Air SUZUKI SWIFT 2000 1.G Transmission Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 380 of 447

10B-6 AIR BAG SYSTEM

CONNECTOR “Q06” (SDM connector)

DIAGNOSIS

DIAGNOSTIC TROUBLE CODE (DTC)

The AIR BAG DIAGNOSTIC SYSTEM CHECK must always be the starting point of any air bag system diagno-

sis. The AIR BAG DIAGNOSTIC SYSTEM CHECK checks for proper “AIR BAG” warning lamp operation and

checks for air bag diagnostic trouble codes (DTCs) using on-board diagnosis function or SUZUKI scan tool.

USE OF SPECIAL TOOL

You should be familiar with the tools listed in this section under the heading SPECIAL TOOLS. You should be

able to measure voltage and resistance. You should be familiar with proper use of a scan tool such as Air Bag

Driver/Passenger Load Tool, Connector Test Adapter Kit and the Digital Multimeter.

Special tool

(A) : 09932-76010 (Connector Test Adapter Kit)

This must be used whenever a diagnostic procedure requests

checking or probing a terminal.

Using the appropriate adapter in the special tool will ensure that

no damage to the terminal will occur from the multimeter probe,

such as spreading or bending. TERMINAL CIRCUIT TERMINAL CIRCUIT

Q06-1–Q06-11 Driver pretensioner

(if equipped)Low

Q06-2“AIR BAG” warning lamp Q06-12 High

Q06-3–Q06-13–

Q06-4 Ignition switch (power source) Q06-14 Data link connector (DLC)

Q06-5 Passenger pretensioner

(if equipped)High Q06-15 Diagnosis switch

Q06-6 Low Q06-16–

Q06-7 Passenger air bag (inflator)

moduleHigh Q06-17 Ground

Q06-8 Low Q06-18–

Q06-9 Driver air bag (inflator)

moduleLow Q06-19–

Q06-10 High Q06-20–

WARNING:

To avoid deployment when troubleshooting the air bag system, do not use electrical test equipment

such as a battery powered or AC powered voltmeter, ohmmeter, etc., or any type of electrical equip-

ment other than that specified in this manual. Do not use a non-powered probe type tester.

Instructions in this manual must be followed carefully, otherwise personal injury may result.

WARNING:

To avoid deployment when troubleshooting the air bag system, do not use electrical test equipment

such as a battery powered or AC powered voltmeter, ohmmeter, etc., or any type of electrical equip-

ment other than that specified in this manual. Do not use a non-powered probe type tester.

Instructions in this manual must be followed carefully, otherwise personal injury may result.

Page 381 of 447

AIR BAG SYSTEM 10B-7

The adapter will also give an idea of whether contact tension is

sufficient, helping to find an open or intermittent open due to poor

terminal contact.

Special tool

(B) : 09932-75010 (Air Bag Driver/Passenger Load Tool)

This tool is used only when called for in this section. It is used as

a diagnostic aid and safety device to prevent inadvertent air bag

(inflator) module deployment.

The load tool has three connectors attached to its case which are

electrically functional and serve as resistive load substitutions.

No more than two connectors are used at any time.

One of connectors (“STEERING WHEEL”) is used to substitute

the load of followings.

driver air bag (inflator) module when it is connected at the

top of the column to the contact coil assembly.

passenger air bag (inflator) module when it is connected to

the air bag harness connector for passenger air bag (inflator)

module.

Another connector (“BASE OF COLUMN”) is used to substitute

the load of the driver air bag (inflator) module and the contact coil

assembly when it is connected at the base of the column to the air

bag wire harness.

The third connector (“PASSENGER INFLATOR”) is not used.

By substituting the resistance of the load tool when called for, a

determination can be made as to whether an inflator circuit com-

ponent is causing system malfunction and which component is

causing the malfunction.

The load tool should be used only when specifically called for in

the diagnostic procedures.

1. Connector for contact coil and driver air bag (inflator) module

(Located near the base of the steering column)

2. Connector for driver, passenger air bag (inflator) module and driver and

passenger seat belt pretensioners

3. Not used

Page 382 of 447

10B-8 AIR BAG SYSTEM

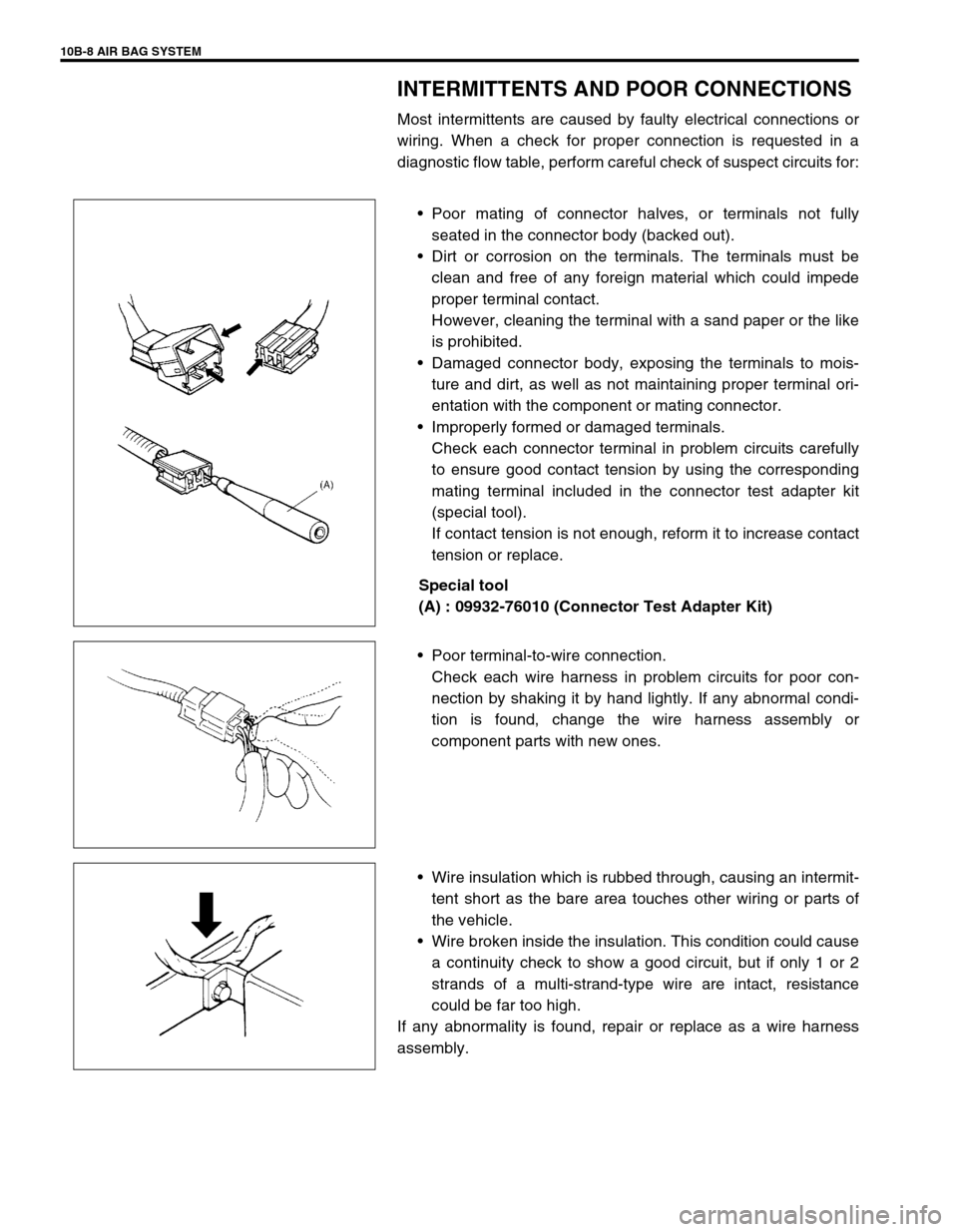

INTERMITTENTS AND POOR CONNECTIONS

Most intermittents are caused by faulty electrical connections or

wiring. When a check for proper connection is requested in a

diagnostic flow table, perform careful check of suspect circuits for:

Poor mating of connector halves, or terminals not fully

seated in the connector body (backed out).

Dirt or corrosion on the terminals. The terminals must be

clean and free of any foreign material which could impede

proper terminal contact.

However, cleaning the terminal with a sand paper or the like

is prohibited.

Damaged connector body, exposing the terminals to mois-

ture and dirt, as well as not maintaining proper terminal ori-

entation with the component or mating connector.

Improperly formed or damaged terminals.

Check each connector terminal in problem circuits carefully

to ensure good contact tension by using the corresponding

mating terminal included in the connector test adapter kit

(special tool).

If contact tension is not enough, reform it to increase contact

tension or replace.

Special tool

(A) : 09932-76010 (Connector Test Adapter Kit)

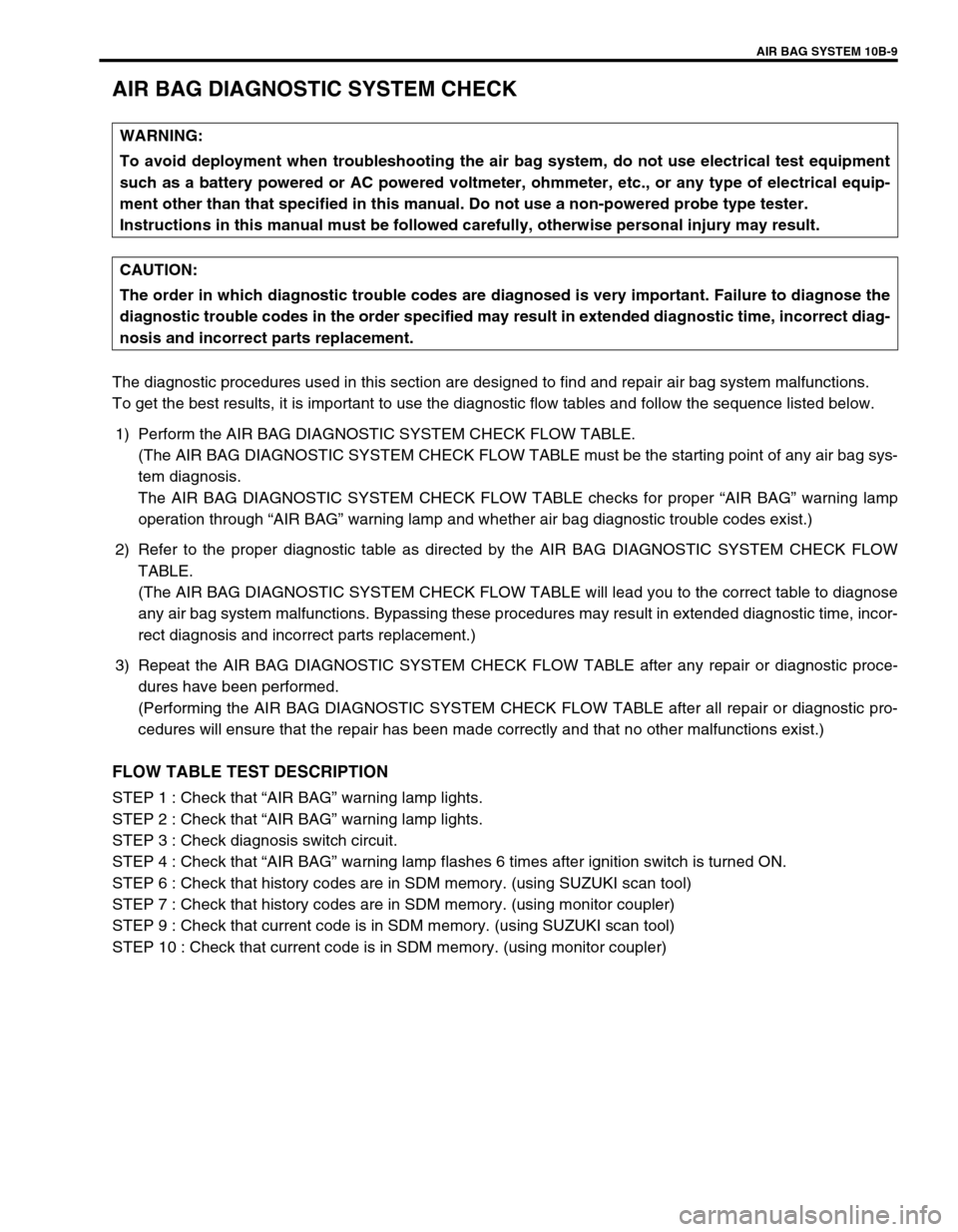

Poor terminal-to-wire connection.

Check each wire harness in problem circuits for poor con-

nection by shaking it by hand lightly. If any abnormal condi-

tion is found, change the wire harness assembly or

component parts with new ones.

Wire insulation which is rubbed through, causing an intermit-

tent short as the bare area touches other wiring or parts of

the vehicle.

Wire broken inside the insulation. This condition could cause

a continuity check to show a good circuit, but if only 1 or 2

strands of a multi-strand-type wire are intact, resistance

could be far too high.

If any abnormality is found, repair or replace as a wire harness

assembly.

Page 383 of 447

AIR BAG SYSTEM 10B-9

AIR BAG DIAGNOSTIC SYSTEM CHECK

The diagnostic procedures used in this section are designed to find and repair air bag system malfunctions.

To get the best results, it is important to use the diagnostic flow tables and follow the sequence listed below.

1) Perform the AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE.

(The AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE must be the starting point of any air bag sys-

tem diagnosis.

The AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE checks for proper “AIR BAG” warning lamp

operation through “AIR BAG” warning lamp and whether air bag diagnostic trouble codes exist.)

2) Refer to the proper diagnostic table as directed by the AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW

TABLE.

(The AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE will lead you to the correct table to diagnose

any air bag system malfunctions. Bypassing these procedures may result in extended diagnostic time, incor-

rect diagnosis and incorrect parts replacement.)

3) Repeat the AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE after any repair or diagnostic proce-

dures have been performed.

(Performing the AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE after all repair or diagnostic pro-

cedures will ensure that the repair has been made correctly and that no other malfunctions exist.)

FLOW TABLE TEST DESCRIPTION

STEP 1 : Check that “AIR BAG” warning lamp lights.

STEP 2 : Check that “AIR BAG” warning lamp lights.

STEP 3 : Check diagnosis switch circuit.

STEP 4 : Check that “AIR BAG” warning lamp flashes 6 times after ignition switch is turned ON.

STEP 6 : Check that history codes are in SDM memory. (using SUZUKI scan tool)

STEP 7 : Check that history codes are in SDM memory. (using monitor coupler)

STEP 9 : Check that current code is in SDM memory. (using SUZUKI scan tool)

STEP 10 : Check that current code is in SDM memory. (using monitor coupler)WARNING:

To avoid deployment when troubleshooting the air bag system, do not use electrical test equipment

such as a battery powered or AC powered voltmeter, ohmmeter, etc., or any type of electrical equip-

ment other than that specified in this manual. Do not use a non-powered probe type tester.

Instructions in this manual must be followed carefully, otherwise personal injury may result.

CAUTION:

The order in which diagnostic trouble codes are diagnosed is very important. Failure to diagnose the

diagnostic trouble codes in the order specified may result in extended diagnostic time, incorrect diag-

nosis and incorrect parts replacement.

Page 384 of 447

10B-10 AIR BAG SYSTEM

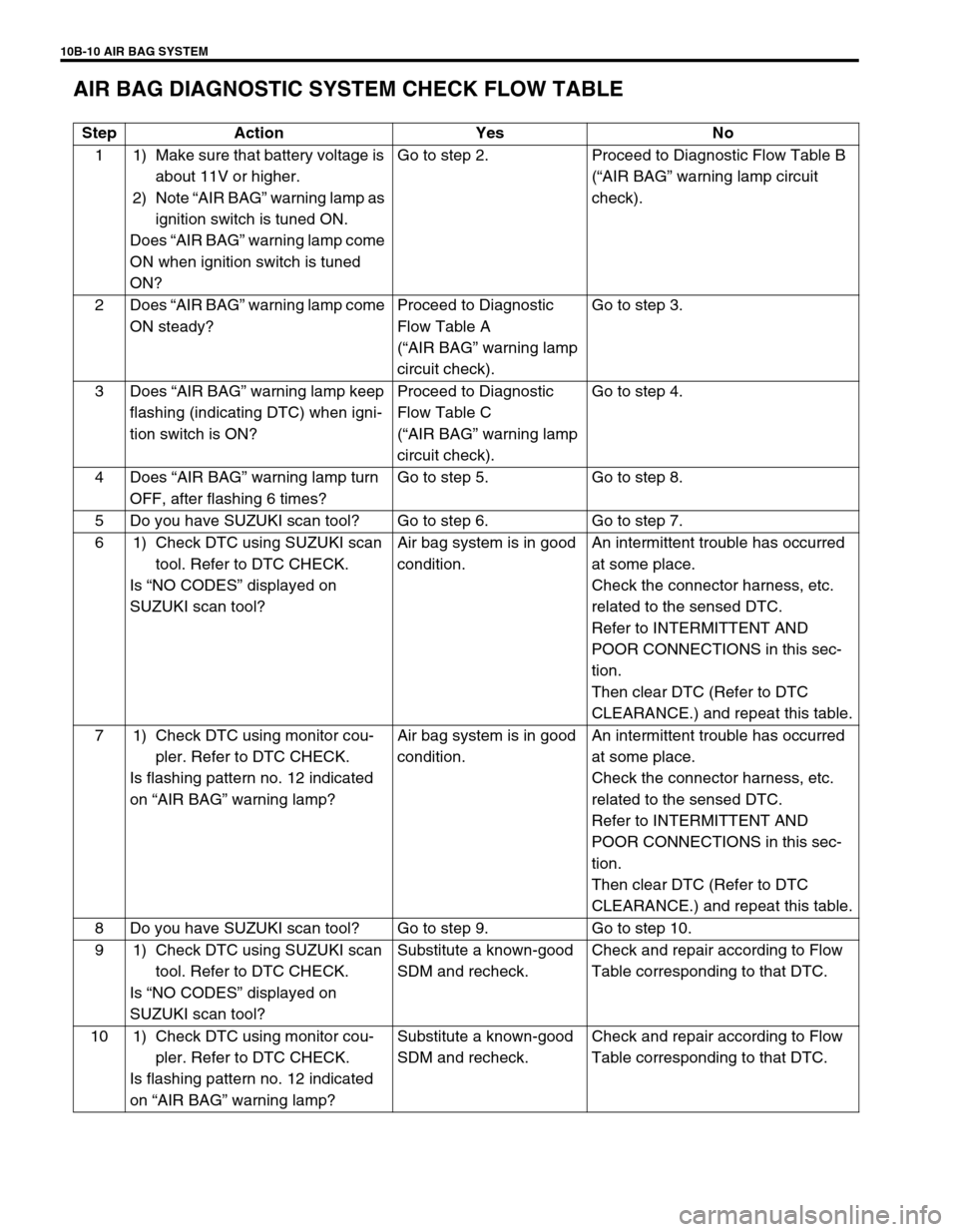

AIR BAG DIAGNOSTIC SYSTEM CHECK FLOW TABLE

Step Action Yes No

1 1) Make sure that battery voltage is

about 11V or higher.

2) Note “AIR BAG” warning lamp as

ignition switch is tuned ON.

Does “AIR BAG” warning lamp come

ON when ignition switch is tuned

ON?Go to step 2. Proceed to Diagnostic Flow Table B

(“AIR BAG” warning lamp circuit

check).

2Does “AIR BAG” warning lamp come

ON steady?Proceed to Diagnostic

Flow Table A

(“AIR BAG” warning lamp

circuit check).Go to step 3.

3Does “AIR BAG” warning lamp keep

flashing (indicating DTC) when igni-

tion switch is ON?Proceed to Diagnostic

Flow Table C

(“AIR BAG” warning lamp

circuit check).Go to step 4.

4Does “AIR BAG” warning lamp turn

OFF, after flashing 6 times?Go to step 5. Go to step 8.

5 Do you have SUZUKI scan tool? Go to step 6. Go to step 7.

6 1) Check DTC using SUZUKI scan

tool. Refer to DTC CHECK.

Is “NO CODES” displayed on

SUZUKI scan tool?Air bag system is in good

condition.An intermittent trouble has occurred

at some place.

Check the connector harness, etc.

related to the sensed DTC.

Refer to INTERMITTENT AND

POOR CONNECTIONS in this sec-

tion.

Then clear DTC (Refer to DTC

CLEARANCE.) and repeat this table.

7 1) Check DTC using monitor cou-

pler. Refer to DTC CHECK.

Is flashing pattern no. 12 indicated

on “AIR BAG” warning lamp?Air bag system is in good

condition.An intermittent trouble has occurred

at some place.

Check the connector harness, etc.

related to the sensed DTC.

Refer to INTERMITTENT AND

POOR CONNECTIONS in this sec-

tion.

Then clear DTC (Refer to DTC

CLEARANCE.) and repeat this table.

8 Do you have SUZUKI scan tool? Go to step 9. Go to step 10.

9 1) Check DTC using SUZUKI scan

tool. Refer to DTC CHECK.

Is “NO CODES” displayed on

SUZUKI scan tool?Substitute a known-good

SDM and recheck.Check and repair according to Flow

Table corresponding to that DTC.

10 1) Check DTC using monitor cou-

pler. Refer to DTC CHECK.

Is flashing pattern no. 12 indicated

on “AIR BAG” warning lamp?Substitute a known-good

SDM and recheck.Check and repair according to Flow

Table corresponding to that DTC.

Page 385 of 447

AIR BAG SYSTEM 10B-11

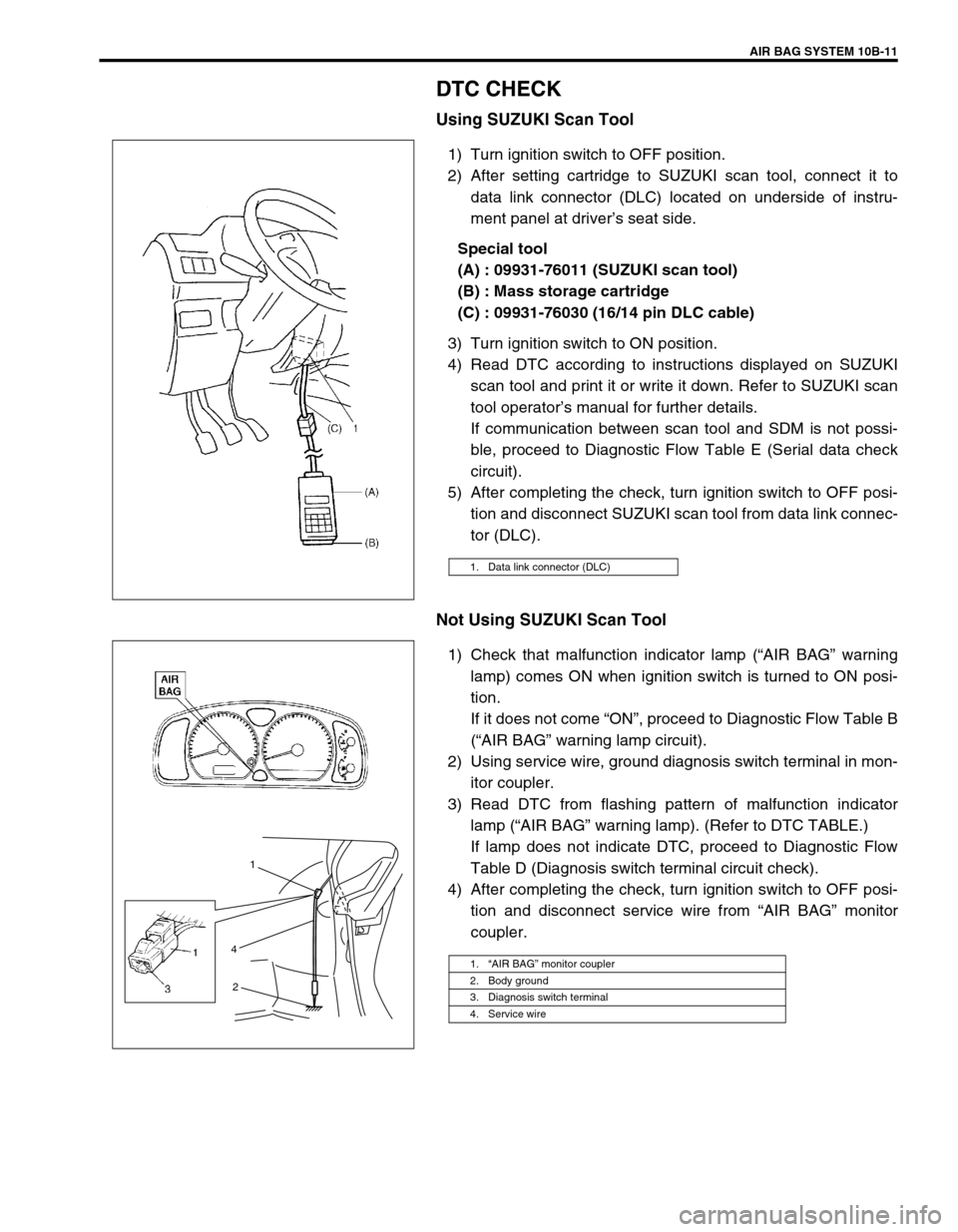

DTC CHECK

Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) After setting cartridge to SUZUKI scan tool, connect it to

data link connector (DLC) located on underside of instru-

ment panel at driver’s seat side.

Special tool

(A) : 09931-76011 (SUZUKI scan tool)

(B) : Mass storage cartridge

(C) : 09931-76030 (16/14 pin DLC cable)

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on SUZUKI

scan tool and print it or write it down. Refer to SUZUKI scan

tool operator’s manual for further details.

If communication between scan tool and SDM is not possi-

ble, proceed to Diagnostic Flow Table E (Serial data check

circuit).

5) After completing the check, turn ignition switch to OFF posi-

tion and disconnect SUZUKI scan tool from data link connec-

tor (DLC).

Not Using SUZUKI Scan Tool

1) Check that malfunction indicator lamp (“AIR BAG” warning

lamp) comes ON when ignition switch is turned to ON posi-

tion.

If it does not come “ON”, proceed to Diagnostic Flow Table B

(“AIR BAG” warning lamp circuit).

2) Using service wire, ground diagnosis switch terminal in mon-

itor coupler.

3) Read DTC from flashing pattern of malfunction indicator

lamp (“AIR BAG” warning lamp). (Refer to DTC TABLE.)

If lamp does not indicate DTC, proceed to Diagnostic Flow

Table D (Diagnosis switch terminal circuit check).

4) After completing the check, turn ignition switch to OFF posi-

tion and disconnect service wire from “AIR BAG” monitor

coupler.

1. Data link connector (DLC)

1.“AIR BAG” monitor coupler

2. Body ground

3. Diagnosis switch terminal

4. Service wire

1

4

2

Page 386 of 447

10B-12 AIR BAG SYSTEM

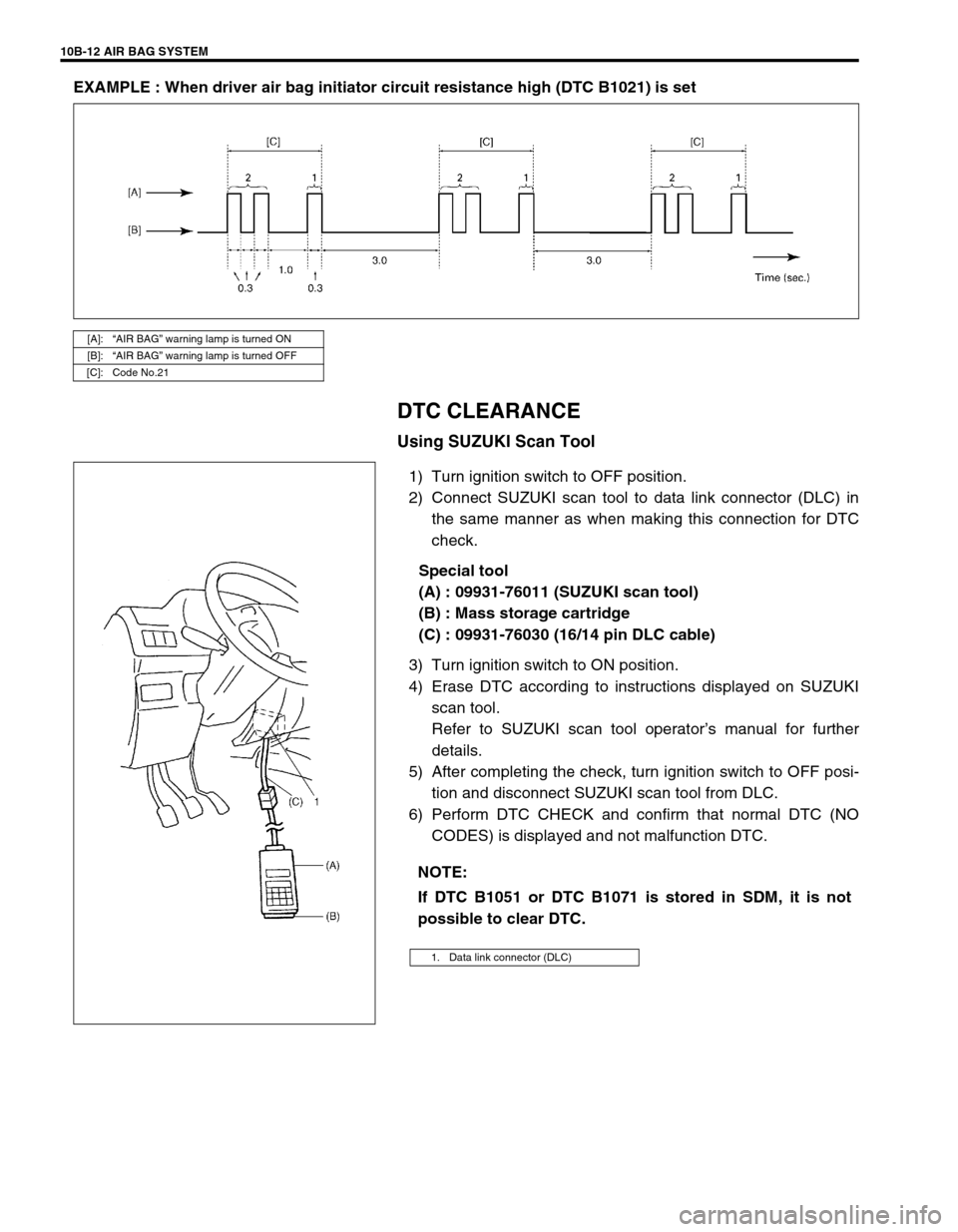

EXAMPLE : When driver air bag initiator circuit resistance high (DTC B1021) is set

DTC CLEARANCE

Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) in

the same manner as when making this connection for DTC

check.

Special tool

(A) : 09931-76011 (SUZUKI scan tool)

(B) : Mass storage cartridge

(C) : 09931-76030 (16/14 pin DLC cable)

3) Turn ignition switch to ON position.

4) Erase DTC according to instructions displayed on SUZUKI

scan tool.

Refer to SUZUKI scan tool operator’s manual for further

details.

5) After completing the check, turn ignition switch to OFF posi-

tion and disconnect SUZUKI scan tool from DLC.

6) Perform DTC CHECK and confirm that normal DTC (NO

CODES) is displayed and not malfunction DTC.

[A]:“AIR BAG” warning lamp is turned ON

[B]:“AIR BAG” warning lamp is turned OFF

[C]: Code No.21

NOTE:

If DTC B1051 or DTC B1071 is stored in SDM, it is not

possible to clear DTC.

1. Data link connector (DLC)

Page 387 of 447

AIR BAG SYSTEM 10B-13

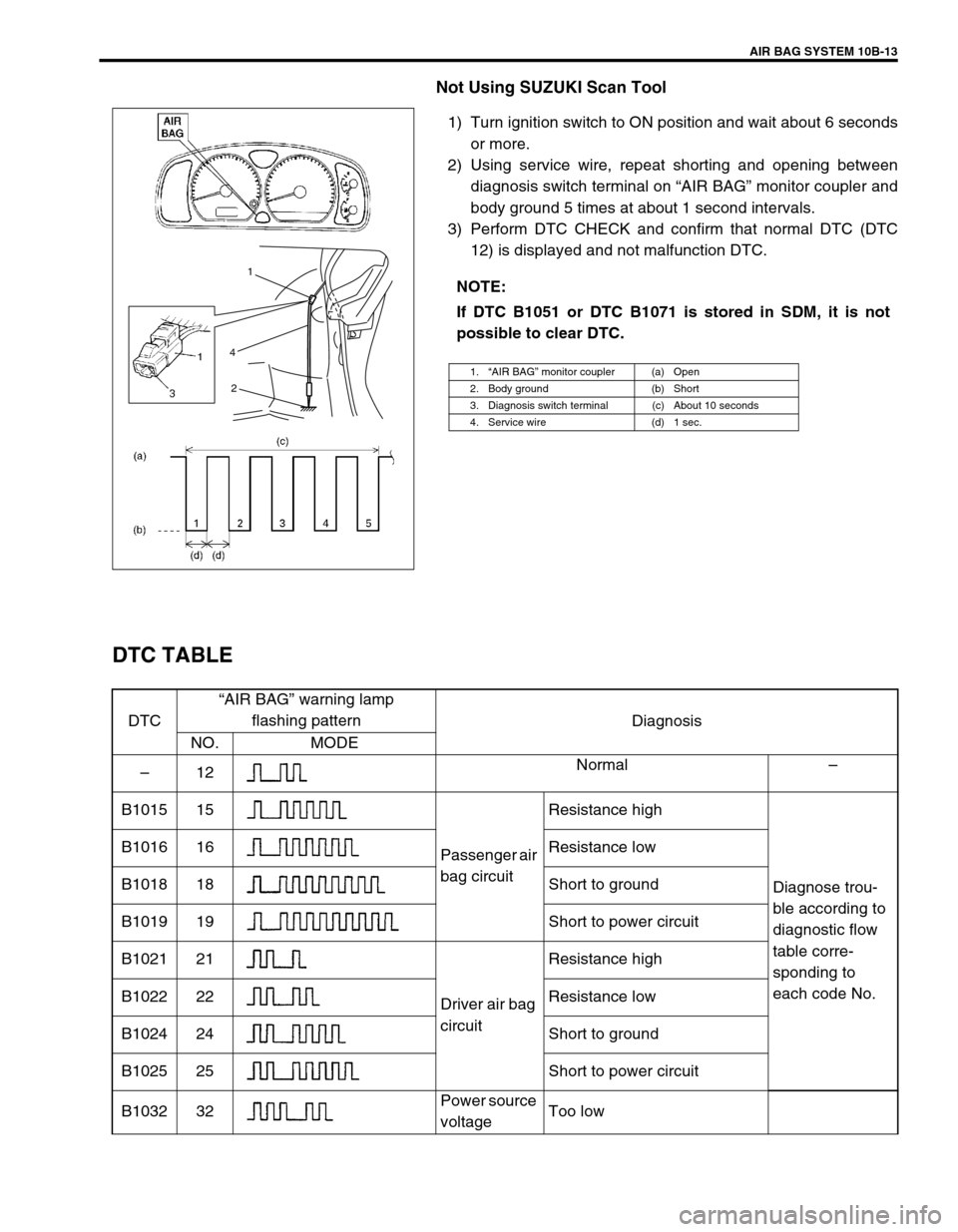

Not Using SUZUKI Scan Tool

1) Turn ignition switch to ON position and wait about 6 seconds

or more.

2) Using service wire, repeat shorting and opening between

diagnosis switch terminal on “AIR BAG” monitor coupler and

body ground 5 times at about 1 second intervals.

3) Perform DTC CHECK and confirm that normal DTC (DTC

12) is displayed and not malfunction DTC.

DTC TABLE

NOTE:

If DTC B1051 or DTC B1071 is stored in SDM, it is not

possible to clear DTC.

1.“AIR BAG” monitor coupler (a) Open

2. Body ground (b) Short

3. Diagnosis switch terminal (c) About 10 seconds

4. Service wire (d) 1 sec.

1

4

2

DTC“AIR BAG” warning lamp

flashing pattern

Diagnosis

NO. MODE

–12Normal–

B1015 15

Passenger air

bag circuitResistance high

Diagnose trou-

ble according to

diagnostic flow

table corre-

sponding to

each code No. B1016 16 Resistance low

B1018 18 Short to ground

B1019 19 Short to power circuit

B1021 21

Driver air bag

circuitResistance high

B1022 22 Resistance low

B1024 24 Short to ground

B1025 25 Short to power circuit

B1032 32Power source

voltageToo low

Page 388 of 447

10B-14 AIR BAG SYSTEM

DTC“AIR BAG” warning lamp

flashing pattern

Diagnosis

NO. MODE

B1041 41

Driver preten-

sioner circuitResistance high

Diagnose trou-

ble according to

diagnostic flow

table corre-

sponding to

each code No. B1042 42 Resistance low

B1043 43 Short to ground

B1044 44 Short to power circuit

B1045 45

Passenger

pretensioner

circuitResistance high

B1046 46 Resistance low

B1047 47 Short to ground

B1048 48 Short to power circuit

B1051 51

SDMFrontal crash detected

B1071 71 Internal fault

B1013 13Specifications different

between air bag system and

SDM

NOTE:

When 2 or more codes are indicated, the lowest numbered code will appear first.

Current DTC and history DTC can be identified by lighting and flashing of “AIR BAG” warning lamp

as follows. However, if a multiple number of DTC’s are set an even one of them is a current DTC,

“AIR BAG” warning lamp remains on after ignition switch is turned ON. Therefore, it is not possible

to identify any of them as to whether it is a current one or a history one. (But use of SUZUKI scan

tool will make identification possible.)

Current DTC is set.

(Abnormality exists at present.)History DTC is set only.

(Faulty condition occurred once

in the past but normal condition

is restored at present.)

“AIR BAG” warning lamp after

ignition switch ONFlashing 6 times and turns on. Flashing 6 times and turns off.

“AIR BAG” warning lamp when

grounding diagnosis switchCurrent DTC is displayed. History DTC is displayed.

Page 389 of 447

AIR BAG SYSTEM 10B-15

TABLE A - “AIR BAG” WARNING LAMP COMES ON STEADY

TABLE B - “AIR BAG” WARNING LAMP DOES NOT COME ON

TABLE C - “AIR BAG” WARNING LAMP FLASHES

TABLE D - “AIR BAG” WARNING LAMP CANNOT INDICATE FLASHING PAT-

TERN OF DTC

WIRING DIAGRAM

1. From main fuse 5.“AIR BAG” fuse 9. To ECM, TCM (if equipped) and ABS control

module (if equipped)

2. Ignition switch 6. Connection detection pin 10.“AIR BAG” monitor coupler

3.“IG·COIL METER” fuse 7. SDM 11. Ground for air bag system

4.“AIR BAG” warning lamp in combination meter 8. To DLC [A]: Air bag harness

1

2

34 BLK/YEL

BLK/YELBLK/WHTYEL/BLKYEL/BLK

6

REDRED

BLU

BLU

5

8

9

10

11

PPL

BLK

“Q04”“Q06”

Q06-2

Q06-4

Q06-14

Q06-15

Q06-17L1

L2

IG

SDL

DNS

GNDLA

7

[A]

12V

5V

“G39”“Q02”

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adapter from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.