Main bolt torque SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 37 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-7

Fuel Filter ReplacementS7RS0B0206011

Fuel filter is installed in fuel pump assembly in fuel tank.

Replace fuel filter or fuel pump assembly with new one,

referring to “Fuel Pump Assembly Removal and

Installation in Section 1G” for proper procedure.

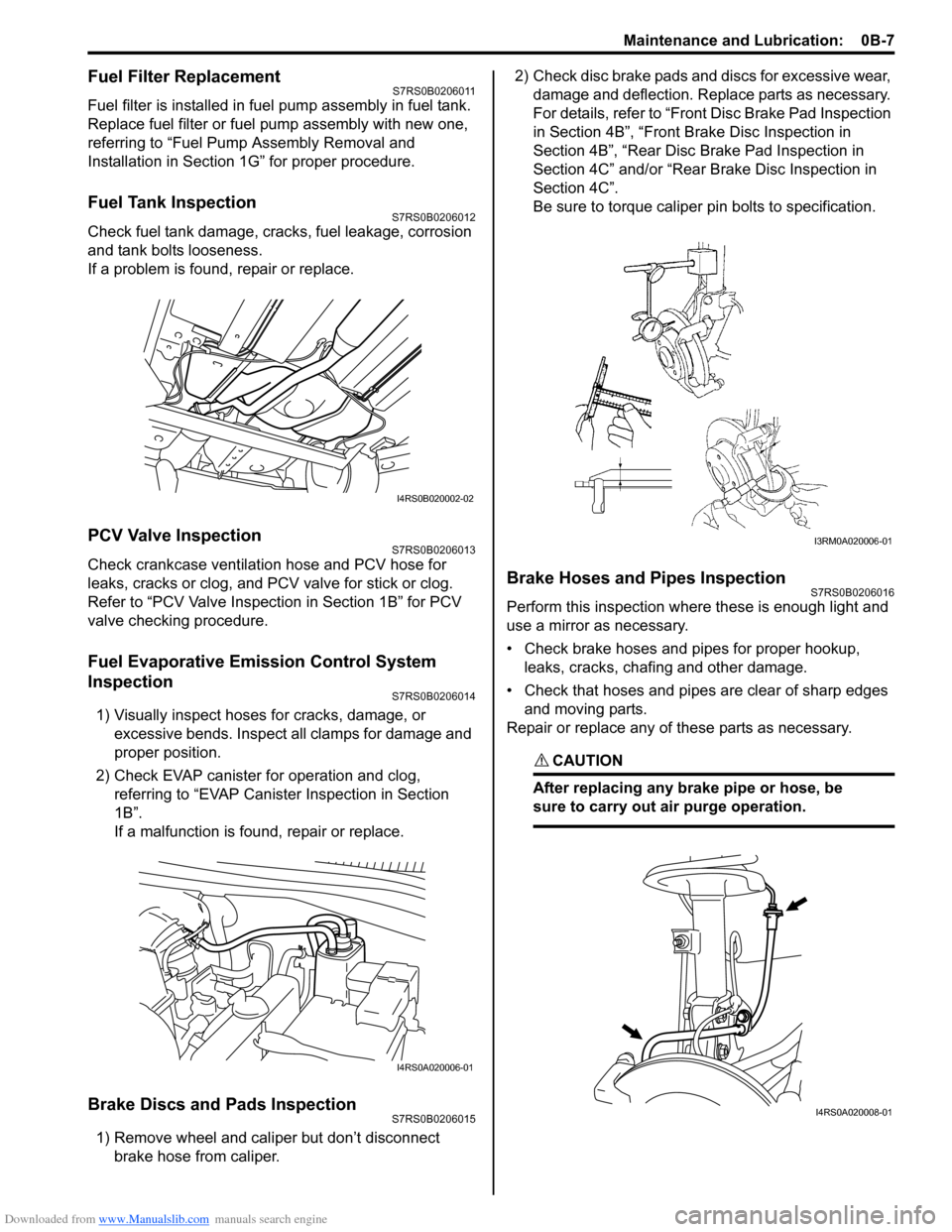

Fuel Tank InspectionS7RS0B0206012

Check fuel tank damage, cracks, fuel leakage, corrosion

and tank bolts looseness.

If a problem is found, repair or replace.

PCV Valve InspectionS7RS0B0206013

Check crankcase ventilation hose and PCV hose for

leaks, cracks or clog, and PCV valve for stick or clog.

Refer to “PCV Valve Inspection in Section 1B” for PCV

valve checking procedure.

Fuel Evaporative Emission Control System

Inspection

S7RS0B0206014

1) Visually inspect hoses for cracks, damage, or excessive bends. Inspect a ll clamps for damage and

proper position.

2) Check EVAP canister for operation and clog, referring to “EVAP Canister Inspection in Section

1B”.

If a malfunction is found, repair or replace.

Brake Discs and Pads InspectionS7RS0B0206015

1) Remove wheel and caliper but don’t disconnect brake hose from caliper. 2) Check disc brake pads and discs for excessive wear,

damage and deflection. Replace parts as necessary.

For details, refer to “Front Disc Brake Pad Inspection

in Section 4B”, “Front Brake Disc Inspection in

Section 4B”, “Rear Disc Brake Pad Inspection in

Section 4C” and/or “Rear Brake Disc Inspection in

Section 4C”.

Be sure to torque caliper pin bolts to specification.

Brake Hoses and Pipes InspectionS7RS0B0206016

Perform this inspection where these is enough light and

use a mirror as necessary.

• Check brake hoses and pipes for proper hookup, leaks, cracks, chafing and other damage.

• Check that hoses and pipes are clear of sharp edges and moving parts.

Repair or replace any of these parts as necessary.

CAUTION!

After replacing any brake pipe or hose, be

sure to carry out air purge operation.

I4RS0B020002-02

I4RS0A020006-01

I3RM0A020006-01

I4RS0A020008-01

Page 40 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-10 Maintenance and Lubrication:

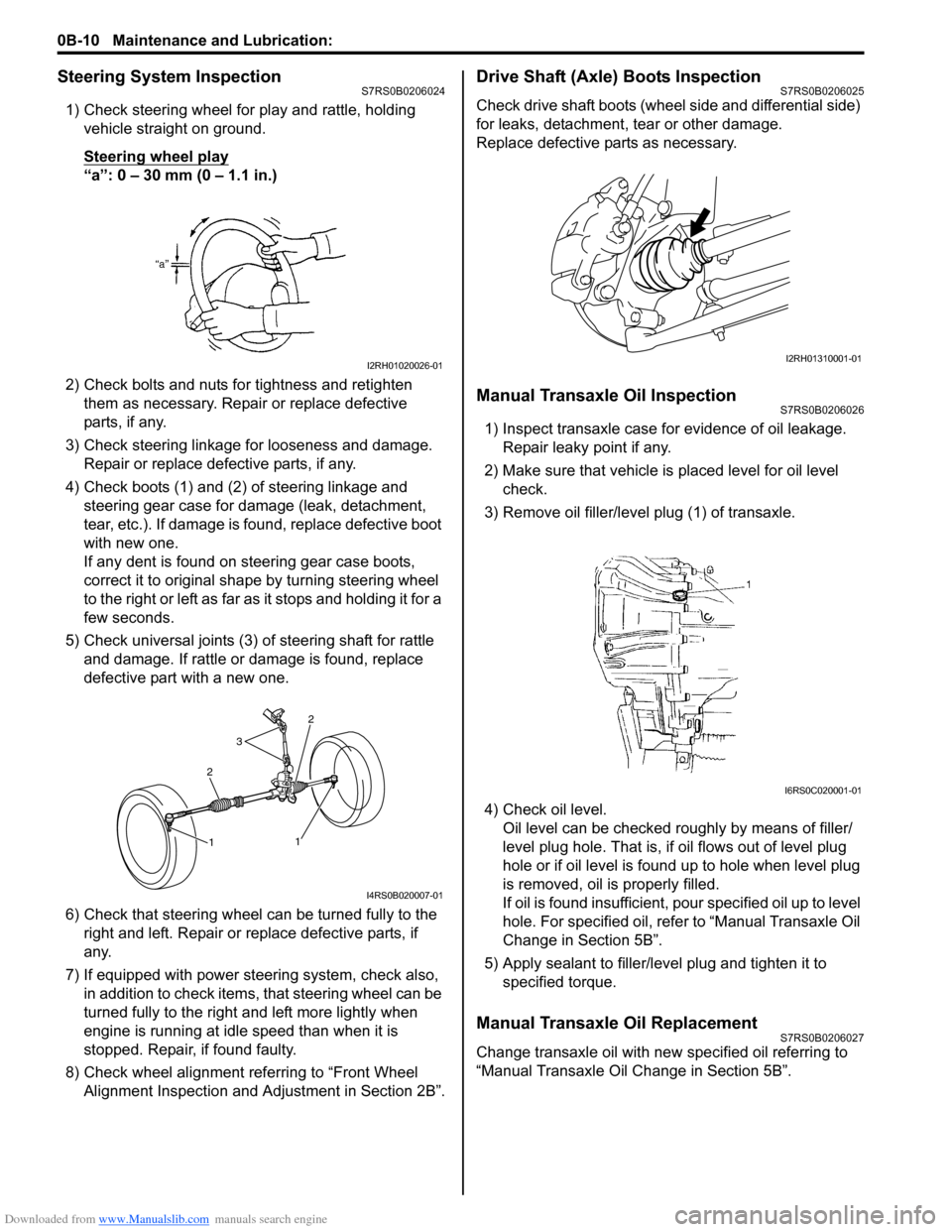

Steering System InspectionS7RS0B0206024

1) Check steering wheel for play and rattle, holding vehicle straight on ground.

Steering wheel play

“a”: 0 – 30 mm (0 – 1.1 in.)

2) Check bolts and nuts for tightness and retighten them as necessary. Repair or replace defective

parts, if any.

3) Check steering linkage for looseness and damage. Repair or replace defective parts, if any.

4) Check boots (1) and (2) of steering linkage and steering gear case for damage (leak, detachment,

tear, etc.). If damage is fo und, replace defective boot

with new one.

If any dent is found on steering gear case boots,

correct it to original shape by turning steering wheel

to the right or left as far as it stops and holding it for a

few seconds.

5) Check universal joints (3) of steering shaft for rattle and damage. If rattle or damage is found, replace

defective part with a new one.

6) Check that steering wheel can be turned fully to the

right and left. Repair or replace defective parts, if

any.

7) If equipped with power steering system, check also, in addition to check items, that steering wheel can be

turned fully to the right and left more lightly when

engine is running at idle speed than when it is

stopped. Repair, if found faulty.

8) Check wheel alignment referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B”.

Drive Shaft (Axle) Boots InspectionS7RS0B0206025

Check drive shaft boots (wheel side and differential side)

for leaks, detachment, tear or other damage.

Replace defective parts as necessary.

Manual Transaxle Oil InspectionS7RS0B0206026

1) Inspect transaxle case for evidence of oil leakage. Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Remove oil filler/leve l plug (1) of transaxle.

4) Check oil level. Oil level can be checked roughly by means of filler/

level plug hole. That is, if oil flows out of level plug

hole or if oil level is found up to hole when level plug

is removed, oil is properly filled.

If oil is found insufficient, po ur specified oil up to level

hole. For specified oil, refe r to “Manual Transaxle Oil

Change in Section 5B”.

5) Apply sealant to filler/leve l plug and tighten it to

specified torque.

Manual Transaxle Oil ReplacementS7RS0B0206027

Change transaxle oil with new specified oil referring to

“Manual Transaxle Oil Change in Section 5B”.

I2RH01020026-01

2

3

2

1

1

I4RS0B020007-01

I2RH01310001-01

I6RS0C020001-01

Page 285 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-13

Without Using SUZUKI Scan Tool1) Measure sensor voltage between “C37-23” terminal of ECM connector and vehicle body ground referring

to “Inspection of ECM and Its Circuits in Section 1A”.

If check result is satisfactory, electric load current

sensor is in good condition.

If check result is not satisfactory, check the following

parts and circuit.

• Electric load current sensor circuit (power, ground and output)

• Following charging system components – Battery (refer to “Battery Inspection in Section

1J”)

– Generator (refer to “Generator Inspection in Section 1J”)

– Generator output control circuit (refer to “Generator Test (Undercharged Battery Check)

in Section 1J”)

– Generator field coil monitor circuit (refer to “Generator Inspection in Section 1J”) If electric load current sensor circuit and charging

system is in good condition,

electric load current sensor

(1) is faulty.

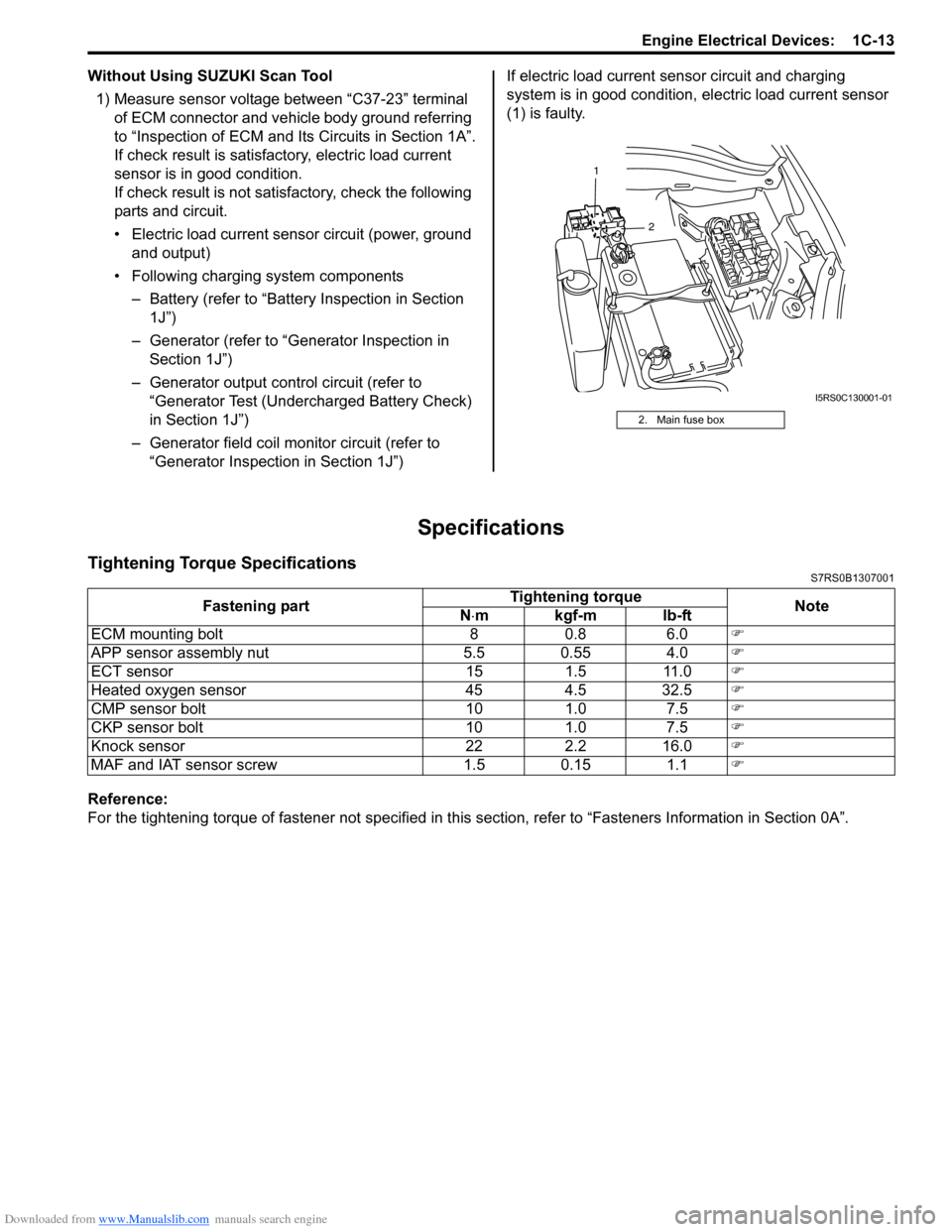

Specifications

Tightening Torque SpecificationsS7RS0B1307001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

2. Main fuse box

2

1

I5RS0C130001-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

ECM mounting bolt 8 0.8 6.0 �)

APP sensor assembly nut 5.5 0.55 4.0 �)

ECT sensor 15 1.5 11.0 �)

Heated oxygen sensor 45 4.5 32.5 �)

CMP sensor bolt 10 1.0 7.5 �)

CKP sensor bolt 10 1.0 7.5 �)

Knock sensor 22 2.2 16.0 �)

MAF and IAT sensor screw 1.5 0.15 1.1 �)

Page 340 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-55 Engine Mechanical:

Installation

NOTE

• Use new bearing cap No.1 bolts. They are deformed once they are used because they

are plastic deformation tightening bolts.

• All parts to be insta lled must be perfectly

clean.

• Be sure to oil crankshaft journals, journal bearings, thrust bearings, crankpins,

connecting rod bearings, pistons, piston

rings and cylinder bores.

• Journal bearings, bearing caps, connecting rods, rod bearings, rod bearing

caps, pistons and piston rings are in

combination sets. Do not disturb such

combination and make sure that each part

goes back to where it came from, when

installing.

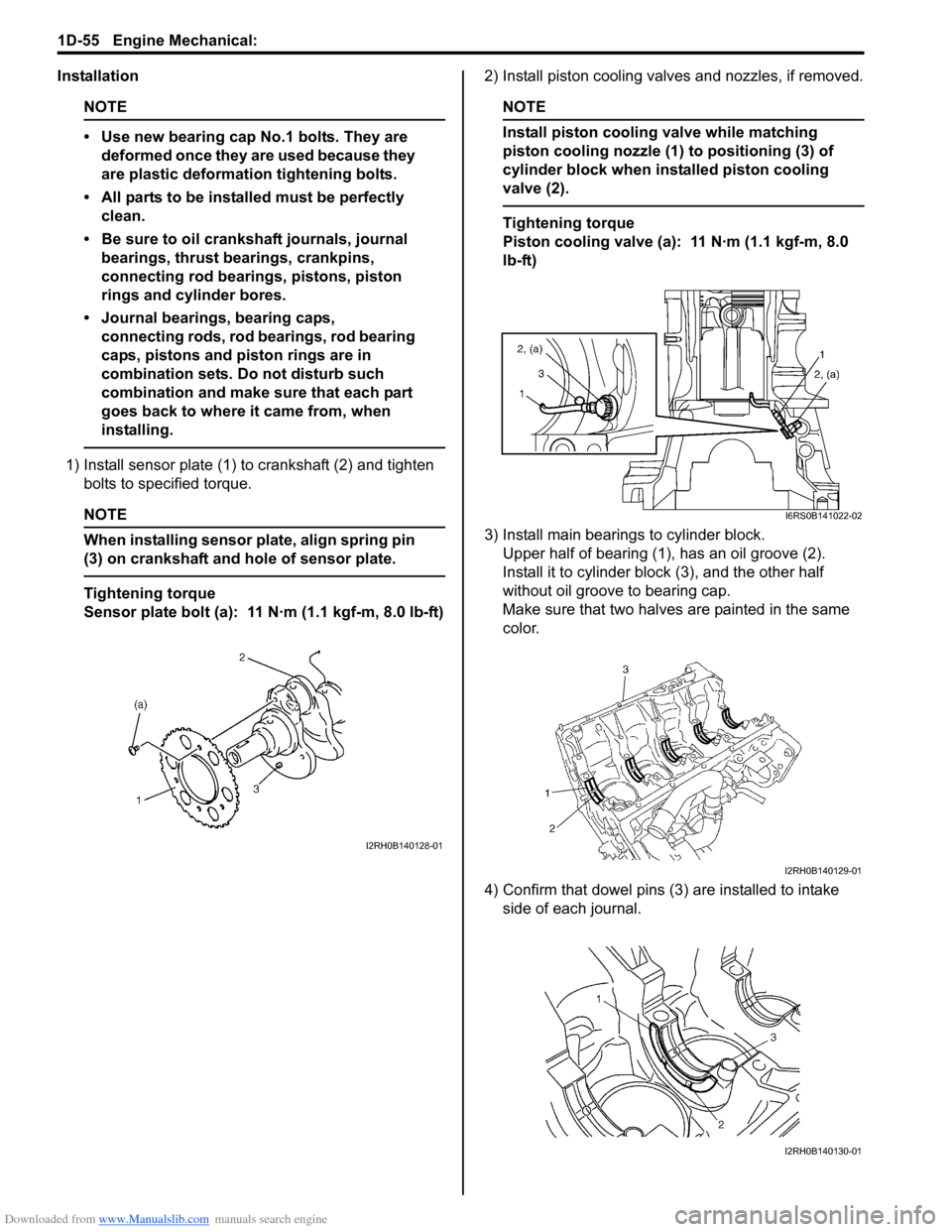

1) Install sensor plate (1) to crankshaft (2) and tighten bolts to spec ified torque.

NOTE

When installing sensor plate, align spring pin

(3) on crankshaft and hole of sensor plate.

Tightening torque

Sensor plate bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft) 2) Install piston cooling valves and nozzles, if removed.

NOTE

Install piston cooling valve while matching

piston cooling nozzle (1) to positioning (3) of

cylinder block when installed piston cooling

valve (2).

Tightening torque

Piston cooling valve (a): 11 N·m (1.1 kgf-m, 8.0

lb-ft)

3) Install main bearings to cylinder block. Upper half of bearing (1), has an oil groove (2).

Install it to cylinder block (3), and the other half

without oil groove to bearing cap.

Make sure that two halves are painted in the same

color.

4) Confirm that dowel pins (3 ) are installed to intake

side of each journal.

I2RH0B140128-01

I6RS0B141022-02

I2RH0B140129-01

I2RH0B140130-01

Page 341 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-56

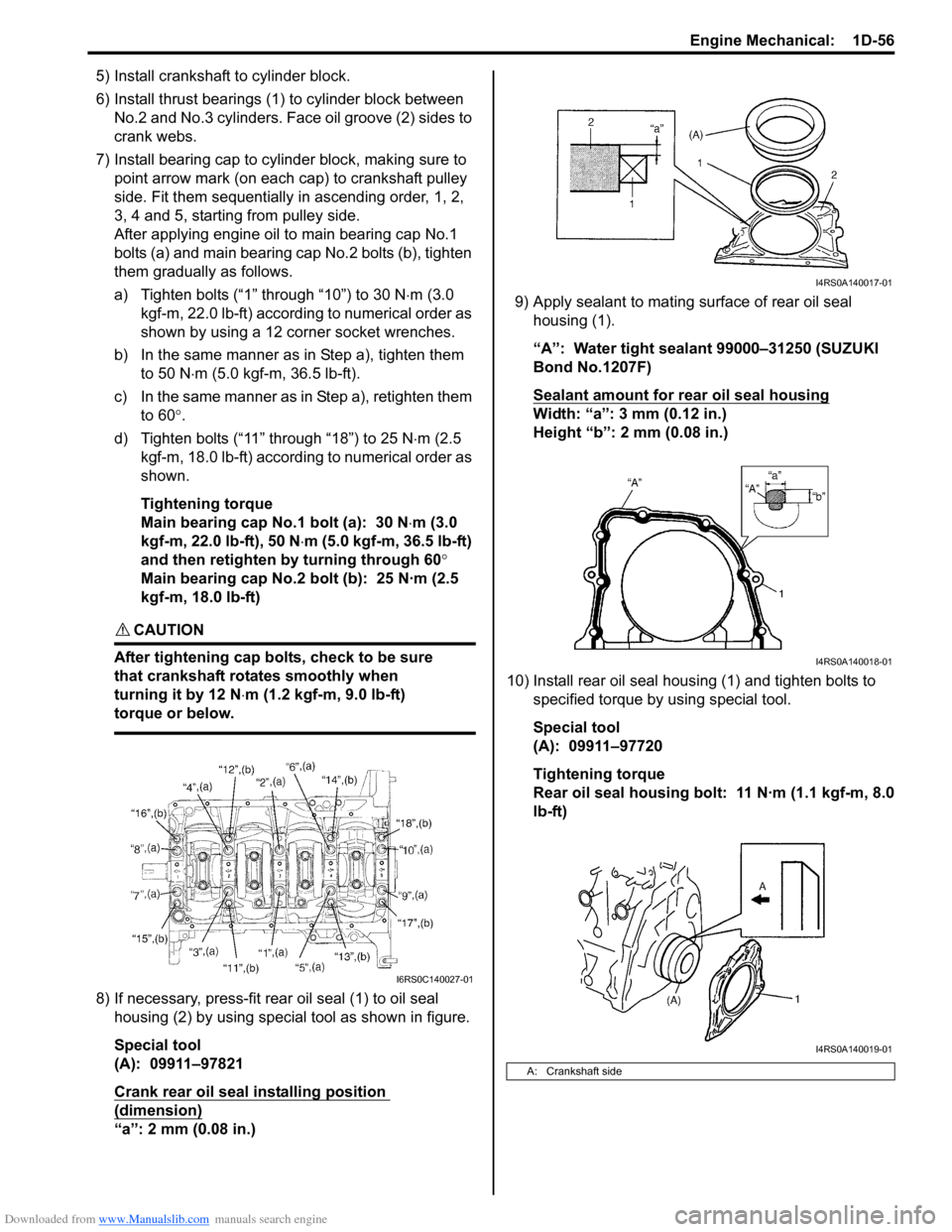

5) Install crankshaft to cylinder block.

6) Install thrust bearings (1) to cylinder block between No.2 and No.3 cylinders. Face oil groove (2) sides to

crank webs.

7) Install bearing cap to cylinder block, making sure to point arrow mark (on each cap) to crankshaft pulley

side. Fit them sequentially in ascending order, 1, 2,

3, 4 and 5, starting from pulley side.

After applying engine oil to main bearing cap No.1

bolts (a) and main bearing cap No.2 bolts (b), tighten

them gradually as follows.

a) Tighten bolts (“1” through “10”) to 30 N ⋅m (3.0

kgf-m, 22.0 lb-ft) according to numerical order as

shown by using a 12 corner socket wrenches.

b) In the same manner as in Step a), tighten them to 50 N ⋅m (5.0 kgf-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them to 60 °.

d) Tighten bolts (“11” through “18”) to 25 N ⋅m (2.5

kgf-m, 18.0 lb-ft) according to numerical order as

shown.

Tightening torque

Main bearing cap No.1 bolt (a): 30 N ⋅m (3.0

kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0 kgf-m, 36.5 lb-ft)

and then retighten by turning through 60 °

Main bearing cap No.2 bolt (b): 25 N·m (2.5

kgf-m, 18.0 lb-ft)

CAUTION!

After tightening cap bolts, check to be sure

that crankshaft rotates smoothly when

turning it by 12 N ⋅m (1.2 kgf-m, 9.0 lb-ft)

torque or below.

8) If necessary, press-fit rear oil seal (1) to oil seal housing (2) by using special tool as shown in figure.

Special tool

(A): 09911–97821

Crank rear oil seal installing position

(dimension)

“a”: 2 mm (0.08 in.) 9) Apply sealant to mating surface of rear oil seal

housing (1).

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

Sealant amount for rear oil seal housing

Width: “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.)

10) Install rear oil seal housing (1) and tighten bolts to specified torque by using special tool.

Special tool

(A): 09911–97720

Tightening torque

Rear oil seal housing bolt: 11 N·m (1.1 kgf-m, 8.0

lb-ft)

I6RS0C140027-01

A: Crankshaft side

I4RS0A140017-01

I4RS0A140018-01

I4RS0A140019-01

Page 343 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-58

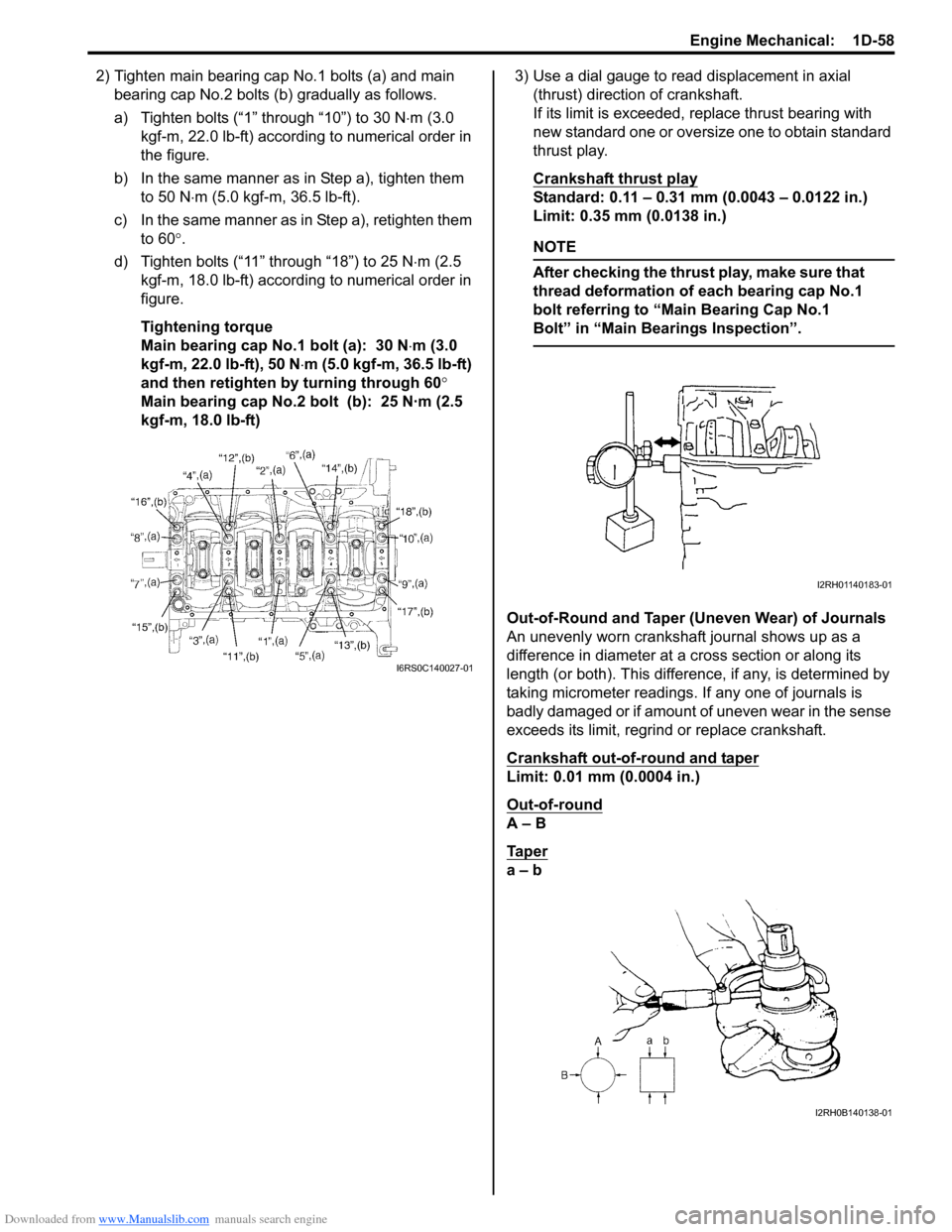

2) Tighten main bearing cap No.1 bolts (a) and main bearing cap No.2 bolts (b ) gradually as follows.

a) Tighten bolts (“1” through “10”) to 30 N ⋅m (3.0

kgf-m, 22.0 lb-ft) according to numerical order in

the figure.

b) In the same manner as in Step a), tighten them to 50 N ⋅m (5.0 kgf-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them to 60 °.

d) Tighten bolts (“11” through “18”) to 25 N ⋅m (2.5

kgf-m, 18.0 lb-ft) according to numerical order in

figure.

Tightening torque

Main bearing cap No.1 bolt (a): 30 N ⋅m (3.0

kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0 kgf-m, 36.5 lb-ft)

and then retighten by turning through 60 °

Main bearing cap No.2 bolt (b): 25 N·m (2.5

kgf-m, 18.0 lb-ft) 3) Use a dial gauge to read displacement in axial

(thrust) direction of crankshaft.

If its limit is exceeded, replace thrust bearing with

new standard one or oversize one to obtain standard

thrust play.

Crankshaft thrust play

Standard: 0.11 – 0.31 mm (0.0043 – 0.0122 in.)

Limit: 0.35 mm (0.0138 in.)

NOTE

After checking the thrust play, make sure that

thread deformation of each bearing cap No.1

bolt referring to “Main Bearing Cap No.1

Bolt” in “Main Bear ings Inspection”.

Out-of-Round and Taper (Uneven Wear) of Journals

An unevenly worn crankshaft journal shows up as a

difference in diameter at a cross section or along its

length (or both). This difference, if any, is determined by

taking micrometer readings. If any one of journals is

badly damaged or if amount of uneven wear in the sense

exceeds its limit, regrind or replace crankshaft.

Crankshaft out-of-round and taper

Limit: 0.01 mm (0.0004 in.)

Out-of-round

A – B

Ta p e r

a – b

I6RS0C140027-01

I2RH01140183-01

I2RH0B140138-01

Page 344 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-59 Engine Mechanical:

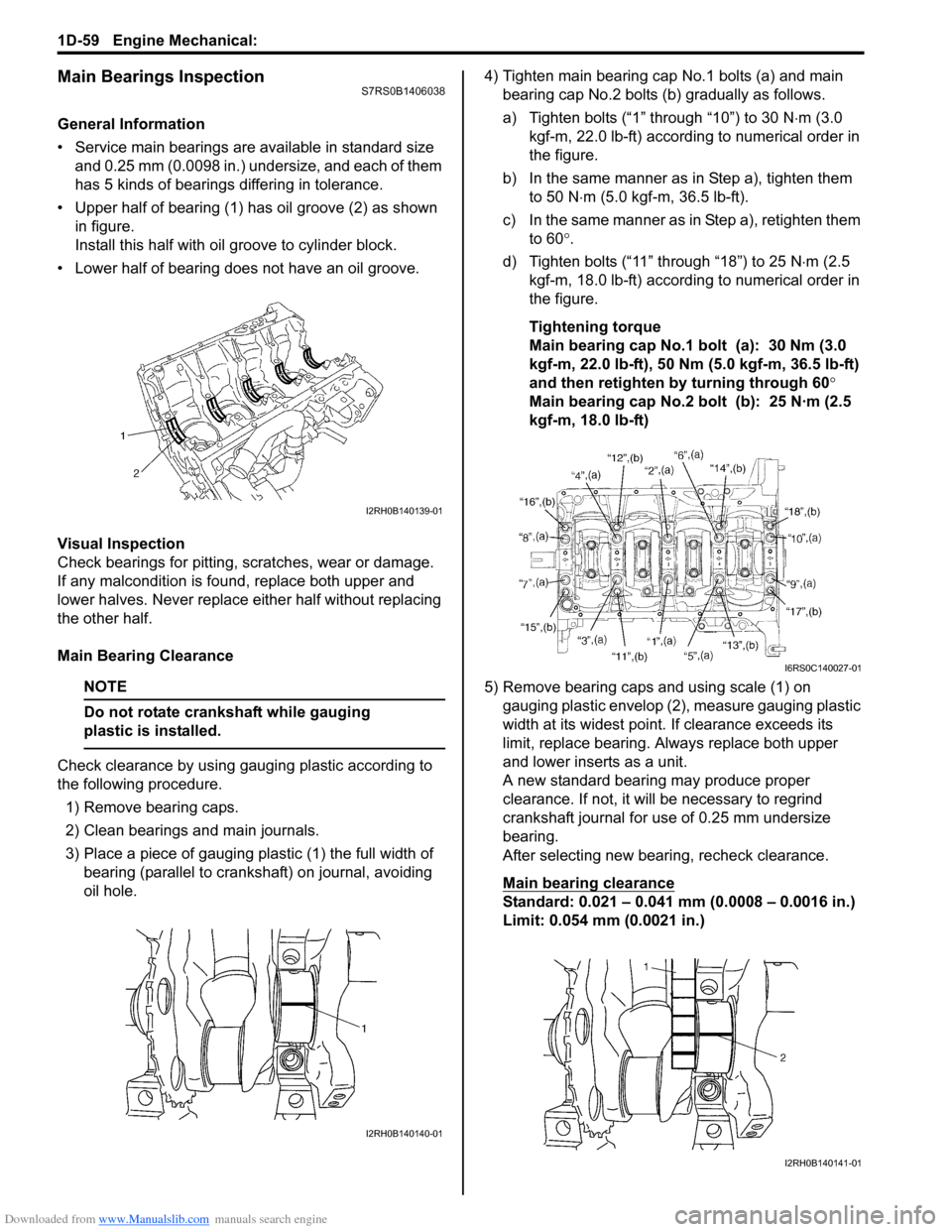

Main Bearings InspectionS7RS0B1406038

General Information

• Service main bearings are available in standard size and 0.25 mm (0.0098 in.) undersize, and each of them

has 5 kinds of bearings differing in tolerance.

• Upper half of bearing (1) has oil groove (2) as shown in figure.

Install this half with o il groove to cylinder block.

• Lower half of bearing does not have an oil groove.

Visual Inspection

Check bearings for pitting, scratches, wear or damage.

If any malcondition is foun d, replace both upper and

lower halves. Never replace either half without replacing

the other half.

Main Bearing Clearance

NOTE

Do not rotate crankshaft while gauging

plastic is installed.

Check clearance by using ga uging plastic according to

the following procedure.

1) Remove bearing caps.

2) Clean bearings and main journals.

3) Place a piece of gauging plastic (1) the full width of bearing (parallel to crankshaft) on journal, avoiding

oil hole. 4) Tighten main bearing cap No.1 bolts (a) and main

bearing cap No.2 bolts (b) gradually as follows.

a) Tighten bolts (“1” through “10”) to 30 N ⋅m (3.0

kgf-m, 22.0 lb-ft) according to numerical order in

the figure.

b) In the same manner as in Step a), tighten them to 50 N ⋅m (5.0 kgf-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them to 60 °.

d) Tighten bolts (“11” through “18”) to 25 N ⋅m (2.5

kgf-m, 18.0 lb-ft) according to numerical order in

the figure.

Tightening torque

Main bearing cap No.1 bolt (a): 30 Nm (3.0

kgf-m, 22.0 lb-ft), 50 Nm (5.0 kgf-m, 36.5 lb-ft)

and then retighten by turning through 60°

Main bearing cap No.2 bolt (b): 25 N·m (2.5

kgf-m, 18.0 lb-ft)

5) Remove bearing caps and using scale (1) on gauging plastic envelop (2), measure gauging plastic

width at its widest point. If clearance exceeds its

limit, replace bearing. Always replace both upper

and lower inserts as a unit.

A new standard bearing may produce proper

clearance. If not, it will be necessary to regrind

crankshaft journal for use of 0.25 mm undersize

bearing.

After selecting new bearing, recheck clearance.

Main bearing clearance

Standard: 0.021 – 0.041 mm (0.0008 – 0.0016 in.)

Limit: 0.054 mm (0.0021 in.)

I2RH0B140139-01

I2RH0B140140-01

I6RS0C140027-01

I2RH0B140141-01

Page 349 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-64

Honing or Reboring Cylinders1) When any cylinder needs reboring, all other cylinders must also be rebored at the same time.

2) Select oversized piston according to amount of cylinder wear.

Oversize piston specification

Oversize 0.50: 78.453 – 78.468 mm (3.0887 –

3.0893 in.)

3) Using micrometer, measure piston diameter. Measurement position for piston diameter

“a”: 7.0 mm (0.28 in.) 4) Rebore and hone cylinder to the following

dimension.

NOTE

Before reboring, install all main bearing caps

in place and tighten to specification to avoid

distortion of bearing bores.

Cylinder bore diameter to be rebored

Oversize 0.50: 78.500 – 78.514 mm (3.0906 –

3.0911 in.)

5) Measure piston clearance after honing. Piston clearance

0.032 – 0.061 mm (0.0013 – 0.0024 in.)

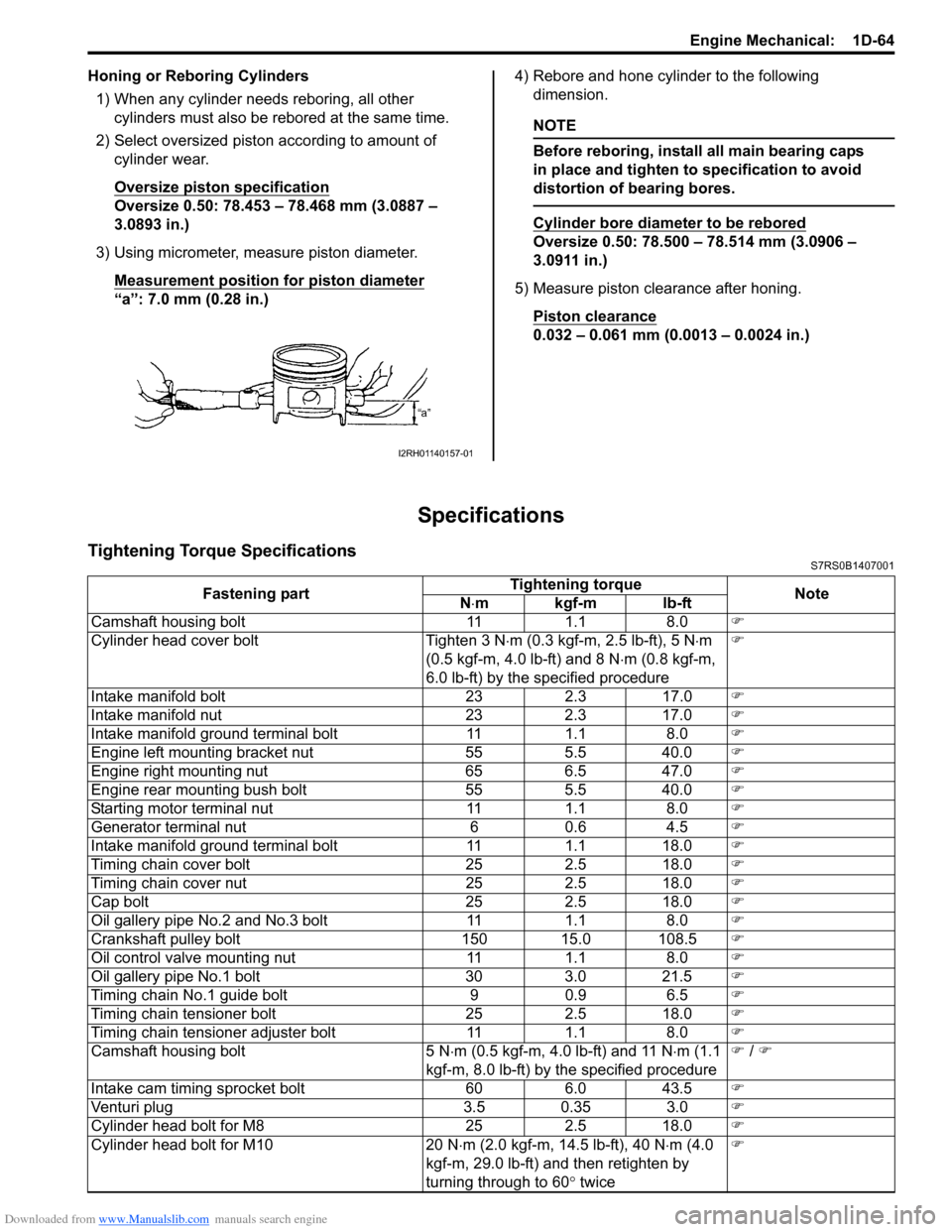

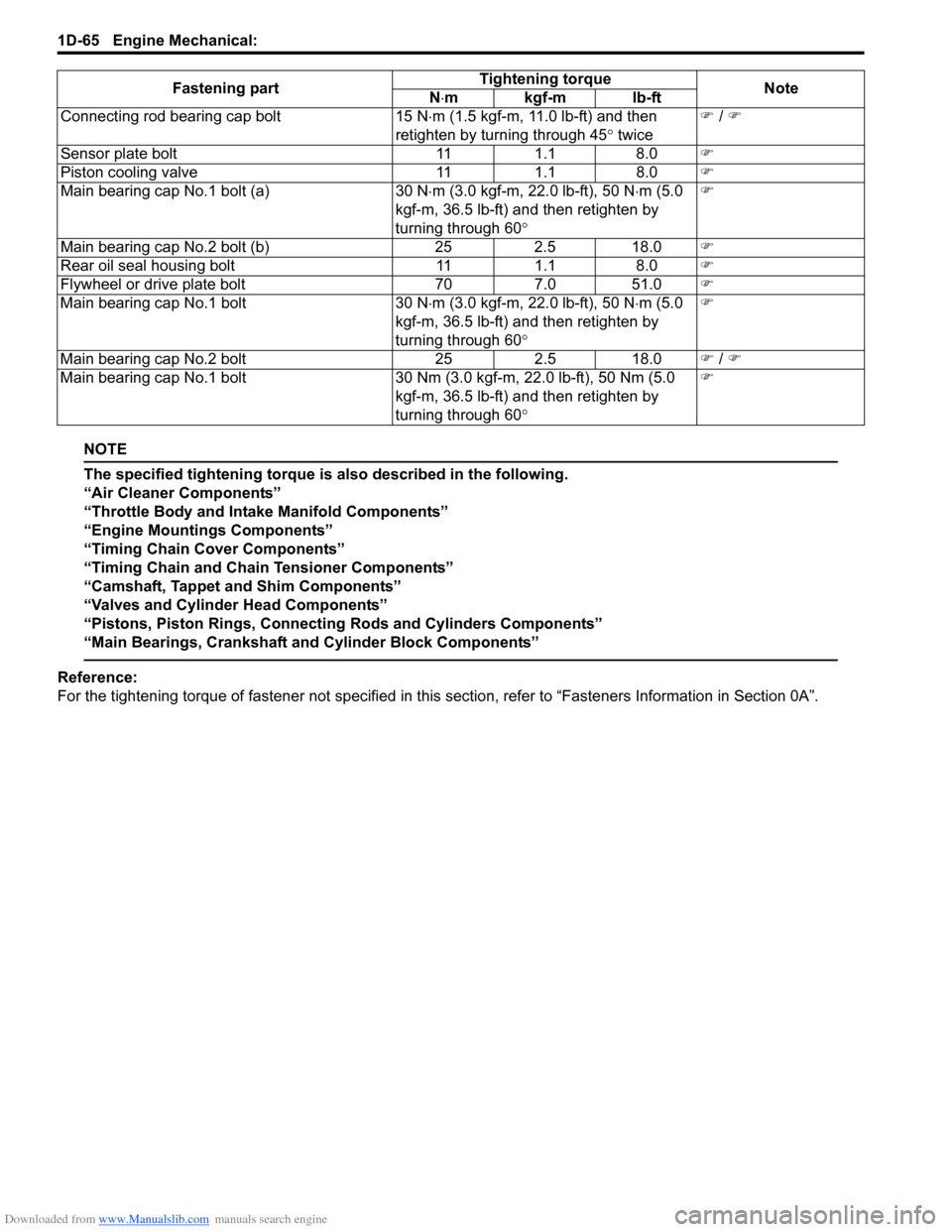

Specifications

Tightening Torque SpecificationsS7RS0B1407001

I2RH01140157-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Camshaft housing bolt 11 1.1 8.0 �)

Cylinder head cover bolt Tighten 3 N ⋅m (0.3 kgf-m, 2.5 lb-ft), 5 N ⋅m

(0.5 kgf-m, 4.0 lb-ft) and 8 N ⋅m (0.8 kgf-m,

6.0 lb-ft) by the specified procedure �)

Intake manifold bolt 23 2.3 17.0 �)

Intake manifold nut 23 2.3 17.0 �)

Intake manifold ground terminal bolt 11 1.1 8.0 �)

Engine left mounting bracket nut 55 5.5 40.0 �)

Engine right mounting nut 65 6.5 47.0 �)

Engine rear mounting bush bolt 55 5.5 40.0 �)

Starting motor terminal nut 11 1.1 8.0 �)

Generator terminal nut 6 0.6 4.5 �)

Intake manifold ground terminal bolt 11 1.1 18.0 �)

Timing chain cover bolt 25 2.5 18.0 �)

Timing chain cover nut 25 2.5 18.0 �)

Cap bolt 25 2.5 18.0 �)

Oil gallery pipe No.2 and No.3 bolt 11 1.1 8.0 �)

Crankshaft pulley bolt 150 15.0 108.5 �)

Oil control valve mounting nut 11 1.1 8.0 �)

Oil gallery pipe No.1 bolt 30 3.0 21.5 �)

Timing chain No.1 guide bolt 9 0.9 6.5 �)

Timing chain tensioner bolt 25 2.5 18.0 �)

Timing chain tensioner adjuster bolt 11 1.1 8.0 �)

Camshaft housing bolt 5 N ⋅m (0.5 kgf-m, 4.0 lb-ft) and 11 N ⋅m (1.1

kgf-m, 8.0 lb-ft) by the specified procedure �)

/ �)

Intake cam timing sprocket bolt 60 6.0 43.5 �)

Venturi plug 3.5 0.35 3.0 �)

Cylinder head bolt for M8 25 2.5 18.0 �)

Cylinder head bolt for M10 20 N ⋅m (2.0 kgf-m, 14.5 lb-ft), 40 N ⋅m (4.0

kgf-m, 29.0 lb-ft) and then retighten by

turning through to 60 ° twice �)

Page 350 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-65 Engine Mechanical:

NOTE

The specified tightening torque is also described in the following.

“Air Cleaner Components”

“Throttle Body and Intake Manifold Components”

“Engine Mountings Components”

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Connecting rod bearing cap bolt

15 N⋅m (1.5 kgf-m, 11.0 lb-ft) and then

retighten by turning through 45 ° twice �)

/ �)

Sensor plate bolt 111.1 8.0 �)

Piston cooling valve 111.1 8.0 �)

Main bearing cap No.1 bolt (a) 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt (b) 252.5 18.0 �)

Rear oil seal housing bolt 111.1 8.0 �)

Flywheel or drive plate bolt 707.0 51.0 �)

Main bearing cap No.1 bolt 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt 252.5 18.0 �) / �)

Main bearing cap No.1 bolt 30 Nm (3.0 kgf-m, 22.0 lb-ft), 50 Nm (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Page 390 of 1496

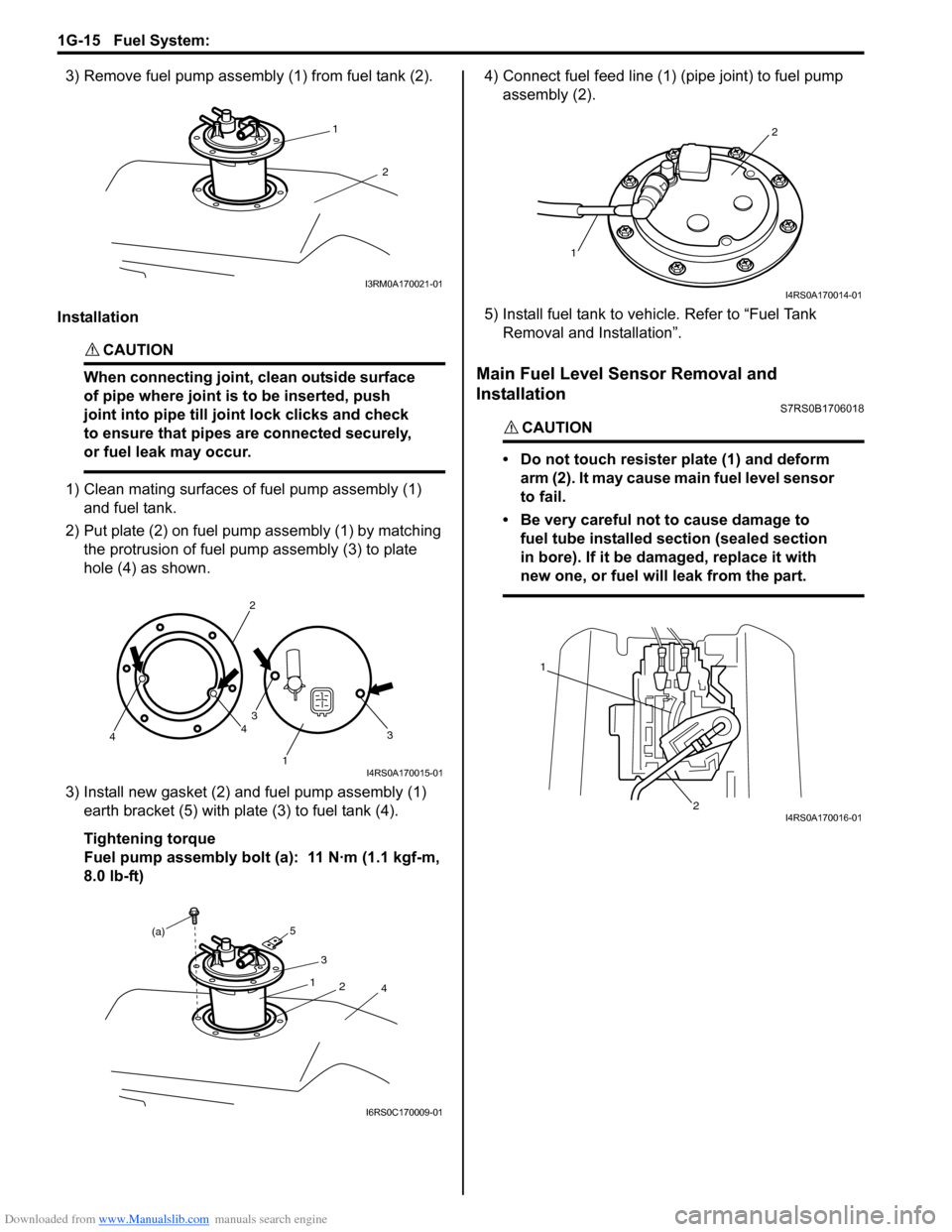

Downloaded from www.Manualslib.com manuals search engine 1G-15 Fuel System:

3) Remove fuel pump assembly (1) from fuel tank (2).

Installation

CAUTION!

When connecting joint, clean outside surface

of pipe where joint is to be inserted, push

joint into pipe till jo int lock clicks and check

to ensure that pipes are connected securely,

or fuel leak may occur.

1) Clean mating surfaces of fuel pump assembly (1) and fuel tank.

2) Put plate (2) on fuel pump assembly (1) by matching the protrusion of fuel pump assembly (3) to plate

hole (4) as shown.

3) Install new gasket (2) and fuel pump assembly (1) earth bracket (5) with plate (3) to fuel tank (4).

Tightening torque

Fuel pump assembly bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft) 4) Connect fuel feed line (1) (pipe joint) to fuel pump

assembly (2).

5) Install fuel tank to vehi cle. Refer to “Fuel Tank

Removal and Installation”.

Main Fuel Level Sensor Removal and

Installation

S7RS0B1706018

CAUTION!

• Do not touch resister plate (1) and deform arm (2). It may cause main fuel level sensor

to fail.

• Be very careful not to cause damage to fuel tube installed section (sealed section

in bore). If it be damaged, replace it with

new one, or fuel will leak from the part.

1

2

I3RM0A170021-01

3

1

3

2

44

I4RS0A170015-01

3

1 2

(a)

4

5

I6RS0C170009-01

2

1

I4RS0A170014-01

1

2I4RS0A170016-01