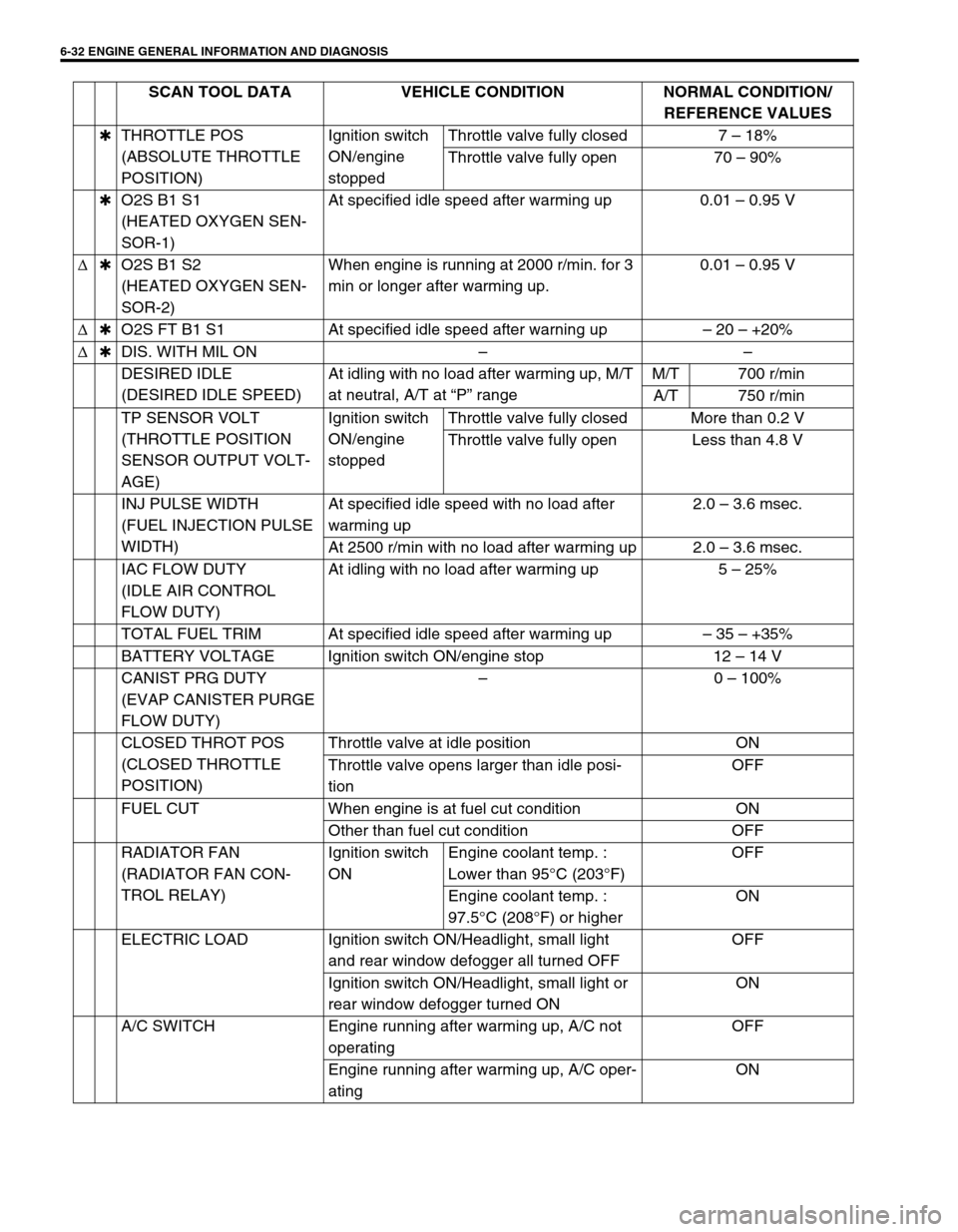

6-32 ENGINE GENERAL INFORMATION AND DIAGNOSIS

✱THROTTLE POS

(ABSOLUTE THROTTLE

POSITION)Ignition switch

ON/engine

stoppedThrottle valve fully closed 7 – 18%

Throttle valve fully open 70 – 90%

✱O2S B1 S1

(HEATED OXYGEN SEN-

SOR-1)At specified idle speed after warming up 0.01 – 0.95 V

∆✱O2S B1 S2

(HEATED OXYGEN SEN-

SOR-2)When engine is running at 2000 r/min. for 3

min or longer after warming up.0.01 – 0.95 V

∆✱O2S FT B1 S1 At specified idle speed after warning up– 20 – +20%

∆✱DIS. WITH MIL ON––

DESIRED IDLE

(DESIRED IDLE SPEED)At idling with no load after warming up, M/T

at neutral, A/T at “P” rangeM/T 700 r/min

A/T 750 r/min

TP SENSOR VOLT

(THROTTLE POSITION

SENSOR OUTPUT VOLT-

AGE)Ignition switch

ON/engine

stoppedThrottle valve fully closed More than 0.2 V

Throttle valve fully open Less than 4.8 V

INJ PULSE WIDTH

(FUEL INJECTION PULSE

WIDTH)At specified idle speed with no load after

warming up2.0 – 3.6 msec.

At 2500 r/min with no load after warming up 2.0 – 3.6 msec.

IAC FLOW DUTY

(IDLE AIR CONTROL

FLOW DUTY)At idling with no load after warming up 5 – 25%

TOTAL FUEL TRIM At specified idle speed after warming up– 35 – +35%

BATTERY VOLTAGE Ignition switch ON/engine stop 12 – 14 V

CANIST PRG DUTY

(EVAP CANISTER PURGE

FLOW DUTY)–0 – 100%

CLOSED THROT POS

(CLOSED THROTTLE

POSITION)Throttle valve at idle position ON

Throttle valve opens larger than idle posi-

tionOFF

FUEL CUT When engine is at fuel cut condition ON

Other than fuel cut condition OFF

RADIATOR FAN

(RADIATOR FAN CON-

TROL RELAY)Ignition switch

ONEngine coolant temp. :

Lower than 95°C (203°F)OFF

Engine coolant temp. :

97.5°C (208°F) or higherON

ELECTRIC LOAD Ignition switch ON/Headlight, small light

and rear window defogger all turned OFFOFF

Ignition switch ON/Headlight, small light or

rear window defogger turned ONON

A/C SWITCH Engine running after warming up, A/C not

operatingOFF

Engine running after warming up, A/C oper-

atingON SCAN TOOL DATA VEHICLE CONDITION NORMAL CONDITION/

REFERENCE VALUES

Page 415 of 698

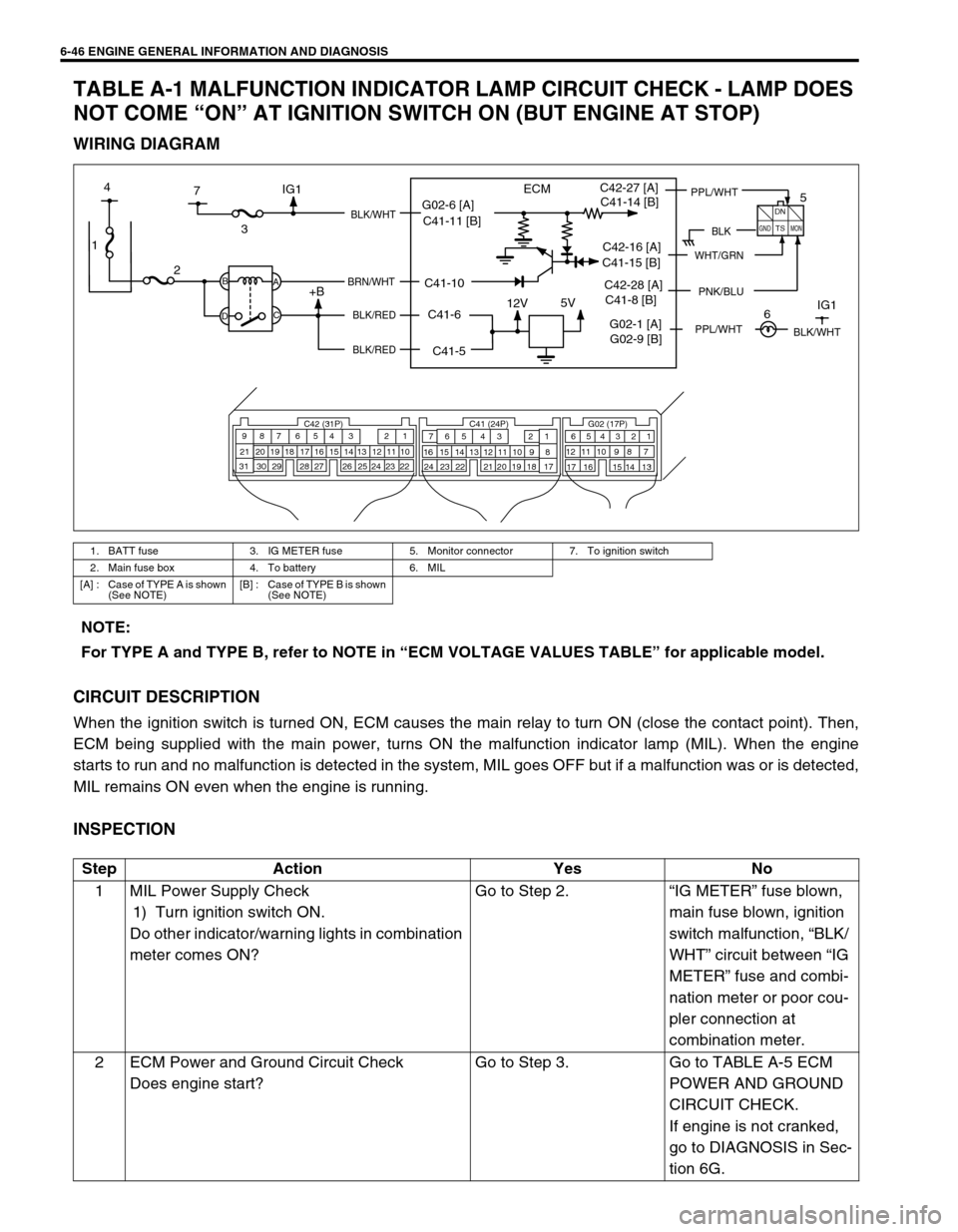

6-46 ENGINE GENERAL INFORMATION AND DIAGNOSIS

TABLE A-1 MALFUNCTION INDICATOR LAMP CIRCUIT CHECK - LAMP DOES

NOT COME “ON” AT IGNITION SWITCH ON (BUT ENGINE AT STOP)

WIRING DIAGRAM

CIRCUIT DESCRIPTION

When the ignition switch is turned ON, ECM causes the main relay to turn ON (close the contact point). Then,

ECM being supplied with the main power, turns ON the malfunction indicator lamp (MIL). When the engine

starts to run and no malfunction is detected in the system, MIL goes OFF but if a malfunction was or is detected,

MIL remains ON even when the engine is running.

INSPECTION

1. BATT fuse 3. IG METER fuse 5. Monitor connector 7. To ignition switch

2. Main fuse box 4. To battery 6. MIL

[A] : Case of TYPE A is shown

(See NOTE)[B] : Case of TYPE B is shown

(See NOTE)

1

12V5V

ECM

23

+BB

DA

C

BLK/WHT

BRN/WHT

BLK/RED

BLK/RED

C42 (31P) C41 (24P) G02 (17P)1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 28 27 29 30 315 6

1 2 3 4 5 6 7

11 12

9 10 11 13 12 14 15 16

16 171 2

7 8

13 14 3 4

9 10

15 17 188

19 20 21 22 23 24

BLK

DN

TS

GNDMON

PPL/WHTC42-27 [A]

C42-16 [A]

PNK/BLUC42-28 [A]

7 4

G02-1 [A]IG1

5

6IG1

WHT/GRN

BLK/WHT

G02-6 [A]

C41-5 C41-6 C41-10 C41-11 [B]C41-14 [B]

C41-15 [B]

C41-8 [B]

G02-9 [B]

PPL/WHT

NOTE:

For TYPE A and TYPE B, refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.

Step Action Yes No

1 MIL Power Supply Check

1) Turn ignition switch ON.

Do other indicator/warning lights in combination

meter comes ON?Go to Step 2.“IG METER” fuse blown,

main fuse blown, ignition

switch malfunction, “BLK/

WHT” circuit between “IG

METER” fuse and combi-

nation meter or poor cou-

pler connection at

combination meter.

2 ECM Power and Ground Circuit Check

Does engine start?Go to Step 3. Go to TABLE A-5 ECM

POWER AND GROUND

CIRCUIT CHECK.

If engine is not cranked,

go to DIAGNOSIS in Sec-

tion 6G.

Page 689 of 698

CHARGING SYSTEM 6H-9

ON-VEHICLE SERVICE

BATTERY

JUMP STARTING IN CASE OF EMERGENCY

WITH AUXILIARY (BOOSTER) BATTERY

Both booster and discharged battery should be treated carefully when using jumper cables. Follow procedure

outlined below, being careful not to cause sparks.

1) Set parking brake and place automatic transmission in PARK (NEUTRAL on manual transmission). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add distilled water.

3) Attach end of one jumper cable to positive terminal of booster battery and the other end of the same cable to

positive terminal of discharged battery. (Use 12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to negative terminal of booster battery, and the other end to

a solid engine ground (such as exhaust manifold) at least 45 cm (18 in.) away from battery of vehicle being

started.

5) Start engine of vehicle with booster battery and turn off electrical accessories. Then Start engine of the vehi-

cle with discharged battery.

6) Disconnect jumper cables in the exact reverse order.

WITH CHARGING EQUIPMENT

CAUTION:

If vehicle is manual transmission model and has a catalytic converter, do not push or tow it to start.

Damage to its emission system and/or to other parts may result.

WARNING:

Departure from these conditions or procedure described below could result in:

–Serious personal injury (particularly to eyes) or property damage from such causes as battery

explosion, battery acid, or electrical burns.

–Damage to electronic components of either vehicle.

Remove rings, watches, and other jewelry. Wear approved eye protection.

Be careful so that metal tools or jumper cables do not contact positive battery terminal (or metal in

contact with it) and any other metal on vehicle, because a short circuit could occur.

WARNING:

Do not connect negative cable directly to negative terminal of dead battery.

CAUTION:

When jump starting engine with charging equipment, be sure equipment used is 12-volt and negative

ground. Do not use 24-volt charging equipment. Using such equipment can cause serious damage to

electrical system or electronic parts.