check engine SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 66 of 447

7B-24 AUTOMATIC TRANSMISSION (4 A/T)

ELECTRONIC CONTROL SYSTEM DIAGNO-

SIS

TCM has on-board diagnostic system (a system self-diagnosis

function). Investigate where the trouble is by referring to “DIAG-

NOSTIC FLOW TABLE” and “DTC TABLE” in this section.

PRECAUTIONS IN DIAGNOSING TROUBLES

[PRECAUTIONS IN IDENTIFYING DTC]

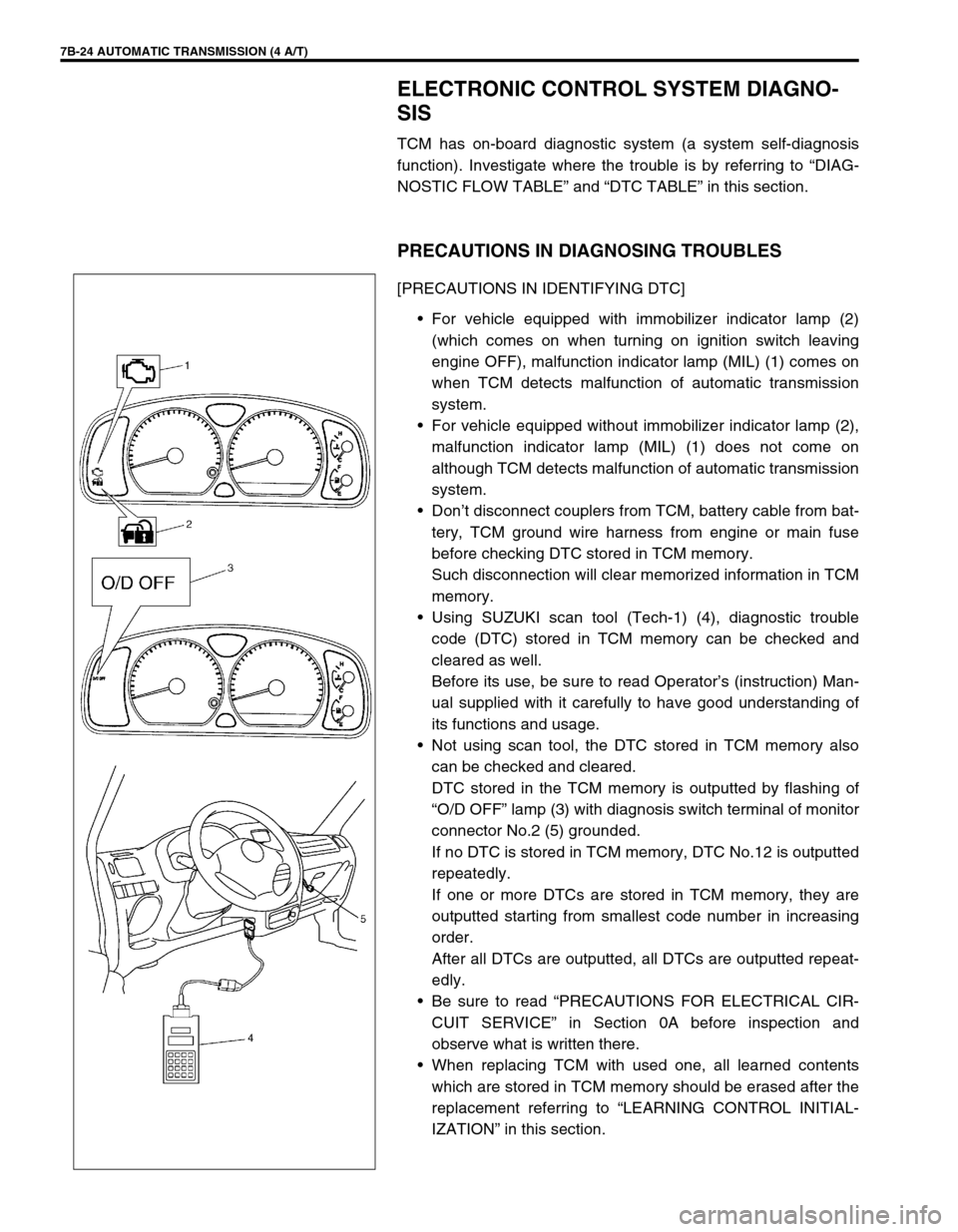

For vehicle equipped with immobilizer indicator lamp (2)

(which comes on when turning on ignition switch leaving

engine OFF), malfunction indicator lamp (MIL) (1) comes on

when TCM detects malfunction of automatic transmission

system.

For vehicle equipped without immobilizer indicator lamp (2),

malfunction indicator lamp (MIL) (1) does not come on

although TCM detects malfunction of automatic transmission

system.

Don’t disconnect couplers from TCM, battery cable from bat-

tery, TCM ground wire harness from engine or main fuse

before checking DTC stored in TCM memory.

Such disconnection will clear memorized information in TCM

memory.

Using SUZUKI scan tool (Tech-1) (4), diagnostic trouble

code (DTC) stored in TCM memory can be checked and

cleared as well.

Before its use, be sure to read Operator’s (instruction) Man-

ual supplied with it carefully to have good understanding of

its functions and usage.

Not using scan tool, the DTC stored in TCM memory also

can be checked and cleared.

DTC stored in the TCM memory is outputted by flashing of

“O/D OFF” lamp (3) with diagnosis switch terminal of monitor

connector No.2 (5) grounded.

If no DTC is stored in TCM memory, DTC No.12 is outputted

repeatedly.

If one or more DTCs are stored in TCM memory, they are

outputted starting from smallest code number in increasing

order.

After all DTCs are outputted, all DTCs are outputted repeat-

edly.

Be sure to read “PRECAUTIONS FOR ELECTRICAL CIR-

CUIT SERVICE” in Section 0A before inspection and

observe what is written there.

When replacing TCM with used one, all learned contents

which are stored in TCM memory should be erased after the

replacement referring to “LEARNING CONTROL INITIAL-

IZATION” in this section.

Page 79 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-37

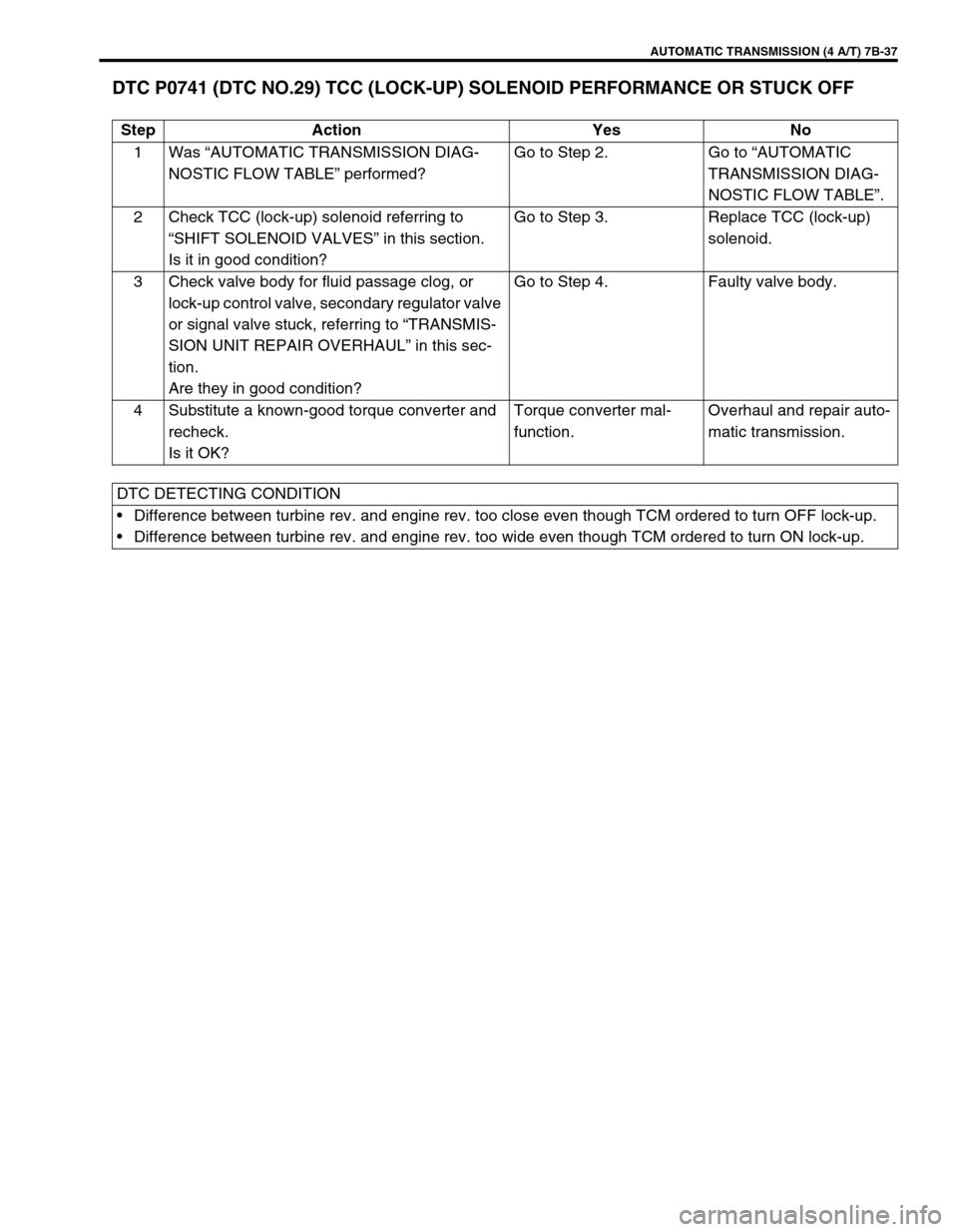

DTC P0741 (DTC NO.29) TCC (LOCK-UP) SOLENOID PERFORMANCE OR STUCK OFF

Step Action Yes No

1Was “AUTOMATIC TRANSMISSION DIAG-

NOSTIC FLOW TABLE” performed?Go to Step 2. Go to “AUTOMATIC

TRANSMISSION DIAG-

NOSTIC FLOW TABLE”.

2 Check TCC (lock-up) solenoid referring to

“SHIFT SOLENOID VALVES” in this section.

Is it in good condition?Go to Step 3. Replace TCC (lock-up)

solenoid.

3 Check valve body for fluid passage clog, or

lock-up control valve, secondary regulator valve

or signal valve stuck, referring to “TRANSMIS-

SION UNIT REPAIR OVERHAUL” in this sec-

tion.

Are they in good condition?Go to Step 4. Faulty valve body.

4 Substitute a known-good torque converter and

recheck.

Is it OK?Torque converter mal-

function.Overhaul and repair auto-

matic transmission.

DTC DETECTING CONDITION

Difference between turbine rev. and engine rev. too close even though TCM ordered to turn OFF lock-up.

Difference between turbine rev. and engine rev. too wide even though TCM ordered to turn ON lock-up.

Page 83 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-41

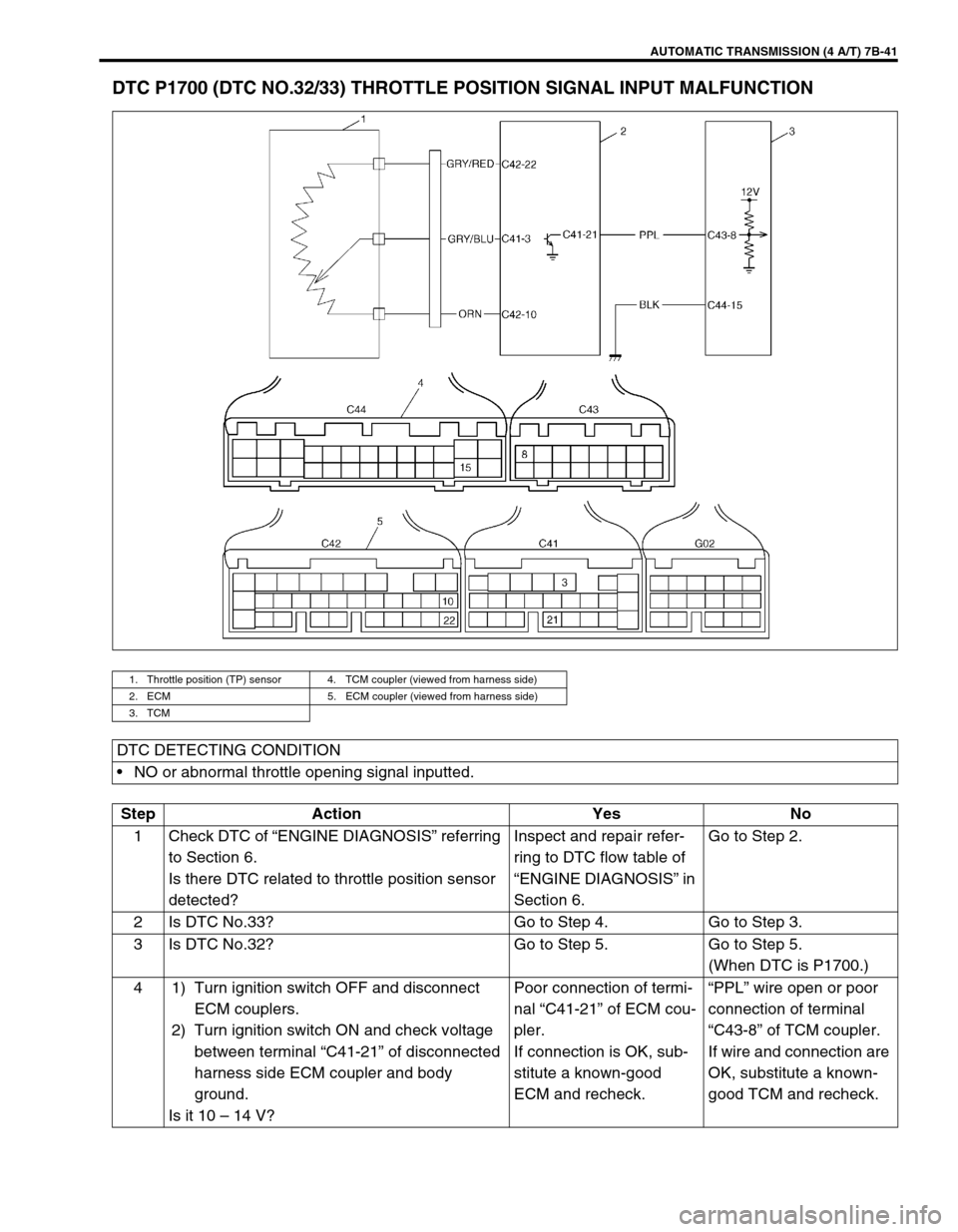

DTC P1700 (DTC NO.32/33) THROTTLE POSITION SIGNAL INPUT MALFUNCTION

1. Throttle position (TP) sensor 4. TCM coupler (viewed from harness side)

2. ECM 5. ECM coupler (viewed from harness side)

3. TCM

DTC DETECTING CONDITION

NO or abnormal throttle opening signal inputted.

Step Action Yes No

1 Check DTC of “ENGINE DIAGNOSIS” referring

to Section 6.

Is there DTC related to throttle position sensor

detected?Inspect and repair refer-

ring to DTC flow table of

“ENGINE DIAGNOSIS” in

Section 6.Go to Step 2.

2 Is DTC No.33? Go to Step 4. Go to Step 3.

3 Is DTC No.32? Go to Step 5. Go to Step 5.

(When DTC is P1700.)

4 1) Turn ignition switch OFF and disconnect

ECM couplers.

2) Turn ignition switch ON and check voltage

between terminal “C41-21” of disconnected

harness side ECM coupler and body

ground.

Is it 10 – 14 V?Poor connection of termi-

nal “C41-21” of ECM cou-

pler.

If connection is OK, sub-

stitute a known-good

ECM and recheck.“PPL” wire open or poor

connection of terminal

“C43-8” of TCM coupler.

If wire and connection are

OK, substitute a known-

good TCM and recheck.

Page 87 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-45

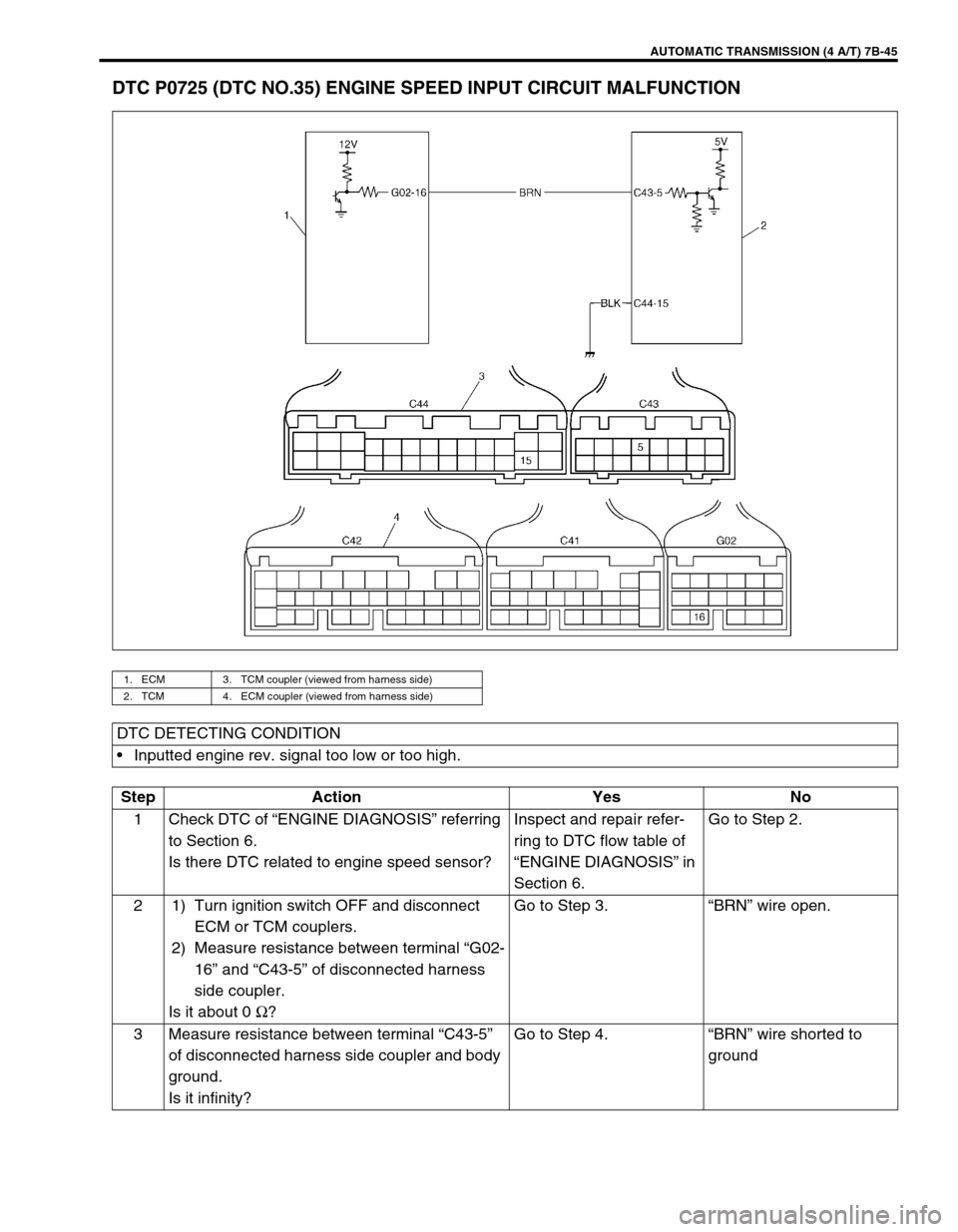

DTC P0725 (DTC NO.35) ENGINE SPEED INPUT CIRCUIT MALFUNCTION

1. ECM 3. TCM coupler (viewed from harness side)

2. TCM 4. ECM coupler (viewed from harness side)

DTC DETECTING CONDITION

Inputted engine rev. signal too low or too high.

Step Action Yes No

1 Check DTC of “ENGINE DIAGNOSIS” referring

to Section 6.

Is there DTC related to engine speed sensor?Inspect and repair refer-

ring to DTC flow table of

“ENGINE DIAGNOSIS” in

Section 6.Go to Step 2.

2 1) Turn ignition switch OFF and disconnect

ECM or TCM couplers.

2) Measure resistance between terminal “G02-

16” and “C43-5” of disconnected harness

side coupler.

Is it about 0 Ω

?Go to Step 3.“BRN” wire open.

3 Measure resistance between terminal “C43-5”

of disconnected harness side coupler and body

ground.

Is it infinity?Go to Step 4.“BRN” wire shorted to

ground

Page 89 of 447

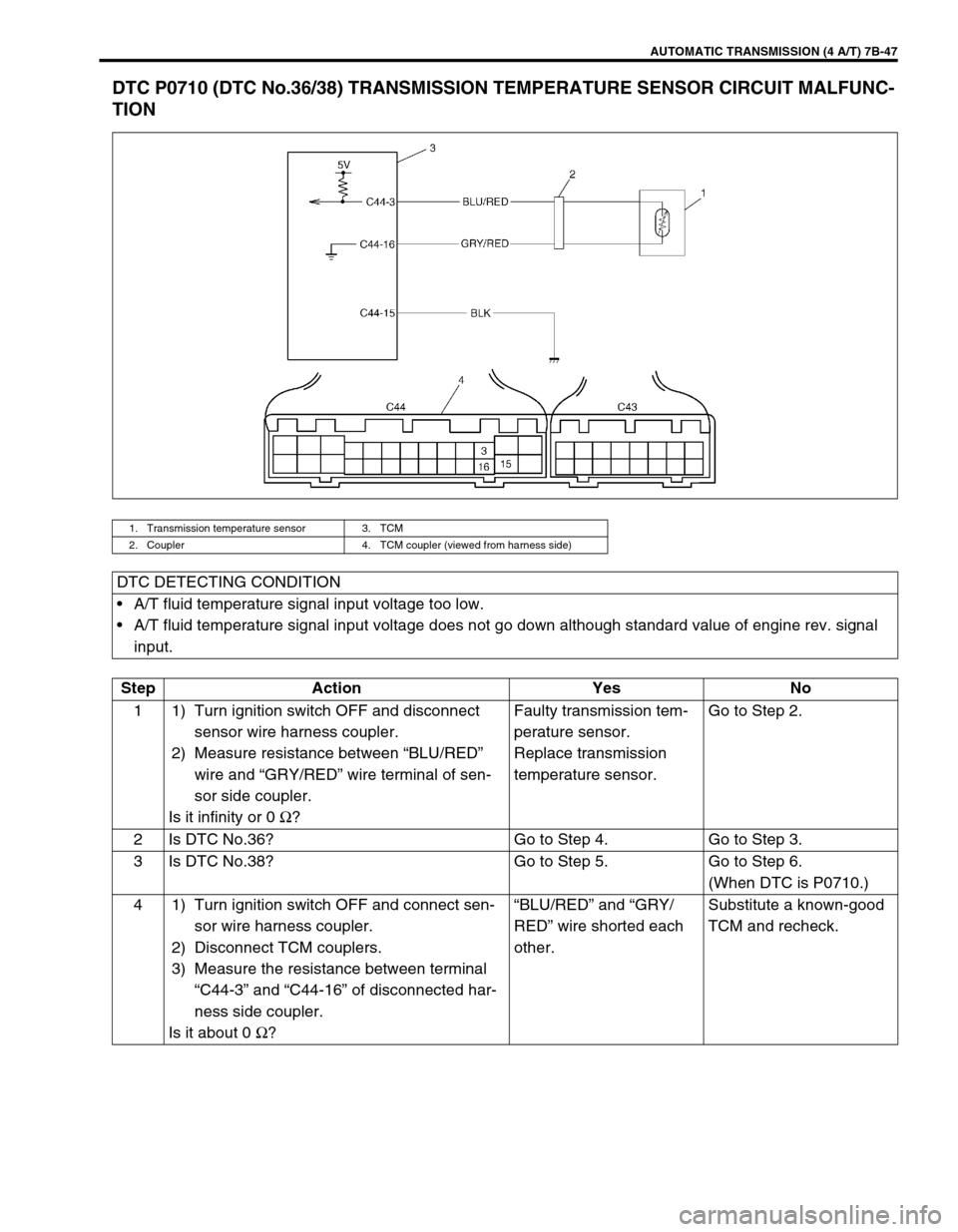

AUTOMATIC TRANSMISSION (4 A/T) 7B-47

DTC P0710 (DTC No.36/38) TRANSMISSION TEMPERATURE SENSOR CIRCUIT MALFUNC-

TION

1. Transmission temperature sensor 3. TCM

2. Coupler 4. TCM coupler (viewed from harness side)

DTC DETECTING CONDITION

A/T fluid temperature signal input voltage too low.

A/T fluid temperature signal input voltage does not go down although standard value of engine rev. signal

input.

Step Action Yes No

1 1) Turn ignition switch OFF and disconnect

sensor wire harness coupler.

2) Measure resistance between “BLU/RED”

wire and “GRY/RED” wire terminal of sen-

sor side coupler.

Is it infinity or 0 Ω

?Faulty transmission tem-

perature sensor.

Replace transmission

temperature sensor.Go to Step 2.

2 Is DTC No.36? Go to Step 4. Go to Step 3.

3 Is DTC No.38? Go to Step 5. Go to Step 6.

(When DTC is P0710.)

4 1) Turn ignition switch OFF and connect sen-

sor wire harness coupler.

2) Disconnect TCM couplers.

3) Measure the resistance between terminal

“C44-3” and “C44-16” of disconnected har-

ness side coupler.

Is it about 0 Ω

?“BLU/RED” and “GRY/

RED” wire shorted each

other.Substitute a known-good

TCM and recheck.

Page 90 of 447

7B-48 AUTOMATIC TRANSMISSION (4 A/T)

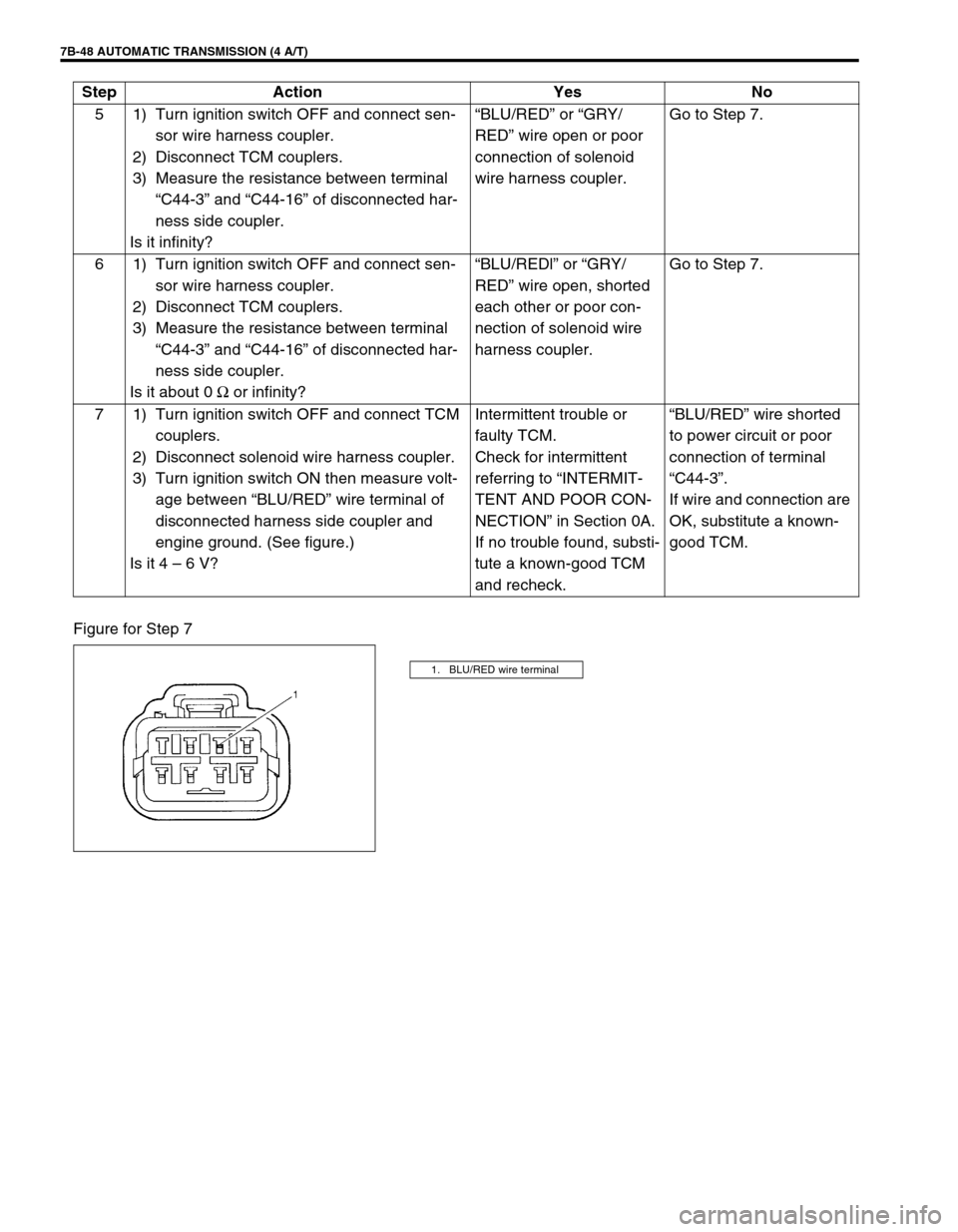

Figure for Step 75 1) Turn ignition switch OFF and connect sen-

sor wire harness coupler.

2) Disconnect TCM couplers.

3) Measure the resistance between terminal

“C44-3” and “C44-16” of disconnected har-

ness side coupler.

Is it infinity?“BLU/RED” or “GRY/

RED” wire open or poor

connection of solenoid

wire harness coupler.Go to Step 7.

6 1) Turn ignition switch OFF and connect sen-

sor wire harness coupler.

2) Disconnect TCM couplers.

3) Measure the resistance between terminal

“C44-3” and “C44-16” of disconnected har-

ness side coupler.

Is it about 0 Ω

or infinity?“BLU/REDl” or “GRY/

RED” wire open, shorted

each other or poor con-

nection of solenoid wire

harness coupler.Go to Step 7.

7 1) Turn ignition switch OFF and connect TCM

couplers.

2) Disconnect solenoid wire harness coupler.

3) Turn ignition switch ON then measure volt-

age between “BLU/RED” wire terminal of

disconnected harness side coupler and

engine ground. (See figure.)

Is it 4 – 6 V?Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.

If no trouble found, substi-

tute a known-good TCM

and recheck.“BLU/RED” wire shorted

to power circuit or poor

connection of terminal

“C44-3”.

If wire and connection are

OK, substitute a known-

good TCM. Step Action Yes No

1. BLU/RED wire terminal

Page 93 of 447

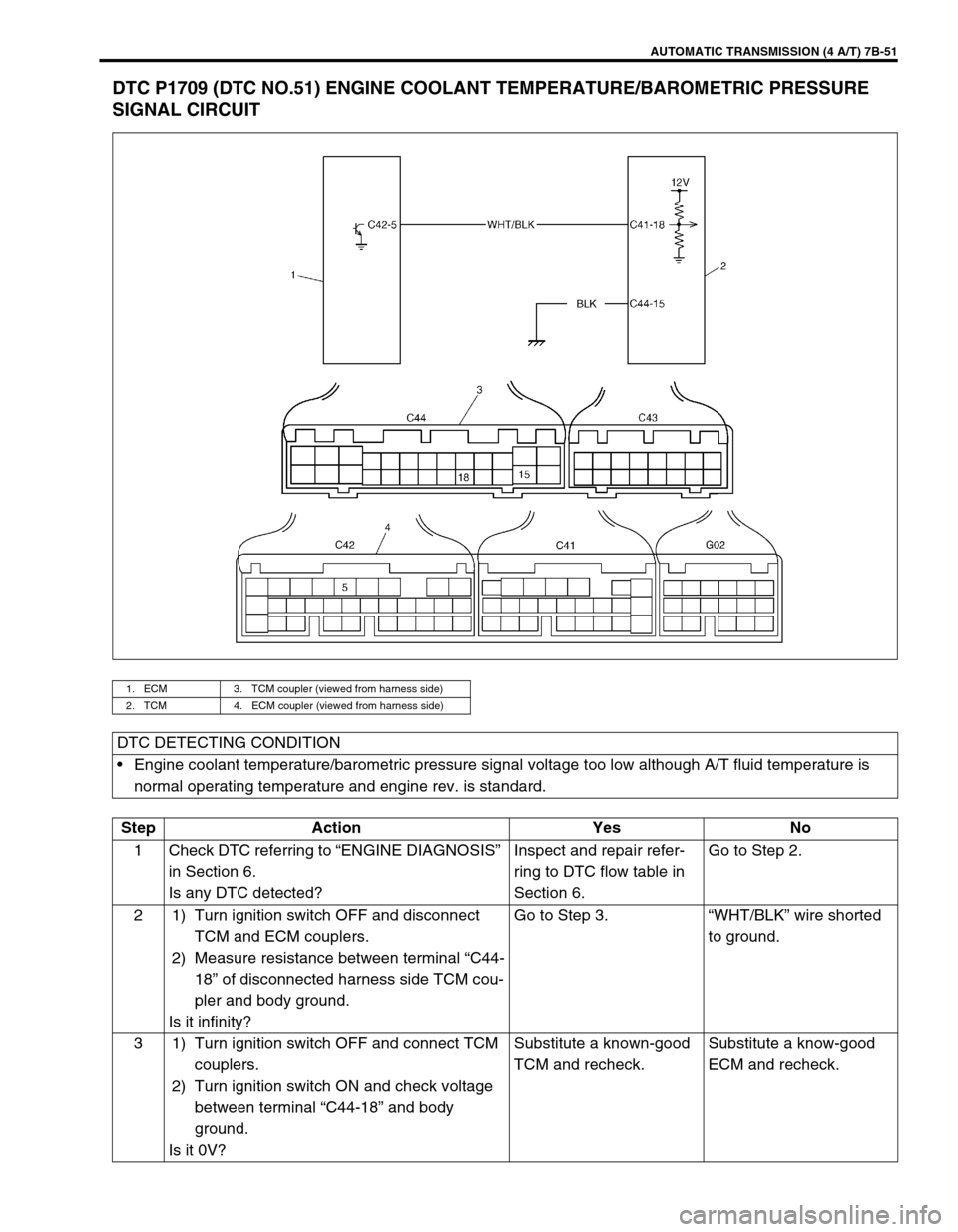

AUTOMATIC TRANSMISSION (4 A/T) 7B-51

DTC P1709 (DTC NO.51) ENGINE COOLANT TEMPERATURE/BAROMETRIC PRESSURE

SIGNAL CIRCUIT

1. ECM 3. TCM coupler (viewed from harness side)

2. TCM 4. ECM coupler (viewed from harness side)

DTC DETECTING CONDITION

Engine coolant temperature/barometric pressure signal voltage too low although A/T fluid temperature is

normal operating temperature and engine rev. is standard.

Step Action Yes No

1 Check DTC referring to “ENGINE DIAGNOSIS”

in Section 6.

Is any DTC detected?Inspect and repair refer-

ring to DTC flow table in

Section 6.Go to Step 2.

2 1) Turn ignition switch OFF and disconnect

TCM and ECM couplers.

2) Measure resistance between terminal “C44-

18” of disconnected harness side TCM cou-

pler and body ground.

Is it infinity?Go to Step 3.“WHT/BLK” wire shorted

to ground.

3 1) Turn ignition switch OFF and connect TCM

couplers.

2) Turn ignition switch ON and check voltage

between terminal “C44-18” and body

ground.

Is it 0V?Substitute a known-good

TCM and recheck.Substitute a know-good

ECM and recheck.

Page 95 of 447

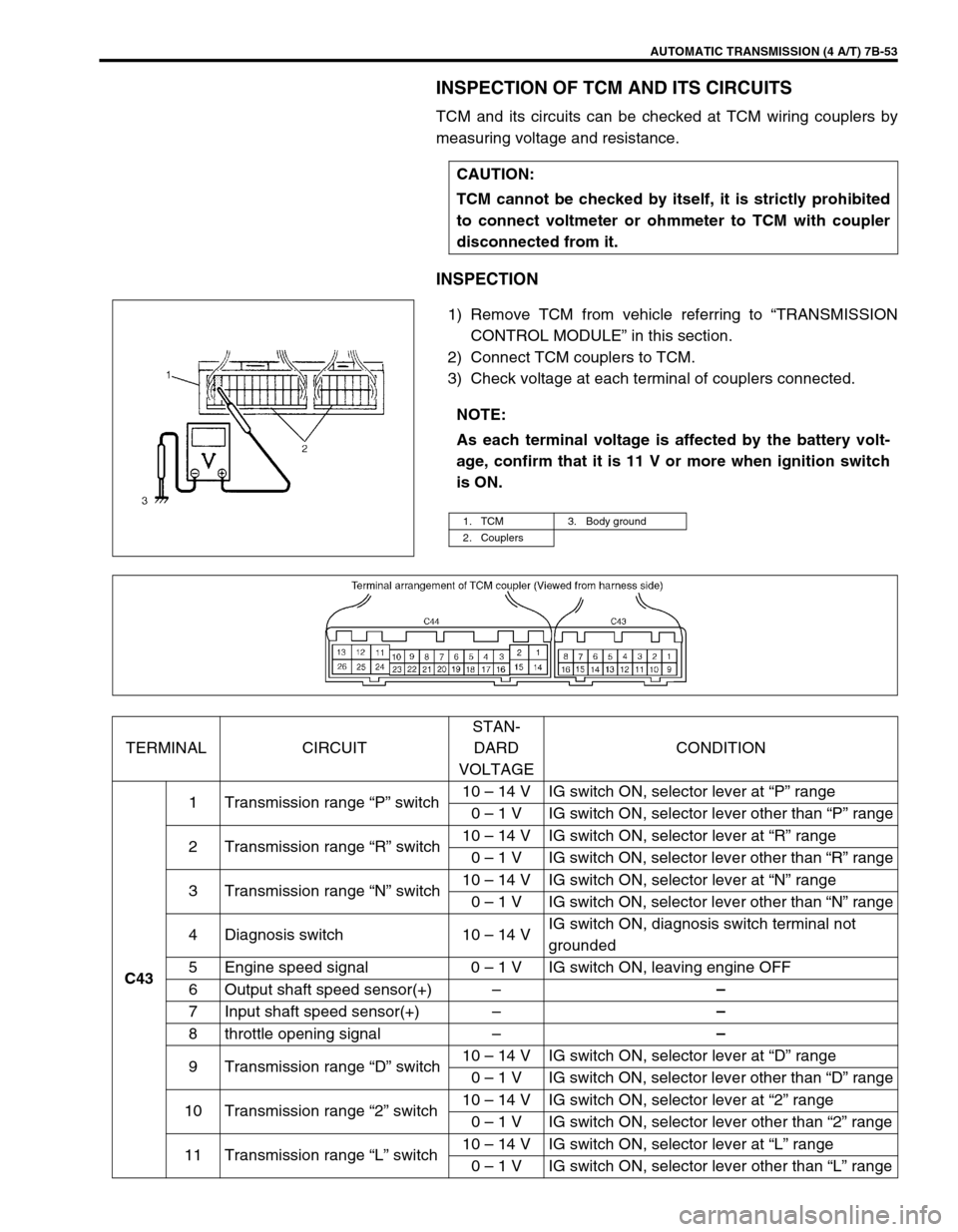

AUTOMATIC TRANSMISSION (4 A/T) 7B-53

INSPECTION OF TCM AND ITS CIRCUITS

TCM and its circuits can be checked at TCM wiring couplers by

measuring voltage and resistance.

INSPECTION

1) Remove TCM from vehicle referring to “TRANSMISSION

CONTROL MODULE” in this section.

2) Connect TCM couplers to TCM.

3) Check voltage at each terminal of couplers connected.CAUTION:

TCM cannot be checked by itself, it is strictly prohibited

to connect voltmeter or ohmmeter to TCM with coupler

disconnected from it.

NOTE:

As each terminal voltage is affected by the battery volt-

age, confirm that it is 11 V or more when ignition switch

is ON.

1. TCM 3. Body ground

2. Couplers

TERMINAL CIRCUITSTAN-

DARD

VOLTAGECONDITION

C431 Transmission range “P” switch10 – 14 V IG switch ON, selector lever at “P” range

0 – 1 V IG switch ON, selector lever other than “P” range

2 Transmission range “R” switch10 – 14 V IG switch ON, selector lever at “R” range

0 – 1 V IG switch ON, selector lever other than “R” range

3 Transmission range “N” switch10 – 14 V IG switch ON, selector lever at “N” range

0 – 1 V IG switch ON, selector lever other than “N” range

4 Diagnosis switch 10 – 14 VIG switch ON, diagnosis switch terminal not

grounded

5 Engine speed signal 0 – 1 V IG switch ON, leaving engine OFF

6 Output shaft speed sensor(+)––

7 Input shaft speed sensor(+)––

8 throttle opening signal––

9 Transmission range “D” switch10 – 14 V IG switch ON, selector lever at “D” range

0 – 1 V IG switch ON, selector lever other than “D” range

10 Transmission range “2” switch10 – 14 V IG switch ON, selector lever at “2” range

0 – 1 V IG switch ON, selector lever other than “2” range

11 Transmission range “L” switch10 – 14 V IG switch ON, selector lever at “L” range

0 – 1 V IG switch ON, selector lever other than “L” range

Page 97 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-55

ON-VEHICLE SERVICE

MAINTENANCE SERVICE

FLUID LEVEL AT NORMAL OPERATING TEMPERA-

TURE

INSPECTION

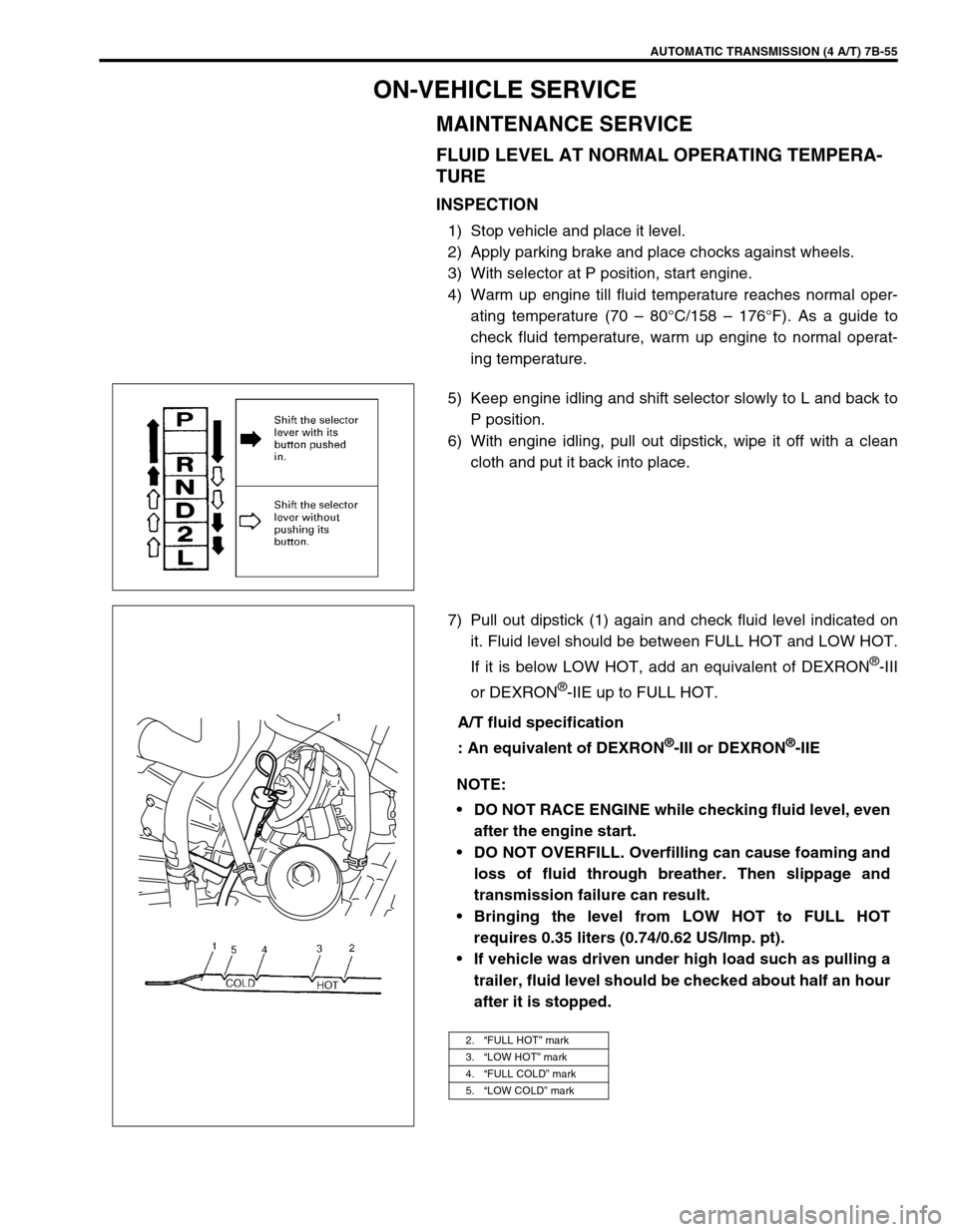

1) Stop vehicle and place it level.

2) Apply parking brake and place chocks against wheels.

3) With selector at P position, start engine.

4) Warm up engine till fluid temperature reaches normal oper-

ating temperature (70 – 80°C/158 – 176°F). As a guide to

check fluid temperature, warm up engine to normal operat-

ing temperature.

5) Keep engine idling and shift selector slowly to L and back to

P position.

6) With engine idling, pull out dipstick, wipe it off with a clean

cloth and put it back into place.

7) Pull out dipstick (1) again and check fluid level indicated on

it. Fluid level should be between FULL HOT and LOW HOT.

If it is below LOW HOT, add an equivalent of DEXRON

®-III

or DEXRON

®-IIE up to FULL HOT.

A/T fluid specification

: An equivalent of DEXRON

®-III or DEXRON®-IIE

NOTE:

DO NOT RACE ENGINE while checking fluid level, even

after the engine start.

DO NOT OVERFILL. Overfilling can cause foaming and

loss of fluid through breather. Then slippage and

transmission failure can result.

Bringing the level from LOW HOT to FULL HOT

requires 0.35 liters (0.74/0.62 US/Imp. pt).

If vehicle was driven under high load such as pulling a

trailer, fluid level should be checked about half an hour

after it is stopped.

2.“FULL HOT” mark

3.“LOW HOT” mark

4.“FULL COLD” mark

5.“LOW COLD” mark

1

Page 98 of 447

7B-56 AUTOMATIC TRANSMISSION (4 A/T)

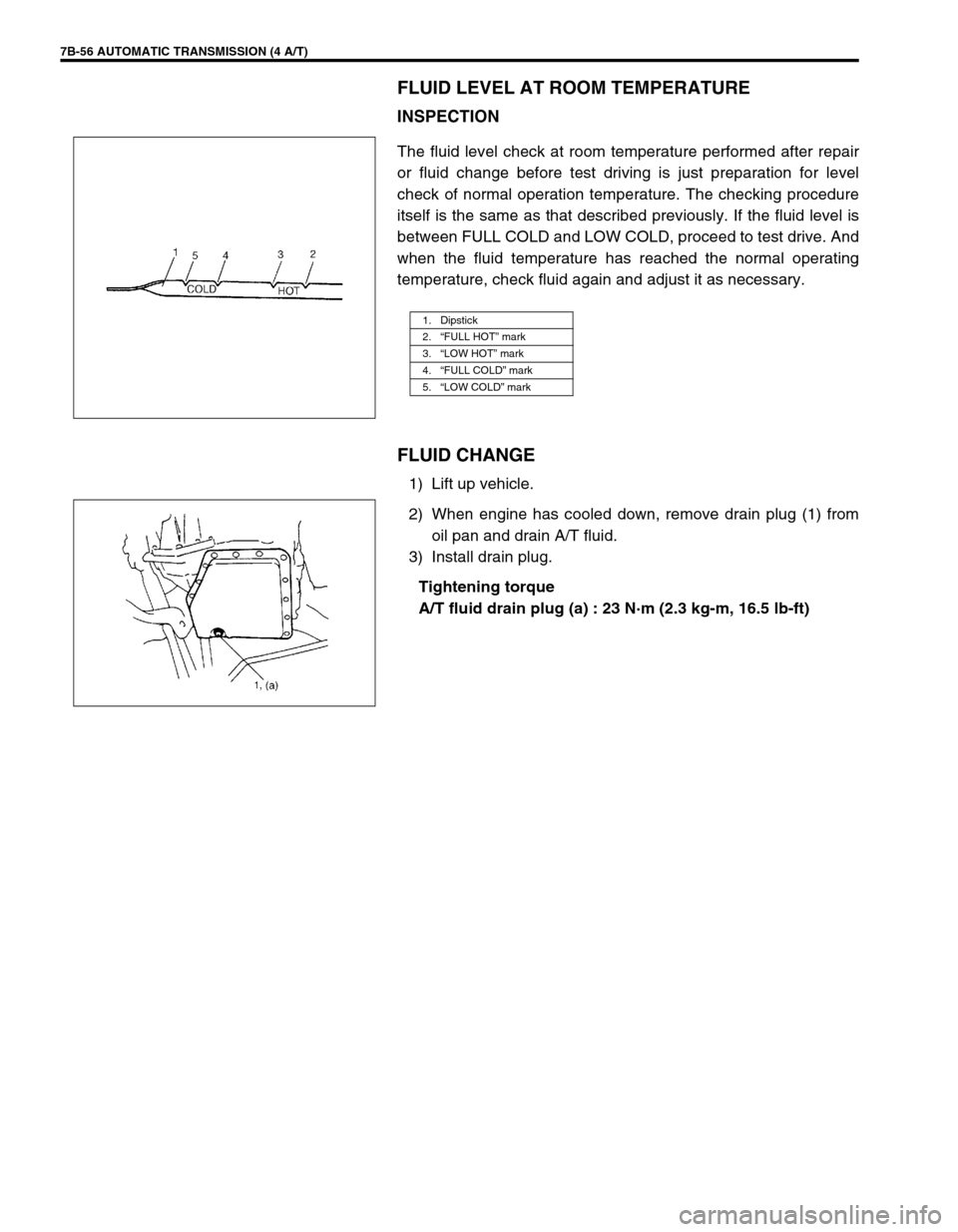

FLUID LEVEL AT ROOM TEMPERATURE

INSPECTION

The fluid level check at room temperature performed after repair

or fluid change before test driving is just preparation for level

check of normal operation temperature. The checking procedure

itself is the same as that described previously. If the fluid level is

between FULL COLD and LOW COLD, proceed to test drive. And

when the fluid temperature has reached the normal operating

temperature, check fluid again and adjust it as necessary.

FLUID CHANGE

1) Lift up vehicle.

2) When engine has cooled down, remove drain plug (1) from

oil pan and drain A/T fluid.

3) Install drain plug.

Tightening torque

A/T fluid drain plug (a) : 23 N·m (2.3 kg-m, 16.5 lb-ft)

1. Dipstick

2.“FULL HOT” mark

3.“LOW HOT” mark

4.“FULL COLD” mark

5.“LOW COLD” mark