warning SUZUKI SWIFT 2000 1.G RG413 Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 149 of 698

3B1-8 ELECTRICAL POWER STEERING (P/S) SYSTEM

DTC CHECK

USING SUZUKI SCAN TOOL

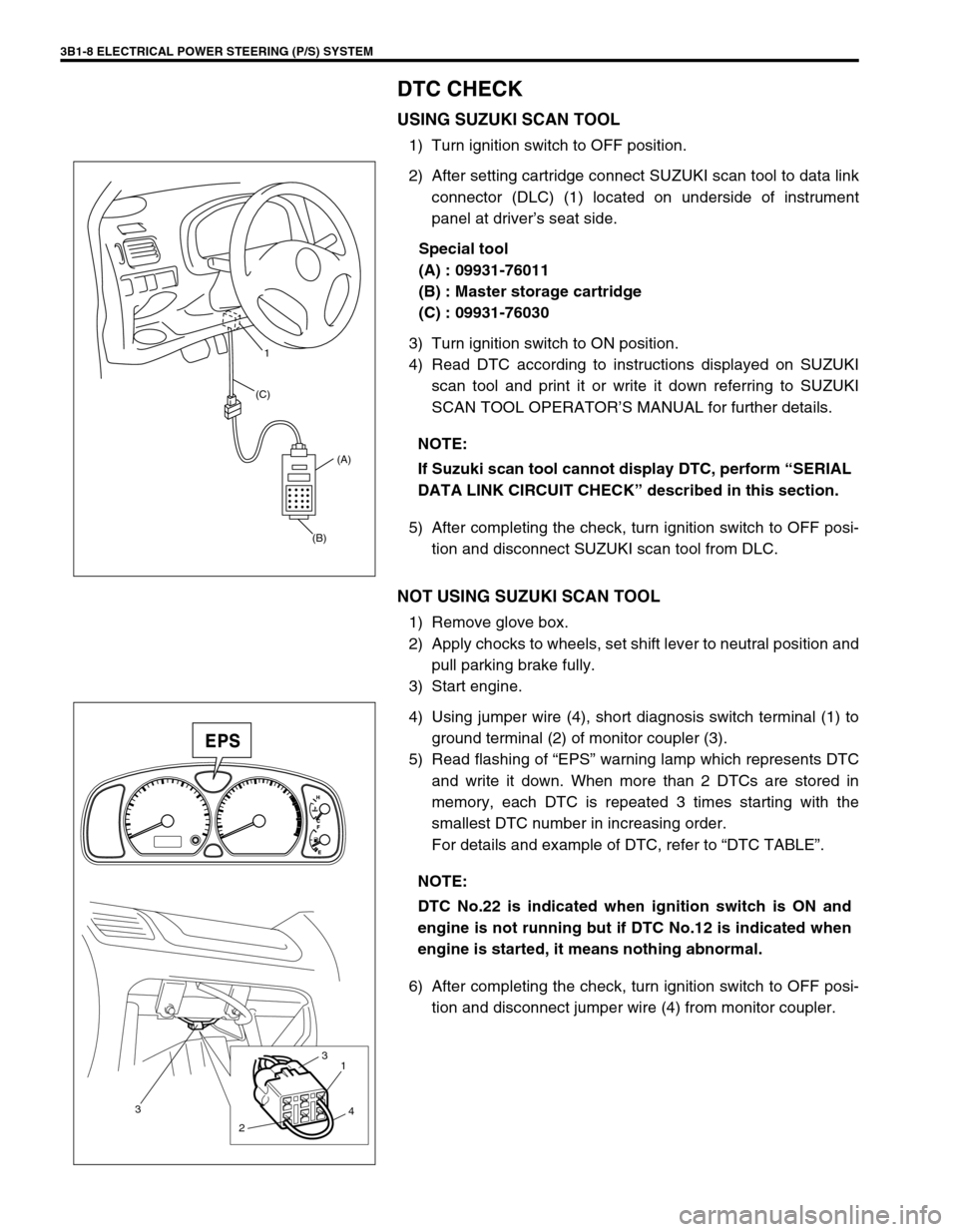

1) Turn ignition switch to OFF position.

2) After setting cartridge connect SUZUKI scan tool to data link

connector (DLC) (1) located on underside of instrument

panel at driver’s seat side.

Special tool

(A) : 09931-76011

(B) : Master storage cartridge

(C) : 09931-76030

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on SUZUKI

scan tool and print it or write it down referring to SUZUKI

SCAN TOOL OPERATOR’S MANUAL for further details.

5) After completing the check, turn ignition switch to OFF posi-

tion and disconnect SUZUKI scan tool from DLC.

NOT USING SUZUKI SCAN TOOL

1) Remove glove box.

2) Apply chocks to wheels, set shift lever to neutral position and

pull parking brake fully.

3) Start engine.

4) Using jumper wire (4), short diagnosis switch terminal (1) to

ground terminal (2) of monitor coupler (3).

5) Read flashing of “EPS” warning lamp which represents DTC

and write it down. When more than 2 DTCs are stored in

memory, each DTC is repeated 3 times starting with the

smallest DTC number in increasing order.

For details and example of DTC, refer to “DTC TABLE”.

6) After completing the check, turn ignition switch to OFF posi-

tion and disconnect jumper wire (4) from monitor coupler. NOTE:

If Suzuki scan tool cannot display DTC, perform “SERIAL

DATA LINK CIRCUIT CHECK” described in this section.

(B)(A) (C)1

NOTE:

DTC No.22 is indicated when ignition switch is ON and

engine is not running but if DTC No.12 is indicated when

engine is started, it means nothing abnormal.

3

21

3

4

Page 151 of 698

3B1-10 ELECTRICAL POWER STEERING (P/S) SYSTEM

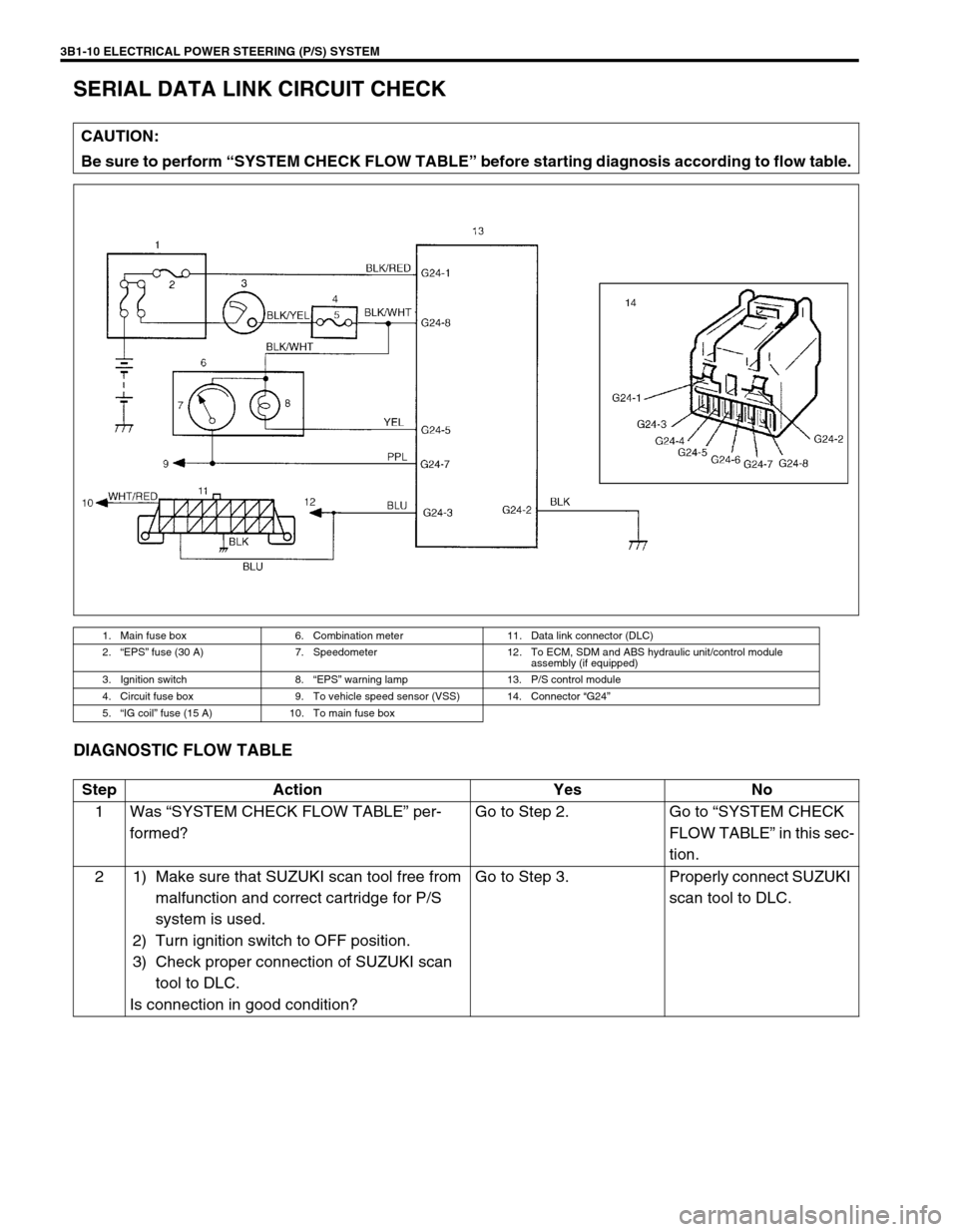

SERIAL DATA LINK CIRCUIT CHECK

DIAGNOSTIC FLOW TABLE

CAUTION:

Be sure to perform “SYSTEM CHECK FLOW TABLE” before starting diagnosis according to flow table.

1. Main fuse box 6. Combination meter 11. Data link connector (DLC)

2.“EPS” fuse (30 A) 7. Speedometer 12. To ECM, SDM and ABS hydraulic unit/control module

assembly (if equipped)

3. Ignition switch 8.“EPS” warning lamp 13. P/S control module

4. Circuit fuse box 9. To vehicle speed sensor (VSS) 14. Connector “G24”

5.“IG coil” fuse (15 A) 10. To main fuse box

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” per-

formed?Go to Step 2. Go to “SYSTEM CHECK

FLOW TABLE” in this sec-

tion.

2 1) Make sure that SUZUKI scan tool free from

malfunction and correct cartridge for P/S

system is used.

2) Turn ignition switch to OFF position.

3) Check proper connection of SUZUKI scan

tool to DLC.

Is connection in good condition?Go to Step 3. Properly connect SUZUKI

scan tool to DLC.

Page 154 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-13

TABLE A - MALFUNCTION INDICATOR LAMP DOES NOT COME ON AT IGNI-

TION SWITCH ON BUT LEAVING ENGINE OFF

CIRCUIT

1. To main fuse 5.“EPS” warning lamp 9. Ground terminal

2. Ignition switch 6. Combination meter 10. P/S control module

3.“P/S” fuse (30A) in fuse box 7. Monitor coupler 11. Connector “G24”

4.“IG METER” fuse (15A) in fuse box 8. Diagnosis switch terminal

G24-1

G24-8

G24-5

G24-4

G24-2 1

23

4

5 6

7

8

910

BLK/WHT

BLK/WHTBLK/RED

YEL

PPL/WHT

BLKBLK

87 7

6

G24-1

G24-4

G24-5

G24-8G24-2

11

Page 155 of 698

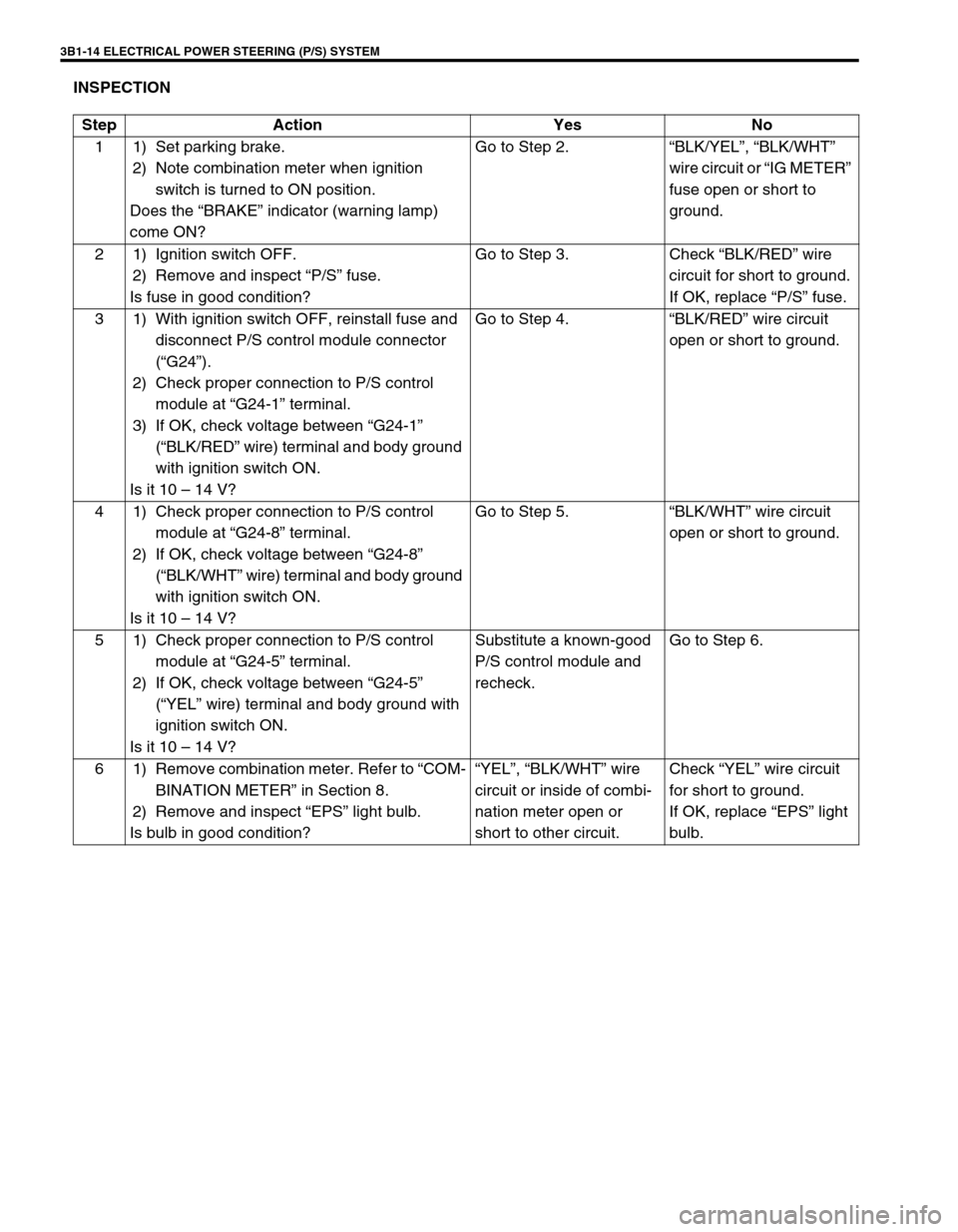

3B1-14 ELECTRICAL POWER STEERING (P/S) SYSTEM

INSPECTION

Step Action Yes No

1 1) Set parking brake.

2) Note combination meter when ignition

switch is turned to ON position.

Does the “BRAKE” indicator (warning lamp)

come ON?Go to Step 2.“BLK/YEL”, “BLK/WHT”

wire circuit or “IG METER”

fuse open or short to

ground.

2 1) Ignition switch OFF.

2) Remove and inspect “P/S” fuse.

Is fuse in good condition?Go to Step 3. Check “BLK/RED” wire

circuit for short to ground.

If OK, replace “P/S” fuse.

3 1) With ignition switch OFF, reinstall fuse and

disconnect P/S control module connector

(“G24”).

2) Check proper connection to P/S control

module at “G24-1” terminal.

3) If OK, check voltage between “G24-1”

(“BLK/RED” wire) terminal and body ground

with ignition switch ON.

Is it 10 – 14 V?Go to Step 4.“BLK/RED” wire circuit

open or short to ground.

4 1) Check proper connection to P/S control

module at “G24-8” terminal.

2) If OK, check voltage between “G24-8”

(“BLK/WHT” wire) terminal and body ground

with ignition switch ON.

Is it 10 – 14 V?Go to Step 5.“BLK/WHT” wire circuit

open or short to ground.

5 1) Check proper connection to P/S control

module at “G24-5” terminal.

2) If OK, check voltage between “G24-5”

(“YEL” wire) terminal and body ground with

ignition switch ON.

Is it 10 – 14 V?Substitute a known-good

P/S control module and

recheck.Go to Step 6.

6 1) Remove combination meter. Refer to “COM-

BINATION METER” in Section 8.

2) Remove and inspect “EPS” light bulb.

Is bulb in good condition?“YEL”, “BLK/WHT” wire

circuit or inside of combi-

nation meter open or

short to other circuit.Check “YEL” wire circuit

for short to ground.

If OK, replace “EPS” light

bulb.

Page 160 of 698

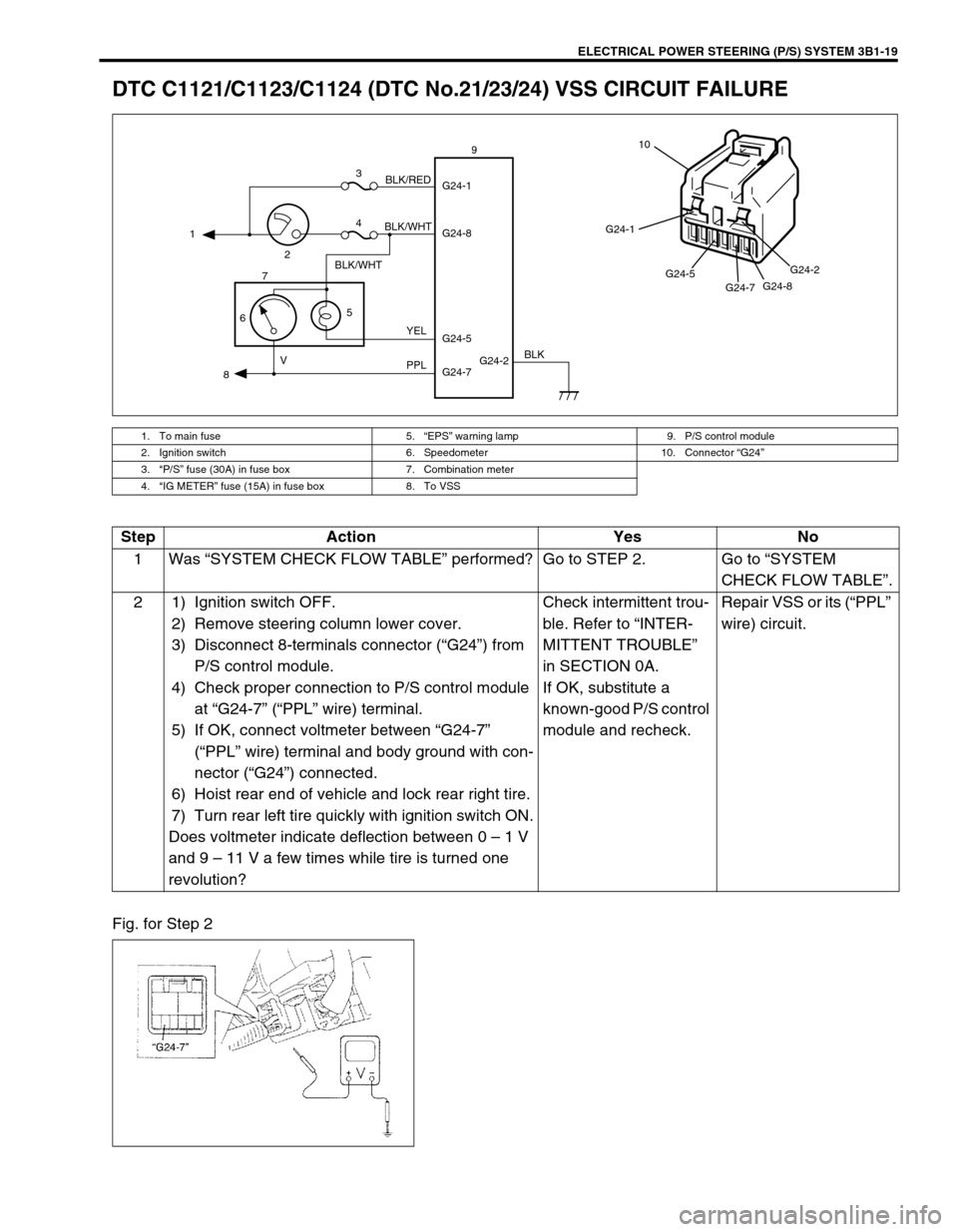

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-19

DTC C1121/C1123/C1124 (DTC No.21/23/24) VSS CIRCUIT FAILURE

Fig. for Step 2

1. To main fuse 5.“EPS” warning lamp 9. P/S control module

2. Ignition switch 6. Speedometer 10. Connector “G24”

3.“P/S” fuse (30A) in fuse box 7. Combination meter

4.“IG METER” fuse (15A) in fuse box 8. To VSS

G24-2 G24-1

G24-8

G24-7 G24-5 1

23

4

5

67

89

BLK/WHT

BLK/WHTBLK/RED

YEL

PPL VBLK

G24-1

G24-5

G24-7G24-8G24-2

10

Step Action Yes No

1Was “SYSTEM CHECK FLOW TABLE” performed? Go to STEP 2. Go to “SYSTEM

CHECK FLOW TABLE”.

2 1) Ignition switch OFF.

2) Remove steering column lower cover.

3) Disconnect 8-terminals connector (“G24”) from

P/S control module.

4) Check proper connection to P/S control module

at “G24-7” (“PPL” wire) terminal.

5) If OK, connect voltmeter between “G24-7”

(“PPL” wire) terminal and body ground with con-

nector (“G24”) connected.

6) Hoist rear end of vehicle and lock rear right tire.

7) Turn rear left tire quickly with ignition switch ON.

Does voltmeter indicate deflection between 0 – 1 V

and 9 – 11 V a few times while tire is turned one

revolution?Check intermittent trou-

ble. Refer to “INTER-

MITTENT TROUBLE”

in SECTION 0A.

If OK, substitute a

known-good P/S control

module and recheck.Repair VSS or its (“PPL”

wire) circuit.

Page 168 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-27

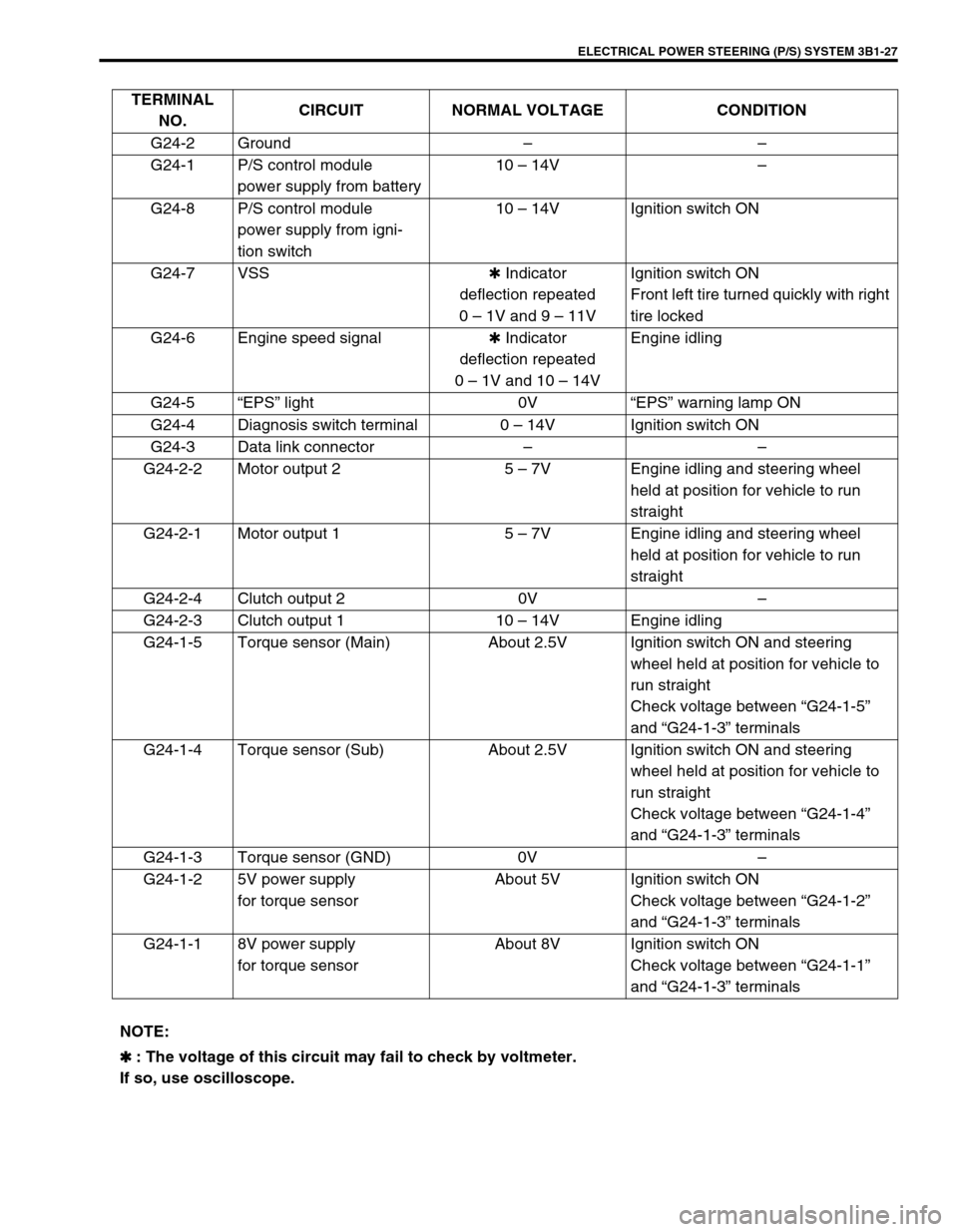

TERMINAL

NO.CIRCUIT NORMAL VOLTAGE CONDITION

G24-2 Ground––

G24-1 P/S control module

power supply from battery10 – 14V–

G24-8 P/S control module

power supply from igni-

tion switch10 – 14V Ignition switch ON

G24-7 VSS✱ Indicator

deflection repeated

0 – 1V and 9 – 11VIgnition switch ON

Front left tire turned quickly with right

tire locked

G24-6 Engine speed signal✱ Indicator

deflection repeated

0 – 1V and 10 – 14VEngine idling

G24-5“EPS” light 0V“EPS” warning lamp ON

G24-4 Diagnosis switch terminal 0 – 14V Ignition switch ON

G24-3 Data link connector––

G24-2-2 Motor output 2 5 – 7V Engine idling and steering wheel

held at position for vehicle to run

straight

G24-2-1 Motor output 1 5 – 7V Engine idling and steering wheel

held at position for vehicle to run

straight

G24-2-4 Clutch output 2 0V–

G24-2-3 Clutch output 1 10 – 14V Engine idling

G24-1-5 Torque sensor (Main) About 2.5V Ignition switch ON and steering

wheel held at position for vehicle to

run straight

Check voltage between “G24-1-5”

and “G24-1-3” terminals

G24-1-4 Torque sensor (Sub) About 2.5V Ignition switch ON and steering

wheel held at position for vehicle to

run straight

Check voltage between “G24-1-4”

and “G24-1-3” terminals

G24-1-3 Torque sensor (GND) 0V–

G24-1-2 5V power supply

for torque sensorAbout 5V Ignition switch ON

Check voltage between “G24-1-2”

and “G24-1-3” terminals

G24-1-1 8V power supply

for torque sensorAbout 8V Ignition switch ON

Check voltage between “G24-1-1”

and “G24-1-3” terminals

NOTE:

✱

✱✱ ✱ : The voltage of this circuit may fail to check by voltmeter.

If so, use oscilloscope.

Page 174 of 698

STEERING WHEEL AND COLUMN 3C-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

3C1

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3C

STEERING WHEEL AND COLUMN

CONTENTS

GENERAL DESCRIPTION .............................. 3C-2

STEERING COLUMN .................................. 3C-2

STEERING WHEEL AND DRIVER AIR

BAG (INFLATOR) MODULE ........................ 3C-2

DIAGNOSIS ..................................................... 3C-2

INSPECTION AND REPAIR REQUIRED

AFTER ACCIDENT ...................................... 3C-2

ON-VEHICLE SERVICE .................................. 3C-3

SERVICE PRECAUTIONS........................... 3C-3

SERVICE AND DIAGNOSIS .................... 3C-3

DISABLING AIR BAG SYSTEM ............... 3C-3

ENABLING AIR BAG SYSTEM ................ 3C-3

HANDLING AND STORAGE.................... 3C-4

DISPOSAL ............................................... 3C-4DRIVER AIR BAG (INFLATOR) MODULE .. 3C-4

STEERING WHEEL ..................................... 3C-6

CENTERING CONTACT COIL .................... 3C-7

CONTACT COIL AND COMBINATION

SWITCH ASSEMBLY .................................. 3C-8

STEERING COLUMN ASSEMBLY............ 3C-10

STEERING LOCK ASSEMBLY

(IGNITION SWITCH) ................................. 3C-16

STEERING LOWER SHAFT...................... 3C-17

CHECKING STEERING COLUMN

ASSEMBLY AND LOWER SHAFT FOR

ACCIDENT DAMAGE ................................... 3C-18

SPECIAL TOOL ............................................ 3C-19

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Please observe all WARNINGS and “Service Precautions” under “On-

Vehicle Service” in air bag system section before performing service on or around the air bag sys-

tem components or wiring. Failure to follow WARNINGS could result in unintentional activation of

the system or could render the system inoperative. Either of these two conditions may result in

severe injury.

The procedures in this section must be followed in the order listed to temporarily disable the air

bag system and prevent false diagnostic codes from setting. Failure to follow procedures could

result in possible air bag system activation, personal injury or otherwise unneeded air bag system

repairs.

CAUTION:

When fasteners are removed, always reinstall them at the same location from which they were

removed. If a fastener needs to be replaced, use the correct part number fastener for that application.

If the correct part number fastener is not available, a fastener of equal size and strength (or stronger)

may be used. Fasteners that are not reused, and those requiring thread-locking compound, will be

called out. The correct torque value must be used when installing fasteners that require it. If the above

procedures are not followed, parts or system damage could result.

Page 175 of 698

3C-2 STEERING WHEEL AND COLUMN

GENERAL DESCRIPTION

STEERING COLUMN

This double tube type steering column has following three important features in addition to the steering function

:

The column is energy absorbing, designed to compress in a front-end collision.

The ignition switch and lock are mounted conveniently on this column.

With the column mounted lock, the ignition and steering operations can be locked to inhibit theft of the vehi-

cle.

To insure the energy absorbing action, it is important that only the specified screws, bolts, and nuts be used as

designated and that they are tightened to the specified torque.

When the column assembly is removed from the vehicle, special care must be taken in handling it. Use of a

steering wheel puller other than the one recommended in this manual or a sharp blow on the end of the steering

shaft, leaning on the assembly, or dropping the assembly could shear the plastic shear pins which maintain col-

umn length and position.

STEERING WHEEL AND DRIVER AIR BAG (INFLATOR) MODULE

The driver air bag (inflator) module is one of the supplemental restraint (air bag) system components and is

mounted to the center of the steering wheel. During certain frontal crashes, the air bag system supplements the

restraint of the driver’s and passenger’s seat belts by deploying the air bags.

The air bag (inflator) module should be handled with care to prevent accidental deployment. When servicing, be

sure to observe all WARNINGS and CAUTIONS and “SERVICE PRECAUTIONS” under “ON-VEHICLE SER-

VICE” in Section 10B.

DIAGNOSIS

For maintenance service of the steering wheel and column, refer to Section 0B.

For diagnosis of the steering wheel and column, refer to Section 3.

For diagnosis of the air bag system, refer to Section 10B.

INSPECTION AND REPAIR REQUIRED AFTER ACCIDENT

After an accident, whether the air bag has been deployed or not, be sure to perform checks, inspections and

repairs described under “CHECKING STEERING COLUMN ASSEMBLY AND LOWER SHAFT FOR ACCI-

DENT DAMAGE” as well as “REPAIRS AND INSPECTIONS REQUIRED AFTER ACCIDENT” under “DIAGNO-

SIS” in Section 10B.

Page 177 of 698

3C-4 STEERING WHEEL AND COLUMN

HANDLING AND STORAGE

For handling and storage, refer to “HANDLING AND STORAGE” under “SERVICE PRECAUTIONS” in Section

10B.

DISPOSAL

For disposal, refer to “DISPOSAL” under “SERVICE PRECAUTIONS” in Section 10B.

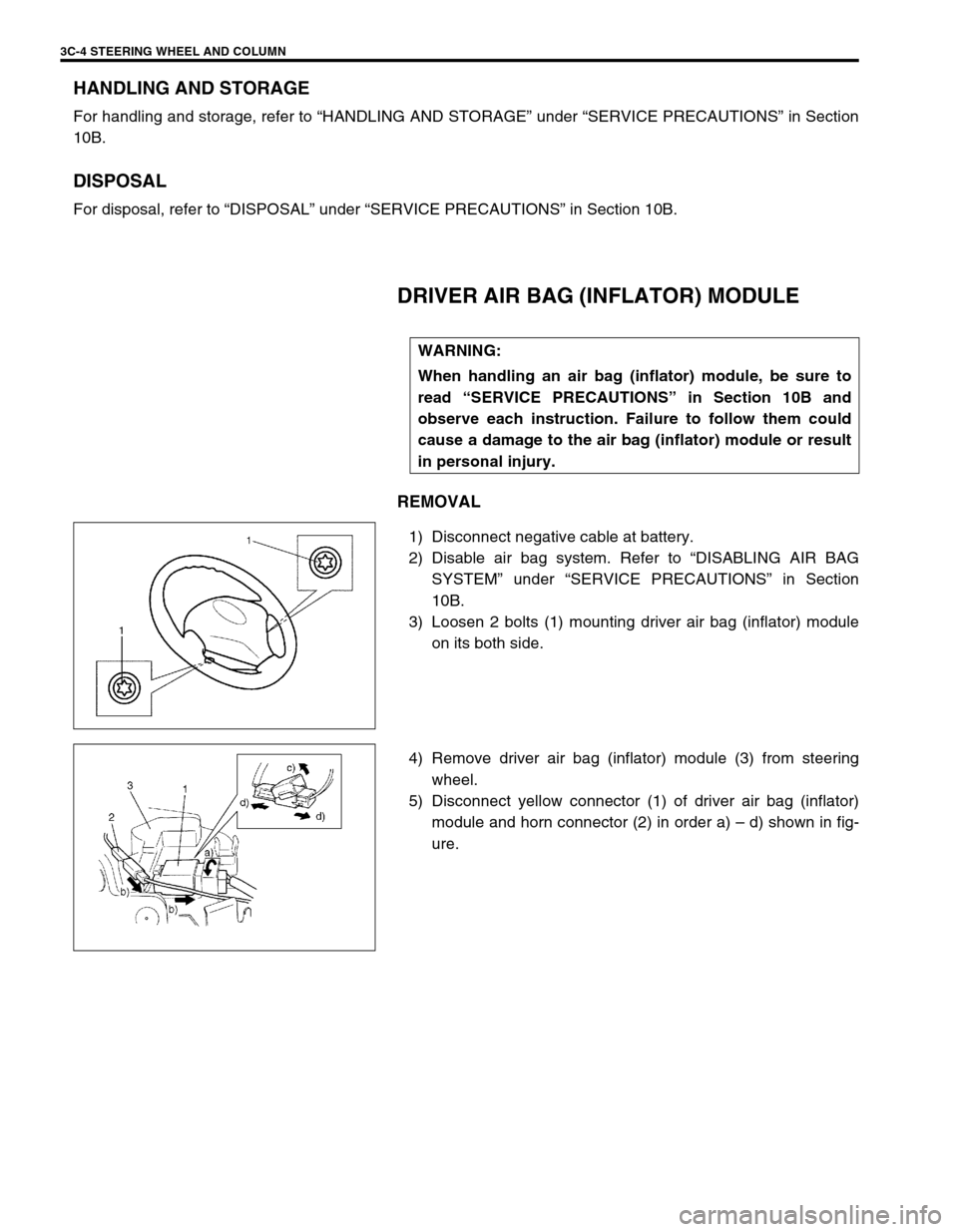

DRIVER AIR BAG (INFLATOR) MODULE

REMOVAL

1) Disconnect negative cable at battery.

2) Disable air bag system. Refer to “DISABLING AIR BAG

SYSTEM” under “SERVICE PRECAUTIONS” in Section

10B.

3) Loosen 2 bolts (1) mounting driver air bag (inflator) module

on its both side.

4) Remove driver air bag (inflator) module (3) from steering

wheel.

5) Disconnect yellow connector (1) of driver air bag (inflator)

module and horn connector (2) in order a) – d) shown in fig-

ure. WARNING:

When handling an air bag (inflator) module, be sure to

read “SERVICE PRECAUTIONS” in Section 10B and

observe each instruction. Failure to follow them could

cause a damage to the air bag (inflator) module or result

in personal injury.

Page 178 of 698

STEERING WHEEL AND COLUMN 3C-5

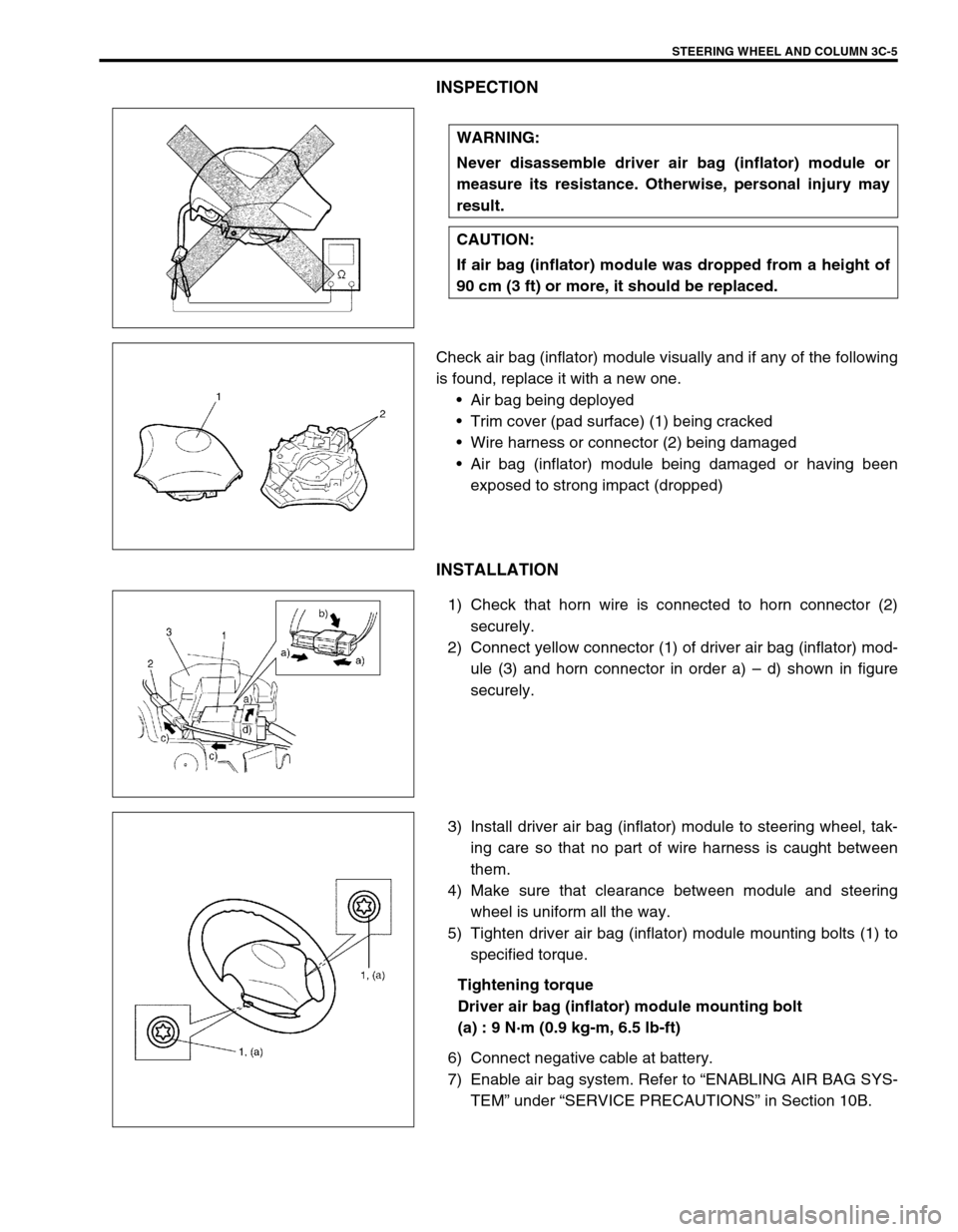

INSPECTION

Check air bag (inflator) module visually and if any of the following

is found, replace it with a new one.

Air bag being deployed

Trim cover (pad surface) (1) being cracked

Wire harness or connector (2) being damaged

Air bag (inflator) module being damaged or having been

exposed to strong impact (dropped)

INSTALLATION

1) Check that horn wire is connected to horn connector (2)

securely.

2) Connect yellow connector (1) of driver air bag (inflator) mod-

ule (3) and horn connector in order a) – d) shown in figure

securely.

3) Install driver air bag (inflator) module to steering wheel, tak-

ing care so that no part of wire harness is caught between

them.

4) Make sure that clearance between module and steering

wheel is uniform all the way.

5) Tighten driver air bag (inflator) module mounting bolts (1) to

specified torque.

Tightening torque

Driver air bag (inflator) module mounting bolt

(a) : 9 N·m (0.9 kg-m, 6.5 lb-ft)

6) Connect negative cable at battery.

7) Enable air bag system. Refer to “ENABLING AIR BAG SYS-

TEM” under “SERVICE PRECAUTIONS” in Section 10B. WARNING:

Never disassemble driver air bag (inflator) module or

measure its resistance. Otherwise, personal injury may

result.

CAUTION:

If air bag (inflator) module was dropped from a height of

90 cm (3 ft) or more, it should be replaced.