brakes SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 3 of 698

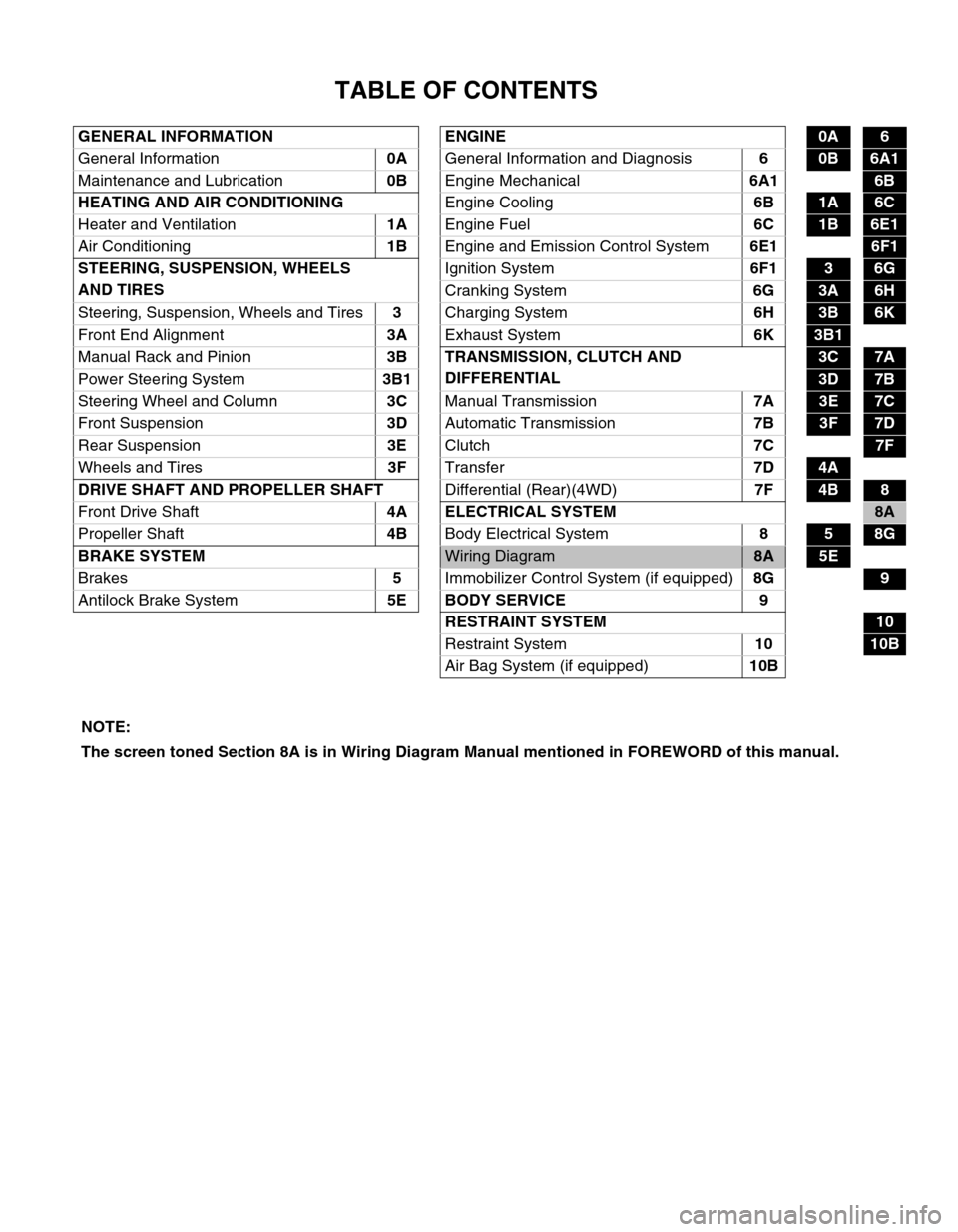

TABLE OF CONTENTS

GENERAL INFORMATION ENGINE0A6

General Information0A

General Information and Diagnosis6

0B6A1

Maintenance and Lubrication0B

Engine Mechanical6A1

6B

HEATING AND AIR CONDITIONING

Engine Cooling6B

1A6C

Heater and Ventilation1A

Engine Fuel6C

1B6E1

Air Conditioning1B

Engine and Emission Control System6E1

6F1

STEERING, SUSPENSION, WHEELS

AND TIRESIgnition System6F1

36G

Cranking System6G

3A6H

Steering, Suspension, Wheels and Tires3

Charging System6H

3B6K

Front End Alignment3A

Exhaust System6K

3B1 6B

Manual Rack and Pinion3B TRANSMISSION, CLUTCH AND

DIFFERENTIAL

3C7A

Power Steering System3B1

3D7B

Steering Wheel and Column3C

Manual Transmission7A

3E7C

Front Suspension3D

Automatic Transmission7B

3F7D

Rear Suspension3E

Clutch7C

7F

Wheels and Tires3F

Transfer7D

4A

DRIVE SHAFT AND PROPELLER SHAFT

Differential (Rear)(4WD)7F

4B8

Front Drive Shaft 4A ELECTRICAL SYSTEM

8A

Propeller Shaft4B

Body Electrical System8

58G

BRAKE SYSTEM

Wiring Diagram8A5E

Brakes5

Immobilizer Control System (if equipped)8G

9

Antilock Brake System5E BODY SERVICE 9

RESTRAINT SYSTEM

10

Restraint System10

10B

Air Bag System (if equipped)10B

NOTE:

The screen toned Section 8A is in Wiring Diagram Manual mentioned in FOREWORD of this manual.

Page 42 of 698

MAINTENANCE AND LUBRICATION 0B-13

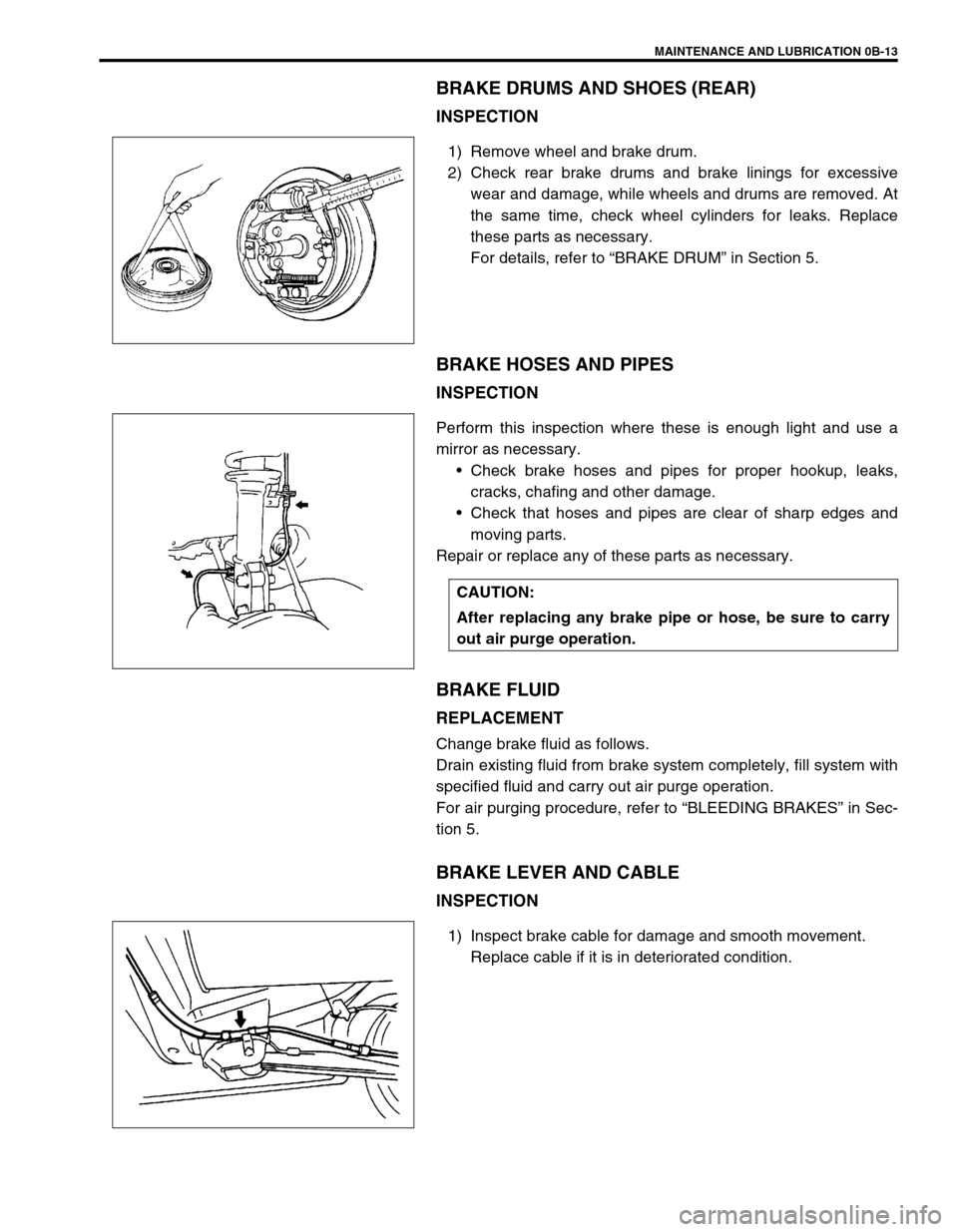

BRAKE DRUMS AND SHOES (REAR)

INSPECTION

1) Remove wheel and brake drum.

2) Check rear brake drums and brake linings for excessive

wear and damage, while wheels and drums are removed. At

the same time, check wheel cylinders for leaks. Replace

these parts as necessary.

For details, refer to “BRAKE DRUM” in Section 5.

BRAKE HOSES AND PIPES

INSPECTION

Perform this inspection where these is enough light and use a

mirror as necessary.

Check brake hoses and pipes for proper hookup, leaks,

cracks, chafing and other damage.

Check that hoses and pipes are clear of sharp edges and

moving parts.

Repair or replace any of these parts as necessary.

BRAKE FLUID

REPLACEMENT

Change brake fluid as follows.

Drain existing fluid from brake system completely, fill system with

specified fluid and carry out air purge operation.

For air purging procedure, refer to “BLEEDING BRAKES” in Sec-

tion 5.

BRAKE LEVER AND CABLE

INSPECTION

1) Inspect brake cable for damage and smooth movement.

Replace cable if it is in deteriorated condition.

CAUTION:

After replacing any brake pipe or hose, be sure to carry

out air purge operation.

Page 49 of 698

0B-20 MAINTENANCE AND LUBRICATION

ENGINE START

Check engine start for readiness.

On automatic transmission vehicles, try to start the engine in each select lever position. The starting motor

should crank only in “P” (Park) or “N” (Neutral).

On manual transmission vehicles, place the shift lever in “Neutral,” depress clutch pedal fully any try to start.

EXHAUST SYSTEM CHECK

Check for leakage, cracks or loose supports.

CLUTCH (FOR MANUAL TRANSMISSION)

Check for the following.

Clutch is completely released when depressing clutch pedal,

No slipping clutch occurs when releasing pedal and accelerating.

Clutch itself is free from any abnormal condition.

GEARSHIFT OR SELECT LEVER (TRANSMISSION)

Check gear shift or select lever for smooth shifting to all positions and for good performance of transmission in

any position.

With automatic transmission equipped vehicle, also check that shift indicator indicates properly according to

which position select lever is shifted to.

With automatic transmission equipped vehicle, make sure that vehicle is at complete stop when shifting select

lever to “P” range position and release all brakes.

BRAKE

Foot Brake

Check the followings:

that brake pedal has proper travel,

that brake works properly,

that it is free from noise,

that vehicle does not pull to one side when brake is applied.

and that brake do not drag.

Parking Brake

Check that lever has proper travel.

Check to ensure that parking brake is fully effective when the vehicle is stopped on the safe slope and brake

lever is pulled all the way.WARNING:

Before performing the following check, be sure to have enough room around the vehicle. Then, firmly

apply both the parking brake and the regular brakes. Do not use the accelerator pedal. If the engine

starts, be ready to turn off the ignition promptly. Take these precautions because the vehicle could

move without warning and possibly cause personal injury or property damage.

WARNING:

With vehicle parked on a fairly steep slope, make sure nothing is in the way downhill to avoid any per-

sonal injury or property damage. Be prepared to apply regular brake quickly even if vehicle should

start to move.

Page 113 of 698

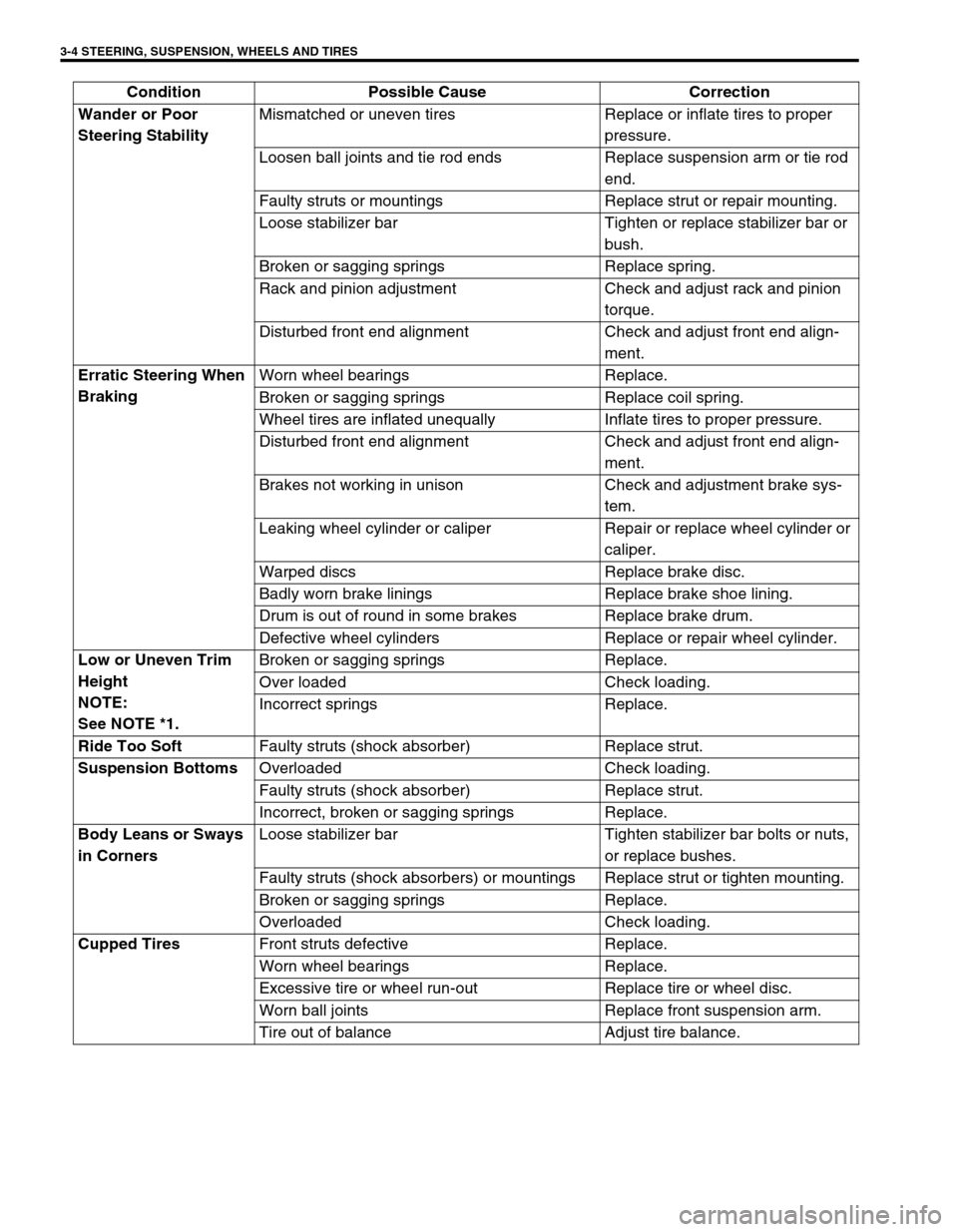

3-4 STEERING, SUSPENSION, WHEELS AND TIRES

Wander or Poor

Steering StabilityMismatched or uneven tires Replace or inflate tires to proper

pressure.

Loosen ball joints and tie rod ends Replace suspension arm or tie rod

end.

Faulty struts or mountings Replace strut or repair mounting.

Loose stabilizer bar Tighten or replace stabilizer bar or

bush.

Broken or sagging springs Replace spring.

Rack and pinion adjustment Check and adjust rack and pinion

torque.

Disturbed front end alignment Check and adjust front end align-

ment.

Erratic Steering When

BrakingWorn wheel bearings Replace.

Broken or sagging springs Replace coil spring.

Wheel tires are inflated unequally Inflate tires to proper pressure.

Disturbed front end alignment Check and adjust front end align-

ment.

Brakes not working in unison Check and adjustment brake sys-

tem.

Leaking wheel cylinder or caliper Repair or replace wheel cylinder or

caliper.

Warped discs Replace brake disc.

Badly worn brake linings Replace brake shoe lining.

Drum is out of round in some brakes Replace brake drum.

Defective wheel cylinders Replace or repair wheel cylinder.

Low or Uneven Trim

Height

NOTE:

See NOTE *1.Broken or sagging springs Replace.

Over loaded Check loading.

Incorrect springs Replace.

Ride Too Soft

Faulty struts (shock absorber) Replace strut.

Suspension Bottoms

Overloaded Check loading.

Faulty struts (shock absorber) Replace strut.

Incorrect, broken or sagging springs Replace.

Body Leans or Sways

in CornersLoose stabilizer bar Tighten stabilizer bar bolts or nuts,

or replace bushes.

Faulty struts (shock absorbers) or mountings Replace strut or tighten mounting.

Broken or sagging springs Replace.

Overloaded Check loading.

Cupped Tires

Front struts defective Replace.

Worn wheel bearings Replace.

Excessive tire or wheel run-out Replace tire or wheel disc.

Worn ball joints Replace front suspension arm.

Tire out of balance Adjust tire balance. Condition Possible Cause Correction

Page 238 of 698

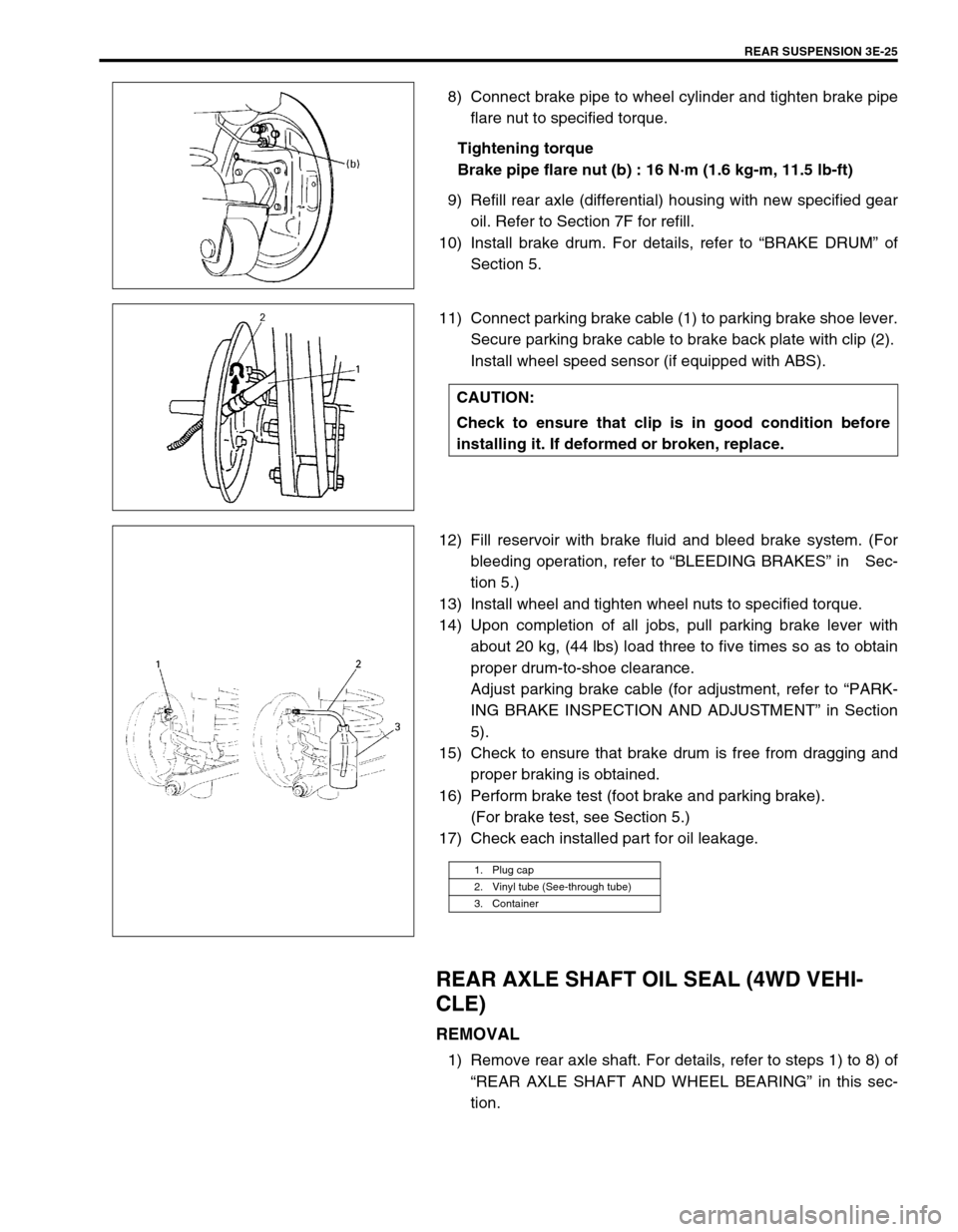

REAR SUSPENSION 3E-25

8) Connect brake pipe to wheel cylinder and tighten brake pipe

flare nut to specified torque.

Tightening torque

Brake pipe flare nut (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

9) Refill rear axle (differential) housing with new specified gear

oil. Refer to Section 7F for refill.

10) Install brake drum. For details, refer to “BRAKE DRUM” of

Section 5.

11) Connect parking brake cable (1) to parking brake shoe lever.

Secure parking brake cable to brake back plate with clip (2).

Install wheel speed sensor (if equipped with ABS).

12) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation, refer to “BLEEDING BRAKES” in Sec-

tion 5.)

13) Install wheel and tighten wheel nuts to specified torque.

14) Upon completion of all jobs, pull parking brake lever with

about 20 kg, (44 lbs) load three to five times so as to obtain

proper drum-to-shoe clearance.

Adjust parking brake cable (for adjustment, refer to “PARK-

ING BRAKE INSPECTION AND ADJUSTMENT” in Section

5).

15) Check to ensure that brake drum is free from dragging and

proper braking is obtained.

16) Perform brake test (foot brake and parking brake).

(For brake test, see Section 5.)

17) Check each installed part for oil leakage.

REAR AXLE SHAFT OIL SEAL (4WD VEHI-

CLE)

REMOVAL

1) Remove rear axle shaft. For details, refer to steps 1) to 8) of

“REAR AXLE SHAFT AND WHEEL BEARING” in this sec-

tion.

CAUTION:

Check to ensure that clip is in good condition before

installing it. If deformed or broken, replace.

1. Plug cap

2. Vinyl tube (See-through tube)

3. Container

Page 274 of 698

BRAKES 5-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

5

9

10

10A

10B

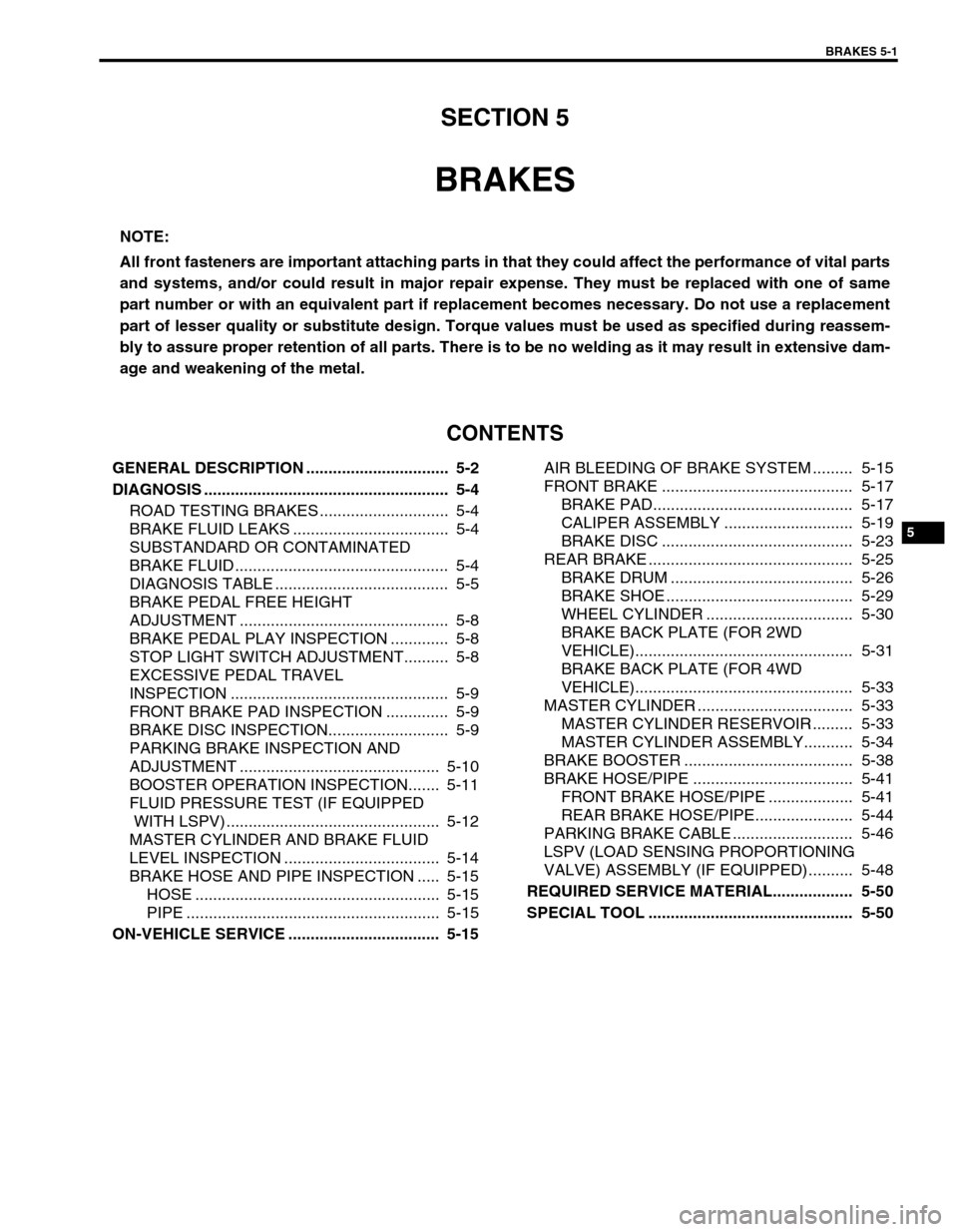

SECTION 5

BRAKES

CONTENTS

GENERAL DESCRIPTION ................................ 5-2

DIAGNOSIS ....................................................... 5-4

ROAD TESTING BRAKES ............................. 5-4

BRAKE FLUID LEAKS ................................... 5-4

SUBSTANDARD OR CONTAMINATED

BRAKE FLUID ................................................ 5-4

DIAGNOSIS TABLE ....................................... 5-5

BRAKE PEDAL FREE HEIGHT

ADJUSTMENT ............................................... 5-8

BRAKE PEDAL PLAY INSPECTION ............. 5-8

STOP LIGHT SWITCH ADJUSTMENT.......... 5-8

EXCESSIVE PEDAL TRAVEL

INSPECTION ................................................. 5-9

FRONT BRAKE PAD INSPECTION .............. 5-9

BRAKE DISC INSPECTION........................... 5-9

PARKING BRAKE INSPECTION AND

ADJUSTMENT ............................................. 5-10

BOOSTER OPERATION INSPECTION....... 5-11

FLUID PRESSURE TEST (IF EQUIPPED

WITH LSPV) ................................................ 5-12

MASTER CYLINDER AND BRAKE FLUID

LEVEL INSPECTION ................................... 5-14

BRAKE HOSE AND PIPE INSPECTION ..... 5-15

HOSE ....................................................... 5-15

PIPE ......................................................... 5-15

ON-VEHICLE SERVICE .................................. 5-15AIR BLEEDING OF BRAKE SYSTEM ......... 5-15

FRONT BRAKE ........................................... 5-17

BRAKE PAD............................................. 5-17

CALIPER ASSEMBLY ............................. 5-19

BRAKE DISC ........................................... 5-23

REAR BRAKE .............................................. 5-25

BRAKE DRUM ......................................... 5-26

BRAKE SHOE .......................................... 5-29

WHEEL CYLINDER ................................. 5-30

BRAKE BACK PLATE (FOR 2WD

VEHICLE)................................................. 5-31

BRAKE BACK PLATE (FOR 4WD

VEHICLE)................................................. 5-33

MASTER CYLINDER ................................... 5-33

MASTER CYLINDER RESERVOIR ......... 5-33

MASTER CYLINDER ASSEMBLY........... 5-34

BRAKE BOOSTER ...................................... 5-38

BRAKE HOSE/PIPE .................................... 5-41

FRONT BRAKE HOSE/PIPE ................... 5-41

REAR BRAKE HOSE/PIPE...................... 5-44

PARKING BRAKE CABLE ........................... 5-46

LSPV (LOAD SENSING PROPORTIONING

VALVE) ASSEMBLY (IF EQUIPPED).......... 5-48

REQUIRED SERVICE MATERIAL.................. 5-50

SPECIAL TOOL .............................................. 5-50

NOTE:

All front fasteners are important attaching parts in that they could affect the performance of vital parts

and systems, and/or could result in major repair expense. They must be replaced with one of same

part number or with an equivalent part if replacement becomes necessary. Do not use a replacement

part of lesser quality or substitute design. Torque values must be used as specified during reassem-

bly to assure proper retention of all parts. There is to be no welding as it may result in extensive dam-

age and weakening of the metal.

Page 275 of 698

5-2 BRAKES

GENERAL DESCRIPTION

When the foot brake pedal is depressed, hydraulic pressure is developed in the master cylinder to actuate pis-

tons (two in front and four in rear).

The master cylinder is a tandem master cylinder. Brake pipes are connected to the master cylinder and they

make two independent circuits. One connects front right & rear left brakes and the other connects front left &

rear right brakes.

The load sensing proportioning valve (LSPV) or the proportioning valve (P valve) is included in these circuits

between the master cylinder and the rear brake for the vehicle without ABS.

In this brake system, the disc brake type is used for the front wheel brake and a drum brake type (leading/trailing

shoes) for the rear brake.

The parking brake system is mechanical. It applies brake force to only rear wheels by means of the cable and

mechanical linkage system. The same brake shoes are used for both parking and foot brakes.

Page 276 of 698

![SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual BRAKES 5-3

NOTE:

The figures shows left-hand steering vehicle.

[A] : For vehicle without ABS 3. Secondary side 7. LSPV (Load Sensing Proportioning valve)

[B] : For vehicle with ABS 4. Primary side 8. SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual BRAKES 5-3

NOTE:

The figures shows left-hand steering vehicle.

[A] : For vehicle without ABS 3. Secondary side 7. LSPV (Load Sensing Proportioning valve)

[B] : For vehicle with ABS 4. Primary side 8.](/img/20/7606/w960_7606-275.png)

BRAKES 5-3

NOTE:

The figures shows left-hand steering vehicle.

[A] : For vehicle without ABS 3. Secondary side 7. LSPV (Load Sensing Proportioning valve)

[B] : For vehicle with ABS 4. Primary side 8. P (Proportioning) valve

1. Brake booster 5. 4-way joint A: Forward

2. Master cylinder 6. ABS hydraulic unit/control module assembly

Page 277 of 698

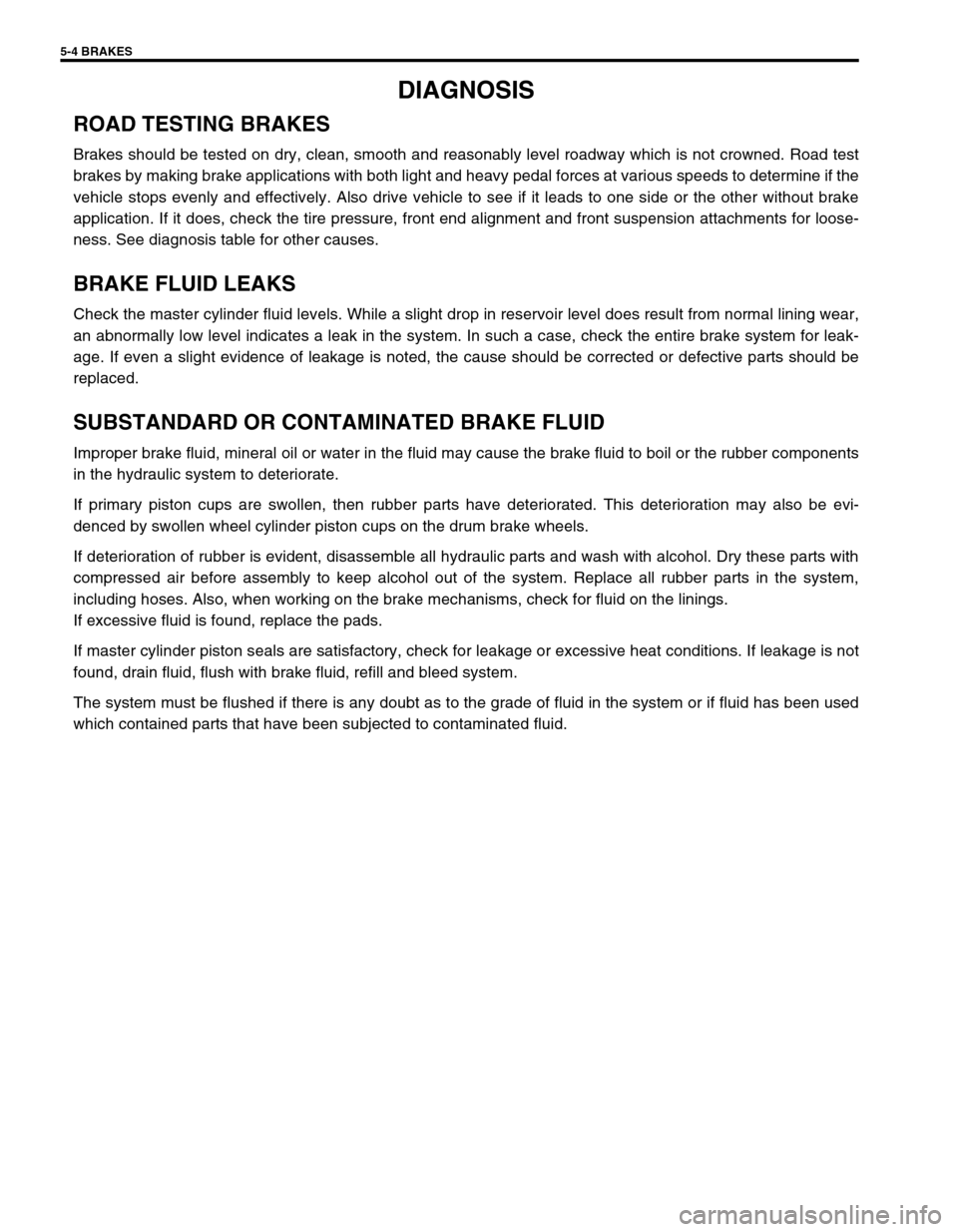

5-4 BRAKES

DIAGNOSIS

ROAD TESTING BRAKES

Brakes should be tested on dry, clean, smooth and reasonably level roadway which is not crowned. Road test

brakes by making brake applications with both light and heavy pedal forces at various speeds to determine if the

vehicle stops evenly and effectively. Also drive vehicle to see if it leads to one side or the other without brake

application. If it does, check the tire pressure, front end alignment and front suspension attachments for loose-

ness. See diagnosis table for other causes.

BRAKE FLUID LEAKS

Check the master cylinder fluid levels. While a slight drop in reservoir level does result from normal lining wear,

an abnormally low level indicates a leak in the system. In such a case, check the entire brake system for leak-

age. If even a slight evidence of leakage is noted, the cause should be corrected or defective parts should be

replaced.

SUBSTANDARD OR CONTAMINATED BRAKE FLUID

Improper brake fluid, mineral oil or water in the fluid may cause the brake fluid to boil or the rubber components

in the hydraulic system to deteriorate.

If primary piston cups are swollen, then rubber parts have deteriorated. This deterioration may also be evi-

denced by swollen wheel cylinder piston cups on the drum brake wheels.

If deterioration of rubber is evident, disassemble all hydraulic parts and wash with alcohol. Dry these parts with

compressed air before assembly to keep alcohol out of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads.

If master cylinder piston seals are satisfactory, check for leakage or excessive heat conditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed system.

The system must be flushed if there is any doubt as to the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to contaminated fluid.

Page 278 of 698

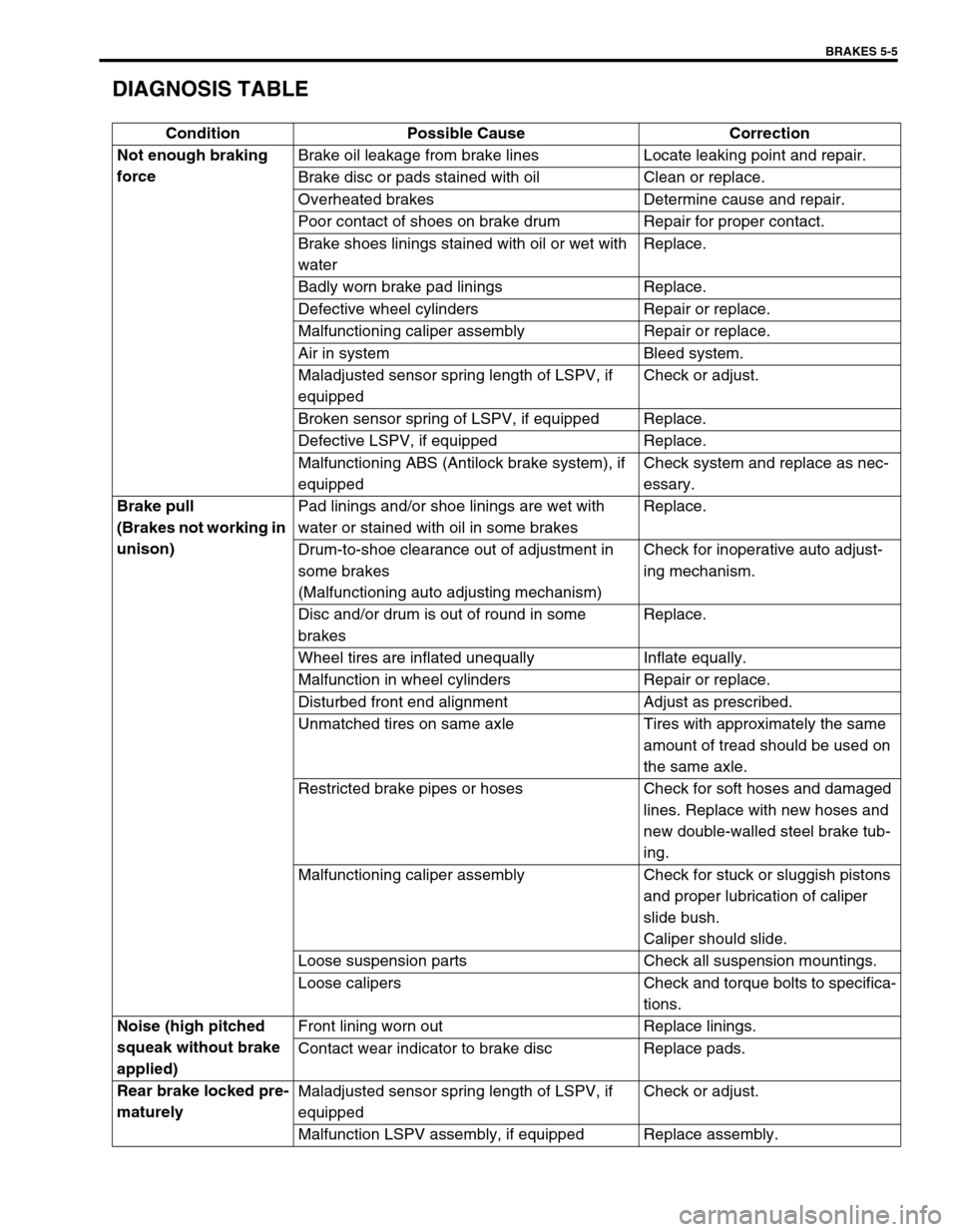

BRAKES 5-5

DIAGNOSIS TABLE

Condition Possible Cause Correction

Not enough braking

forceBrake oil leakage from brake lines Locate leaking point and repair.

Brake disc or pads stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Poor contact of shoes on brake drum Repair for proper contact.

Brake shoes linings stained with oil or wet with

waterReplace.

Badly worn brake pad linings Replace.

Defective wheel cylinders Repair or replace.

Malfunctioning caliper assembly Repair or replace.

Air in system Bleed system.

Maladjusted sensor spring length of LSPV, if

equippedCheck or adjust.

Broken sensor spring of LSPV, if equipped Replace.

Defective LSPV, if equipped Replace.

Malfunctioning ABS (Antilock brake system), if

equippedCheck system and replace as nec-

essary.

Brake pull

(Brakes not working in

unison)Pad linings and/or shoe linings are wet with

water or stained with oil in some brakesReplace.

Drum-to-shoe clearance out of adjustment in

some brakes

(Malfunctioning auto adjusting mechanism)Check for inoperative auto adjust-

ing mechanism.

Disc and/or drum is out of round in some

brakesReplace.

Wheel tires are inflated unequally Inflate equally.

Malfunction in wheel cylinders Repair or replace.

Disturbed front end alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same

amount of tread should be used on

the same axle.

Restricted brake pipes or hoses Check for soft hoses and damaged

lines. Replace with new hoses and

new double-walled steel brake tub-

ing.

Malfunctioning caliper assembly Check for stuck or sluggish pistons

and proper lubrication of caliper

slide bush.

Caliper should slide.

Loose suspension parts Check all suspension mountings.

Loose calipers Check and torque bolts to specifica-

tions.

Noise (high pitched

squeak without brake

applied)Front lining worn out Replace linings.

Contact wear indicator to brake disc Replace pads.

Rear brake locked pre-

maturelyMaladjusted sensor spring length of LSPV, if

equippedCheck or adjust.

Malfunction LSPV assembly, if equipped Replace assembly.