air cond SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 626 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-52 Electronic Stability Program:

DTC U1140: Lost Communication with BCM (Reception Error)S7RS0B4604045

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area3

Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1126 detected? Go to Step 4. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module, BCM

and steering angle sensor communicating by means of

CAN.

3) Check CAN communication circuit for open, short and high resistance.

• Between ESP ® control module and BCM

• Between steering angle sensor and BCM

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 5.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6. Repair or replace the

CAN communication

line.

6 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module

• Combination meter

• Steering angle sensor

•BCM

3) Check DTC for ESP ®.

Is DTC U1126 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Step Action Yes No

DTC Detecting Condition

Trouble Area

BCM message data is missing from CAN communication. • CAN communication circuit

•BCM

• ESP® control module

Page 627 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-53

DTC TroubleshootingStep Action Yes No 1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1140 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 DTC check for BCM

1) Check DTC for BCM.

Is DTC U1073 detected? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus Off

in Section 10B”.Go to Step 4.

4 Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1140 detected? Go to Step 4. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module and

BCM communicating by means of CAN.

3) Check CAN communication circuit between ESP®

control module and BCM for open, short and high

resistance.

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 6.

6 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module

• Combination meter

• Steering angle sensor

•BCM

3) Check DTC for ESP ®.

Is DTC U1140 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Page 628 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-54 Electronic Stability Program:

Repair Instructions

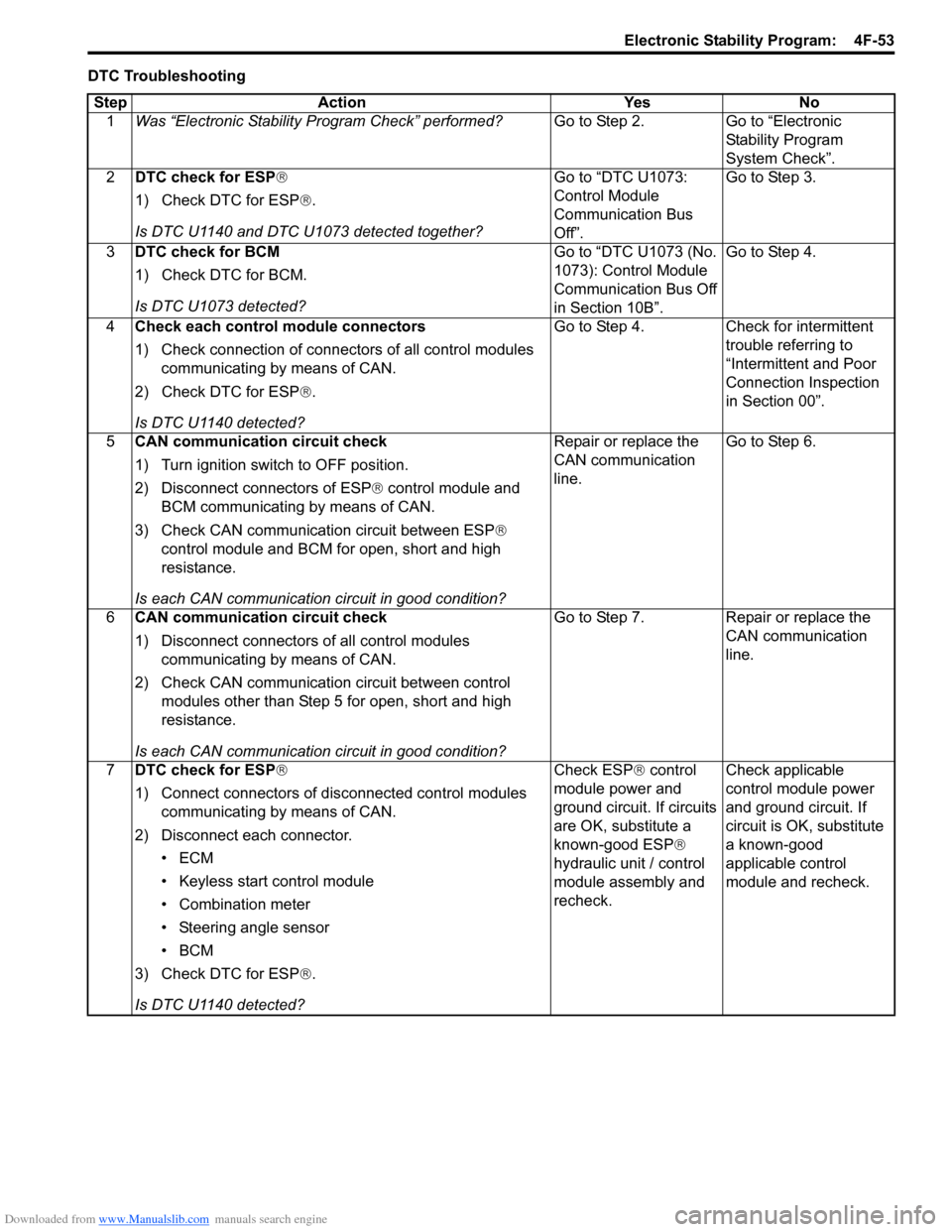

ESP® Hydraulic Unit Operation CheckS7RS0B4606025

1) Check that basic brake system other than ESP ® is

in good condition.

2) Check that battery voltage is 11 V or higher.

3) Lift up vehicle.

4) Set transmission to neutral and release parking brake.

5) Turn each wheel gradually by hand to check if braked ragging occurs. If it does, correct.

6) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

7) Turn ignition switch to ON position and select menu press / depress in “HYDRAULIC CONTROL TEST”

under “miscellaneous test” (“MISC. TEST”) mode of

SUZUKI scan tool.

Refer to SUZUKI scan tool operator’s manual for

further details.

8) Perform the following checks with help of another person.

• Depressurization checkStep on brake pedal (1) and then select testing

wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check whether the wheel rotates freely due

to brake depressurization. • Pressurization check

Step off brake pedal (1) and then select testing

wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check whether the wheel locks due to brake

pressurization.

NOTE

Pressurization / Depressurization by SUZUKI

scan tool is available for 0.5 second.

9) Check for all 4-wheels condition respectively. If a faulty condition is found, replace hydraulic unit /

control module assembly.

10) After completing the check, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

Sensor CalibrationS7RS0B4606015

CAUTION!

If any DTC(s) other than C1075, C1076 or

C1078 are detected, sensor calibration can

not be completed. Repair the detected DTC

first.

NOTE

Steering angle sensor calibration is needed

when battery, “DOME” fuse or the steering

angle sensor is removed.

This sensor calibration can be done with/

without SUZUKI Scan Tool.

When ESP ® control module and/or yaw rate /

G sensor assembly is removed, sensor

calibration is needed with SUZUKI Scan Tool.

(A)

1

I4RS0B450003-01

I4RH01450021-01

Page 629 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-55

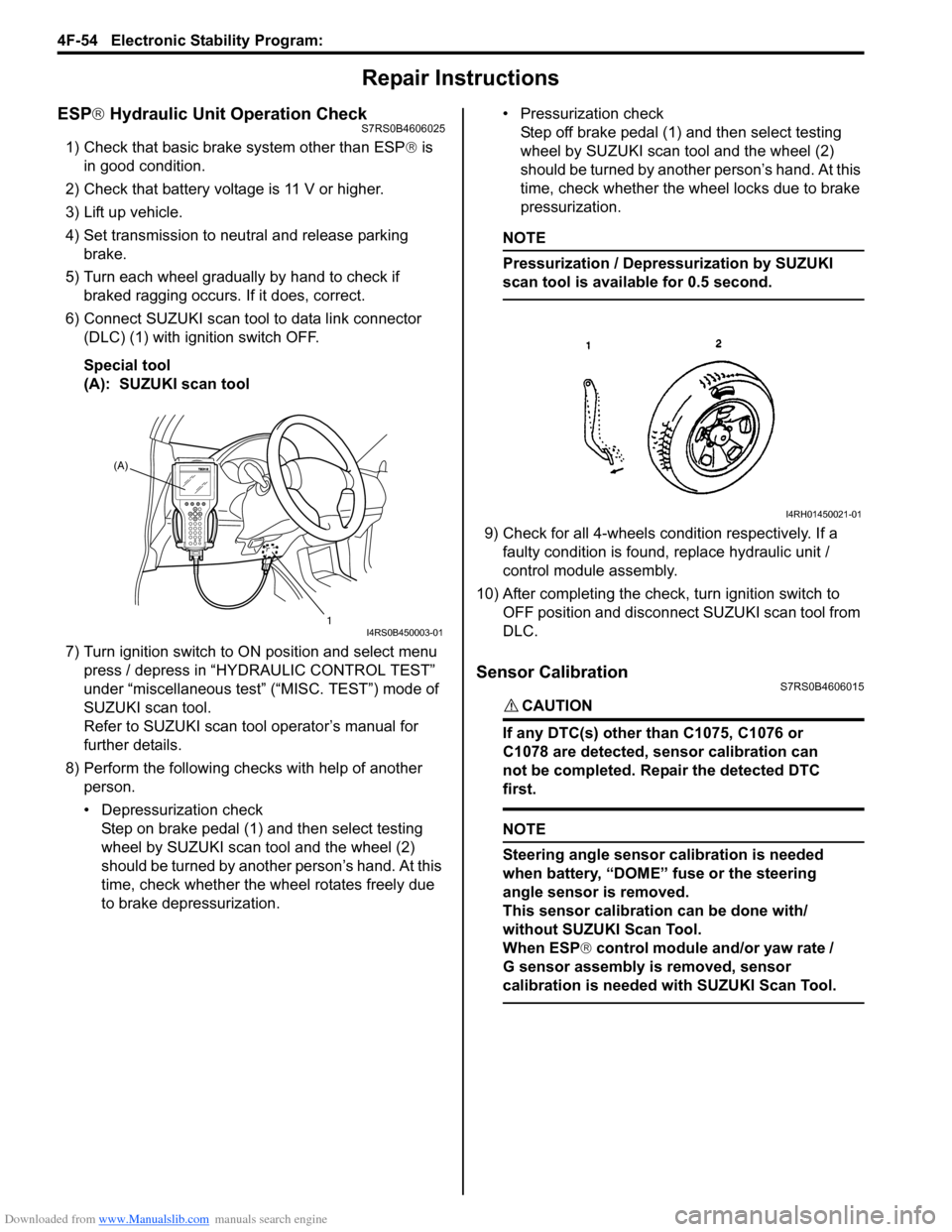

Sensor Calibration (Using SUZUKI Scan Tool)1) Set steering wheel in straight-ahead position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position and confirm that

only any of DTC(s) C1075, C1076 and/or C1077 is

detected. If any other DTC are detected, repair the

detected DTC.

4) Park and level the vehicle with parking brake, stop engine with ignition switch ON, set steering in

straight and without step ping on the brake pedal.

NOTE

Hold the above condition in Step 4) to

calibrate sensor correctly until sensor

calibration is completed.

5) Select menu “SENSOR CALIBRATION” under

“MISC. TEST” mode of SUZUKI scan tool and

calibrate sensor. Refer to scan tool operator's

manual for further derails.

6) After completing the calibra tion, turn ignition switch

to OFF position and disconnect SUZUKI scan tool

from DLC. Steering Angle Sensor Calibration (Not Using

SUZUKI Scan Tool)

1) Set steering wheel in straight-ahead position.

2) Connect battery terminals and/or fuse and start engine.

NOTE

When power is not supplied to the steering

angle sensor by removing battery or fuse,

DTC C1075 is detected and SLIP indicator

lamp (1) flashes.

If DTC other than C1075 is detected, SLIP

indicator lamp flushes and other indicator

illuminate. In that case, repair the detected

DTC first.

3) Drive vehicle straight on level ground at 15 km/h (9.5 mph) or above for few seconds without spinning

wheels. And confirm that SLIP indicator lamp is OFF.

ESP ® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection

S7RS0B4606027

CAUTION!

Never disassemble ESP ® hydraulic unit /

control module assembly, loosen blind plug

or remove motor. Pe rforming any of these

prohibited services will affect original

performance of ESP ® hydraulic unit / control

module assembly.

Check hydraulic unit for fluid leakage.

If any, repair or replace.

(A)

1

I4RS0B450003-01

1

I6RS0B460028-02

Page 636 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-62 Electronic Stability Program:

4) Turn ignition switch to ON position and select menu “DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

5) When brake pedal is released, check “Master Cyl Press” under “DATA LIST” of SUZUKI scan tool.

If pressure is out of specification, replace ESP ®

hydraulic unit / cont rol module assembly.

Master cylinder pressure specification

Brake pedal released: 0 ± 0.8 MPa (0 ± 8 kg/cm2, 0

± 113 psi)

6) Hoist vehicle and remove right-side front wheel.

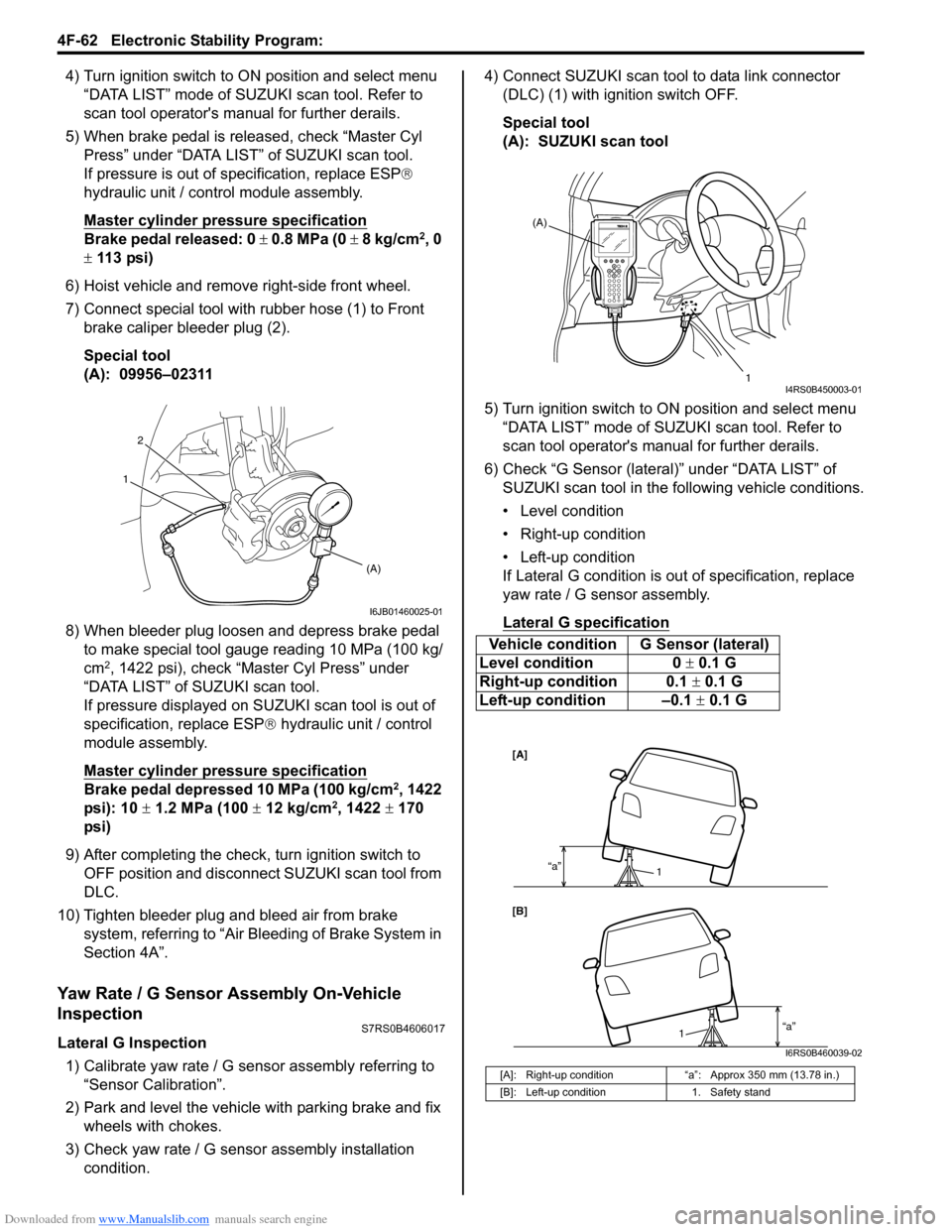

7) Connect special tool with rubber hose (1) to Front brake caliper bleeder plug (2).

Special tool

(A): 09956–02311

8) When bleeder plug loosen and depress brake pedal to make special tool gauge reading 10 MPa (100 kg/

cm

2, 1422 psi), check “Master Cyl Press” under

“DATA LIST” of SUZUKI scan tool.

If pressure displayed on SUZUKI scan tool is out of

specification, replace ESP ® hydraulic unit / control

module assembly.

Master cylinder pressure specification

Brake pedal depressed 10 MPa (100 kg/cm2, 1422

psi): 10 ± 1.2 MPa (100 ± 12 kg/cm2, 1422 ± 170

psi)

9) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

10) Tighten bleeder plug and bleed air from brake system, referring to “Air Bleeding of Brake System in

Section 4A”.

Yaw Rate / G Sensor Assembly On-Vehicle

Inspection

S7RS0B4606017

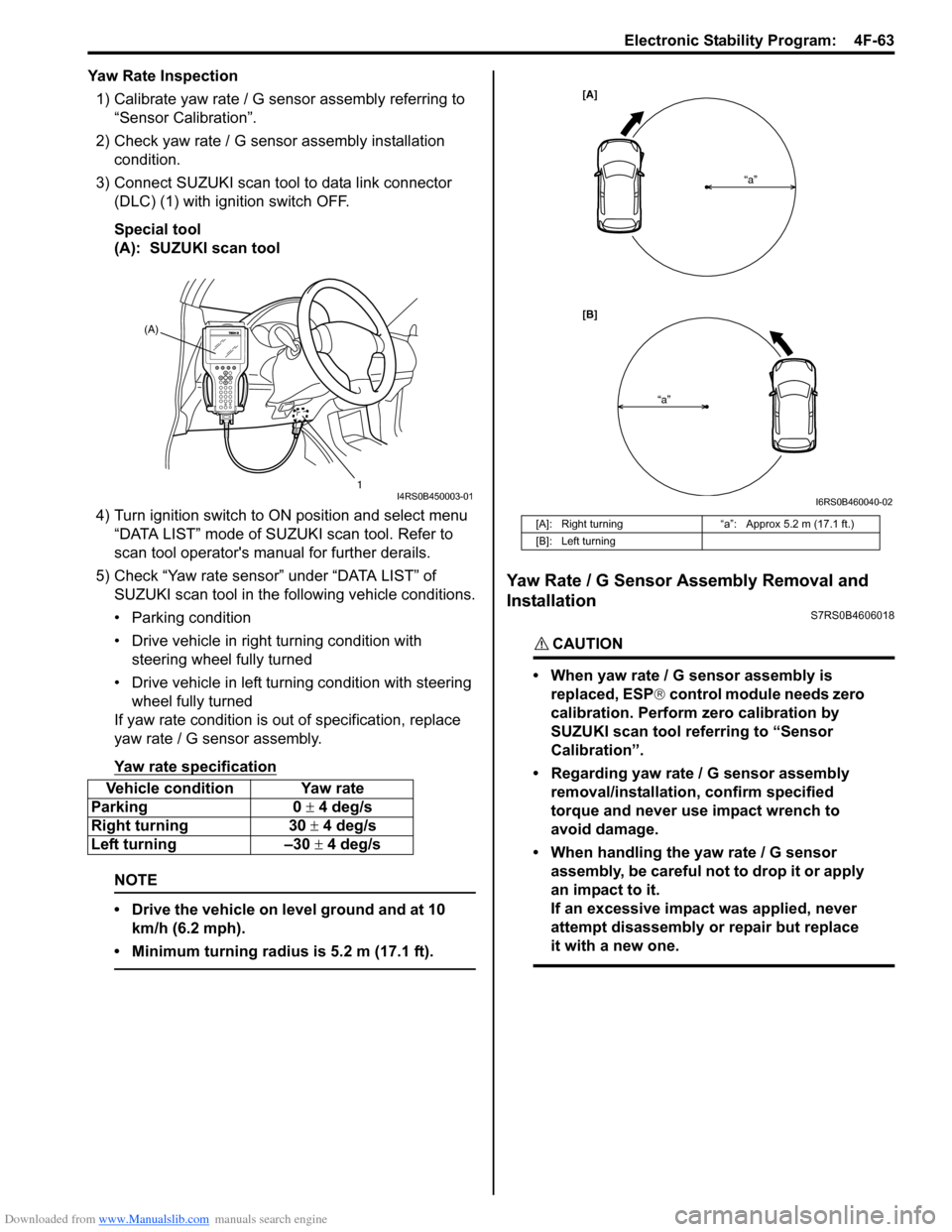

Lateral G Inspection

1) Calibrate yaw rate / G sens or assembly referring to

“Sensor Calibration”.

2) Park and level the vehicle with parking brake and fix wheels with chokes.

3) Check yaw rate / G sensor assembly installation

condition. 4) Connect SUZUKI scan tool to data link connector

(DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

5) Turn ignition switch to ON position and select menu “DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

6) Check “G Sensor (lateral)” under “DATA LIST” of SUZUKI scan tool in the following vehicle conditions.

• Level condition

• Right-up condition

• Left-up condition

If Lateral G condition is ou t of specification, replace

yaw rate / G sensor assembly.

Lateral G sp ecification

2

(A)

1

I6JB01460025-01

Vehicle condition G Sensor (lateral)

Level condition 0 ± 0.1 G

Right-up condition 0.1 ± 0.1 G

Left-up condition –0.1 ± 0.1 G

[A]: Right-up condition “a”: Approx 350 mm (13.78 in.)

[B]: Left-up condition 1. Safety stand

(A)

1

I4RS0B450003-01

[A]

[B]“a”

1

“a”1

I6RS0B460039-02

Page 637 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-63

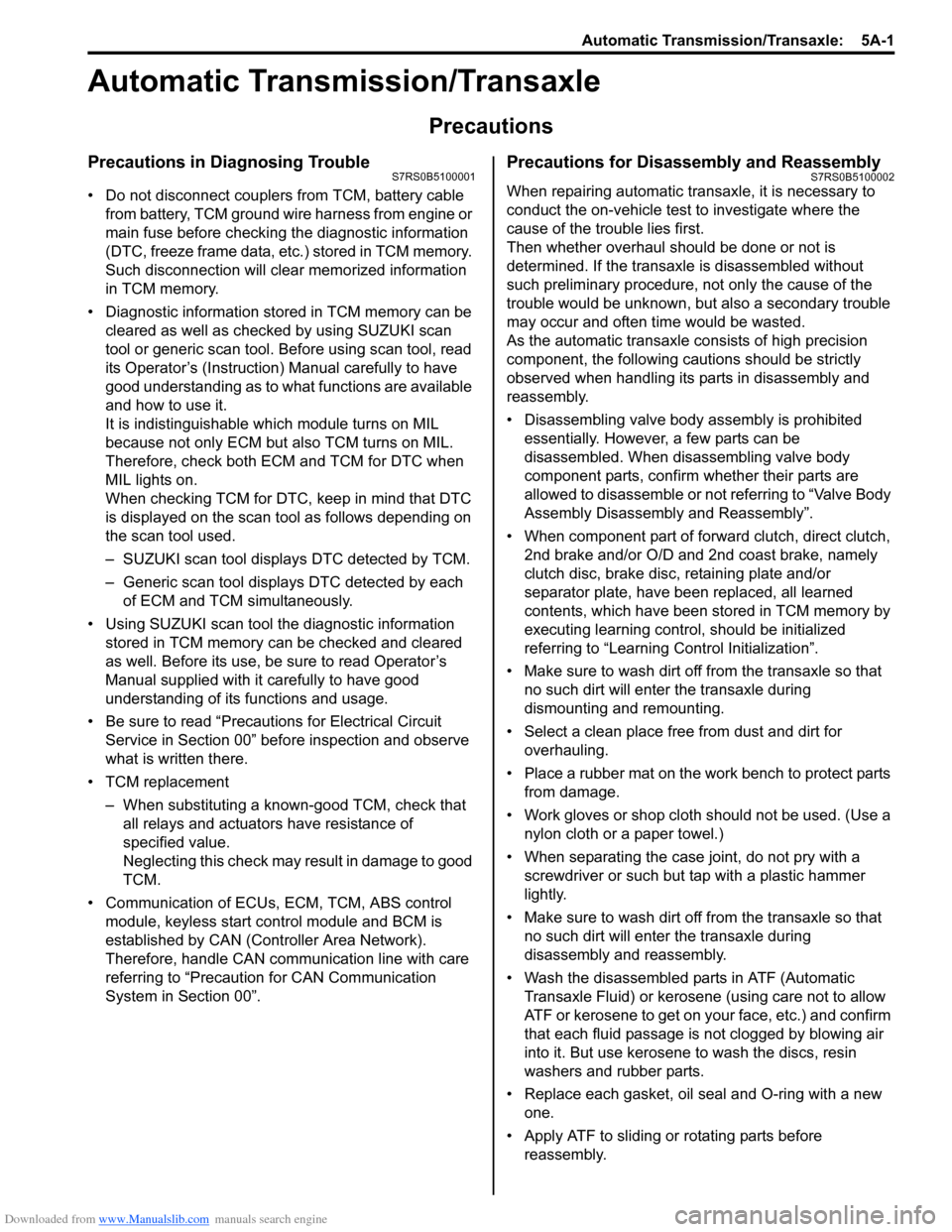

Yaw Rate Inspection1) Calibrate yaw rate / G sens or assembly referring to

“Sensor Calibration”.

2) Check yaw rate / G sensor assembly installation

condition.

3) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

4) Turn ignition switch to ON position and select menu

“DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

5) Check “Yaw rate sensor” under “DATA LIST” of SUZUKI scan tool in the following vehicle conditions.

• Parking condition

• Drive vehicle in right turning condition with steering wheel fully turned

• Drive vehicle in left tu rning condition with steering

wheel fully turned

If yaw rate condition is ou t of specification, replace

yaw rate / G sensor assembly.

Yaw rate specification

NOTE

• Drive the vehicle on level ground and at 10 km/h (6.2 mph).

• Minimum turning radius is 5.2 m (17.1 ft).

Yaw Rate / G Sensor Assembly Removal and

Installation

S7RS0B4606018

CAUTION!

• When yaw rate / G sensor assembly is replaced, ESP ® control module needs zero

calibration. Perform zero calibration by

SUZUKI scan tool referring to “Sensor

Calibration”.

• Regarding yaw rate / G sensor assembly removal/installation, confirm specified

torque and never use impact wrench to

avoid damage.

• When handling the yaw rate / G sensor assembly, be careful not to drop it or apply

an impact to it.

If an excessive impact was applied, never

attempt disassembly or repair but replace

it with a new one.

Vehicle condition Yaw rate

Parking 0 ± 4 deg/s

Right turning 30 ± 4 deg/s

Left turning –30 ± 4 deg/s

(A)

1

I4RS0B450003-01

[A]: Right turning“a”: Approx 5.2 m (17.1 ft.)

[B]: Left turning

[A]

[B] “a”

“a”

I6RS0B460040-02

Page 645 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-1

Transmission / Transaxle

Automatic Transmission/Transaxle

Precautions

Precautions in Diagnosing TroubleS7RS0B5100001

• Do not disconnect couplers from TCM, battery cable from battery, TCM ground wire harness from engine or

main fuse before checking the diagnostic information

(DTC, freeze frame data, etc.) stored in TCM memory.

Such disconnection will clea r memorized information

in TCM memory.

• Diagnostic information stored in TCM memory can be cleared as well as checked by using SUZUKI scan

tool or generic scan tool. Before using scan tool, read

its Operator’s (Instruction) Manual carefully to have

good understanding as to what functions are available

and how to use it.

It is indistinguishable wh ich module turns on MIL

because not only ECM but also TCM turns on MIL.

Therefore, check both ECM and TCM for DTC when

MIL lights on.

When checking TCM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by TCM.

– Generic scan tool displays DTC detected by each of ECM and TCM simultaneously.

• Using SUZUKI scan tool the diagnostic information stored in TCM memory can be checked and cleared

as well. Before its use, be sure to read Operator’s

Manual supplied with it carefully to have good

understanding of its functions and usage.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• TCM replacement

– When substituting a known-good TCM, check that all relays and actuators have resistance of

specified value.

Neglecting this check may result in damage to good

TCM.

• Communication of ECUs , ECM, TCM, ABS control

module, keyless start control module and BCM is

established by CAN (Controller Area Network).

Therefore, handle CAN communication line with care

referring to “Precaution for CAN Communication

System in Section 00”.

Precautions for Disassembly and ReassemblyS7RS0B5100002

When repairing automatic transaxle, it is necessary to

conduct the on-vehicle test to investigate where the

cause of the trouble lies first.

Then whether overhaul should be done or not is

determined. If the transaxle is disassembled without

such preliminary procedure, not only the cause of the

trouble would be unknown, but also a secondary trouble

may occur and often time would be wasted.

As the automatic transaxle consists of high precision

component, the following cautions should be strictly

observed when handling its parts in disassembly and

reassembly.

• Disassembling valve body assembly is prohibited

essentially. However, a few parts can be

disassembled. When disassembling valve body

component parts, confirm whether their parts are

allowed to disassemble or not referring to “Valve Body

Assembly Disassembly and Reassembly”.

• When component part of forward clutch, direct clutch, 2nd brake and/or O/D and 2nd coast brake, namely

clutch disc, brake disc, retaining plate and/or

separator plate, have been replaced, all learned

contents, which have been stored in TCM memory by

executing learning control, should be initialized

referring to “Learning Control Initialization”.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

dismounting and remounting.

• Select a clean place free from dust and dirt for overhauling.

• Place a rubber mat on the work bench to protect parts from damage.

• Work gloves or shop cloth should not be used. (Use a nylon cloth or a paper towel.)

• When separating the case joint, do not pry with a screwdriver or such but tap with a plastic hammer

lightly.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

disassembly and reassembly.

• Wash the disassembled parts in ATF (Automatic Transaxle Fluid) or kerosene (using care not to allow

ATF or kerosene to get on your face, etc.) and confirm

that each fluid passage is not clogged by blowing air

into it. But use kerosene to wash the discs, resin

washers and rubber parts.

• Replace each gasket, oil seal and O-ring with a new one.

• Apply ATF to sliding or rotating parts before

reassembly.

Page 659 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-15

Diagnostic Information and Procedures

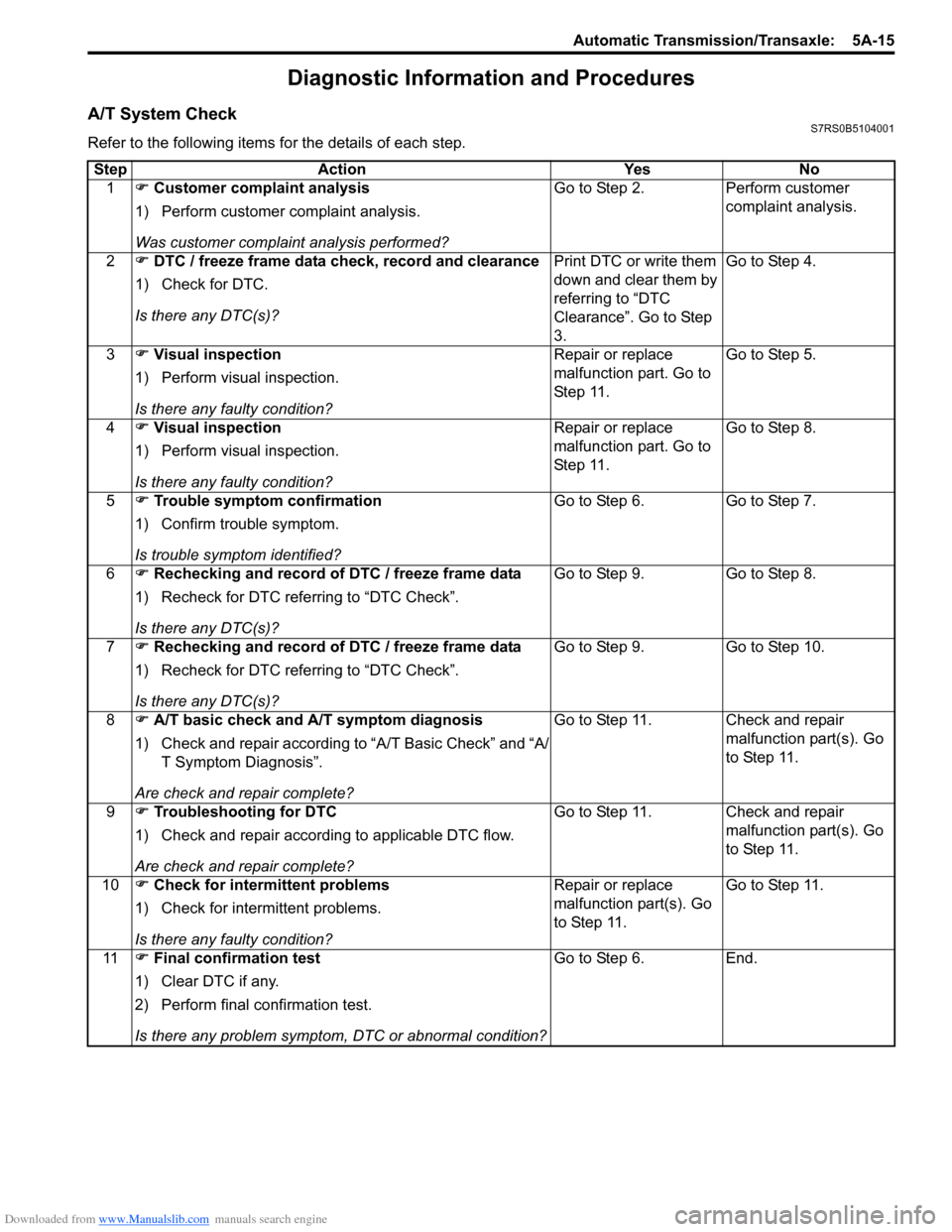

A/T System CheckS7RS0B5104001

Refer to the following items for the details of each step.Step Action Yes No 1 �) Customer complaint analysis

1) Perform customer complaint analysis.

Was customer complaint analysis performed? Go to Step 2. Perform customer

complaint analysis.

2 �) DTC / freeze frame data check, record and clearance

1) Check for DTC.

Is there any DTC(s)? Print DTC or write them

down and clear them by

referring to “DTC

Clearance”. Go to Step

3.Go to Step 4.

3 �) Visual inspection

1) Perform visual inspection.

Is there any faulty condition? Repair or replace

malfunction part. Go to

St ep 11 .

Go to Step 5.

4 �) Visual inspection

1) Perform visual inspection.

Is there any faulty condition? Repair or replace

malfunction part. Go to

St ep 11 .

Go to Step 8.

5 �) Trouble symptom confirmation

1) Confirm trouble symptom.

Is trouble symptom identified? Go to Step 6.

Go to Step 7.

6 �) Rechecking and record of DTC / freeze frame data

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9.

Go to Step 8.

7 �) Rechecking and record of DTC / freeze frame data

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9.

Go to Step 10.

8 �) A/T basic check and A/T symptom diagnosis

1) Check and repair according to “A/T Basic Check” and “A/

T Symptom Diagnosis”.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s). Go

to Step 11.

9 �) Troubleshooting for DTC

1) Check and repair according to applicable DTC flow.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s). Go

to Step 11.

10 �) Check for intermittent problems

1) Check for interm ittent problems.

Is there any faulty condition? Repair or replace

malfunction part(s). Go

to Step 11.

Go to Step 11.

11 �) Final confirmation test

1) Clear DTC if any.

2) Perform final confirmation test.

Is there any problem symptom, DTC or abnormal condition? Go to Step 6.

End.

Page 661 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-17

Step 2. DTC / Freeze Frame Data Check, Record and Clearance

First, referring to “DTC Check”, check DTC and pending DTC. If DTC exists, print or write down DTC and freeze frame

data and then clear malfunction DTC(s) by referring to “DTC Clearance”. Malfunction DTC indicates malfunction in the

system but it is not possible to know from it whether the malfunction is occurring now or it occurred in the past and

normal condition has been restored. In order to know that, check symptom in question according to Step 5 and then

recheck DTC according to Step 6.

Diagnosing a trouble based on the DTC in this step only or fa ilure to clear the DTC in this step may result in an faulty

diagnosis, trouble diagnosis of a normal circuit or difficulty in troubleshooting which is otherwise unnecessary.

Step 3 and 4. Visual Inspection

As a preliminary step, be sure to perform visual check of the items that support proper function of the engine and

automatic transaxle referring to “Visual Inspection”.

Step 5. Trouble Symptom Confirmation

Check trouble symptoms based on information obtained in “Step 1. Customer Complaint Analysis: ” and “Step 2. DTC

/ Freeze Frame Data Check, Record and Clearance: ”.

Also, reconfirm DTC according to “DTC Confirmation Procedure” described in each DTC flow.

Step 6 and 7. Rechecking and Record of DTC and Freeze Frame Data

Refer to “DTC Check” for checking procedure.

Step 8. A/T Basic Check and A/T Symptom Diagnosis

Perform basic check of A/T according to “A/T Basic Check” first. When the end of the flow has been reached, check

the parts of the system suspected as a possible cause referring to “A/T Symptom Diagnosis” and based on symptoms

appearing on the vehicle (symptoms obtained through step s of customer complaint analysis, trouble symptom

confirmation and/or A/T basic check) and re pair or replace faulty parts, if any.

Step 9. Troubleshooting for DTC

Based on the DTC indicated in Step 6 / 7 and referring to “a pplicable DTC flow”, locate the cause of the trouble,

namely in a sensor, switch, wire harness, connector, actuator, TCM or other part and repair or replace faulty parts.

Step 10. Check for Intermittent Problem

Check parts where an intermittent trouble is easy to occur (e.g . wire harness, connector, etc.), referring to “Intermittent

and Poor Connection Inspection in Section 00” and related circuit of DTC recorded in Step 2.

Step 11. Final Confirmation Test

Confirm that the problem symptom has gone and the vehicl e is free from any abnormal conditions. If what has been

repaired is related to the malfunction DTC, clear the DTC once and check to ensure that no malfunction DTC is

indicated.

Page 669 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-25

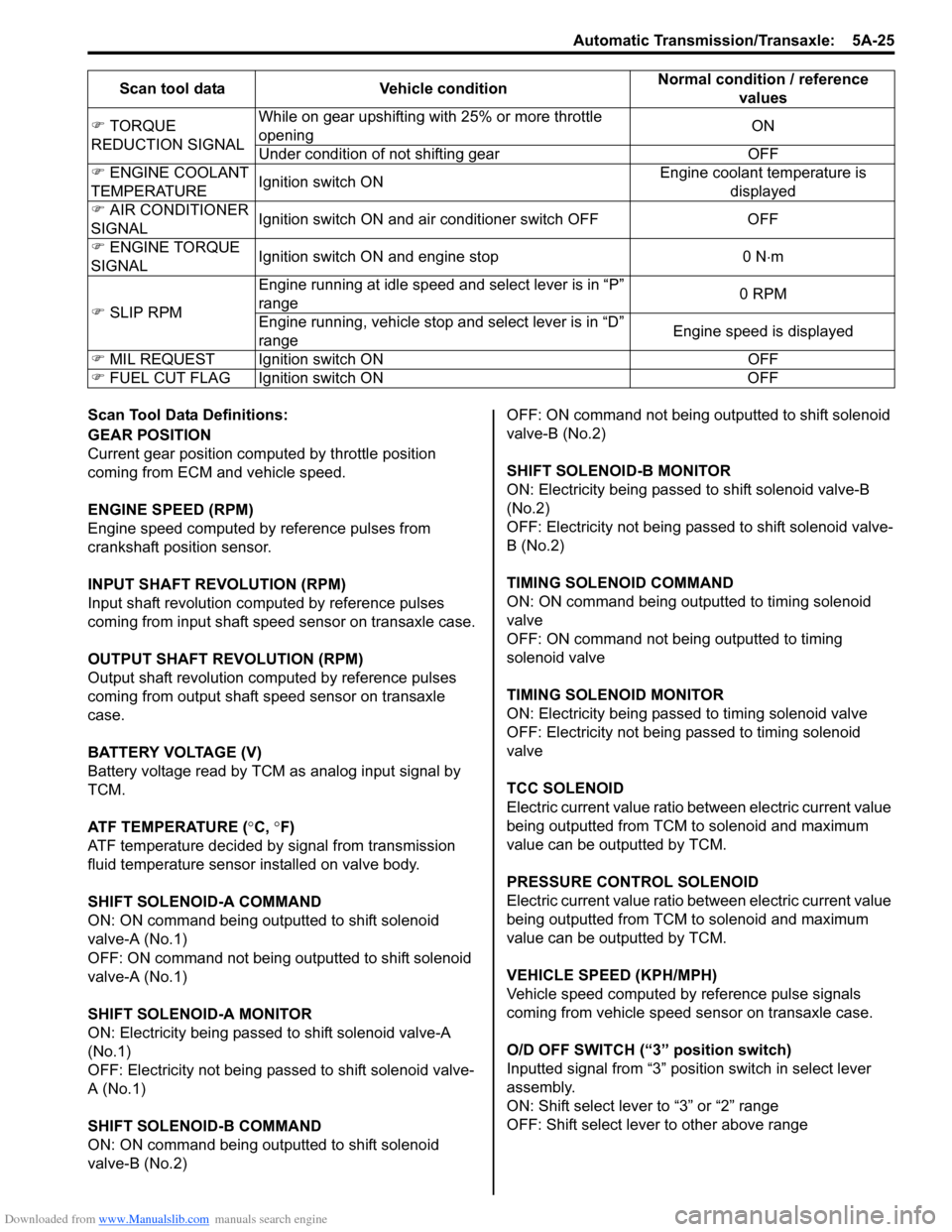

Scan Tool Data Definitions:

GEAR POSITION

Current gear position computed by throttle position

coming from ECM and vehicle speed.

ENGINE SPEED (RPM)

Engine speed computed by reference pulses from

crankshaft position sensor.

INPUT SHAFT REVOLUTION (RPM)

Input shaft revolution computed by reference pulses

coming from input shaft speed sensor on transaxle case.

OUTPUT SHAFT REVOLUTION (RPM)

Output shaft revolution computed by reference pulses

coming from output shaft speed sensor on transaxle

case.

BATTERY VOLTAGE (V)

Battery voltage read by TCM as analog input signal by

TCM.

ATF TEMPERATURE (°C, °F)

ATF temperature decided by signal from transmission

fluid temperature sensor installed on valve body.

SHIFT SOLENOID-A COMMAND

ON: ON command being outputted to shift solenoid

valve-A (No.1)

OFF: ON command not being outputted to shift solenoid

valve-A (No.1)

SHIFT SOLENOID-A MONITOR

ON: Electricity being passed to shift solenoid valve-A

(No.1)

OFF: Electricity not being passed to shift solenoid valve-

A (No.1)

SHIFT SOLENOID-B COMMAND

ON: ON command being outputted to shift solenoid

valve-B (No.2) OFF: ON command not being outputted to shift solenoid

valve-B (No.2)

SHIFT SOLENOID-B MONITOR

ON: Electricity being passed to shift solenoid valve-B

(No.2)

OFF: Electricity not being passed to shift solenoid valve-

B (No.2)

TIMING SOLENOID COMMAND

ON: ON command being outputted to timing solenoid

valve

OFF: ON command not being outputted to timing

solenoid valve

TIMING SOLENOID MONITOR

ON: Electricity being passed to timing solenoid valve

OFF: Electricity not being passed to timing solenoid

valve

TCC SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

PRESSURE CONTROL SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

VEHICLE SPEED (KPH/MPH)

Vehicle speed computed by reference pulse signals

coming from vehicle speed sensor on transaxle case.

O/D OFF SWITCH (“3” position switch)

Inputted signal from “3” position switch in select lever

assembly.

ON: Shift select lever to “3” or “2” range

OFF: Shift select lever to other above range

�)

TORQUE

REDUCTION SIGNAL While on gear upshifting with 25% or more throttle

opening

ON

Under condition of not shifting gear OFF

�) ENGINE COOLANT

TEMPERATURE Ignition switch ON Engine coolant temperature is

displayed

�) AIR CONDITIONER

SIGNAL Ignition switch ON and air conditioner switch OFF OFF

�) ENGINE TORQUE

SIGNAL Ignition switch ON and engine stop 0 N

⋅m

�) SLIP RPM Engine running at idle speed

and select lever is in “P”

range 0 RPM

Engine running, vehicle stop and select lever is in “D”

range Engine speed is displayed

�) MIL REQUEST Ignition switch ON OFF

�) FUEL CUT FLAG Ignition switch ON OFFScan tool data Vehicle condition

Normal condition / reference

values