Air SUZUKI SWIFT 2000 1.G Transmission Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 316 of 447

9-12 BODY SERVICE

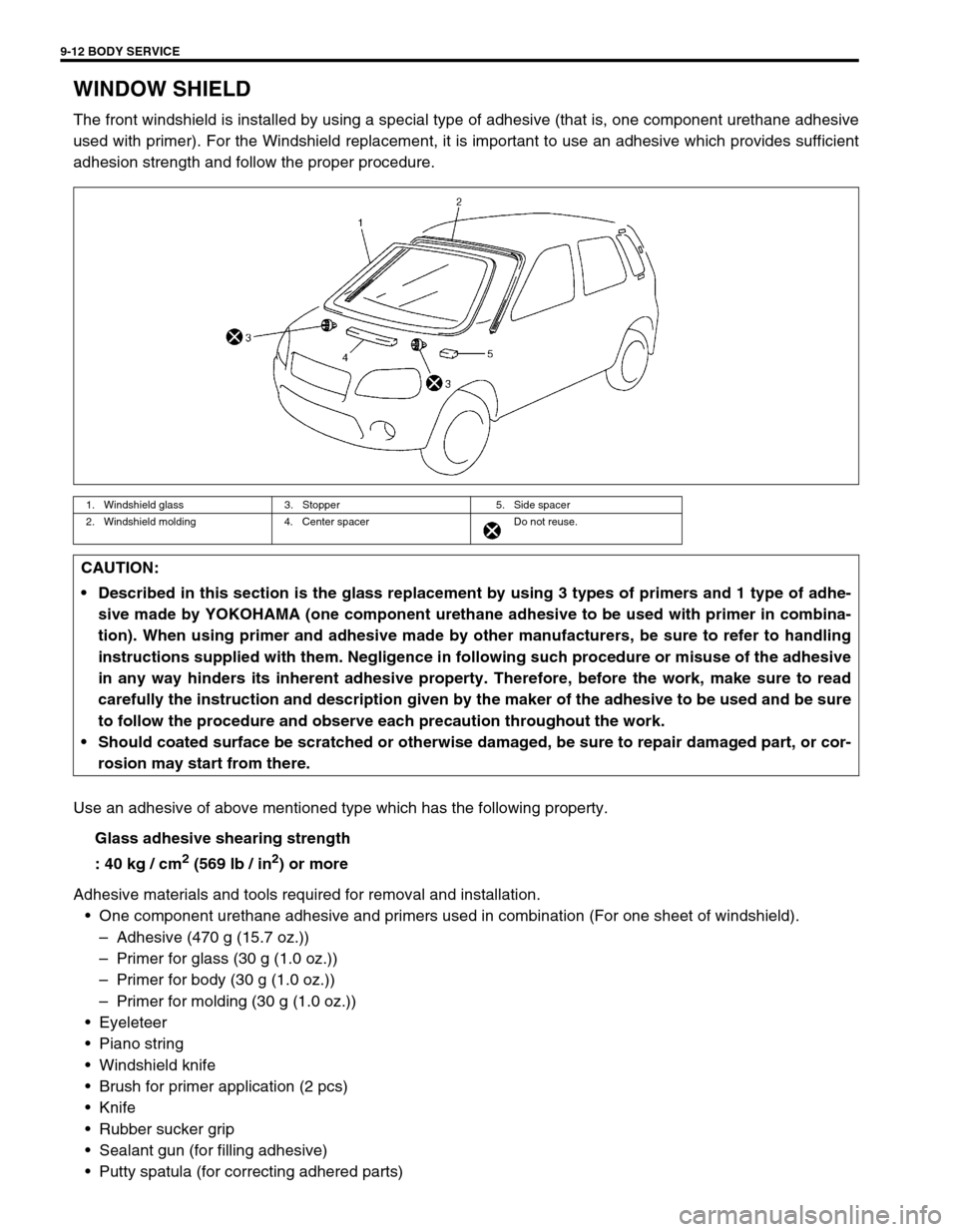

WINDOW SHIELD

The front windshield is installed by using a special type of adhesive (that is, one component urethane adhesive

used with primer). For the Windshield replacement, it is important to use an adhesive which provides sufficient

adhesion strength and follow the proper procedure.

Use an adhesive of above mentioned type which has the following property.

Glass adhesive shearing strength

: 40 kg / cm

2 (569 lb / in2) or more

Adhesive materials and tools required for removal and installation.

One component urethane adhesive and primers used in combination (For one sheet of windshield).

–Adhesive (470 g (15.7 oz.))

–Primer for glass (30 g (1.0 oz.))

–Primer for body (30 g (1.0 oz.))

–Primer for molding (30 g (1.0 oz.))

Eyeleteer

Piano string

Windshield knife

Brush for primer application (2 pcs)

Knife

Rubber sucker grip

Sealant gun (for filling adhesive)

Putty spatula (for correcting adhered parts)

1. Windshield glass 3. Stopper 5. Side spacer

2. Windshield molding 4. Center spacer Do not reuse.

CAUTION:

Described in this section is the glass replacement by using 3 types of primers and 1 type of adhe-

sive made by YOKOHAMA (one component urethane adhesive to be used with primer in combina-

tion). When using primer and adhesive made by other manufacturers, be sure to refer to handling

instructions supplied with them. Negligence in following such procedure or misuse of the adhesive

in any way hinders its inherent adhesive property. Therefore, before the work, make sure to read

carefully the instruction and description given by the maker of the adhesive to be used and be sure

to follow the procedure and observe each precaution throughout the work.

Should coated surface be scratched or otherwise damaged, be sure to repair damaged part, or cor-

rosion may start from there.

Page 320 of 447

9-16 BODY SERVICE

9) Apply primer for molding along molding surface all around.

10) Apply adhesive (1) referring to figure.

Adhesive amount specifications and position for wind-

shield

Width “a” : Approx. 7 mm (0.27 in.)

Height “b” : Approx. 15 mm (0.59 in.)

Position “c” : Approx. 10 mm (0.39 in.) for front, rear and

upper sections

Position “d” : Approx. 17 mm (0.67 in.) for bottom section.

11) Holding rubber sucker grips (1), place glass onto body by

aligning mating marks marked in step 3) and press it.

12) Check for water leakage by pouring water over windshield

through hose. If leakage is found, dry windshield and fill

leaky point with adhesive. If water still leaks even after that,

remove glass and start installation procedure all over again. NOTE:

Press glass (2) against fittings surface of body panel

quickly after adhesive (1) is applied.

Use of rubber sucker grip is helpful to hold and carry

glass after adhesive (1) is applied.

Perform steps 8) to 9) within 10 min. to ensure suffi-

cient adhesion.

Be sure to refer to adhesive maker’s instruction for

proper handling and drying time.

Start from bottom side of glass (2).

Be careful not to damage primer.

3. Molding

3

2

1

1“b”

“b”“b” “a”

“c”

“d”“c”

2

2

2

3

3

1

“a”“a”

NOTE:

Do not use high pressure water.

Do not blow compressed air directly at adhesive

applied part when drying.

Do not use infrared lamp or like for drying.

Page 342 of 447

9-38 BODY SERVICE

INSTRUMENTATION AND DRIVER INFORMATION

INSTRUMENT PANEL

REMOVAL

1) Disconnect negative cable at battery.

2) Disable air bag system, if equipped. Refer to “DISABLE AIR

BAG SYSTEM” in Section 10B.

3) Remove steering column hole cover (1).

4) Remove glove box (1) and food latch release lever (2).

5) Disconnect instrument panel harness connectors, antenna

and heater control cables which need to be disconnected for

removal for instrument panel.

6) Remove instrument panel ground wire.

7) Remove steering column assembly referring to “STEERING

COLUMN ASSEMBLY” in Section 3C.

8) Remove front pillar trims (1) and dash side trims (2).

9) Remove speaker covers (3).WARNING:

See WARNING at the beginning of this section.

“A”

“A”“A”

“A”

“A”

1

2“A” 1

3

“A”

Page 343 of 447

BODY SERVICE 9-39

10) Remove instrument panel mounting bolts (2).

11) Remove instrument panel (1) with steering support member

and instrument panel harness.

INSTALLATION

Reverse removal procedure to install instrument panel noting the

following instructions.

When installing each part, be careful not to catch any cable

or wiring harness.

Tighten instrument panel mounting bolts (1) to specified

torque

Tightening torque

Instrument panel mounting bolts (a) :

23 N·m (2.3 kg-m, 17.0 lb-ft)

When installing steering column assembly, refer to “STEER-

ING COLUMN ASSEMBLY” in Section 3C.

Adjust control cables. Refer to “HEATER CONTROL

ASSEMBLY” in Section 1A.

Enable air bag system if equipped. Refer to “ENABLING AIR

BAG SYSTEM” in Section 10B.

2

2

22 2

1

1, (a)1, (a)

Page 344 of 447

9-40 BODY SERVICE

SEATS

FRONT SEAT

REMOVAL

1) Remove console box.

2) Remove 4 mounting bolts to remove seat assembly.

3) Disassemble and repair seat as necessary.

INSTALLATION

Reverse removal procedure to install front seat.

Torque to specifications as shown.

1. Seat cushion 4. Cover 7. Reclining bolt

2. Seat back 5. Seat adjuster 8. Seat cushion bolt

3. Head rest 6. Seat adjuster bolt Tightening torque

3

2

7 35 N·m (3.5 kg-m)

6 35 N·m (3.5 kg-m)

8 23 N·m (2.3 kg-m)

4

5

5

4

1

Page 345 of 447

BODY SERVICE 9-41

REAR SEAT

REMOVAL

1) Remove 2 seat cushion bolts to remove seat cushion.

2) Remove 3 seat back bolts to remove seat back.

3) Disassemble and repair seat as necessary.

INSTALLATION

Reverse removal procedure to install rear seat.

Torque to specifications as shown.

1. Seat cushion 4. Seat cushion bolt

2. Seat back Tightening torquer

3. Seat back bolt

22

1

3 35 N·m (3.5 kg-m)

4 35 N·m (3.5 kg-m)

Page 354 of 447

9-50 BODY SERVICE

PAINT AND COATINGS

ANTI-CORROSION TREATMENT

As rust proof treatment, steel sheets are given corrosion resistance on the interior and/or exterior.

These corrosion resistance steel sheet materials are called one of two-side galvanized steel sheets.

It is for the sake of rust protection that these materials are selected and given a variety of treatments as

described blow.

Steel sheets are treated with cathodic electroprimer which is excellent in corrosion resistance.

Rust proof wax coatings are applied to door and side sill insides where moisture is liable to stay.

Vinyl coating is applied to body underside and wheel housing inside.

Sealer is applied to door hem, engine compartment steel sheet-to-steel sheet joint, and the like portions to

prevent water penetration and resulting in rust occurrence.

In panel replacement or collision damage repair, leaving the relevant area untreated as it is in any operation

which does disturb the above-mentioned rust proof treatment will cause corrosion to that area. Therefore, it is

the essential function of any repair operation to correctly recoat the related surfaces of the relevant area.

All the metal panels are coated with metal conditioners and primer coating during vehicle production. Following

the repair and/or replacement parts installation, every accessible bare metal surface should be cleaned and

coated with rust proof primer. Perform this operation prior to the application of sealer and rust proof wax coating.

Sealer is applied to the specific joints of a vehicle during production. The sealer is intended to prevent dust from

entering the vehicle and serves also as an anticorrosion barrier. The sealer is applied to the door and hood hem

areas and between panels. Correct and reseal the originally sealed joints if damaged. Reseal the attaching

joints of a new replacement panel and reseal the hem area of a replacement door or hood.

Use a quality sealer to seal the flanged joints, overlap joints and seams. The sealer must have flexible character-

istics and paint ability after it’s applied to repair areas.

For the sealer to fill open joints, use caulking material. Select a sealer in conformance with the place and pur-

pose of a specific use. Observe the manufacturer’s label-stand instructions when using the sealer.

In many cases, repaired places require color painting. When this is required, follow the ordinary techniques

specified for the finish preparation, color painting and undercoating build-up.

Rust proof wax, a penetrative compound, is applied to the metal-to-metal surfaces (door and side sill insides)

where it is difficult to use ordinary undercoating material for coating. Therefore, when selecting the rust proof

wax, it may be the penetrative type.

During the undercoating (vinyl coating) application, care should be taken that sealer is not applied to the engine-

related parts and shock absorber mounting or rotating parts. Following the under coating, make sure that body

drain holes are kept open.

The sequence of the application steps of the anti-corrosion materials are as follows:

1) Clean and prepare the metal surface.

2) Apply primer.

3) Apply sealer (all joints sealed originally).

4) Apply color in areas where color is required such as hem flanges, exposed joints and under body compo-

nents.

5) Apply anticorrosion compound (penetrative wax).

6) Apply undercoating (rust proof material).WARNING:

Standard shop practices, particularly eye protection, should be followed during the performance of the

below-itemized operations to avoid personal injury.

Page 365 of 447

BODY SERVICE 9-61

PLASTIC PARTS FINISHING

Paintable plastic parts are ABS plastic parts.

Painting

Rigid or hand ABS plastic needs no primer coating.

General acrylic lacquers can be painted properly over hard ABS plastic in terms of adherence.

1) Use cleaning solvent for paint finish to wash each part.

2) Apply conventional acrylic color lacquer to part surface.

3) Follow lacquer directions for required drying time. (Proper drying temperature range is 60 – 70 °C (140 – 158

°F)).

Reference

Plastic parts employ not only ABS (Acrylonitrile Butadiene Styrene) plastic but also polypropylene, vinyl, or the

like plastic. Burning test method to identify ABS plastic is described below.

1) Use a sharp blade to cut off a plastic sliver from the part at its hidden backside.

2) Hold sliver with pincers and set it on fire.

3) Carefully observe condition of the burning plastic.

4) ABS plastic must raise readily distinguishable back smoke while burning with its residue suspended in air

temporarily.

5) Polypropylene must raise no readily distinguishable smoke while burning.

REQUIRED SERVICE MATERIAL

Material Recommended SUZUKI product Use

Lithium grease SUZUKI SUPER GREASE A

(99000-25010)Window regulator

Door hinge

Sealant SUZUKI BOND No. 1215

(99000-31110)Hood hinge

Door hinge

Page 367 of 447

RESTRAINT SYSTEM 10-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 10

RESTRAINT SYSTEM

CONTENTS

GENERAL DESCRIPTION .............................. 10-2

SYSTEM SPECIFICATION .......................... 10-3

SEAT BELT PRETENSIONER

(IF EQUIPPED) ............................................ 10-3

DIAGNOSIS ..................................................... 10-3

INSPECTION AND REPAIR REQUIRED

AFTER ACCIDENT ...................................... 10-3

ON-VEHICLE SERVICE .................................. 10-4SERVICE PRECAUTIONS .......................... 10-4

SERVICE AND DIAGNOSIS .................... 10-4

DISABLING AIR BAG SYSTEM............... 10-4

ENABLING AIR BAG SYSTEM................ 10-4

HANDLING AND STORAGE ................... 10-4

DISPOSAL ............................................... 10-4

FRONT SEAT BELT .................................... 10-5

REAR SEAT BELT....................................... 10-8

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System with seat belt pretensioner:

Service on or around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Please observe all WARNINGS and “Service Precautions” under “On-

Vehicle Service” in air bag system section before performing service on or around the air bag sys-

tem components or wiring. Failure to follow WARNINGS could result in unintentional activation of

the system or could render the system inoperative. Either of these two conditions may result in

severe injury.

The procedures in this section must be followed in the order listed to disable the air bag system

temporarily and prevent false diagnostic trouble codes from setting. Failure to follow procedures

could result in possible activation of the air bag system, personal injury or otherwise unneeded air

bag system repairs.

CAUTION:

When fasteners are removed, always reinstall them at the same location from which they were

removed. If a fastener needs to be replaced, use the correct part number fastener for that application.

If the correct part number fastener is not available, a fastener of equal size and strength (or stronger)

may be used. Fasteners that are not reused, and those requiring thread-locking compound, will be

called out. The correct torque value must be used when installing fasteners that require it. If the above

procedures are not followed, parts or system damage could result.

Page 368 of 447

10-2 RESTRAINT SYSTEM

GENERAL DESCRIPTION

Seat Belt with ELR

The seat belt with emergency locking retractor (ELR) is designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any further) when any of the following items is detected as

exceeding each set value;

speed at which the webbing is pulled out of the retractor,

acceleration or deceleration of the vehicle speed, and

inclination.

Seat Belt with A-ELR

The automatic and emergency locking retractor (A-ELR) works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an Automatic Locking Retractor (ALR) till it is retracted fully.

ALR: Automatically locks when the webbing is pulled out from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further, unless it is wound all the way back into the retractor, which

releases the lock and allows the webbing to be pulled out.

Seat Belt with ELR and Pretensioner

The seat belt with ELR and a pretensioner has a pretensioner mechanism which operates in linkage with the air

bag in addition to the above described ELR. The pretensioner takes up the sag of the seat belt in occurrence of

a front collision with an impact larger than a certain set value, thereby enhancing restraint performance.

1. Front seat belt 4. Passenger air bag (if equipped)

2. Rear seat belt 5. Label (for seat belt with pretensioner)

3. Driver air bag (if equipped) 6. Rear center seat belt