Engine harness SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 52 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-2 Engine General Information and Diagnosis:

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• ECM replacement: When substituting a known-good ECM, check for the

following conditions. Neglec ting this check may cause

damage to a known-good ECM.

– Resistance value of all relays, actuators is as specified respectively.

– MAP sensor, A/C refrigerant pressure sensor and TP sensor are in good condition and none of power

circuits of these sensors is shorted to ground.

• Communication of ECM, BCM, ABS/ESP ® control

module, combination meter, keyless start control

module, steering angle sensor (ESP ® model) and

TCM (A/T model), is esta blished by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Immobilizer transponder code registration after

replacing ECM

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.Precautions of ECM Circuit InspectionS7RS0B1100003

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the grommet.

Therefore, when measuring ci rcuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into th e sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S7RS0B1100004

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of battery replacement or “DOME” fuse removal

• To erase DTCs P0122, P01 23, P0222, P0223, P2101,

P2102, P2103, P2111, P2112, P2113, P2119, P2123,

P2127, P2128, P2135 and/or P2138

• To replace ECM

• To replace throttle body and/or accelerator pedal position (APP) sensor assembly

General Description

Statement on Cleanliness and CareS7RS0B1101001

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thous ands of an inch).

Accordingly, when any internal engine parts are

serviced, care and cleanliness are important.

It should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate

the surfaces on initial operation. • Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to

wire harness or other electrical parts.

Page 65 of 1496

![SUZUKI SWIFT 2005 2.G Service User Guide Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS / SUZUKI SWIFT 2005 2.G Service User Guide Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS /](/img/20/7607/w960_7607-64.png)

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS / ESP® control module 49. Radiator cooling fan motor

[B]: Auto A/C model 25. TCM 50. “RDTR FAN” fuse

1. ECM 26. To other control module connected CAN 51. A/C compressor relay

2. APP sensor assembly 27. Generator 52. Magnet clutch of compressor (A/C model)

3. Shield wire 28. Electric load current sensor (if equipped) 53. “A/C CPRSR” fuse

4. CMP sensor 29. Brake light 54. Ignition coil assembly (for No.1 and No.4 spark

plugs)

5. CKP sensor 30. Brake light switch 55. Ignition coil assembly (for No.2 and No.3 spark

plugs)

6. MAF and IAT sensor 31. Diagnosis connector (Hong Kong model) 56. P/S control module

7. MAP sensor 32. Throttle actuator control relay 57. “RADIO” fuse

8. ECT sensor 33. “THR MOT” fuse 58. Main relay

9. A/C refrigerant pressure sensor 34. Throttle throttle body assembly 59. “IG COIL” fuse

10. A/C evaporator outlet air temp. sensor (Manual A/C model) 35. Throttle actuator

60. Ignition switch

11. HO2S-1 36. TP sensor 61. “IG ACC” fuse

12. HO2S-2 37. Injector No.1 62. “FI” fuse

13. Knock sensor 38. Injector No.2 63. Starting motor control relay

14. Blower motor relay 39. Injector No.3 64. “ST SIG” fuse

15. Blower motor 40. Injector No.4 65. “ST MOT” fuse

16. Blower motor resistor 41. EVAP canister purge valve66. Transmission range switch (A/T model) or CPP

switch (Hong Kong model with M/T)

17. Blower speed selector 42. EGR valve 67. Starting motor

18. A/C switch 43. Oil control valve (Camshaft position

control) (VVT model) 68. Immobilizer coil antenna

19. Blower motor controller 44. Fuel pump relay 69. Main fuse box

20. HVAC control module 45. Fuel pump 70. Battery

21. Data link connector (DLC) 46. Radiator cooling fan motor relay No.1 71. Barometric pressure sensor

22. To other control module connected with DLC 47. Radiator cooling fan motor relay No.2

72. Engine ground

23. BCM 48. Radiator cooling fan motor relay No.3 73. Body ground

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A110008-01

Page 75 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-25

Step 2: DTC / Freeze Frame Data Check, Record and

Clearance

First, check DTC (including pending DTC), referring to

“DTC Check”. If DTC is indicated, print it and freeze

frame data or write them down and then clear them by

referring to “DTC Clearance”. DTC indicates malfunction

that occurred in the system but does not indicate

whether it exists now or it occurred in the past and the

normal condition has been restored now. To check which

case applies, check the sy mptom in question according

to Step 5 and recheck DTC according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “Step 2: DTC / Freeze Frame

Data Check, Record and Clearance: ”, confirm trouble

symptoms. Also, reconfirm DTC according to “DTC

Confirmation Procedure” described in each DTC diag.

flow.

Step 6 and 7: Rechecking and Record of DTC /

Freeze Frame Data

Refer to “DTC Check” for checking procedure.

Step 8: Engine Basic Inspection and Engine

Symptom Diagnosis

Perform basic engine check according to “Engine Basic

Inspection” first. When the end of the flow has been

reached, check the parts of the system suspected as a

possible cause referring to “Engine Symptom Diagnosis”

and based on symptoms appearing on the vehicle

(symptoms obtained through steps of customer

complaint analysis, trouble symptom confirmation and/or

basic engine check) and repair or replace faulty parts, if

any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, ECM or other part and repair or

replace faulty parts. Step 10: Intermittent Problems Check

Check parts where an intermit

tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the

engine is free from any abnormal conditions. If what has

been repaired is re lated to the DTC, clear the DTC once,

perform DTC confirmation procedure and confirm that no

DTC is indicated.

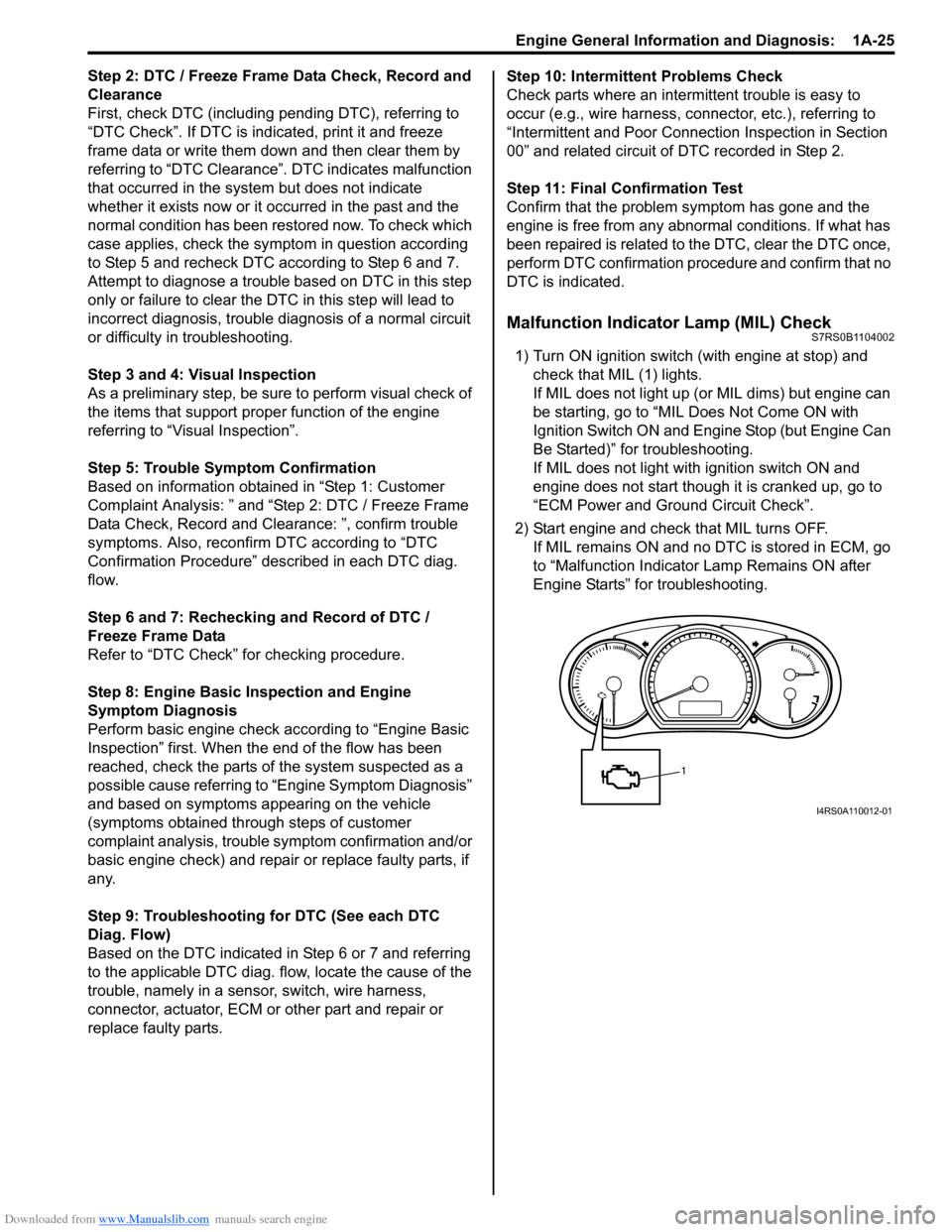

Malfunction Indicator Lamp (MIL) CheckS7RS0B1104002

1) Turn ON ignition switch (with engine at stop) and check that MIL (1) lights.

If MIL does not light up (or MIL dims) but engine can

be starting, go to “MIL Does Not Come ON with

Ignition Switch ON and Engine Stop (but Engine Can

Be Started)” for troubleshooting.

If MIL does not light with ignition switch ON and

engine does not start though it is cranked up, go to

“ECM Power and Ground Circuit Check”.

2) Start engine and check that MIL turns OFF. If MIL remains ON and no DTC is stored in ECM, go

to “Malfunction Indicator Lamp Remains ON after

Engine Starts” for troubleshooting.

1

I4RS0A110012-01

Page 87 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-37

TP SENSOR 2 VOLT (THROTTLE POSITION SENSOR

(SUB) OUTPUT VOLTAGE, V)

The TP sensor (sub) reading provides throttle valve

opening information in the form of voltage.

APP SENSOR 1 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (MAIN) OUTPUT

VOLTAGE, V)

The APP sensor (main) read ing provides accelerator

pedal opening information in the form of voltage.

APP SENSOR 2 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (S UB) OUTPUT VOLTAGE,

V)

The APP sensor (sub) reading provides accelerator

pedal opening information in the form of voltage.

ACCEL POSITION (ABSOLUTE ACCELERATOR

PEDAL POSITION, %)

When accelerator pedal is at fully released position,

accelerator pedal is indicated as 0 – 5% and 90 – 100%

fully depressed position. THROTTLE TARGET POSI (TARGET THROTTLE

VALVE POSITION, %)

Target throttle valve position is ECM internal parameter

which indicates the ECM requested throttle valve

position.

BATTERY CURRENT (A)

This parameter indicates elec

tric load value (current

consumption) that detected by electric load current

sensor.

GENERATOR CONT DUTY (GENERATOR CONTROL

DUTY, %)

This parameter indicates generator control duty ratio that

controls production electricity of generator by ECM.

100%: No limitation for the generating

0%: Maximum limitation for the generating

GENERATOR FIELD DUTY (GENERATOR FIELD

COIL DUTY, %)

This parameter indicates ope rating rate (status of

production electricity) for gen erator by field coil duty

ratio.

100%: maximum operation.

0%: minimum operation.

Visual InspectionS7RS0B1104008

Visually check the following parts and systems.

Inspection item Reference section

• Engine oil – level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant – level, leakage “Co olant Level Check in Section 1F”

• Fuel – level, leakage “Fuel Lines and Connections Inspection in Section 0B”

• Air cleaner element – dirt, clogging “Air Cleaner Filter Inspection in Section 0B”

• Battery – fluid level, corrosion of terminal “Battery Description in Section 1J”

• Water pump belt – tension damage “Accessory Drive Belt Inspection in Section 0B”

• Throttle valve – operating sound “Electric Throttle Body Assembly On-Vehicle Inspection in Section 1C”

• Vacuum hoses of air intake system – disconnection, looseness,

deterioration, bend “Vacuum Hose and Purge Valve Chamber

Inspection in Section 1B”

• Connectors of electric wire harness – disconnection, friction

• Fuses – burning

• Parts – installation, bolt – looseness

• Parts – deformation

• Other parts that can be checked visually

Also check the following items at engine start, if possible

• Malfunction indicator lamp – Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp – Operation “Genera tor Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp – Operation “O il Pressure Switch Inspection in Section 9C”

• Engine coolant temp. meter – Operation “ECT Sensor Inspection in Section 1C”

• Fuel level meter – Operation “Fuel Level Sensor Inspection in Section 9C”

• Tachometer – Operation

• Abnormal air being inhaled from air intake system

• Exhaust system – leakage of exhaust gas, noise

• Other parts that can be checked visually

Page 97 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-47

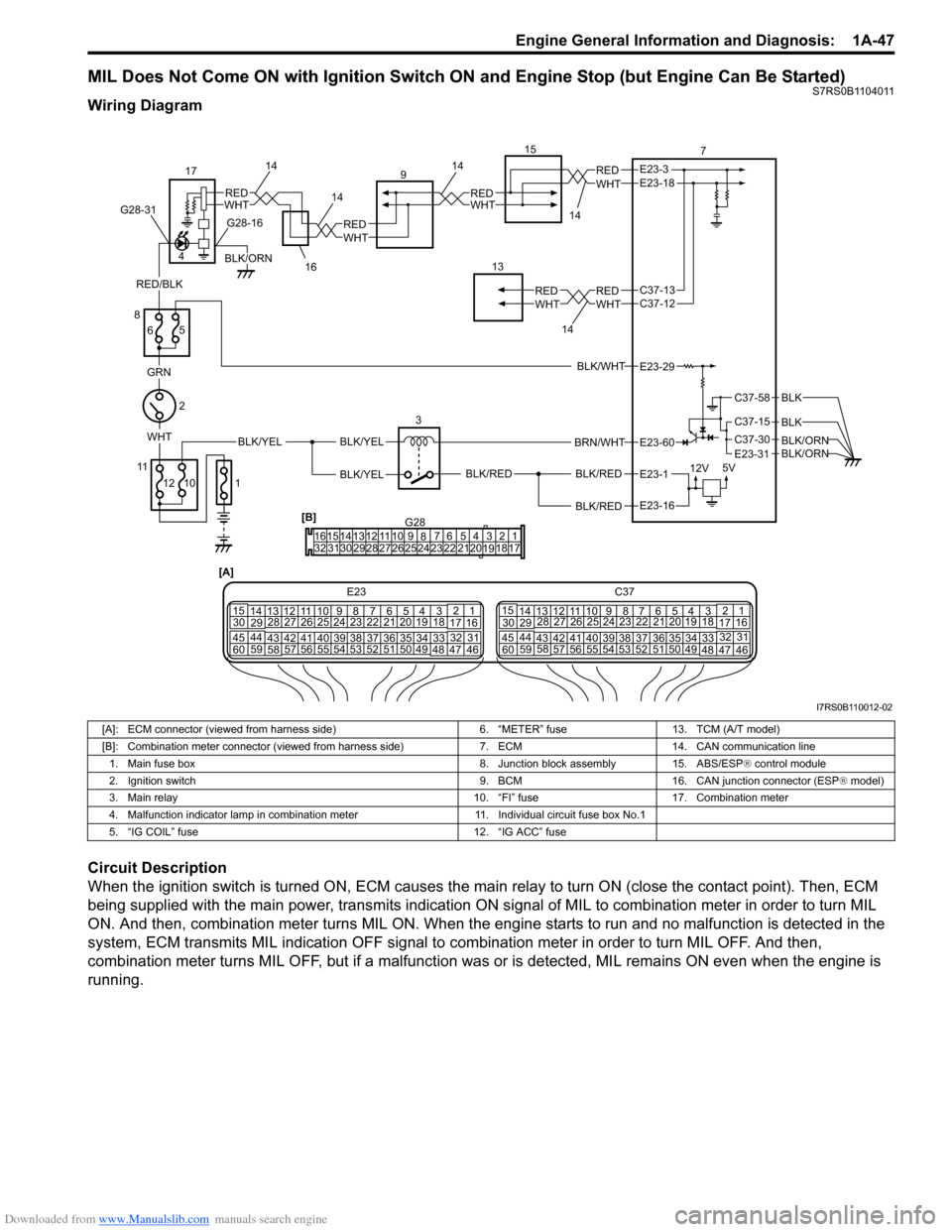

MIL Does Not Come ON with Ignition Switch ON and Engine Stop (but Engine Can Be Started)S7RS0B1104011

Wiring Diagram

Circuit Description

When the ignition switch is turned ON, ECM causes the main relay to turn ON (close the contact point). Then, ECM

being supplied with the main power, transmits indication ON si gnal of MIL to combination meter in order to turn MIL

ON. And then, combination meter turns MIL ON. When the engine starts to run and no malfunction is detected in the

system, ECM transmits MIL indication OFF signal to combination meter in order to turn MIL OFF. And then,

combination meter turns MIL OFF, but if a malfunction was or is detected, MIL remains ON even when the engine is

running.

G281234567

8

910

11

1213141516

1718

19

20

212223242526272829303132

[B]

[A]

E23 C37

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

12

13

238

BLK/WHT

BLK/RED

BLK/RED

BRN/WHT

BLK/REDWHTBLK/YEL

GRN

12V 5V

2

3

8

6 7

E23-29

E23-3

E23-1

E23-60

E23-18

E23-16

1014

14

12

11

RED/BLK

C37-58

C37-15

C37-30

BLK

E23-31

BLK

BLK/ORNBLK/ORN

4

WHTREDWHTRED

BLK/ORN

G28-16

15

13

14

1414

G28-31

BLK/YEL

BLK/YEL

WHTRED

WHTRED

WHTREDC37-13 C37-12

WHTRED

9

17

5 1 16

I7RS0B110012-02

[A]: ECM connector (viewed from harness side)

6. “METER” fuse13. TCM (A/T model)

[B]: Combination meter connector (viewed from harness side) 7. ECM14. CAN communication line

1. Main fuse box 8. Junction block assembly15. ABS/ESP® control module

2. Ignition switch 9. BCM16. CAN junction connector (ESP® model)

3. Main relay 10. “FI” fuse17. Combination meter

4. Malfunction indicator lamp in combination meter 11. Individual circuit fuse box No.1

5. “IG COIL” fuse 12. “IG ACC” fuse

Page 121 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-71

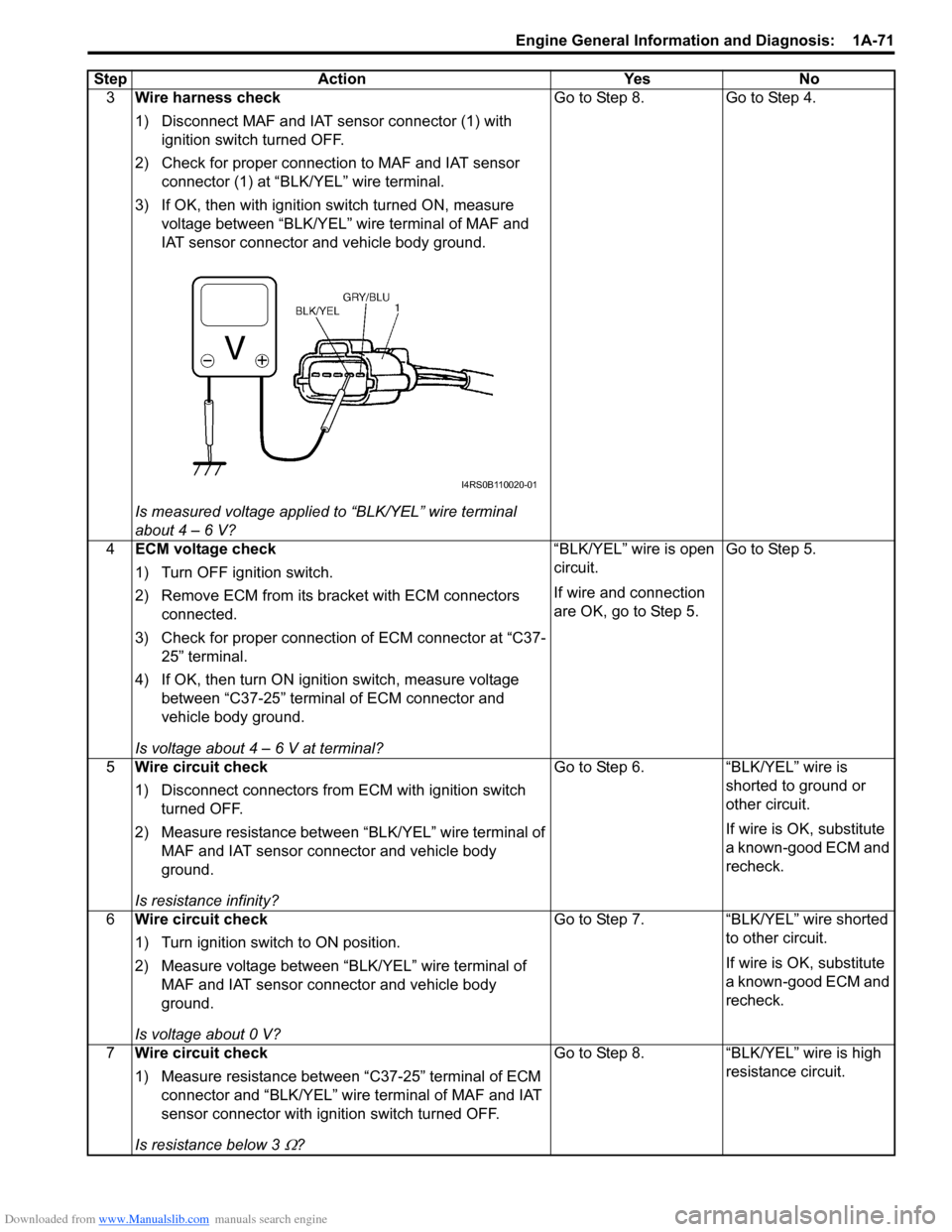

3Wire harness check

1) Disconnect MAF and IAT sensor connector (1) with

ignition switch turned OFF.

2) Check for proper connection to MAF and IAT sensor connector (1) at “BLK/YEL” wire terminal.

3) If OK, then with ignition switch turned ON, measure voltage between “BLK/YEL” wire terminal of MAF and

IAT sensor connector and vehicle body ground.

Is measured voltage applied to “BLK/YEL” wire terminal

about 4 – 6 V? Go to Step 8. Go to Step 4.

4 ECM voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “C37- 25” terminal.

4) If OK, then turn ON igniti on switch, measure voltage

between “C37-25” terminal of ECM connector and

vehicle body ground.

Is voltage about 4 – 6 V at terminal? “BLK/YEL” wire is open

circuit.

If wire and connection

are OK, go to Step 5.

Go to Step 5.

5 Wire circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “BLK/YEL” wire terminal of MAF and IAT sensor connector and vehicle body

ground.

Is resistance infinity? Go to Step 6. “BLK/YEL” wire is

shorted to ground or

other circuit.

If wire is OK, substitute

a known-good ECM and

recheck.

6 Wire circuit check

1) Turn ignition switch to ON position.

2) Measure voltage between “BLK/YEL” wire terminal of

MAF and IAT sensor connector and vehicle body

ground.

Is voltage about 0 V? Go to Step 7. “BLK/YEL” wire shorted

to other circuit.

If wire is OK, substitute

a known-good ECM and

recheck.

7 Wire circuit check

1) Measure resistance between “C37-25” terminal of ECM

connector and “BLK/YEL” wire terminal of MAF and IAT

sensor connector with ignition switch turned OFF.

Is resistance below 3

Ω? Go to Step 8.

“BLK/YEL” wire is high

resistance circuit.

Step

Action YesNo

I4RS0B110020-01

Page 128 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-78 Engine General Information and Diagnosis:

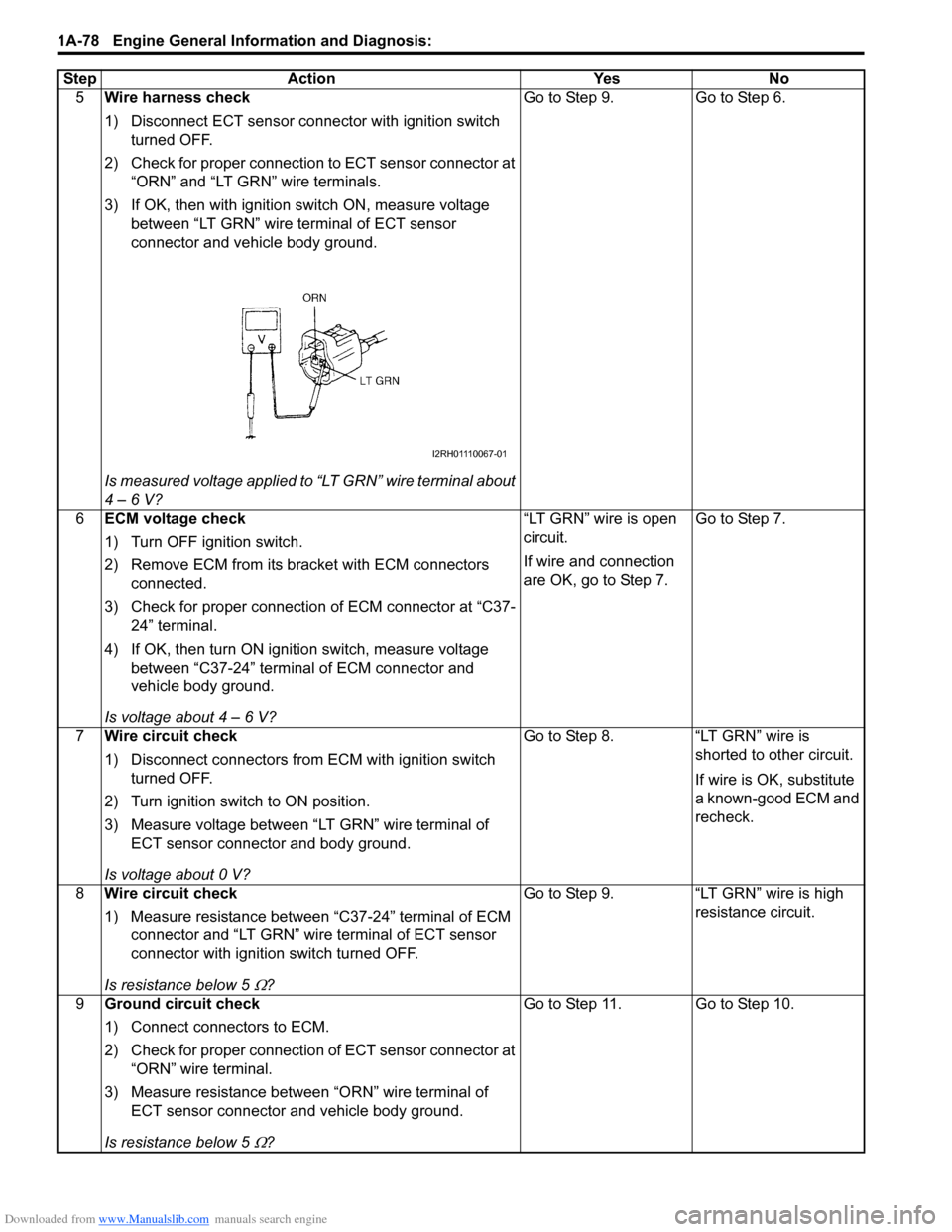

5Wire harness check

1) Disconnect ECT sensor connector with ignition switch

turned OFF.

2) Check for proper connection to ECT sensor connector at “ORN” and “LT GRN” wire terminals.

3) If OK, then with ignition switch ON, measure voltage

between “LT GRN” wire terminal of ECT sensor

connector and vehicle body ground.

Is measured voltage applied to “LT GRN” wire terminal about

4 – 6 V? Go to Step 9.

Go to Step 6.

6 ECM voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “C37- 24” terminal.

4) If OK, then turn ON igniti on switch, measure voltage

between “C37-24” terminal of ECM connector and

vehicle body ground.

Is voltage about 4 – 6 V? “LT GRN” wire is open

circuit.

If wire and connection

are OK, go to Step 7.

Go to Step 7.

7 Wire circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Turn ignition switch to ON position.

3) Measure voltage between “LT GRN” wire terminal of ECT sensor connector and body ground.

Is voltage about 0 V? Go to Step 8.

“LT GRN” wire is

shorted to other circuit.

If wire is OK, substitute

a known-good ECM and

recheck.

8 Wire circuit check

1) Measure resistance between “C37-24” terminal of ECM

connector and “LT GRN” wire terminal of ECT sensor

connector with ignition switch turned OFF.

Is resistance below 5

Ω? Go to Step 9. “LT GRN” wire is high

resistance circuit.

9 Ground circuit check

1) Connect connectors to ECM.

2) Check for proper connection of ECT sensor connector at

“ORN” wire terminal.

3) Measure resistance between “ORN” wire terminal of ECT sensor connector and vehicle body ground.

Is resistance below 5

Ω? Go to Step 11. Go to Step 10.

Step Action Yes No

I2RH01110067-01

Page 132 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-82 Engine General Information and Diagnosis:

4ECM voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “C37- 24” terminal.

4) If OK, then turn ON igniti on switch, measure voltage

between “C37-24” wire terminal of ECM connector and

vehicle body ground.

Is voltage about 4 – 6 V? “LT GRN” wire is open

circuit. If wire and

connection are OK, go

to Step 5.

Go to Step 5.

5 ECT sensor harness voltage check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Turn ON ignition switch.

3) Measure voltage between “LT GRN” wire terminal of ECT sensor connector and vehicle body ground.

Is voltage about 0 V? Go to Step 6. “LT GRN” wire is

shorted to other circuit.

If wire is OK, substitute

a known-good ECM and

recheck.

6 ECT sensor harness resistance check

1) Measure resistance between “C37-24” terminal of ECM

connector and “LT GRN” wire terminal of ECT sensor

connector with ignition switch turn OFF.

Is resistance below 5

Ω? Go to Step 7. “LT GRN” wire is high

resistance circuit.

7 ECT sensor ground circuit check

1) Connect connectors to ECM.

2) Check for proper connection of ECT sensor connector at

“ORN” wire terminal.

3) Measure resistance between “ORN” wire terminal of ECT sensor connector and vehicle body ground.

Is resistance below 5

Ω? Go to Step 9. Go to Step 8.

8 ECT sensor ground circuit check

1) Measure resistance between “C37-55” terminal of ECM

connector and vehicle body ground.

Is resistance below 5

Ω? “ORN” wire is open

circuit or high resistance

circuit. Poor “C37-55”

connection.

Faulty ECM ground

circuit. If circuit is OK,

substitute a known-

good ECM and recheck.

9 ECT sensor for performance check

1) Check ECT sensor according to “ECT Sensor Inspection

in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace ECT sensor.

Step Action Yes No

Page 134 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-84 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 TP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “TP Sensor 1 Volt” displayed on scan tool when accelerator pedal is idle

position and fully depressed.

Is displayed TP sensor value as described voltage in “Scan

Tool Data:”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

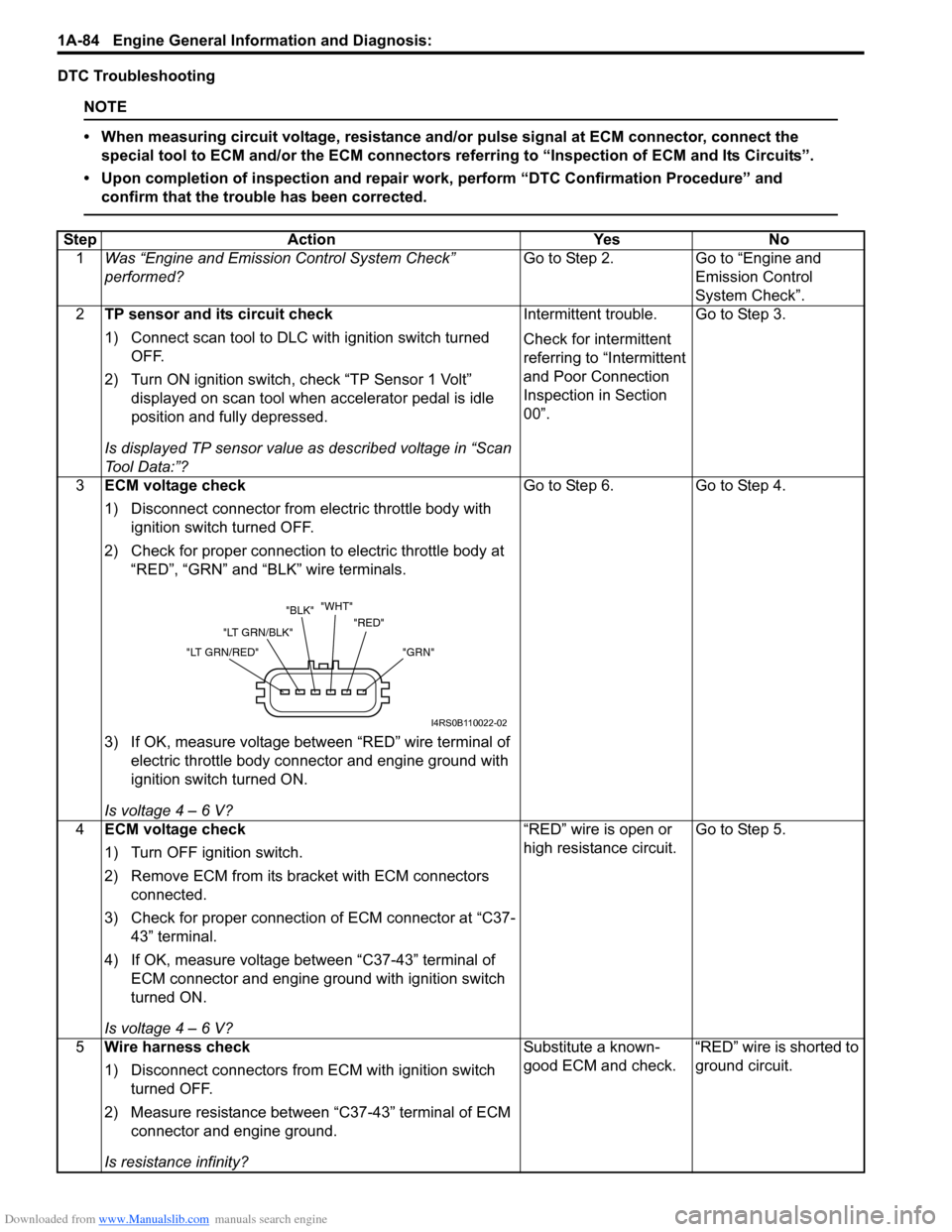

3 ECM voltage check

1) Disconnect connector from electric throttle body with

ignition switch turned OFF.

2) Check for proper connection to electric throttle body at “RED”, “GRN” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of electric throttle body connector and engine ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

4 ECM voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “C37- 43” terminal.

4) If OK, measure voltage between “C37-43” terminal of ECM connector and engine ground with ignition switch

turned ON.

Is voltage 4 – 6 V? “RED” wire is open or

high resistance circuit.

Go to Step 5.

5 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “C37-43” terminal of ECM connector and engine ground.

Is resistance infinity? Substitute a known-

good ECM and check.

“RED” wire is shorted to

ground circuit.

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 135 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-85

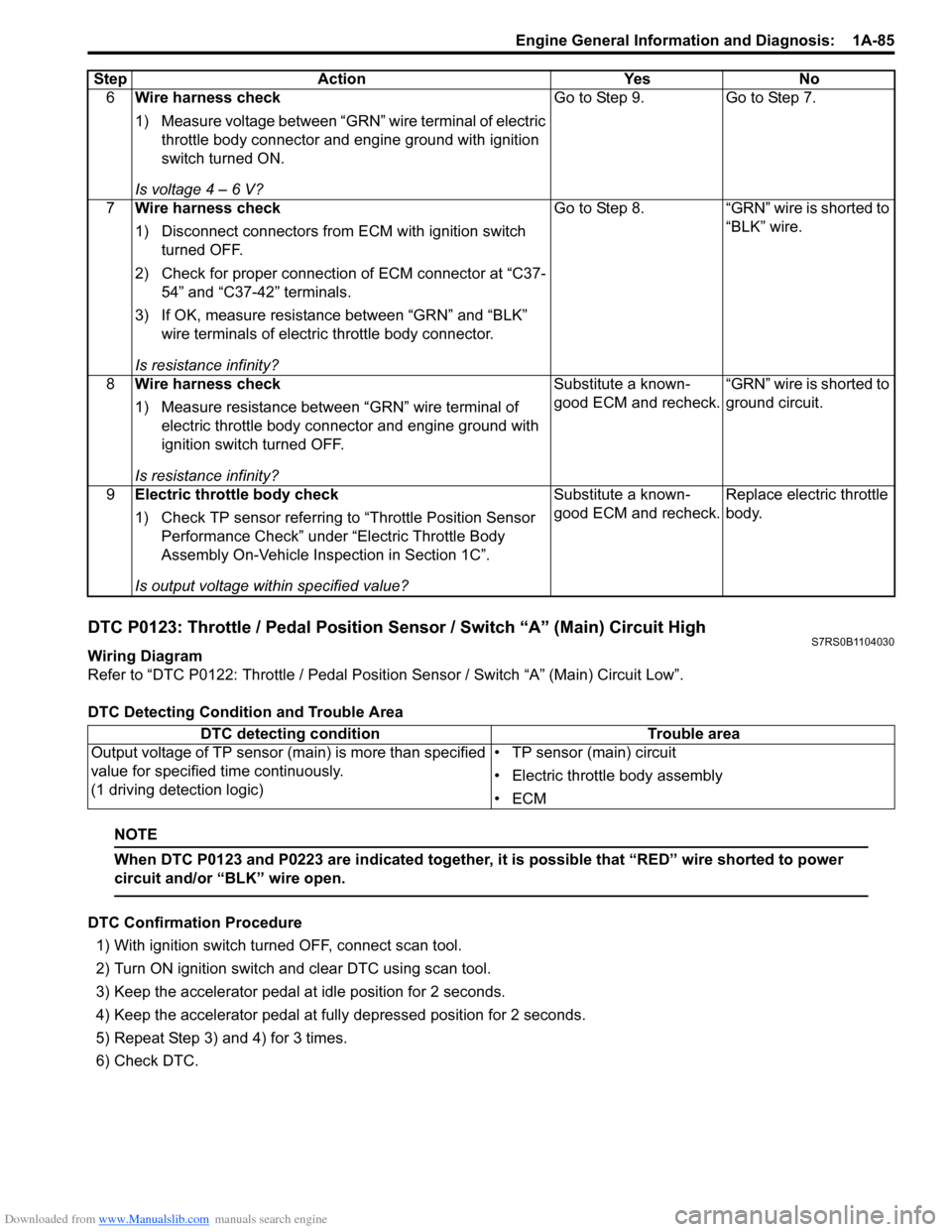

DTC P0123: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit HighS7RS0B1104030

Wiring Diagram

Refer to “DTC P0122: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit Low”.

DTC Detecting Condition and Trouble Area

NOTE

When DTC P0123 and P0223 are indicated together, it is possible that “RED” wire shorted to power

circuit and/or “BLK” wire open.

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC. 6

Wire harness check

1) Measure voltage between “GRN” wire terminal of electric

throttle body connector and engine ground with ignition

switch turned ON.

Is voltage 4 – 6 V? Go to Step 9. Go to Step 7.

7 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “C37- 54” and “C37-42” terminals.

3) If OK, measure resistance between “GRN” and “BLK” wire terminals of electric throttle body connector.

Is resistance infinity? Go to Step 8. “GRN” wire is shorted to

“BLK” wire.

8 Wire harness check

1) Measure resistance between “GRN” wire terminal of

electric throttle body connector and engine ground with

ignition switch turned OFF.

Is resistance infinity? Substitute a known-

good ECM and recheck.

“GRN” wire is shorted to

ground circuit.

9 Electric throttle body check

1) Check TP sensor referring to “Throttle Position Sensor

Performance Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

Step Action Yes No

DTC detecting condition

Trouble area

Output voltage of TP sensor (main) is more than specified

value for specified time continuously.

(1 driving detection logic) • TP sensor (main) circuit

• Electric throttle body assembly

•ECM