ignition SUZUKI SWIFT 2000 1.G Transmission Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 87 of 447

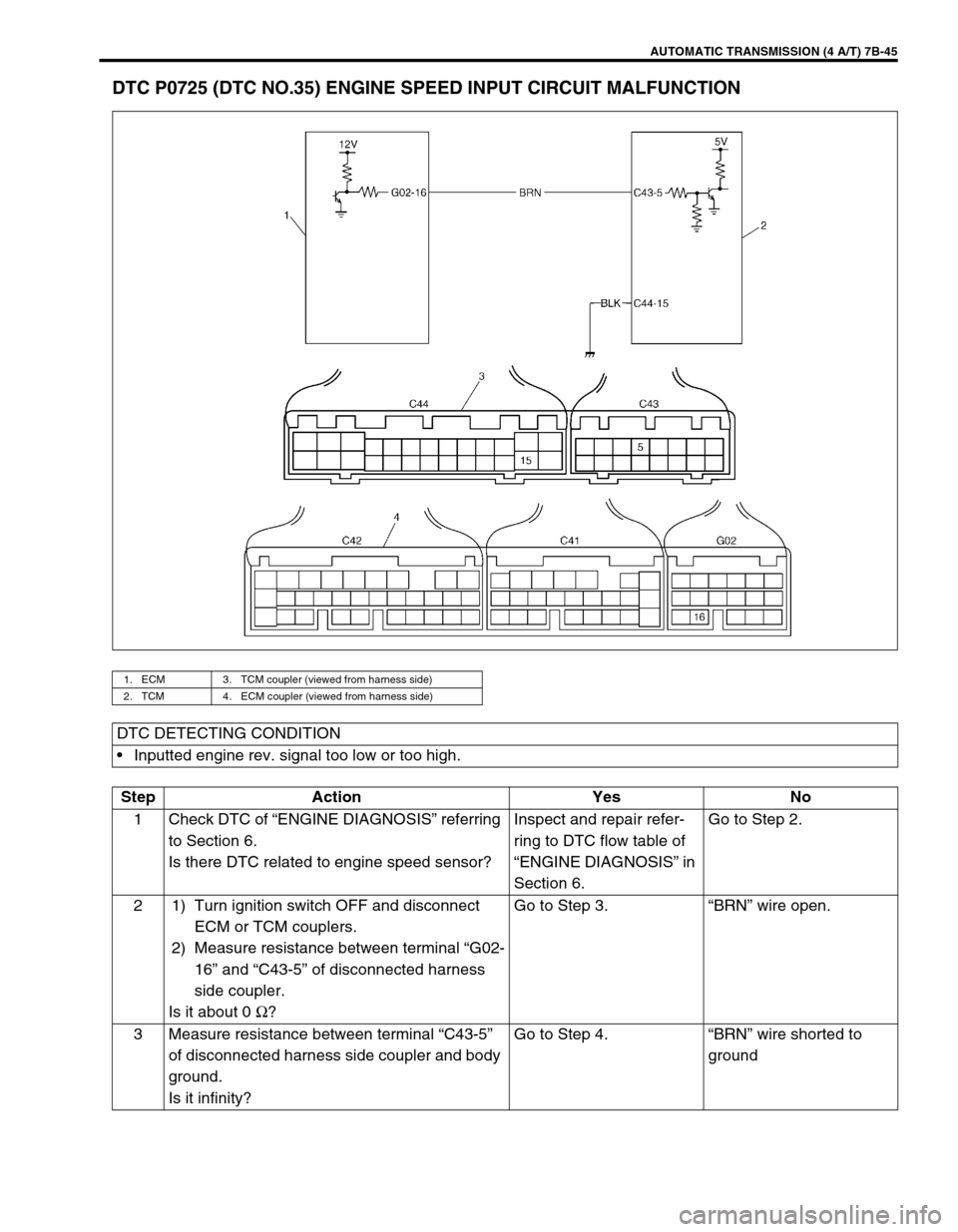

AUTOMATIC TRANSMISSION (4 A/T) 7B-45

DTC P0725 (DTC NO.35) ENGINE SPEED INPUT CIRCUIT MALFUNCTION

1. ECM 3. TCM coupler (viewed from harness side)

2. TCM 4. ECM coupler (viewed from harness side)

DTC DETECTING CONDITION

Inputted engine rev. signal too low or too high.

Step Action Yes No

1 Check DTC of “ENGINE DIAGNOSIS” referring

to Section 6.

Is there DTC related to engine speed sensor?Inspect and repair refer-

ring to DTC flow table of

“ENGINE DIAGNOSIS” in

Section 6.Go to Step 2.

2 1) Turn ignition switch OFF and disconnect

ECM or TCM couplers.

2) Measure resistance between terminal “G02-

16” and “C43-5” of disconnected harness

side coupler.

Is it about 0 Ω

?Go to Step 3.“BRN” wire open.

3 Measure resistance between terminal “C43-5”

of disconnected harness side coupler and body

ground.

Is it infinity?Go to Step 4.“BRN” wire shorted to

ground

Page 88 of 447

7B-46 AUTOMATIC TRANSMISSION (4 A/T)

4 1) Turn ignition switch OFF and connect ECM

couplers.

2) Turn ignition switch ON and measure volt-

age between terminal “C43-5” of discon-

nected harness side TCM coupler and body

ground.

Is it 10 – 14 V?Intermittent trouble or

faulty ECM or TCM.

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.

If no trouble found, substi-

tute a known-good ECM

or TCM and recheck.“BRN” wire is shorted to

power circuit or faulty

ECM.

If “BRN” wire is OK, sub-

stitute a known-good

ECM and recheck. Step Action Yes No

Page 89 of 447

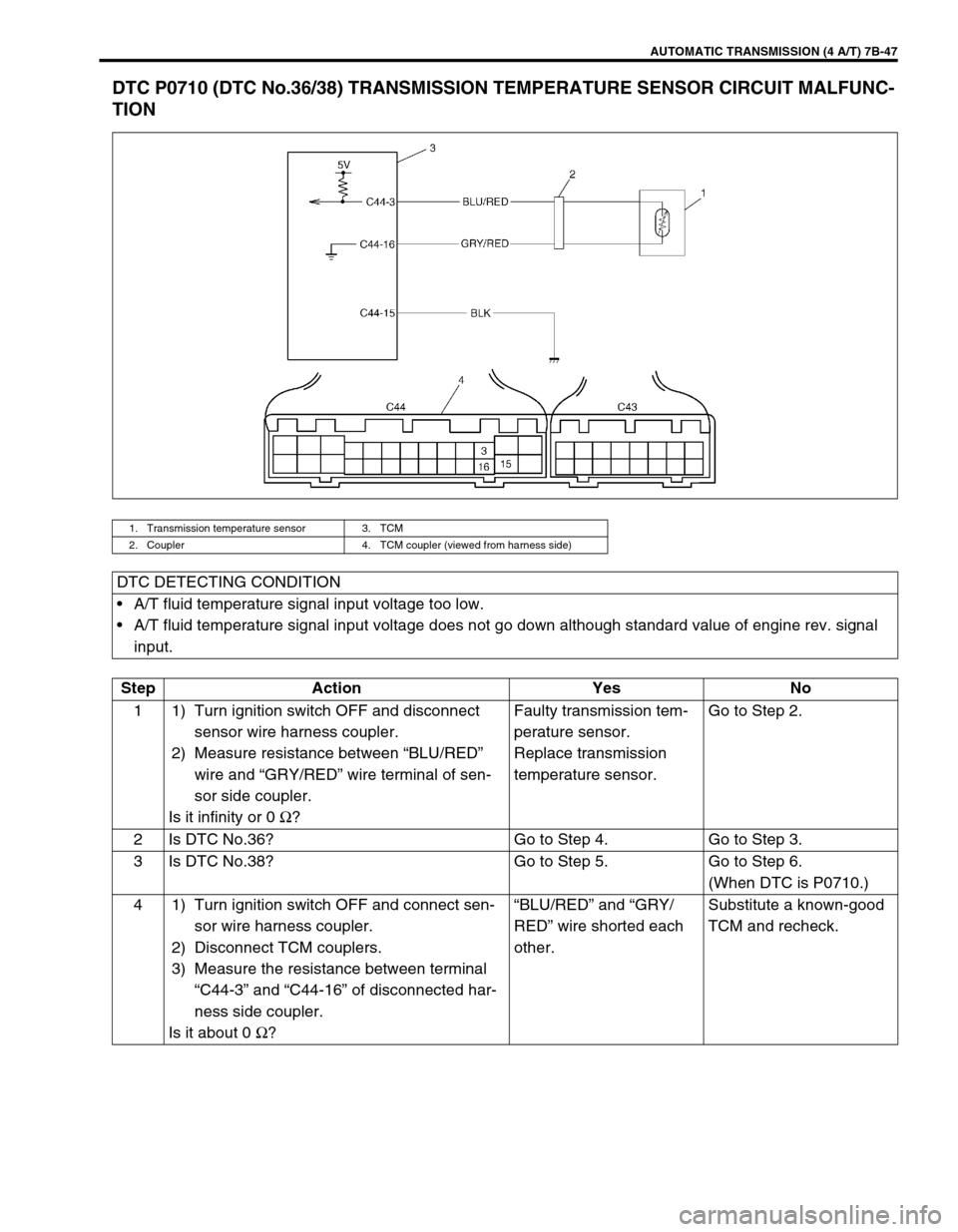

AUTOMATIC TRANSMISSION (4 A/T) 7B-47

DTC P0710 (DTC No.36/38) TRANSMISSION TEMPERATURE SENSOR CIRCUIT MALFUNC-

TION

1. Transmission temperature sensor 3. TCM

2. Coupler 4. TCM coupler (viewed from harness side)

DTC DETECTING CONDITION

A/T fluid temperature signal input voltage too low.

A/T fluid temperature signal input voltage does not go down although standard value of engine rev. signal

input.

Step Action Yes No

1 1) Turn ignition switch OFF and disconnect

sensor wire harness coupler.

2) Measure resistance between “BLU/RED”

wire and “GRY/RED” wire terminal of sen-

sor side coupler.

Is it infinity or 0 Ω

?Faulty transmission tem-

perature sensor.

Replace transmission

temperature sensor.Go to Step 2.

2 Is DTC No.36? Go to Step 4. Go to Step 3.

3 Is DTC No.38? Go to Step 5. Go to Step 6.

(When DTC is P0710.)

4 1) Turn ignition switch OFF and connect sen-

sor wire harness coupler.

2) Disconnect TCM couplers.

3) Measure the resistance between terminal

“C44-3” and “C44-16” of disconnected har-

ness side coupler.

Is it about 0 Ω

?“BLU/RED” and “GRY/

RED” wire shorted each

other.Substitute a known-good

TCM and recheck.

Page 90 of 447

7B-48 AUTOMATIC TRANSMISSION (4 A/T)

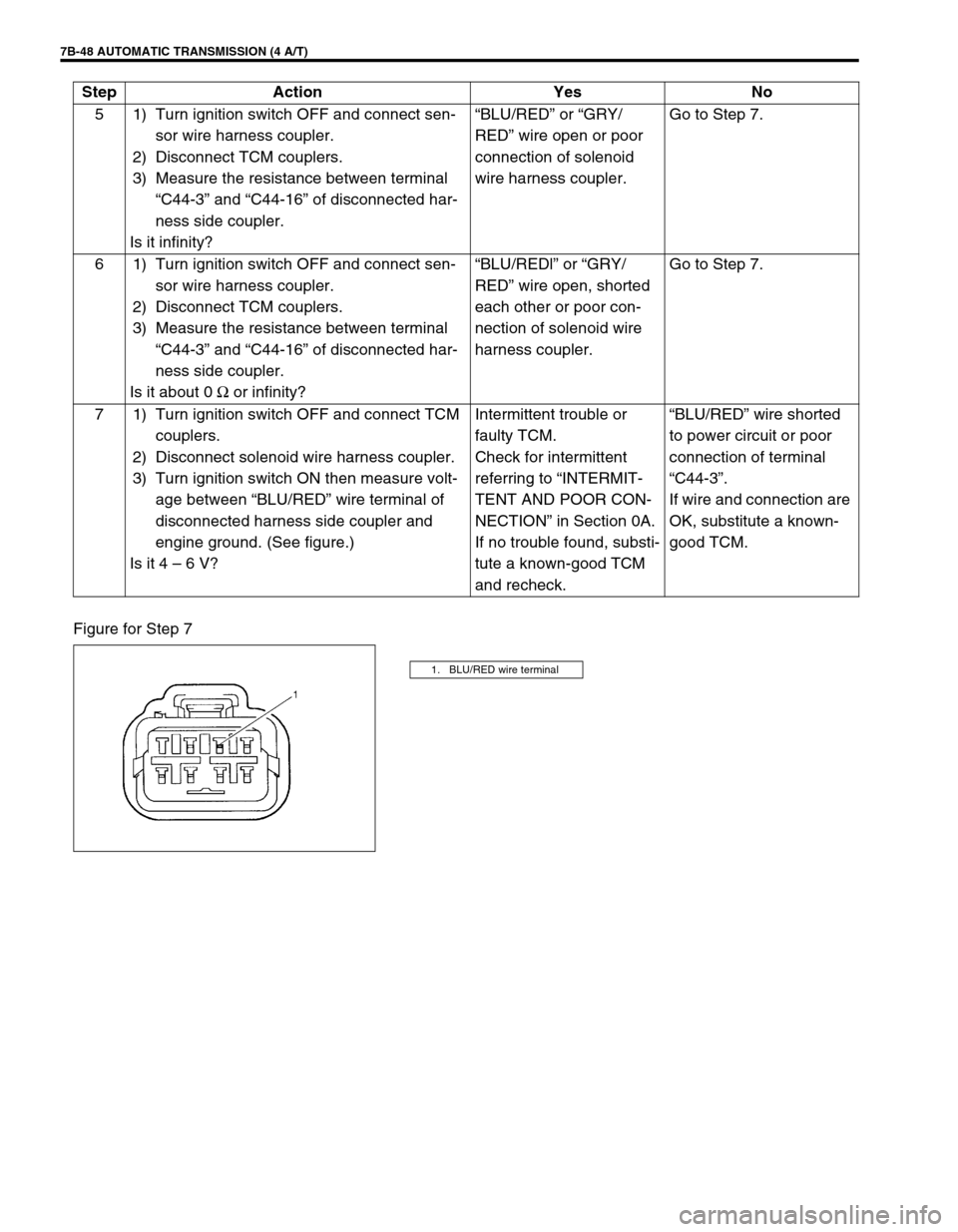

Figure for Step 75 1) Turn ignition switch OFF and connect sen-

sor wire harness coupler.

2) Disconnect TCM couplers.

3) Measure the resistance between terminal

“C44-3” and “C44-16” of disconnected har-

ness side coupler.

Is it infinity?“BLU/RED” or “GRY/

RED” wire open or poor

connection of solenoid

wire harness coupler.Go to Step 7.

6 1) Turn ignition switch OFF and connect sen-

sor wire harness coupler.

2) Disconnect TCM couplers.

3) Measure the resistance between terminal

“C44-3” and “C44-16” of disconnected har-

ness side coupler.

Is it about 0 Ω

or infinity?“BLU/REDl” or “GRY/

RED” wire open, shorted

each other or poor con-

nection of solenoid wire

harness coupler.Go to Step 7.

7 1) Turn ignition switch OFF and connect TCM

couplers.

2) Disconnect solenoid wire harness coupler.

3) Turn ignition switch ON then measure volt-

age between “BLU/RED” wire terminal of

disconnected harness side coupler and

engine ground. (See figure.)

Is it 4 – 6 V?Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.

If no trouble found, substi-

tute a known-good TCM

and recheck.“BLU/RED” wire shorted

to power circuit or poor

connection of terminal

“C44-3”.

If wire and connection are

OK, substitute a known-

good TCM. Step Action Yes No

1. BLU/RED wire terminal

Page 91 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-49

DTC P0763 (DTC NO.43) SHIFT SOLENOID-C (NO.3) ELECTRICAL

DTC P0768 (DTC NO.45) SHIFT SOLENOID-B (NO.4) ELECTRICAL

DTC P0773 (DTC NO.48) SHIFT SOLENOID-E (NO.5) ELECTRICAL

1. Dropping resistor 4. Shift solenoid-D (No.4) 7. TCM coupler (viewed from harness side)

2. solenoid coupler 5. Shift solenoid-E (No.5)

3. Shift solenoid-C (No.3) 6. TCM

12V

C44-24

C44-13

C44-12

C44-11

C44-25

C44-26

C44-15

1

6

23

4

5

BRN/WHTGRY/BLU

RED/BLU

BLU/ORN

BRN

BLK/YEL

BRN/WHT

BLK/YEL

BRN

BLK

RED

YEL

BRN

7

DTC DETECTING CONDITION

Solenoid output voltage too high or too low differently from TCM order.

Step Action Yes No

1 1) Turn ignition switch OFF and disconnect sole-

noid coupler.

2) Measure resistance between terminal of sole-

noid coupler and transmission ground. (See

figure.)

Is it 2.5 – 3.5 Ω

?Go to Step 2.Solenoid lead wire open or

shorted to ground.

Malfunction of solenoid

valve.

2 1) Disconnect TCM couplers.

2) Measure resistance between terminal of dis-

connected body side solenoid coupler and

terminal “C44-11”, “C44-12” or “C44-13” of

disconnected harness side TCM coupler.

(See chart.)

Is it 6.5 – 8.5 Ω

?Go to Step 3. Inspect dropping resister refer-

ring to “DROPPING RESIS-

TOR” in this section.

If OK, circuit between TCM

and dropping resister or drop-

ping resister and solenoid cou-

pler open.

3 Check continuity between terminal “C44-24”,

“C44-25” or “C44-26” of disconnected TCM cou-

pler and terminal of disconnected body side sole-

noid coupler. (See chart.)

Is there continuity?Go to Step 4. Circuit between TCM and sole-

noid coupler open.

Page 93 of 447

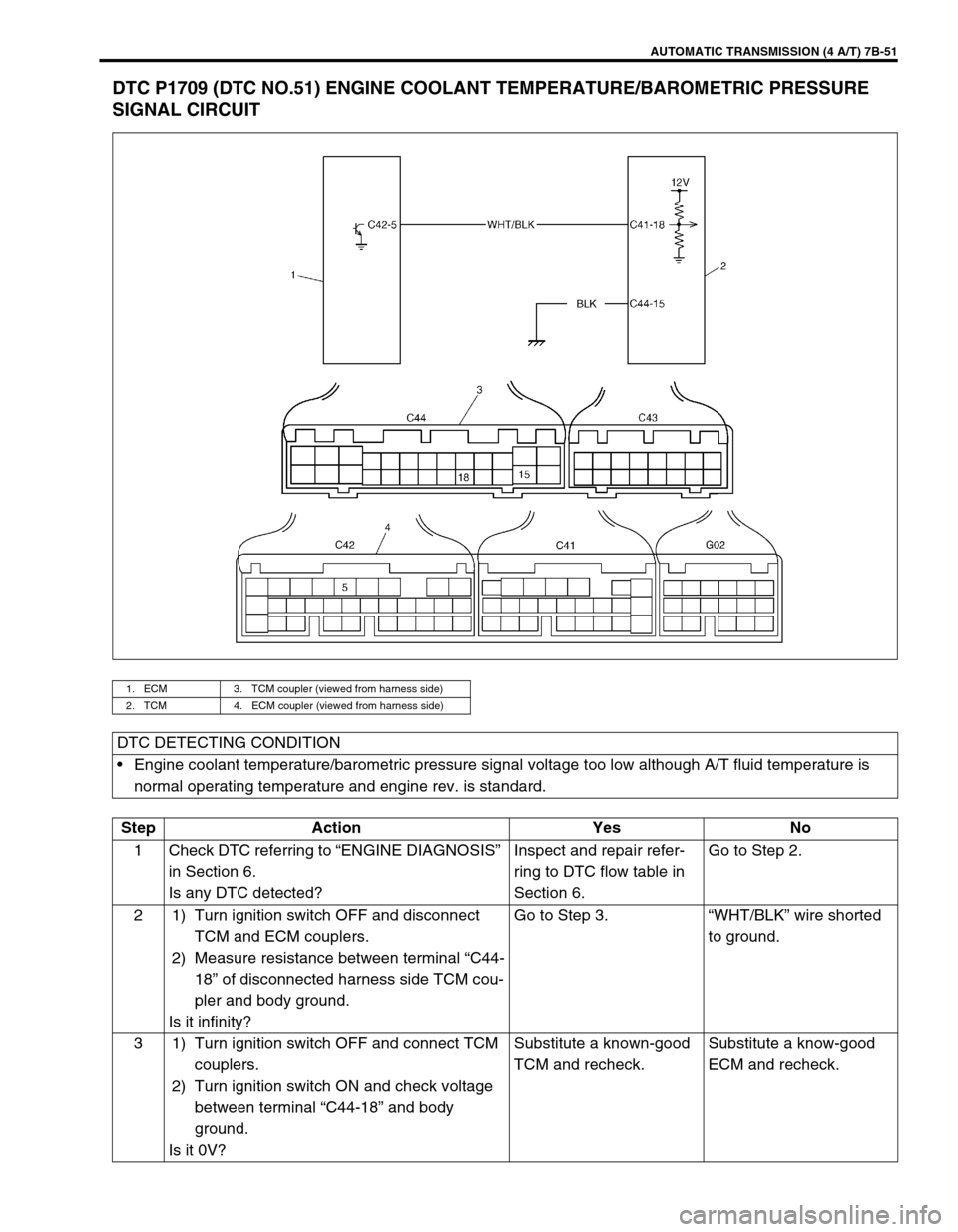

AUTOMATIC TRANSMISSION (4 A/T) 7B-51

DTC P1709 (DTC NO.51) ENGINE COOLANT TEMPERATURE/BAROMETRIC PRESSURE

SIGNAL CIRCUIT

1. ECM 3. TCM coupler (viewed from harness side)

2. TCM 4. ECM coupler (viewed from harness side)

DTC DETECTING CONDITION

Engine coolant temperature/barometric pressure signal voltage too low although A/T fluid temperature is

normal operating temperature and engine rev. is standard.

Step Action Yes No

1 Check DTC referring to “ENGINE DIAGNOSIS”

in Section 6.

Is any DTC detected?Inspect and repair refer-

ring to DTC flow table in

Section 6.Go to Step 2.

2 1) Turn ignition switch OFF and disconnect

TCM and ECM couplers.

2) Measure resistance between terminal “C44-

18” of disconnected harness side TCM cou-

pler and body ground.

Is it infinity?Go to Step 3.“WHT/BLK” wire shorted

to ground.

3 1) Turn ignition switch OFF and connect TCM

couplers.

2) Turn ignition switch ON and check voltage

between terminal “C44-18” and body

ground.

Is it 0V?Substitute a known-good

TCM and recheck.Substitute a know-good

ECM and recheck.

Page 94 of 447

7B-52 AUTOMATIC TRANSMISSION (4 A/T)

DTC P0702/P1702 (DTC No.52)TRANSMISSION CONTROL SYSTEM ELECTRICAL OR

INTERNAL MALFUNCTION OF TCM

1. TCM 3. A/T relay

2. Ignition switch 4. TCM coupler (viewed from harness side)

DTC DETECTING CONDITION

Relay output voltage too high although TCM orders the relay to turn OFF or relay output voltage too low

although TCM orders the relay to turn on.

Incorrect calculations of checking TCM programmed data indicated.

Step Action Yes No

1 1) Turn ignition switch ON.

2) Erase all DTCs referring to “HOW TO

CLEAR DTC” in this section.

3) Turn ignition switch OFF.

4) Turn ignition switch ON once again and

check for any DTC.

Is it DTC P1702 (DTC No.52) or P0702 (DTC

No.52)?Replace TCM. Could be a temporary

malfunction of the TCM.

Page 95 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-53

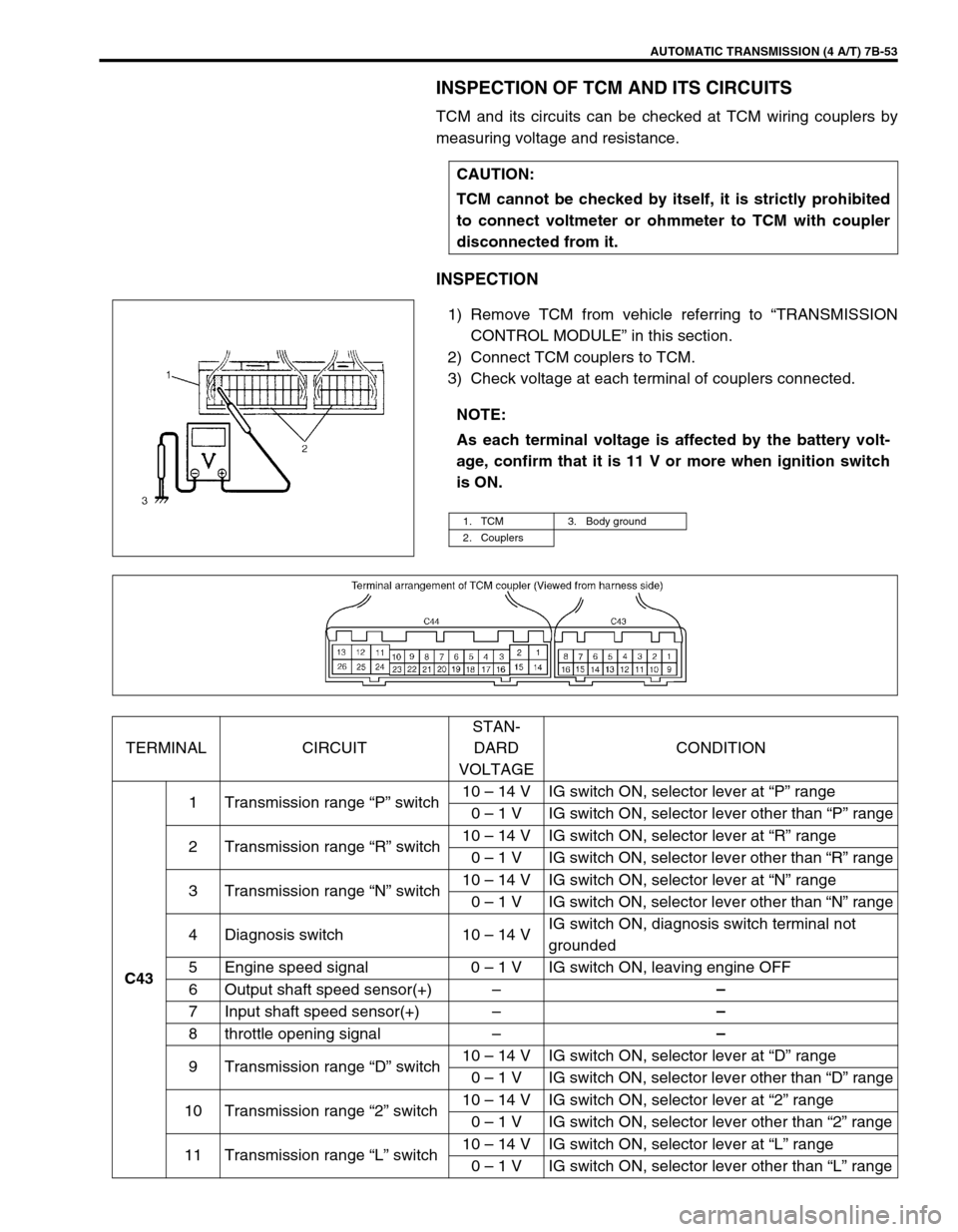

INSPECTION OF TCM AND ITS CIRCUITS

TCM and its circuits can be checked at TCM wiring couplers by

measuring voltage and resistance.

INSPECTION

1) Remove TCM from vehicle referring to “TRANSMISSION

CONTROL MODULE” in this section.

2) Connect TCM couplers to TCM.

3) Check voltage at each terminal of couplers connected.CAUTION:

TCM cannot be checked by itself, it is strictly prohibited

to connect voltmeter or ohmmeter to TCM with coupler

disconnected from it.

NOTE:

As each terminal voltage is affected by the battery volt-

age, confirm that it is 11 V or more when ignition switch

is ON.

1. TCM 3. Body ground

2. Couplers

TERMINAL CIRCUITSTAN-

DARD

VOLTAGECONDITION

C431 Transmission range “P” switch10 – 14 V IG switch ON, selector lever at “P” range

0 – 1 V IG switch ON, selector lever other than “P” range

2 Transmission range “R” switch10 – 14 V IG switch ON, selector lever at “R” range

0 – 1 V IG switch ON, selector lever other than “R” range

3 Transmission range “N” switch10 – 14 V IG switch ON, selector lever at “N” range

0 – 1 V IG switch ON, selector lever other than “N” range

4 Diagnosis switch 10 – 14 VIG switch ON, diagnosis switch terminal not

grounded

5 Engine speed signal 0 – 1 V IG switch ON, leaving engine OFF

6 Output shaft speed sensor(+)––

7 Input shaft speed sensor(+)––

8 throttle opening signal––

9 Transmission range “D” switch10 – 14 V IG switch ON, selector lever at “D” range

0 – 1 V IG switch ON, selector lever other than “D” range

10 Transmission range “2” switch10 – 14 V IG switch ON, selector lever at “2” range

0 – 1 V IG switch ON, selector lever other than “2” range

11 Transmission range “L” switch10 – 14 V IG switch ON, selector lever at “L” range

0 – 1 V IG switch ON, selector lever other than “L” range

Page 112 of 447

7B-70 AUTOMATIC TRANSMISSION (4 A/T)

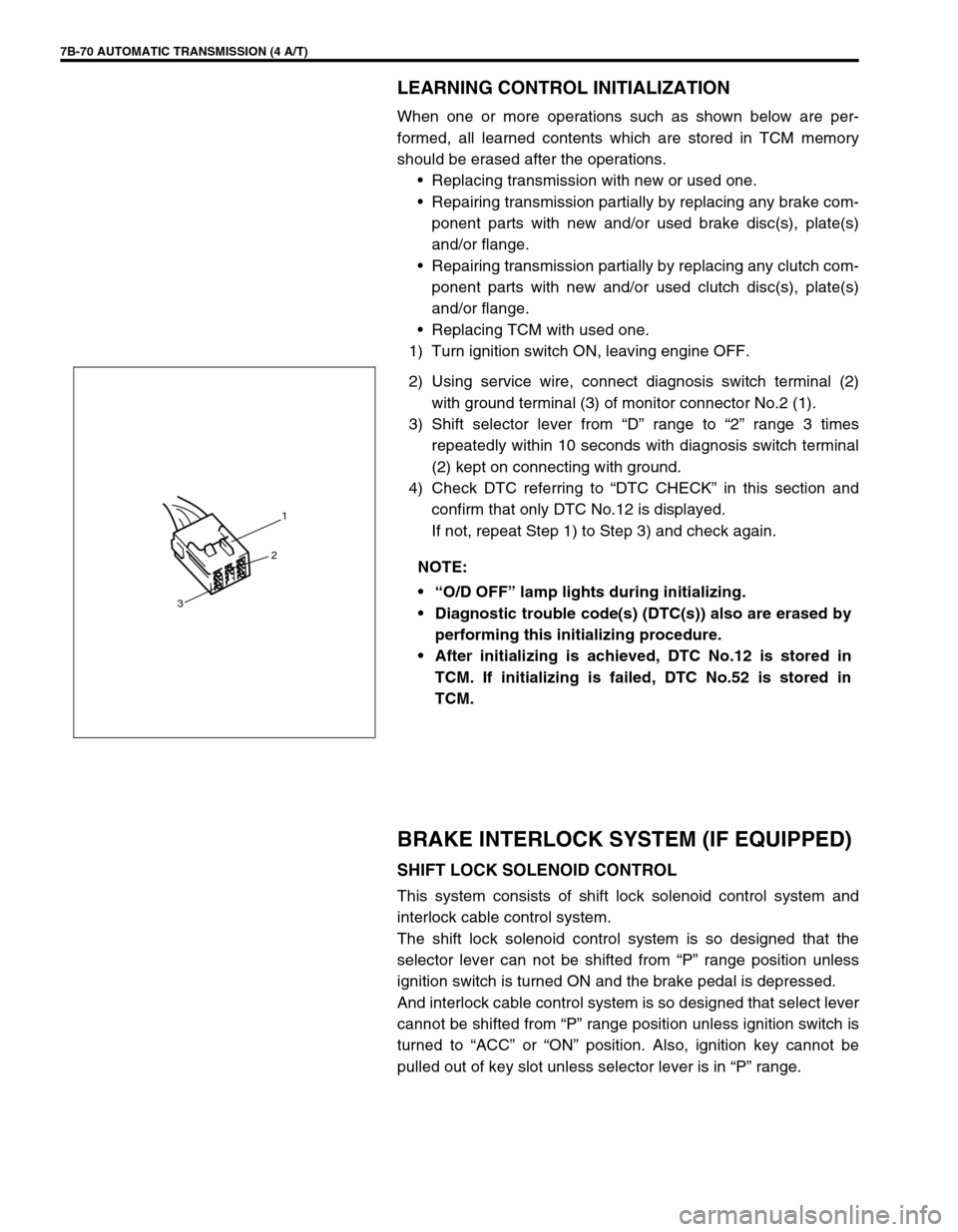

LEARNING CONTROL INITIALIZATION

When one or more operations such as shown below are per-

formed, all learned contents which are stored in TCM memory

should be erased after the operations.

Replacing transmission with new or used one.

Repairing transmission partially by replacing any brake com-

ponent parts with new and/or used brake disc(s), plate(s)

and/or flange.

Repairing transmission partially by replacing any clutch com-

ponent parts with new and/or used clutch disc(s), plate(s)

and/or flange.

Replacing TCM with used one.

1) Turn ignition switch ON, leaving engine OFF.

2) Using service wire, connect diagnosis switch terminal (2)

with ground terminal (3) of monitor connector No.2 (1).

3) Shift selector lever from “D” range to “2” range 3 times

repeatedly within 10 seconds with diagnosis switch terminal

(2) kept on connecting with ground.

4) Check DTC referring to “DTC CHECK” in this section and

confirm that only DTC No.12 is displayed.

If not, repeat Step 1) to Step 3) and check again.

BRAKE INTERLOCK SYSTEM (IF EQUIPPED)

SHIFT LOCK SOLENOID CONTROL

This system consists of shift lock solenoid control system and

interlock cable control system.

The shift lock solenoid control system is so designed that the

selector lever can not be shifted from “P” range position unless

ignition switch is turned ON and the brake pedal is depressed.

And interlock cable control system is so designed that select lever

cannot be shifted from “P” range position unless ignition switch is

turned to “ACC” or “ON” position. Also, ignition key cannot be

pulled out of key slot unless selector lever is in “P” range. NOTE:

“O/D OFF” lamp lights during initializing.

Diagnostic trouble code(s) (DTC(s)) also are erased by

performing this initializing procedure.

After initializing is achieved, DTC No.12 is stored in

TCM. If initializing is failed, DTC No.52 is stored in

TCM.

1

2

3

Page 113 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-71

SHIFT LOCK SOLENOID MANUAL RLEASE

Without using brake pedal, shift lock can be moved by pushing

shift lock solenoid cam (1) with screw driver or like through hole

(2). (To shift selector lever from “P” range to any other position,

turn ignition switch to “ACC” or “ON” position.)

INSPECTION

1) Check to make sure that selector lever cannot be moved to

any other range from “P” range position when ignition switch

key is at “ACC” position, at “LOCK” position (or it is removed

from keyhole of ignition switch) or brake pedal is not

depressed.

2) Shift selector lever to “P” range position, release knob button

and check for the following.

Ignition key can be turned between “LOCK” and “ACC” posi-

tions back and forth and also it can be removed from ignition

switch.

With shift lock solenoid cam (1) moved in arrow direction and

ignition key turned to “ACC” position, selector lever can be

shifted from “P” range position to any other range.

With shift lock solenoid cam moved in arrow direction and

ignition key turned to “LOCK” position, selector lever can not

be shifted from “P” range position to any other range.

1

2

1