low battery SUZUKI SWIFT 2004 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2004, Model line: SWIFT, Model: SUZUKI SWIFT 2004 2.GPages: 1496, PDF Size: 34.44 MB

Page 1057 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-19

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The power source voltage to SDM is above an approx. 21 V for specified time.

Flow Test Description

Step 1: Check if voltage applie d to SDM is within normal range.

Step 2: Check if DTC B1016 still exists.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

Step Action YesNo

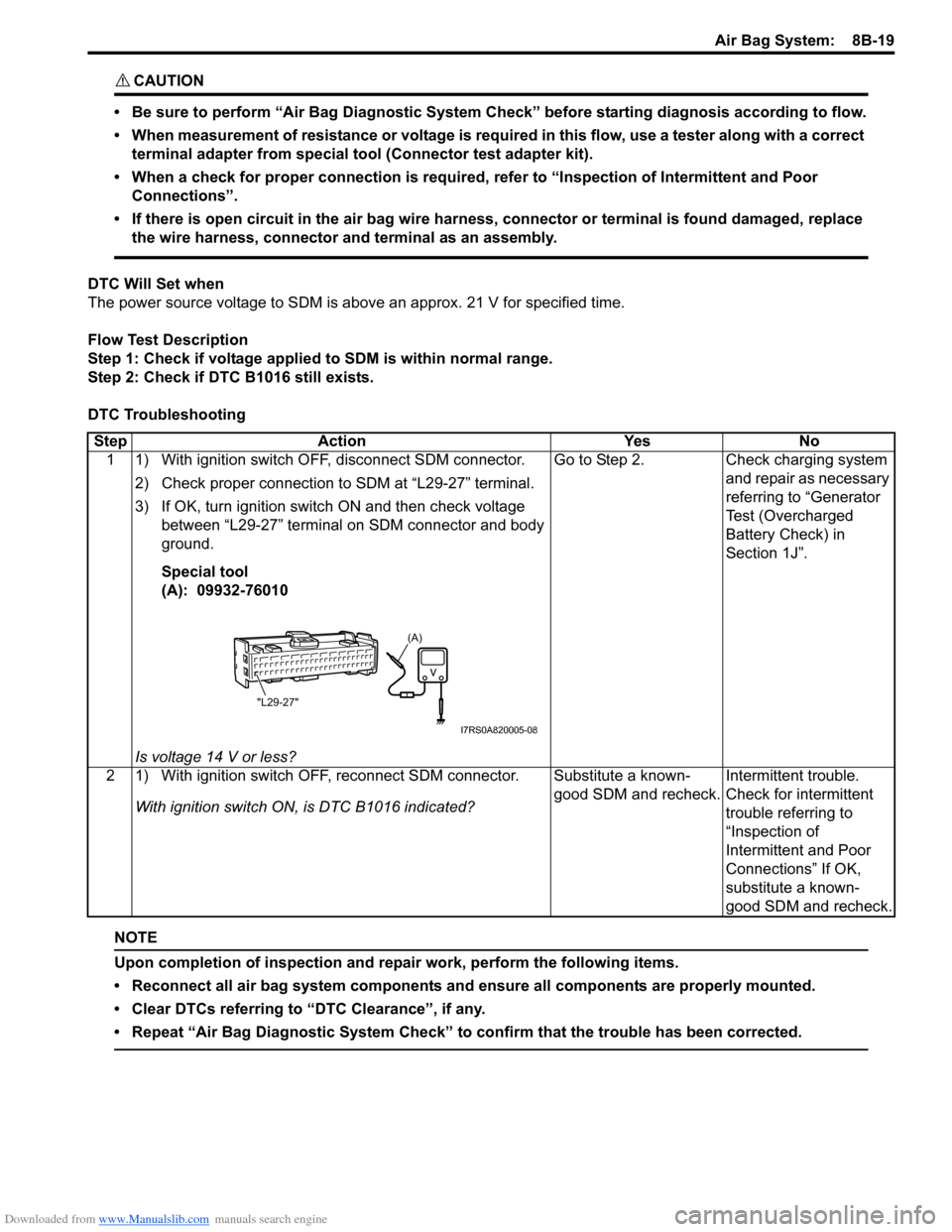

1 1) With ignition switch OFF, disconnect SDM connector.

2) Check proper connection to SDM at “L29-27” terminal.

3) If OK, turn ignition switch ON and then check voltage between “L29-27” terminal on SDM connector and body

ground.

Special tool

(A): 09932-76010

Is voltage 14 V or less? Go to Step 2.

Check charging system

and repair as necessary

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

2 1) With ignition switch OFF, reconnect SDM connector. With ignition switch ON , is DTC B1016 indicated? Substitute a known-

good SDM and recheck.

Intermittent trouble.

Check for intermittent

trouble referring to

“Inspection of

Intermittent and Poor

Connections” If OK,

substitute a known-

good SDM and recheck.

(A)

"L29-27"

I7RS0A820005-08

Page 1058 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-20 Air Bag System:

DTC B1017: Power Source Voltage LowS7RS0B8204013

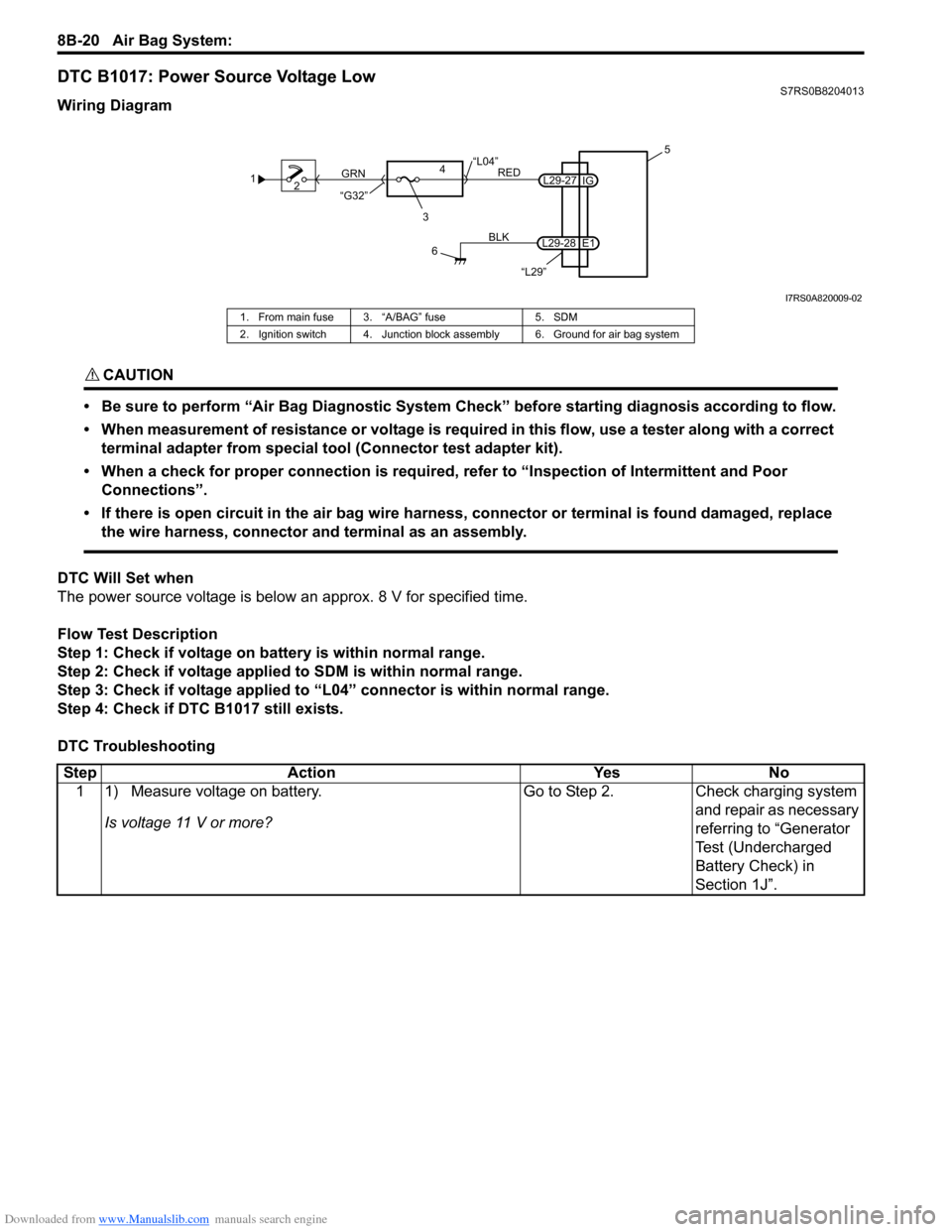

Wiring Diagram

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The power source voltage is below an approx. 8 V for specified time.

Flow Test Description

Step 1: Check if voltage on ba ttery is within normal range.

Step 2: Check if voltage applie d to SDM is within normal range.

Step 3: Check if voltage applied to “L04” connector is within normal range.

Step 4: Check if DTC B1017 still exists.

DTC Troubleshooting

1 2

3

GRN

RED

6

BLK

L29-27

L29-28 IG

E1 5

4

“L29”

“L04”

“G32”

I7RS0A820009-02

1. From main fuse 3. “A/BAG” fuse 5. SDM

2. Ignition switch 4. Junction block assembly 6. Ground for air bag system

Step Action YesNo

1 1) Measure voltage on battery.

Is voltage 11 V or more? Go to Step 2.

Check charging system

and repair as necessary

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

Page 1059 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-21

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

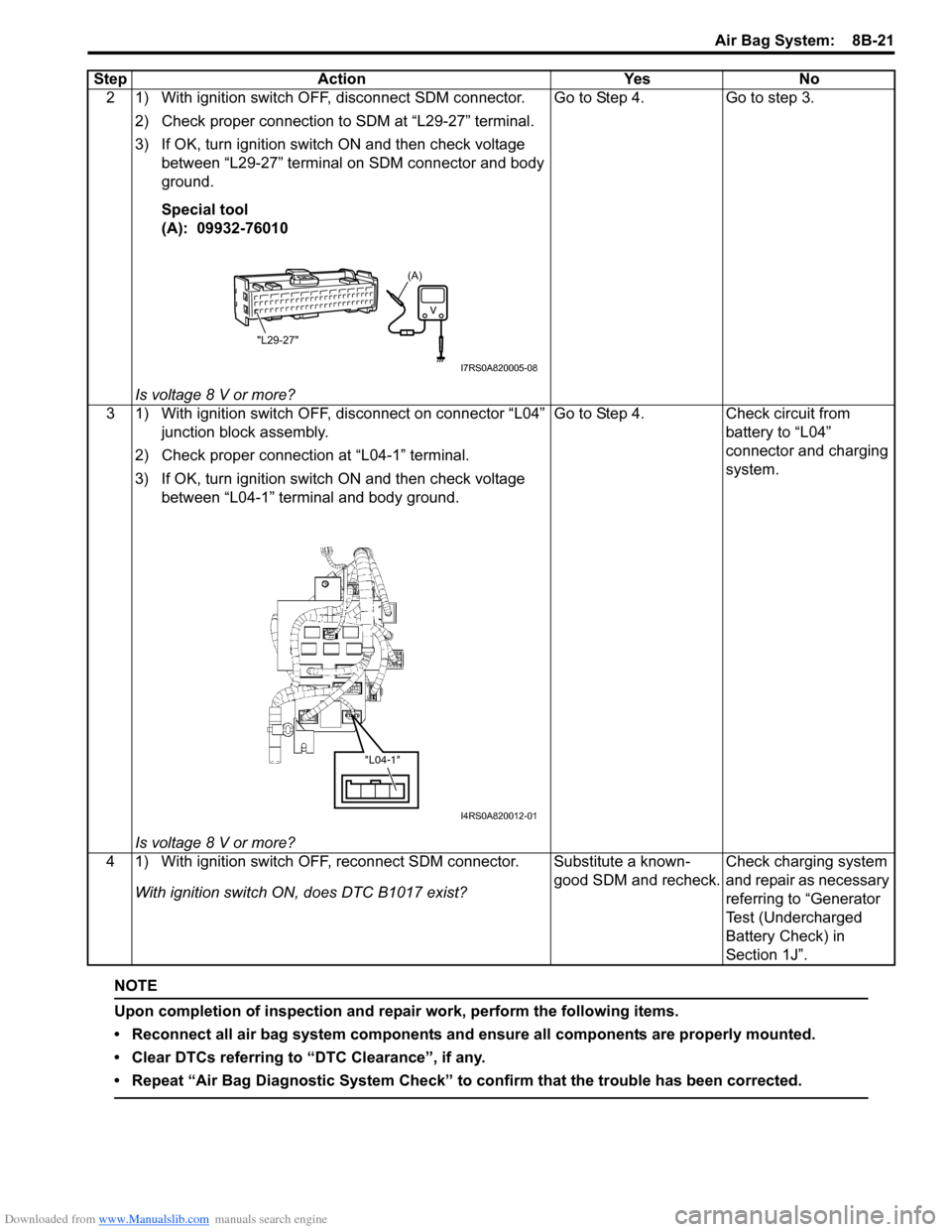

2 1) With ignition switch OFF, disconnect SDM connector.2) Check proper connection to SDM at “L29-27” terminal.

3) If OK, turn ignition switch ON and then check voltage between “L29-27” terminal on SDM connector and body

ground.

Special tool

(A): 09932-76010

Is voltage 8 V or more? Go to Step 4. Go to step 3.

3 1) With ignition switch OFF, disconnect on connector “L04” junction block assembly.

2) Check proper connection at “L04-1” terminal.

3) If OK, turn ignition switch ON and then check voltage between “L04-1” terminal and body ground.

Is voltage 8 V or more? Go to Step 4. Check circuit from

battery to “L04”

connector and charging

system.

4 1) With ignition switch OFF, reconnect SDM connector. With ignition switch ON, does DTC B1017 exist? Substitute a known-

good SDM and recheck.

Check charging system

and repair as necessary

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

Step Action Yes No

(A)

"L29-27"

I7RS0A820005-08

"L04-1"

I4RS0A820012-01

Page 1136 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-98 Air Bag System:

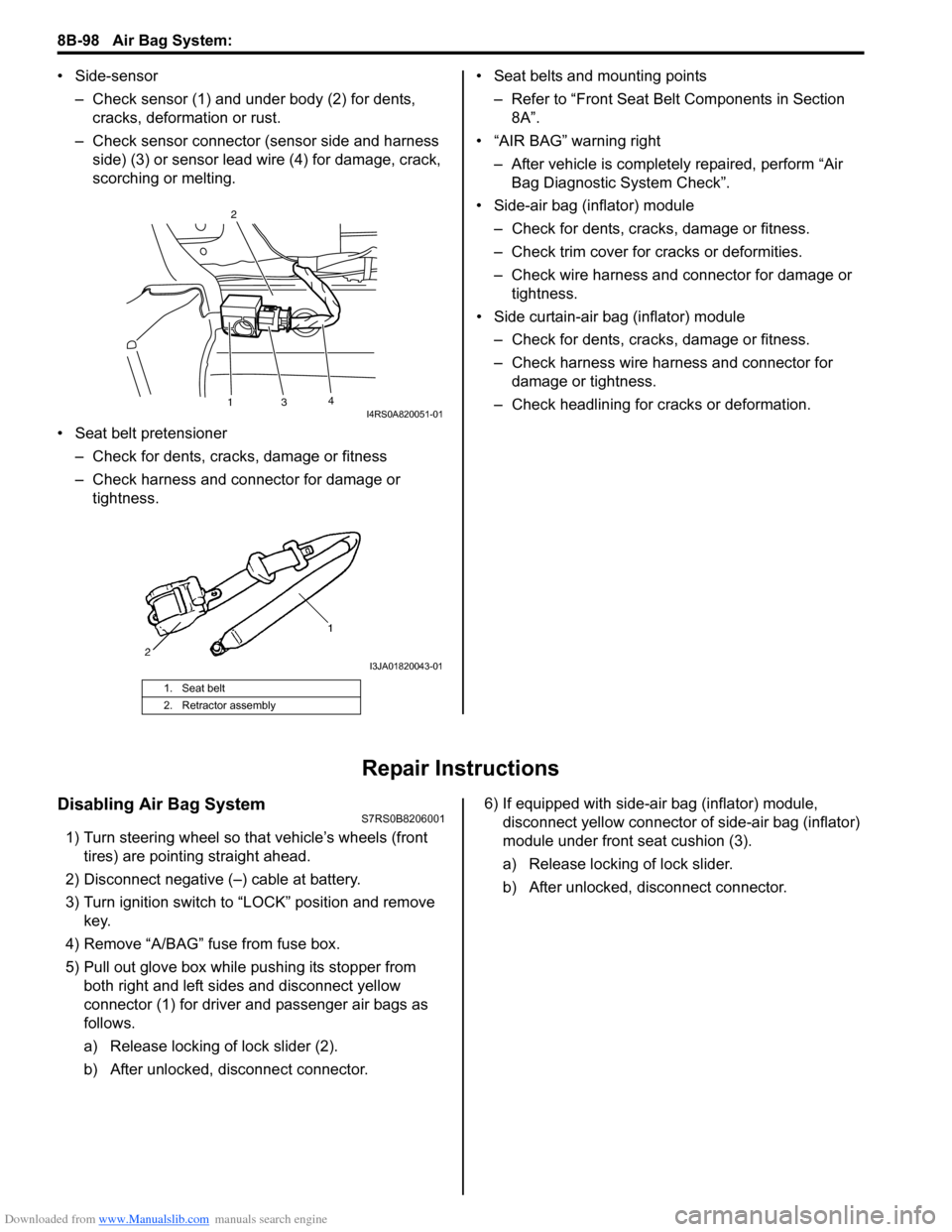

• Side-sensor– Check sensor (1) and under body (2) for dents, cracks, deformation or rust.

– Check sensor connector (sensor side and harness side) (3) or sensor lead wire (4) for damage, crack,

scorching or melting.

• Seat belt pretensioner – Check for dents, cracks , damage or fitness

– Check harness and connector for damage or tightness. • Seat belts and mounting points

– Refer to “Front Seat Belt Components in Section 8A”.

• “AIR BAG” warning right

– After vehicle is completely repaired, perform “Air Bag Diagnostic System Check”.

• Side-air bag (inflator) module – Check for dents, cra cks, damage or fitness.

– Check trim cover for cracks or deformities.

– Check wire harness and connector for damage or tightness.

• Side curtain-air bag (inflator) module – Check for dents, cra cks, damage or fitness.

– Check harness wire harness and connector for damage or tightness.

– Check headlining for cracks or deformation.

Repair Instructions

Disabling Air Bag SystemS7RS0B8206001

1) Turn steering wheel so that vehicle’s wheels (front tires) are pointing straight ahead.

2) Disconnect negative (–) cable at battery.

3) Turn ignition switch to “LOCK” position and remove key.

4) Remove “A/BAG” fu se from fuse box.

5) Pull out glove box while pushing its stopper from

both right and left sides and disconnect yellow

connector (1) for driver and passenger air bags as

follows.

a) Release locking of lock slider (2).

b) After unlocked, disconnect connector. 6) If equipped with side-air bag (inflator) module,

disconnect yellow connector of side-air bag (inflator)

module under front seat cushion (3).

a) Release locking of lock slider.

b) After unlocked, disconnect connector.

1. Seat belt

2. Retractor assembly

13 4

2I4RS0A820051-01

I3JA01820043-01

Page 1137 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-99

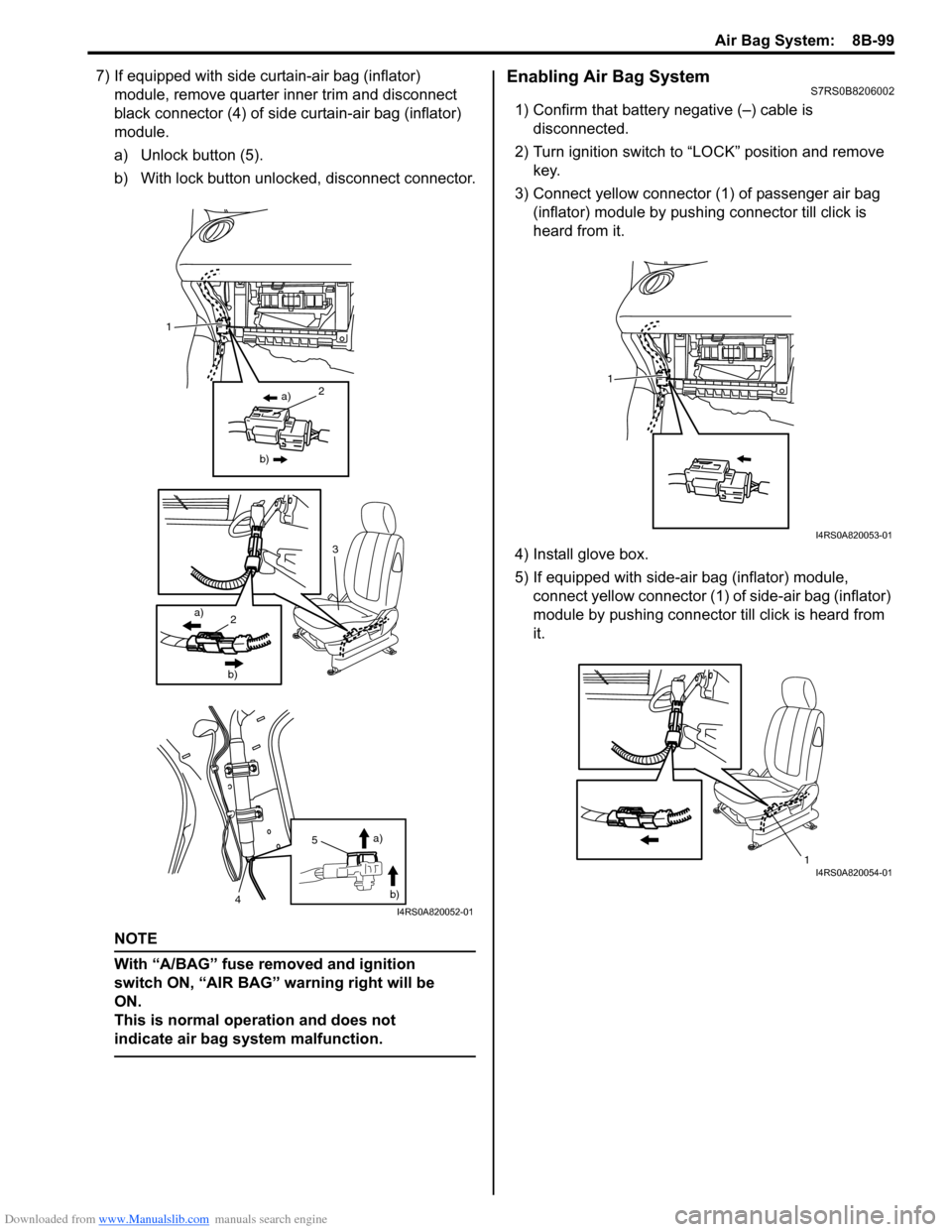

7) If equipped with side curtain-air bag (inflator) module, remove quarter inner trim and disconnect

black connector (4) of side curtain-air bag (inflator)

module.

a) Unlock button (5).

b) With lock button unlocked, disconnect connector.

NOTE

With “A/BAG” fuse removed and ignition

switch ON, “AIR BAG” warning right will be

ON.

This is normal operation and does not

indicate air bag system malfunction.

Enabling Air Bag SystemS7RS0B8206002

1) Confirm that battery negative (–) cable is disconnected.

2) Turn ignition switch to “LOCK” position and remove key.

3) Connect yellow connector (1) of passenger air bag (inflator) module by push ing connector till click is

heard from it.

4) Install glove box.

5) If equipped with side-air bag (inflator) module, connect yellow connector (1) of side-air bag (inflator)

module by pushing connector till click is heard from

it.

a)

b)2

3

2a)

b)

1

5

4 a)

b)

I4RS0A820052-01

1

I4RS0A820053-01

1I4RS0A820054-01

Page 1139 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-101

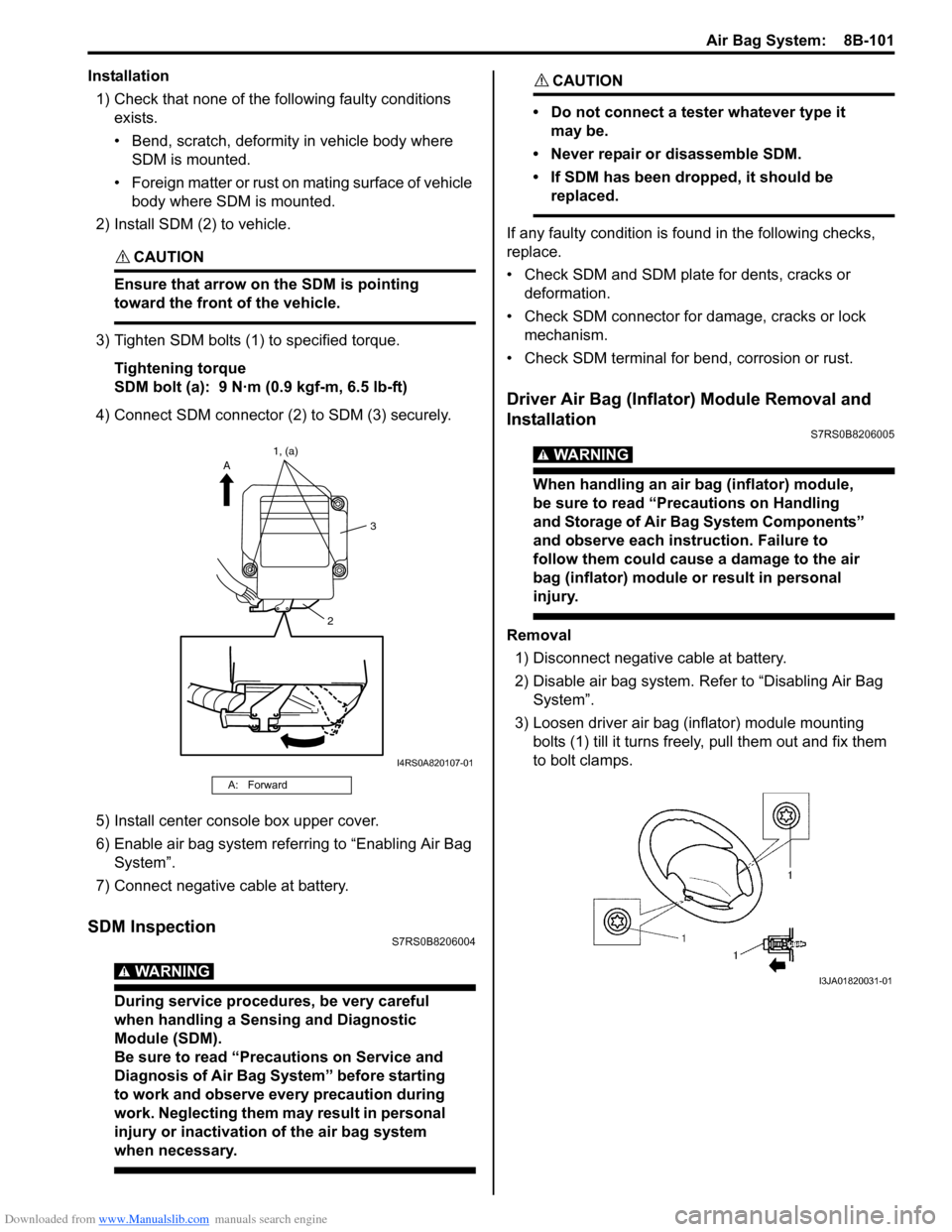

Installation1) Check that none of the following faulty conditions exists.

• Bend, scratch, deformity in vehicle body where SDM is mounted.

• Foreign matter or rust on mating surface of vehicle body where SDM is mounted.

2) Install SDM (2) to vehicle.

CAUTION!

Ensure that arrow on the SDM is pointing

toward the front of the vehicle.

3) Tighten SDM bolts (1) to specified torque.

Tightening torque

SDM bolt (a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

4) Connect SDM connector (2) to SDM (3) securely.

5) Install center console box upper cover.

6) Enable air bag system referring to “Enabling Air Bag System”.

7) Connect negative cable at battery.

SDM InspectionS7RS0B8206004

WARNING!

During service procedures, be very careful

when handling a Sensing and Diagnostic

Module (SDM).

Be sure to read “Precautions on Service and

Diagnosis of Air Bag System” before starting

to work and observe every precaution during

work. Neglecting them ma y result in personal

injury or inactivation of the air bag system

when necessary.

CAUTION!

• Do not connect a tester whatever type it may be.

• Never repair or disassemble SDM.

• If SDM has been dropped, it should be replaced.

If any faulty condition is fo und in the following checks,

replace.

• Check SDM and SDM plate for dents, cracks or deformation.

• Check SDM connector for damage, cracks or lock mechanism.

• Check SDM terminal for bend, corrosion or rust.

Driver Air Bag (Inflator) Module Removal and

Installation

S7RS0B8206005

WARNING!

When handling an air bag (inflator) module,

be sure to read “Precautions on Handling

and Storage of Air Bag System Components”

and observe each instruction. Failure to

follow them could cause a damage to the air

bag (inflator) module or result in personal

injury.

Removal 1) Disconnect negative cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System”.

3) Loosen driver air bag (inflator) module mounting bolts (1) till it turns freely, pull them out and fix them

to bolt clamps.

A: Forward

2 3

A

1, (a)

I4RS0A820107-01

I3JA01820031-01

Page 1147 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-109

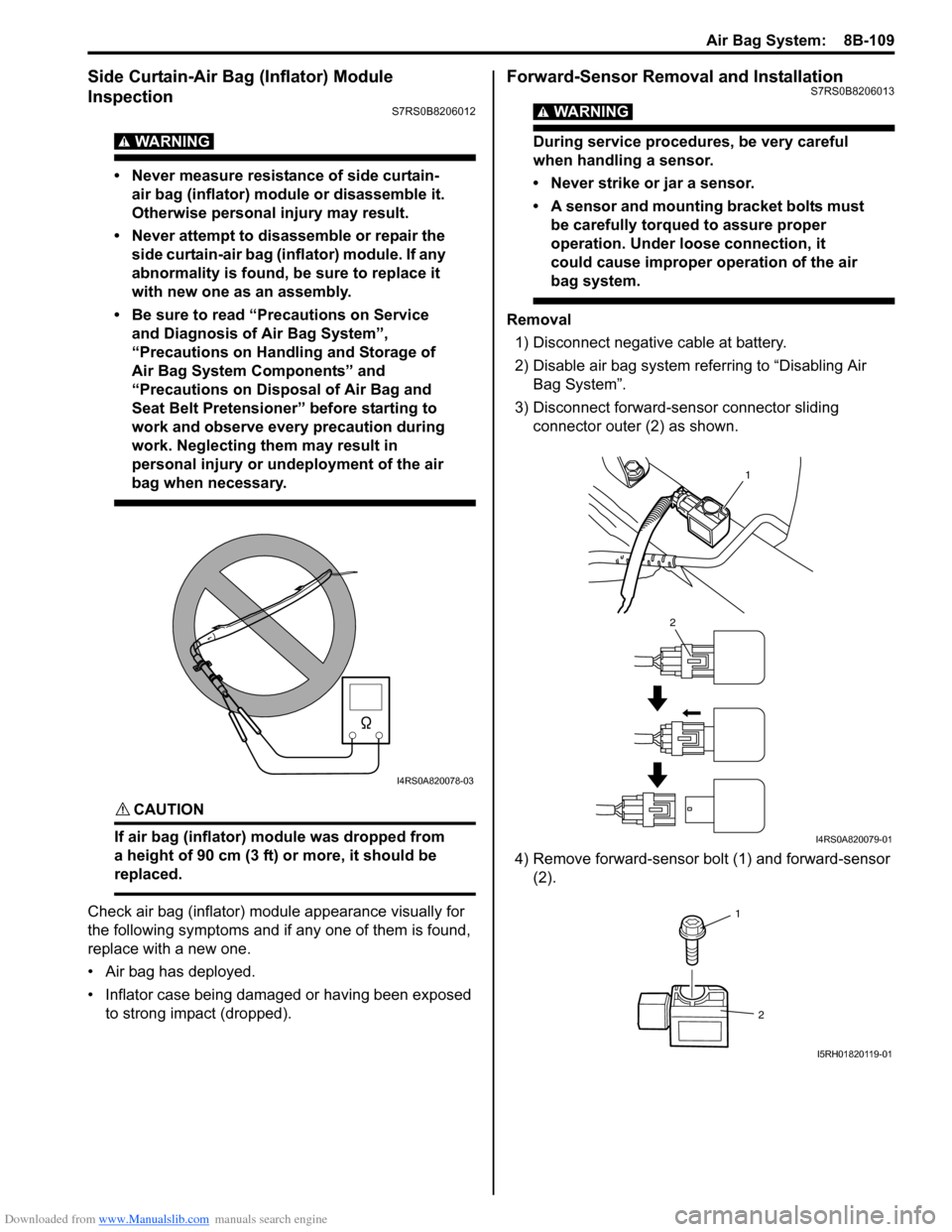

Side Curtain-Air Bag (Inflator) Module

Inspection

S7RS0B8206012

WARNING!

• Never measure resistance of side curtain-air bag (inflator) module or disassemble it.

Otherwise personal injury may result.

• Never attempt to disassemble or repair the side curtain-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• Inflator case being damaged or having been exposed to strong impact (dropped).

Forward-Sensor Removal and InstallationS7RS0B8206013

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

Removal

1) Disconnect negative cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System”.

3) Disconnect forward-sensor connector sliding connector outer (2) as shown.

4) Remove forward-sensor bolt (1) and forward-sensor (2).

I4RS0A820078-03

1

2

I4RS0A820079-01

1

2

I5RH01820119-01

Page 1148 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-110 Air Bag System:

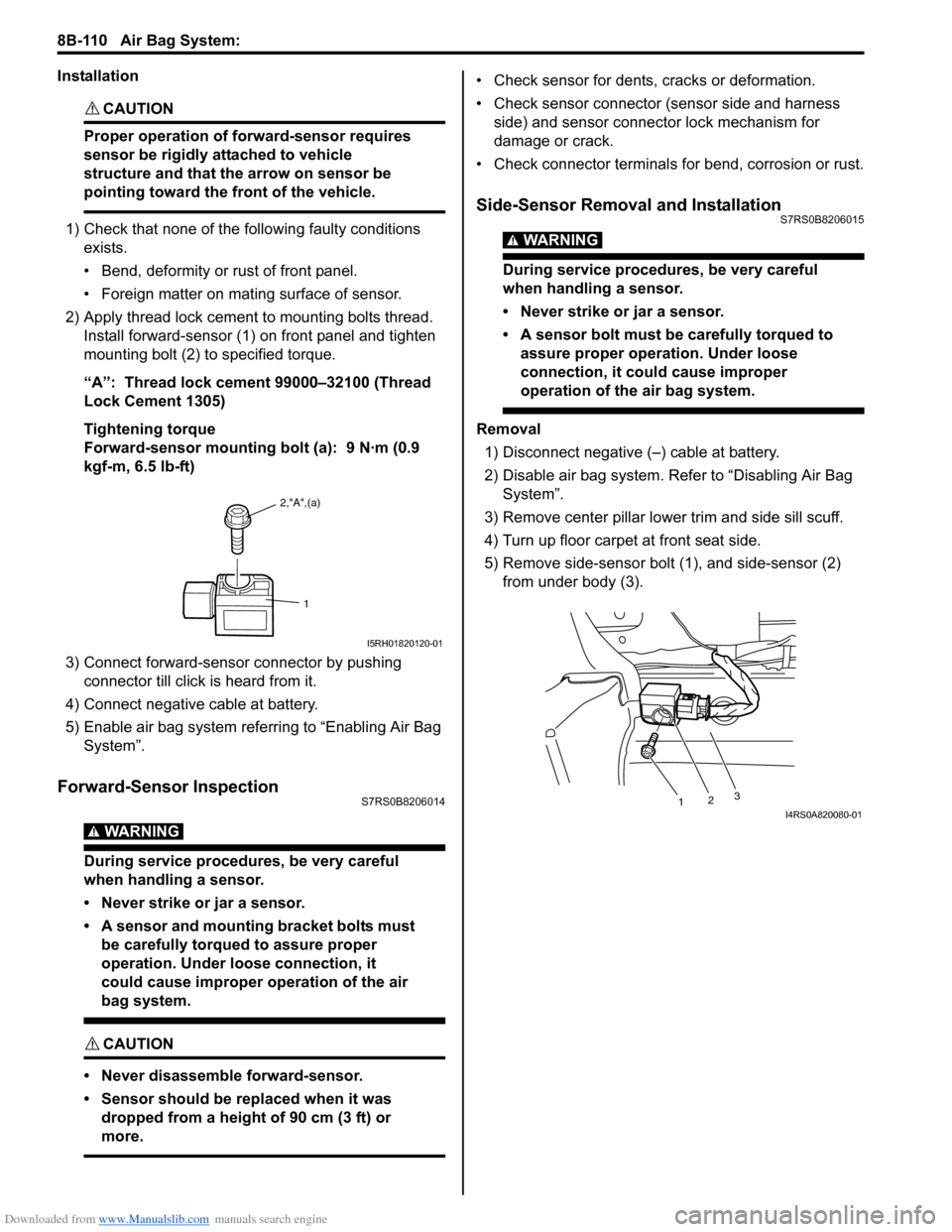

Installation

CAUTION!

Proper operation of forward-sensor requires

sensor be rigidly attached to vehicle

structure and that the arrow on sensor be

pointing toward the front of the vehicle.

1) Check that none of the following faulty conditions exists.

• Bend, deformity or rust of front panel.

• Foreign matter on mating surface of sensor.

2) Apply thread lock cement to mounting bolts thread. Install forward-sensor (1) on front panel and tighten

mounting bolt (2) to specified torque.

“A”: Thread lock cement 99000–32100 (Thread

Lock Cement 1305)

Tightening torque

Forward-sensor mounting bolt (a): 9 N·m (0.9

kgf-m, 6.5 lb-ft)

3) Connect forward-sensor connector by pushing connector till click is heard from it.

4) Connect negative cable at battery.

5) Enable air bag system referring to “Enabling Air Bag System”.

Forward-Sensor InspectionS7RS0B8206014

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

CAUTION!

• Never disassemble forward-sensor.

• Sensor should be replaced when it was dropped from a height of 90 cm (3 ft) or

more.

• Check sensor for dents, cracks or deformation.

• Check sensor connector (sensor side and harness side) and sensor connector lock mechanism for

damage or crack.

• Check connector terminals for bend, corrosion or rust.

Side-Sensor Removal and InstallationS7RS0B8206015

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor bolt must be carefully torqued to assure proper operation. Under loose

connection, it could cause improper

operation of the air bag system.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System”.

3) Remove center pillar lowe r trim and side sill scuff.

4) Turn up floor carpet at front seat side.

5) Remove side-sensor bolt (1), and side-sensor (2) from under body (3).

2,"A",(a)

1

I5RH01820120-01

1 23I4RS0A820080-01

Page 1149 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-111

6) Disconnect side-sensor connector sliding connector

outer (1) as shown.

Installation

CAUTION!

Proper operation of side-sensor requires

sensor be rigidly attached to specified

position.

1) Check that none of following faulty conditions exists.

• Bend, deformity or rust of under body.

• Foreign matter on mating surface of sensor.

2) Install side-sensor (1) on under body (2) and tighten side-sensor bolt (3) to specified torque.

Tightening torque

Side-sensor bolt (a): 9 N·m (0.9 kgf-m, 6.5 lb-ft) 3) Connect side-sensor connector pushing connector

inner (1) as shown.

4) Connect negative cable at battery.

5) Enable air bag system. Refer to “Enabling Air Bag System”.

Side-Sensor InspectionS7RS0B8206016

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

CAUTION!

• Never disassemble side-sensor.

• Sensor should be replaced when it was dropped from a height of 90 cm (3 ft) or

more.

1

1

I4RS0A820109-01

1 2

3, (a)I4RS0A820081-01

1

1

I4RS0A820106-01

Page 1151 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-113

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal

S7RS0B8206018

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. Do not dispose of live

(undeployed) air bag (inflator) modules and

seat belt pretensioners. Because undeployed

air bag (inflator) module / inactivated seat

belt pretensioner must not be disposed of

through normal refuse channels. Undeployed

air bag (inflator) module and inactivated seat

belt pretensioner contain substances that

can cause severe illness or personal injury if

sealed container is damaged during disposal.

Air bag (inflator) module / seat belt pretensioner can be

deployed / activated inside or outside of vehicle.

Deployment / Activation method used depends upon

final disposition of vehicle. Review the following

instructions in order to deter mine which will work best in

a given situation.

Deployment / Activation Ou tside of Vehicle: When you

intend to return the vehicle to service, deploy the air bag

(inflator) module(s) and/or activate seat belt

pretensioner(s) outside of the vehicle.

Deployment / Activation Insi de of Vehicle: When the

vehicle will be destroyed, or salvaged for component

parts, deploy the air bag module(s) and/or activate seat

belt pretensioner(s) installed on vehicle.

WARNING!

The following precautions must be observed

for this work. Failure to observe any of them

may result in personal injury.

• Procedure should be followed strictly as described here.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”

beforehand.

• To avoid accidental deployment / activation, this work should be performed

by no more than one person.

• Since smoke is produced when air bag (inflator) module is deployed and

pretensioner is activated, select well-

ventilated area.

• Air bag (inflator) module and seat belt pretensioner will immediately deploy /

activate when 12 volts vehicle battery is

connected to it. Wear safety glasses

throughout this entire deployment /

activation and disposal procedure.

• Wear suitable ear protection when deploying air bag (inflator) module /

activating seat belt pretensioner. Also,

advise those who are in area close to

deployment / activation site to wear

suitable ear protection.

• Do not deploy / activate two or more air bag system components (air bag (inflator)

modules and seat belt pretensioners) at

the same time.

• Never connect deployment harness to any 12 volts vehicle battery before connecting

deployment harness to air bag (inflator)

module and seat belt pretensioner.

Deployment harness sh all remain shorted

and not be connected to 12 volts vehicle

battery till you are ready to deploy air bag

(inflator) module or activate seat belt

pretensioner.