Replace bulb SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 504 of 1496

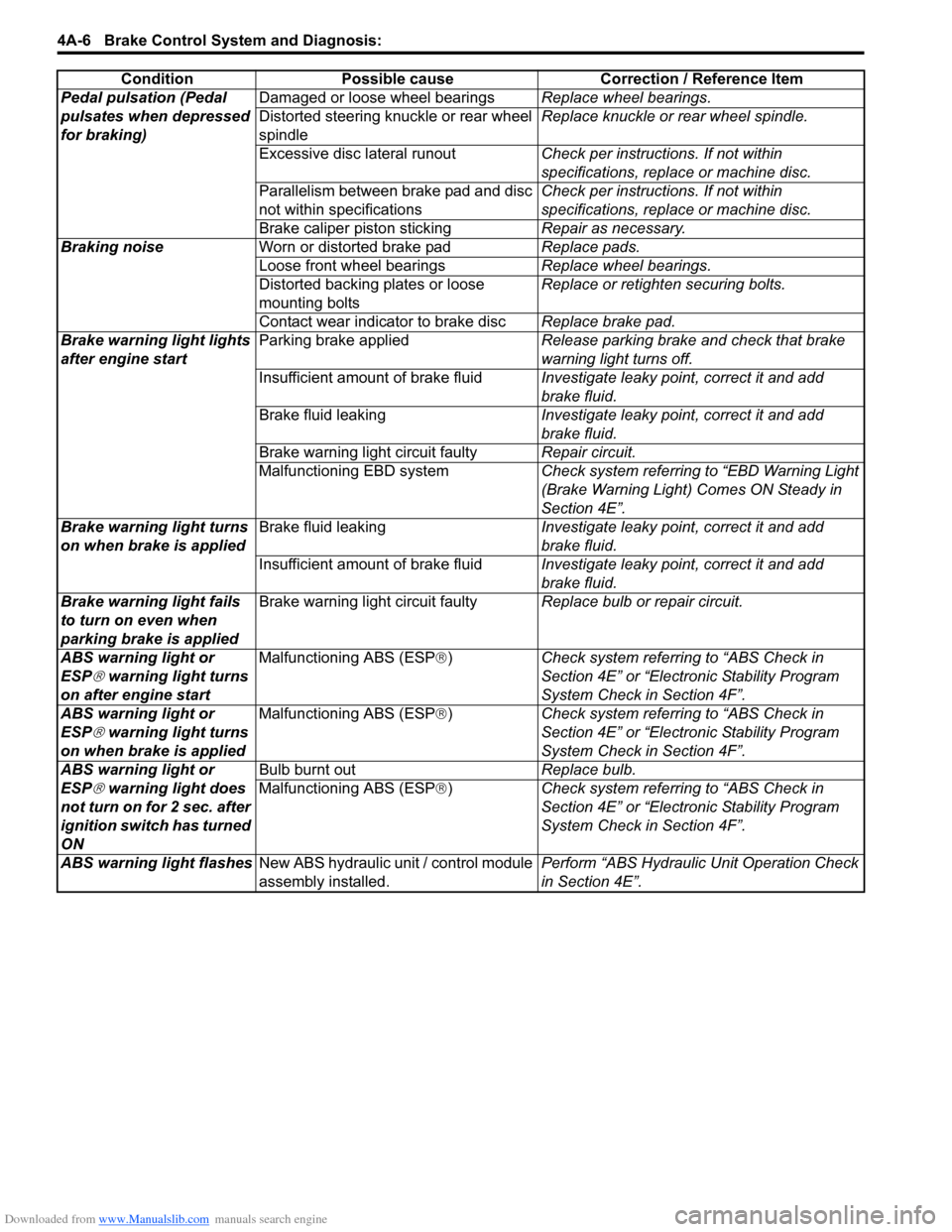

Downloaded from www.Manualslib.com manuals search engine 4A-6 Brake Control System and Diagnosis:

Pedal pulsation (Pedal

pulsates when depressed

for braking)Damaged or loose wheel bearings

Replace wheel bearings.

Distorted steering knuckle or rear wheel

spindle Replace knuckle or rear wheel spindle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine disc.

Parallelism between brake pad and disc

not within specifications Check per instructions. If not within

specifications, replace or machine disc.

Brake caliper piston sticking Repair as necessary.

Braking noise Worn or distorted brake pad Replace pads.

Loose front wheel bearings Replace wheel bearings.

Distorted backing plates or loose

mounting bolts Replace or retighten securing bolts.

Contact wear indicator to brake disc Replace brake pad.

Brake warning light lights

after engine start Parking brake applied

Release parking brake and check that brake

warning light turns off.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake fluid leaking Investigate leaky point, correct it and add

brake fluid.

Brake warning light circuit faulty Repair circuit.

Malfunctioning EBD system Check system referring to “EBD Warning Light

(Brake Warning Light) Comes ON Steady in

Section 4E”.

Brake warning light turns

on when brake is applied Brake fluid leaking

Investigate leaky point, correct it and add

brake fluid.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake warning light fails

to turn on even when

parking brake is applied Brake warning light circuit faulty

Replace bulb or repair circuit.

ABS warning light or

ESP

® warning light turns

on after engine start Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light turns

on when brake is applied Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light does

not turn on for 2 sec. after

ignition switch has turned

ON Bulb burnt out

Replace bulb.

Malfunctioning ABS (ESP ®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light flashes New ABS hydraulic unit / control module

assembly installed. Perform “ABS Hydraulic

Unit Operation Check

in Section 4E”.

Condition Possible cause Correction / Reference Item

Page 746 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-102 Automatic Transmission/Transaxle:

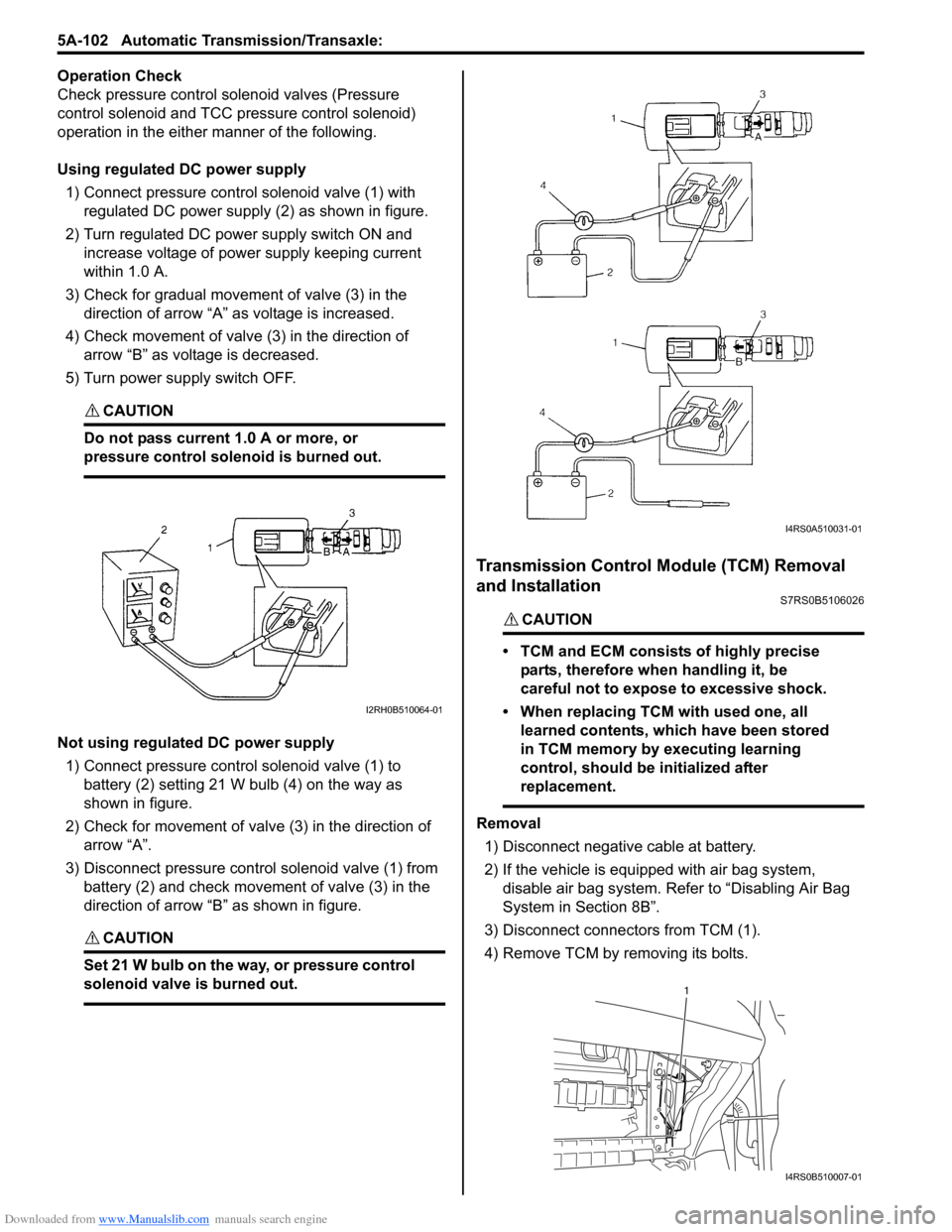

Operation Check

Check pressure control solenoid valves (Pressure

control solenoid and TCC pressure control solenoid)

operation in the either manner of the following.

Using regulated DC power supply

1) Connect pressure contro l solenoid valve (1) with

regulated DC power supply (2) as shown in figure.

2) Turn regulated DC power supply switch ON and increase voltage of power supply keeping current

within 1.0 A.

3) Check for gradual movement of valve (3) in the direction of arrow “A” as voltage is increased.

4) Check movement of valve (3) in the direction of arrow “B” as voltage is decreased.

5) Turn power supply switch OFF.

CAUTION!

Do not pass current 1.0 A or more, or

pressure control solenoid is burned out.

Not using regulated DC power supply 1) Connect pressure control solenoid valve (1) to battery (2) setting 21 W bulb (4) on the way as

shown in figure.

2) Check for movement of valve (3) in the direction of arrow “A”.

3) Disconnect pressure control solenoid valve (1) from battery (2) and check movement of valve (3) in the

direction of arrow “B” as shown in figure.

CAUTION!

Set 21 W bulb on the way, or pressure control

solenoid valve is burned out.

Transmission Control Module (TCM) Removal

and Installation

S7RS0B5106026

CAUTION!

• TCM and ECM consists of highly precise

parts, therefore when handling it, be

careful not to expose to excessive shock.

• When replacing TCM with used one, all learned contents, which have been stored

in TCM memory by executing learning

control, should be initialized after

replacement.

Removal

1) Disconnect negative cable at battery.

2) If the vehicle is equipped with air bag system, disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Disconnect connectors from TCM (1).

4) Remove TCM by removing its bolts.

I2RH0B510064-01

I4RS0A510031-01

1

I4RS0B510007-01

Page 942 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-6 Heater and Ventilation:

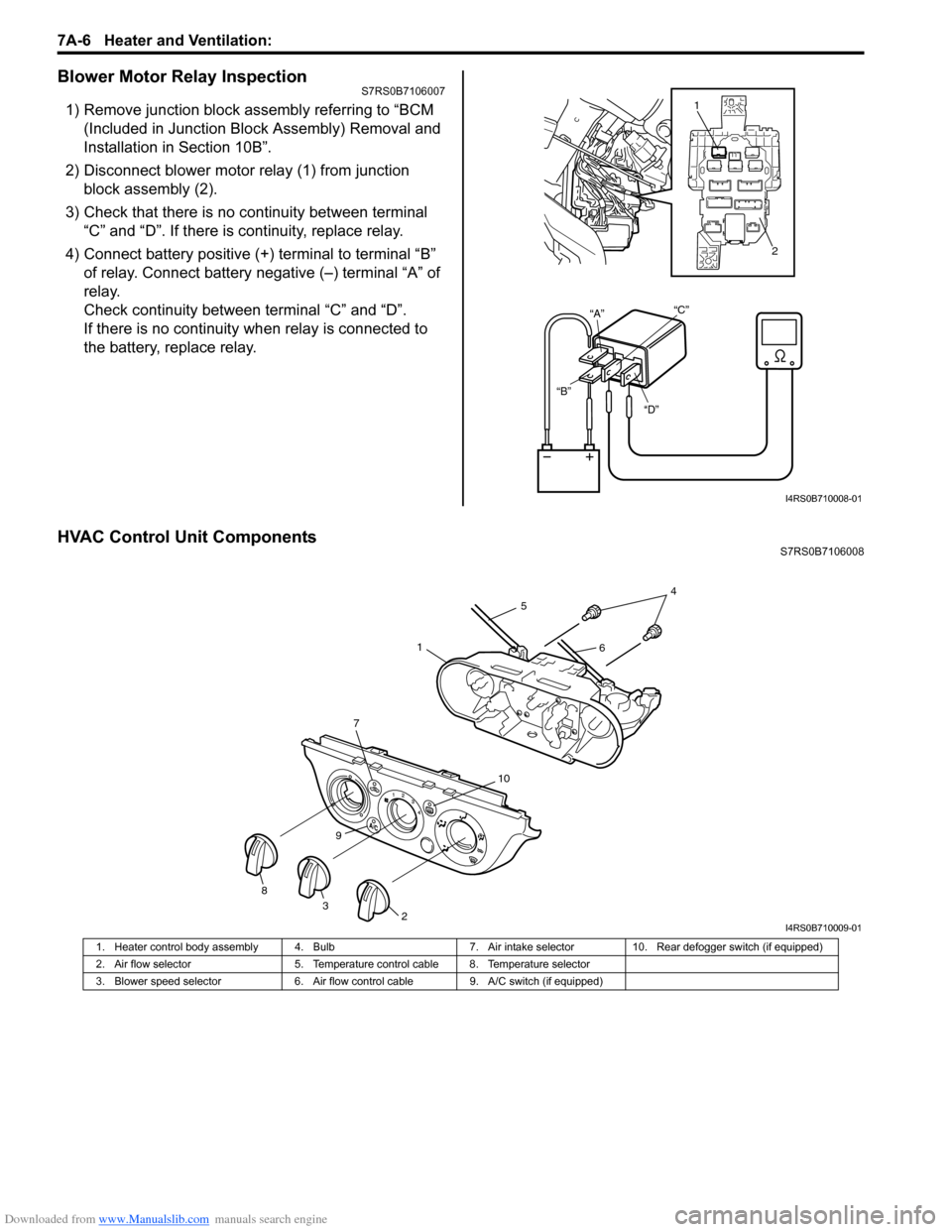

Blower Motor Relay InspectionS7RS0B7106007

1) Remove junction block assembly referring to “BCM (Included in Junction Block Assembly) Removal and

Installation in Section 10B”.

2) Disconnect blower motor relay (1) from junction block assembly (2).

3) Check that there is no continuity between terminal “C” and “D”. If there is continuity, replace relay.

4) Connect battery positive (+ ) terminal to terminal “B”

of relay. Connect battery negative (–) terminal “A” of

relay.

Check continuity between terminal “C” and “D”.

If there is no continuity wh en relay is connected to

the battery, replace relay.

HVAC Control Unit ComponentsS7RS0B7106008

“D”

“B” “A”

“C”

1

2

I4RS0B710008-01

45

61

7

10

9

238

I4RS0B710009-01

1. Heater control body assembly 4. Bulb 7. Air intake selector10. Rear defogger switch (if equipped)

2. Air flow selector 5. Temperature control cable 8. Temperature selector

3. Blower speed selector 6. Air flow control cable9. A/C switch (if equipped)

Page 1024 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-76 Air Conditioning System: Automatic Type

Actuator Linkage InspectionS7RS0B7226010

• Check if each actuator linkage operates smoothly.

• Check actuator rod for bend.

• Check each actuator linkage for breakage.

• Make sure if there is not any obstruction in operating range of actuator linkage.

If any malfunction is found, repair or replace faulty

part(s).

Blower Motor Controller Removal and

Installation

S7RS0B7226011

Refer to “Blower Motor Resistor Removal and

Installation in Section 7A”.

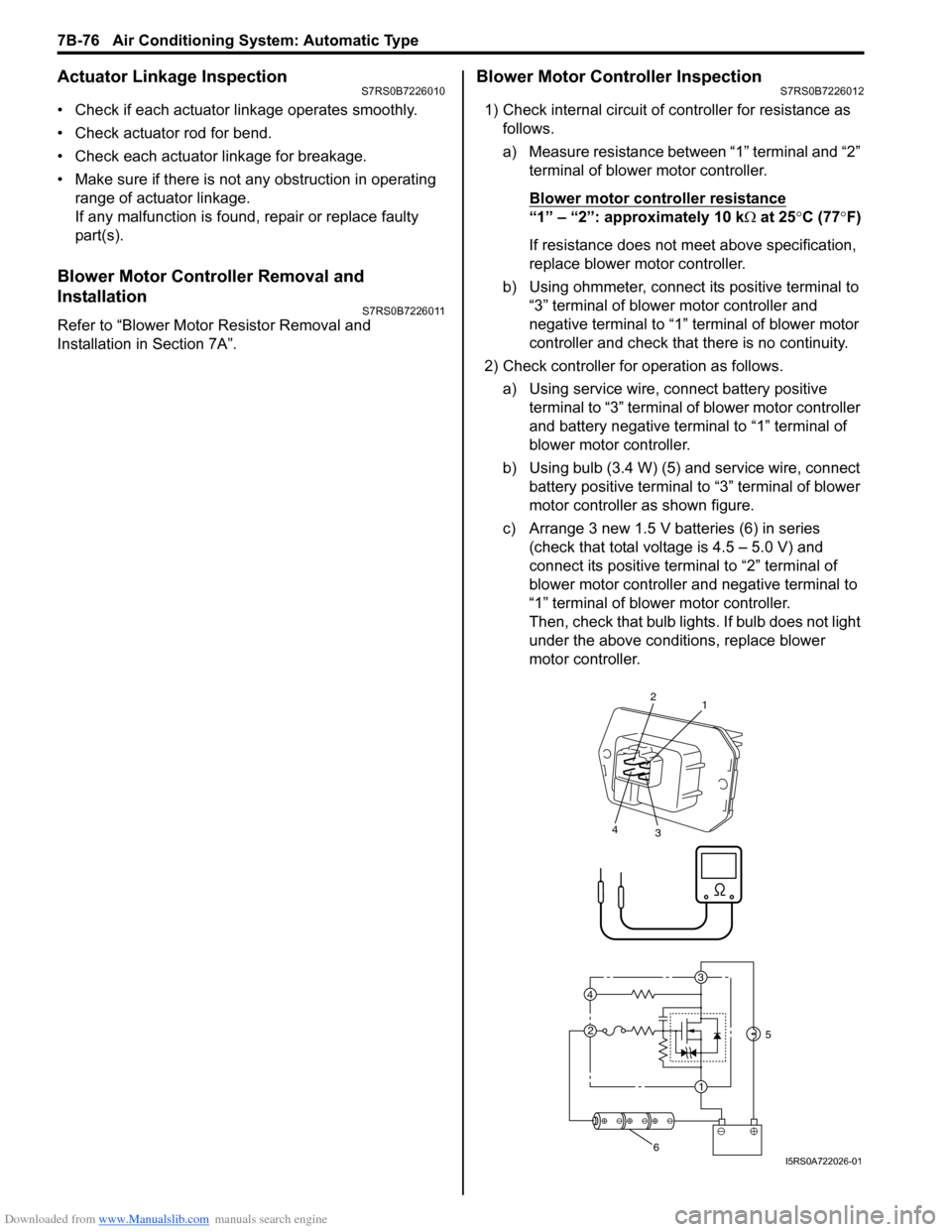

Blower Motor Controller InspectionS7RS0B7226012

1) Check internal circuit of controller for resistance as follows.

a) Measure resistance between “1” terminal and “2” terminal of blower motor controller.

Blower motor cont roller resistance

“1” – “2”: approximately 10 k Ω at 25 °C (77 °F)

If resistance does not meet above specification,

replace blower motor controller.

b) Using ohmmeter, connect its positive terminal to “3” terminal of blower motor controller and

negative terminal to “1” terminal of blower motor

controller and check that there is no continuity.

2) Check controller for operation as follows. a) Using service wire, connect battery positive terminal to “3” terminal of blower motor controller

and battery negative terminal to “1” terminal of

blower motor controller.

b) Using bulb (3.4 W) (5) and service wire, connect battery positive terminal to “3” terminal of blower

motor controller as shown figure.

c) Arrange 3 new 1.5 V batteries (6) in series (check that total voltage is 4.5 – 5.0 V) and

connect its positive term inal to “2” terminal of

blower motor controller and negative terminal to

“1” terminal of blower motor controller.

Then, check that bulb lights. If bulb does not light

under the above conditions, replace blower

motor controller.

3

1

2

4

2

1

3

4

5

6I5RS0A722026-01

Page 1168 of 1496

Downloaded from www.Manualslib.com manuals search engine 9-ii Table of Contents

List of Connectors ........................................... 9A-103

C Connector .................................................... 9A-103

D Connector (M16A engine) ........................... 9A-104

E Connector .................................................... 9A-104

G Connector .................................................... 9A-106

J Connector ..................................................... 9A-108

K Connector .................................................... 9A-109

L Connector..................................................... 9A-109

M Connector (SPORT model) ......................... 9A-111

O Connector .................................................... 9A-111

R Connector .................................................... 9A-111

Lighting Systems .................................... 9B-1

Component Location ........... ................................9B-1

Lighting System Component s Location............... 9B-1

Interior Light System Location............................. 9B-2

Diagnostic Information and Procedures ............ 9B-2 Headlight Symptom Diagnosis ............................ 9B-2

Headlight Leveling System Symptom Diagnosis (If Equipped) ..................................... 9B-2

Turn Signal and Hazard Warning Light Symptom Diagnosis .......................................... 9B-3

Clearance, Tail and License Plate Light Symptom Diagnosis .......................................... 9B-3

Back-Up Light Symptom Diagnosis..................... 9B-4

Brake Light Symptom Diagnosis ......................... 9B-4

Front Fog Light Symptom Diagnosis (If Equipped) .......................................................... 9B-4

Interior Light Symptom Diagnosis ....................... 9B-5

Repair Instructions ..............................................9B-5 Headlight Housing Removal and Installation ...... 9B-5

Headlight Bulb Replacemen t............................... 9B-6

Headlight Aiming Adjustment with Screen .......... 9B-6

Headlight Switch (in Lighting Switch) Removal and Installation ................................... 9B-8

Headlight Switch (in Lighting Switch) Inspection .......................................................... 9B-8

Hazard Warning Switch Removal and Installation ......................................................... 9B-8

Hazard Warning Switch Inspection ..................... 9B-9

Brake Light Switch Inspection ............................. 9B-9

Turn Signal Light Switch (in Lighting Switch) Removal and Installation ................................... 9B-9

Turn Signal Light Switch (in Lighting Switch) Inspection .......................................................... 9B-9

Turn Signal and Hazard Warning Relay Removal and Installation ................................... 9B-9

Turn Signal and Hazard Warning Relay Inspection ........................................................ 9B-10

License Light Removal and Installation............. 9B-10

Front Fog Light Removal and Installation (If Equipped) ........................................................ 9B-11

Front Fog Light Bulb Replacement (If Equipped) ........................................................ 9B-11

Front Fog Light Switch Inspection (If Equipped) ........................................................ 9B-11

Front Fog Light Relay Inspection (If Equipped) ........................................................ 9B-11

Front Fog Light Aiming Adjustment with Screen (If Equipped) ....................................... 9B-12 Headlight Leveling Switch Inspection (If

Equipped) ........................................................ 9B-13

Headlight Leveling Actuator Inspection (If Equipped) ........................................................ 9B-13

Instrumentation / Driver Info. / Horn ...... 9C-1

Precautions ...........................................................9C-1 Precautions in Diagnosing Troubles for Combination Meter ............................................9C-1

General Description .............................................9C-1 CAN Communication System Description...........9C-1

Auto Volume Co ntrol System Description (If

Equipped) ..........................................................9C-3

Schematic and Routing Diagram ........................9C-4 Combination Meter Circuit Diagram ....................9C-4

Component Location ............ ...............................9C-6

Audio System Component Location ....................9C-6

Diagnostic Information and Procedures ............9C-6 Speedometer and VSS Symp tom Diagnosis ......9C-6

Tachometer Symptom Diagnosis ........................9C-6

Engine Coolant Temperature (ECT) Meter Symptom Diagnosis ..........................................9C-7

Fuel Meter Symptom Diagnosis ..........................9C-7

Low Fuel Warning Light Symptom Diagnosis .....9C-7

Oil Pressure Warning Light Symptom Diagnosis ..........................................................9C-8

Brake and Parking Brake Warning Light Symptom Diagnosis ..........................................9C-8

Seat Belt Reminder Light Symptom Diagnosis (If Equipped)......................................................9C-8

A/T Shift Position Indicator Symptom Diagnosis (A/T Model).......................................9C-9

Charge Warning Light Sy mptom Diagnosis ........9C-9

Main Beam (High Beam) Indicator Symptom Diagnosis ..........................................................9C-9

Warning Buzzer Circuit Sy mptom Diagnosis ....9C-10

Cigarette Lighter Symptom Diagnosis (If Equipped) ........................................................9C-10

Horn Symptom Diagnosis .................................9C-10

Information Display Symptom Diagnosis (If Equipped) ........................................................9C-11

Clock Symptom Diagnosis (If Equipped)...........9C-12

Audio System Symptom Diagnosis (If Equipped) ........................................................9C-12

Remote Audio Control Switch Symptom Diagnosis (If Equipped) ...................................9C-13

Navigation Symptom Diagnosis (If Equipped)...9C-14

Repair Instructions ............ ................................9C-14

Ignition Switch Removal and Installation...........9C-14

Ignition Switch Inspection..................................9C-14

Combination Meter Removal and Installation ...9C-15

Fuel Level Sensor Removal and Installation .....9C-15

Fuel Level Sensor Inspection ............................9C-15

Oil Pressure Switch Remova l and Installation ..9C-15

Oil Pressure Switch Inspec tion .........................9C-16

Engine Coolant Temperature (ECT) Sensor Inspection ........................................................9C-16

Brake Fluid Level Switch Inspection .................9C-16

Parking Brake Switch Inspec tion.......................9C-16

Page 1284 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-2 Lighting Systems:

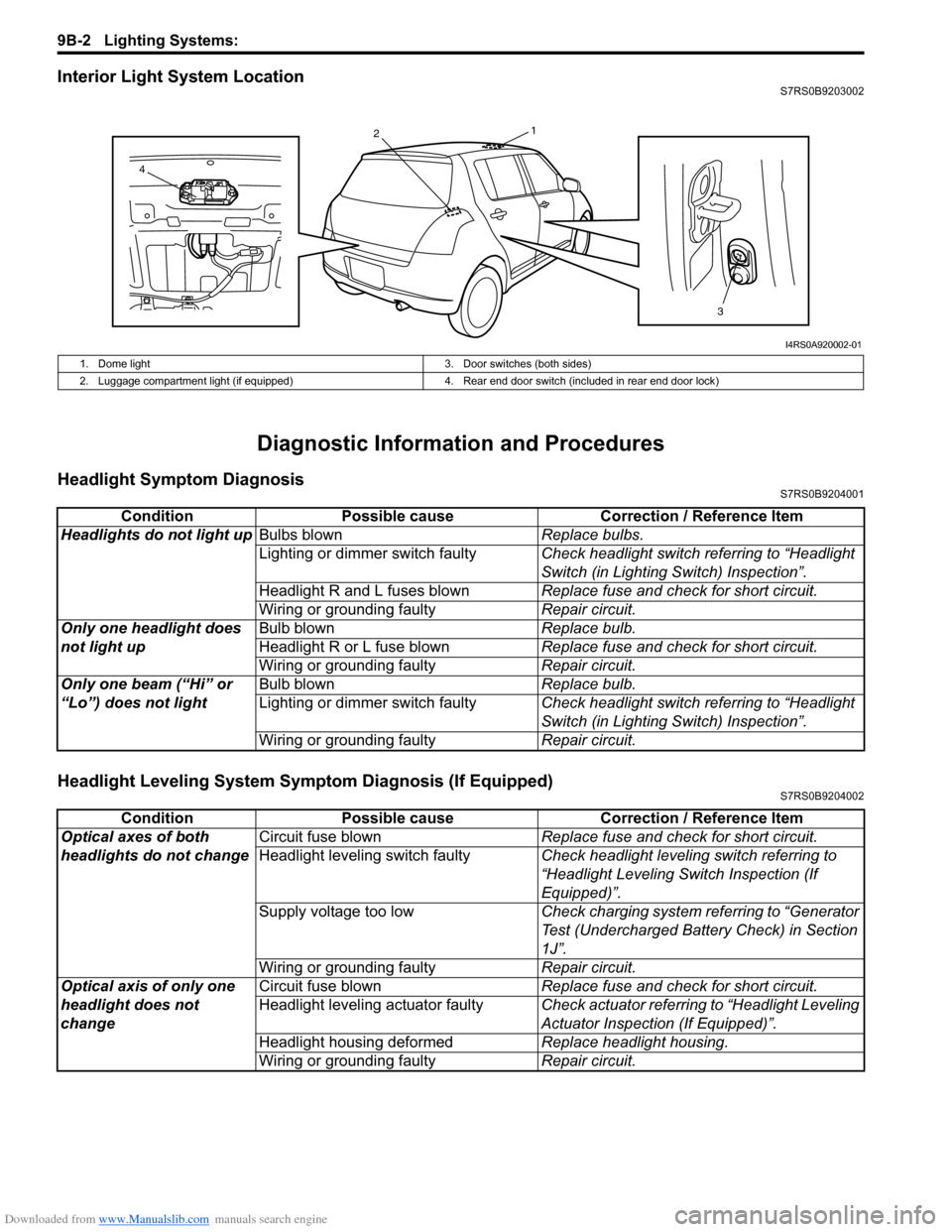

Interior Light System LocationS7RS0B9203002

Diagnostic Information and Procedures

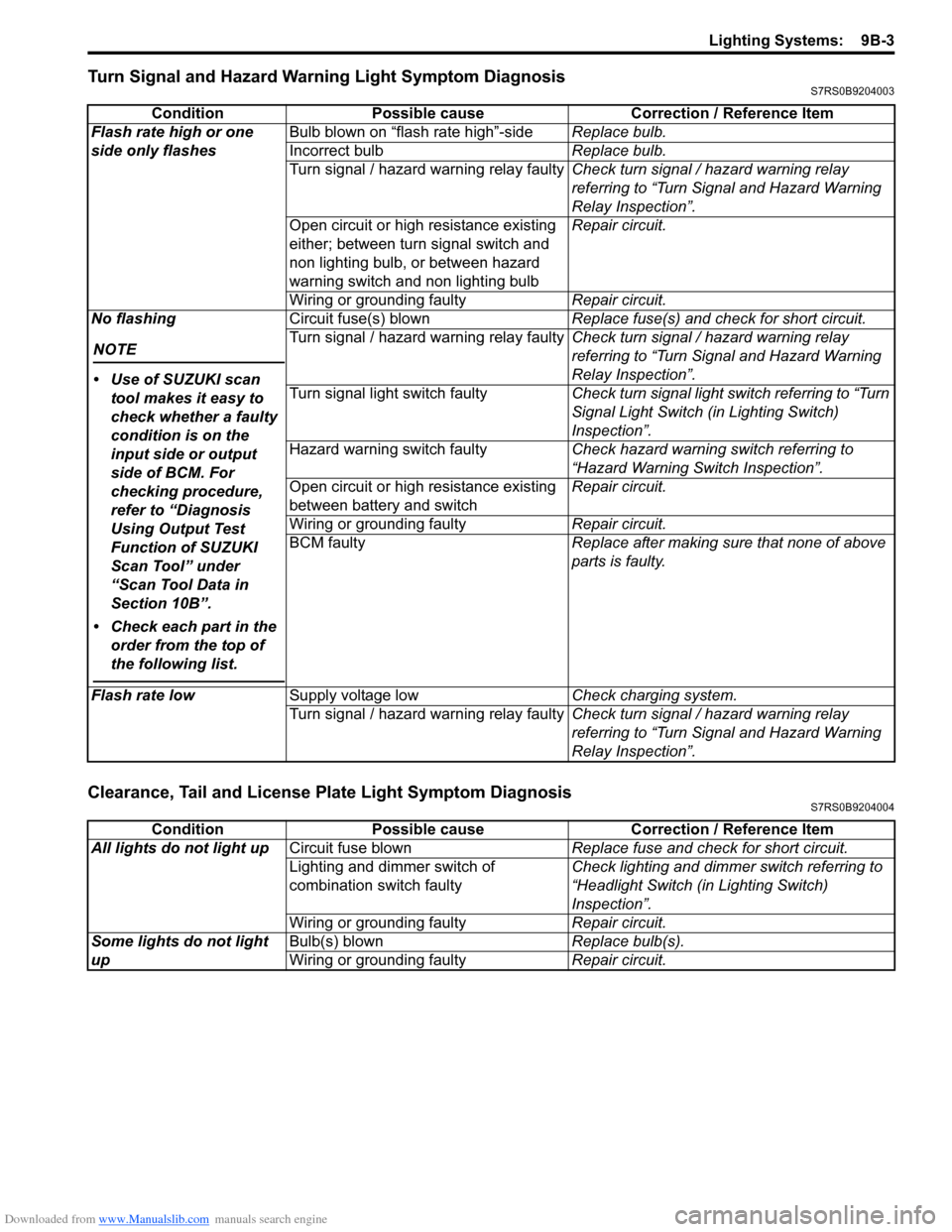

Headlight Symptom DiagnosisS7RS0B9204001

Headlight Leveling System Symptom Diagnosis (If Equipped)S7RS0B9204002

13

2

4

I4RS0A920002-01

1. Dome light 3. Door switches (both sides)

2. Luggage compartment light (if equipped) 4. Rear end door switch (included in rear end door lock)

ConditionPossible cause Correction / Reference Item

Headlights do not light up Bulbs blown Replace bulbs.

Lighting or dimmer switch faulty Check headlight switch referring to “Headlight

Switch (in Lighting Switch) Inspection”.

Headlight R and L fuses blown Replace fuse and check for short circuit.

Wiring or grounding faulty Repair circuit.

Only one headlight does

not light up Bulb blown

Replace bulb.

Headlight R or L fuse blown Replace fuse and check for short circuit.

Wiring or grounding faulty Repair circuit.

Only one beam (“Hi” or

“Lo”) does not light Bulb blown

Replace bulb.

Lighting or dimmer switch faulty Check headlight switch referring to “Headlight

Switch (in Lighting Switch) Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Optical axes of both

headlights do not change Circuit fuse blown

Replace fuse and check for short circuit.

Headlight leveling switch faulty Check headlight leveling switch referring to

“Headlight Leveling Switch Inspection (If

Equipped)”.

Supply voltage too low Check charging system referring to “Generator

Test (Undercharged Battery Check) in Section

1J”.

Wiring or grounding faulty Repair circuit.

Optical axis of only one

headlight does not

change Circuit fuse blown

Replace fuse and check for short circuit.

Headlight leveling actuator faulty Check actuator referring to “Headlight Leveling

Actuator Inspection (If Equipped)”.

Headlight housing deformed Replace headlight housing.

Wiring or grounding faulty Repair circuit.

Page 1285 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-3

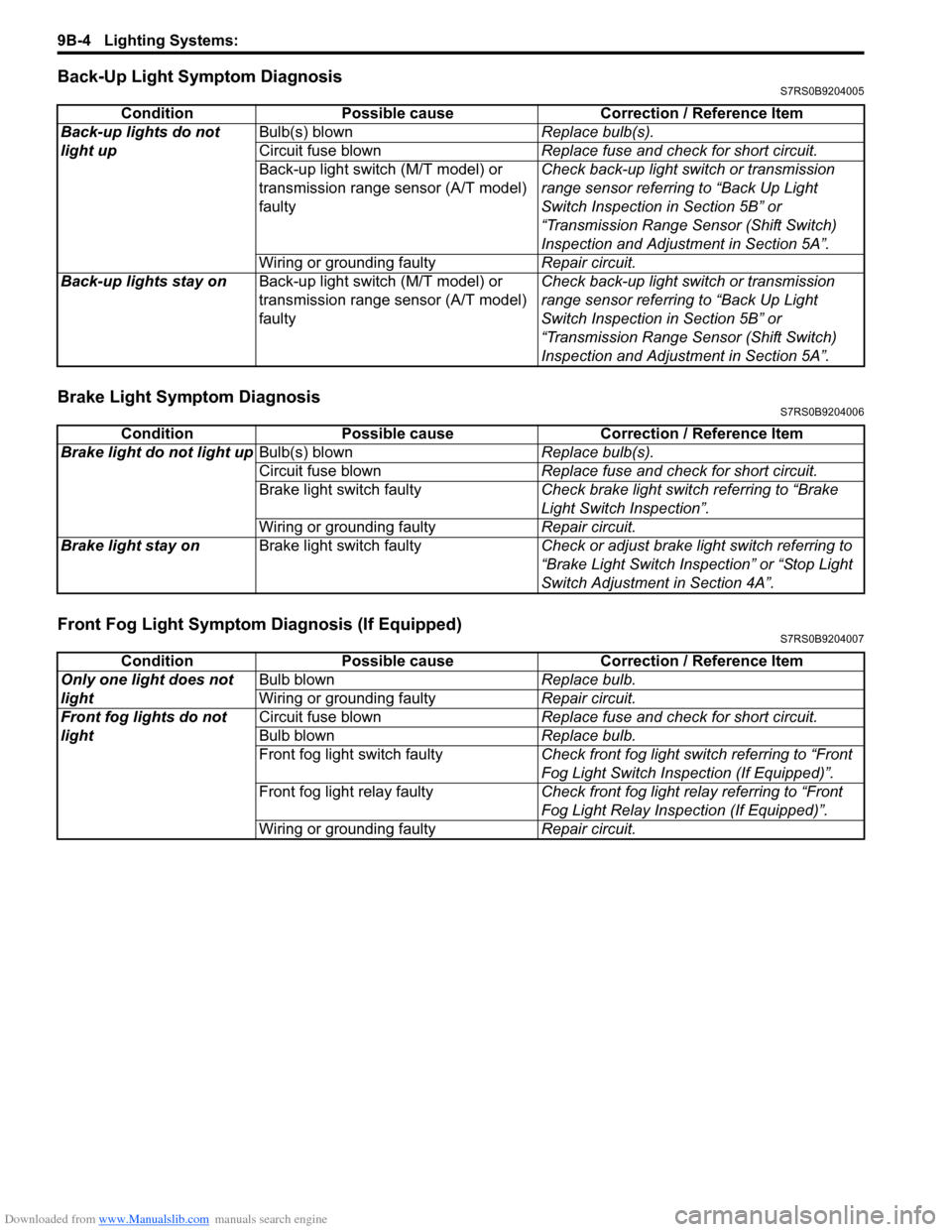

Turn Signal and Hazard Warning Light Symptom DiagnosisS7RS0B9204003

Clearance, Tail and License Plate Light Symptom DiagnosisS7RS0B9204004

ConditionPossible cause Correction / Reference Item

Flash rate high or one

side only flashes Bulb blown on “flash rate high”-side

Replace bulb.

Incorrect bulb Replace bulb.

Turn signal / hazard warning relay faulty Check turn signal / hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection”.

Open circuit or high resistance existing

either; between turn signal switch and

non lighting bulb, or between hazard

warning switch and non lighting bulb Repair circuit.

Wiring or grounding faulty Repair circuit.

No flashing

NOTE

• Use of SUZUKI scan tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the order from the top of

the following list.

Circuit fuse(s) blown Replace fuse(s) and check for short circuit.

Turn signal / hazard warning relay faulty Check turn signal / hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection”.

Turn signal light switch faulty Check turn signal light switch referring to “Turn

Signal Light Switch (in Lighting Switch)

Inspection”.

Hazard warning switch faulty Check hazard warning switch referring to

“Hazard Warning Switch Inspection”.

Open circuit or high resistance existing

between battery and switch Repair circuit.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Flash rate low Supply voltage low Check charging system.

Turn signal / hazard warning relay faulty Check turn signal / hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection”.

ConditionPossible cause Correction / Reference Item

All lights do not light up Circuit fuse blown Replace fuse and check for short circuit.

Lighting and dimmer switch of

combination switch faulty Check lighting and dimmer switch referring to

“Headlight Switch (in Lighting Switch)

Inspection”.

Wiring or grounding faulty Repair circuit.

Some lights do not light

up Bulb(s) blown

Replace bulb(s).

Wiring or grounding faulty Repair circuit.

Page 1286 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-4 Lighting Systems:

Back-Up Light Symptom DiagnosisS7RS0B9204005

Brake Light Symptom DiagnosisS7RS0B9204006

Front Fog Light Symptom Diagnosis (If Equipped)S7RS0B9204007

ConditionPossible cause Correction / Reference Item

Back-up lights do not

light up Bulb(s) blown

Replace bulb(s).

Circuit fuse blown Replace fuse and check for short circuit.

Back-up light switch (M/T model) or

transmission range sensor (A/T model)

faulty Check back-up light switch or transmission

range sensor referring to “Back Up Light

Switch Inspection in Section 5B” or

“Transmission Range Sensor (Shift Switch)

Inspection and Adjustment in Section 5A”.

Wiring or grounding faulty Repair circuit.

Back-up lights stay on Back-up light switch (M/T model) or

transmission range sensor (A/T model)

faulty Check back-up light switch or transmission

range sensor referring to “Back Up Light

Switch Inspection in Section 5B” or

“Transmission Range Sensor (Shift Switch)

Inspection and Adjustment in Section 5A”.

Condition

Possible cause Correction / Reference Item

Brake light do not light up Bulb(s) blown Replace bulb(s).

Circuit fuse blown Replace fuse and check for short circuit.

Brake light switch faulty Check brake light switch referring to “Brake

Light Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Brake light stay on Brake light switch faulty Check or adjust brake light switch referring to

“Brake Light Switch Inspection” or “Stop Light

Switch Adjustment in Section 4A”.

ConditionPossible cause Correction / Reference Item

Only one light does not

light Bulb blown

Replace bulb.

Wiring or grounding faulty Repair circuit.

Front fog lights do not

light Circuit fuse blown

Replace fuse and check for short circuit.

Bulb blown Replace bulb.

Front fog light switch faulty Check front fog light switch referring to “Front

Fog Light Switch Inspection (If Equipped)”.

Front fog light relay faulty Check front fog light relay referring to “Front

Fog Light Relay Inspection (If Equipped)”.

Wiring or grounding faulty Repair circuit.

Page 1287 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-5

Interior Light Symptom DiagnosisS7RS0B9204008

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Repair Instructions

Headlight Housing Removal and InstallationS7RS0B9206001

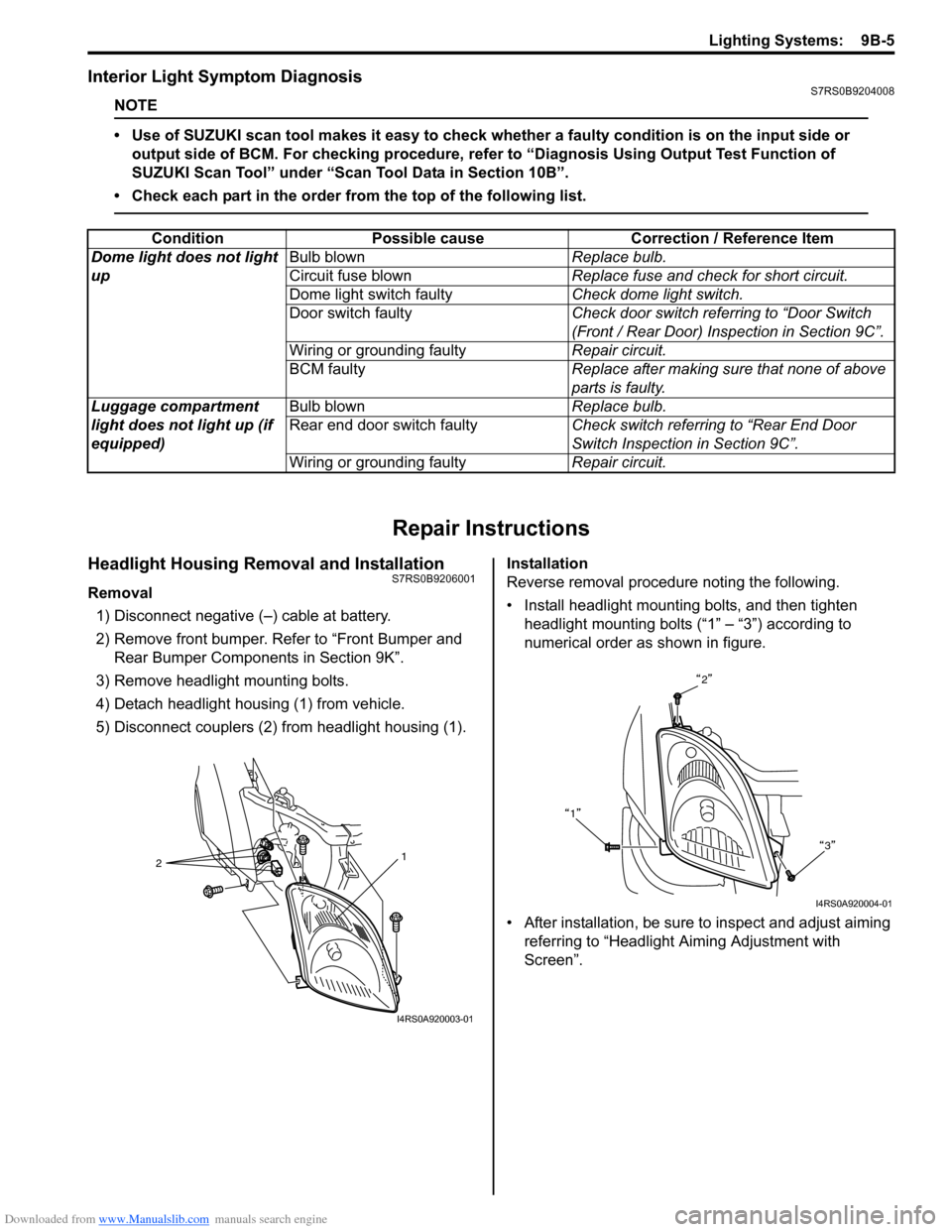

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper. Refer to “Front Bumper and Rear Bumper Componen ts in Section 9K”.

3) Remove headlight mounting bolts.

4) Detach headlight housing (1) from vehicle.

5) Disconnect couplers (2) from headlight housing (1). Installation

Reverse removal procedure noting the following.

• Install headlight mounting bolts, and then tighten

headlight mounting bolts (“1” – “3”) according to

numerical order as shown in figure.

• After installation, be sure to inspect and adjust aiming referring to “Headlight Aiming Adjustment with

Screen”.

Condition Possible cause Correction / Reference Item

Dome light does not light

up Bulb blown

Replace bulb.

Circuit fuse blown Replace fuse and check for short circuit.

Dome light switch faulty Check dome light switch.

Door switch faulty Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Luggage compartment

light does not light up (if

equipped) Bulb blown

Replace bulb.

Rear end door switch faulty Check switch referring to “Rear End Door

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

2 1

I4RS0A920003-01

2

1 3

I4RS0A920004-01

Page 1288 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-6 Lighting Systems:

Headlight Bulb ReplacementS7RS0B9206002

WARNING!

• To avoid danger of being burned, don’t touch when the bulb is hot.

• Don’t touch glass surface of bulb, to avoid deteriorate as the case may be unclear

when bulb light on at dirty condition.

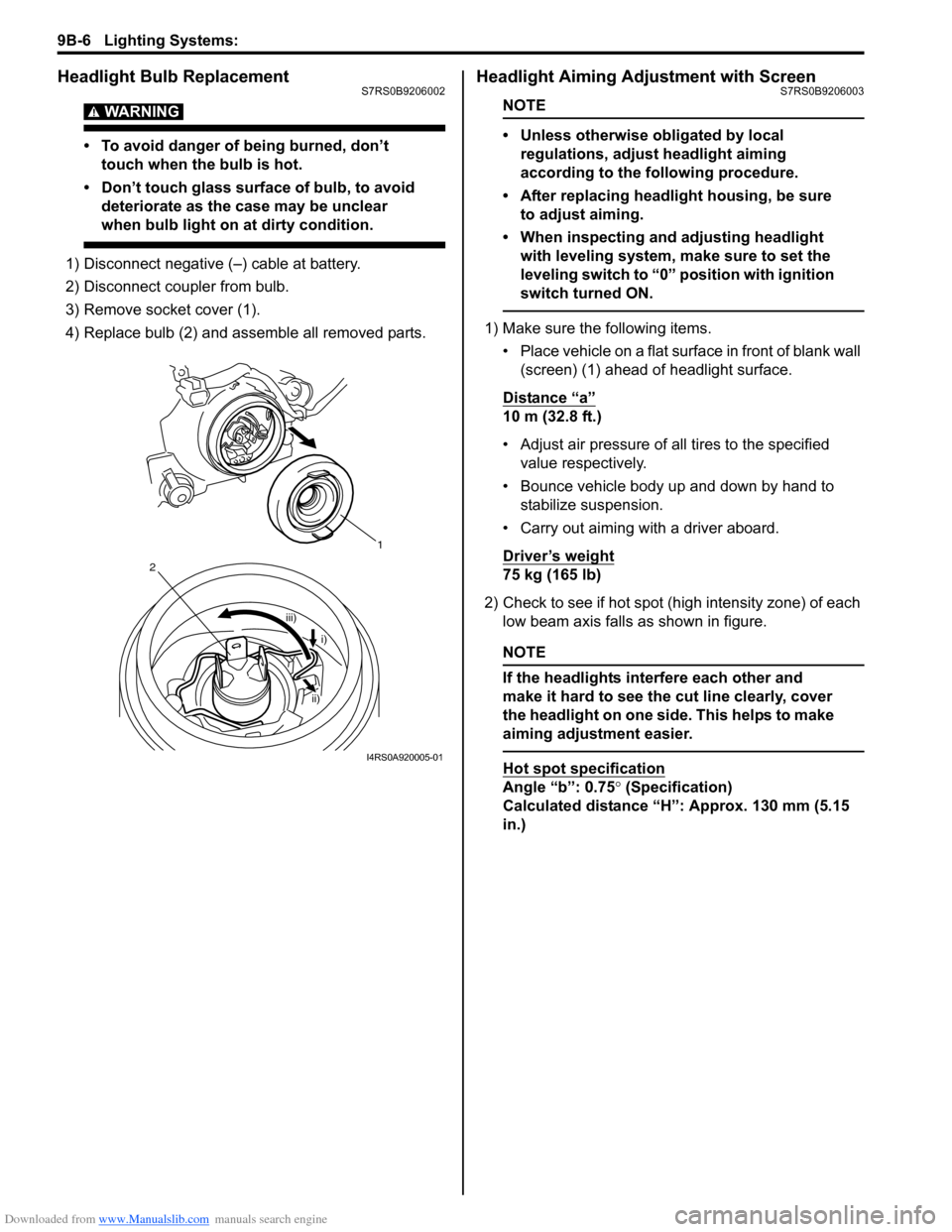

1) Disconnect negative (–) cable at battery.

2) Disconnect coupler from bulb.

3) Remove socket cover (1).

4) Replace bulb (2) and assemble all removed parts.

Headlight Aiming Adjustment with ScreenS7RS0B9206003

NOTE

• Unless otherwise obligated by local regulations, adjust headlight aiming

according to the following procedure.

• After replacing headlight housing, be sure to adjust aiming.

• When inspecting and adjusting headlight with leveling system, make sure to set the

leveling switch to “0 ” position with ignition

switch turned ON.

1) Make sure the following items.

• Place vehicle on a flat surface in front of blank wall (screen) (1) ahead of headlight surface.

Distance “a”

10 m (32.8 ft.)

• Adjust air pressure of all tires to the specified value respectively.

• Bounce vehicle body up and down by hand to stabilize suspension.

• Carry out aiming with a driver aboard.

Driver’s weight

75 kg (165 lb)

2) Check to see if hot spot (high intensity zone) of each low beam axis falls as shown in figure.

NOTE

If the headlights interfere each other and

make it hard to see the cut line clearly, cover

the headlight on one side. This helps to make

aiming adjustment easier.

Hot spot specification

Angle “b”: 0.75 ° (Specification)

Calculated distance “H”: Approx. 130 mm (5.15

in.)

1

iii)

2

i)

ii)

I4RS0A920005-01