glove box SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 49 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-7

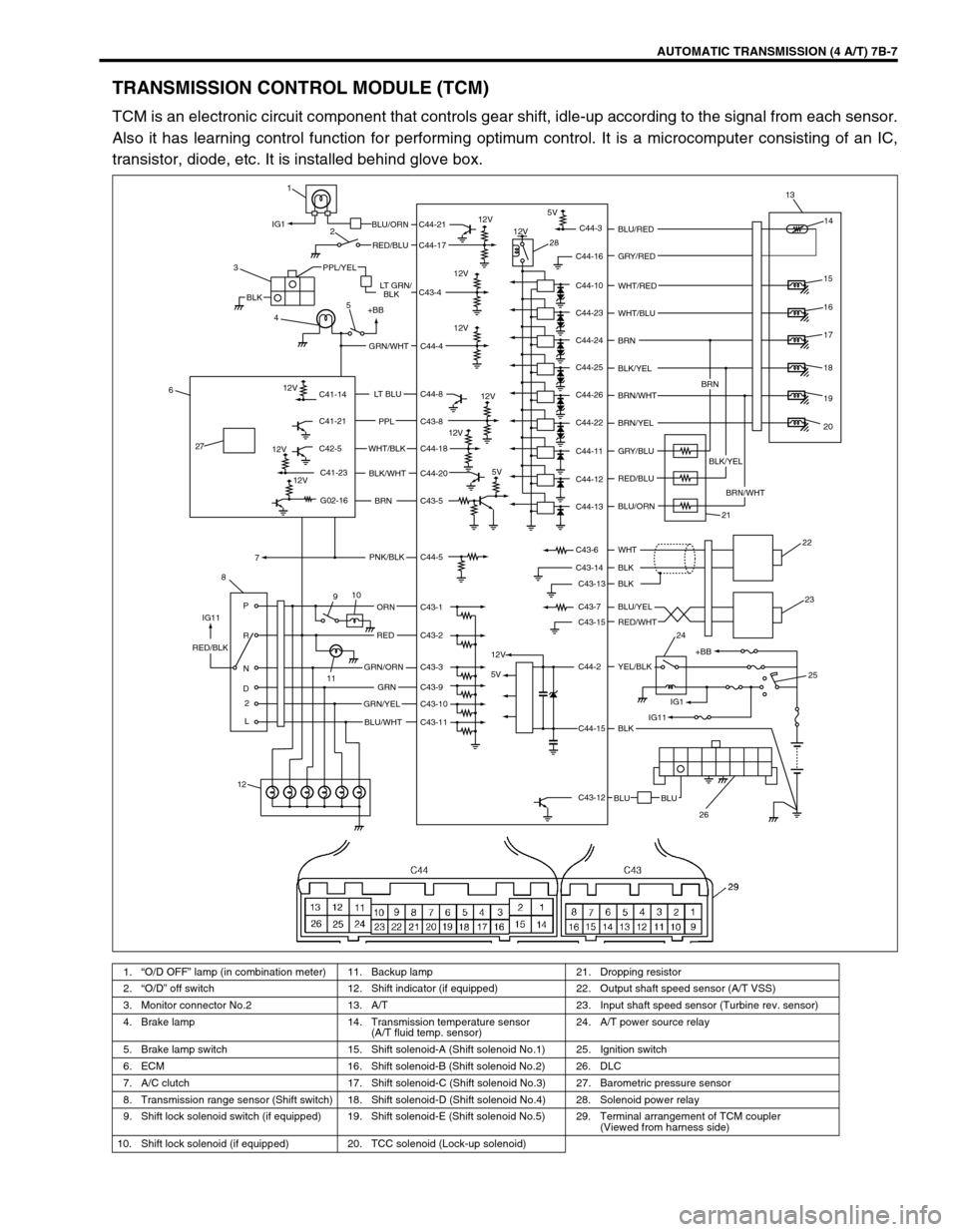

TRANSMISSION CONTROL MODULE (TCM)

TCM is an electronic circuit component that controls gear shift, idle-up according to the signal from each sensor.

Also it has learning control function for performing optimum control. It is a microcomputer consisting of an IC,

transistor, diode, etc. It is installed behind glove box.

1.“O/D OFF” lamp (in combination meter) 11. Backup lamp 21. Dropping resistor

2.“O/D” off switch 12. Shift indicator (if equipped) 22. Output shaft speed sensor (A/T VSS)

3. Monitor connector No.2 13. A/T 23. Input shaft speed sensor (Turbine rev. sensor)

4. Brake lamp 14. Transmission temperature sensor

(A/T fluid temp. sensor)24. A/T power source relay

5. Brake lamp switch 15. Shift solenoid-A (Shift solenoid No.1) 25. Ignition switch

6. ECM 16. Shift solenoid-B (Shift solenoid No.2) 26. DLC

7. A/C clutch 17. Shift solenoid-C (Shift solenoid No.3) 27. Barometric pressure sensor

8. Transmission range sensor (Shift switch) 18. Shift solenoid-D (Shift solenoid No.4) 28. Solenoid power relay

9. Shift lock solenoid switch (if equipped) 19. Shift solenoid-E (Shift solenoid No.5) 29. Terminal arrangement of TCM coupler

(Viewed from harness side)

10. Shift lock solenoid (if equipped) 20. TCC solenoid (Lock-up solenoid)

C41-14

C41-21

C42-5

C41-23

G02-16

BLKBLKLT GRN/ RED/BLU BLU/ORN

PPL/YEL

3

45

+BB

GRN/WHT

LT BLU

PPL

WHT/BLK

BLK/WHT

BRN

PNK/BLK 6

7

8

C44-8

C43-8

C44-18

C44-20

C43-5

C44-5

910

ORN

RED

GRN/ORN RED/BLK

GRNC43-1

C43-2

C43-3

C43-9

C43-10

C43-11 GRN/YEL

BLU/WHT P

R

N

D

2

L11

12C44-21

C44-17

C43-4

C44-4

12V 12V

12V

12V

12V IG1

IG115V

5VC44-3

C44-16

C44-10

C44-23

C44-24

C44-25

C44-26

C44-22

C44-11

C44-12

C44-13

C43-6

C43-14

C43-13

C43-7

C43-15

C44-2

C44-15

C43-12

BLU BLUBLK

BLK BLK

BLU/YEL

YEL/BLK RED/WHT WHT BLU/ORN RED/BLU GRY/BLU

BLK/YEL WHT/BLU

BRN/WHT BRN/WHT BRN WHT/RED

BLK/YEL

BRN/YEL BLU/RED

GRY/RED13

14

15

16

17

19

20 BRN

21

22

23

+BB 24

25

26

12V

12V

12V

12V

18

12V

IG1

IG11

5V

1

2

28

27

Page 67 of 447

![SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual AUTOMATIC TRANSMISSION (4 A/T) 7B-25

[INTERMITTENT TROUBLES] and [NOTES ON SYSTEM CIR-

CUIT INSPECTION]

Refer to Section 0A.

DTC CHECK

[Check DTC with SUZUKI scan tool]

1) Turn ignition switch OFF.

2) SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual AUTOMATIC TRANSMISSION (4 A/T) 7B-25

[INTERMITTENT TROUBLES] and [NOTES ON SYSTEM CIR-

CUIT INSPECTION]

Refer to Section 0A.

DTC CHECK

[Check DTC with SUZUKI scan tool]

1) Turn ignition switch OFF.

2)](/img/20/7605/w960_7605-66.png)

AUTOMATIC TRANSMISSION (4 A/T) 7B-25

[INTERMITTENT TROUBLES] and [NOTES ON SYSTEM CIR-

CUIT INSPECTION]

Refer to Section 0A.

DTC CHECK

[Check DTC with SUZUKI scan tool]

1) Turn ignition switch OFF.

2) After setting cartridge, connect SUZUKI scan tool to data link

connector (DLC) (1) located on underside of instrument

panel at driver’s seat side.

Special tool

(A) : 09931-76011 (SUZUKI scan tool)

(B) : Mass storage cartridge

(C) : 09931-76030 (16/14 pin DLC cable)

3) Turn ignition switch ON.

4) Read DTC according to instructions displayed on SUZUKI

scan tool and print it or write it down. Refer to SUZUKI scan

tool operator’s manual for further details.

5) After completing the check, turn ignition switch OFF and dis-

connect SUZUKI scan tool from data link connector (DLC)

(1).

[Check DTC without SUZUKI scan tool]

1) Turn ignition switch ON and make sure that O/D OFF lamp is

OFF in combination meter (O/D off switch OFF).

2) Turn ignition switch OFF.

3) Pull out clip (3) and remove glove box (2) from instrument

panel (1).

Page 342 of 447

9-38 BODY SERVICE

INSTRUMENTATION AND DRIVER INFORMATION

INSTRUMENT PANEL

REMOVAL

1) Disconnect negative cable at battery.

2) Disable air bag system, if equipped. Refer to “DISABLE AIR

BAG SYSTEM” in Section 10B.

3) Remove steering column hole cover (1).

4) Remove glove box (1) and food latch release lever (2).

5) Disconnect instrument panel harness connectors, antenna

and heater control cables which need to be disconnected for

removal for instrument panel.

6) Remove instrument panel ground wire.

7) Remove steering column assembly referring to “STEERING

COLUMN ASSEMBLY” in Section 3C.

8) Remove front pillar trims (1) and dash side trims (2).

9) Remove speaker covers (3).WARNING:

See WARNING at the beginning of this section.

“A”

“A”“A”

“A”

“A”

1

2“A” 1

3

“A”

Page 398 of 447

10B-24 AIR BAG SYSTEM

DIAGNOSTIC FLOW TABLE

DTC B1015 :

Fig. for STEP 1 and 2

Fig. for STEP 2

Special tool

(A) : 09932-76010

(B) : 09932-75010 Step Action Yes No

1 1) With ignition switch OFF, disconnect passenger air

bag (inflator) module connector behind the glove box.

2) Check proper connection to passenger air bag (infla-

tor) module at terminals in “Q03” connector.

3) If OK then connect Special Tool (B) to passenger air

bag (inflator) module connector disconnected at the

step 1).

With ignition switch ON, is DTC B1015 current?Go to step 2. Ignition switch OFF.

Replace passenger air

bag (inflator) module

(Refer to PASSENGER

AIR BAG (INFLATOR)

MODULE in this sec-

tion).

2 1) With ignition switch OFF, disconnect SDM.

2) Check proper connection to SDM at terminals “Q06-7”

and “Q06-8”.

3) If OK then measure resistance between “Q06-7” and

“Q06-8” terminals with connected Special Tool (B).

Is resistance 4.5 Ω or less?Substitute a

known-good SDM

and recheck.Repair high resistance

or open in “YEL/RED” or

“BLU/RED” wire circuit.

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Clear diagnostic trouble codes (Refer to DTC CLEARANCE), if any.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Page 399 of 447

AIR BAG SYSTEM 10B-25

DTC B1016:

Fig. for STEP 1 and 2

Fig. for STEP 2

Special tool

(A) : 09932-76010

(B) : 09932-75010 Step Action Yes No

1 1) With ignition switch OFF, disconnect passenger air

bag (inflator) module connector behind the glove box.

2) Check proper connection to passenger air bag (infla-

tor) module at terminals in “Q03” connector.

3) If OK then connect Special Tool (B) to passenger air

bag (inflator) module connector disconnected at the

step 1).

With ignition switch ON, is DTC B1016 current?Go to step 2. Ignition switch OFF.

Replace passenger air

bag (inflator) module

(Refer to PASSENGER

AIR BAG (INFLATOR)

MODULE in this section).

2 1) With ignition switch OFF, disconnect SDM.

2) Check proper connection to SDM at terminals “Q06-7”

and “Q06-8”.

3) If OK then measure resistance between “Q06-7” and

“Q06-8” terminals with connected Special Tool (B).

Is resistance 1.4 Ω or more?Substitute a

known-good

SDM and

recheck.Repair short from “YEL/

RED” wire circuit to “BLU/

RED” wire circuit or from

“YEL/RED” or “BLU/RED”

wire circuit to other wire

circuit.

NOTE:

Upon completion of inspection and repair work, perform following items.

1) Reconnect all air bag system components, ensure all components are properly mounted.

2) Clear diagnostic trouble codes (Refer to DTC CLEARANCE), if any.

3) Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Page 400 of 447

10B-26 AIR BAG SYSTEM

DTC B1018:

Fig. for STEP 1, 2 and 3

Fig. for STEP 2Step Action Yes No

1 1) With ignition switch OFF, disconnect passenger air

bag (inflator) module connector behind the glove box.

2) Check proper connection to passenger air bag (infla-

tor) module at terminals in “Q03” connector.

3) If OK then connect Special Tool (B) to passenger air

bag (inflator) module connector disconnected at the

step 1).

With ignition switch ON, is DTC B1018 current?Go to step 2. Ignition switch OFF.

Replace passenger air

bag (inflator) module

(Refer to PASSENGER

AIR BAG (INFLATOR)

MODULE in this section).

2 1) With ignition switch OFF, disconnect Special Tool (B)

and SDM.

2) Measure resistance between “Q06-7” terminals and

body ground.

Is resistance 10 W or more?Go to step 3. Repair short from “BLU/

RED” wire circuit to

ground.

3 1) Measure resistance between “Q06-8” terminal and

body ground.

Is resistance 10 Ω or more?Substitute a

known-good

SDM and

recheck.Repair short from “YEL/

RED” wire circuit to

ground.

Page 401 of 447

AIR BAG SYSTEM 10B-27

Fig. for STEP 3

Special tool

(A) : 09932-76010

(B) : 09932-75010

DTC B1019:

Fig. for STEP 1, 2 and 3

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Clear diagnostic trouble codes (Refer to DTC CLEARANCE), if any.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Step Action Yes No

1 1) With ignition switch OFF, disconnect passenger

air bag (inflator) module connector behind the

glove box.

2) Check proper connection to passenger air bag

(inflator) module at terminals in “Q03” connector.

3) If OK then connect Special Tool (B) to passenger

air bag (inflator) module connector disconnected

at the step 1).

With ignition switch ON, is DTC B1019 current?Go to step 2. Ignition switch OFF.

Replace passenger air

bag (inflator) module

(Refer to PASSENGER

AIR BAG (INFLATOR)

MODULE in this section).

2 1) With ignition switch OFF, disconnect Special Tool

(B) and SDM.

2) Measure voltage from “Q06-7” terminal to body

ground.

With ignition switch ON, is voltage 1 V or less?Go to step 3. Repair short from “BLU/

RED” wire circuit to power

circuit.

3 1) Measure voltage from “Q06-8” terminal to body

ground.

With ignition switch ON, is voltage 1 V or less?Substitute a known-

good SDM and

recheck.Repair short from “YEL/

RED” wire circuit to power

circuit.

Page 421 of 447

AIR BAG SYSTEM 10B-47

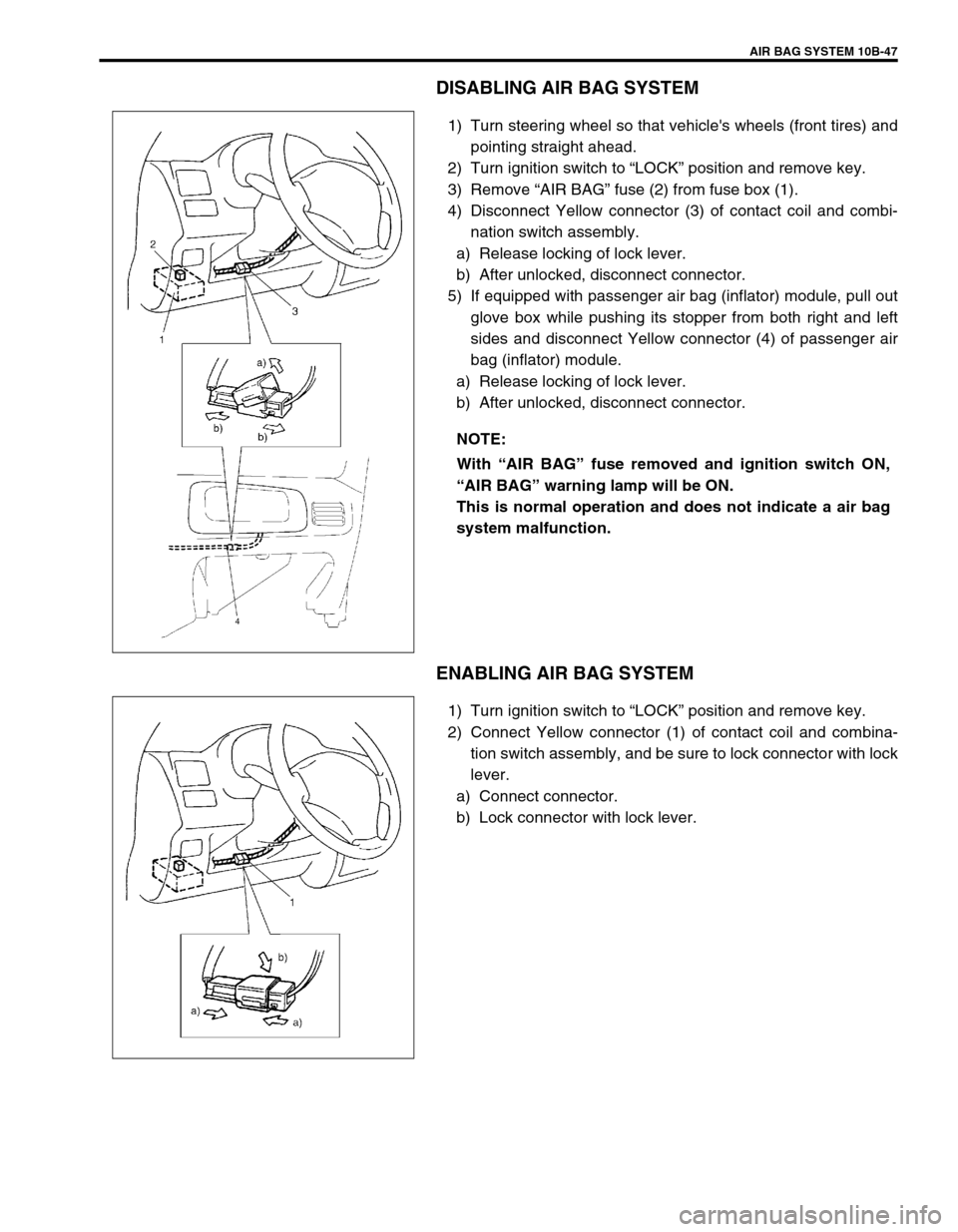

DISABLING AIR BAG SYSTEM

1) Turn steering wheel so that vehicle's wheels (front tires) and

pointing straight ahead.

2) Turn ignition switch to “LOCK” position and remove key.

3) Remove “AIR BAG” fuse (2) from fuse box (1).

4) Disconnect Yellow connector (3) of contact coil and combi-

nation switch assembly.

a) Release locking of lock lever.

b) After unlocked, disconnect connector.

5) If equipped with passenger air bag (inflator) module, pull out

glove box while pushing its stopper from both right and left

sides and disconnect Yellow connector (4) of passenger air

bag (inflator) module.

a) Release locking of lock lever.

b) After unlocked, disconnect connector.

ENABLING AIR BAG SYSTEM

1) Turn ignition switch to “LOCK” position and remove key.

2) Connect Yellow connector (1) of contact coil and combina-

tion switch assembly, and be sure to lock connector with lock

lever.

a) Connect connector.

b) Lock connector with lock lever.NOTE:

With “AIR BAG” fuse removed and ignition switch ON,

“AIR BAG” warning lamp will be ON.

This is normal operation and does not indicate a air bag

system malfunction.

Page 422 of 447

10B-48 AIR BAG SYSTEM

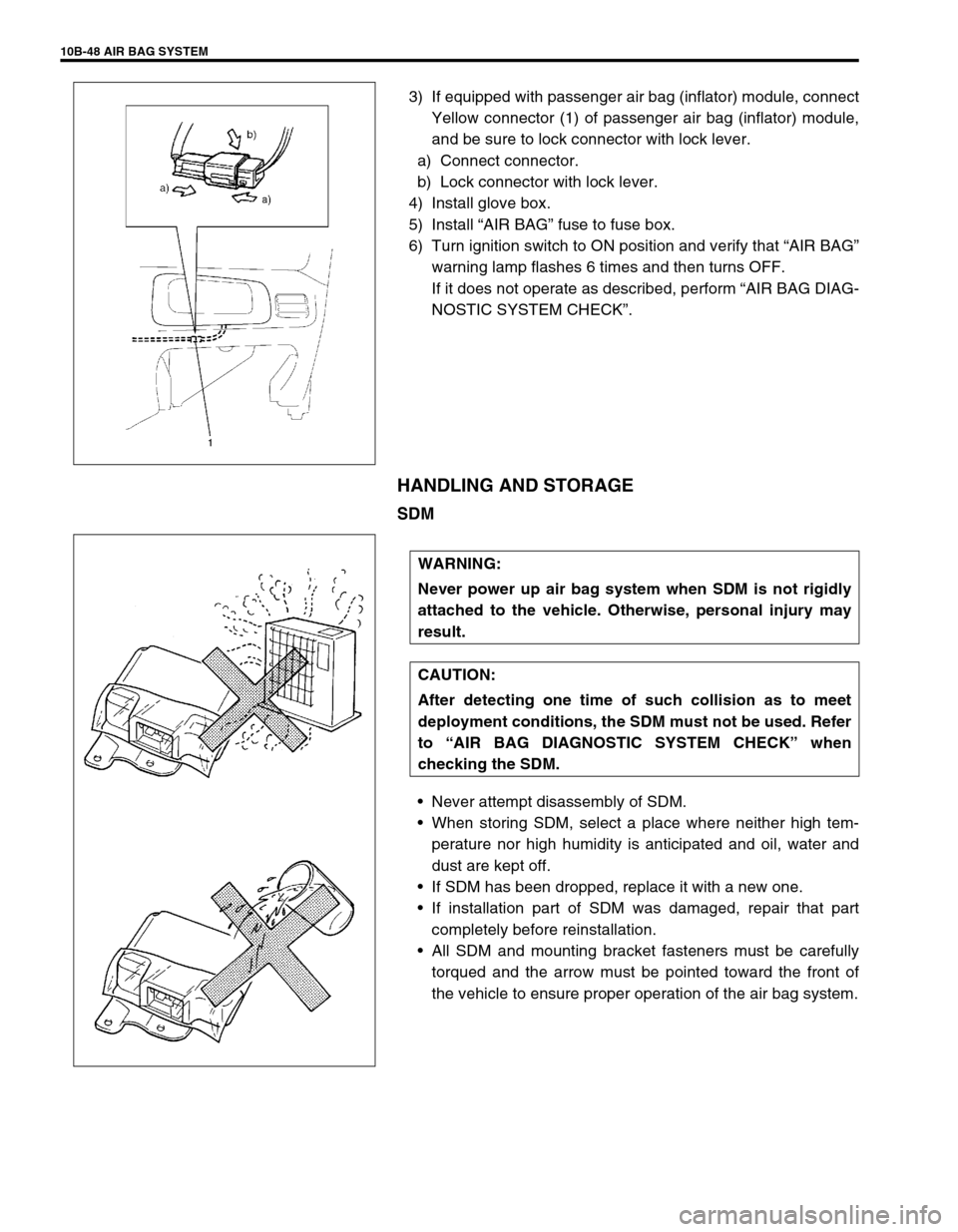

3) If equipped with passenger air bag (inflator) module, connect

Yellow connector (1) of passenger air bag (inflator) module,

and be sure to lock connector with lock lever.

a) Connect connector.

b) Lock connector with lock lever.

4) Install glove box.

5) Install “AIR BAG” fuse to fuse box.

6) Turn ignition switch to ON position and verify that “AIR BAG”

warning lamp flashes 6 times and then turns OFF.

If it does not operate as described, perform “AIR BAG DIAG-

NOSTIC SYSTEM CHECK”.

HANDLING AND STORAGE

SDM

Never attempt disassembly of SDM.

When storing SDM, select a place where neither high tem-

perature nor high humidity is anticipated and oil, water and

dust are kept off.

If SDM has been dropped, replace it with a new one.

If installation part of SDM was damaged, repair that part

completely before reinstallation.

All SDM and mounting bracket fasteners must be carefully

torqued and the arrow must be pointed toward the front of

the vehicle to ensure proper operation of the air bag system.

WARNING:

Never power up air bag system when SDM is not rigidly

attached to the vehicle. Otherwise, personal injury may

result.

CAUTION:

After detecting one time of such collision as to meet

deployment conditions, the SDM must not be used. Refer

to “AIR BAG DIAGNOSTIC SYSTEM CHECK” when

checking the SDM.

Page 432 of 447

10B-58 AIR BAG SYSTEM

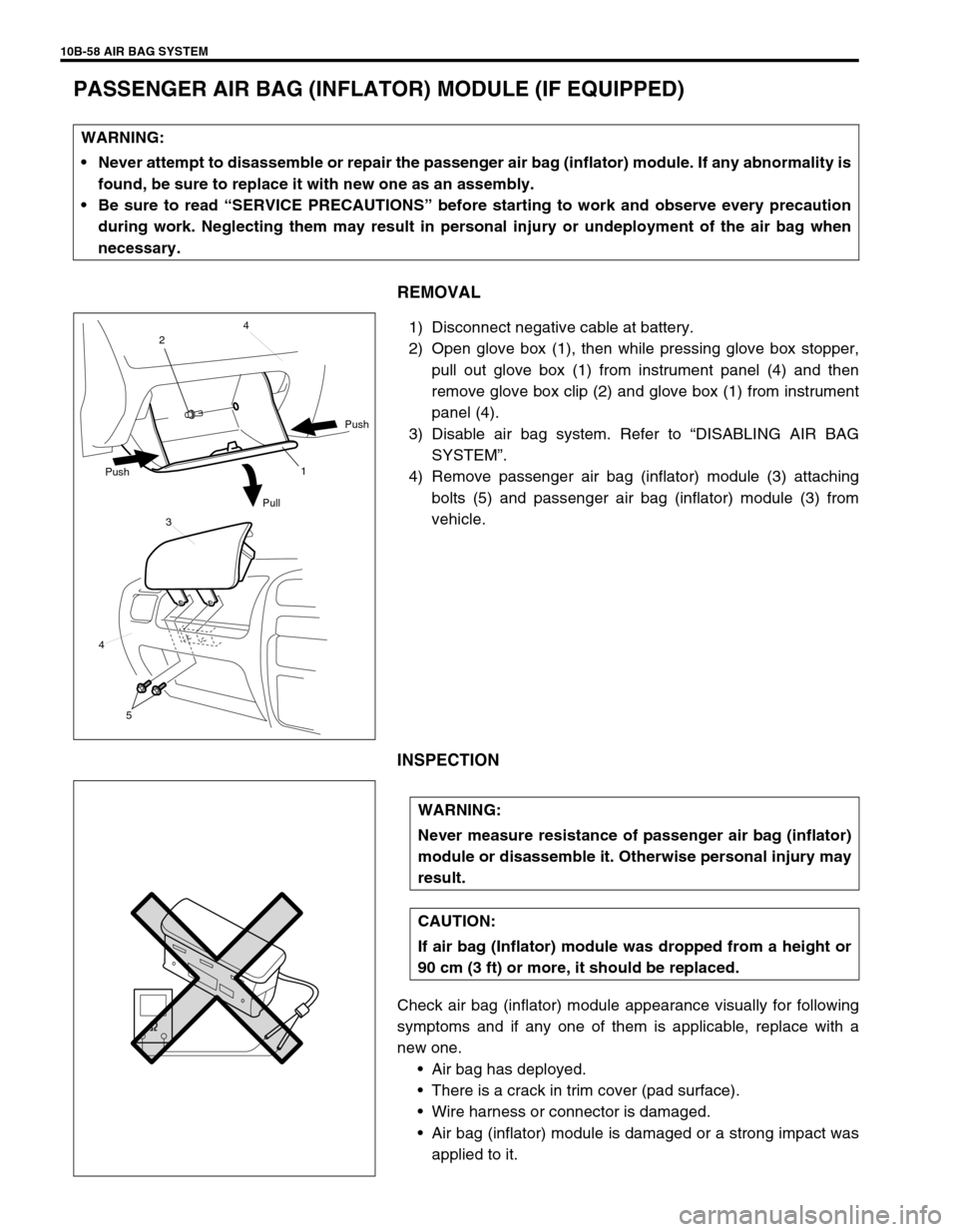

PASSENGER AIR BAG (INFLATOR) MODULE (IF EQUIPPED)

REMOVAL

1) Disconnect negative cable at battery.

2) Open glove box (1), then while pressing glove box stopper,

pull out glove box (1) from instrument panel (4) and then

remove glove box clip (2) and glove box (1) from instrument

panel (4).

3) Disable air bag system. Refer to “DISABLING AIR BAG

SYSTEM”.

4) Remove passenger air bag (inflator) module (3) attaching

bolts (5) and passenger air bag (inflator) module (3) from

vehicle.

INSPECTION

Check air bag (inflator) module appearance visually for following

symptoms and if any one of them is applicable, replace with a

new one.

Air bag has deployed.

There is a crack in trim cover (pad surface).

Wire harness or connector is damaged.

Air bag (inflator) module is damaged or a strong impact was

applied to it. WARNING:

Never attempt to disassemble or repair the passenger air bag (inflator) module. If any abnormality is

found, be sure to replace it with new one as an assembly.

Be sure to read “SERVICE PRECAUTIONS” before starting to work and observe every precaution

during work. Neglecting them may result in personal injury or undeployment of the air bag when

necessary.

1 24

Push

Pull Push

3

4

5

WARNING:

Never measure resistance of passenger air bag (inflator)

module or disassemble it. Otherwise personal injury may

result.

CAUTION:

If air bag (Inflator) module was dropped from a height or

90 cm (3 ft) or more, it should be replaced.