oil change SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 201 of 447

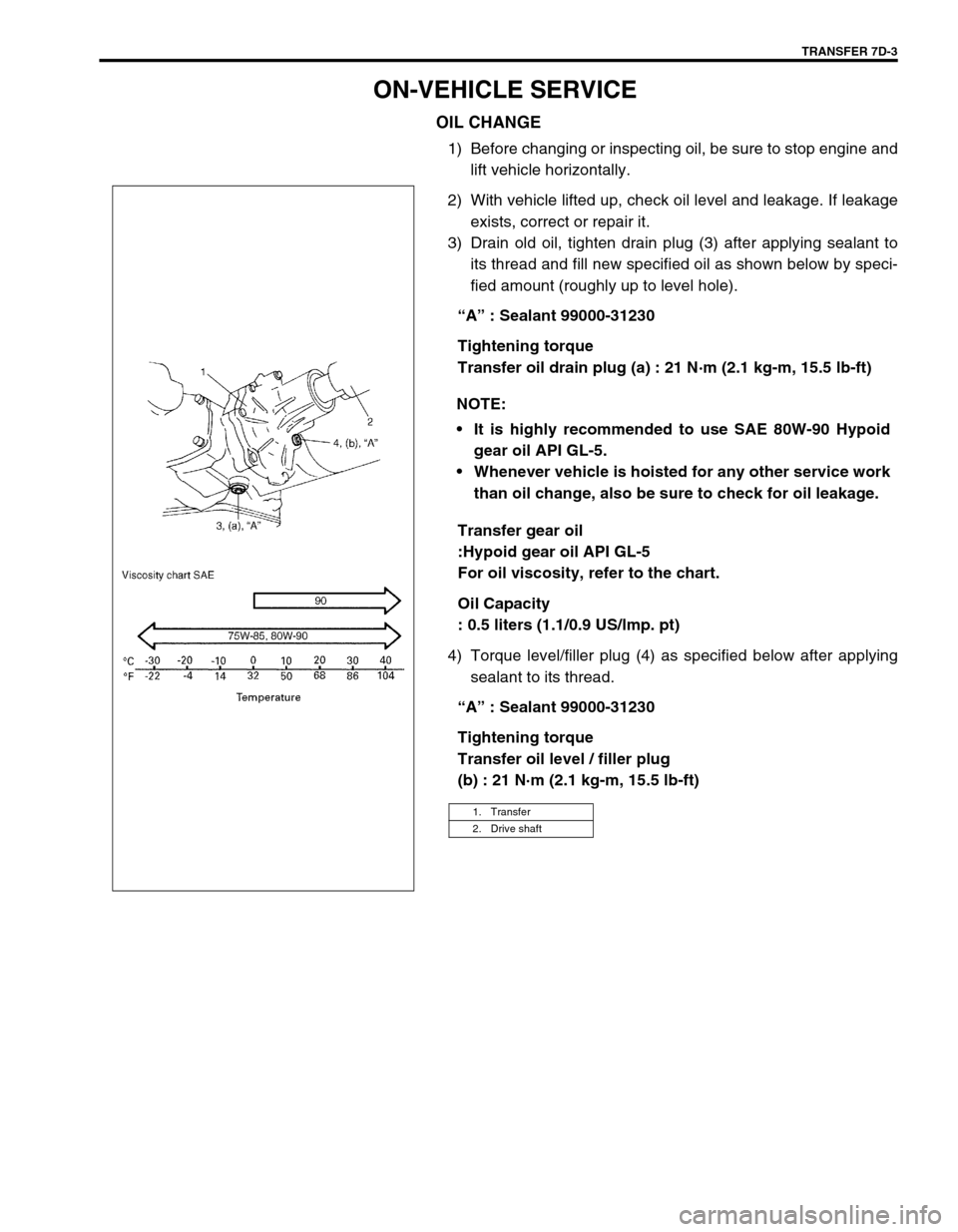

TRANSFER 7D-3

ON-VEHICLE SERVICE

OIL CHANGE

1) Before changing or inspecting oil, be sure to stop engine and

lift vehicle horizontally.

2) With vehicle lifted up, check oil level and leakage. If leakage

exists, correct or repair it.

3) Drain old oil, tighten drain plug (3) after applying sealant to

its thread and fill new specified oil as shown below by speci-

fied amount (roughly up to level hole).

“A” : Sealant 99000-31230

Tightening torque

Transfer oil drain plug (a) : 21 N·m (2.1 kg-m, 15.5 lb-ft)

Transfer gear oil

:Hypoid gear oil API GL-5

For oil viscosity, refer to the chart.

Oil Capacity

: 0.5 liters (1.1/0.9 US/lmp. pt)

4) Torque level/filler plug (4) as specified below after applying

sealant to its thread.

“A” : Sealant 99000-31230

Tightening torque

Transfer oil level / filler plug

(b) : 21 N·m (2.1 kg-m, 15.5 lb-ft) NOTE:

It is highly recommended to use SAE 80W-90 Hypoid

gear oil API GL-5.

Whenever vehicle is hoisted for any other service work

than oil change, also be sure to check for oil leakage.

1. Transfer

2. Drive shaft

Page 219 of 447

TRANSFER 7D-21

Tighten mounting bolt and mounting bracket bolts and nuts

to specified torque.

Tightening torque

Transfer rear mounting bracket nuts

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Transfer mounting bolt

(b) : 55 N·m (5.5 kg-m, 40.0 lb-ft)

Transfer rear mounting bracket No.2 bolts

(c) : 55 N·m (5.5 kg-m, 40.0 lb-ft)

Tighten transfer stiffener bolts (4) to specified torque.

Tightening torque

Transfer stiffener bolts (a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Tighten exhaust pipe bolts.

Tightening torque

Exhaust pipe bolts

(a) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Install right side drive shaft, refer to Section 4A.

Install propeller shaft and tighten propeller shaft bolts and

center support bolts to specified torque (refer to Section 4B).

Fill gear oil to transfer as specified, refer to OIL CHANGE of

ON-VEHICLE SERVICE.

Check oil level and leakage.

(a)

(b)

(c)

1. Transmission

2. Transfer

3. Stiffener

1. Exhaust No.1 pipe

2. Exhaust No.2 pipe

1

(a)(a)2

Page 223 of 447

REAR DIFFERENTIAL 7F-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7E

7F

7F

8B

8C

8D

8E

9

10

10A

10B

SECTION 7F

REAR DIFFERENTIAL

CONTENTS

GENERAL DESCRIPTION ............................... 7F-2

VISCOUS COUPLING .................................. 7F-2

DIAGNOSIS ...................................................... 7F-3

ON-VEHICLE SERVICE ................................... 7F-4

OIL CHANGE ................................................ 7F-4

UNIT REPAIR OVERHAUL .............................. 7F-5

DIFFERENTIAL UNIT ................................... 7F-6

UNIT DISASSEMBLY ................................... 7F-7SUB-ASSEMBLY REPAIR............................ 7F-8

VISCOUS COUPLING .............................. 7F-8

REAR DIFFERENTIAL............................ 7F-10

UNIT ASSEMBLY ....................................... 7F-20

TIGHTENING TORQUE SPECIFICATION..... 7F-20

REQUIRED SERVICE MATERIAL................. 7F-21

SPECIAL TOOL ............................................. 7F-21

Page 226 of 447

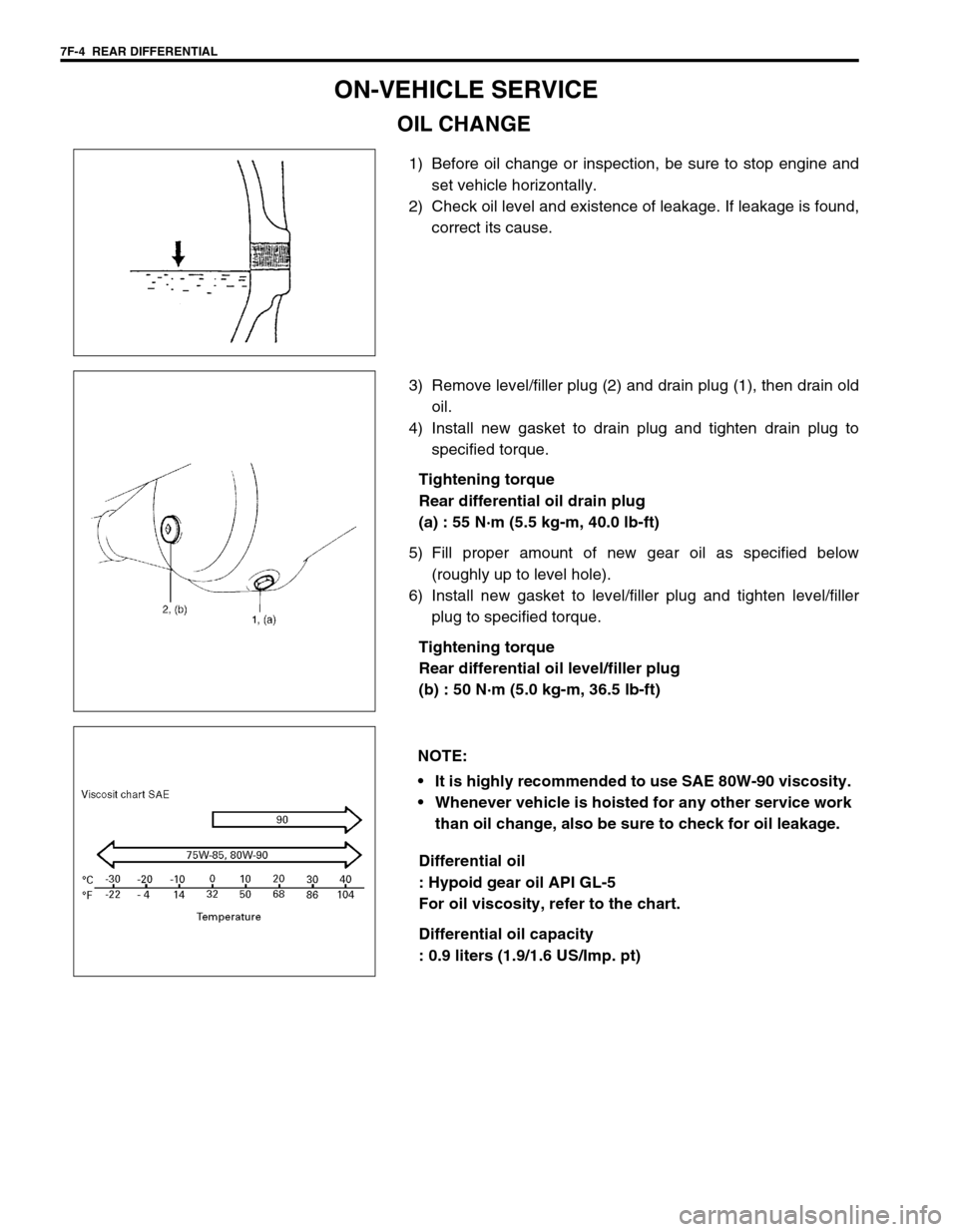

7F-4 REAR DIFFERENTIAL

ON-VEHICLE SERVICE

OIL CHANGE

1) Before oil change or inspection, be sure to stop engine and

set vehicle horizontally.

2) Check oil level and existence of leakage. If leakage is found,

correct its cause.

3) Remove level/filler plug (2) and drain plug (1), then drain old

oil.

4) Install new gasket to drain plug and tighten drain plug to

specified torque.

Tightening torque

Rear differential oil drain plug

(a) : 55 N·m (5.5 kg-m, 40.0 lb-ft)

5) Fill proper amount of new gear oil as specified below

(roughly up to level hole).

6) Install new gasket to level/filler plug and tighten level/filler

plug to specified torque.

Tightening torque

Rear differential oil level/filler plug

(b) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Differential oil

: Hypoid gear oil API GL-5

For oil viscosity, refer to the chart.

Differential oil capacity

: 0.9 liters (1.9/1.6 US/Imp. pt)

NOTE:

It is highly recommended to use SAE 80W-90 viscosity.

Whenever vehicle is hoisted for any other service work

than oil change, also be sure to check for oil leakage.

Page 228 of 447

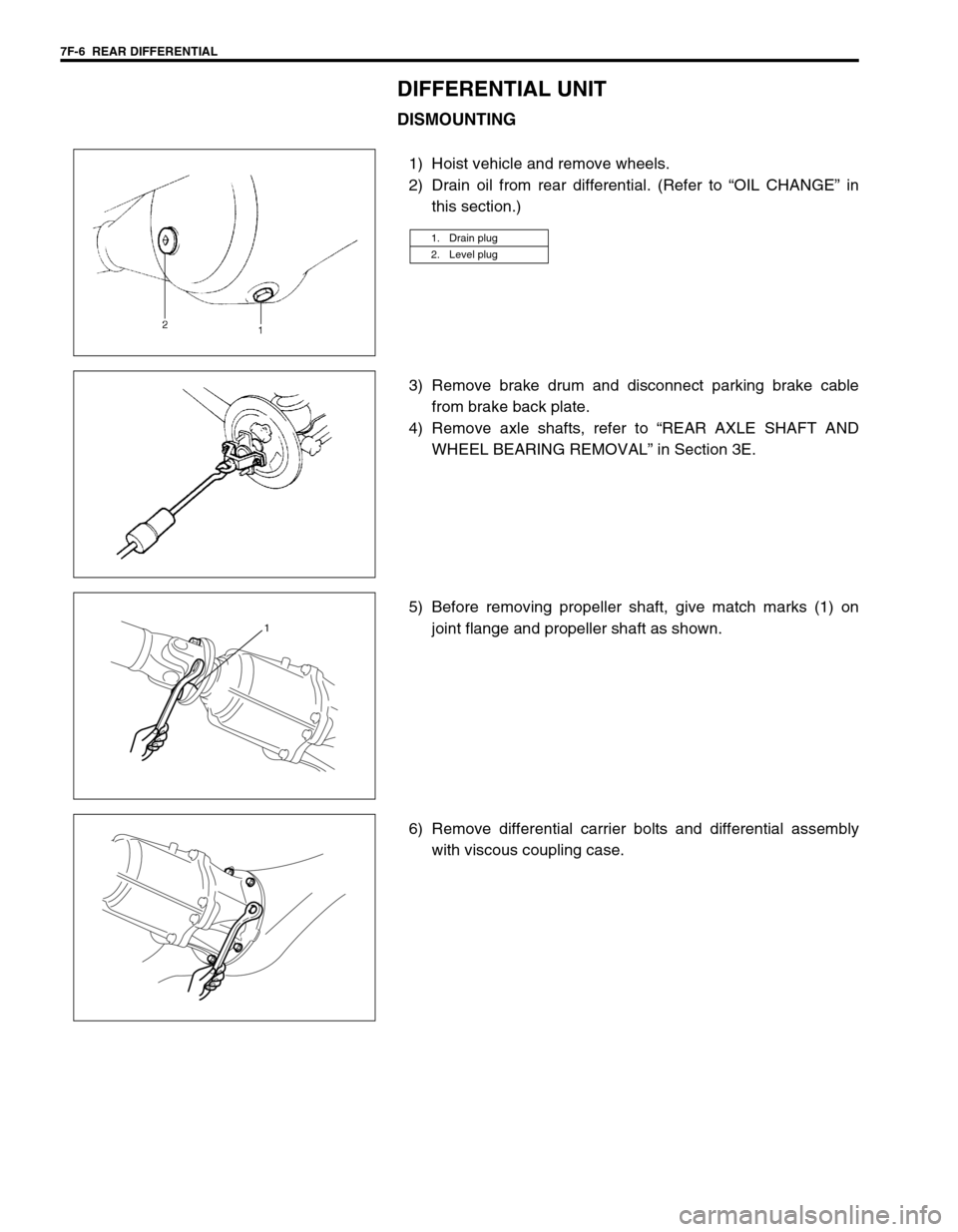

7F-6 REAR DIFFERENTIAL

DIFFERENTIAL UNIT

DISMOUNTING

1) Hoist vehicle and remove wheels.

2) Drain oil from rear differential. (Refer to “OIL CHANGE” in

this section.)

3) Remove brake drum and disconnect parking brake cable

from brake back plate.

4) Remove axle shafts, refer to “REAR AXLE SHAFT AND

WHEEL BEARING REMOVAL” in Section 3E.

5) Before removing propeller shaft, give match marks (1) on

joint flange and propeller shaft as shown.

6) Remove differential carrier bolts and differential assembly

with viscous coupling case.

1. Drain plug

2. Level plug

1

Page 229 of 447

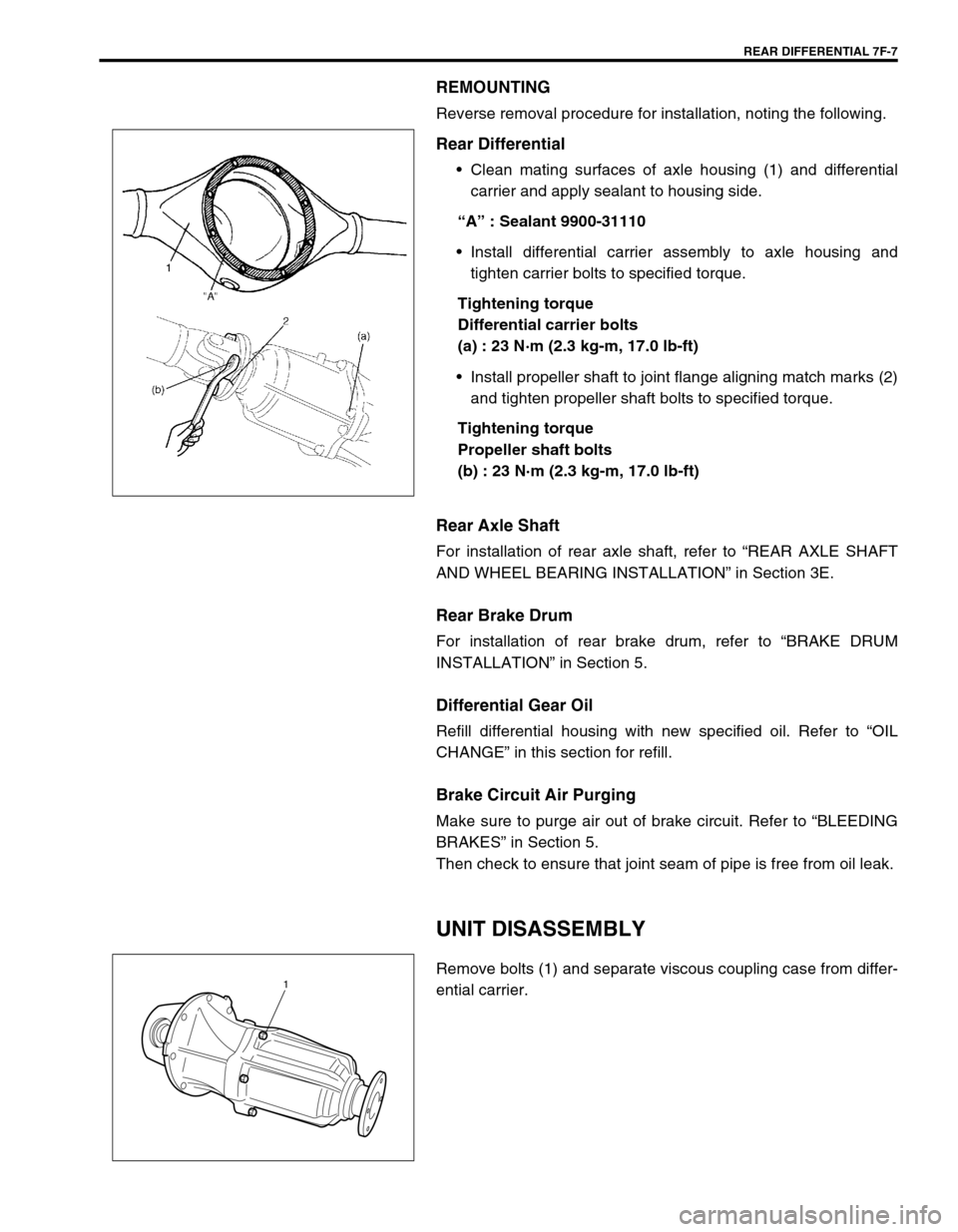

REAR DIFFERENTIAL 7F-7

REMOUNTING

Reverse removal procedure for installation, noting the following.

Rear Differential

Clean mating surfaces of axle housing (1) and differential

carrier and apply sealant to housing side.

“A” : Sealant 9900-31110

Install differential carrier assembly to axle housing and

tighten carrier bolts to specified torque.

Tightening torque

Differential carrier bolts

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

Install propeller shaft to joint flange aligning match marks (2)

and tighten propeller shaft bolts to specified torque.

Tightening torque

Propeller shaft bolts

(b) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

Rear Axle Shaft

For installation of rear axle shaft, refer to “REAR AXLE SHAFT

AND WHEEL BEARING INSTALLATION” in Section 3E.

Rear Brake Drum

For installation of rear brake drum, refer to “BRAKE DRUM

INSTALLATION” in Section 5.

Differential Gear Oil

Refill differential housing with new specified oil. Refer to “OIL

CHANGE” in this section for refill.

Brake Circuit Air Purging

Make sure to purge air out of brake circuit. Refer to “BLEEDING

BRAKES” in Section 5.

Then check to ensure that joint seam of pipe is free from oil leak.

UNIT DISASSEMBLY

Remove bolts (1) and separate viscous coupling case from differ-

ential carrier.1

Page 282 of 447

8G-4 IMMOBILIZER CONTROL SYSTEM

ON-BOARD DIAGNOSTIC SYSTEM

(SELF-DIAGNOSIS FUNCTION)

Immobilizer Control Module and ECM diagnose troubles which

may occur in the area including the following parts when the igni-

tion switch is ON.

ECM :

ECM/Immobilizer Control Module code

Serial data link circuit

ECM

Immobilizer Control Module :

Transponder code

Coil antenna

ECM/Immobilizer Control Module code

Serial data link circuit

Immobilizer Control Module

Ignition signal

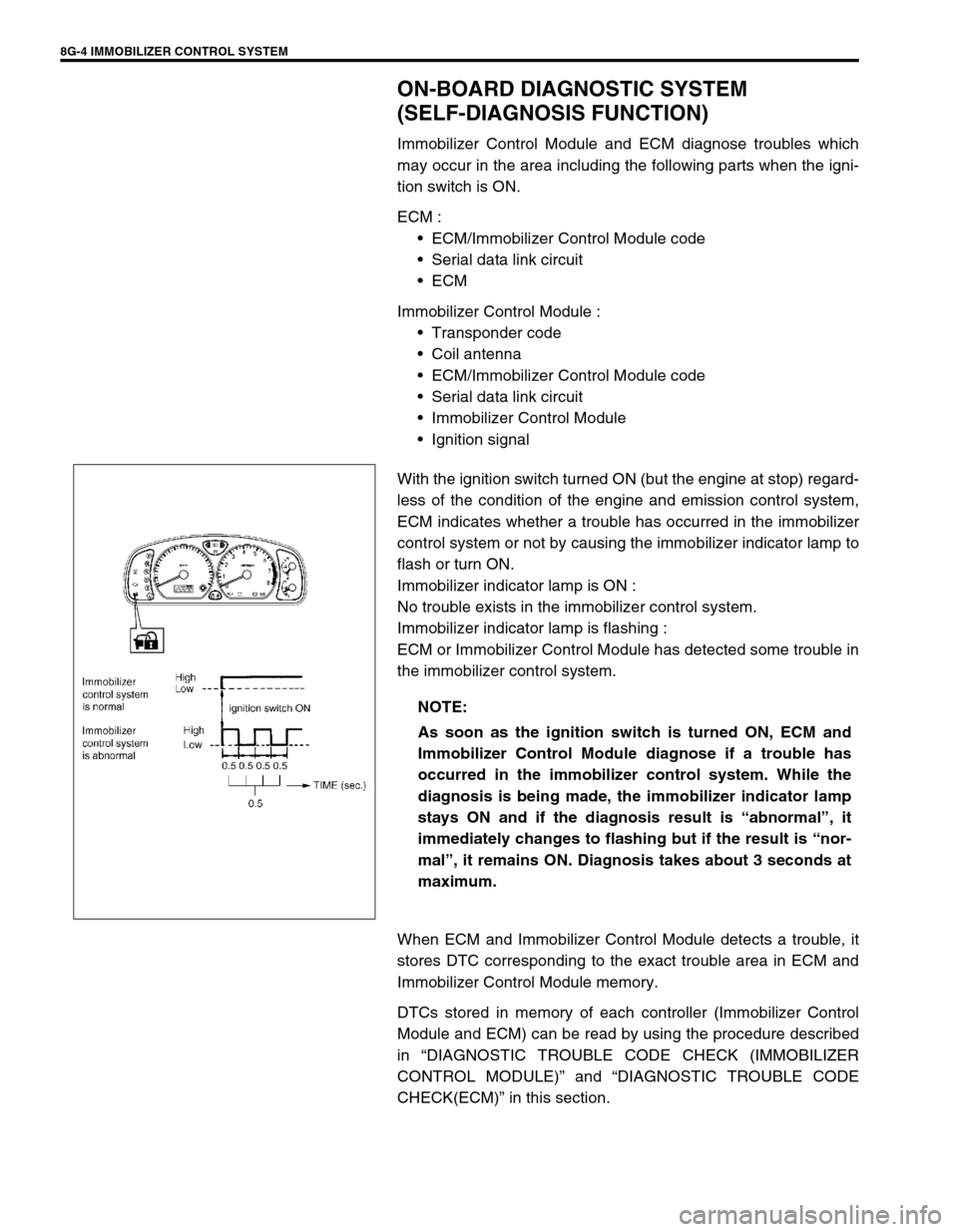

With the ignition switch turned ON (but the engine at stop) regard-

less of the condition of the engine and emission control system,

ECM indicates whether a trouble has occurred in the immobilizer

control system or not by causing the immobilizer indicator lamp to

flash or turn ON.

Immobilizer indicator lamp is ON :

No trouble exists in the immobilizer control system.

Immobilizer indicator lamp is flashing :

ECM or Immobilizer Control Module has detected some trouble in

the immobilizer control system.

When ECM and Immobilizer Control Module detects a trouble, it

stores DTC corresponding to the exact trouble area in ECM and

Immobilizer Control Module memory.

DTCs stored in memory of each controller (Immobilizer Control

Module and ECM) can be read by using the procedure described

in “DIAGNOSTIC TROUBLE CODE CHECK (IMMOBILIZER

CONTROL MODULE)” and “DIAGNOSTIC TROUBLE CODE

CHECK(ECM)” in this section. NOTE:

As soon as the ignition switch is turned ON, ECM and

Immobilizer Control Module diagnose if a trouble has

occurred in the immobilizer control system. While the

diagnosis is being made, the immobilizer indicator lamp

stays ON and if the diagnosis result is “abnormal”, it

immediately changes to flashing but if the result is “nor-

mal”, it remains ON. Diagnosis takes about 3 seconds at

maximum.