Inspection SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 309 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-24

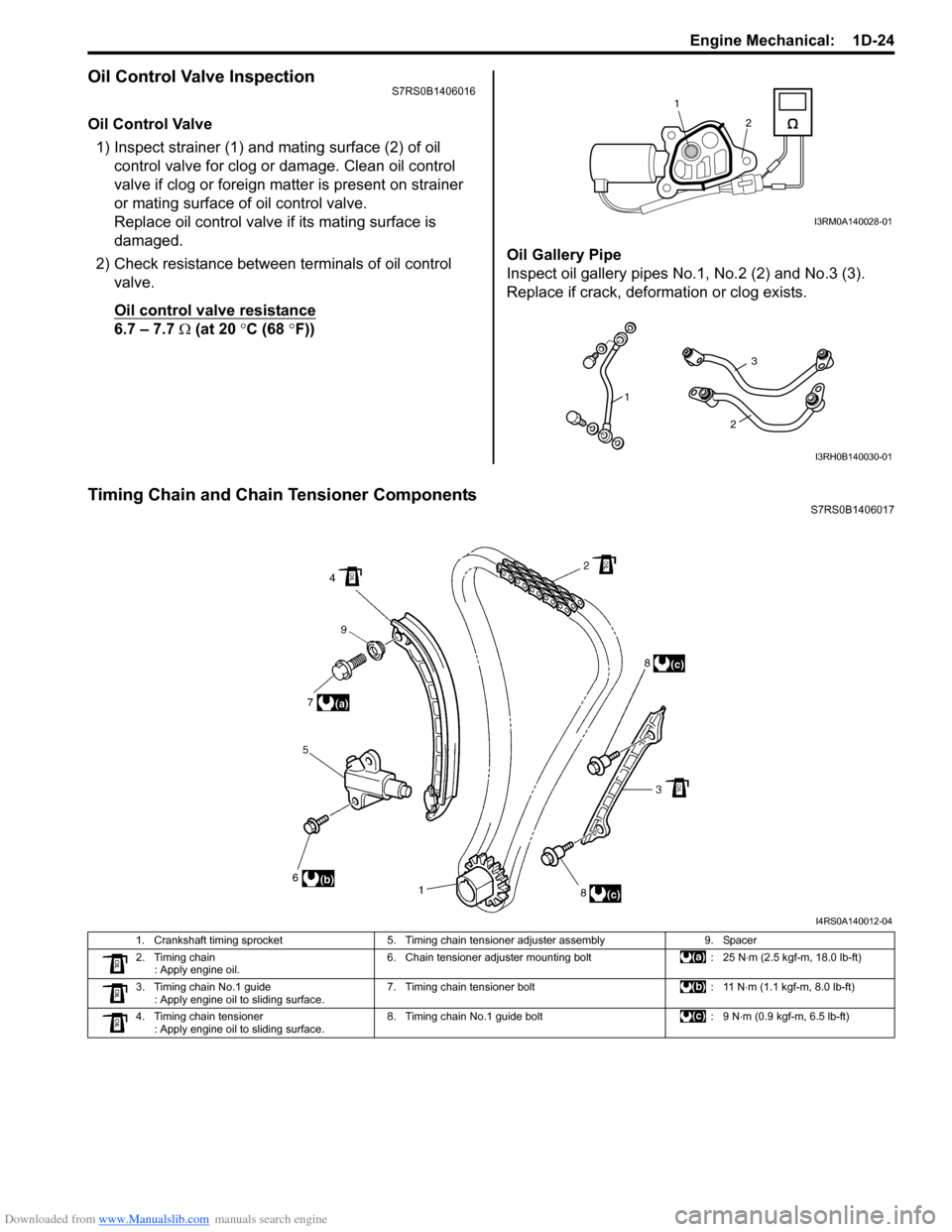

Oil Control Valve InspectionS7RS0B1406016

Oil Control Valve1) Inspect strainer (1) and mating surface (2) of oil control valve for clog or damage. Clean oil control

valve if clog or foreign matter is present on strainer

or mating surface of oil control valve.

Replace oil control valve if its mating surface is

damaged.

2) Check resistance between terminals of oil control

valve.

Oil control valve resistance

6.7 – 7.7 Ω (at 20 °C (68 °F)) Oil Gallery Pipe

Inspect oil gallery pipes No

.1, No.2 (2) and No.3 (3).

Replace if crack, deformation or clog exists.

Timing Chain and Chain Tensioner ComponentsS7RS0B1406017

1

2

I3RM0A140028-01

1

3

2

I3RH0B140030-01

I4RS0A140012-04

1. Crankshaft timing sprocket 5. Timing chain tensioner adjuster assembly 9. Spacer

2. Timing chain : Apply engine oil. 6. Chain tensioner adjuster mounting bolt

: 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

3. Timing chain No.1 guide : Apply engine oil to sliding surface. 7. Timing chain tensioner bolt

: 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

4. Timing chain tensioner : Apply engine oil to sliding surface. 8. Timing chain No.1 guide bolt

: 9 N⋅m (0.9 kgf-m, 6.5 lb-ft)

Page 312 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-27 Engine Mechanical:

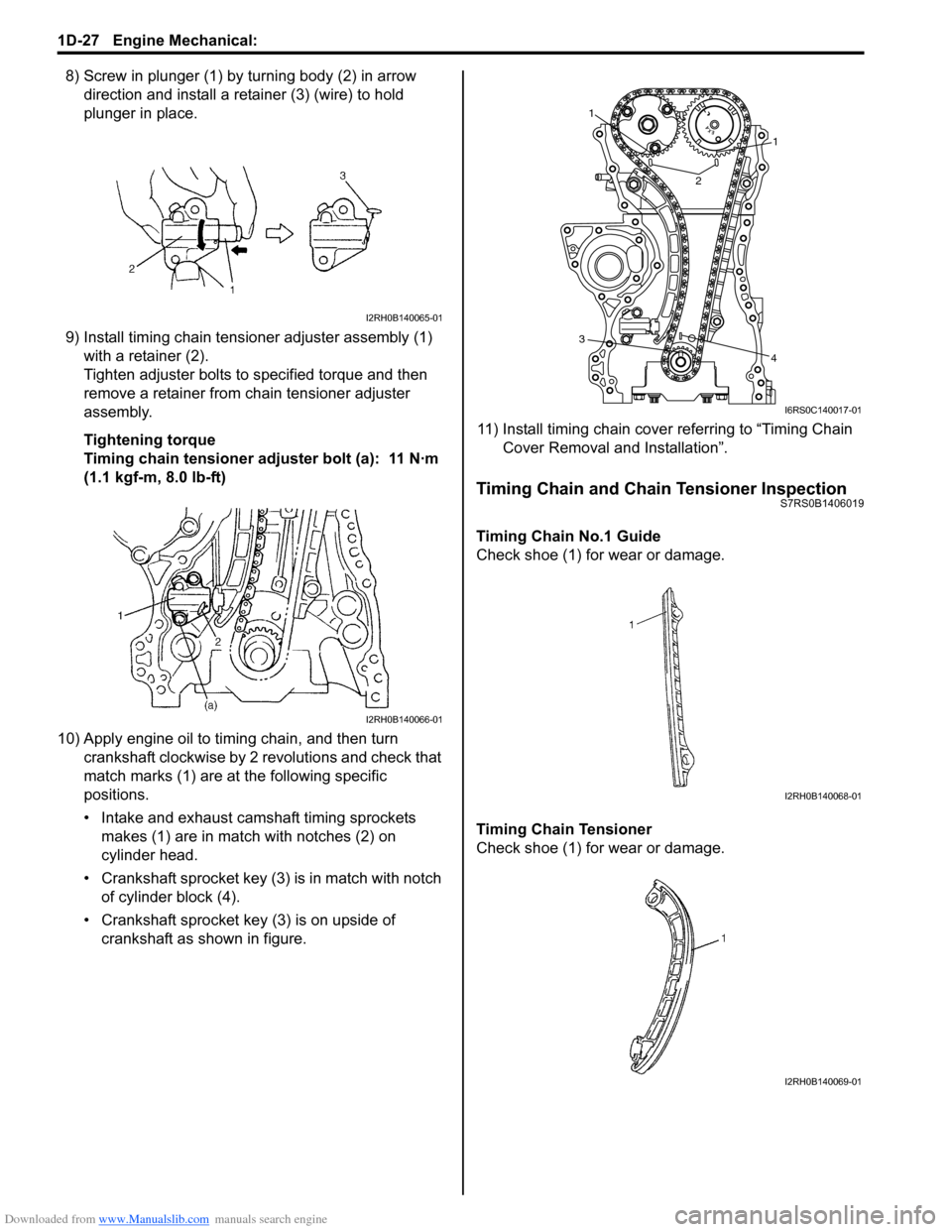

8) Screw in plunger (1) by turning body (2) in arrow direction and install a reta iner (3) (wire) to hold

plunger in place.

9) Install timing chain tensioner adjuster assembly (1) with a retainer (2).

Tighten adjuster bolts to specified torque and then

remove a retainer from chain tensioner adjuster

assembly.

Tightening torque

Timing chain tensioner adjuster bolt (a): 11 N·m

(1.1 kgf-m, 8.0 lb-ft)

10) Apply engine oil to timing chain, and then turn crankshaft clockwise by 2 revolutions and check that

match marks (1) are at the following specific

positions.

• Intake and exhaust camshaft timing sprockets makes (1) are in match with notches (2) on

cylinder head.

• Crankshaft sprocket key (3) is in match with notch of cylinder block (4).

• Crankshaft sprocket key (3) is on upside of crankshaft as shown in figure. 11) Install timing chain cover referring to “Timing Chain

Cover Removal and Installation”.

Timing Chain and Chain Tensioner InspectionS7RS0B1406019

Timing Chain No.1 Guide

Check shoe (1) for wear or damage.

Timing Chain Tensioner

Check shoe (1) for wear or damage.

I2RH0B140065-01

I2RH0B140066-01

1

1

2

3 4

I6RS0C140017-01

I2RH0B140068-01

I2RH0B140069-01

Page 316 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-31 Engine Mechanical:

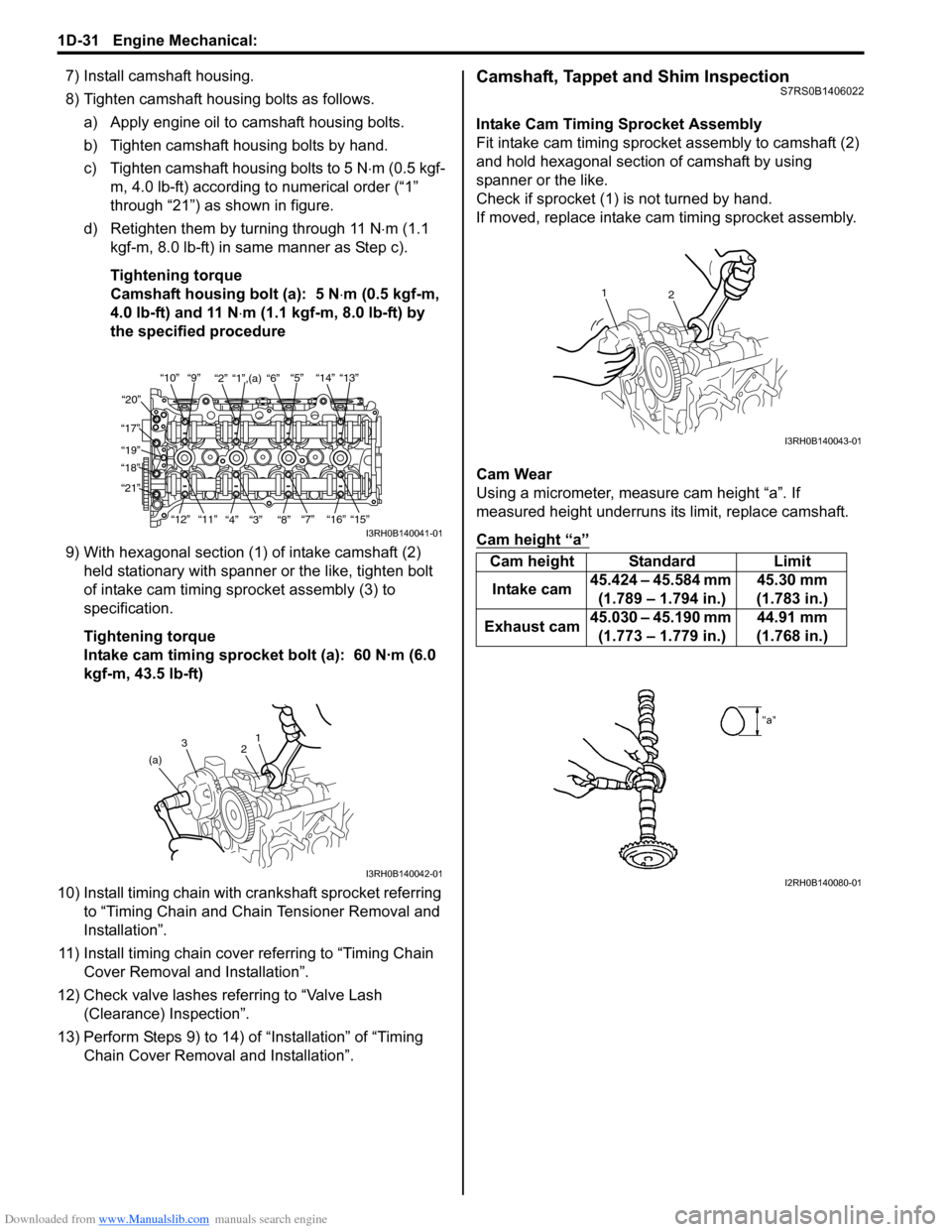

7) Install camshaft housing.

8) Tighten camshaft housing bolts as follows.a) Apply engine oil to camshaft housing bolts.

b) Tighten camshaft housing bolts by hand.

c) Tighten camshaft housing bolts to 5 N ⋅m (0.5 kgf-

m, 4.0 lb-ft) according to numerical order (“1”

through “21”) as shown in figure.

d) Retighten them by turning through 11 N⋅ m (1.1

kgf-m, 8.0 lb-ft) in same manner as Step c).

Tightening torque

Camshaft housing bolt (a): 5 N ⋅m (0.5 kgf-m,

4.0 lb-ft) and 11 N ⋅m (1.1 kgf-m, 8.0 lb-ft) by

the specified procedure

9) With hexagonal section (1) of intake camshaft (2) held stationary with spanner or the like, tighten bolt

of intake cam timing sp rocket assembly (3) to

specification.

Tightening torque

Intake cam timing sprocket bolt (a): 60 N·m (6.0

kgf-m, 43.5 lb-ft)

10) Install timing chain with cr ankshaft sprocket referring

to “Timing Chain and Chain Tensioner Removal and

Installation”.

11) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

12) Check valve lashes referring to “Valve Lash (Clearance) Inspection”.

13) Perform Steps 9) to 14) of “Installation” of “Timing Chain Cover Removal and Installation”.Camshaft, Tappet and Shim InspectionS7RS0B1406022

Intake Cam Timing Sprocket Assembly

Fit intake cam timing sprocket assembly to camshaft (2)

and hold hexagonal section of camshaft by using

spanner or the like.

Check if sprocket (1) is not turned by hand.

If moved, replace intake ca m timing sprocket assembly.

Cam Wear

Using a micrometer, measure cam height “a”. If

measured height underruns its limit, replace camshaft.

Cam height “a”

“10”“9” “2” “1”,(a) “6” “5” “14” “13”

“20”

“17” “19”

“18”

“21”

“12”“11”

“4” “3” “8” “7” “16” “15”

I3RH0B140041-01

1

2

3

(a)

I3RH0B140042-01

Cam height Standard Limit

Intake cam 45.424 – 45.584 mm

(1.789 – 1.794 in.) 45.30 mm

(1.783 in.)

Exhaust cam 45.030 – 45.190 mm

(1.773 – 1.779 in.) 44.91 mm

(1.768 in.)

2

1

I3RH0B140043-01

I2RH0B140080-01

Page 325 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-40

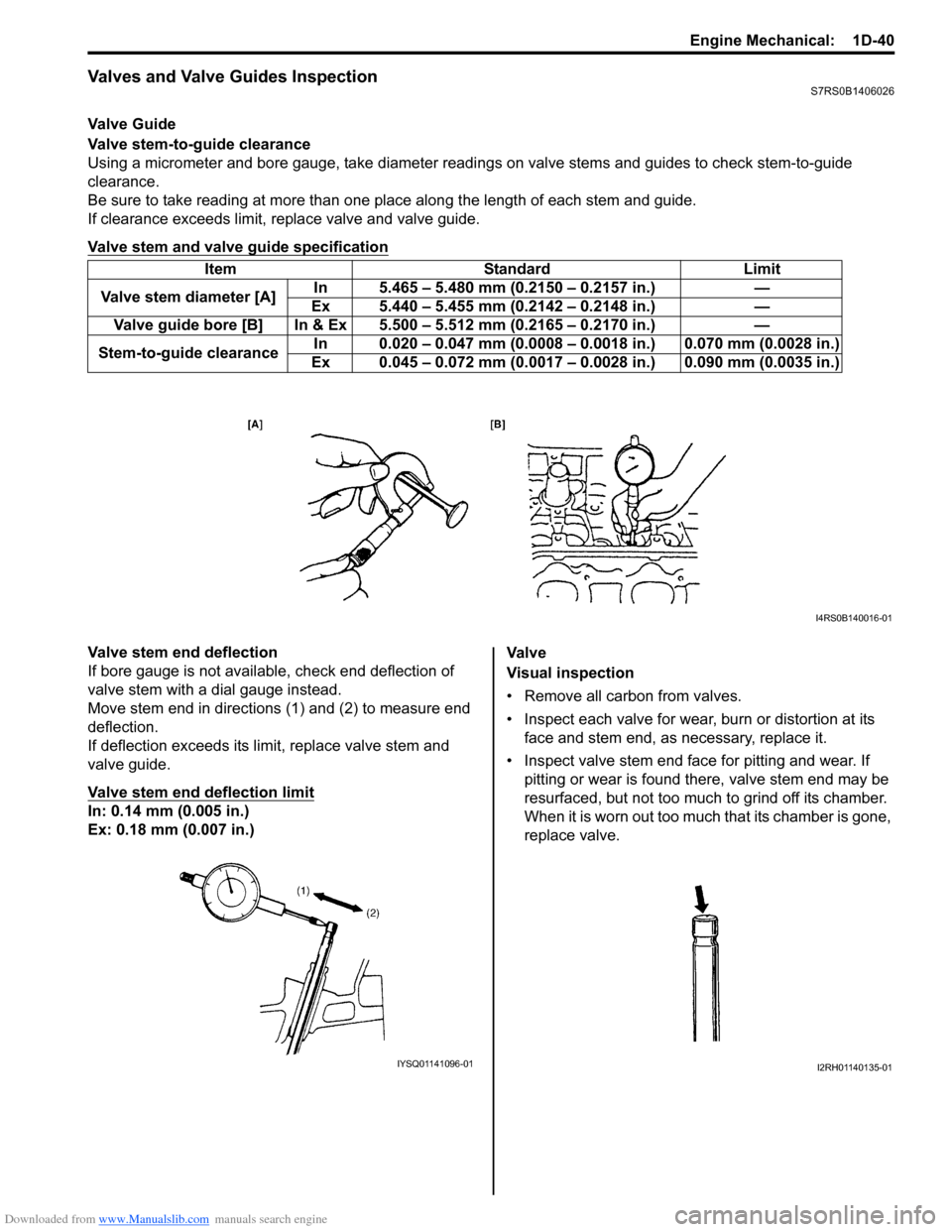

Valves and Valve Guides InspectionS7RS0B1406026

Valve Guide

Valve stem-to-guide clearance

Using a micrometer and bore gauge, take diameter readings on valve stems and guides to check stem-to-guide

clearance.

Be sure to take reading at more than one place along the length of each stem and guide.

If clearance exceeds limit, replace valve and valve guide.

Valve stem and valve guide specification

Valve stem end deflection

If bore gauge is not available, check end deflection of

valve stem with a dial gauge instead.

Move stem end in directions (1) and (2) to measure end

deflection.

If deflection exceeds its limit, replace valve stem and

valve guide.

Valve stem end deflection limit

In: 0.14 mm (0.005 in.)

Ex: 0.18 mm (0.007 in.) Va l v e

Visual inspection

• Remove all carbon from valves.

• Inspect each valve for wear, burn or distortion at its

face and stem end, as necessary, replace it.

• Inspect valve stem end face for pitting and wear. If pitting or wear is found there, valve stem end may be

resurfaced, but not too much to grind off its chamber.

When it is worn out too much that its chamber is gone,

replace valve.

Item Standard Limit

Valve stem diameter [A] In 5.465 – 5.480 mm (0.2150 – 0.2157 in.) —

Ex 5.440 – 5.455 mm (0.2142 – 0.2148 in.) —

Valve guide bore [B] In & Ex 5.500 – 5.512 mm (0.2165 – 0.2170 in.) —

Stem-to-guide clearance In 0.020 – 0.047 mm (0.0008 – 0.

0018 in.) 0.070 mm (0.0028 in.)

Ex 0.045 – 0.072 mm (0.0017 – 0. 0028 in.) 0.090 mm (0.0035 in.)

I4RS0B140016-01

IYSQ01141096-01I2RH01140135-01

Page 327 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-42

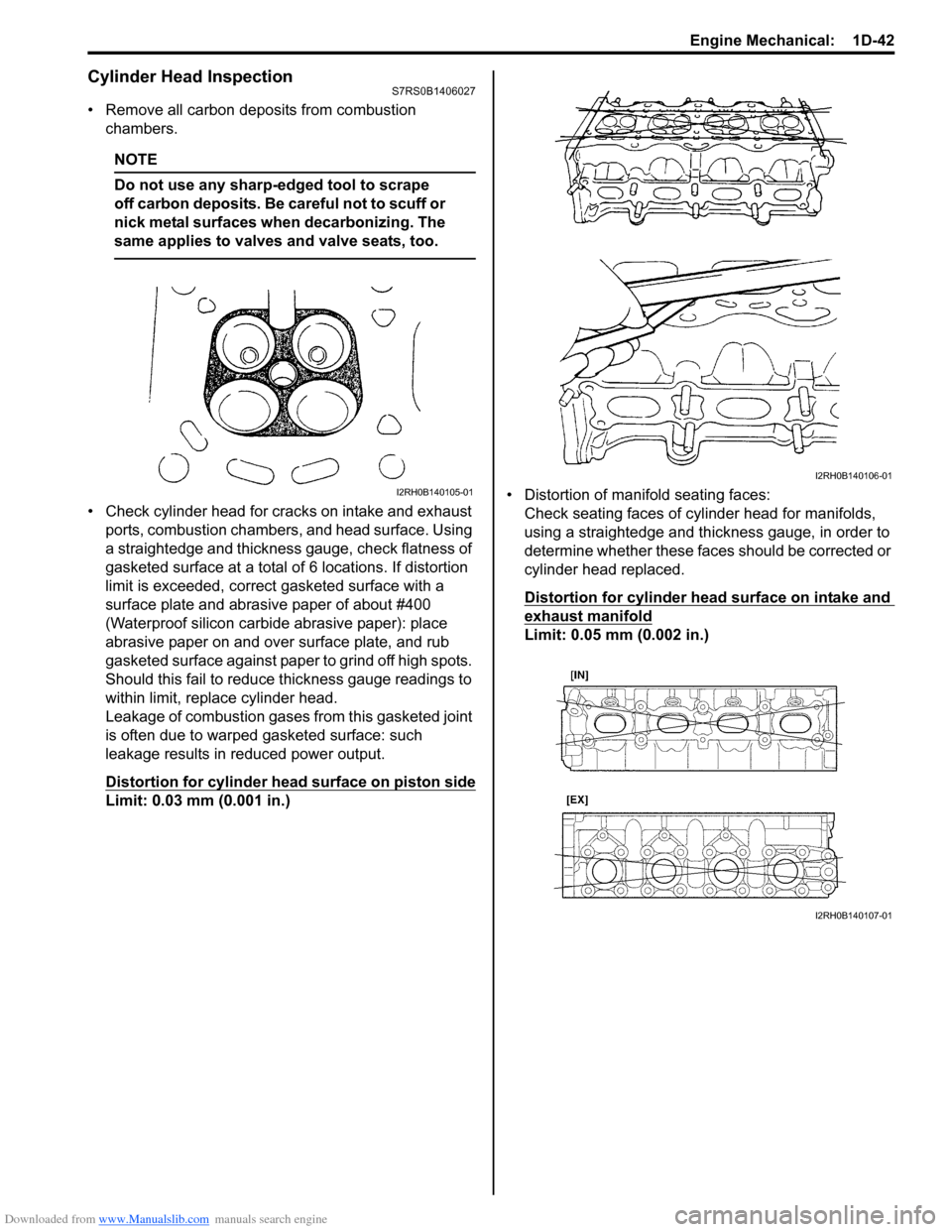

Cylinder Head InspectionS7RS0B1406027

• Remove all carbon deposits from combustion chambers.

NOTE

Do not use any sharp-edged tool to scrape

off carbon deposits. Be careful not to scuff or

nick metal surfaces when decarbonizing. The

same applies to valves and valve seats, too.

• Check cylinder head for cracks on intake and exhaust ports, combustion chambers, and head surface. Using

a straightedge and thickness gauge, check flatness of

gasketed surface at a total of 6 locations. If distortion

limit is exceeded, correct gasketed surface with a

surface plate and abrasive paper of about #400

(Waterproof silicon carbide abrasive paper): place

abrasive paper on and over surface plate, and rub

gasketed surface against paper to grind off high spots.

Should this fail to reduce thickness gauge readings to

within limit, replace cylinder head.

Leakage of combustion gases from this gasketed joint

is often due to warped gasketed surface: such

leakage results in reduced power output.

Distortion for cylinder head surface on piston side

Limit: 0.03 mm (0.001 in.) • Distortion of manifold seating faces:

Check seating faces of cylinder head for manifolds,

using a straightedge and thickness gauge, in order to

determine whether these faces should be corrected or

cylinder head replaced.

Distortion for cylinder head surface on intake and

exhaust manifold

Limit: 0.05 mm (0.002 in.)

I2RH0B140105-01

I2RH0B140106-01

I2RH0B140107-01

Page 328 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-43 Engine Mechanical:

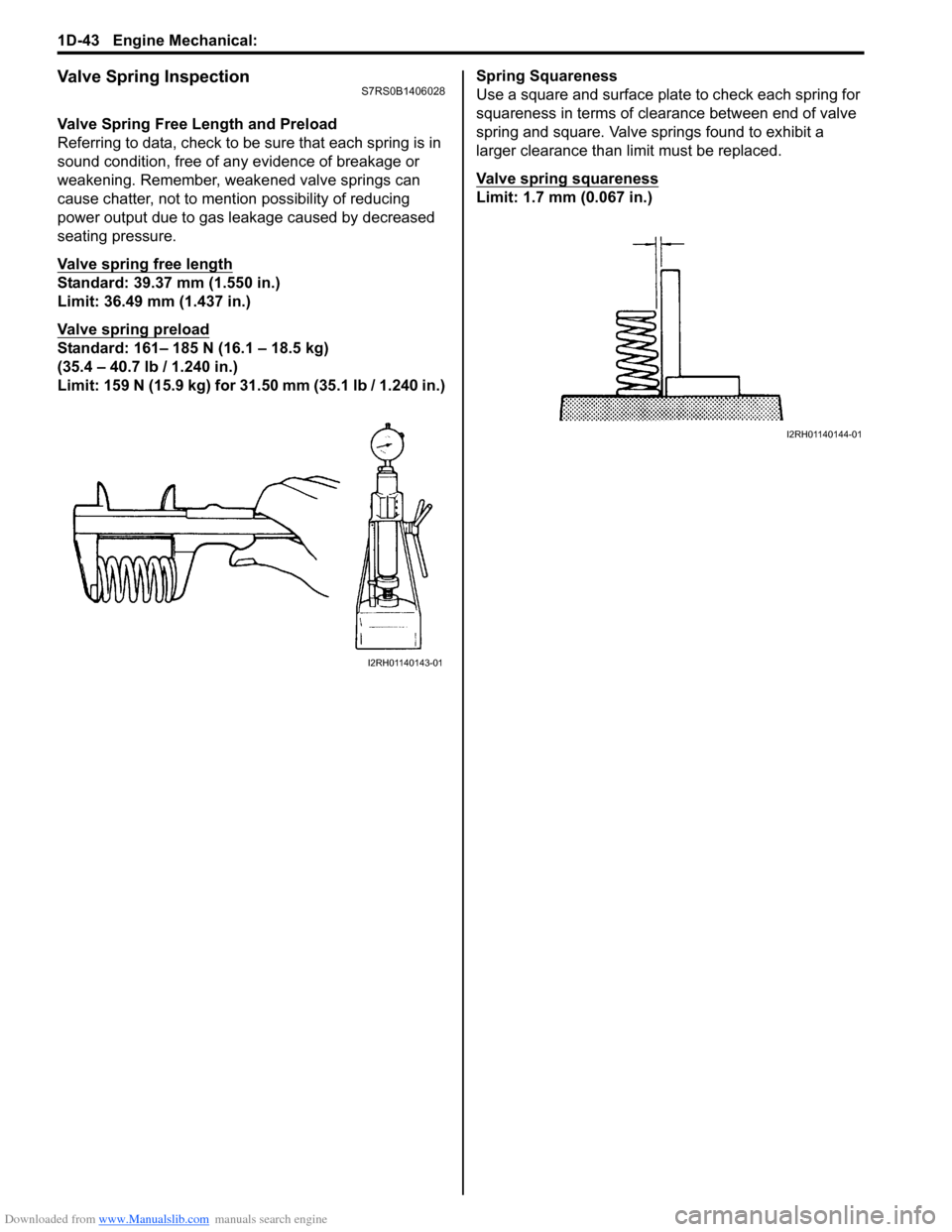

Valve Spring InspectionS7RS0B1406028

Valve Spring Free Length and Preload

Referring to data, check to be sure that each spring is in

sound condition, free of any evidence of breakage or

weakening. Remember, weakened valve springs can

cause chatter, not to mention possibility of reducing

power output due to gas leakage caused by decreased

seating pressure.

Valve spring free length

Standard: 39.37 mm (1.550 in.)

Limit: 36.49 mm (1.437 in.)

Valve spring preload

Standard: 161– 185 N (16.1 – 18.5 kg)

(35.4 – 40.7 lb / 1.240 in.)

Limit: 159 N (15.9 kg) for 31.50 mm (35.1 lb / 1.240 in.) Spring Squareness

Use a square and surface plate to check each spring for

squareness in terms of clearance between end of valve

spring and square. Valve springs found to exhibit a

larger clearance than limit must be replaced.

Valve spring squareness

Limit: 1.7 mm (0.067 in.)

I2RH01140143-01

I2RH01140144-01

Page 329 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-44

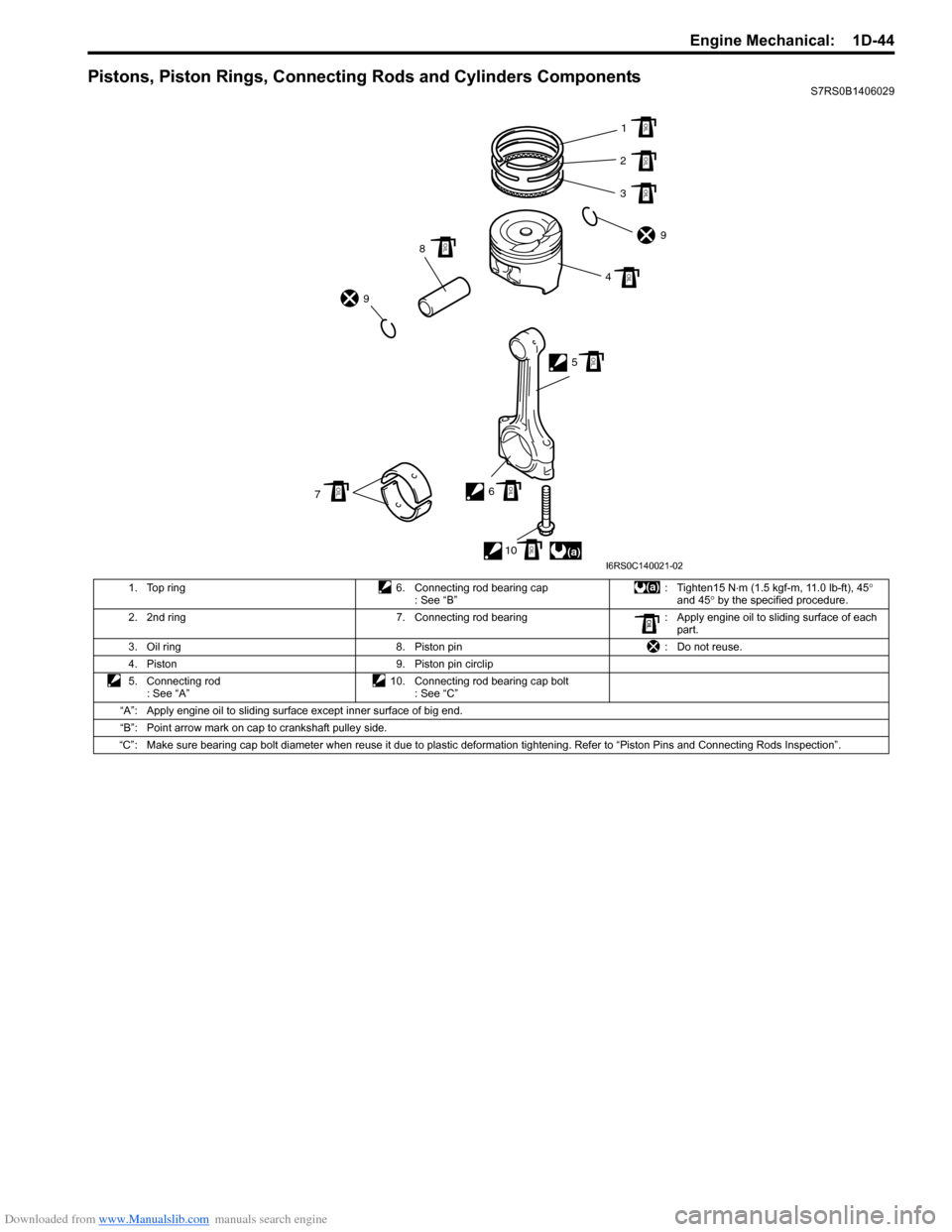

Pistons, Piston Rings, Connecting Rods and Cylinders ComponentsS7RS0B1406029

1. Top ring 6. Connecting rod bearing cap : See “B”: Tighten15 N

⋅m (1.5 kgf-m, 11.0 lb-ft), 45 °

and 45 ° by the specified procedure.

2. 2nd ring 7. Connecting rod bearing : Apply engine oil to sliding surface of each

part.

3. Oil ring 8. Piston pin : Do not reuse.

4. Piston 9. Piston pin circlip

5. Connecting rod : See “A” 10. Connecting rod bearing cap bolt

: See “C”

“A”: Apply engine oil to sliding surface except inner surface of big end.

“B”: Point arrow mark on cap to crankshaft pulley side.

“C”: Make sure bearing cap bolt diameter when reuse it due to plastic deformation tightening. Refer to “Piston Pins and Connecti ng Rods Inspection”.

(a)1

2

3

9

4

5

6 10

7 8

9

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

I6RS0C140021-02

Page 330 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-45 Engine Mechanical:

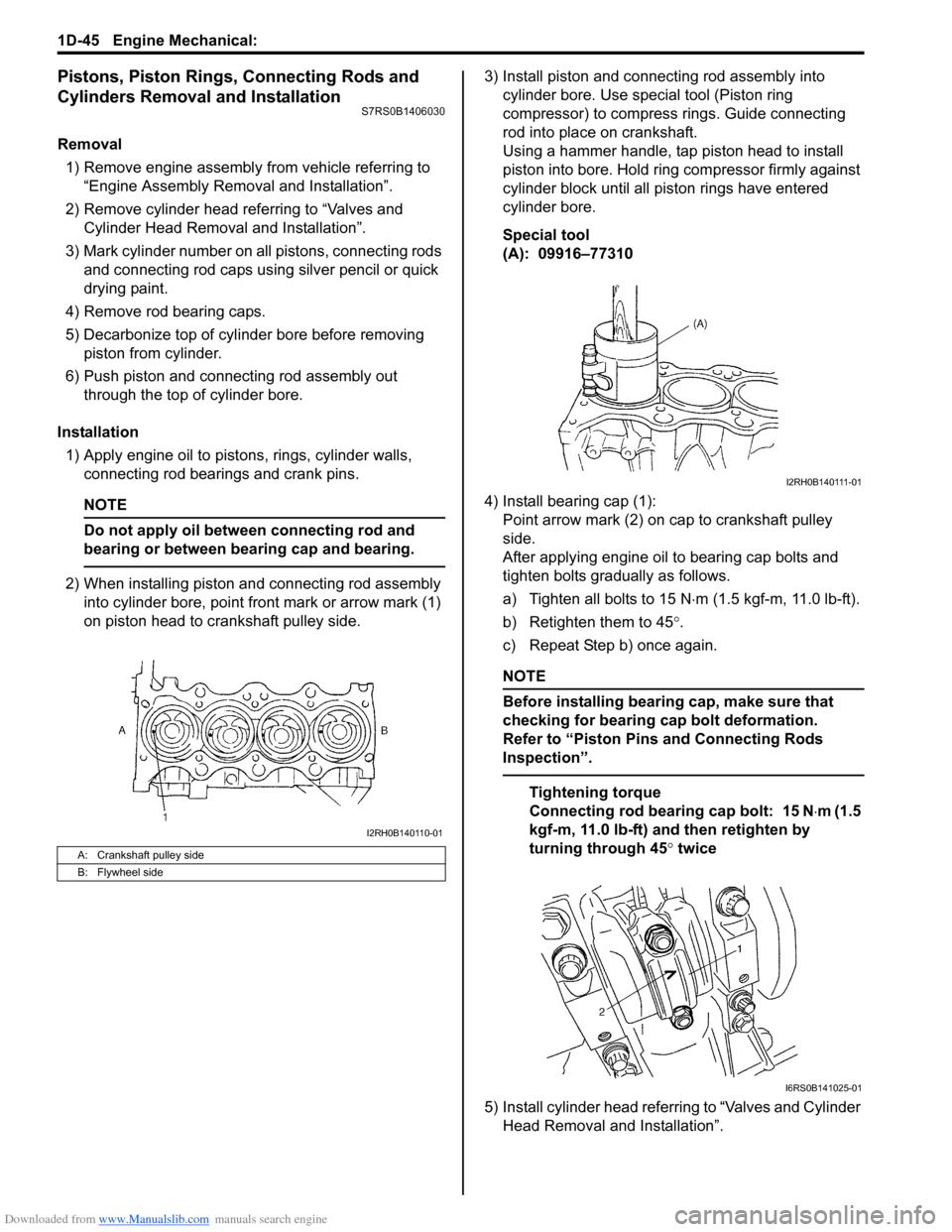

Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation

S7RS0B1406030

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

3) Mark cylinder number on all pistons, connecting rods

and connecting rod caps using silver pencil or quick

drying paint.

4) Remove rod bearing caps.

5) Decarbonize top of cylinder bore before removing piston from cylinder.

6) Push piston and connecting rod assembly out through the top of cylinder bore.

Installation 1) Apply engine oil to pistons, rings, cylinder walls, connecting rod bearings and crank pins.

NOTE

Do not apply oil between connecting rod and

bearing or between bearing cap and bearing.

2) When installing piston and connecting rod assembly into cylinder bore, point front mark or arrow mark (1)

on piston head to crankshaft pulley side. 3) Install piston and connecting rod assembly into

cylinder bore. Use special tool (Piston ring

compressor) to compress rings. Guide connecting

rod into place on crankshaft.

Using a hammer handle, tap piston head to install

piston into bore. Hold ring compressor firmly against

cylinder block until all piston rings have entered

cylinder bore.

Special tool

(A): 09916–77310

4) Install bearing cap (1): Point arrow mark (2) on cap to crankshaft pulley

side.

After applying engine oil to bearing cap bolts and

tighten bolts gradually as follows.

a) Tighten all bolts to 15 N ⋅m (1.5 kgf-m, 11.0 lb-ft).

b) Retighten them to 45 °.

c) Repeat Step b) once again.

NOTE

Before installing bearing cap, make sure that

checking for bearing cap bolt deformation.

Refer to “Piston Pins and Connecting Rods

Inspection”.

Tightening torque

Connecting rod bearing cap bolt: 15 N ⋅m (1.5

kgf-m, 11.0 lb-ft) and then retighten by

turning through 45 ° twice

5) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

A: Crankshaft pulley side

B: Flywheel side

I2RH0B140110-01

I2RH0B140111-01

I6RS0B141025-01

Page 332 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-47 Engine Mechanical:

Cylinders, Pistons and Piston Rings InspectionS7RS0B1406032

Cylinder

Visual inspection

Inspect cylinder walls for scratches, roughness or ridges

which indicate excessive wear. If cylinder bore is very

rough or deeply scratched, or ridged, rebore cylinder and

use over size piston.

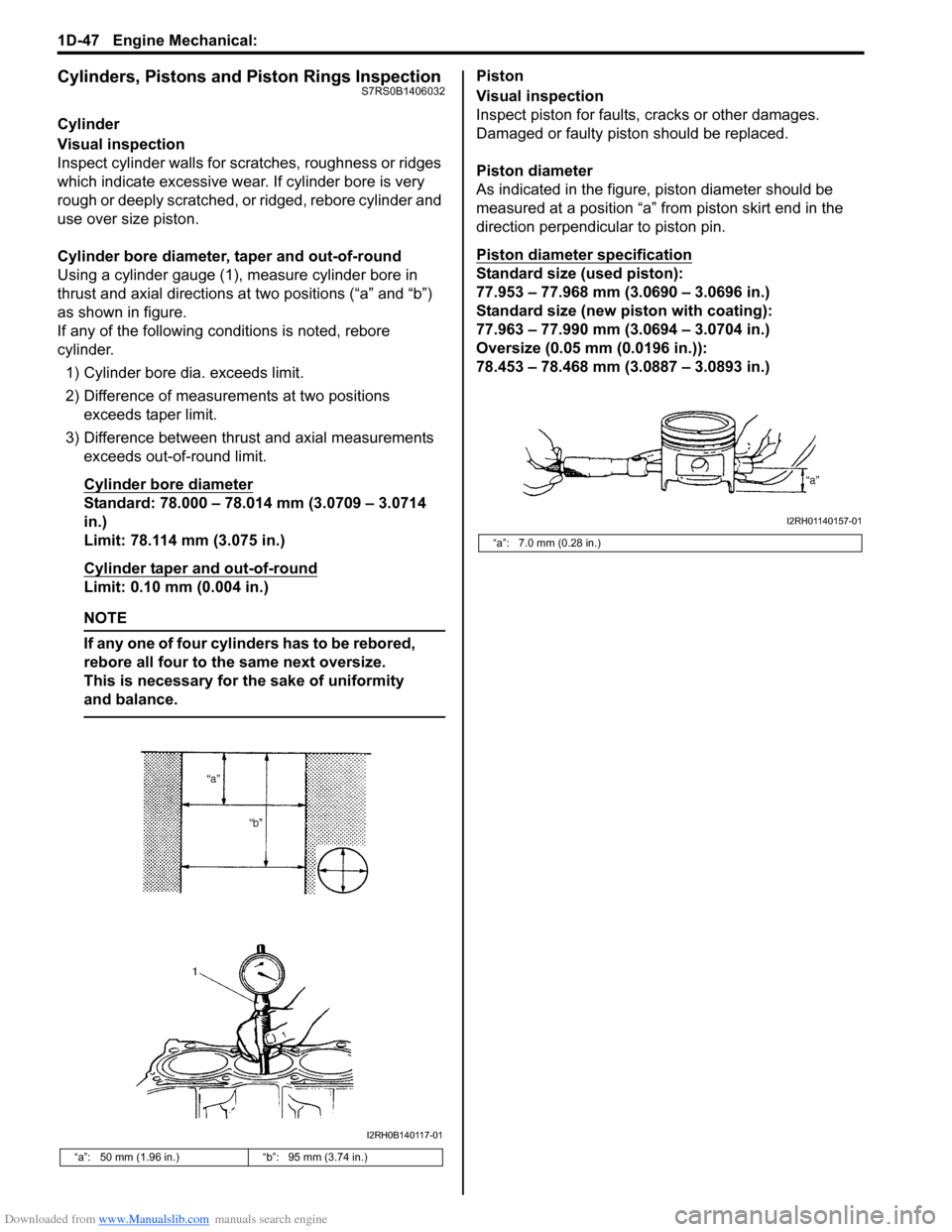

Cylinder bore diameter, taper and out-of-round

Using a cylinder gauge (1), measure cylinder bore in

thrust and axial directions at two positions (“a” and “b”)

as shown in figure.

If any of the following conditions is noted, rebore

cylinder.1) Cylinder bore dia. exceeds limit.

2) Difference of measurements at two positions exceeds taper limit.

3) Difference between thrust and axial measurements exceeds out-of-round limit.

Cylinder bore diameter

Standard: 78.000 – 78.014 mm (3.0709 – 3.0714

in.)

Limit: 78.114 mm (3.075 in.)

Cylinder taper and out-of-round

Limit: 0.10 mm (0.004 in.)

NOTE

If any one of four cylinders has to be rebored,

rebore all four to the same next oversize.

This is necessary for the sake of uniformity

and balance.

Piston

Visual inspection

Inspect piston for faults, cracks or other damages.

Damaged or faulty piston should be replaced.

Piston diameter

As indicated in the figure, piston diameter should be

measured at a position “a” from piston skirt end in the

direction perpendicular to piston pin.

Piston diameter specification

Standard size (used piston):

77.953 – 77.968 mm (3.0690 – 3.0696 in.)

Standard size (new piston with coating):

77.963 – 77.990 mm (3.0694 – 3.0704 in.)

Oversize (0.05 mm (0.0196 in.)):

78.453 – 78.468 mm (3.0887 – 3.0893 in.)

“a”: 50 mm (1.96 in.) “b”: 95 mm (3.74 in.)

I2RH0B140117-01

“a”: 7.0 mm (0.28 in.)

I2RH01140157-01

Page 334 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-49 Engine Mechanical:

Piston Pins and Connecting Rods InspectionS7RS0B1406033

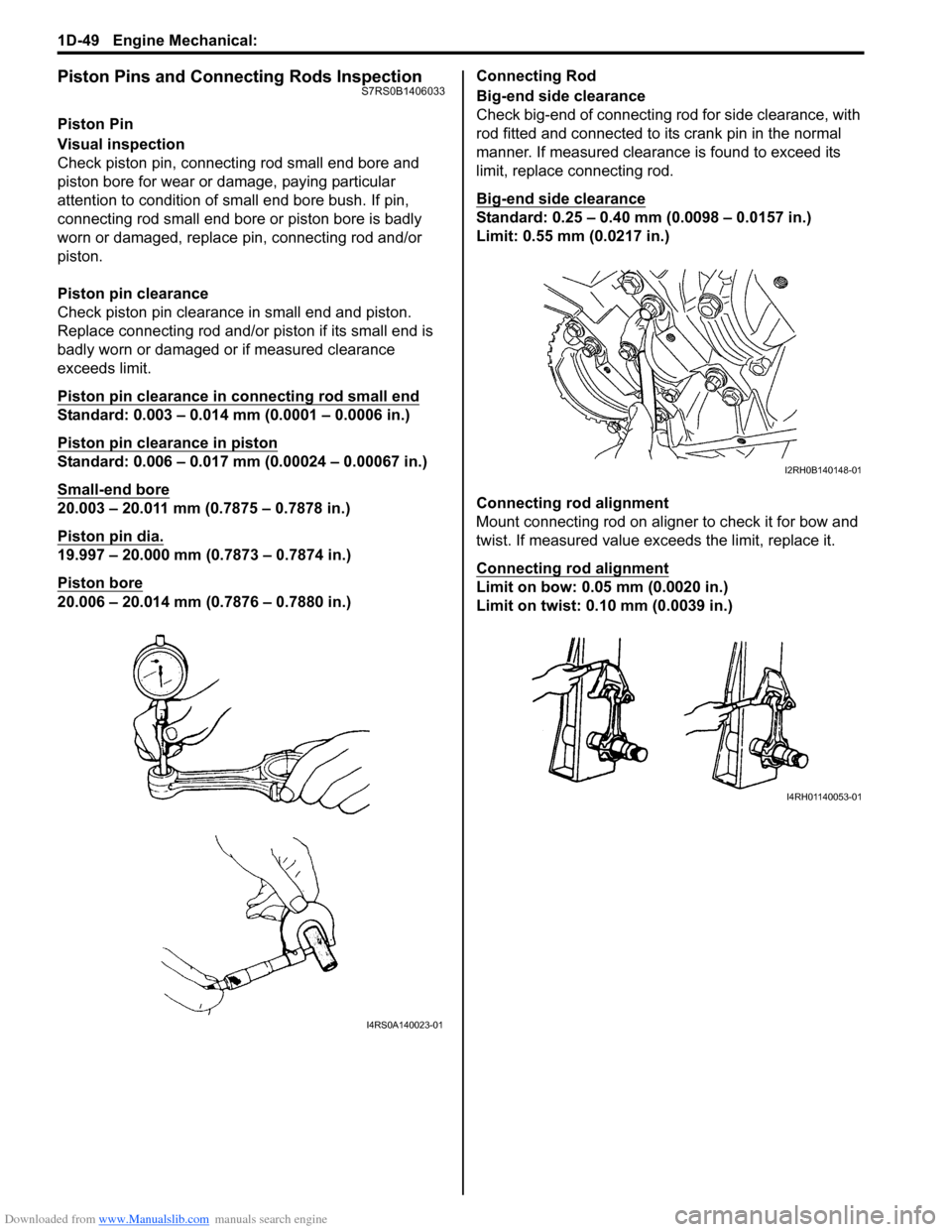

Piston Pin

Visual inspection

Check piston pin, connecting rod small end bore and

piston bore for wear or damage, paying particular

attention to condition of small end bore bush. If pin,

connecting rod small end bore or piston bore is badly

worn or damaged, replace pin, connecting rod and/or

piston.

Piston pin clearance

Check piston pin clearance in small end and piston.

Replace connecting rod and/or piston if its small end is

badly worn or damaged or if measured clearance

exceeds limit.

Piston pin clearance in connecting rod small end

Standard: 0.003 – 0.014 mm (0.0001 – 0.0006 in.)

Piston pin clearance in piston

Standard: 0.006 – 0.017 mm (0.00024 – 0.00067 in.)

Small-end bore

20.003 – 20.011 mm (0.7875 – 0.7878 in.)

Piston pin dia.

19.997 – 20.000 mm (0.7873 – 0.7874 in.)

Piston bore

20.006 – 20.014 mm (0.7876 – 0.7880 in.)Connecting Rod

Big-end side clearance

Check big-end of connecting rod for side clearance, with

rod fitted and connected to its crank pin in the normal

manner. If measured clearance is found to exceed its

limit, replace connecting rod.

Big-end side clearance

Standard: 0.25 – 0.40 mm (0.0098 – 0.0157 in.)

Limit: 0.55 mm (0.0217 in.)

Connecting rod alignment

Mount connecting rod on aligner to check it for bow and

twist. If measured value exceeds the limit, replace it.

Connecting rod alignment

Limit on bow: 0.05 mm (0.0020 in.)

Limit on twist: 0.10 mm (0.0039 in.)

I4RS0A140023-01

I2RH0B140148-01

I4RH01140053-01