checking oil SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 37 of 698

0B-8 MAINTENANCE AND LUBRICATION

6) Replenish oil until oil level is brought to FULL level mark on

dipstick. (oil pan and oil filter capacity). The filler inlet is at

the top of the cylinder head cover.

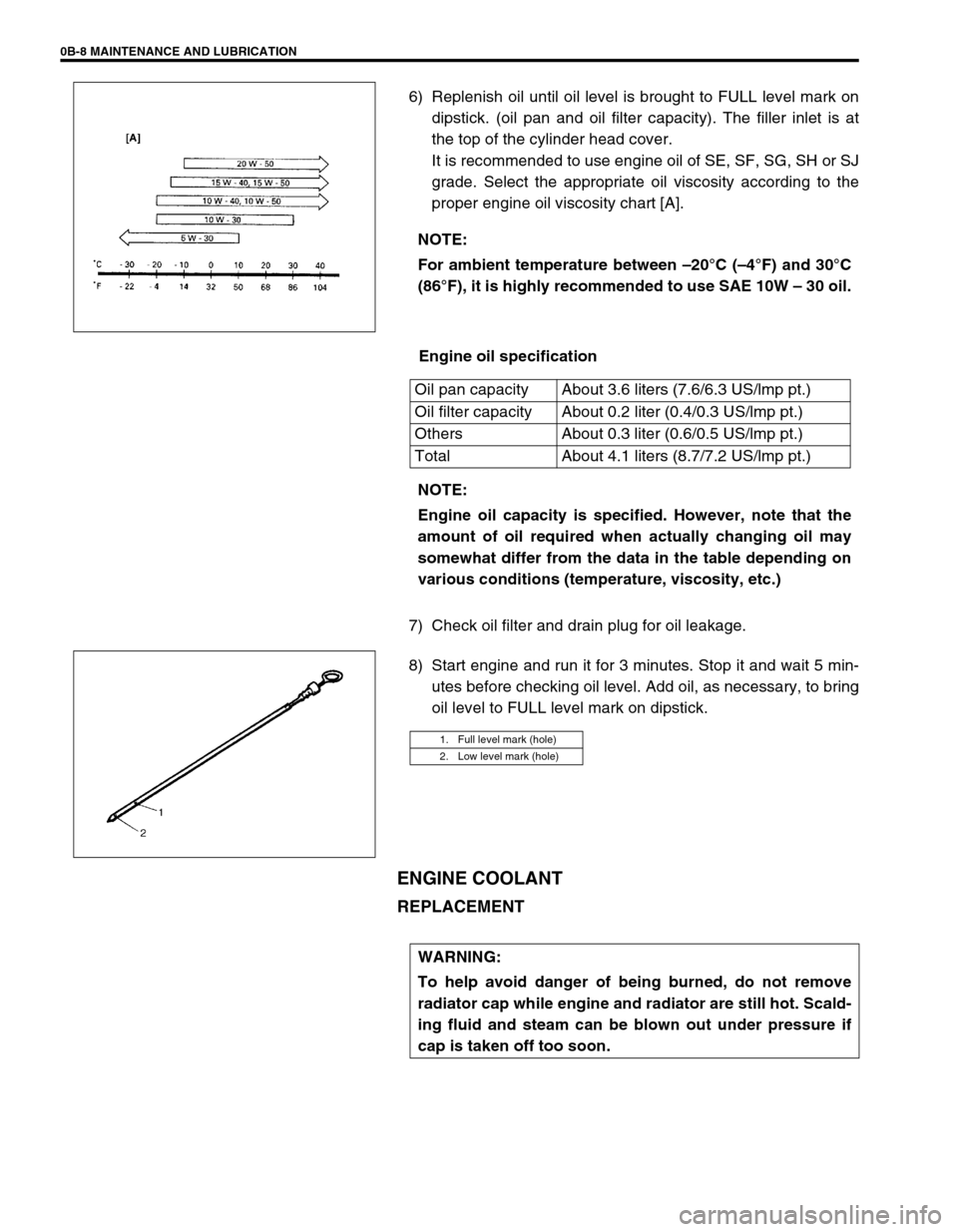

It is recommended to use engine oil of SE, SF, SG, SH or SJ

grade. Select the appropriate oil viscosity according to the

proper engine oil viscosity chart [A].

Engine oil specification

7) Check oil filter and drain plug for oil leakage.

8) Start engine and run it for 3 minutes. Stop it and wait 5 min-

utes before checking oil level. Add oil, as necessary, to bring

oil level to FULL level mark on dipstick.

ENGINE COOLANT

REPLACEMENT

NOTE:

For ambient temperature between –20°C (–4°F) and 30°C

(86°F), it is highly recommended to use SAE 10W – 30 oil.

Oil pan capacity About 3.6 liters (7.6/6.3 US/lmp pt.)

Oil filter capacity About 0.2 liter (0.4/0.3 US/lmp pt.)

Others About 0.3 liter (0.6/0.5 US/lmp pt.)

Total About 4.1 liters (8.7/7.2 US/lmp pt.)

NOTE:

Engine oil capacity is specified. However, note that the

amount of oil required when actually changing oil may

somewhat differ from the data in the table depending on

various conditions (temperature, viscosity, etc.)

1. Full level mark (hole)

2. Low level mark (hole)

WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot. Scald-

ing fluid and steam can be blown out under pressure if

cap is taken off too soon.

Page 46 of 698

MAINTENANCE AND LUBRICATION 0B-17

MANUAL TRANSMISSION OIL

INSPECTION

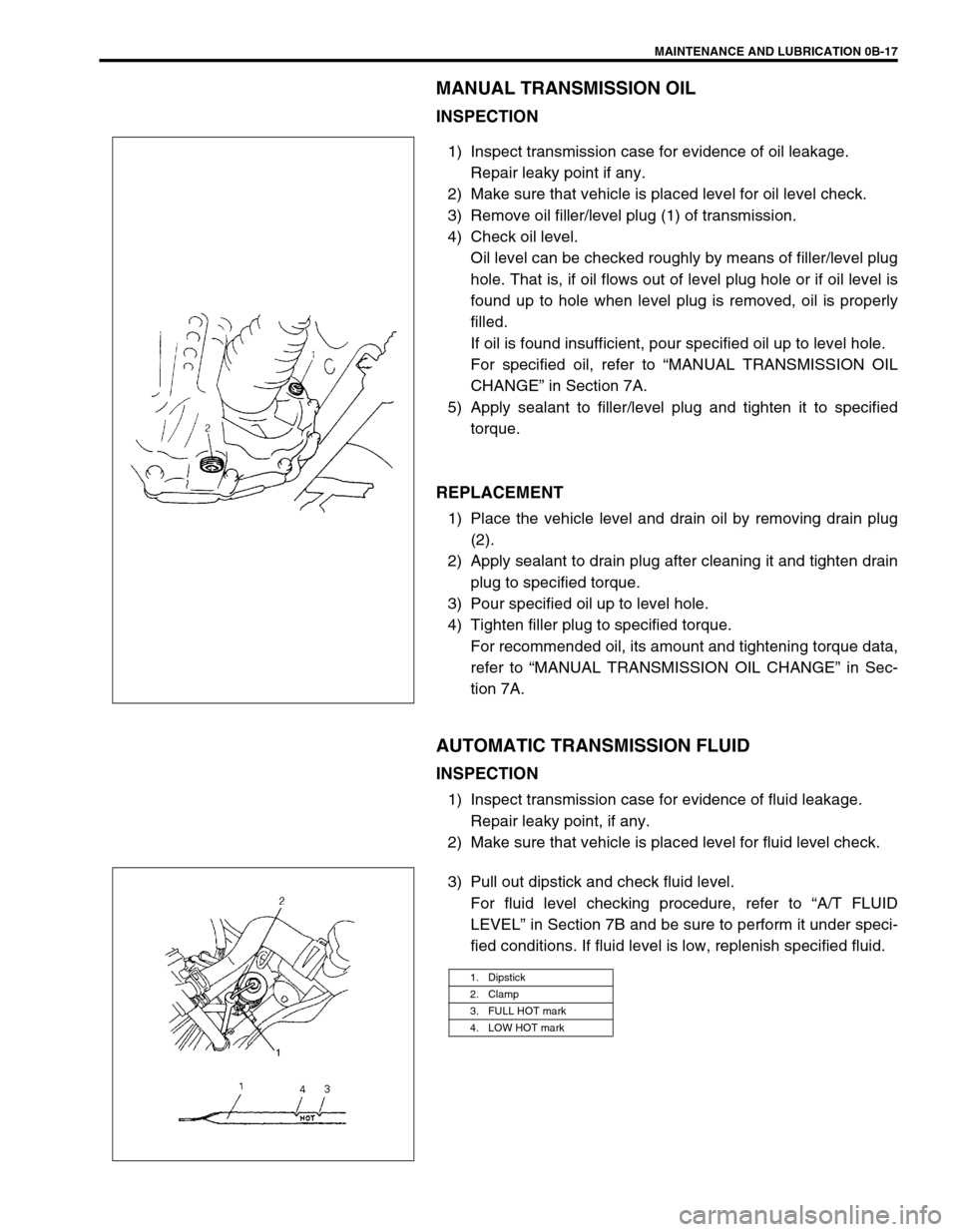

1) Inspect transmission case for evidence of oil leakage.

Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level check.

3) Remove oil filler/level plug (1) of transmission.

4) Check oil level.

Oil level can be checked roughly by means of filler/level plug

hole. That is, if oil flows out of level plug hole or if oil level is

found up to hole when level plug is removed, oil is properly

filled.

If oil is found insufficient, pour specified oil up to level hole.

For specified oil, refer to “MANUAL TRANSMISSION OIL

CHANGE” in Section 7A.

5) Apply sealant to filler/level plug and tighten it to specified

torque.

REPLACEMENT

1) Place the vehicle level and drain oil by removing drain plug

(2).

2) Apply sealant to drain plug after cleaning it and tighten drain

plug to specified torque.

3) Pour specified oil up to level hole.

4) Tighten filler plug to specified torque.

For recommended oil, its amount and tightening torque data,

refer to “MANUAL TRANSMISSION OIL CHANGE” in Sec-

tion 7A.

AUTOMATIC TRANSMISSION FLUID

INSPECTION

1) Inspect transmission case for evidence of fluid leakage.

Repair leaky point, if any.

2) Make sure that vehicle is placed level for fluid level check.

3) Pull out dipstick and check fluid level.

For fluid level checking procedure, refer to “A/T FLUID

LEVEL” in Section 7B and be sure to perform it under speci-

fied conditions. If fluid level is low, replenish specified fluid.

1. Dipstick

2. Clamp

3. FULL HOT mark

4. LOW HOT mark

Page 66 of 698

AIR CONDITIONING (OPTIONAL) 1B-1

6F1

6F2

6G

1B

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 1B

AIR CONDITIONING (OPTIONAL)

CONTENTS

GENERAL DESCRIPTION .............................. 1B-3

REFRIGERANT CIRCULATION .................. 1B-3

REFRIGERANT TYPE ................................. 1B-3

MAJOR COMPONENTS AND

LOCATION ................................................... 1B-4

DIAGNOSIS ..................................................... 1B-5

GENERAL DIAGNOSIS TABLE ................... 1B-5

ABNORMAL NOISE DIAGNOSIS ................ 1B-7

QUICKLY CHECKING OF REFRIGERANT

CHARGE ...................................................... 1B-9

PERFORMANCE DIAGNOSIS .................. 1B-10

PERFORMANCE DIAGNOSIS TABLE .. 1B-12

DETAIL DIAGNOSIS TABLE (AMBIENT

TEMPERATURE AT 30°C (86°F)) ......... 1B-13

COMPRESSOR DRIVE BELT ................... 1B-15ELECTRICAL DIAGNOSIS ........................... 1B-16

WIRING DIAGRAM .................................... 1B-16

A/C SYSTEM INSPECTION OF ECM AND

ITS CIRCUITS ........................................... 1B-17

REFRIGERANT RECOVERY, EVACUATING

AND CHARGING........................................... 1B-20

OPERATION PROCEDURE FOR

REFRIGERANT CHARGING ..................... 1B-20

RECOVERY ............................................... 1B-21

REPLENISHING COMPRESSOR OIL ...... 1B-21

EVACUATING............................................ 1B-22

EVACUATING PROCEDURE ................ 1B-22

CHECKING SYSTEM FOR PRESSURE

LEAKS.................................................... 1B-23

CHARGING................................................ 1B-24

CHARGING PROCEDURE .................... 1B-24 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

CAUTION:

The air conditioning system of this vehicle uses refrigerant HFC-134a (R-134a).

None of refrigerant, compressor oil and component parts is interchangeable between two types of

A/C : one using refrigerant HFC-134a (R-134a) and the other using refrigerant CFC-12 (R-12).

Be sure to check which refrigerant is used before any service work including inspection and mainte-

nance. For identification between these two types, refer to “REFRIGERANT TYPE” in this section.

When replenishing or changing refrigerant and compressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

NOTE:

For basic servicing method of the air conditioning system that is not described in this section, refer to

“AIR CONDITIONING BASIC MANUAL (Part number : 99520-02130)”.

Page 141 of 698

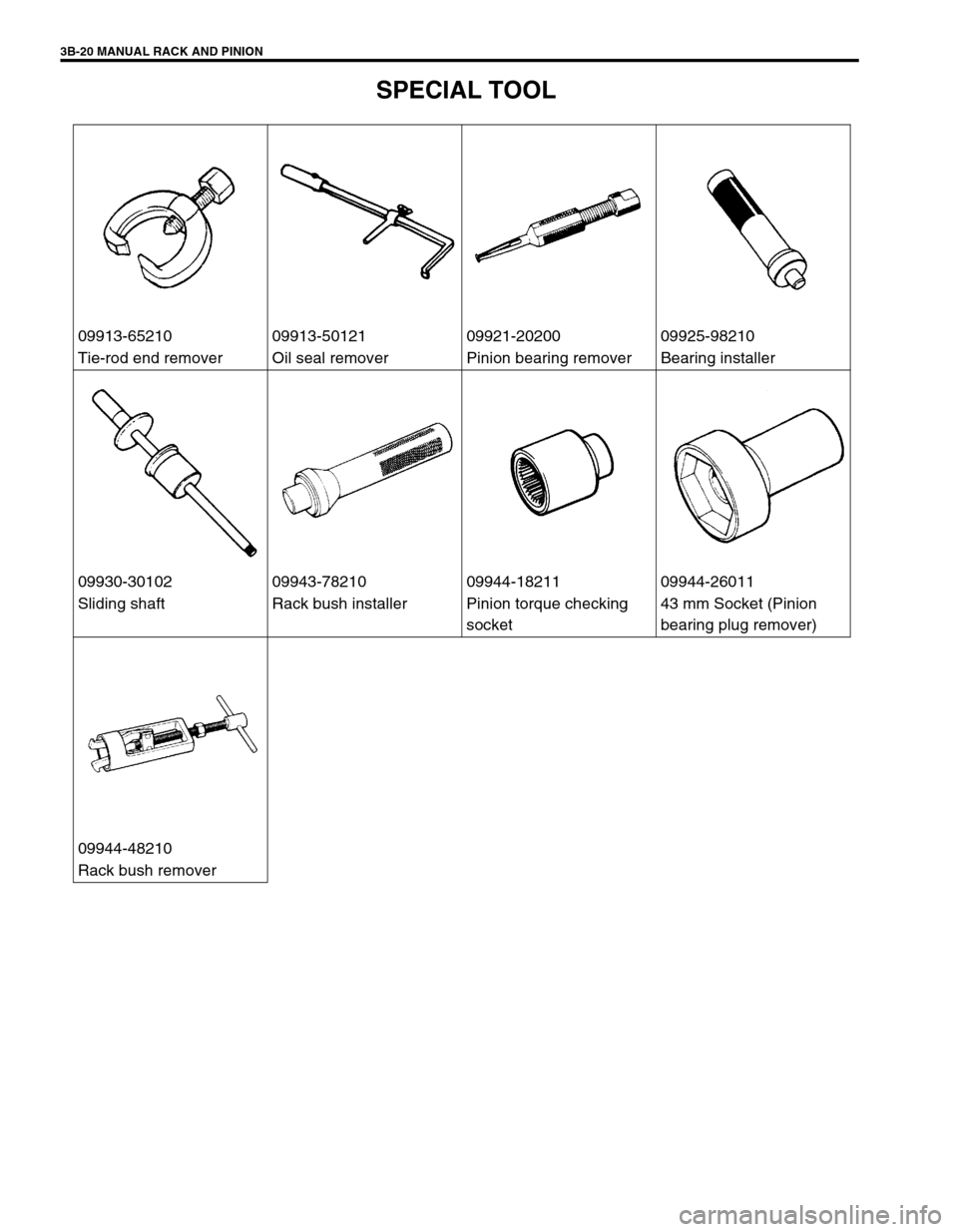

3B-20 MANUAL RACK AND PINION

SPECIAL TOOL

09913-65210 09913-50121 09921-20200 09925-98210

Tie-rod end remover Oil seal remover Pinion bearing remover Bearing installer

09930-30102 09943-78210 09944-18211 09944-26011

Sliding shaft Rack bush installer Pinion torque checking

socket43 mm Socket (Pinion

bearing plug remover)

09944-48210

Rack bush remover

Page 174 of 698

STEERING WHEEL AND COLUMN 3C-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

3C1

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3C

STEERING WHEEL AND COLUMN

CONTENTS

GENERAL DESCRIPTION .............................. 3C-2

STEERING COLUMN .................................. 3C-2

STEERING WHEEL AND DRIVER AIR

BAG (INFLATOR) MODULE ........................ 3C-2

DIAGNOSIS ..................................................... 3C-2

INSPECTION AND REPAIR REQUIRED

AFTER ACCIDENT ...................................... 3C-2

ON-VEHICLE SERVICE .................................. 3C-3

SERVICE PRECAUTIONS........................... 3C-3

SERVICE AND DIAGNOSIS .................... 3C-3

DISABLING AIR BAG SYSTEM ............... 3C-3

ENABLING AIR BAG SYSTEM ................ 3C-3

HANDLING AND STORAGE.................... 3C-4

DISPOSAL ............................................... 3C-4DRIVER AIR BAG (INFLATOR) MODULE .. 3C-4

STEERING WHEEL ..................................... 3C-6

CENTERING CONTACT COIL .................... 3C-7

CONTACT COIL AND COMBINATION

SWITCH ASSEMBLY .................................. 3C-8

STEERING COLUMN ASSEMBLY............ 3C-10

STEERING LOCK ASSEMBLY

(IGNITION SWITCH) ................................. 3C-16

STEERING LOWER SHAFT...................... 3C-17

CHECKING STEERING COLUMN

ASSEMBLY AND LOWER SHAFT FOR

ACCIDENT DAMAGE ................................... 3C-18

SPECIAL TOOL ............................................ 3C-19

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Please observe all WARNINGS and “Service Precautions” under “On-

Vehicle Service” in air bag system section before performing service on or around the air bag sys-

tem components or wiring. Failure to follow WARNINGS could result in unintentional activation of

the system or could render the system inoperative. Either of these two conditions may result in

severe injury.

The procedures in this section must be followed in the order listed to temporarily disable the air

bag system and prevent false diagnostic codes from setting. Failure to follow procedures could

result in possible air bag system activation, personal injury or otherwise unneeded air bag system

repairs.

CAUTION:

When fasteners are removed, always reinstall them at the same location from which they were

removed. If a fastener needs to be replaced, use the correct part number fastener for that application.

If the correct part number fastener is not available, a fastener of equal size and strength (or stronger)

may be used. Fasteners that are not reused, and those requiring thread-locking compound, will be

called out. The correct torque value must be used when installing fasteners that require it. If the above

procedures are not followed, parts or system damage could result.

Page 396 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-27

Engine noise

Note : Before

checking mechani-

cal noise, make sure

that :

Specified spark

plug is used.

Specified fuel is

used.Improper valve lash Valve lash in Section 6A1.

Worn valve stem and guide Valves inspection in Section 6A1.

Weak or broken valve spring Valve springs inspection in Section

6A1.

Warped or bent valve Valves inspection in Section 6A1.

Worn piston, ring and cylinder bore Pistons and cylinders inspection in Sec-

tion 6A1.

Worn rod bearing Crank pin and connecting rod bearing

inspection in Section 6A1.

Worn crank pin Crank pin and connecting rod bearing

inspection in Section 6A1.

Loose connecting rod nuts Connecting rod installation in Section

6A1.

Low oil pressure Previously outlined.

Low oil pressure Previously outlined.

Worn bearing Crankshaft and bearing inspection in

Section 6A1.

Worn crankshaft journal Crankshaft and bearing inspection in

Section 6A1.

Loose bearing cap bolts Crankshaft inspection in Section 6A1.

Excessive crankshaft thrust play Crankshaft thrust play inspection in

Section 6A1.

Overheating

Inoperative thermostat Thermostat in Section 6B.

Poor water pump performance Water pump in Section 6B.

Clogged or leaky radiator Radiator in Section 6B.

Improper engine oil grade Engine oil and oil filter change in Sec-

tion 0B.

Clogged oil filter or oil strainer Oil pressure check in Section 6A1.

Poor oil pump performance Oil pressure check in Section 6A1.

Faulty radiator fan control system Radiator fan control system in Section

6E1.

Dragging brakes Trouble diagnosis in Section 5.

Slipping clutch Trouble diagnosis in Section 7C.

Blown cylinder head gasket Cylinder head in Section 6A1. Condition Possible Cause Correction

Page 507 of 698

6A1-6 ENGINE MECHANICAL (M13 ENGINE)

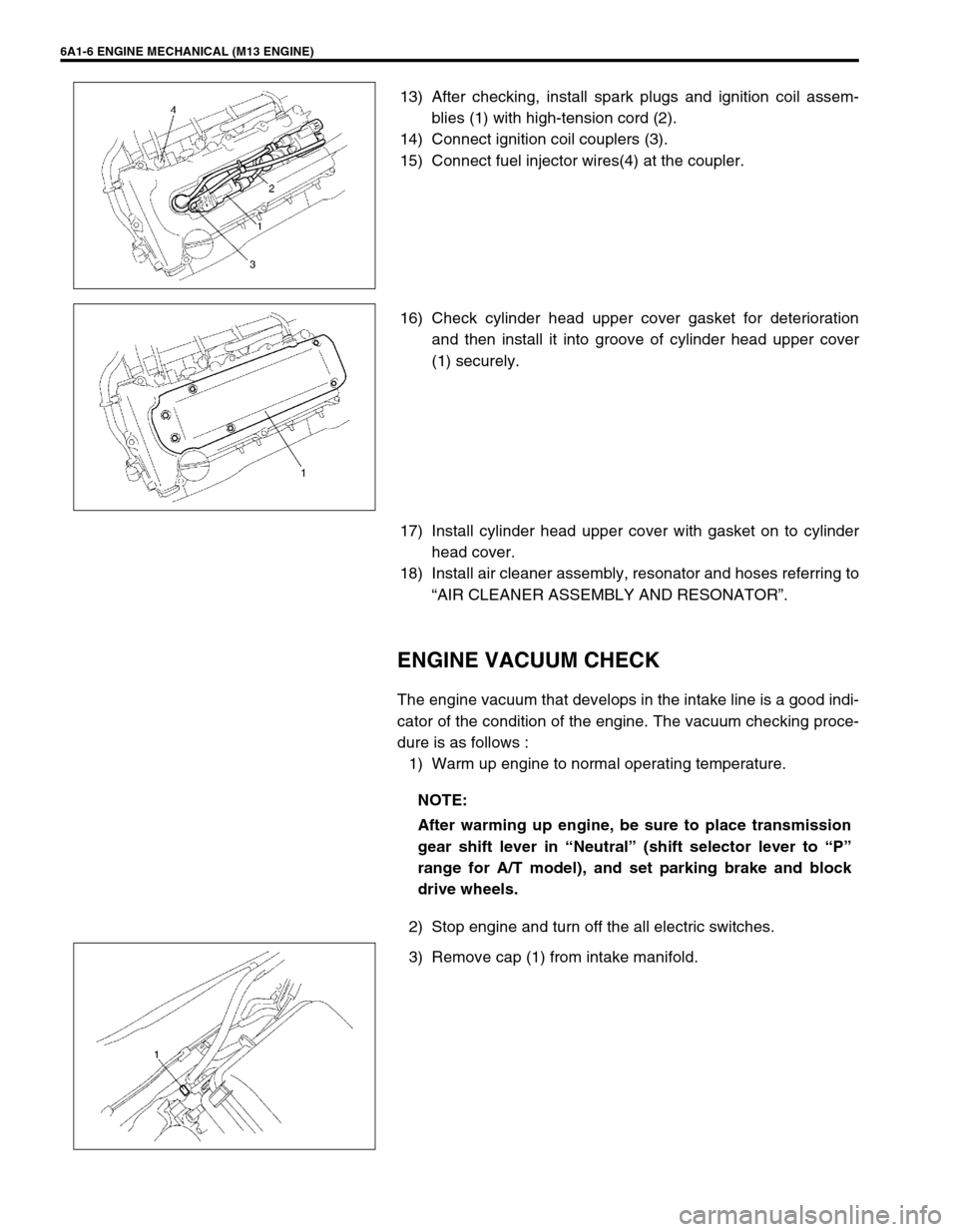

13) After checking, install spark plugs and ignition coil assem-

blies (1) with high-tension cord (2).

14) Connect ignition coil couplers (3).

15) Connect fuel injector wires(4) at the coupler.

16) Check cylinder head upper cover gasket for deterioration

and then install it into groove of cylinder head upper cover

(1) securely.

17) Install cylinder head upper cover with gasket on to cylinder

head cover.

18) Install air cleaner assembly, resonator and hoses referring to

“AIR CLEANER ASSEMBLY AND RESONATOR”.

ENGINE VACUUM CHECK

The engine vacuum that develops in the intake line is a good indi-

cator of the condition of the engine. The vacuum checking proce-

dure is as follows :

1) Warm up engine to normal operating temperature.

2) Stop engine and turn off the all electric switches.

3) Remove cap (1) from intake manifold.

NOTE:

After warming up engine, be sure to place transmission

gear shift lever in “Neutral” (shift selector lever to “P”

range for A/T model), and set parking brake and block

drive wheels.

Page 508 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-7

4) Connect special tool (Vacuum gauge) to intake manifold.

Special tool

(A) : 09915-67310

5) Run engine at specified idle speed and read vacuum gauge.

Vacuum should be within specification.

Vacuum specification (at sea level)

: 59 – 73 kPa (45 – 55 cmHg, 17.7 – 21.6 inHg)

at specified idle speed

6) After checking, disconnect special tool (Vacuum gauge) from

intake manifold.

7) Install cap to intake manifold.

OIL PRESSURE CHECK

Oil level in oil pan

If oil level is low, add oil up to Full level mark (hole) on oil

level gauge.

Oil quality

If oil is discolored, or deteriorated, change it.

For particular oil to be used referring to the table in Section

0B.

Oil leaks

If leak is found, repair it.

1) Disconnect oil pressure switch coupler (1) and remove oil

pressure switch (2) from cylinder block.

NOTE:

Prior to checking oil pressure, check the following items.

1. Full level mark (hole)

2. Low level mark (hole)

Page 561 of 698

6A1-60 ENGINE MECHANICAL (M13 ENGINE)

Piston clearance:

Measure cylinder bore diameter and piston diameter to find

their difference which is piston clearance. Piston clearance

should be within specification as given below. If it is out of

specification, rebore cylinder and use oversize piston.

Piston clearance

: 0.032 – 0.061 mm (0.0013 – 0.0024 in.)

: 0.016 – 0.045 mm (0.0006 – 0.0018 in.) with coating

Ring groove clearance:

Before checking, piston grooves must be clean, dry and free

of carbon deposits.

Fit new piston ring (1) into piston groove, and measure clear-

ance between ring and ring land by using thickness gauge

(2). If clearance is out of limit, replace piston.

Ring groove clearance

Top ring

Standard : 0.03 – 0.07 mm (0.0012 – 0.0028 in.)

Limit : 0.12 mm (0.0047 in.)

2nd ring

Standard : 0.02 – 0.06 mm (0.0008 – 0.0024 in.)

Limit : 0.10 mm (0.0039 in.)

Oil ring

Standard : 0.03 – 0.17 mm (0.0012 – 0.0067 in.)

Piston Pin

Check piston pin, connecting rod small end bore and piston

bore for wear or damage, paying particular attention to con-

dition of small end bore bush. If pin, connecting rod small

end bore or piston bore is badly worn or damaged, replace

pin, connecting rod and/or piston. NOTE:

Cylinder bore diameters used here are measured in

thrust direction at two positions.

“a” : 19.5 mm (0.77 in.)

Page 564 of 698

ENGINE MECHANICAL (M13 ENGINE) 6A1-63

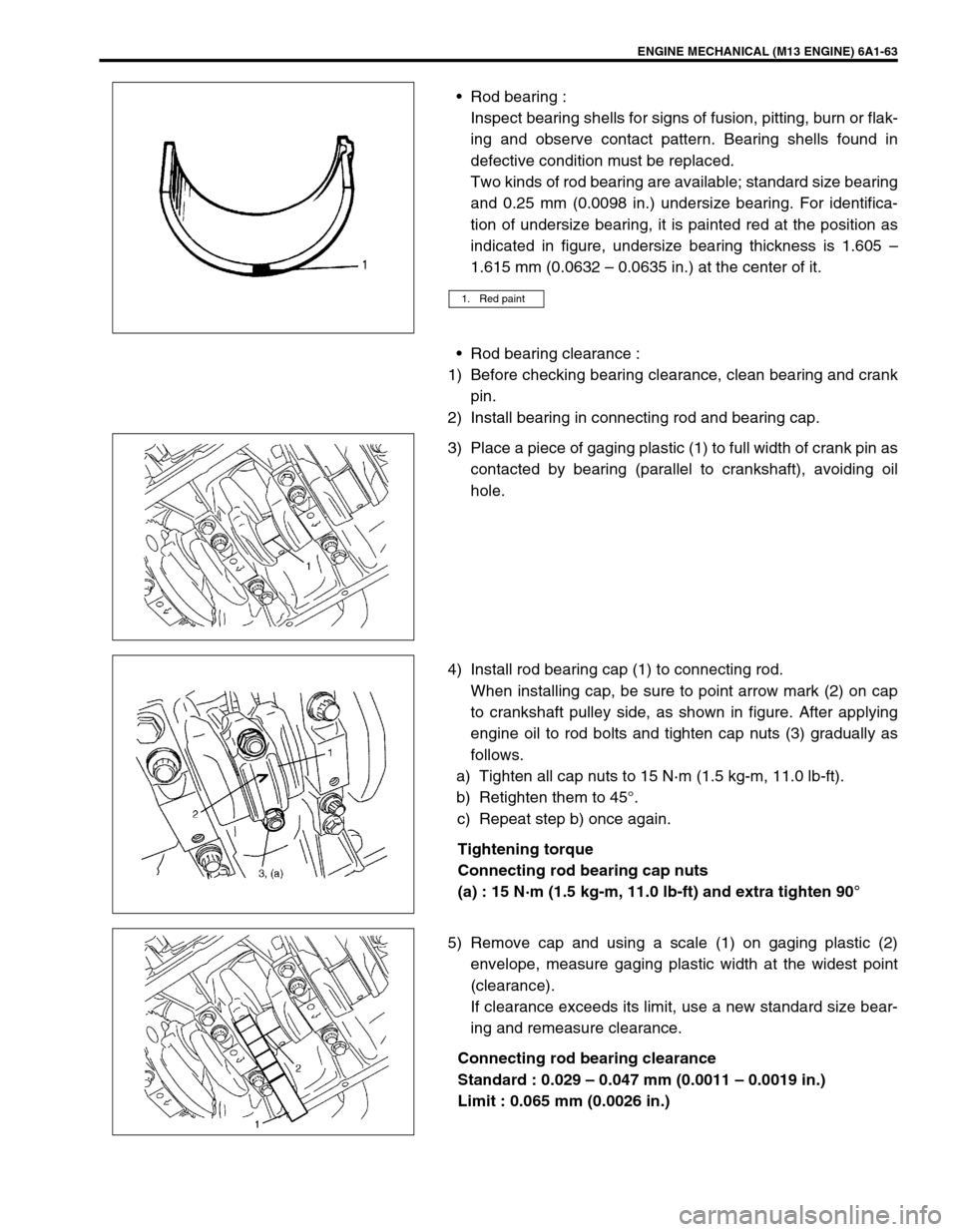

Rod bearing :

Inspect bearing shells for signs of fusion, pitting, burn or flak-

ing and observe contact pattern. Bearing shells found in

defective condition must be replaced.

Two kinds of rod bearing are available; standard size bearing

and 0.25 mm (0.0098 in.) undersize bearing. For identifica-

tion of undersize bearing, it is painted red at the position as

indicated in figure, undersize bearing thickness is 1.605 –

1.615 mm (0.0632 – 0.0635 in.) at the center of it.

Rod bearing clearance :

1) Before checking bearing clearance, clean bearing and crank

pin.

2) Install bearing in connecting rod and bearing cap.

3) Place a piece of gaging plastic (1) to full width of crank pin as

contacted by bearing (parallel to crankshaft), avoiding oil

hole.

4) Install rod bearing cap (1) to connecting rod.

When installing cap, be sure to point arrow mark (2) on cap

to crankshaft pulley side, as shown in figure. After applying

engine oil to rod bolts and tighten cap nuts (3) gradually as

follows.

a) Tighten all cap nuts to 15 N·m (1.5 kg-m, 11.0 lb-ft).

b) Retighten them to 45°.

c) Repeat step b) once again.

Tightening torque

Connecting rod bearing cap nuts

(a) : 15 N·m (1.5 kg-m, 11.0 lb-ft) and extra tighten 90°

5) Remove cap and using a scale (1) on gaging plastic (2)

envelope, measure gaging plastic width at the widest point

(clearance).

If clearance exceeds its limit, use a new standard size bear-

ing and remeasure clearance.

Connecting rod bearing clearance

Standard : 0.029 – 0.047 mm (0.0011 – 0.0019 in.)

Limit : 0.065 mm (0.0026 in.)

1. Red paint