ECU SUZUKI SWIFT 2000 1.G Transmission Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 419 of 447

AIR BAG SYSTEM 10B-45

DTC B1071 - INTERNAL SDM FAULT

DTC WILL SET WHEN

An internal SDM fault is detected by SDM.

DTC B1013 – SYSTEM SPECIFICATIONS DIFFERENT FROM SDM SPECIFICA-

TIONS

DTC WILL SET WHEN

Specifications of the air bag system differ from those of SDM.2 1) Inspect front of vehicle and undercarriage

for signs of impact.

Are there signs of impact?Replace components and

perform inspections as

directed in “REPAIRS

AND INSPECTIONS

REQUIRED AFTER AN

ACCIDENT”.Substitute a known-good

SDM and recheck. Step Action Yes No

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

NOTE:

Before executing items below, be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK.

NOTE:

DTC B1071 can never be cleared once it has been set.

Ignition switch OFF.

Replace SDM.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK.

NOTE:

Before executing items below, be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK.

Ignition switch OFF.

Replace SDM.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK.

Page 424 of 447

10B-50 AIR BAG SYSTEM

LIVE (INACTIVATED) SEAT BELT PRETENSIONER

Special care is necessary when handling and storing a live (inac-

tivated) seat belt pretensioners.

Also, when the seat belt pretensioners activate, gas is generated

and the seat belt (1) is retracted into the retractor assembly (2)

quickly.

Note, therefore, that if they activate accidentally, the seat belt pre-

tensioners and other object(s) around them may be thrown

through the air.

Never attempt to disassemble the seat belt pretensioners

(retractor assembly).

If any abnormality is found, be sure to replace it with new

one as an assembly.

When an abnormality is noted as existing in the live (inacti-

vated) seat belt pretensioner, be sure to activate it before

discarding it.

When grease, cleaning agent oil, water, etc., got on the seat

belt pretensioners (retractor assembly), wipe it off immedi-

ately with a dry cloth.

If seat belt pretensioner was dropped from a height of 30 cm

(1 ft) or more, it should be replaced with a new one as an

assembly. WARNING:

When placing a live air bag (inflator) module on bench or

other surface, always face the bag up, away from the sur-

face. As the live passenger air bag (inflator) module must

be placed with its bag (trim cover) facing up, place it on

the workbench with a slit (1) or use the workbench vise

(2) to hold it securely at its lower mounting bracket (3).

It is also prohibited to place anything on top of the trim

cover and stack air bag (inflator) modules.

This is necessary so that a free space is provided to

allow the air bag to expand in the unlikely event of acci-

dental deployment.

Otherwise, personal injury may result.

1

2 3

WARNING:

Never attempt to measure the resistance of the seat belt

pretensioners. It is very dangerous as the electric current

from the tester may activate pretensioner.

Page 426 of 447

10B-52 AIR BAG SYSTEM

AIR BAG WIRE HARNESS AND CONNECTOR

Air bag wire harness (1) can be identified easily as it is covered

with a yellow protection tube. Be very careful when handling it.

When an open in air bag wire harness (1), damaged wire

harness, connector or terminal is found, replace wire har-

ness, connectors and terminals as an assembly.

When installing it, be careful so that the air bag wire harness

(1) is not caught or does not interfere with other parts.

Make sure all air bag system grounding points (2) are clean

and grounds are securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent prob-

lems that are difficult to diagnose.

DISPOSAL

Do not dispose of the live (undeployed) air bag (inflator) modules

and the live (inactivated) seat belt pretensioners. When disposal

is necessary, be sure to deploy/activate the air bag and seat belt

pretensioner according to deployment/activation procedure

described in “AIR BAG (INFLATOR) MODULE AND SEAT BELT

PRETENSIONER DISPOSAL”.

2

1

WARNING:

Failure to follow proper air bag (inflator) module and seat

belt pretensioner disposal procedures can result in air

bag deployment and pretensioner activation which could

cause personal injury. Undeployed air bag (inflator) mod-

ule and inactivated seat belt pretensioner must not be

disposed of through normal refuse channels.

The undeployed air bag (inflator) module and inactivated

seat belt pretensioner contain substances that can cause

severe illness or personal injury if the sealed container is

damaged during disposal.

Page 428 of 447

10B-54 AIR BAG SYSTEM

Steering wheel and driver air bag (inflator) module

–Check for damage or air bag (inflator) module fitness.

–Check trim cover (pad surface) for cracks.

–Check wire harness and connector for damage or tight-

ness.

If any faulty condition is found in above checks, replace faulty

part.

Contact coil and combination switch assembly

–Check wire harness and connectors for damage or tight-

ness.

–Check contact coil case for damage.

If any faulty condition is found in above checks, replace.

SDM and SDM plate

–Check for external damage such as deformation, scratch,

crack, peeled paint, etc.

–Check that SDM cannot be installed properly due to a

cause in itself. (There is a gap between SDM and SDM

plate, or it cannot be fixed securely.)

–Check that connector or lead wire of SDM has a scorching,

melting or damage.

–Check SDM connector and terminals for tightness.

–Check SDM sets a diagnostic trouble code (Refer to “DTC

CHECK”.) and the diagnostic table leads to a malfunction-

ing SDM.

If any faulty condition is found in above checks, replace.

Instrument panel member and reinforcement

–Check for any distortion, bending, cracking or other dam-

age.

If any faulty condition is found in above checks, replace.

Passenger air bag (inflator) module

–Check for dents, cracks, damage or fitness.

–Check trim cover for cracks or deformities.

–Check harness and connector for damage or tightness.

If any faulty condition is found in above checks, replace.

Page 431 of 447

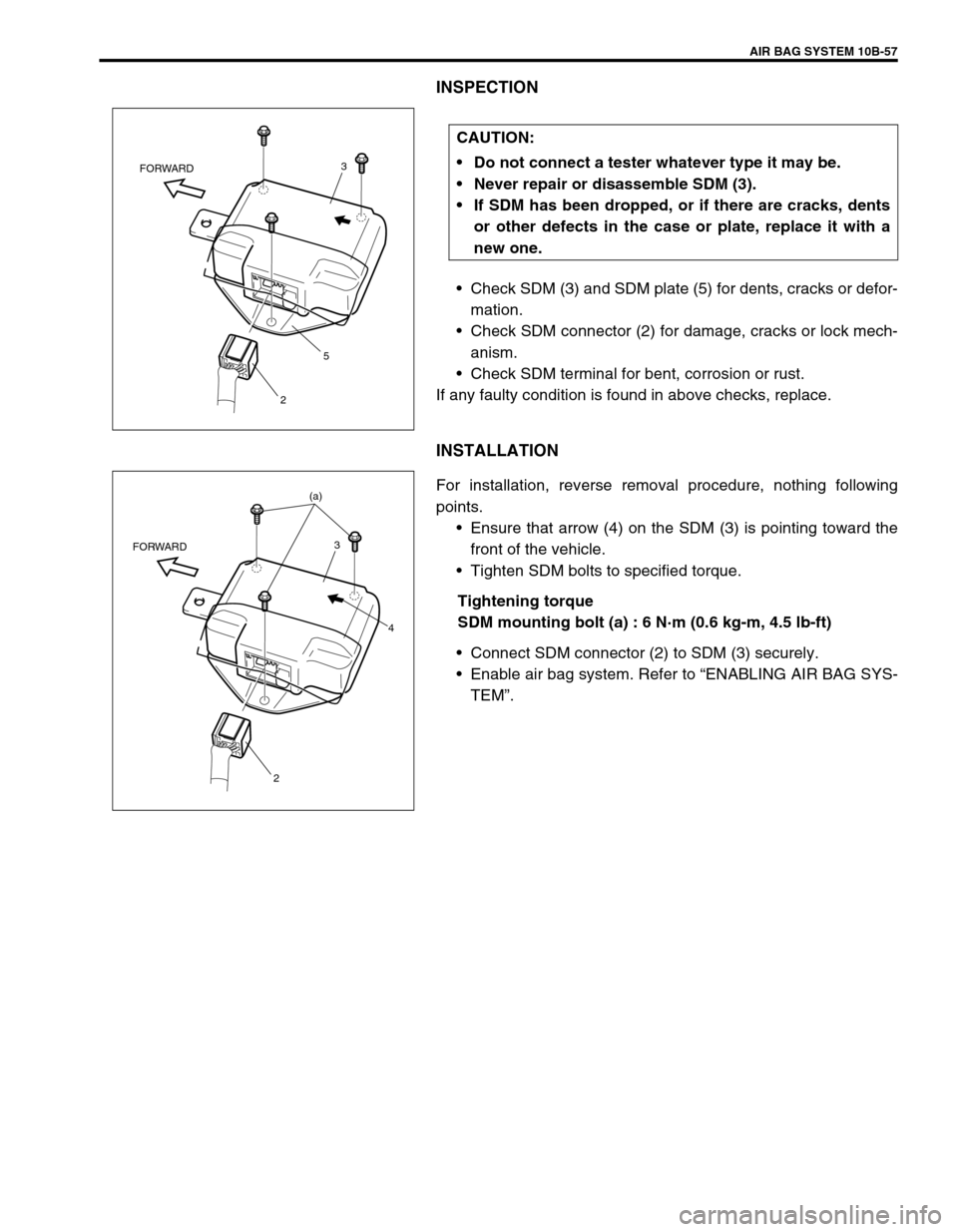

AIR BAG SYSTEM 10B-57

INSPECTION

Check SDM (3) and SDM plate (5) for dents, cracks or defor-

mation.

Check SDM connector (2) for damage, cracks or lock mech-

anism.

Check SDM terminal for bent, corrosion or rust.

If any faulty condition is found in above checks, replace.

INSTALLATION

For installation, reverse removal procedure, nothing following

points.

Ensure that arrow (4) on the SDM (3) is pointing toward the

front of the vehicle.

Tighten SDM bolts to specified torque.

Tightening torque

SDM mounting bolt (a) : 6 N·m (0.6 kg-m, 4.5 lb-ft)

Connect SDM connector (2) to SDM (3) securely.

Enable air bag system. Refer to “ENABLING AIR BAG SYS-

TEM”. CAUTION:

Do not connect a tester whatever type it may be.

Never repair or disassemble SDM (3).

If SDM has been dropped, or if there are cracks, dents

or other defects in the case or plate, replace it with a

new one.

3

5

2 FORWARD

(a)

3

4

2 FORWARD

Page 435 of 447

AIR BAG SYSTEM 10B-61

DEPLOYMENT/ACTIVATION OUTSIDE VEHI-

CLE

Use this procedure when the vehicle itself is used again (only the

air bag (inflator) module(s) and seat belt pretensioner(s) are dis-

posed).

1) Turn ignition switch to “LOCK”, position remove key and put

on safety glasses.

2) Check that there is no open, short or damage in special tool

(deployment harness). If any faulty is found, do not use it

and be sure to use new deployment harness.

Special tool

(A) : 09932-75030

3) Short (1) the two deployment harness leads together by fully

seating one banana plug into the other.

4) Remove air bag (inflator) module(s) and seat belt preten-

sioner(s) from vehicle, referring to SECTION 3C, 10B and

10. WARNING:

Deployment harness shall remain shorted and not be

connected to a power source until the air bag is to be

deployed and seat belt pretensioner is to be activated.

WARNING:

Always carry live air bag (inflator) module with trim

cover away from you.

When storing a live air bag (inflator) module or when

leaving a live air bag (inflator) module unattended on a

bench or other surface, always face the bag and trim

cover up and away from the surface. As the live pas-

senger air bag (inflator) module must be placed with its

bag (trim cover) facing up, place it on the workbench

with a slit (1) or use the workbench vise (2) to hold it

securely at its lower mounting bracket (3).

This is necessary so that a free space is provided to

allow the air bag to expand in the unlikely event of

accidental deployment.

Failure to follow procedures may result in personal

injury.

1

3

32

Page 437 of 447

AIR BAG SYSTEM 10B-63

c) Fill plastic reservoir in fixture (special tool) with water or

sand. This is necessary to provide sufficient stabilization of

the fixture during deployment.

d) Attach the passenger air bag (inflator) module in the fixture

(special tool) using mounting attachment, hold-down bolts

and nuts and M8 bolts and nuts (3).

Securely hand-tighten all fastener prior to deployment.

[In case of seat belt pretensioner]

a) Pull out the webbing (2) fully as shown in the figure and cut

it at the root of the pretensioner (retractor assembly) (1) as

shown in the figure.

b) Clear a space on the ground about 185 cm (6 ft) (4) in

diameter where the seat belt pretensioner (retractor assem-

bly) (1) is to be activated. A paved, outdoor location where

there is no activity is preferred. If an outdoor location is not

available, a space on the shop floor where there is no activ-

ity and sufficient ventilation is recommended.

Ensure no loose or flammable objects are within the activa-

tion area.

c) Place the seat belt pretensioner (retractor assembly) (1) as

shown in the figure on the ground in the space just cleared. CAUTION:

Be sure to use the following bolt and nut for fixing

passenger air bag (inflator) module to mounting

attachment.

Size : M8, Strength : 7T

WARNING:

As the drum (3) of the retractor assembly (1) turns very

quickly as soon as the webbing (2) is cut, fix the retractor

assembly (1) with a vise on the workbench and keep your

hands and fingers away from it when cutting the webbing

(2).

Page 438 of 447

10B-64 AIR BAG SYSTEM

6) Stretch the deployment harness from the driver or passen-

ger air bag (inflator) module to its full length 10 m (33 ft) (1).

Special tool

(A) : 09932-75030

7) Place a power source (3) near the shorted end of the deploy-

ment harness. Recommended application: 12 Volts mini-

mum, 2 amps minimum. A vehicle battery is suggested.

8) Verify that the area around the air bag (inflator) module or

seat belt pretensioner is clear of all people and loose or flam-

mable objects.

9) Verify setting condition of air bag (inflator) module or preten-

sioner as follows.

[In case of driver air bag (inflater) module]

Verify that the driver air bag (inflator) module is resting with

its vinyl trim cover facing up.

[In case of passenger air bag (inflator) module]

Verify that the passenger air bag (inflator) module is firmly

and properly secured in passenger air bag (inflator) module

deployment fixture (special tool).

[In case of seat belt pretensioner]

Verify that the seat belt pretensioner, is placed as shown in

the figure on the ground in the space just cleared.

10) Connect (2) the air bag (inflator) module or seat belt preten-

sioner to the deployment harness connector and lock con-

nector with lock lever.

11) Notify all people in the immediate area that you intend to

deploy/activate the air bag (inflator) module or seat belt pre-

tensioner.

NOTE:

When the air bag deploys and the pretensioner acti-

vates, the rapid gas expansion will create a substantial

report. Wear suitable ear protection. Notify all people

in the immediate area that you intend to deploy the air

bag (inflator) module or activate the seat belt preten-

sioner and suitable ear protection should be worn.

When the driver air bag deploys and the pretensioner

activates, driver air bag (inflator) module and preten-

sioner (retractor assembly) may jump about 30 cm (1

ft) vertically. This is a normal reaction of them to the

force of the rapid gas expansion inside the air bag and

pretensioner.

After the air bag (inflator) module has been deployed,

the surface of the air bag may contain a powdery resi-

due. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-prod-

ucts of the chemical reaction.

Page 441 of 447

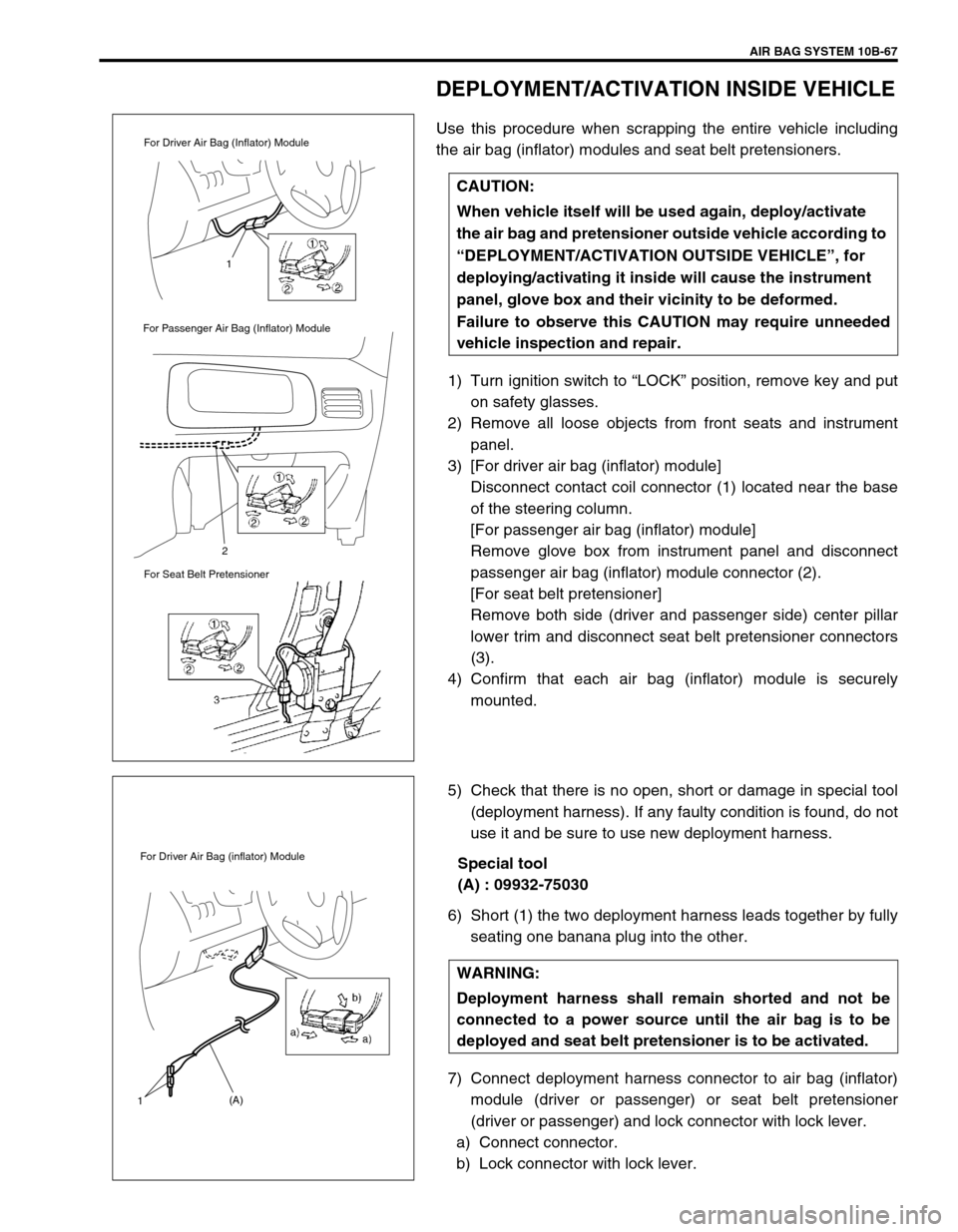

AIR BAG SYSTEM 10B-67

DEPLOYMENT/ACTIVATION INSIDE VEHICLE

Use this procedure when scrapping the entire vehicle including

the air bag (inflator) modules and seat belt pretensioners.

1) Turn ignition switch to “LOCK” position, remove key and put

on safety glasses.

2) Remove all loose objects from front seats and instrument

panel.

3) [For driver air bag (inflator) module]

Disconnect contact coil connector (1) located near the base

of the steering column.

[For passenger air bag (inflator) module]

Remove glove box from instrument panel and disconnect

passenger air bag (inflator) module connector (2).

[For seat belt pretensioner]

Remove both side (driver and passenger side) center pillar

lower trim and disconnect seat belt pretensioner connectors

(3).

4) Confirm that each air bag (inflator) module is securely

mounted.

5) Check that there is no open, short or damage in special tool

(deployment harness). If any faulty condition is found, do not

use it and be sure to use new deployment harness.

Special tool

(A) : 09932-75030

6) Short (1) the two deployment harness leads together by fully

seating one banana plug into the other.

7) Connect deployment harness connector to air bag (inflator)

module (driver or passenger) or seat belt pretensioner

(driver or passenger) and lock connector with lock lever.

a) Connect connector.

b) Lock connector with lock lever.CAUTION:

When vehicle itself will be used again, deploy/activate

the air bag and pretensioner outside vehicle according to

“DEPLOYMENT/ACTIVATION OUTSIDE VEHICLE”, for

deploying/activating it inside will cause the instrument

panel, glove box and their vicinity to be deformed.

Failure to observe this CAUTION may require unneeded

vehicle inspection and repair.

1

2

For Driver Air Bag (Inflator) Module

For Passenger Air Bag (Inflator) Module

For Seat Belt Pretensioner

WARNING:

Deployment harness shall remain shorted and not be

connected to a power source until the air bag is to be

deployed and seat belt pretensioner is to be activated.

(A)

1

For Driver Air Bag (inflator) Module