low battery SUZUKI SWIFT 2004 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2004, Model line: SWIFT, Model: SUZUKI SWIFT 2004 2.GPages: 1496, PDF Size: 34.44 MB

Page 1314 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-19 Instrumentation / Driver Info. / Horn:

Installation

Reverse removal procedure noting the following.

• When installing each part, be careful not to catch any

cable or wiring harness.

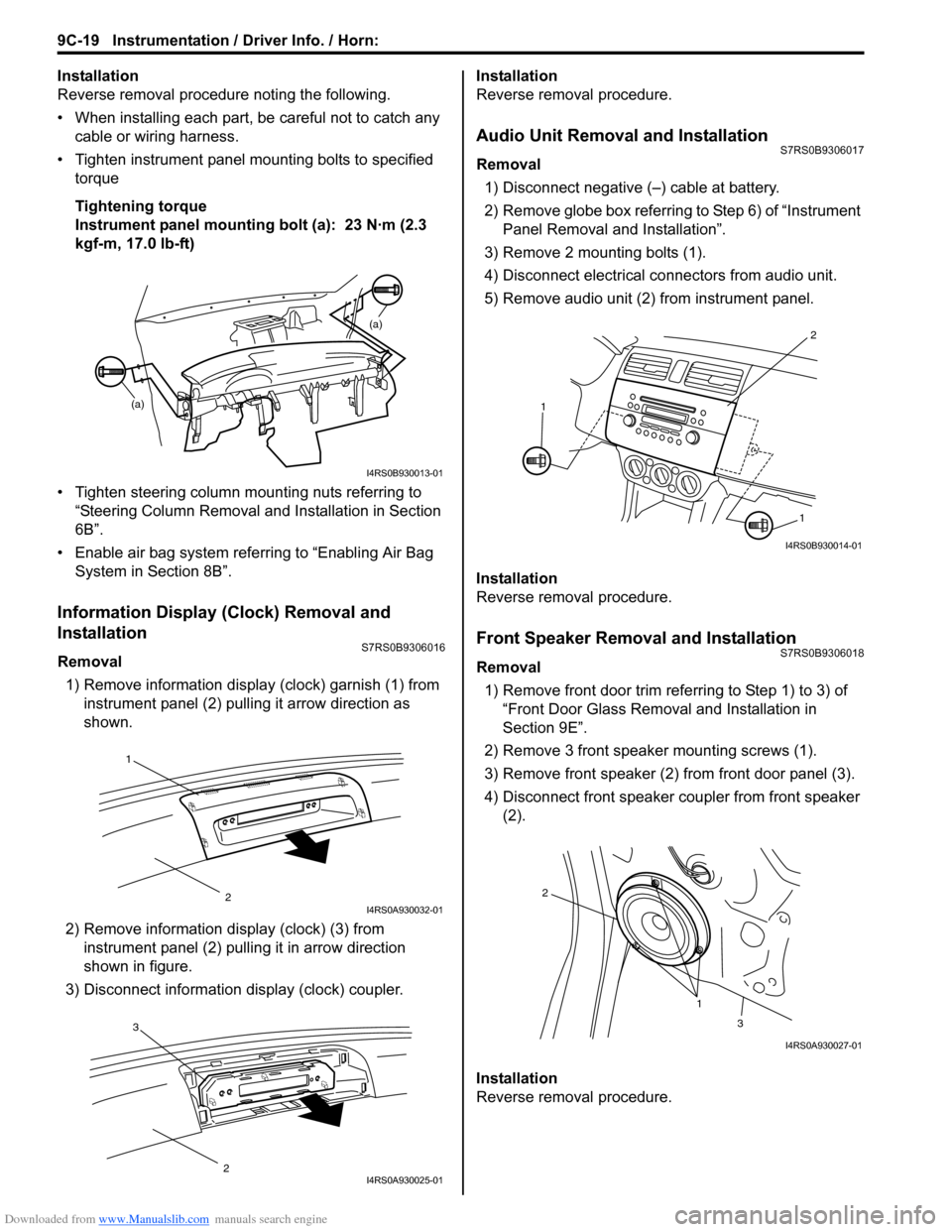

• Tighten instrument panel mounting bolts to specified

torque

Tightening torque

Instrument panel mounting bolt (a): 23 N·m (2.3

kgf-m, 17.0 lb-ft)

• Tighten steering column mounting nuts referring to “Steering Column Removal an d Installation in Section

6B”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Information Display (Clock) Removal and

Installation

S7RS0B9306016

Removal

1) Remove information display (clock) garnish (1) from instrument panel (2) pulling it arrow direction as

shown.

2) Remove information di splay (clock) (3) from

instrument panel (2) pulli ng it in arrow direction

shown in figure.

3) Disconnect information display (clock) coupler. Installation

Reverse removal procedure.

Audio Unit Removal and InstallationS7RS0B9306017

Removal

1) Disconnect negative (–) cable at battery.

2) Remove globe box referring to Step 6) of “Instrument Panel Removal and Installation”.

3) Remove 2 mounting bolts (1).

4) Disconnect electrical connectors from audio unit.

5) Remove audio unit (2) from instrument panel.

Installation

Reverse removal procedure.

Front Speaker Removal and InstallationS7RS0B9306018

Removal 1) Remove front door trim refe rring to Step 1) to 3) of

“Front Door Glass Remo val and Installation in

Section 9E”.

2) Remove 3 front speaker mounting screws (1).

3) Remove front speaker (2) from front door panel (3).

4) Disconnect front speaker coupler from front speaker (2).

Installation

Reverse removal procedure.

(a) (a)

I4RS0B930013-01

1

2I4RS0A930032-01

3

2I4RS0A930025-01

2

1

1

I4RS0B930014-01

1

2

3

I4RS0A930027-01

Page 1320 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-3 Wipers / Washers:

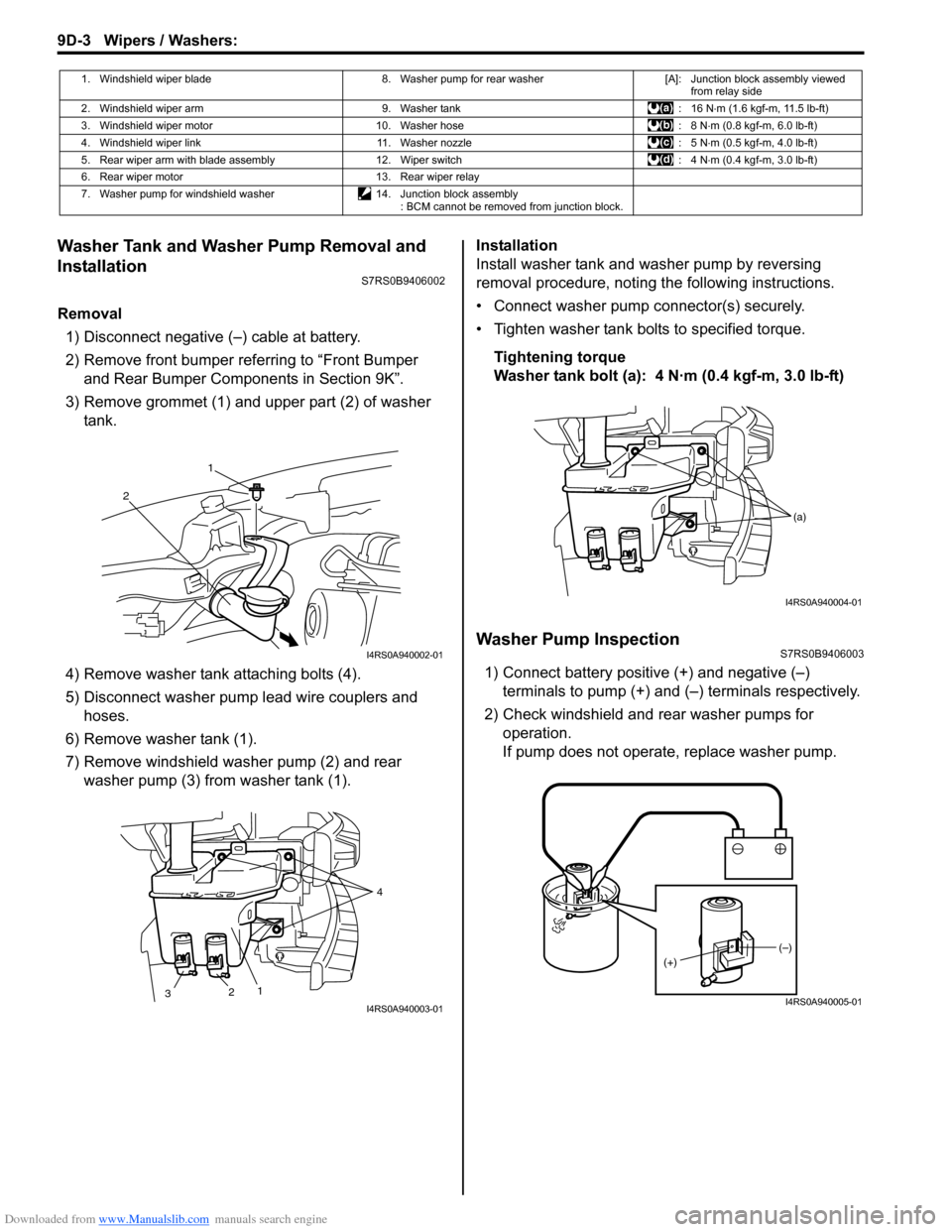

Washer Tank and Washer Pump Removal and

Installation

S7RS0B9406002

Removal1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Remove grommet (1) and upper part (2) of washer tank.

4) Remove washer tank attaching bolts (4).

5) Disconnect washer pump lead wire couplers and hoses.

6) Remove washer tank (1).

7) Remove windshield washer pump (2) and rear washer pump (3) from washer tank (1). Installation

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) securely.

• Tighten washer tank bolts to specified torque.

Tightening torque

Washer tank bolt (a): 4 N·m (0.4 kgf-m, 3.0 lb-ft)

Washer Pump InspectionS7RS0B9406003

1) Connect battery positive (+) and negative (–) terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

1. Windshield wiper blade 8. Washer pump for rear washer[A]: Junction block assembly viewed

from relay side

2. Windshield wiper arm 9. Washer tank: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Windshield wiper motor 10. Washer hose : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

4. Windshield wiper link 11. Washer nozzle : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

5. Rear wiper arm with blade assembly 12. Wiper switch : 4 N⋅m (0.4 kgf-m, 3.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay

7. Washer pump for windshield washer 14. Junction block assembly

: BCM cannot be removed from junction block.

1

2

I4RS0A940002-01

2 1 4

3

I4RS0A940003-01

(a)

I4RS0A940004-01

(–)

(+)

I4RS0A940005-01

Page 1322 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-5 Wipers / Washers:

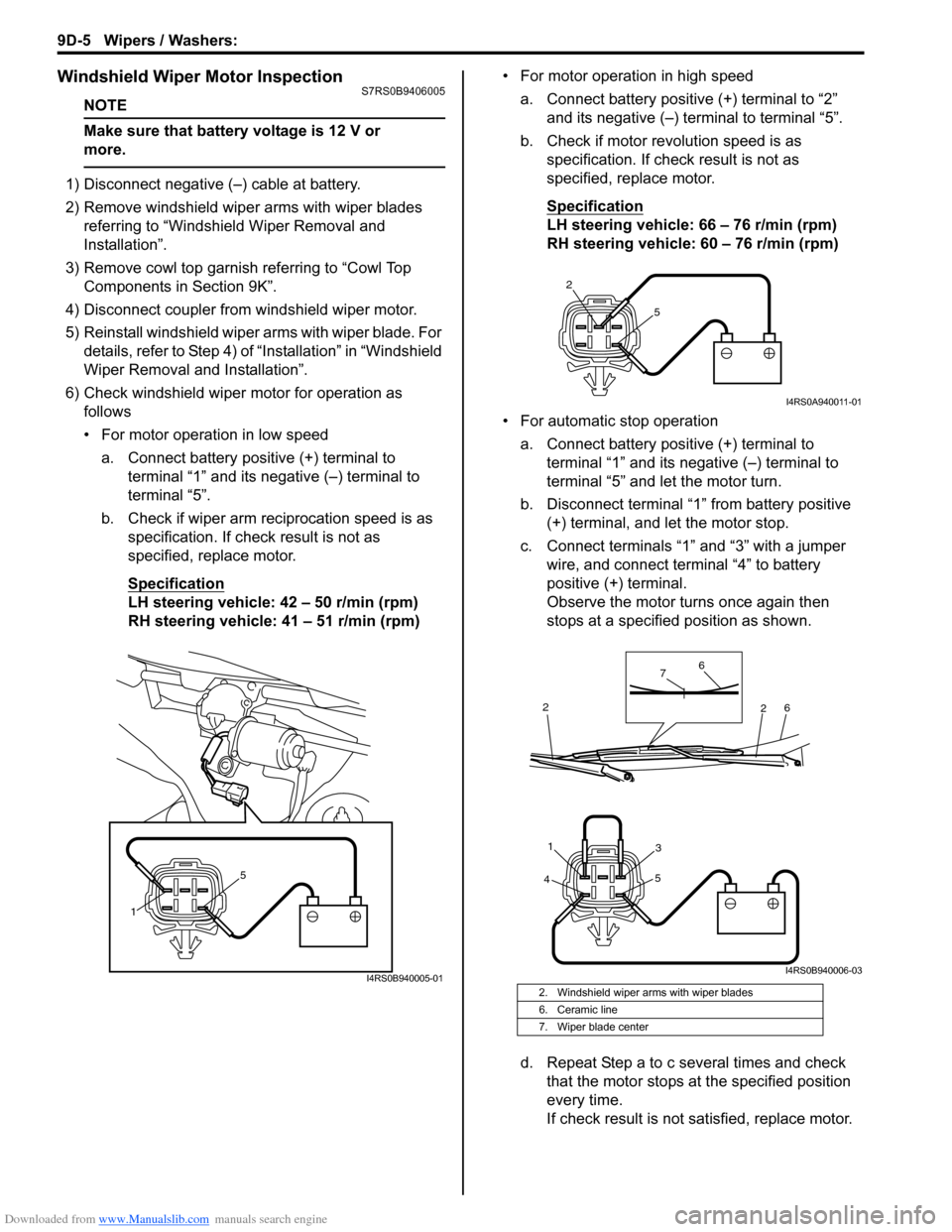

Windshield Wiper Motor InspectionS7RS0B9406005

NOTE

Make sure that battery voltage is 12 V or

more.

1) Disconnect negative (–) cable at battery.

2) Remove windshield wiper arms with wiper blades

referring to “Windshield Wiper Removal and

Installation”.

3) Remove cowl top garnish referring to “Cowl Top Components in Section 9K”.

4) Disconnect coupler from windshield wiper motor.

5) Reinstall windshield wiper arms with wiper blade. For

details, refer to Step 4) of “Installation” in “Windshield

Wiper Removal and Installation”.

6) Check windshield wiper motor for operation as

follows

• For motor operation in low speed

a. Connect battery positive (+) terminal to terminal “1” and its negative (–) terminal to

terminal “5”.

b. Check if wiper arm reciprocation speed is as specification. If check result is not as

specified, replace motor.

Specification

LH steering vehicle: 42 – 50 r/min (rpm)

RH steering vehicle: 41 – 51 r/min (rpm) • For motor operation in high speed

a. Connect battery positive (+) terminal to “2” and its negative (–) terminal to terminal “5”.

b. Check if motor revolution speed is as specification. If chec k result is not as

specified, replace motor.

Specification

LH steering vehicle: 66 – 76 r/min (rpm)

RH steering vehicle: 60 – 76 r/min (rpm)

• For automatic stop operation a. Connect battery positive (+) terminal to terminal “1” and its negative (–) terminal to

terminal “5” and let the motor turn.

b. Disconnect terminal “1” from battery positive (+) terminal, and let the motor stop.

c. Connect terminals “1” and “3” with a jumper wire, and connect terminal “4” to battery

positive (+) terminal.

Observe the motor turns once again then

stops at a specified position as shown.

d. Repeat Step a to c several times and check that the motor stops at the specified position

every time.

If check result is not satisfied, replace motor.

1 5

I4RS0B940005-012. Windshield wiper arms with wiper blades

6. Ceramic line

7. Wiper blade center

2

5

I4RS0A940011-01

4 5

31

6

6

7

2

2

I4RS0B940006-03

Page 1324 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-7 Wipers / Washers:

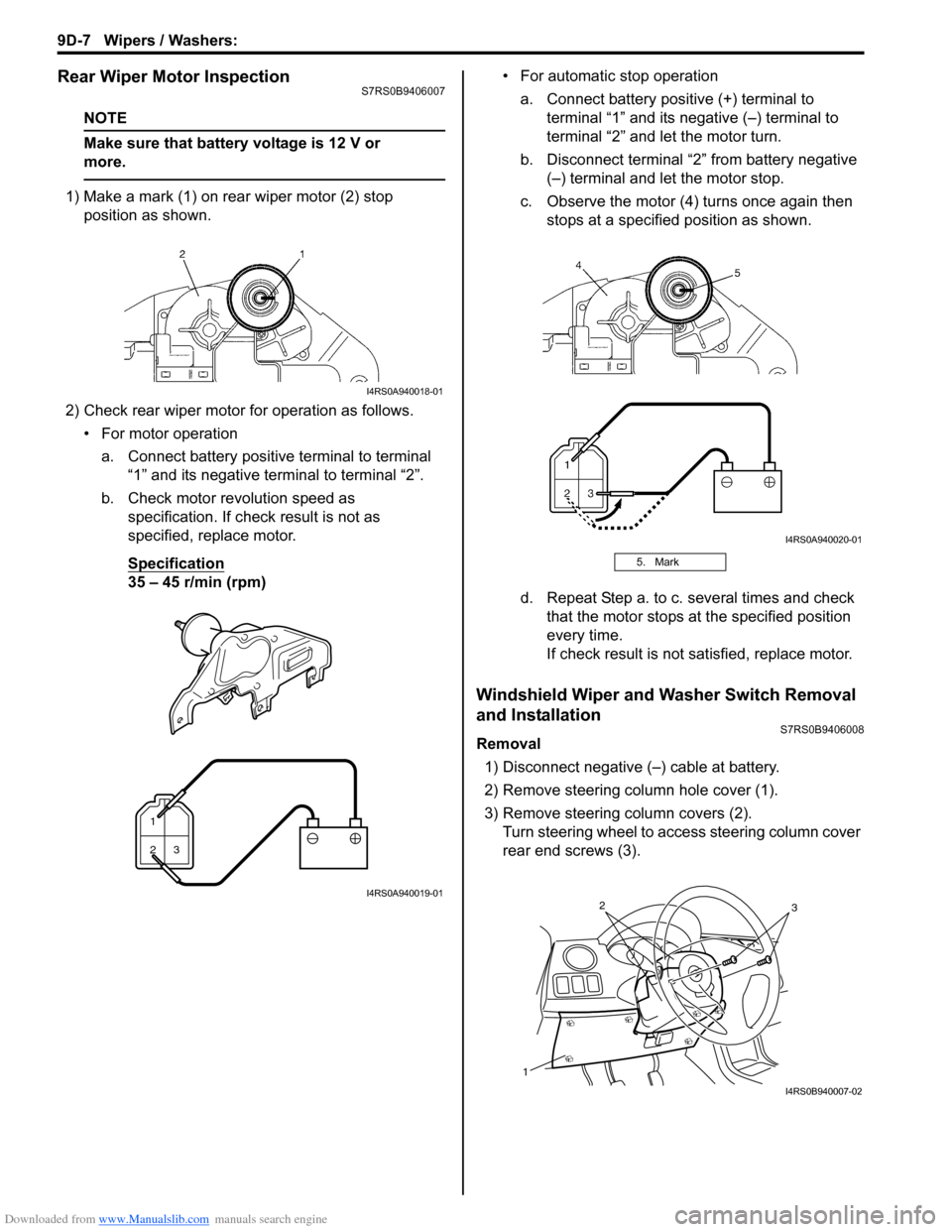

Rear Wiper Motor InspectionS7RS0B9406007

NOTE

Make sure that battery voltage is 12 V or

more.

1) Make a mark (1) on rear wiper motor (2) stop position as shown.

2) Check rear wiper motor for operation as follows. • For motor operationa. Connect battery positive terminal to terminal “1” and its negative terminal to terminal “2”.

b. Check motor revolution speed as specification. If check result is not as

specified, replace motor.

Specification

35 – 45 r/min (rpm) • For automatic stop operation

a. Connect battery positive (+) terminal to terminal “1” and its negative (–) terminal to

terminal “2” and let the motor turn.

b. Disconnect terminal “2” from battery negative (–) terminal and let the motor stop.

c. Observe the motor (4) turns once again then stops at a specified position as shown.

d. Repeat Step a. to c. several times and check that the motor stops at the specified position

every time.

If check result is not satisfied, replace motor.

Windshield Wiper and Washer Switch Removal

and Installation

S7RS0B9406008

Removal

1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover (1).

3) Remove steering column covers (2). Turn steering wheel to a ccess steering column cover

rear end screws (3).

I4RS0A940018-01

1

23

I4RS0A940019-01

5. Mark

I4RS0A940020-01

1

32

I4RS0B940007-02

Page 1326 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-9 Wipers / Washers:

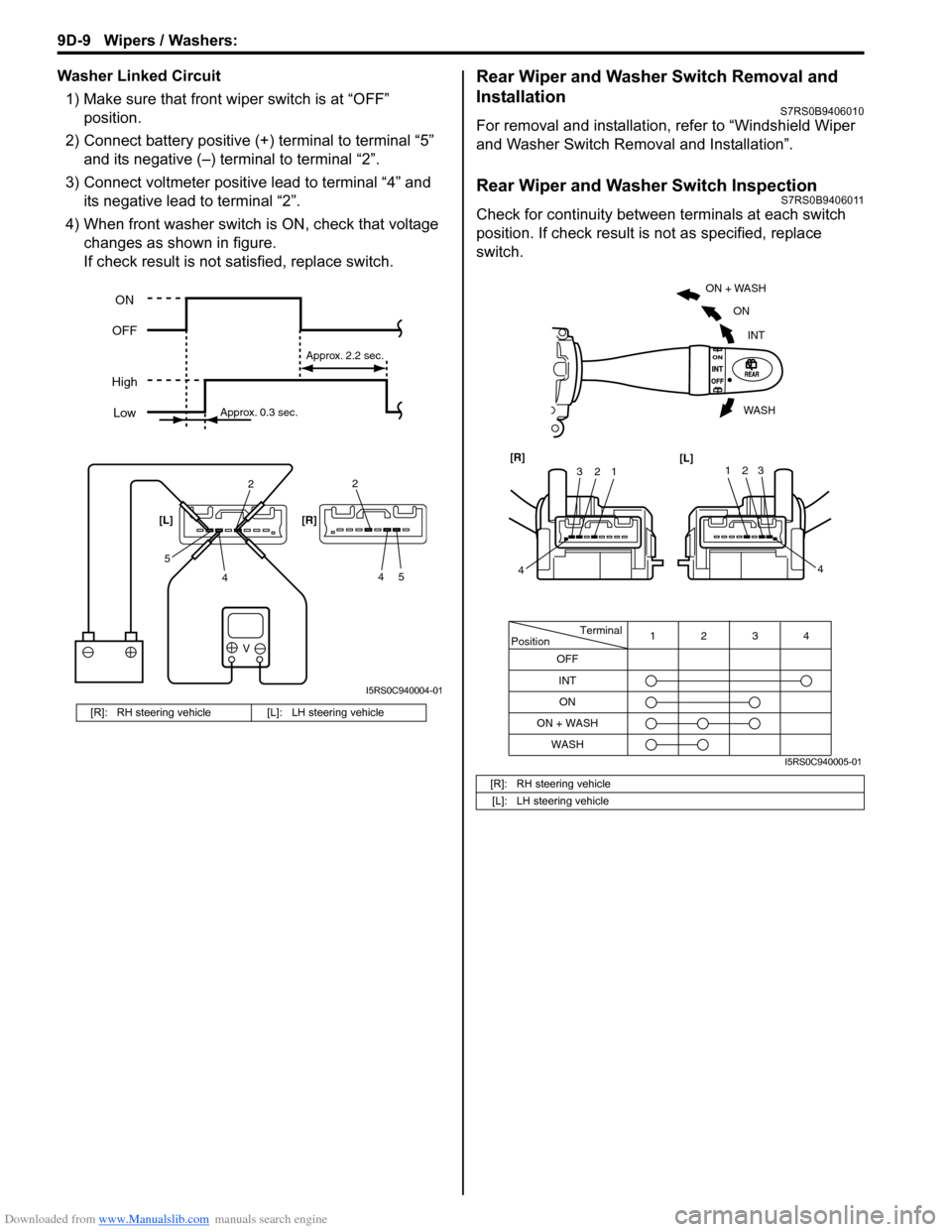

Washer Linked Circuit1) Make sure that front wiper switch is at “OFF” position.

2) Connect battery positive (+ ) terminal to terminal “5”

and its negative (–) terminal to terminal “2”.

3) Connect voltmeter positive lead to terminal “4” and its negative lead to terminal “2”.

4) When front washer switch is ON, check that voltage

changes as shown in figure.

If check result is not satisfied, replace switch.Rear Wiper and Washer Switch Removal and

Installation

S7RS0B9406010

For removal and installation, refer to “Windshield Wiper

and Washer Switch Removal and Installation”.

Rear Wiper and Washer Switch InspectionS7RS0B9406011

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

[R]: RH steering vehicle [L]: LH steering vehicle

V

2

4

52

45

[L] [R]

ON

OFF

High Low

Approx. 0.3 sec. Approx. 2.2 sec.

I5RS0C940004-01

[R]: RH steering vehicle

[L]: LH steering vehicle

Terminal

Position

OFF

INT 4

3

12

WASH ON

ON + WASH

ON + WASH

INT

ON

WASH

123

4

[R]

[L]123

4

I5RS0C940005-01

Page 1327 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-10

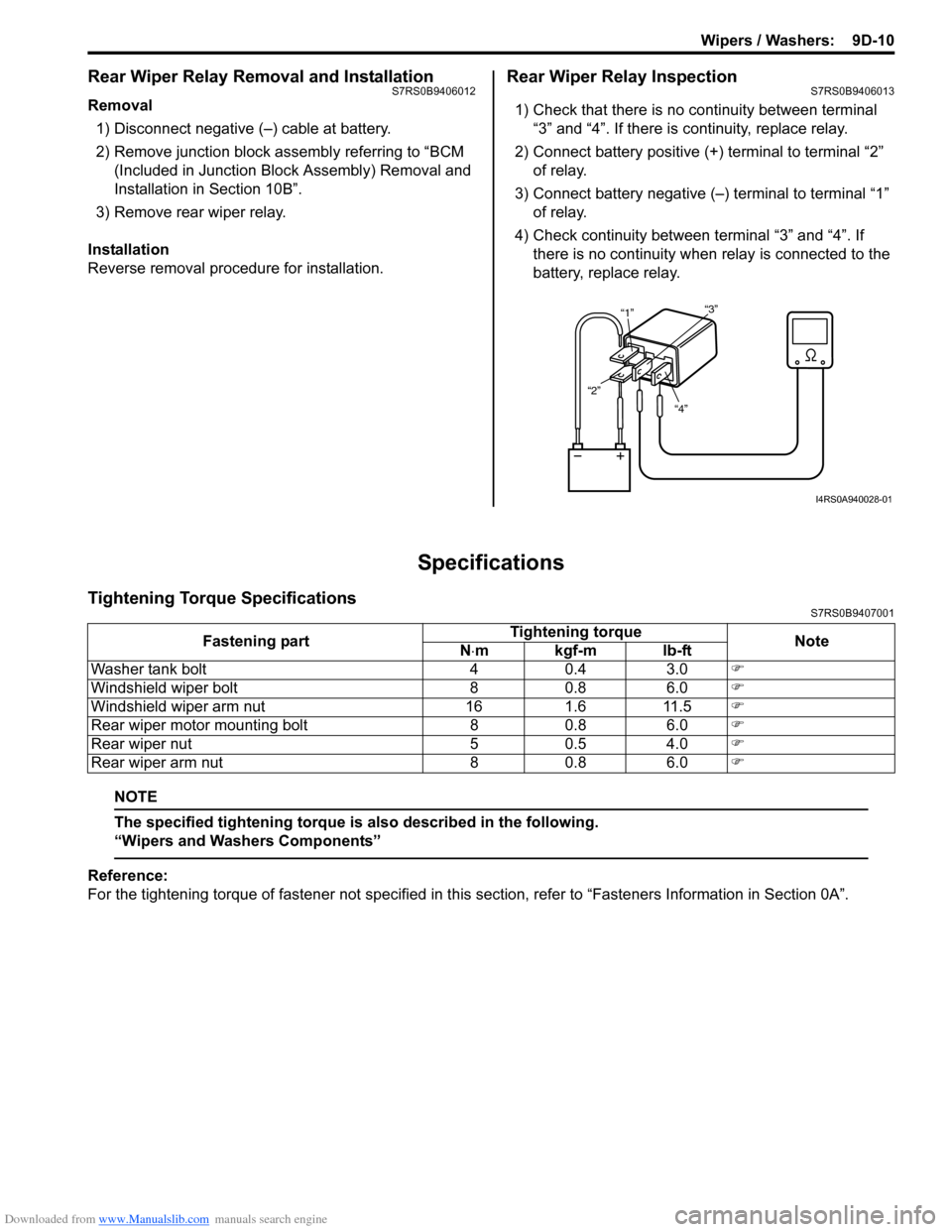

Rear Wiper Relay Removal and InstallationS7RS0B9406012

Removal1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Block Assembly) Removal and

Installation in Section 10B”.

3) Remove rear wiper relay.

Installation

Reverse removal procedure for installation.

Rear Wiper Relay InspectionS7RS0B9406013

1) Check that there is no continuity between terminal “3” and “4”. If there is continuity, replace relay.

2) Connect battery positive (+ ) terminal to terminal “2”

of relay.

3) Connect battery negative (–) terminal to terminal “1” of relay.

4) Check continuity between terminal “3” and “4”. If

there is no continuity when relay is connected to the

battery, replace relay.

Specifications

Tightening Torque SpecificationsS7RS0B9407001

NOTE

The specified tightening torque is also described in the following.

“Wipers and Washers Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“4”

“2” “1”

“3”

I4RS0A940028-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Washer tank bolt 4 0.4 3.0 �)

Windshield wiper bolt 8 0.8 6.0 �)

Windshield wiper arm nut 16 1.6 11.5 �)

Rear wiper motor mounting bolt 8 0.8 6.0 �)

Rear wiper nut 5 0.5 4.0 �)

Rear wiper arm nut 8 0.8 6.0 �)

Page 1341 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-14

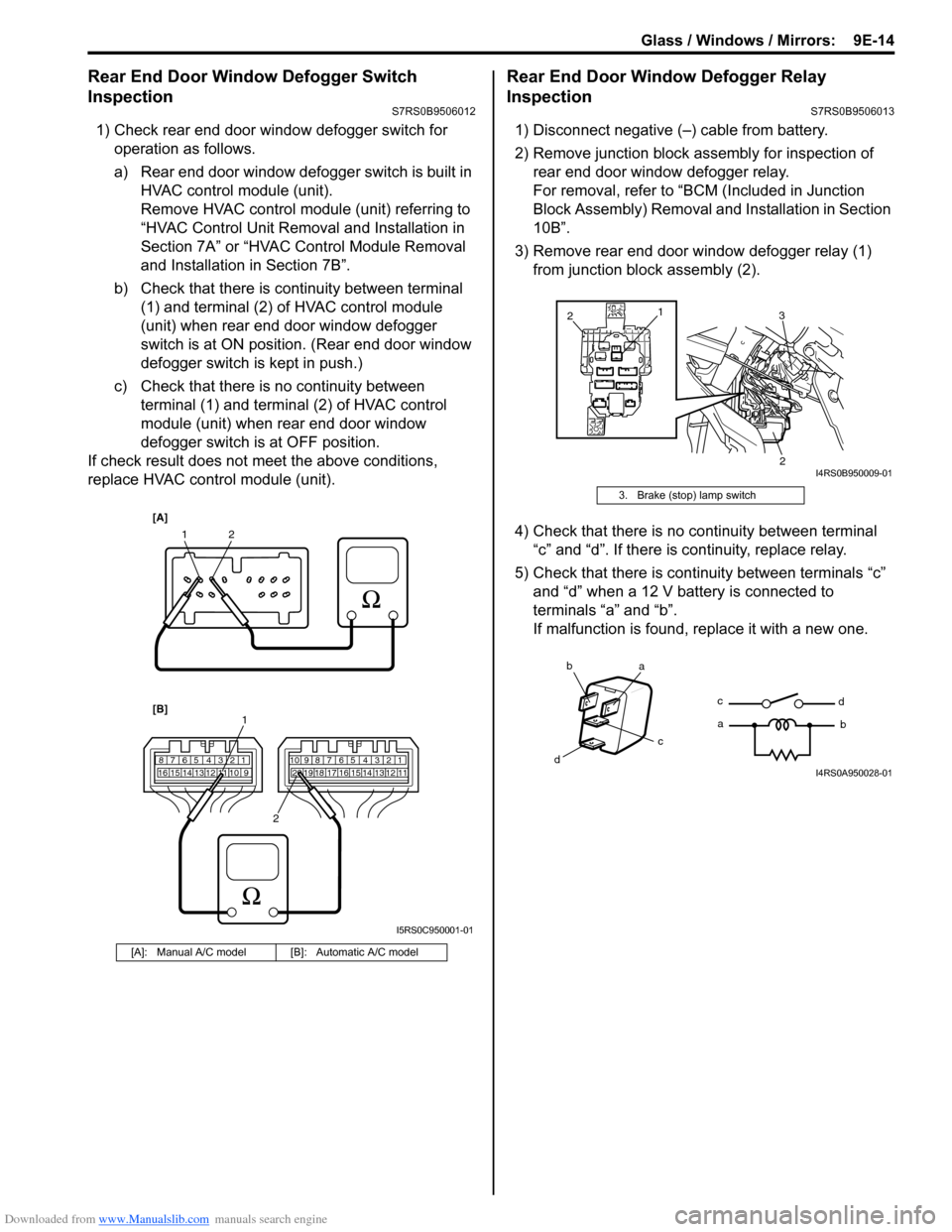

Rear End Door Window Defogger Switch

Inspection

S7RS0B9506012

1) Check rear end door window defogger switch for operation as follows.

a) Rear end door window defogger switch is built in HVAC control module (unit).

Remove HVAC control module (unit) referring to

“HVAC Control Unit Removal and Installation in

Section 7A” or “HVAC Control Module Removal

and Installation in Section 7B”.

b) Check that there is continuity between terminal (1) and terminal (2) of HVAC control module

(unit) when rear end door window defogger

switch is at ON position. (Rear end door window

defogger switch is kept in push.)

c) Check that there is no continuity between terminal (1) and terminal (2) of HVAC control

module (unit) when rear end door window

defogger switch is at OFF position.

If check result does not meet the above conditions,

replace HVAC control module (unit).

Rear End Door Window Defogger Relay

Inspection

S7RS0B9506013

1) Disconnect negative (–) cable from battery.

2) Remove junction block assembly for inspection of rear end door window defogger relay.

For removal, refer to “BCM (Included in Junction

Block Assembly) Removal a nd Installation in Section

10B”.

3) Remove rear end door window defogger relay (1) from junction block assembly (2).

4) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c” and “d” when a 12 V battery is connected to

terminals “a” and “b”.

If malfunction is found, replace it with a new one.

[A]: Manual A/C model [B]: Automatic A/C model

12

7812910

65 431516 14 13 12 11789101920121112

65 431718 16 15 14 13

1

2

[A]

[B]

I5RS0C950001-01

3. Brake (stop) lamp switch

1

3

2

2

I4RS0B950009-01

ba

c

dc

a

d

bI4RS0A950028-01

Page 1343 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-16

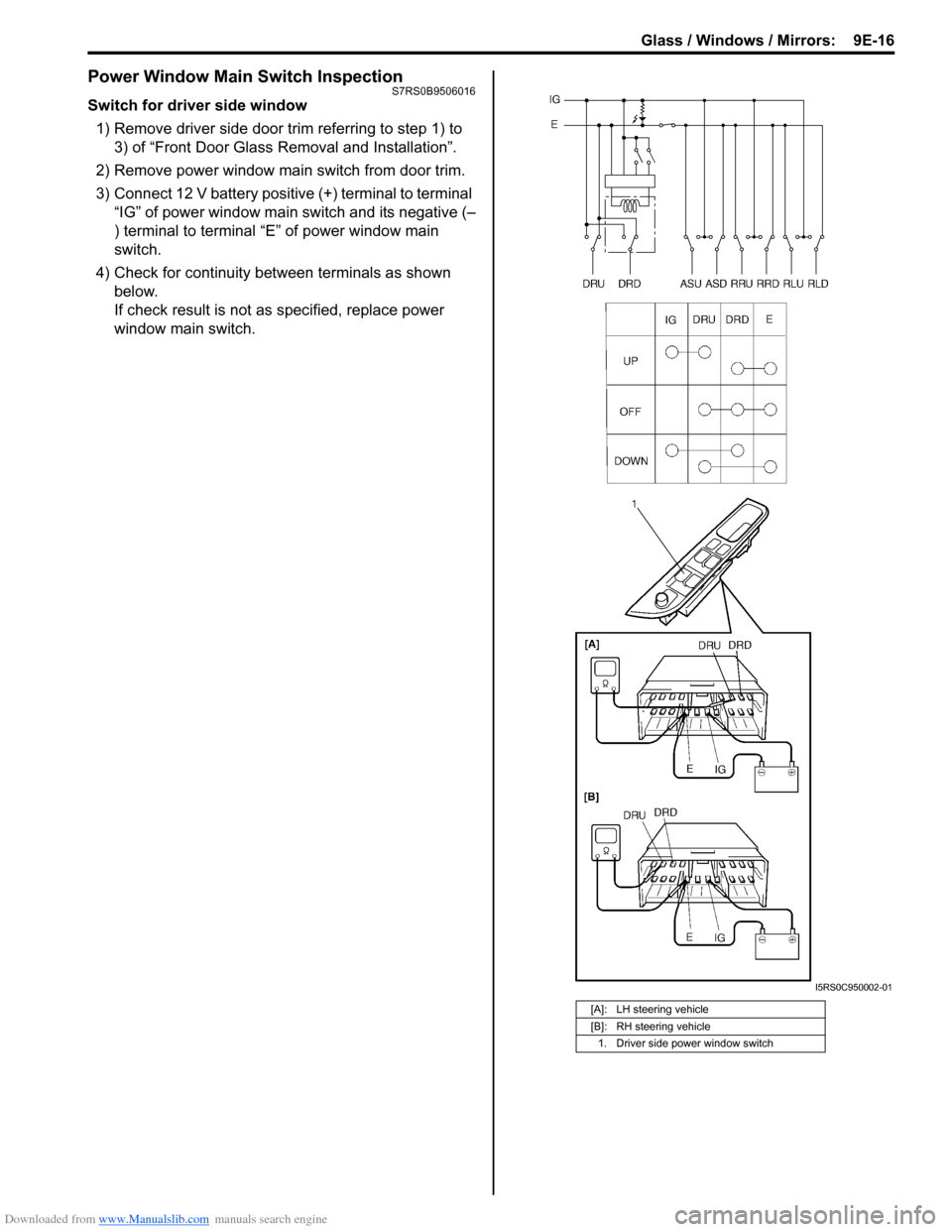

Power Window Main Switch InspectionS7RS0B9506016

Switch for driver side window 1) Remove driver side door trim referring to step 1) to 3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Connect 12 V battery positive (+) terminal to terminal “IG” of power window main switch and its negative (–

) terminal to terminal “E” of power window main

switch.

4) Check for continuity between terminals as shown below.

If check result is not as specified, replace power

window main switch.

[A]: LH steering vehicle

[B]: RH steering vehicle

1. Driver side power window switch

I5RS0C950002-01

Page 1346 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-19 Glass / Windows / Mirrors:

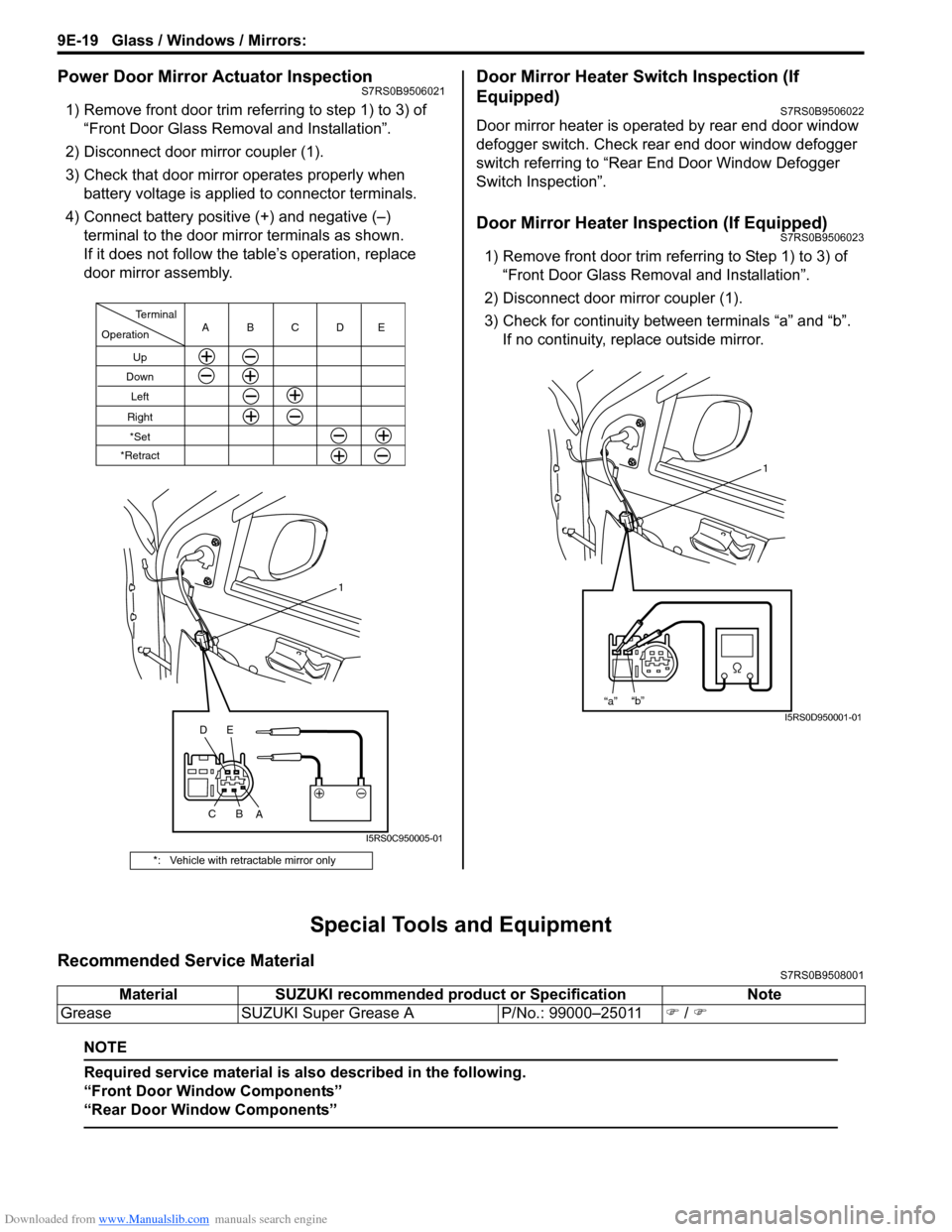

Power Door Mirror Actuator InspectionS7RS0B9506021

1) Remove front door trim referring to step 1) to 3) of “Front Door Glass Removal and Installation”.

2) Disconnect door mirror coupler (1).

3) Check that door mirror operates properly when battery voltage is applied to connector terminals.

4) Connect battery positive (+) and negative (–) terminal to the door mirror terminals as shown.

If it does not follow the table’s operation, replace

door mirror assembly.

Door Mirror Heater Switch Inspection (If

Equipped)

S7RS0B9506022

Door mirror heater is operated by rear end door window

defogger switch. Check rear end door window defogger

switch referring to “Rear End Door Window Defogger

Switch Inspection”.

Door Mirror Heater Inspection (If Equipped)S7RS0B9506023

1) Remove front door trim refe rring to Step 1) to 3) of

“Front Door Glass Removal and Installation”.

2) Disconnect door mirror coupler (1).

3) Check for continuity between terminals “a” and “b”. If no continuity, replace outside mirror.

Special Tools and Equipment

Recommended Service MaterialS7RS0B9508001

NOTE

Required service material is also described in the following.

“Front Door Window Components”

“Rear Door Window Components”

*: Vehicle with retractable mirror only

Operation

Terminal

Up

Down

Left

RightCBA

1

C B

A

*Set

*Retract

DE

DE

I5RS0C950005-01

1

“a” “b”

I5RS0D950001-01

Material

SUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25011�) / �)

Page 1350 of 1496

Downloaded from www.Manualslib.com manuals search engine 9F-4 Security and Locks:

Keyless Entry System Symptom Diagnosis (If Equipped)S7RS0B9604003

NOTE

• Confirm that power door lock system is in good condition before referring to the following possible causes.

• Check each part in the order from the top of the following list.

Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by only

keyless entry transmitter Transmitter battery dead

Replace battery referring to “Replacement of

Transmitter Battery”.

Door switch faulty Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Transmitter faulty Replace transmitter.

Key reminder switch in ignition switch

faulty Check ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

Keyless entry receiver faulty Check keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection”.

BCM faulty Replace after making sure that none of above

parts is faulty.

Interior light does not

light when doors are

unlocked by keyless entry

transmitter Wiring or grounding faulty

Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Hazard warning lights do

not light when doors are

locked/unlocked by

keyless entry transmitter Turn signal and hazard warning relay

faulty

Check turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Transmitter code can not

be programmed to BCM Door switch faulty

Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Keyless entry receiver faulty Check keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection”.

Key reminder switch in ignition switch

faulty Check ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.