engine oil SUZUKI SWIFT 2000 1.G RG413 Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 578 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-77

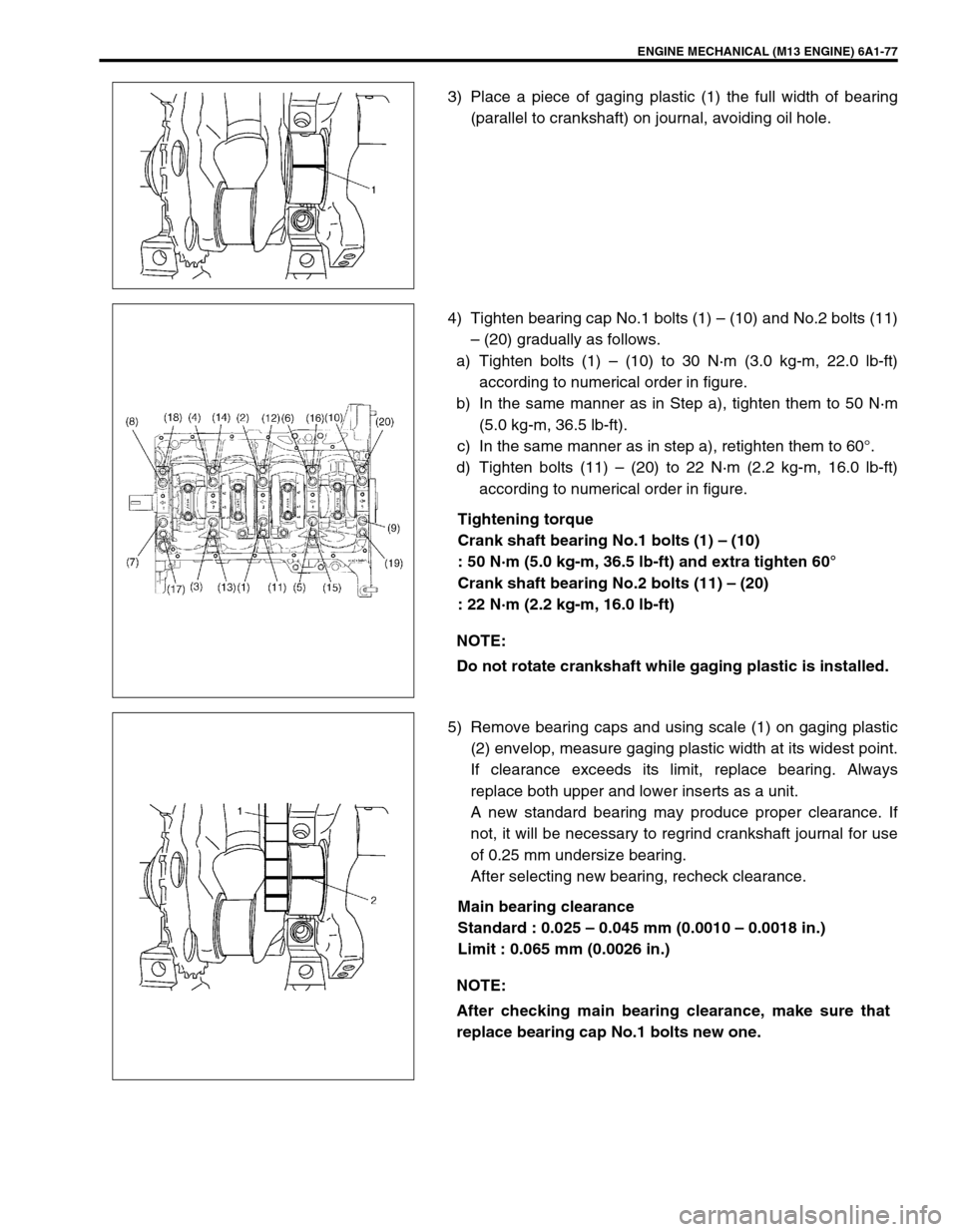

3) Place a piece of gaging plastic (1) the full width of bearing

(parallel to crankshaft) on journal, avoiding oil hole.

4) Tighten bearing cap No.1 bolts (1) – (10) and No.2 bolts (11)

– (20) gradually as follows.

a) Tighten bolts (1) – (10) to 30 N·m (3.0 kg-m, 22.0 lb-ft)

according to numerical order in figure.

b) In the same manner as in Step a), tighten them to 50 N·m

(5.0 kg-m, 36.5 lb-ft).

c) In the same manner as in step a), retighten them to 60°.

d) Tighten bolts (11) – (20) to 22 N·m (2.2 kg-m, 16.0 lb-ft)

according to numerical order in figure.

Tightening torque

Crank shaft bearing No.1 bolts (1) – (10)

: 50 N·m (5.0 kg-m, 36.5 lb-ft) and extra tighten 60°

Crank shaft bearing No.2 bolts (11) – (20)

: 22 N·m (2.2 kg-m, 16.0 lb-ft)

5) Remove bearing caps and using scale (1) on gaging plastic

(2) envelop, measure gaging plastic width at its widest point.

If clearance exceeds its limit, replace bearing. Always

replace both upper and lower inserts as a unit.

A new standard bearing may produce proper clearance. If

not, it will be necessary to regrind crankshaft journal for use

of 0.25 mm undersize bearing.

After selecting new bearing, recheck clearance.

Main bearing clearance

Standard : 0.025 – 0.045 mm (0.0010 – 0.0018 in.)

Limit : 0.065 mm (0.0026 in.)

NOTE:

Do not rotate crankshaft while gaging plastic is installed.

NOTE:

After checking main bearing clearance, make sure that

replace bearing cap No.1 bolts new one.

Page 582 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-81

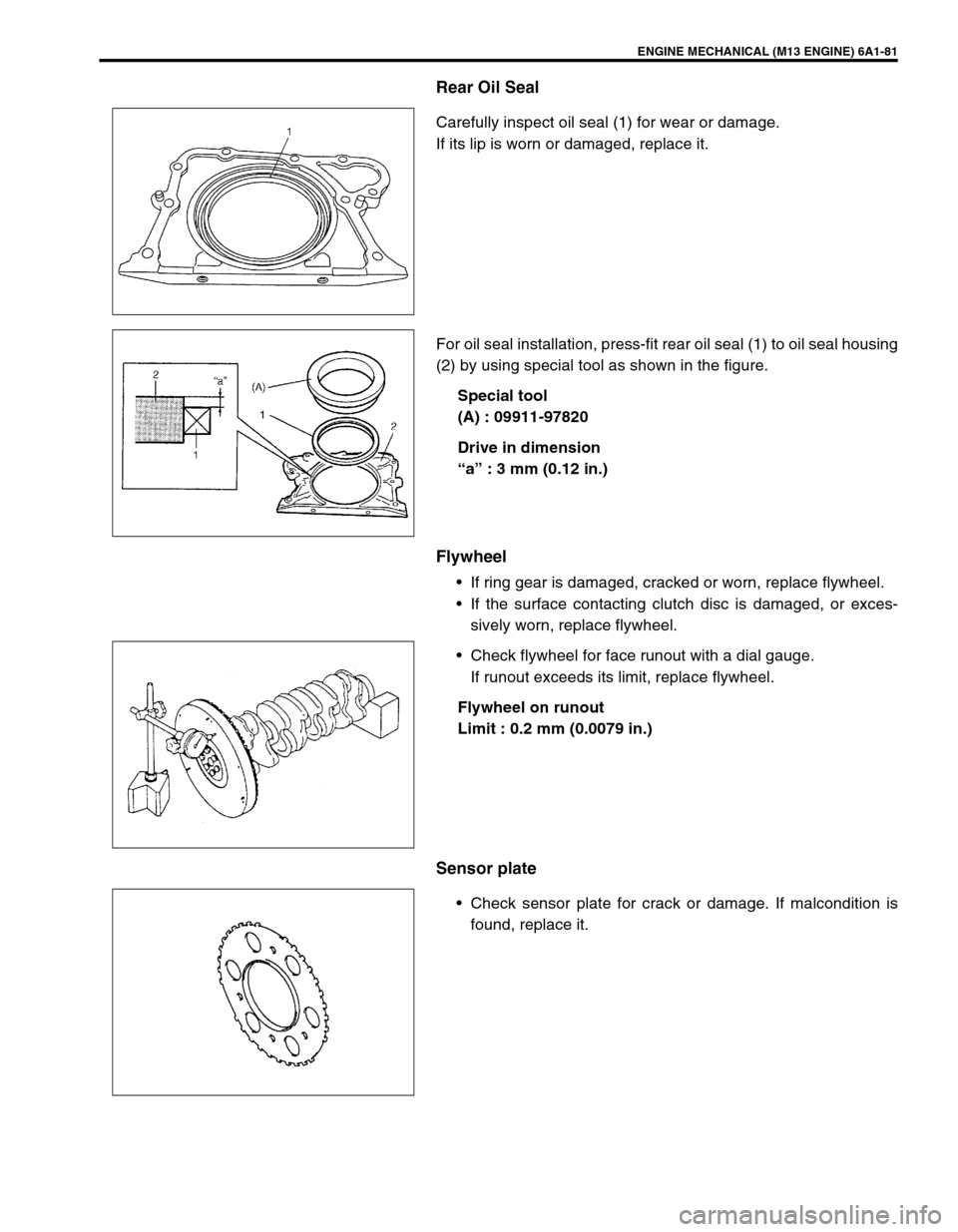

Rear Oil Seal

Carefully inspect oil seal (1) for wear or damage.

If its lip is worn or damaged, replace it.

For oil seal installation, press-fit rear oil seal (1) to oil seal housing

(2) by using special tool as shown in the figure.

Special tool

(A) : 09911-97820

Drive in dimension

“a” : 3 mm (0.12 in.)

Flywheel

If ring gear is damaged, cracked or worn, replace flywheel.

If the surface contacting clutch disc is damaged, or exces-

sively worn, replace flywheel.

Check flywheel for face runout with a dial gauge.

If runout exceeds its limit, replace flywheel.

Flywheel on runout

Limit : 0.2 mm (0.0079 in.)

Sensor plate

Check sensor plate for crack or damage. If malcondition is

found, replace it.

Page 584 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-83

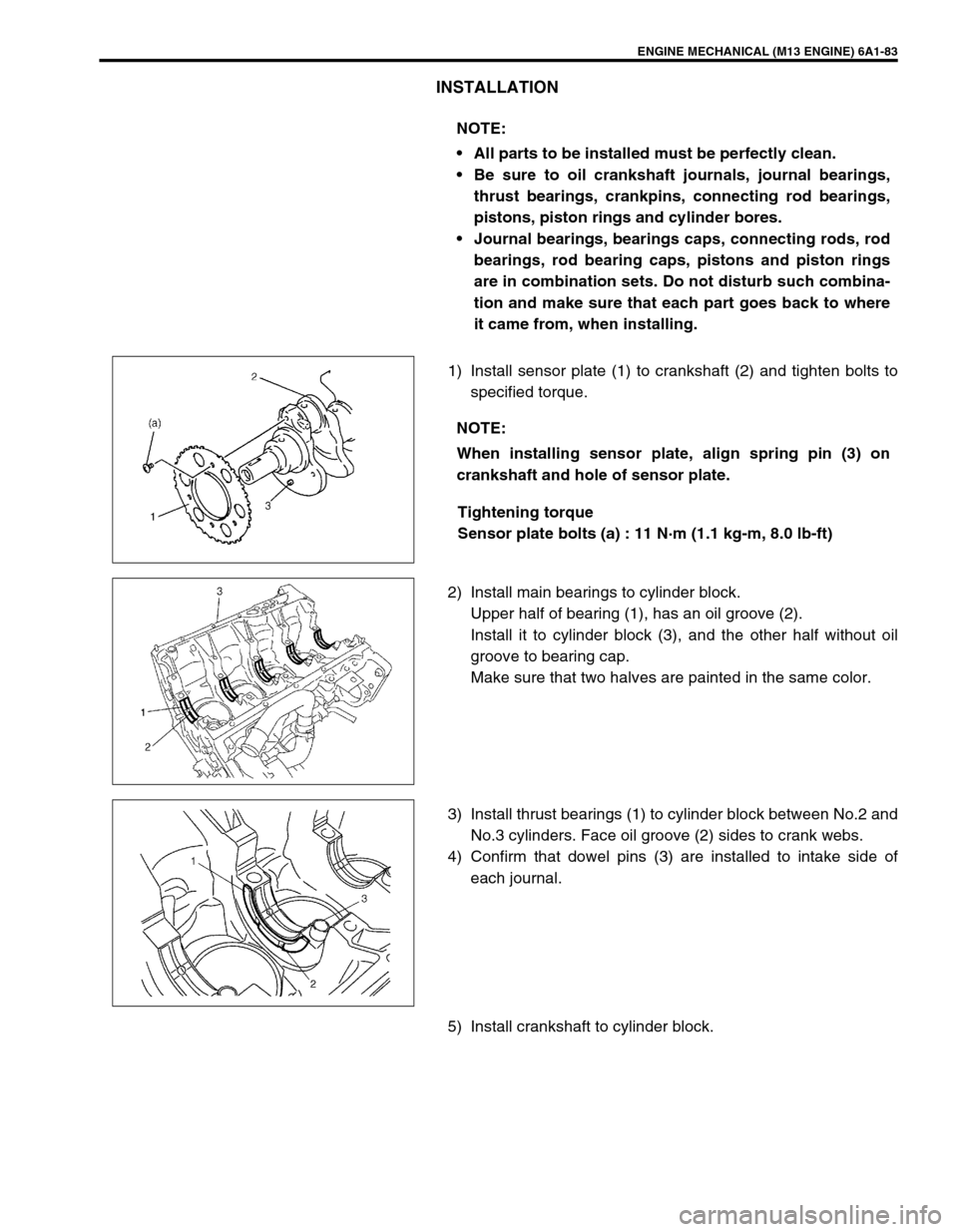

INSTALLATION

1) Install sensor plate (1) to crankshaft (2) and tighten bolts to

specified torque.

Tightening torque

Sensor plate bolts (a) : 11 N·m (1.1 kg-m, 8.0 lb-ft)

2) Install main bearings to cylinder block.

Upper half of bearing (1), has an oil groove (2).

Install it to cylinder block (3), and the other half without oil

groove to bearing cap.

Make sure that two halves are painted in the same color.

3) Install thrust bearings (1) to cylinder block between No.2 and

No.3 cylinders. Face oil groove (2) sides to crank webs.

4) Confirm that dowel pins (3) are installed to intake side of

each journal.

5) Install crankshaft to cylinder block.NOTE:

All parts to be installed must be perfectly clean.

Be sure to oil crankshaft journals, journal bearings,

thrust bearings, crankpins, connecting rod bearings,

pistons, piston rings and cylinder bores.

Journal bearings, bearings caps, connecting rods, rod

bearings, rod bearing caps, pistons and piston rings

are in combination sets. Do not disturb such combina-

tion and make sure that each part goes back to where

it came from, when installing.

NOTE:

When installing sensor plate, align spring pin (3) on

crankshaft and hole of sensor plate.

Page 585 of 698

6A1-84 ENGINE MECHANICAL (M13 ENGINE)

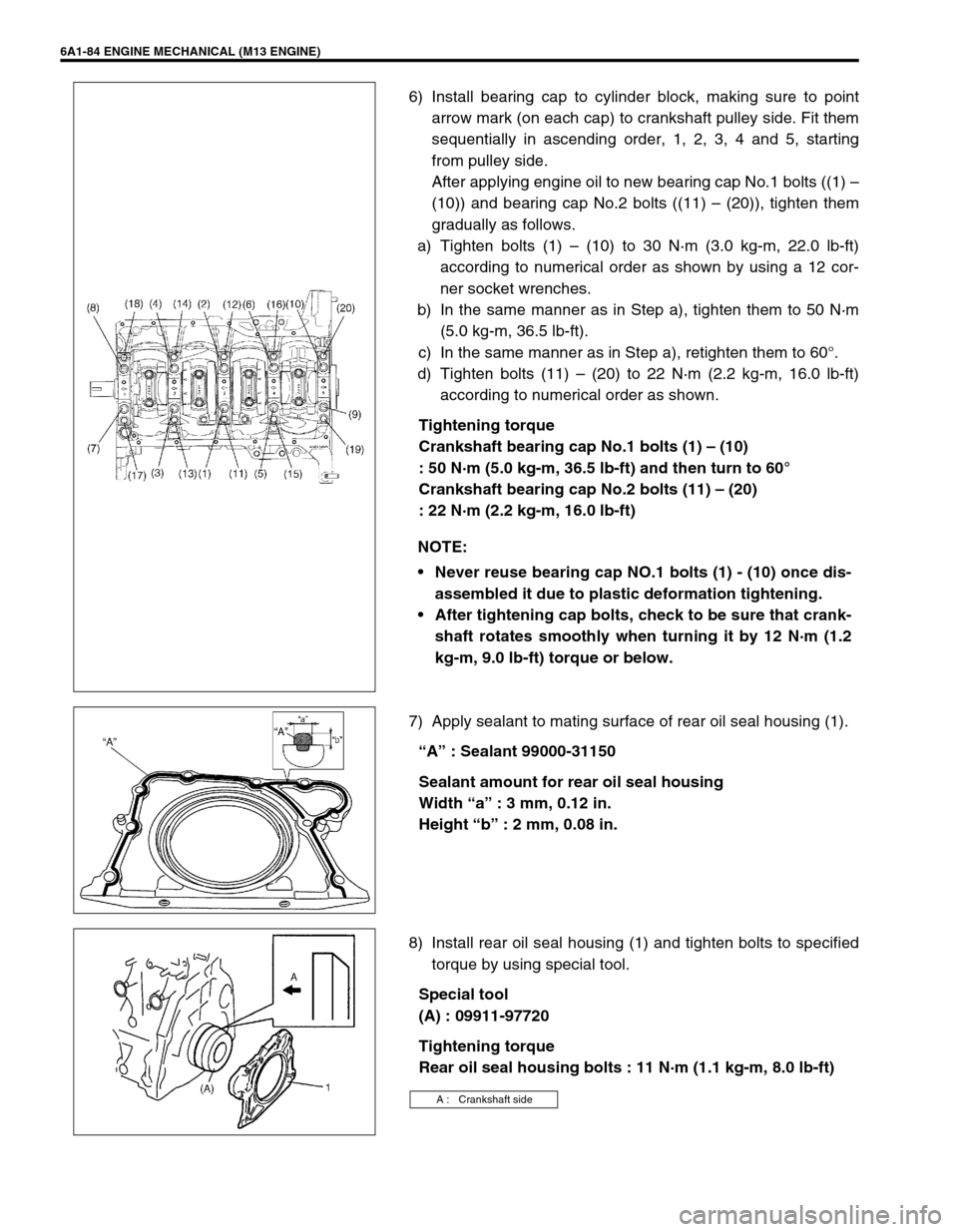

6) Install bearing cap to cylinder block, making sure to point

arrow mark (on each cap) to crankshaft pulley side. Fit them

sequentially in ascending order, 1, 2, 3, 4 and 5, starting

from pulley side.

After applying engine oil to new bearing cap No.1 bolts ((1) –

(10)) and bearing cap No.2 bolts ((11) – (20)), tighten them

gradually as follows.

a) Tighten bolts (1) – (10) to 30 N·m (3.0 kg-m, 22.0 lb-ft)

according to numerical order as shown by using a 12 cor-

ner socket wrenches.

b) In the same manner as in Step a), tighten them to 50 N·m

(5.0 kg-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them to 60°.

d) Tighten bolts (11) – (20) to 22 N·m (2.2 kg-m, 16.0 lb-ft)

according to numerical order as shown.

Tightening torque

Crankshaft bearing cap No.1 bolts (1) – (10)

: 50 N·m (5.0 kg-m, 36.5 lb-ft) and then turn to 60°

Crankshaft bearing cap No.2 bolts (11) – (20)

: 22 N·m (2.2 kg-m, 16.0 lb-ft)

7) Apply sealant to mating surface of rear oil seal housing (1).

“A” : Sealant 99000-31150

Sealant amount for rear oil seal housing

Width “a” : 3 mm, 0.12 in.

Height “b” : 2 mm, 0.08 in.

8) Install rear oil seal housing (1) and tighten bolts to specified

torque by using special tool.

Special tool

(A) : 09911-97720

Tightening torque

Rear oil seal housing bolts : 11 N·m (1.1 kg-m, 8.0 lb-ft) NOTE:

Never reuse bearing cap NO.1 bolts (1) - (10) once dis-

assembled it due to plastic deformation tightening.

After tightening cap bolts, check to be sure that crank-

shaft rotates smoothly when turning it by 12 N·m (1.2

kg-m, 9.0 lb-ft) torque or below.

A : Crankshaft side

Page 586 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-85

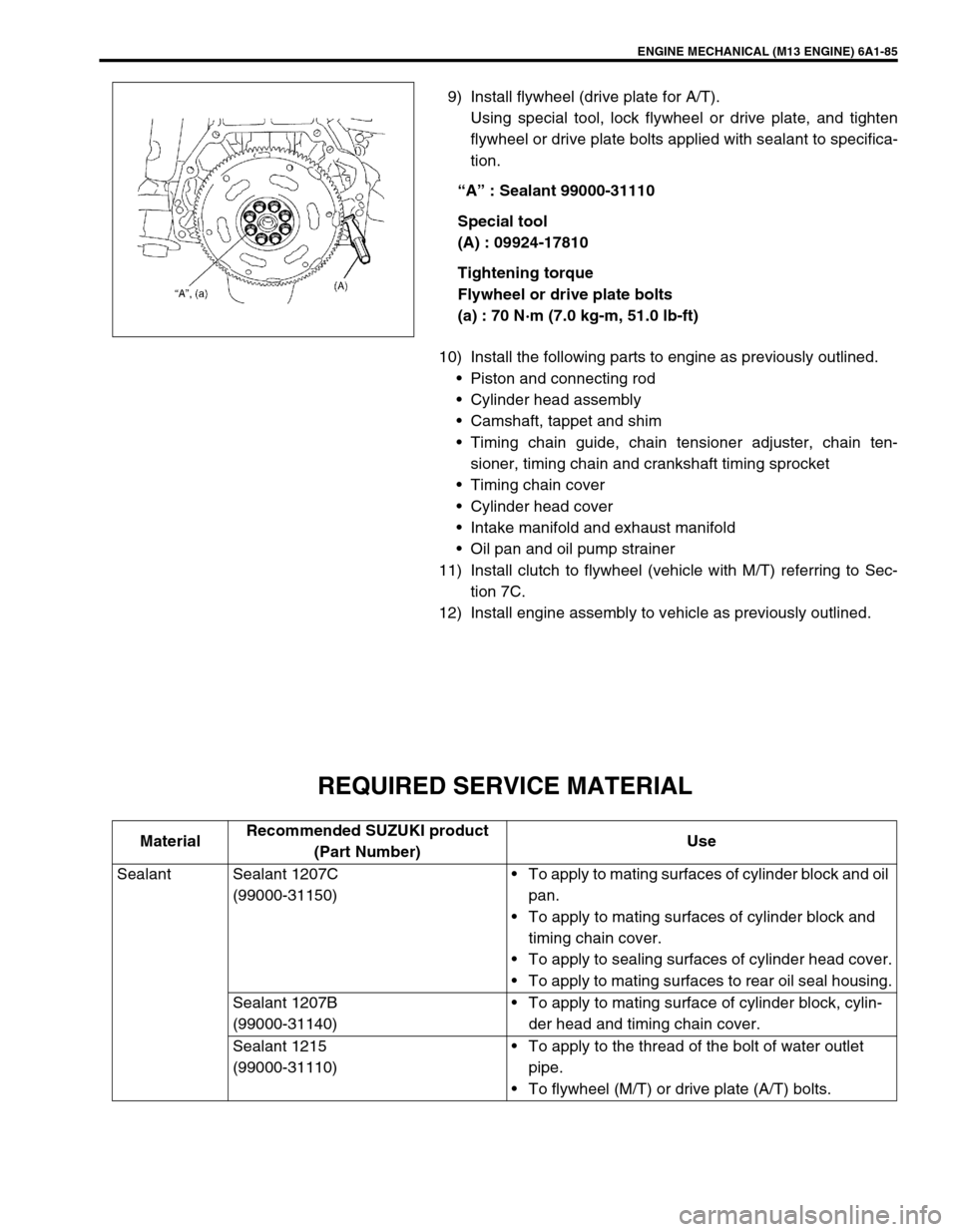

9) Install flywheel (drive plate for A/T).

Using special tool, lock flywheel or drive plate, and tighten

flywheel or drive plate bolts applied with sealant to specifica-

tion.

“A” : Sealant 99000-31110

Special tool

(A) : 09924-17810

Tightening torque

Flywheel or drive plate bolts

(a) : 70 N·m (7.0 kg-m, 51.0 lb-ft)

10) Install the following parts to engine as previously outlined.

Piston and connecting rod

Cylinder head assembly

Camshaft, tappet and shim

Timing chain guide, chain tensioner adjuster, chain ten-

sioner, timing chain and crankshaft timing sprocket

Timing chain cover

Cylinder head cover

Intake manifold and exhaust manifold

Oil pan and oil pump strainer

11) Install clutch to flywheel (vehicle with M/T) referring to Sec-

tion 7C.

12) Install engine assembly to vehicle as previously outlined.

REQUIRED SERVICE MATERIAL

MaterialRecommended SUZUKI product

(Part Number)Use

Sealant Sealant 1207C

(99000-31150)To apply to mating surfaces of cylinder block and oil

pan.

To apply to mating surfaces of cylinder block and

timing chain cover.

To apply to sealing surfaces of cylinder head cover.

To apply to mating surfaces to rear oil seal housing.

Sealant 1207B

(99000-31140)To apply to mating surface of cylinder block, cylin-

der head and timing chain cover.

Sealant 1215

(99000-31110)To apply to the thread of the bolt of water outlet

pipe.

To flywheel (M/T) or drive plate (A/T) bolts.

Page 587 of 698

6A1-86 ENGINE MECHANICAL (M13 ENGINE)

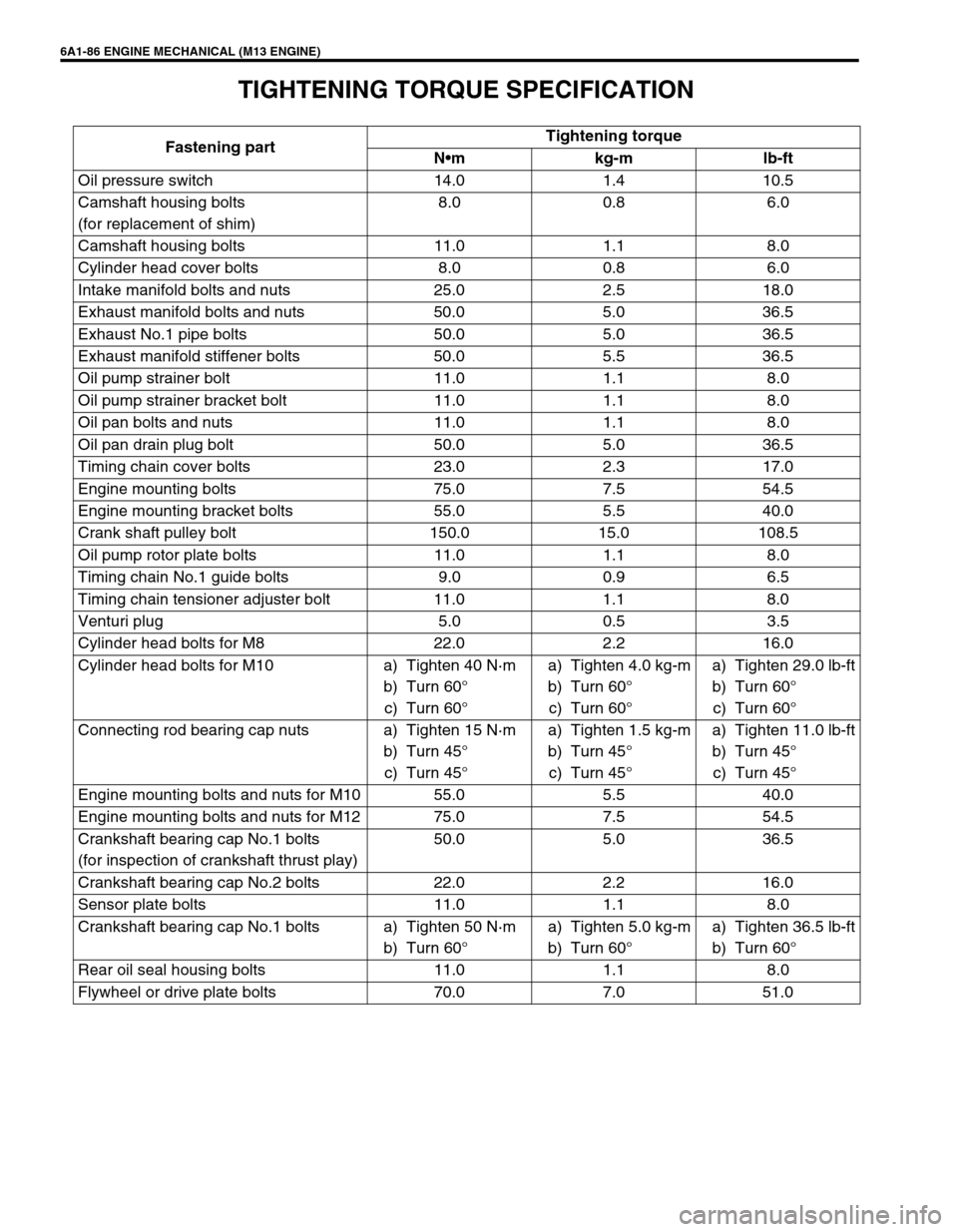

TIGHTENING TORQUE SPECIFICATION

Fastening partTightening torque

Nm kg-m lb-ft

Oil pressure switch 14.0 1.4 10.5

Camshaft housing bolts

(for replacement of shim)8.0 0.8 6.0

Camshaft housing bolts 11.0 1.1 8.0

Cylinder head cover bolts 8.0 0.8 6.0

Intake manifold bolts and nuts 25.0 2.5 18.0

Exhaust manifold bolts and nuts 50.0 5.0 36.5

Exhaust No.1 pipe bolts 50.0 5.0 36.5

Exhaust manifold stiffener bolts 50.0 5.5 36.5

Oil pump strainer bolt 11.0 1.1 8.0

Oil pump strainer bracket bolt 11.0 1.1 8.0

Oil pan bolts and nuts 11.0 1.1 8.0

Oil pan drain plug bolt 50.0 5.0 36.5

Timing chain cover bolts 23.0 2.3 17.0

Engine mounting bolts 75.0 7.5 54.5

Engine mounting bracket bolts 55.0 5.5 40.0

Crank shaft pulley bolt 150.0 15.0 108.5

Oil pump rotor plate bolts 11.0 1.1 8.0

Timing chain No.1 guide bolts 9.0 0.9 6.5

Timing chain tensioner adjuster bolt 11.0 1.1 8.0

Venturi plug 5.0 0.5 3.5

Cylinder head bolts for M8 22.0 2.2 16.0

Cylinder head bolts for M10 a) Tighten 40 N·m

b) Turn 60°

c) Turn 60°a) Tighten 4.0 kg-m

b) Turn 60°

c) Turn 60°a) Tighten 29.0 lb-ft

b) Turn 60°

c) Turn 60°

Connecting rod bearing cap nuts a) Tighten 15 N·m

b) Turn 45°

c) Turn 45°a) Tighten 1.5 kg-m

b) Turn 45°

c) Turn 45°a) Tighten 11.0 lb-ft

b) Turn 45°

c) Turn 45°

Engine mounting bolts and nuts for M10 55.0 5.5 40.0

Engine mounting bolts and nuts for M12 75.0 7.5 54.5

Crankshaft bearing cap No.1 bolts

(for inspection of crankshaft thrust play)50.0 5.0 36.5

Crankshaft bearing cap No.2 bolts 22.0 2.2 16.0

Sensor plate bolts 11.0 1.1 8.0

Crankshaft bearing cap No.1 bolts a) Tighten 50 N·m

b) Turn 60°a) Tighten 5.0 kg-m

b) Turn 60°a) Tighten 36.5 lb-ft

b) Turn 60°

Rear oil seal housing bolts 11.0 1.1 8.0

Flywheel or drive plate bolts 70.0 7.0 51.0

Page 588 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-87

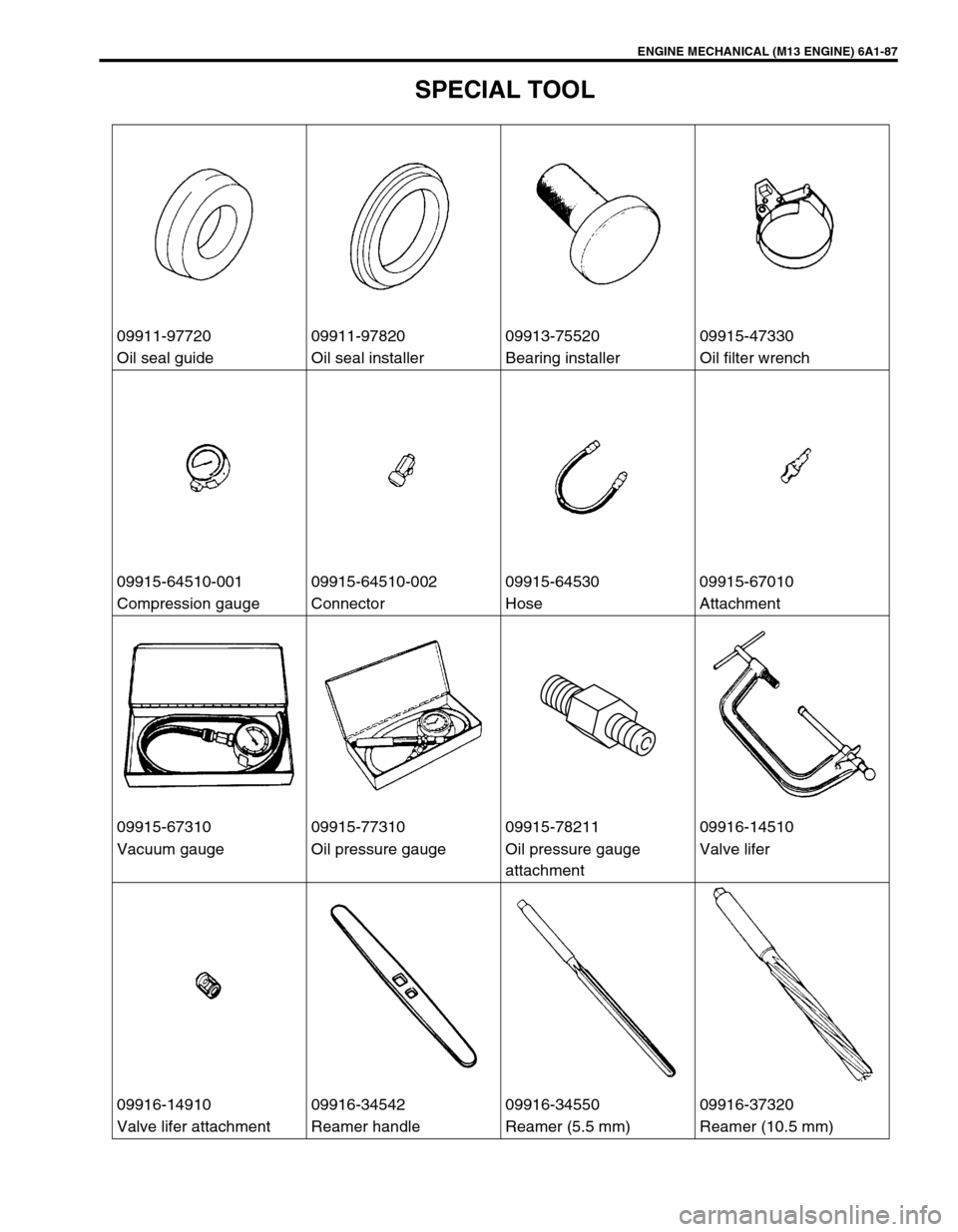

SPECIAL TOOL

09911-97720 09911-97820 09913-75520 09915-47330

Oil seal guide Oil seal installer Bearing installer Oil filter wrench

09915-64510-001 09915-64510-002 09915-64530 09915-67010

Compression gauge Connector Hose Attachment

09915-67310 09915-77310 09915-78211 09916-14510

Vacuum gauge Oil pressure gauge Oil pressure gauge

attachmentValve lifer

09916-14910 09916-34542 09916-34550 09916-37320

Valve lifer attachment Reamer handle Reamer (5.5 mm) Reamer (10.5 mm)

Page 592 of 698

ENGINE COOLING 6B-3

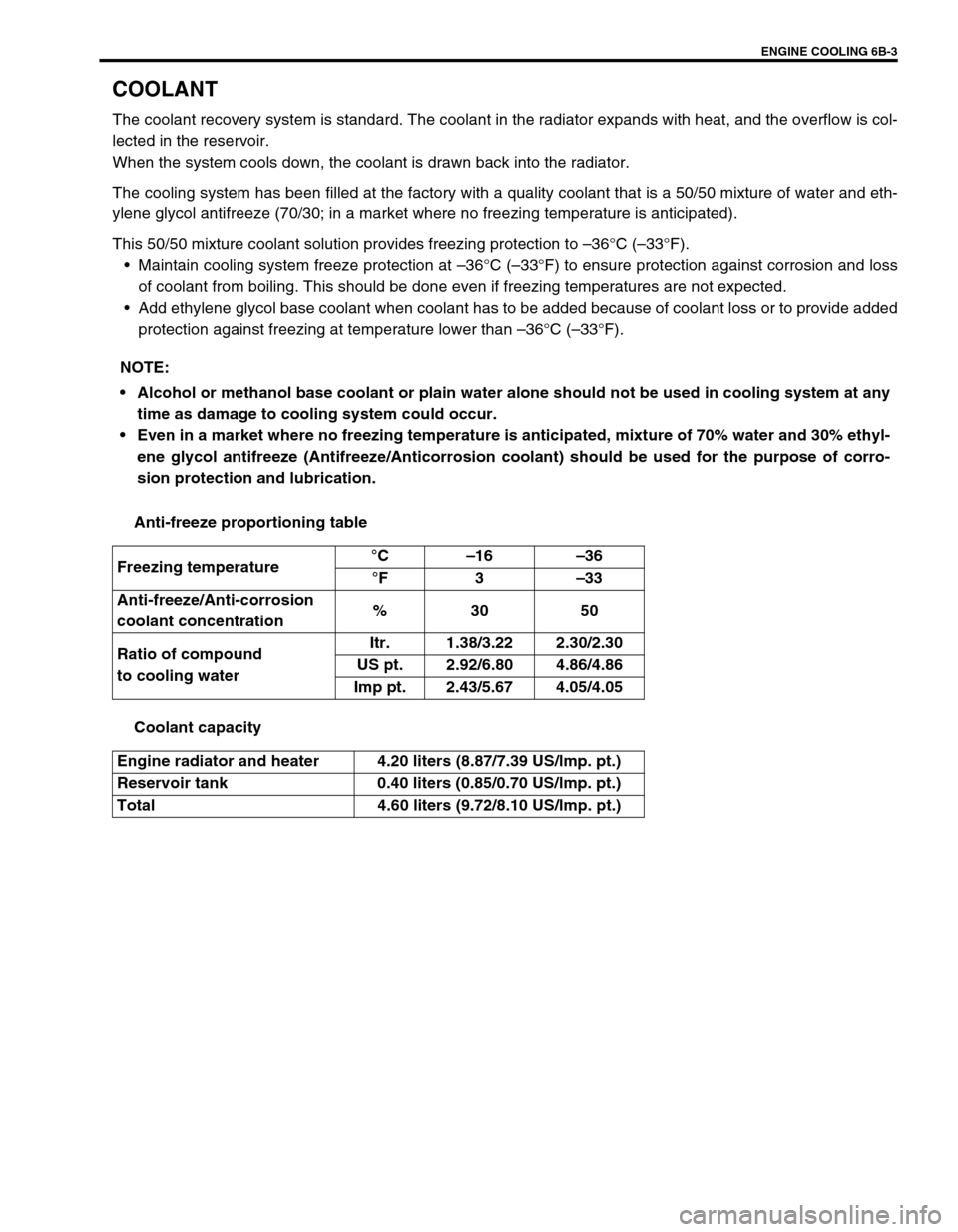

COOLANT

The coolant recovery system is standard. The coolant in the radiator expands with heat, and the overflow is col-

lected in the reservoir.

When the system cools down, the coolant is drawn back into the radiator.

The cooling system has been filled at the factory with a quality coolant that is a 50/50 mixture of water and eth-

ylene glycol antifreeze (70/30; in a market where no freezing temperature is anticipated).

This 50/50 mixture coolant solution provides freezing protection to –36°C (–33°F).

Maintain cooling system freeze protection at –36°C (–33°F) to ensure protection against corrosion and loss

of coolant from boiling. This should be done even if freezing temperatures are not expected.

Add ethylene glycol base coolant when coolant has to be added because of coolant loss or to provide added

protection against freezing at temperature lower than –36°C (–33°F).

Anti-freeze proportioning table

Coolant capacity NOTE:

Alcohol or methanol base coolant or plain water alone should not be used in cooling system at any

time as damage to cooling system could occur.

Even in a market where no freezing temperature is anticipated, mixture of 70% water and 30% ethyl-

ene glycol antifreeze (Antifreeze/Anticorrosion coolant) should be used for the purpose of corro-

sion protection and lubrication.

Freezing temperature°C–16–36

°F3–33

Anti-freeze/Anti-corrosion

coolant concentration%30 50

Ratio of compound

to cooling waterItr. 1.38/3.22 2.30/2.30

US pt. 2.92/6.80 4.86/4.86

Imp pt. 2.43/5.67 4.05/4.05

Engine radiator and heater 4.20 liters (8.87/7.39 US/lmp. pt.)

Reservoir tank 0.40 liters (0.85/0.70 US/lmp. pt.)

Total 4.60 liters (9.72/8.10 US/lmp. pt.)

Page 595 of 698

6B-6 ENGINE COOLING

MAINTENANCE

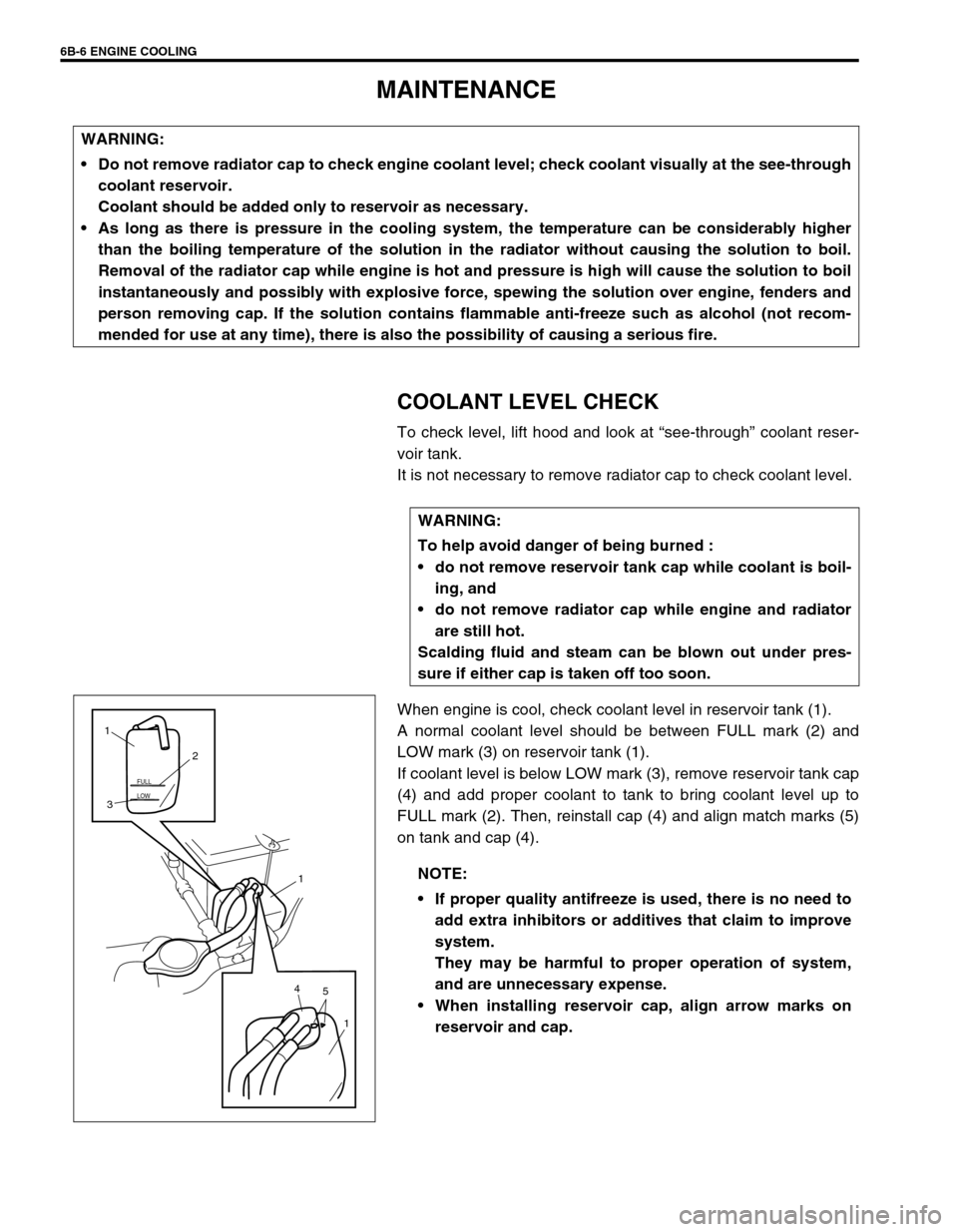

COOLANT LEVEL CHECK

To check level, lift hood and look at “see-through” coolant reser-

voir tank.

It is not necessary to remove radiator cap to check coolant level.

When engine is cool, check coolant level in reservoir tank (1).

A normal coolant level should be between FULL mark (2) and

LOW mark (3) on reservoir tank (1).

If coolant level is below LOW mark (3), remove reservoir tank cap

(4) and add proper coolant to tank to bring coolant level up to

FULL mark (2). Then, reinstall cap (4) and align match marks (5)

on tank and cap (4). WARNING:

Do not remove radiator cap to check engine coolant level; check coolant visually at the see-through

coolant reservoir.

Coolant should be added only to reservoir as necessary.

As long as there is pressure in the cooling system, the temperature can be considerably higher

than the boiling temperature of the solution in the radiator without causing the solution to boil.

Removal of the radiator cap while engine is hot and pressure is high will cause the solution to boil

instantaneously and possibly with explosive force, spewing the solution over engine, fenders and

person removing cap. If the solution contains flammable anti-freeze such as alcohol (not recom-

mended for use at any time), there is also the possibility of causing a serious fire.

WARNING:

To help avoid danger of being burned :

do not remove reservoir tank cap while coolant is boil-

ing, and

do not remove radiator cap while engine and radiator

are still hot.

Scalding fluid and steam can be blown out under pres-

sure if either cap is taken off too soon.

NOTE:

If proper quality antifreeze is used, there is no need to

add extra inhibitors or additives that claim to improve

system.

They may be harmful to proper operation of system,

and are unnecessary expense.

When installing reservoir cap, align arrow marks on

reservoir and cap.

LOW FULL

5 41

1 32 1

Page 619 of 698

6C-12 ENGINE FUEL

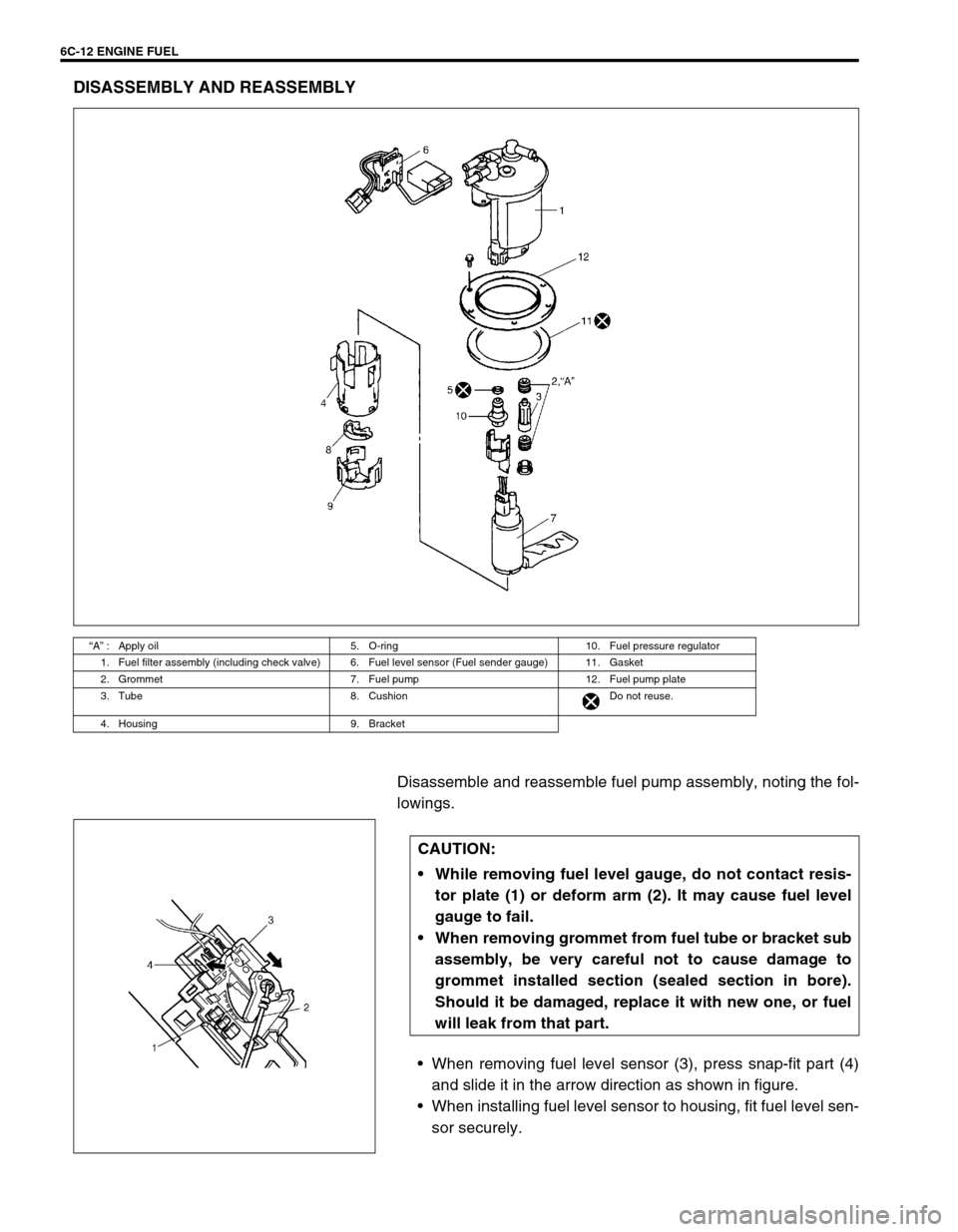

DISASSEMBLY AND REASSEMBLY

Disassemble and reassemble fuel pump assembly, noting the fol-

lowings.

When removing fuel level sensor (3), press snap-fit part (4)

and slide it in the arrow direction as shown in figure.

When installing fuel level sensor to housing, fit fuel level sen-

sor securely.

“A” : Apply oil 5. O-ring 10. Fuel pressure regulator

1. Fuel filter assembly (including check valve) 6. Fuel level sensor (Fuel sender gauge) 11. Gasket

2. Grommet 7. Fuel pump 12. Fuel pump plate

3. Tube 8. Cushion Do not reuse.

4. Housing 9. Bracket

CAUTION:

While removing fuel level gauge, do not contact resis-

tor plate (1) or deform arm (2). It may cause fuel level

gauge to fail.

When removing grommet from fuel tube or bracket sub

assembly, be very careful not to cause damage to

grommet installed section (sealed section in bore).

Should it be damaged, replace it with new one, or fuel

will leak from that part.