check oil SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 52 of 447

7B-10 AUTOMATIC TRANSMISSION (4 A/T)

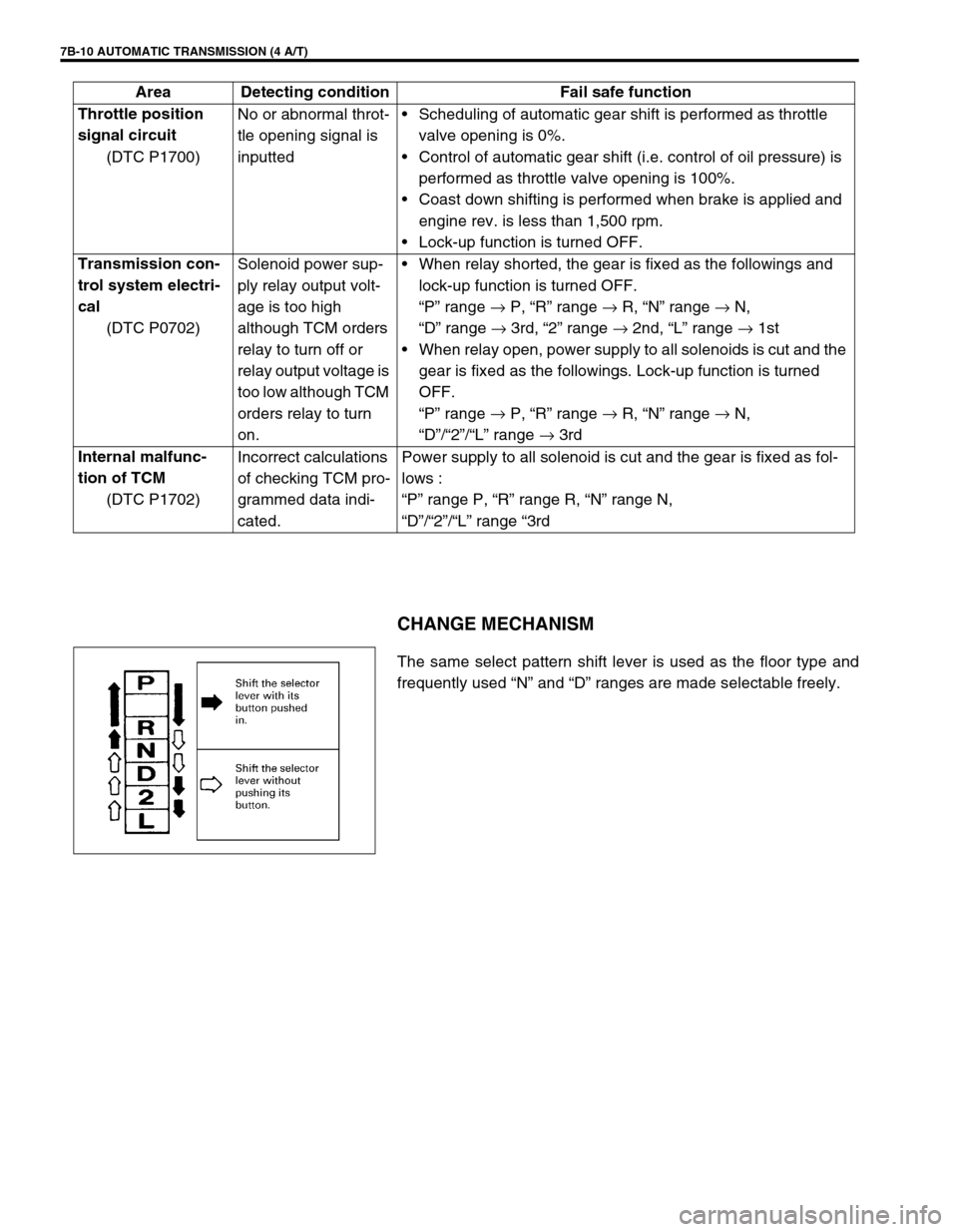

CHANGE MECHANISM

The same select pattern shift lever is used as the floor type and

frequently used “N” and “D” ranges are made selectable freely. Throttle position

signal circuit

(DTC P1700)No or abnormal throt-

tle opening signal is

inputtedScheduling of automatic gear shift is performed as throttle

valve opening is 0%.

Control of automatic gear shift (i.e. control of oil pressure) is

performed as throttle valve opening is 100%.

Coast down shifting is performed when brake is applied and

engine rev. is less than 1,500 rpm.

Lock-up function is turned OFF.

Transmission con-

trol system electri-

cal

(DTC P0702)Solenoid power sup-

ply relay output volt-

age is too high

although TCM orders

relay to turn off or

relay output voltage is

too low although TCM

orders relay to turn

on.When relay shorted, the gear is fixed as the followings and

lock-up function is turned OFF.

“P” range →

P, “R” range →

R, “N” range →

N,

“D” range →

3rd, “2” range →

2nd, “L” range →

1st

When relay open, power supply to all solenoids is cut and the

gear is fixed as the followings. Lock-up function is turned

OFF.

“P” range →

P, “R” range →

R, “N” range →

N,

“D”/“2”/“L” range →

3rd

Internal malfunc-

tion of TCM

(DTC P1702)Incorrect calculations

of checking TCM pro-

grammed data indi-

cated.Power supply to all solenoid is cut and the gear is fixed as fol-

lows :

“P” range P, “R” range R, “N” range N,

“D”/“2”/“L” range “3rd Area Detecting condition Fail safe function

Page 58 of 447

7B-16 AUTOMATIC TRANSMISSION (4 A/T)

2. DIAGNOSTIC TROUBLE CODE (DTC) CHECK, RECORD AND CLEARANCE

To check DTC, refer to “DTC CHECK” in this section. When a DTC exists, it means existence of a malfunction in

the system represented by that code but whether it still exists (current) or it occurred in the past and has gone

(history) is unknown. To know it, clear this DTC once (Refer to “DTC CLEARANCE” in this section.), perform

test drive and/or “TROUBLE SYMPTOM CONFIRMATION” in this section and then check DTC again as

described in “DTC CHECK”. Attempt to diagnose the trouble based on the DTC recorded in this step only or fail-

ure to clear the DTC in this step may mislead the diagnosis or make diagnosing difficult. Even after checking the

DTC with the SUZUKI scan tool, diagnosis should be performed according to this flow chart to check TCM for

proper self-diagnosis function.

3 and 4. VISUAL INSPECTION

As a preliminary step, perform visual check of the following items that support proper function of the automatic

transmission.

5.TROUBLE SYMPTOM CONFIRMATION

Check if what the customer claimed in “CUSTOMER COMPLAINT ANALYSIS” is actually found in the vehicle

and if that symptom is found, whether it is identified as a failure. (This step should be shared with the customer

if possible.)

When the symptom is not actually found, possibility is :

The symptom occurs under certain conditions.

----- Retry with the vehicle under different conditions.

The trouble occurred only temporarily and normal operation has been restored.

----- Perform “DTC CHECK” and if the diagnostic trouble code is indicated, inspect according to the flow

table for that DTC.

6 and 7. RECHECKING AND RECORD OF DTC

Refer to “DTC CHECK” in this section.INSPECTION ITEM REFERRING SECTION

Engine oil ----- level, leakage Section 0B

Engine coolant ----- level, leakage Section 0B

A/T fluid ----- level, leakage, color Section 0B

Battery ----- fluid level, corrosion of terminal

A/T fluid hoses ----- disconnection, looseness, deterioration

Connectors of electric wire harness ----- disconnection, friction Section 8

Fuses ----- burning Section 8

Parts ----- installation, bolt ----- looseness

Parts ----- deformation

Other parts that can be checked visually

Also add following items at engine start.

Indicator, warning lights in combination meter ----- ON

(indicating abnormality in system) or OFFSection 8C

Other parts that can be checked visually

Page 64 of 447

7B-22 AUTOMATIC TRANSMISSION (4 A/T)

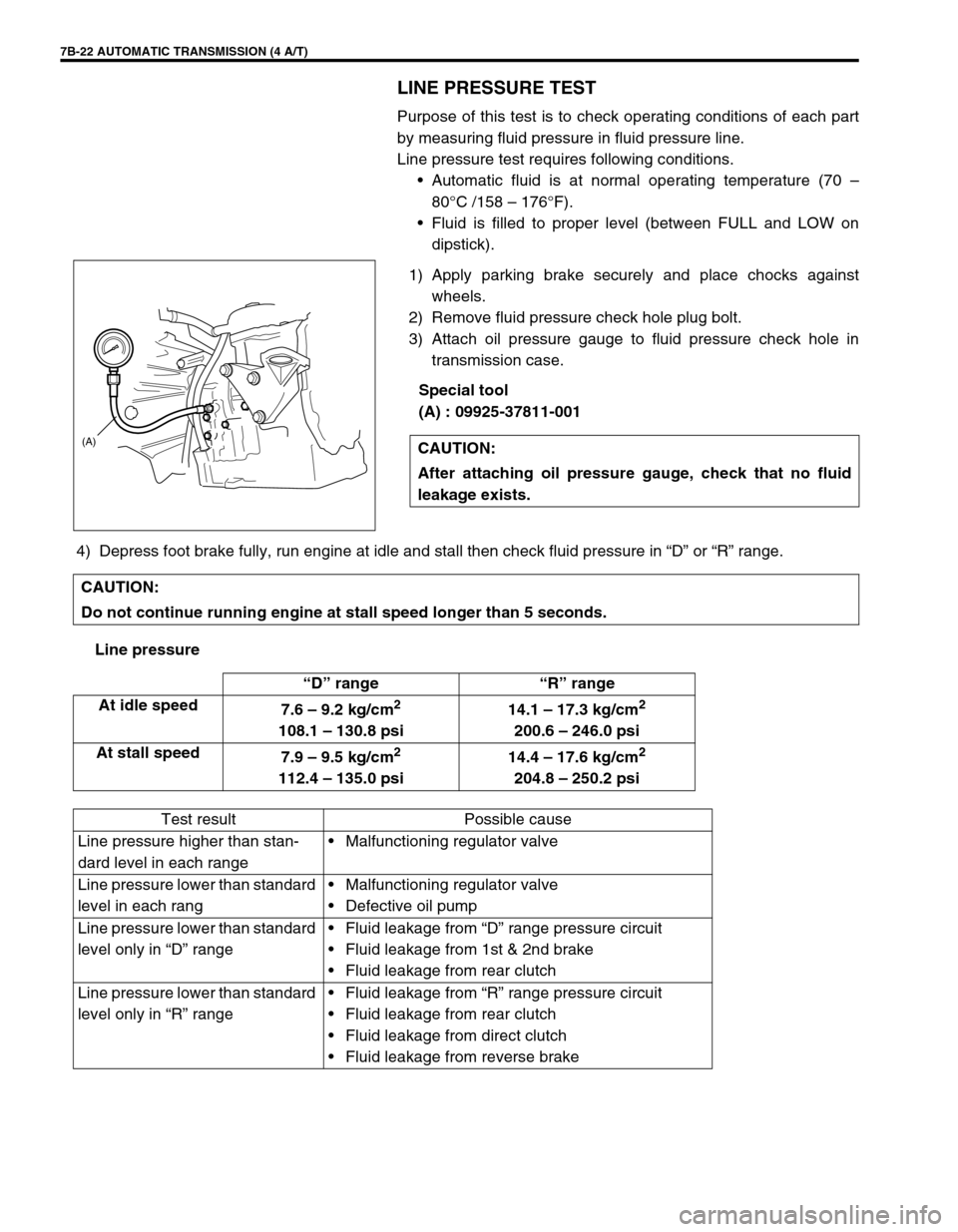

LINE PRESSURE TEST

Purpose of this test is to check operating conditions of each part

by measuring fluid pressure in fluid pressure line.

Line pressure test requires following conditions.

Automatic fluid is at normal operating temperature (70 –

80°C /158 – 176°F).

Fluid is filled to proper level (between FULL and LOW on

dipstick).

1) Apply parking brake securely and place chocks against

wheels.

2) Remove fluid pressure check hole plug bolt.

3) Attach oil pressure gauge to fluid pressure check hole in

transmission case.

Special tool

(A) : 09925-37811-001

4) Depress foot brake fully, run engine at idle and stall then check fluid pressure in “D” or “R” range.

Line pressureCAUTION:

After attaching oil pressure gauge, check that no fluid

leakage exists.

(A)

CAUTION:

Do not continue running engine at stall speed longer than 5 seconds.

“D” range “R” range

At idle speed

7.6 – 9.2 kg/cm

2

108.1 – 130.8 psi14.1 – 17.3 kg/cm

2

200.6 – 246.0 psi

At stall speed

7.9 – 9.5 kg/cm

2

112.4 – 135.0 psi14.4 – 17.6 kg/cm

2

204.8 – 250.2 psi

Test result Possible cause

Line pressure higher than stan-

dard level in each rangeMalfunctioning regulator valve

Line pressure lower than standard

level in each rangMalfunctioning regulator valve

Defective oil pump

Line pressure lower than standard

level only in “D” rangeFluid leakage from “D” range pressure circuit

Fluid leakage from 1st & 2nd brake

Fluid leakage from rear clutch

Line pressure lower than standard

level only in “R” rangeFluid leakage from “R” range pressure circuit

Fluid leakage from rear clutch

Fluid leakage from direct clutch

Fluid leakage from reverse brake

Page 98 of 447

7B-56 AUTOMATIC TRANSMISSION (4 A/T)

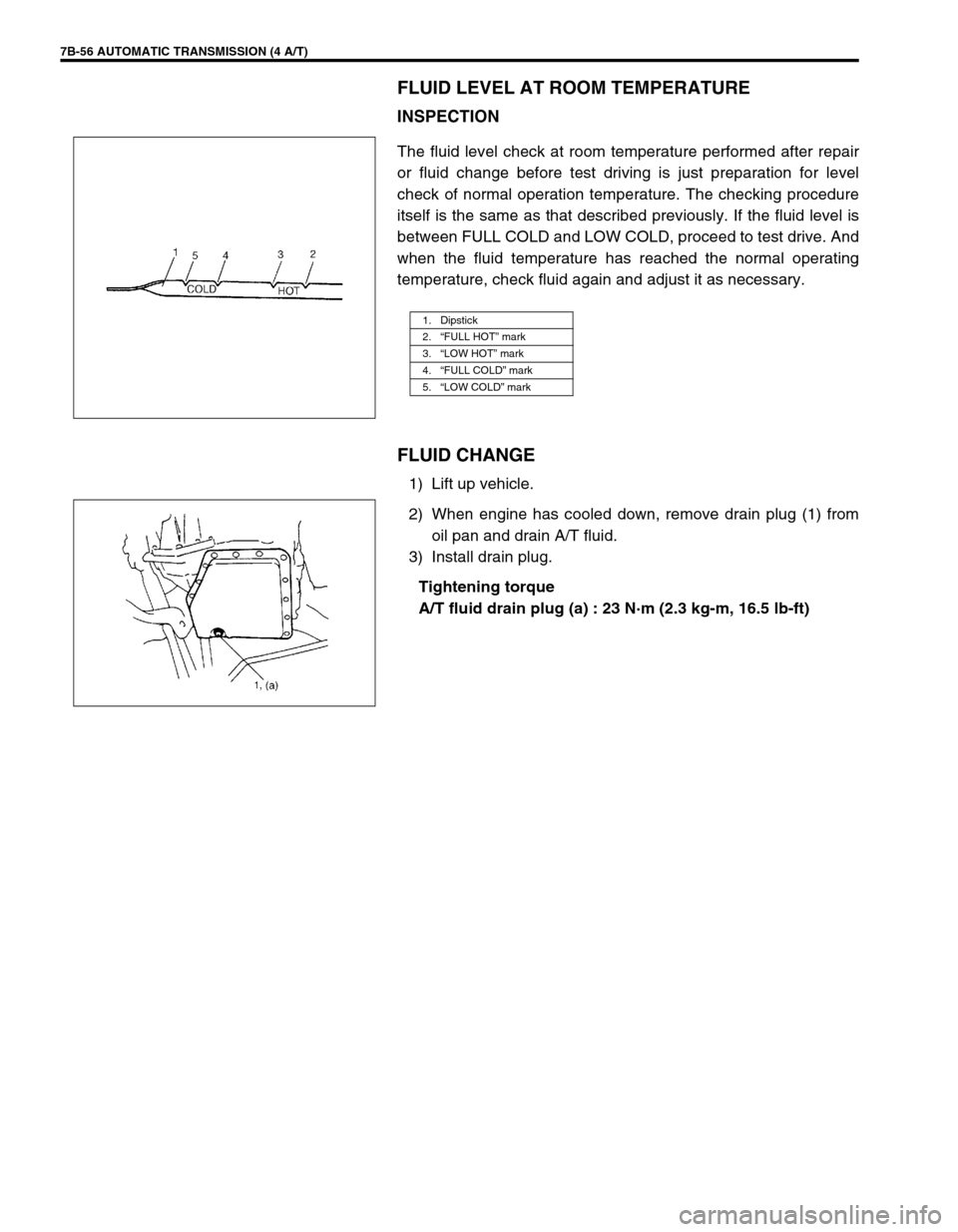

FLUID LEVEL AT ROOM TEMPERATURE

INSPECTION

The fluid level check at room temperature performed after repair

or fluid change before test driving is just preparation for level

check of normal operation temperature. The checking procedure

itself is the same as that described previously. If the fluid level is

between FULL COLD and LOW COLD, proceed to test drive. And

when the fluid temperature has reached the normal operating

temperature, check fluid again and adjust it as necessary.

FLUID CHANGE

1) Lift up vehicle.

2) When engine has cooled down, remove drain plug (1) from

oil pan and drain A/T fluid.

3) Install drain plug.

Tightening torque

A/T fluid drain plug (a) : 23 N·m (2.3 kg-m, 16.5 lb-ft)

1. Dipstick

2.“FULL HOT” mark

3.“LOW HOT” mark

4.“FULL COLD” mark

5.“LOW COLD” mark

Page 107 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-65

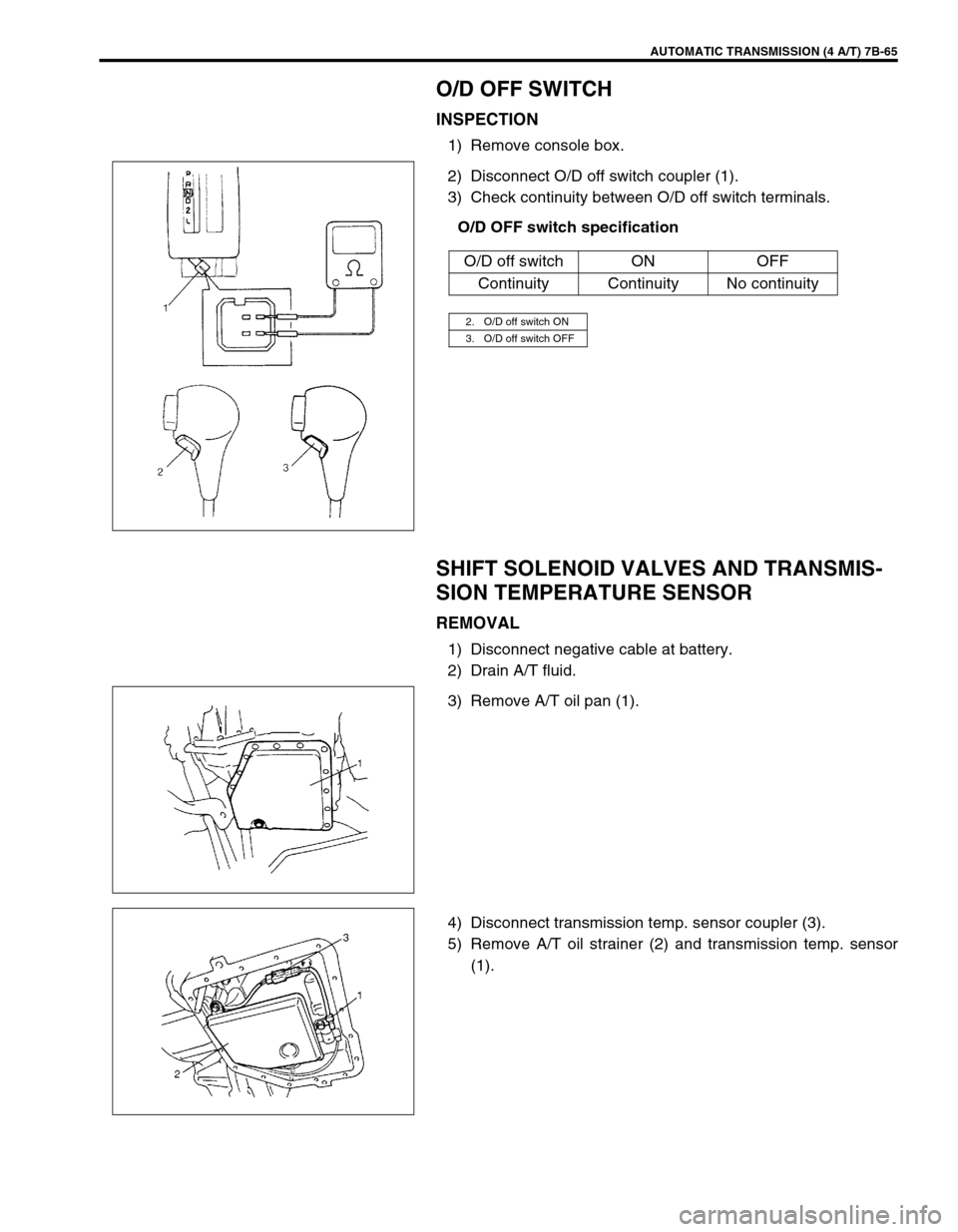

O/D OFF SWITCH

INSPECTION

1) Remove console box.

2) Disconnect O/D off switch coupler (1).

3) Check continuity between O/D off switch terminals.

O/D OFF switch specification

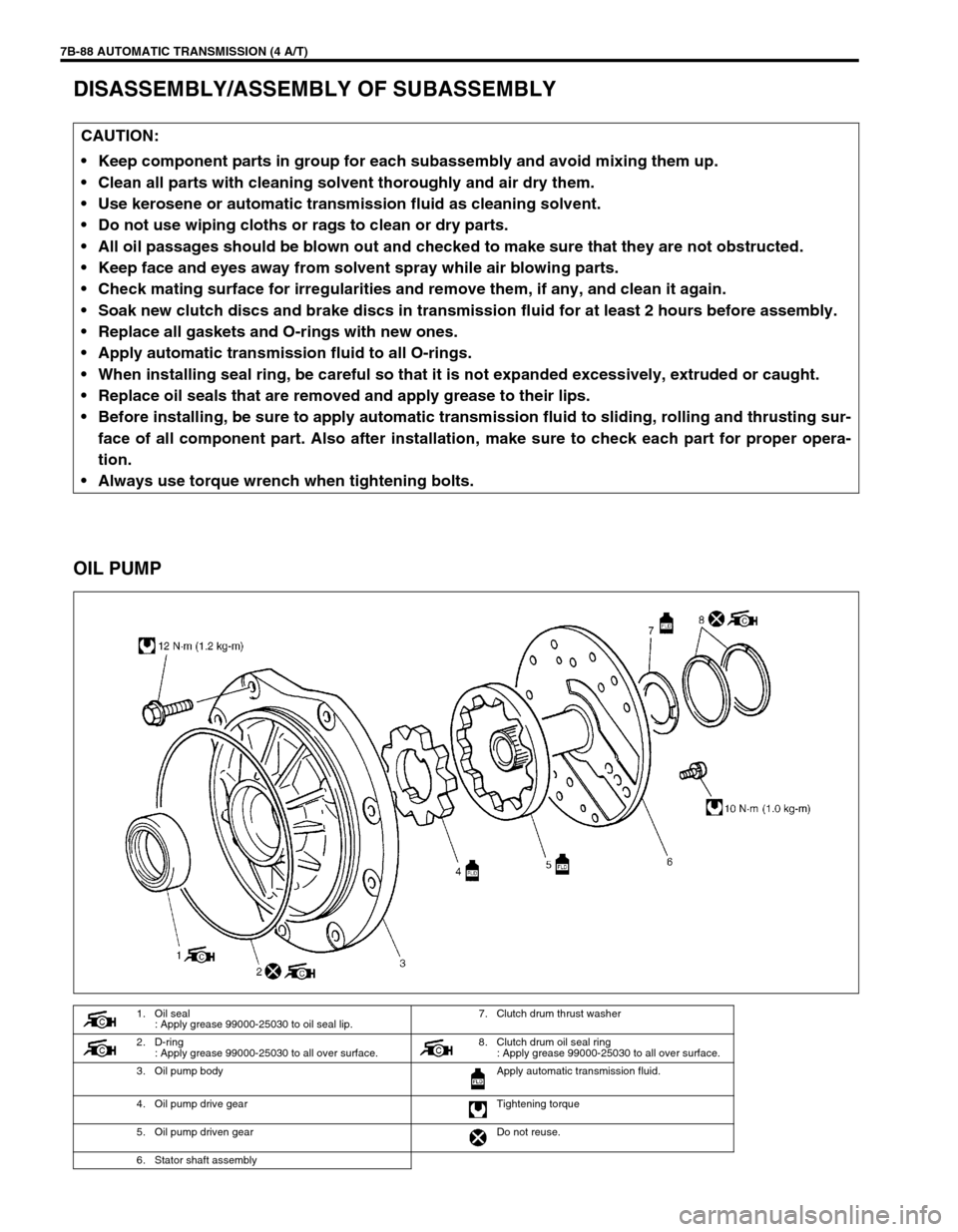

SHIFT SOLENOID VALVES AND TRANSMIS-

SION TEMPERATURE SENSOR

REMOVAL

1) Disconnect negative cable at battery.

2) Drain A/T fluid.

3) Remove A/T oil pan (1).

4) Disconnect transmission temp. sensor coupler (3).

5) Remove A/T oil strainer (2) and transmission temp. sensor

(1). O/D off switch ON OFF

Continuity Continuity No continuity

2. O/D off switch ON

3. O/D off switch OFF

Page 130 of 447

7B-88 AUTOMATIC TRANSMISSION (4 A/T)

DISASSEMBLY/ASSEMBLY OF SUBASSEMBLY

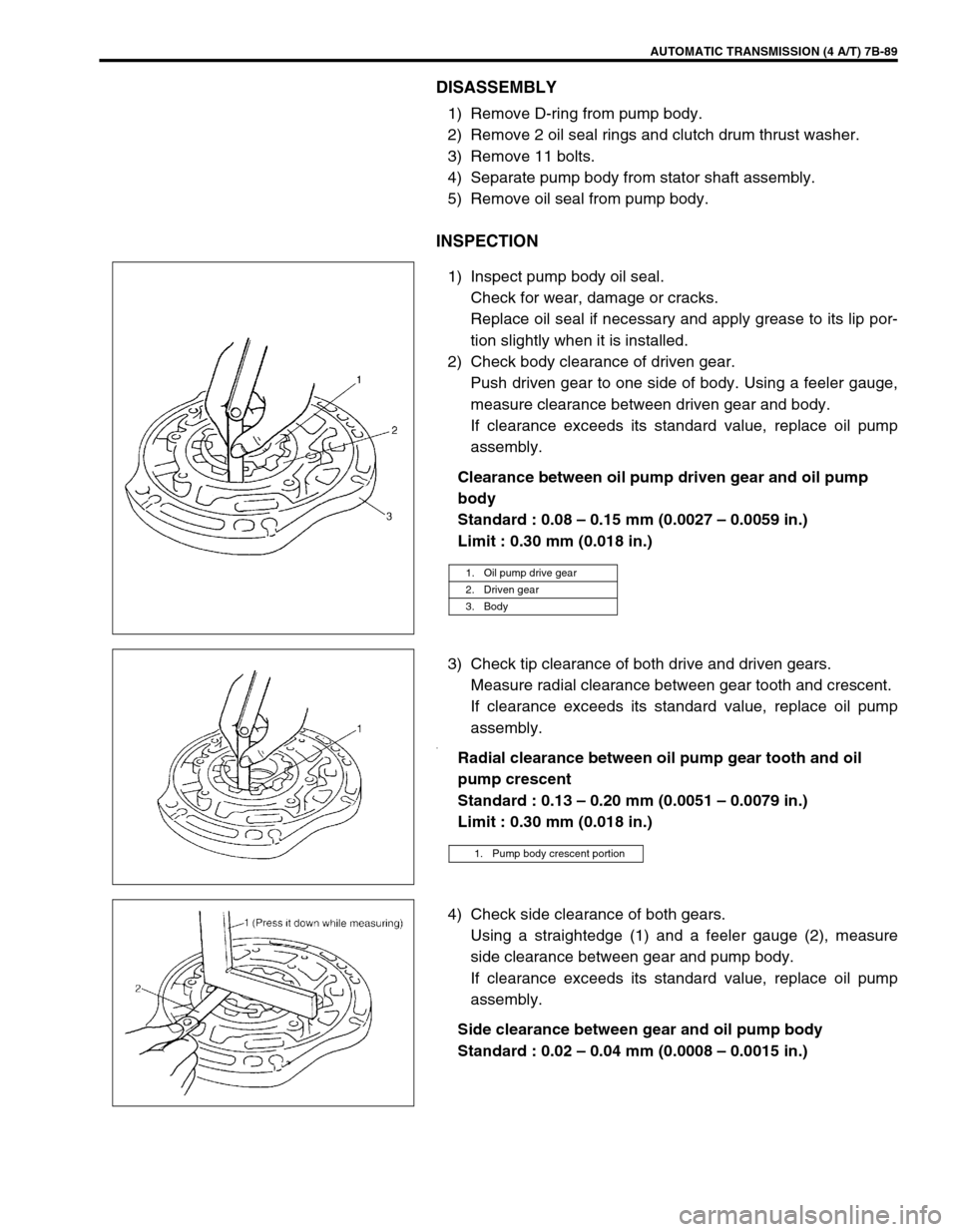

OIL PUMP

CAUTION:

Keep component parts in group for each subassembly and avoid mixing them up.

Clean all parts with cleaning solvent thoroughly and air dry them.

Use kerosene or automatic transmission fluid as cleaning solvent.

Do not use wiping cloths or rags to clean or dry parts.

All oil passages should be blown out and checked to make sure that they are not obstructed.

Keep face and eyes away from solvent spray while air blowing parts.

Check mating surface for irregularities and remove them, if any, and clean it again.

Soak new clutch discs and brake discs in transmission fluid for at least 2 hours before assembly.

Replace all gaskets and O-rings with new ones.

Apply automatic transmission fluid to all O-rings.

When installing seal ring, be careful so that it is not expanded excessively, extruded or caught.

Replace oil seals that are removed and apply grease to their lips.

Before installing, be sure to apply automatic transmission fluid to sliding, rolling and thrusting sur-

face of all component part. Also after installation, make sure to check each part for proper opera-

tion.

Always use torque wrench when tightening bolts.

1. Oil seal

: Apply grease 99000-25030 to oil seal lip.7. Clutch drum thrust washer

2. D-ring

: Apply grease 99000-25030 to all over surface. 8. Clutch drum oil seal ring

: Apply grease 99000-25030 to all over surface.

3. Oil pump body Apply automatic transmission fluid.

4. Oil pump drive gear Tightening torque

5. Oil pump driven gear Do not reuse.

6. Stator shaft assembly

Page 131 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-89

DISASSEMBLY

1) Remove D-ring from pump body.

2) Remove 2 oil seal rings and clutch drum thrust washer.

3) Remove 11 bolts.

4) Separate pump body from stator shaft assembly.

5) Remove oil seal from pump body.

INSPECTION

1) Inspect pump body oil seal.

Check for wear, damage or cracks.

Replace oil seal if necessary and apply grease to its lip por-

tion slightly when it is installed.

2) Check body clearance of driven gear.

Push driven gear to one side of body. Using a feeler gauge,

measure clearance between driven gear and body.

If clearance exceeds its standard value, replace oil pump

assembly.

Clearance between oil pump driven gear and oil pump

body

Standard : 0.08 – 0.15 mm (0.0027 – 0.0059 in.)

Limit : 0.30 mm (0.018 in.)

3) Check tip clearance of both drive and driven gears.

Measure radial clearance between gear tooth and crescent.

If clearance exceeds its standard value, replace oil pump

assembly.

.Radial clearance between oil pump gear tooth and oil

pump crescent

Standard : 0.13 – 0.20 mm (0.0051 – 0.0079 in.)

Limit : 0.30 mm (0.018 in.)

4) Check side clearance of both gears.

Using a straightedge (1) and a feeler gauge (2), measure

side clearance between gear and pump body.

If clearance exceeds its standard value, replace oil pump

assembly.

Side clearance between gear and oil pump body

Standard : 0.02 – 0.04 mm (0.0008 – 0.0015 in.)

1. Oil pump drive gear

2. Driven gear

3. Body

1. Pump body crescent portion

Page 132 of 447

7B-90 AUTOMATIC TRANSMISSION (4 A/T)

ASSEMBLY

1) Install pump body oil seal (1)

Use special tool and hammer to install it, and then apply

grease to its lip portion.

Special tool

(A) : 09913-85210

“A”: Grease 99000-25030

2) Install driven gear and drive gear to pump body (2) after

applying A/T fluid to gears.

3) Install stator shaft assembly to pump body and tighten 11

pump cover bolts to specification.

Tightening torque

Oil pump cover bolts (a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

4) Install 2 new oil seal rings to stator shaft.

5) Apply grease to 2 oil seal rings.

6) Install new D-ring to which grease is applied and make sure

that it is not twisted or extruded.

7) Check drive gear for smooth rotation.

Page 134 of 447

7B-92 AUTOMATIC TRANSMISSION (4 A/T)

4) Remove front clutch balancer (1) and front clutch return

spring seat (2).

5) Remove front clutch piston (3).

Blow compressed air through input shaft oil hole to remove

piston. If piston does not pop out, take it out with long nose

pliers.

6) Remove D-ring (4) from front clutch No.1 drum (5).

INSPECTION

Clutch Discs, Plates and Flange

Check that sliding surfaces of discs, plates and flanges are not

worn or burnt. If necessary, replace.

Front Clutch Return Spring Seat

Measure height of front clutch return spring.

Height of front clutch return spring

: 14.85 mm (0.585 in.)

Front Clutch Piston Lip and Front Clutch Balancer Lip

Check each lip for wear, deformation, cut, and/or hardening. If

necessary, replace.

NOTE:

If disc lining is exfoliated or discolored, replace all

discs.

Before assembling new discs, soak them in A/T fluid

for at least two hours.

NOTE:

Do not apply excessive force when measuring spring

height.

Perform measurement at several points.

Page 138 of 447

7B-96 AUTOMATIC TRANSMISSION (4 A/T)

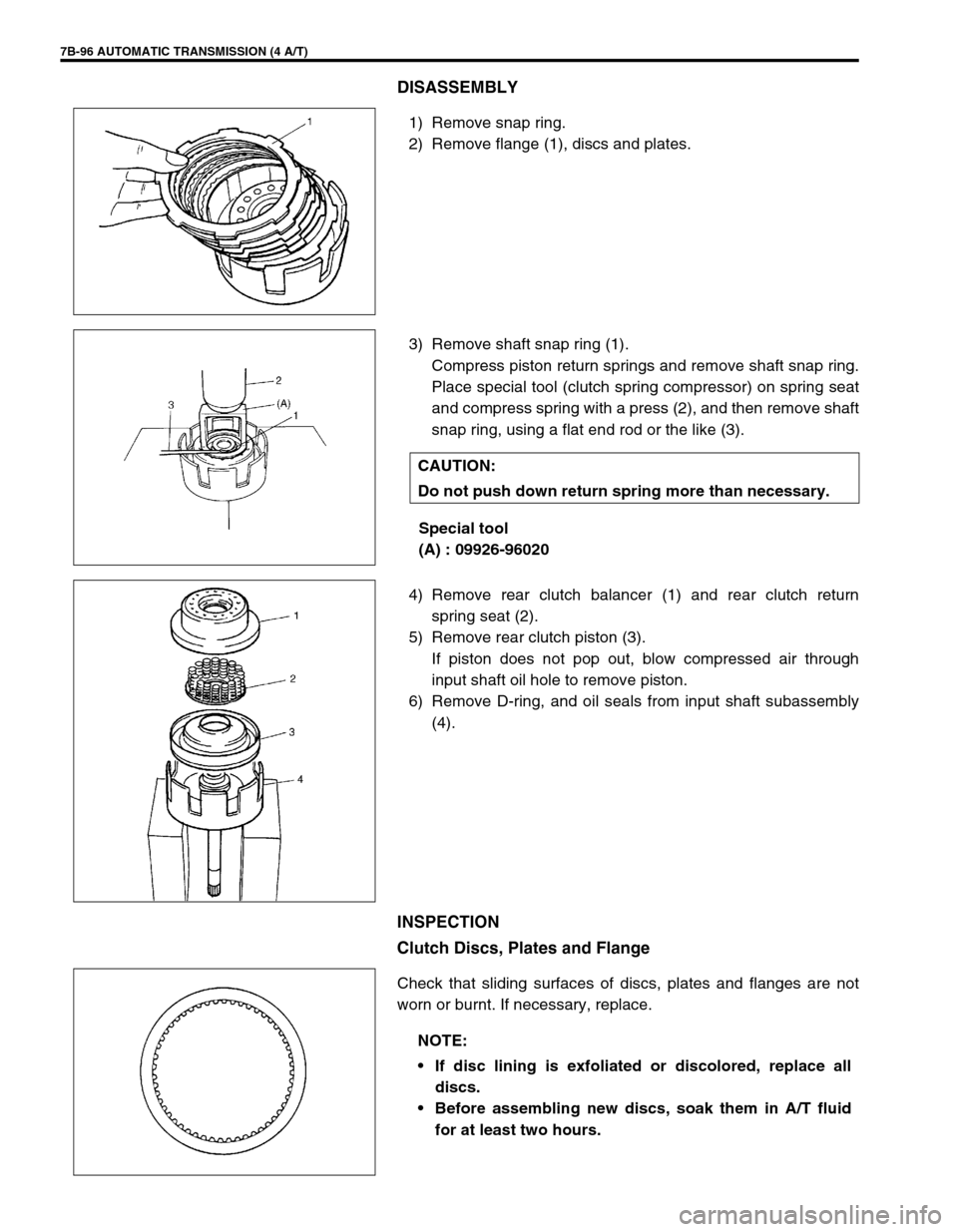

DISASSEMBLY

1) Remove snap ring.

2) Remove flange (1), discs and plates.

3) Remove shaft snap ring (1).

Compress piston return springs and remove shaft snap ring.

Place special tool (clutch spring compressor) on spring seat

and compress spring with a press (2), and then remove shaft

snap ring, using a flat end rod or the like (3).

Special tool

(A) : 09926-96020

4) Remove rear clutch balancer (1) and rear clutch return

spring seat (2).

5) Remove rear clutch piston (3).

If piston does not pop out, blow compressed air through

input shaft oil hole to remove piston.

6) Remove D-ring, and oil seals from input shaft subassembly

(4).

INSPECTION

Clutch Discs, Plates and Flange

Check that sliding surfaces of discs, plates and flanges are not

worn or burnt. If necessary, replace.

CAUTION:

Do not push down return spring more than necessary.

NOTE:

If disc lining is exfoliated or discolored, replace all

discs.

Before assembling new discs, soak them in A/T fluid

for at least two hours.