H4 lamp SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 68 of 1496

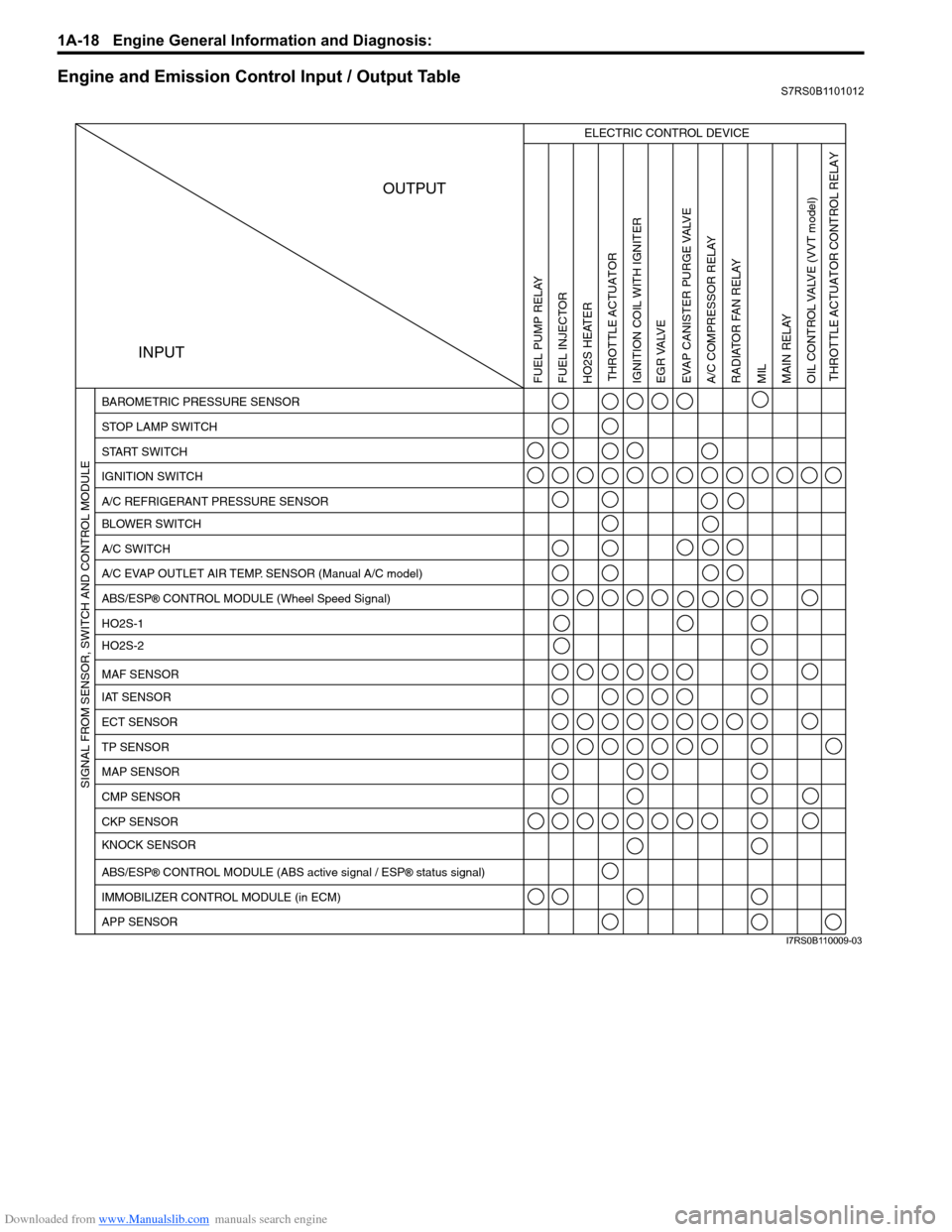

Downloaded from www.Manualslib.com manuals search engine 1A-18 Engine General Information and Diagnosis:

Engine and Emission Control Input / Output TableS7RS0B1101012

INPUTOUTPUT

ELECTRIC CONTROL DEVICE

BAROMETRIC PRESSURE SENSOR

STOP LAMP SWITCH

START SWITCH

IGNITION SWITCH

A/C REFRIGERANT PRESSURE SENSOR

BLOWER SWITCH

A/C SWITCH

A/C EVAP OUTLET AIR TEMP. SENSOR (Manual A/C model)

ABS/ESP

® CONTROL MODULE (Wheel Speed Signal)

HO2S-1

HO2S-2

IAT SENSOR MAF SENSOR

ECT SENSOR

TP SENSOR

MAP SENSOR

CMP SENSOR

CKP SENSOR

KNOCK SENSOR

ABS/ESP

® CONTROL MODULE (ABS active signal / ESP® status signal)

IMMOBILIZER CONTROL MODULE (in ECM)

APP SENSOR

FUEL PUMP RELAY

FUEL INJECTOR

HO2S HEATER THROTTLE ACTUATOR

THROTTLE ACTUATOR CONTROL RELAY

IGNITION COIL WITH IGNITER

EGR VALVE

EVAP CANISTER PURGE VALVEA/C COMPRESSOR RELAY RADIATOR FAN RELAY

MIL

MAIN RELAY

OIL CONTROL VALVE

(VVT model)

SIGNAL FROM SENSOR, SWITCH AND CONTROL MODULE

I7RS0B110009-03

Page 75 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-25

Step 2: DTC / Freeze Frame Data Check, Record and

Clearance

First, check DTC (including pending DTC), referring to

“DTC Check”. If DTC is indicated, print it and freeze

frame data or write them down and then clear them by

referring to “DTC Clearance”. DTC indicates malfunction

that occurred in the system but does not indicate

whether it exists now or it occurred in the past and the

normal condition has been restored now. To check which

case applies, check the sy mptom in question according

to Step 5 and recheck DTC according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “Step 2: DTC / Freeze Frame

Data Check, Record and Clearance: ”, confirm trouble

symptoms. Also, reconfirm DTC according to “DTC

Confirmation Procedure” described in each DTC diag.

flow.

Step 6 and 7: Rechecking and Record of DTC /

Freeze Frame Data

Refer to “DTC Check” for checking procedure.

Step 8: Engine Basic Inspection and Engine

Symptom Diagnosis

Perform basic engine check according to “Engine Basic

Inspection” first. When the end of the flow has been

reached, check the parts of the system suspected as a

possible cause referring to “Engine Symptom Diagnosis”

and based on symptoms appearing on the vehicle

(symptoms obtained through steps of customer

complaint analysis, trouble symptom confirmation and/or

basic engine check) and repair or replace faulty parts, if

any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, ECM or other part and repair or

replace faulty parts. Step 10: Intermittent Problems Check

Check parts where an intermit

tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the

engine is free from any abnormal conditions. If what has

been repaired is re lated to the DTC, clear the DTC once,

perform DTC confirmation procedure and confirm that no

DTC is indicated.

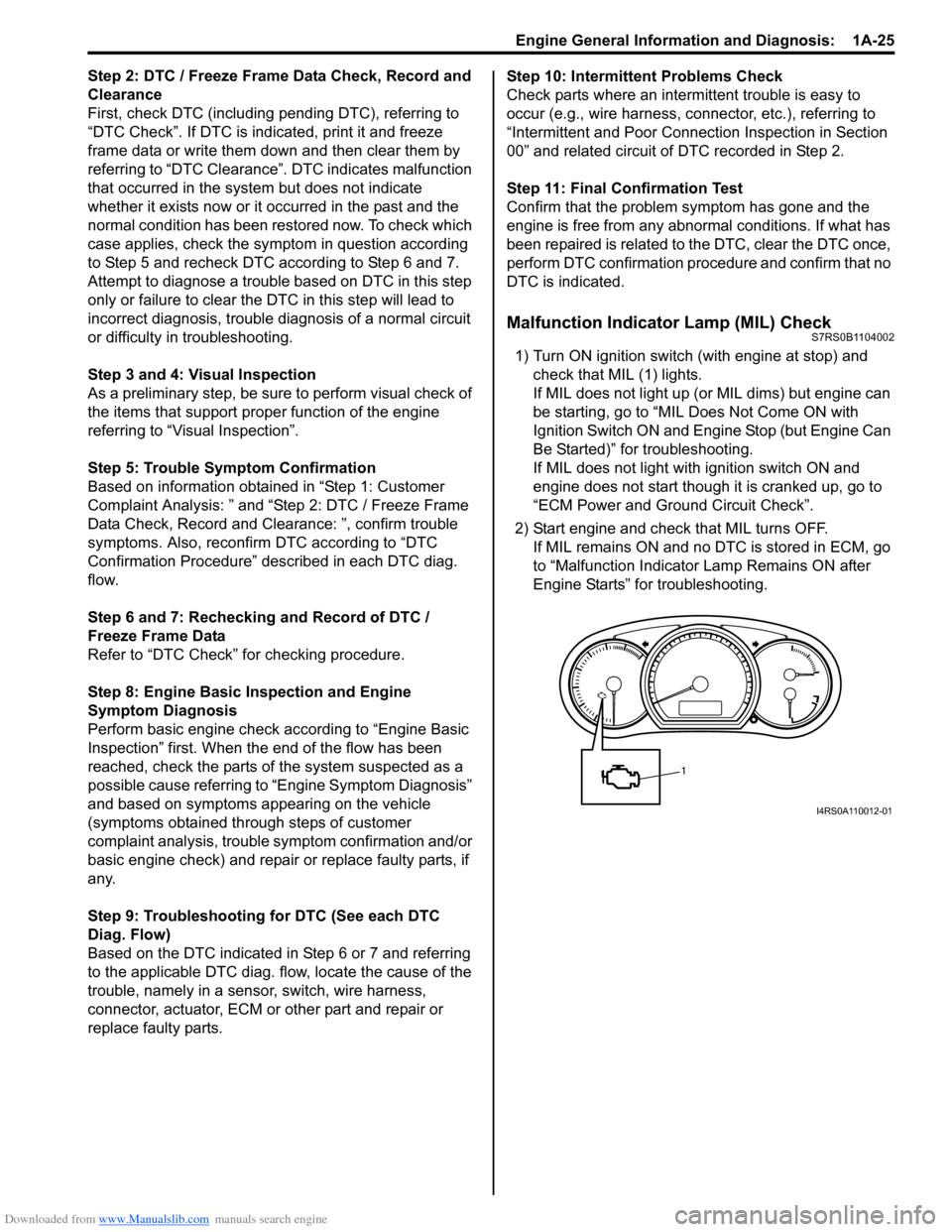

Malfunction Indicator Lamp (MIL) CheckS7RS0B1104002

1) Turn ON ignition switch (with engine at stop) and check that MIL (1) lights.

If MIL does not light up (or MIL dims) but engine can

be starting, go to “MIL Does Not Come ON with

Ignition Switch ON and Engine Stop (but Engine Can

Be Started)” for troubleshooting.

If MIL does not light with ignition switch ON and

engine does not start though it is cranked up, go to

“ECM Power and Ground Circuit Check”.

2) Start engine and check that MIL turns OFF. If MIL remains ON and no DTC is stored in ECM, go

to “Malfunction Indicator Lamp Remains ON after

Engine Starts” for troubleshooting.

1

I4RS0A110012-01

Page 87 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-37

TP SENSOR 2 VOLT (THROTTLE POSITION SENSOR

(SUB) OUTPUT VOLTAGE, V)

The TP sensor (sub) reading provides throttle valve

opening information in the form of voltage.

APP SENSOR 1 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (MAIN) OUTPUT

VOLTAGE, V)

The APP sensor (main) read ing provides accelerator

pedal opening information in the form of voltage.

APP SENSOR 2 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (S UB) OUTPUT VOLTAGE,

V)

The APP sensor (sub) reading provides accelerator

pedal opening information in the form of voltage.

ACCEL POSITION (ABSOLUTE ACCELERATOR

PEDAL POSITION, %)

When accelerator pedal is at fully released position,

accelerator pedal is indicated as 0 – 5% and 90 – 100%

fully depressed position. THROTTLE TARGET POSI (TARGET THROTTLE

VALVE POSITION, %)

Target throttle valve position is ECM internal parameter

which indicates the ECM requested throttle valve

position.

BATTERY CURRENT (A)

This parameter indicates elec

tric load value (current

consumption) that detected by electric load current

sensor.

GENERATOR CONT DUTY (GENERATOR CONTROL

DUTY, %)

This parameter indicates generator control duty ratio that

controls production electricity of generator by ECM.

100%: No limitation for the generating

0%: Maximum limitation for the generating

GENERATOR FIELD DUTY (GENERATOR FIELD

COIL DUTY, %)

This parameter indicates ope rating rate (status of

production electricity) for gen erator by field coil duty

ratio.

100%: maximum operation.

0%: minimum operation.

Visual InspectionS7RS0B1104008

Visually check the following parts and systems.

Inspection item Reference section

• Engine oil – level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant – level, leakage “Co olant Level Check in Section 1F”

• Fuel – level, leakage “Fuel Lines and Connections Inspection in Section 0B”

• Air cleaner element – dirt, clogging “Air Cleaner Filter Inspection in Section 0B”

• Battery – fluid level, corrosion of terminal “Battery Description in Section 1J”

• Water pump belt – tension damage “Accessory Drive Belt Inspection in Section 0B”

• Throttle valve – operating sound “Electric Throttle Body Assembly On-Vehicle Inspection in Section 1C”

• Vacuum hoses of air intake system – disconnection, looseness,

deterioration, bend “Vacuum Hose and Purge Valve Chamber

Inspection in Section 1B”

• Connectors of electric wire harness – disconnection, friction

• Fuses – burning

• Parts – installation, bolt – looseness

• Parts – deformation

• Other parts that can be checked visually

Also check the following items at engine start, if possible

• Malfunction indicator lamp – Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp – Operation “Genera tor Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp – Operation “O il Pressure Switch Inspection in Section 9C”

• Engine coolant temp. meter – Operation “ECT Sensor Inspection in Section 1C”

• Fuel level meter – Operation “Fuel Level Sensor Inspection in Section 9C”

• Tachometer – Operation

• Abnormal air being inhaled from air intake system

• Exhaust system – leakage of exhaust gas, noise

• Other parts that can be checked visually

Page 89 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-39

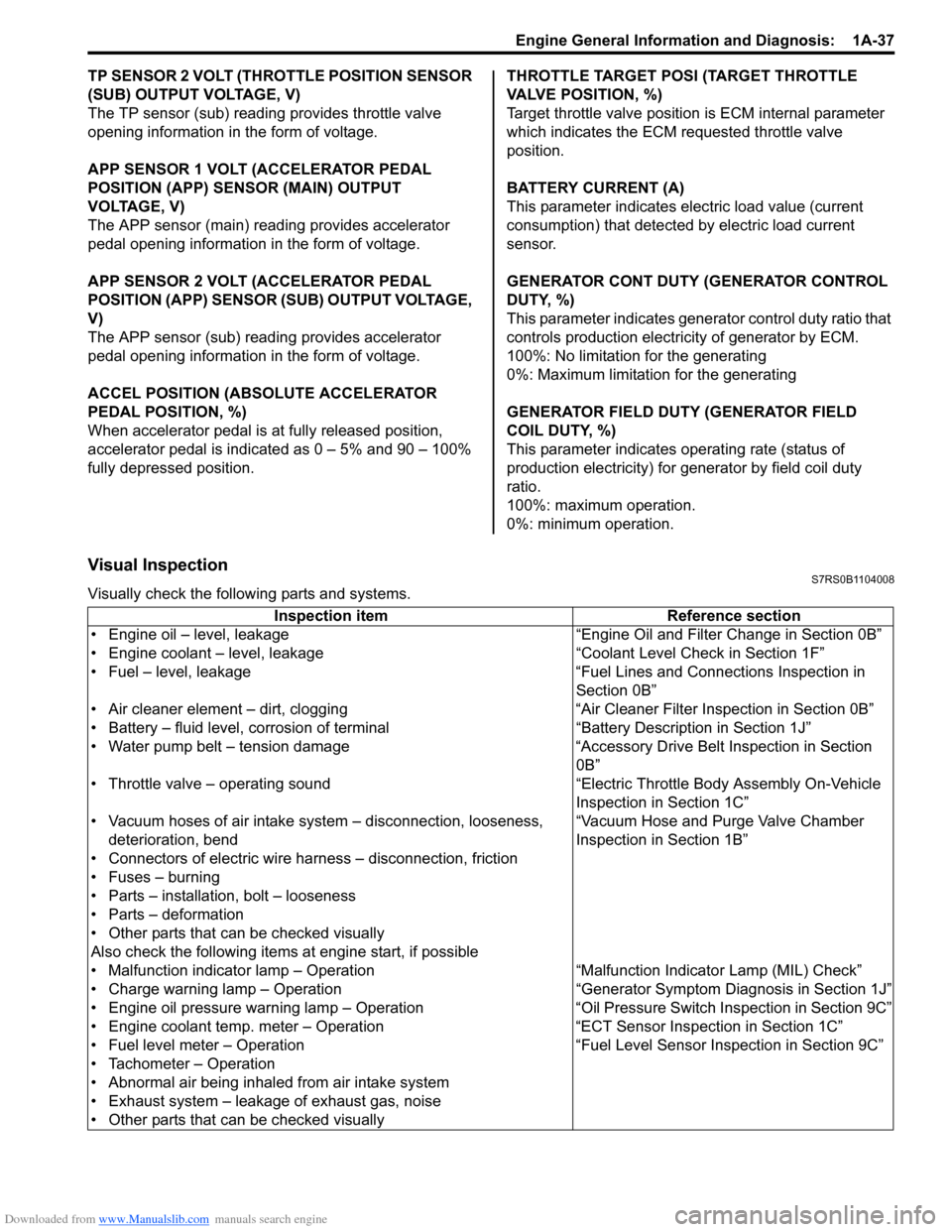

8Check ignition timing

1) Using SUZUKI scan tool, select “Misc Test” mode on

SUZUKI scan tool and fix ignition timing to initial one.

2) Using timing light (1), check initial ignition timing. Special tool

(A): 09930–76420

Is it 5

°± 3° BTDC at specif ied idle speed? Go to “Engine Symptom

Diagnosis”.

Check ignition control

related parts referring to

“Ignition Timing

Inspection in Section

1H”.

9 Check immobilizer system malfunction

1) Check immobilizer indica tor lamp for flashing.

Is it flashing when ignition switch is turned to ON position? Go to “Diagnostic

Trouble Code (DTC)

Check in Section 10C”.

Go to Step 10.

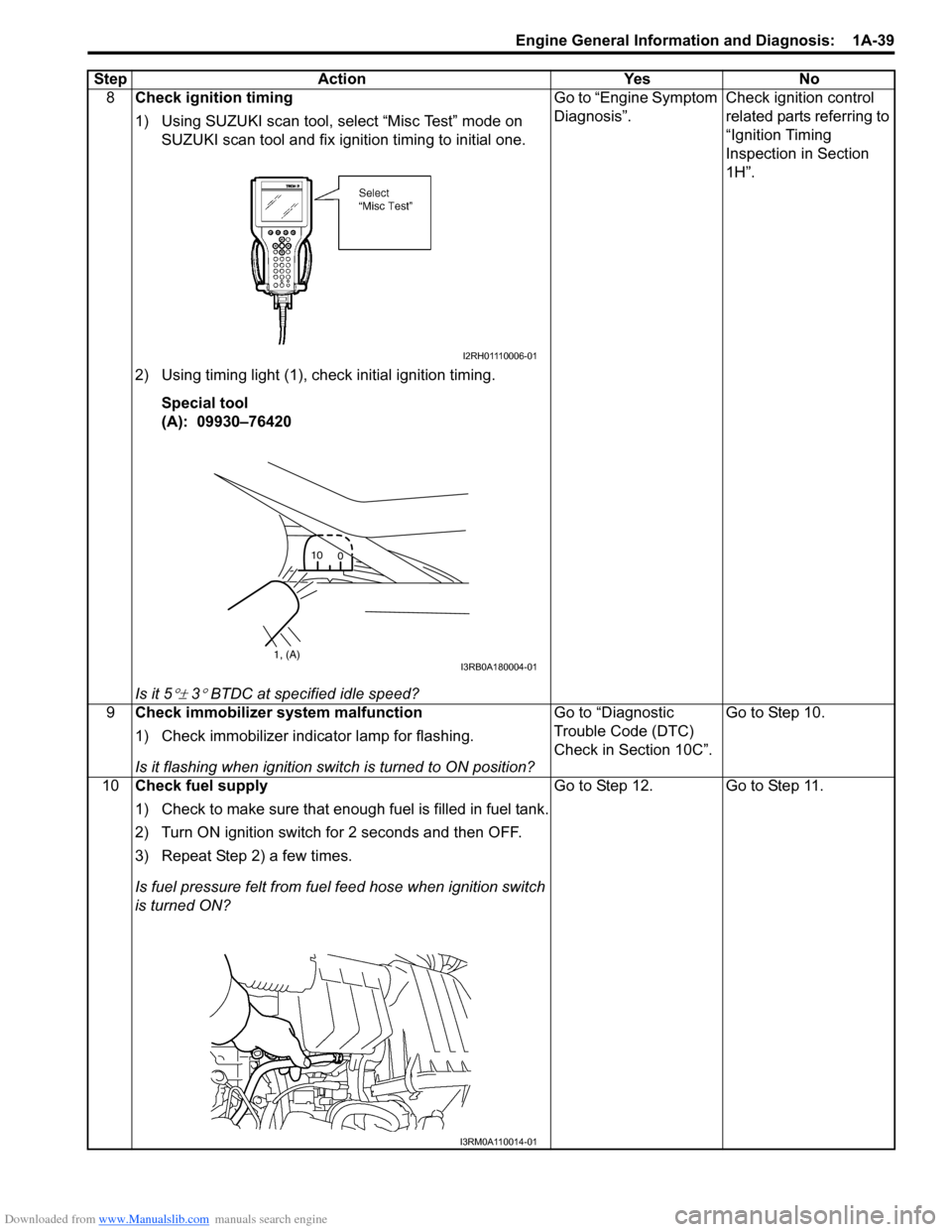

10 Check fuel supply

1) Check to make sure that enough fuel is filled in fuel tank.

2) Turn ON ignition switch for 2 seconds and then OFF.

3) Repeat Step 2) a few times.

Is fuel pressure felt from fuel feed hose when ignition switch

is turned ON? Go to Step 12. Go to Step 11.

Step Action Yes No

I2RH01110006-01

1, (A)

10

0I3RB0A180004-01

I3RM0A110014-01

Page 97 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-47

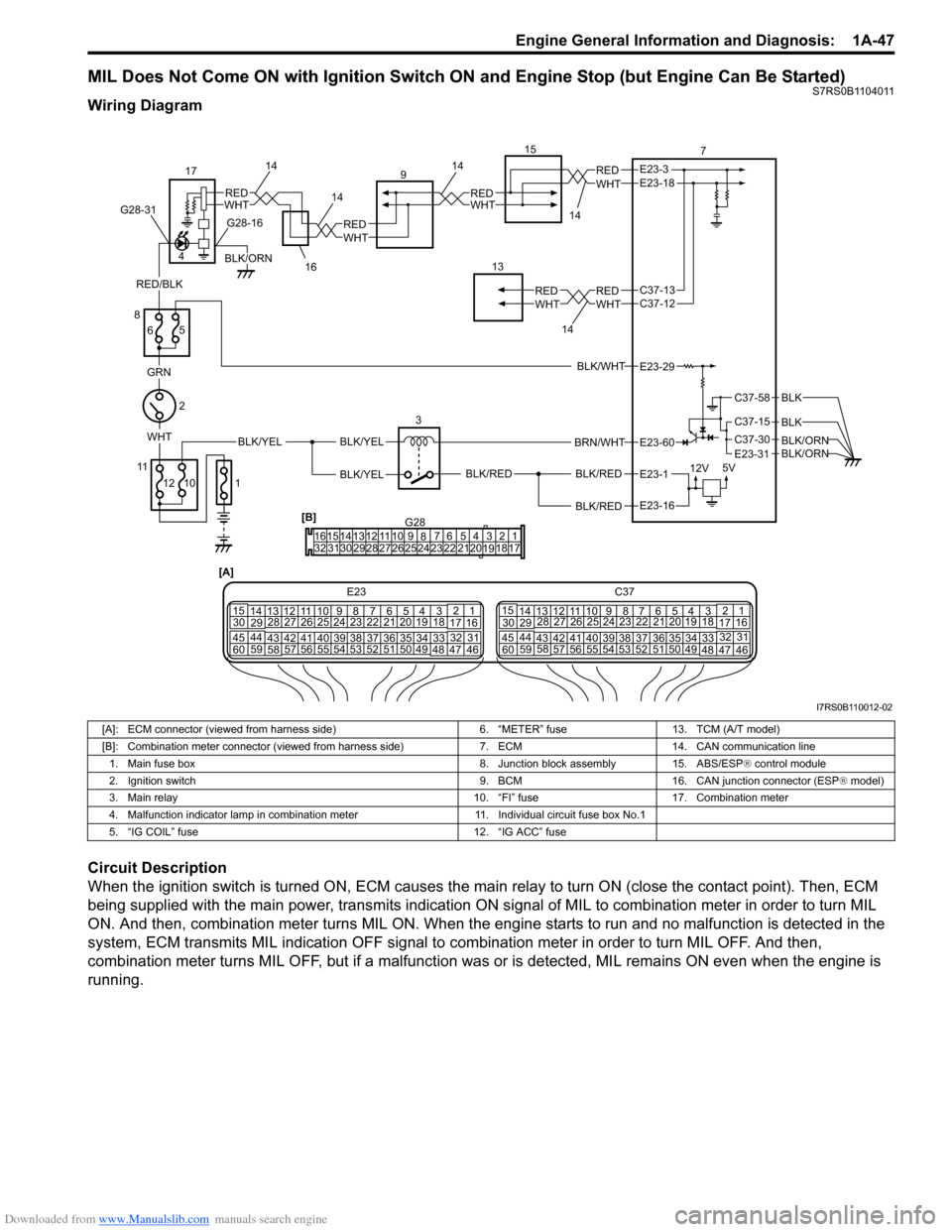

MIL Does Not Come ON with Ignition Switch ON and Engine Stop (but Engine Can Be Started)S7RS0B1104011

Wiring Diagram

Circuit Description

When the ignition switch is turned ON, ECM causes the main relay to turn ON (close the contact point). Then, ECM

being supplied with the main power, transmits indication ON si gnal of MIL to combination meter in order to turn MIL

ON. And then, combination meter turns MIL ON. When the engine starts to run and no malfunction is detected in the

system, ECM transmits MIL indication OFF signal to combination meter in order to turn MIL OFF. And then,

combination meter turns MIL OFF, but if a malfunction was or is detected, MIL remains ON even when the engine is

running.

G281234567

8

910

11

1213141516

1718

19

20

212223242526272829303132

[B]

[A]

E23 C37

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

12

13

238

BLK/WHT

BLK/RED

BLK/RED

BRN/WHT

BLK/REDWHTBLK/YEL

GRN

12V 5V

2

3

8

6 7

E23-29

E23-3

E23-1

E23-60

E23-18

E23-16

1014

14

12

11

RED/BLK

C37-58

C37-15

C37-30

BLK

E23-31

BLK

BLK/ORNBLK/ORN

4

WHTREDWHTRED

BLK/ORN

G28-16

15

13

14

1414

G28-31

BLK/YEL

BLK/YEL

WHTRED

WHTRED

WHTREDC37-13 C37-12

WHTRED

9

17

5 1 16

I7RS0B110012-02

[A]: ECM connector (viewed from harness side)

6. “METER” fuse13. TCM (A/T model)

[B]: Combination meter connector (viewed from harness side) 7. ECM14. CAN communication line

1. Main fuse box 8. Junction block assembly15. ABS/ESP® control module

2. Ignition switch 9. BCM16. CAN junction connector (ESP® model)

3. Main relay 10. “FI” fuse17. Combination meter

4. Malfunction indicator lamp in combination meter 11. Individual circuit fuse box No.1

5. “IG COIL” fuse 12. “IG ACC” fuse

Page 98 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-48 Engine General Information and Diagnosis:

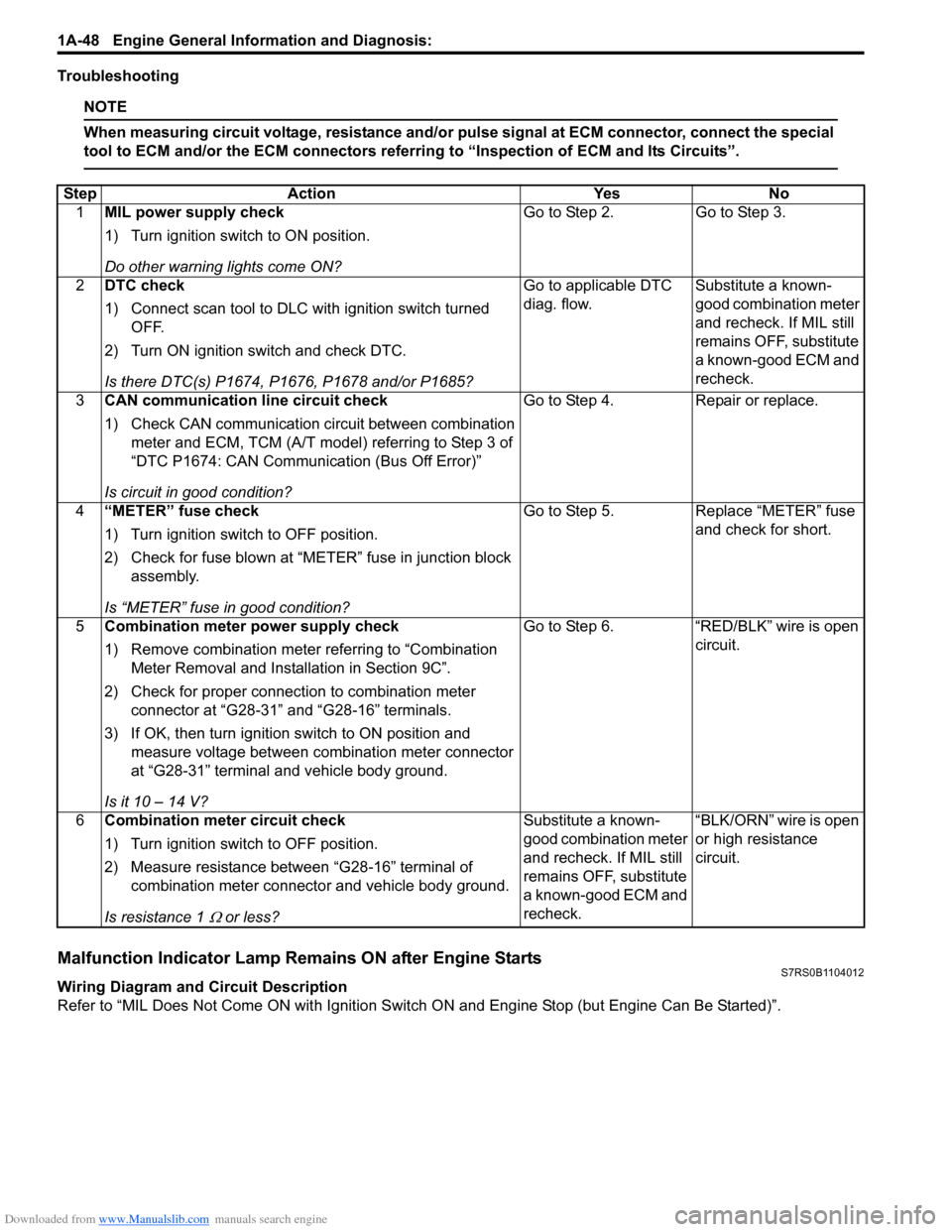

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

Malfunction Indicator Lamp Remains ON after Engine StartsS7RS0B1104012

Wiring Diagram and Circuit Description

Refer to “MIL Does Not Come ON wit h Ignition Switch ON and Engine Stop (but Engine Can Be Started)”.

Step

Action YesNo

1 MIL power supply check

1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 3.

2 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there DTC(s) P1674, P1676, P1678 and/or P1685? Go to applicable DTC

diag. flow.

Substitute a known-

good combination meter

and recheck. If MIL still

remains OFF, substitute

a known-good ECM and

recheck.

3 CAN communication line circuit check

1) Check CAN communication circuit between combination

meter and ECM, TCM (A/T model) referring to Step 3 of

“DTC P1674: CAN Communication (Bus Off Error)”

Is circuit in good condition? Go to Step 4.

Repair or replace.

4 “METER” fuse check

1) Turn ignition switch to OFF position.

2) Check for fuse blown at “M ETER” fuse in junction block

assembly.

Is “METER” fuse in good condition? Go to Step 5.

Replace “METER” fuse

and check for short.

5 Combination meter power supply check

1) Remove combination meter referring to “Combination

Meter Removal and Installation in Section 9C”.

2) Check for proper connection to combination meter connector at “G28-31” and “G28-16” terminals.

3) If OK, then turn ignition switch to ON position and measure voltage between combination meter connector

at “G28-31” terminal and vehicle body ground.

Is it 10 – 14 V? Go to Step 6.

“RED/BLK” wire is open

circuit.

6 Combination meter circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “G28-16” terminal of

combination meter connector and vehicle body ground.

Is resistance 1

Ω or less? Substitute a known-

good combination meter

and recheck. If MIL still

remains OFF, substitute

a known-good ECM and

recheck.

“BLK/ORN” wire is open

or high resistance

circuit.

Page 187 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-137

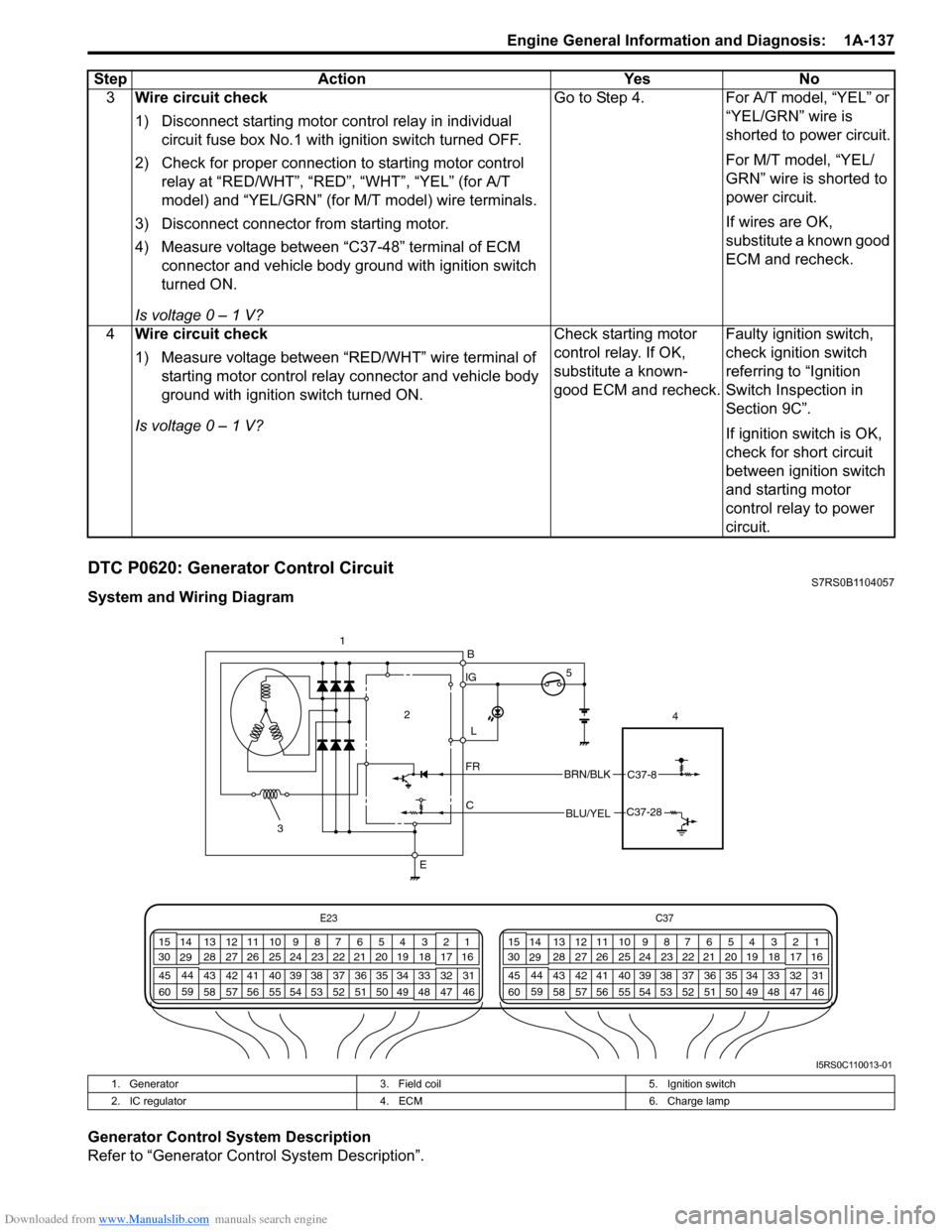

DTC P0620: Generator Control CircuitS7RS0B1104057

System and Wiring Diagram

Generator Control System Description

Refer to “Generator Control System Description”.3

Wire circuit check

1) Disconnect starting motor control relay in individual

circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to starting motor control relay at “RED/WHT”, “RED”, “WHT”, “YEL” (for A/T

model) and “YEL/GRN” (for M/T model) wire terminals.

3) Disconnect connector from starting motor.

4) Measure voltage between “C37-48” terminal of ECM connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 – 1 V? Go to Step 4. For A/T model, “YEL” or

“YEL/GRN” wire is

shorted to power circuit.

For M/T model, “YEL/

GRN” wire is shorted to

power circuit.

If wires are OK,

substitute a known good

ECM and recheck.

4 Wire circuit check

1) Measure voltage between “RED/WHT” wire terminal of

starting motor control relay connector and vehicle body

ground with ignition switch turned ON.

Is voltage 0 – 1 V? Check starting motor

control relay. If OK,

substitute a known-

good ECM and recheck.

Faulty ignition switch,

check ignition switch

referring to “Ignition

Switch Inspection in

Section 9C”.

If ignition switch is OK,

check for short circuit

between ignition switch

and starting motor

control relay to power

circuit.

Step Action Yes No

IG

L

C

FR

E 4

2

BRN/BLKC37-8

BLU/YELC37-28

B

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238 1

3 5

I5RS0C110013-01

1. Generator

3. Field coil 5. Ignition switch

2. IC regulator 4. ECM 6. Charge lamp

Page 231 of 1496

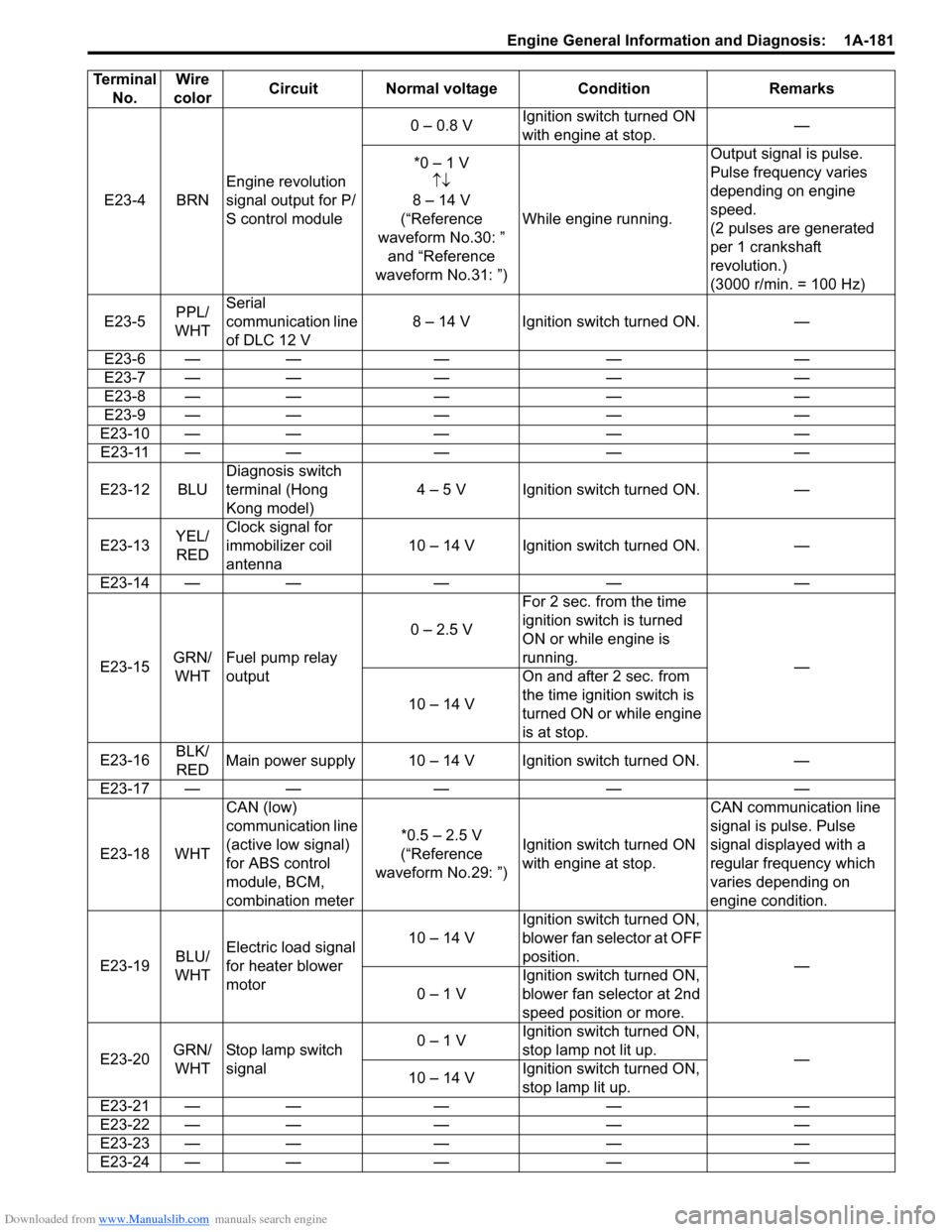

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-181

E23-4 BRNEngine revolution

signal output for P/

S control module 0 – 0.8 V

Ignition switch turned ON

with engine at stop. —

*0 – 1 V ↑↓

8 – 14 V

(“Reference

waveform No.30: ” and “Reference

waveform No.31: ”) While engine running. Output signal is pulse.

Pulse frequency varies

depending on engine

speed.

(2 pulses are generated

per 1 crankshaft

revolution.)

(3000 r/min. = 100 Hz)

E23-5 PPL/

WHT Serial

communication line

of DLC 12 V

8 – 14 V Ignition switch turned ON. —

E23-6 — — — — —

E23-7 — — — — —

E23-8 — — — — —

E23-9 — — — — —

E23-10 — — — — — E23-11 — — — — —

E23-12 BLU Diagnosis switch

terminal (Hong

Kong model) 4 – 5 V Ignition switch turned ON. —

E23-13 YEL/

RED Clock signal for

immobilizer coil

antenna

10 – 14 V Ignition switch turned ON. —

E23-14 — — — — —

E23-15 GRN/

WHT Fuel pump relay

output 0 – 2.5 V

For 2 sec. from the time

ignition switch is turned

ON or while engine is

running.

—

10 – 14 V On and after 2 sec. from

the time ignition switch is

turned ON or while engine

is at stop.

E23-16 BLK/

RED Main power supply 10 – 14 V Ignition switch turned ON. —

E23-17 — — — — —

E23-18 WHT CAN (low)

communication line

(active low signal)

for ABS control

module, BCM,

combination meter *0.5 – 2.5 V

(“Reference

waveform No.29: ”) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

E23-19 BLU/

WHT Electric load signal

for heater blower

motor 10 – 14 V

Ignition switch turned ON,

blower fan selector at OFF

position.

—

0 – 1 V Ignition switch turned ON,

blower fan selector at 2nd

speed position or more.

E23-20 GRN/

WHT Stop lamp switch

signal 0 – 1 V

Ignition switch turned ON,

stop lamp not lit up.

—

10 – 14 V Ignition switch turned ON,

stop lamp lit up.

E23-21 — — — — —

E23-22 — — — — —

E23-23 — — — — —

E23-24 — — — — —

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Page 279 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-7

Installation

Reverse removal procedure noting the following.

• Clean mating surfaces of ECT sensor and thermostat case.

• Check O-ring for damage and replace, if necessary.

• Tighten ECT sensor (1) to specified torque.

Tightening torque

ECT sensor (a): 15 N·m (1.5 kgf-m, 11.0 lb-ft)

• Connect connector to ECT sensor securely.

• Refill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

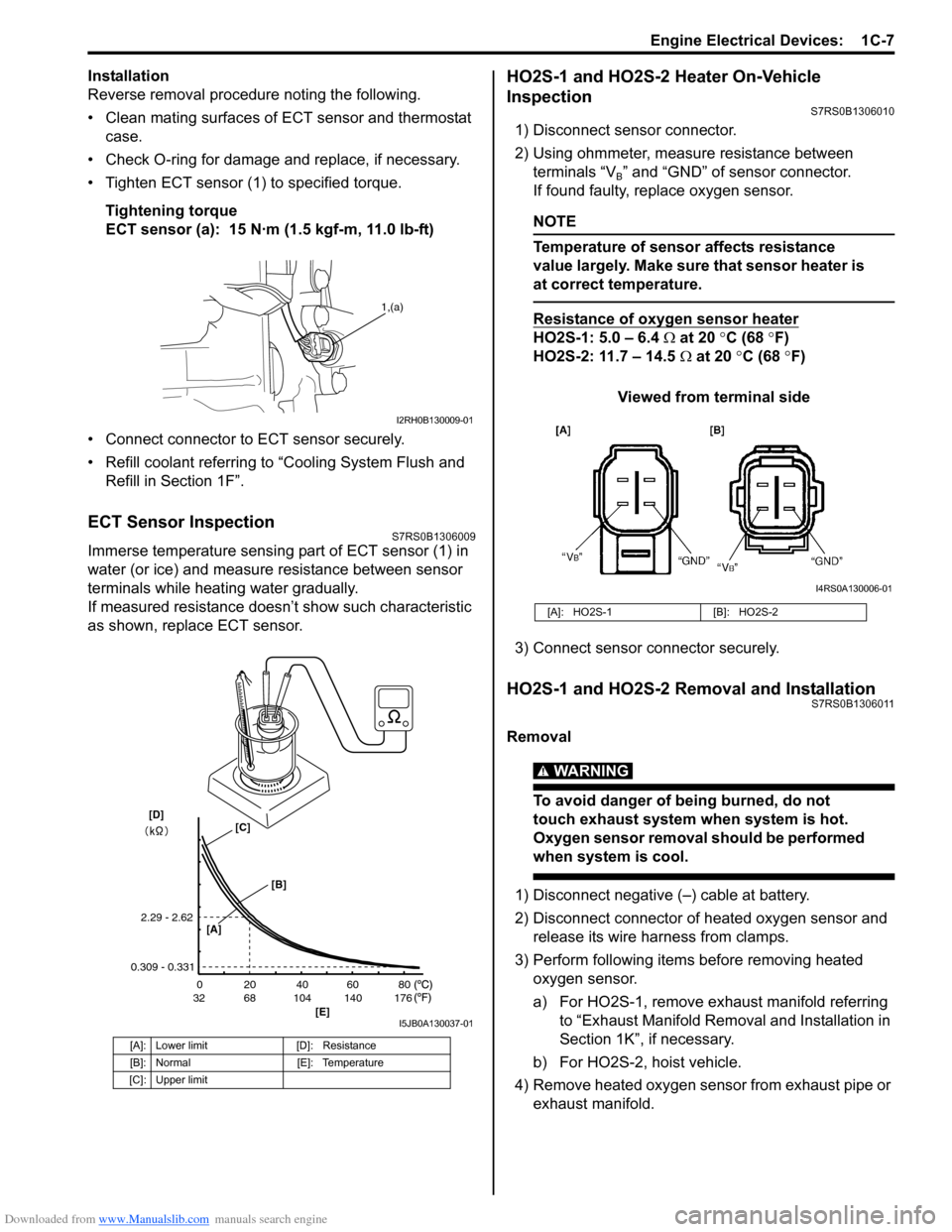

ECT Sensor InspectionS7RS0B1306009

Immerse temperature sensing part of ECT sensor (1) in

water (or ice) and measure resistance between sensor

terminals while heating water gradually.

If measured resistance doesn’t show such characteristic

as shown, replace ECT sensor.

HO2S-1 and HO2S-2 Heater On-Vehicle

Inspection

S7RS0B1306010

1) Disconnect sensor connector.

2) Using ohmmeter, measure resistance between terminals “V

B” and “GND” of sensor connector.

If found faulty, replace oxygen sensor.

NOTE

Temperature of sensor affects resistance

value largely. Make sure that sensor heater is

at correct temperature.

Resistance of oxygen sensor heater

HO2S-1: 5.0 – 6.4 Ω at 20 °C (68 °F)

HO2S-2: 11.7 – 14.5 Ω at 20 °C (68 °F)

Viewed from terminal side

3) Connect sensor co nnector securely.

HO2S-1 and HO2S-2 Removal and InstallationS7RS0B1306011

Removal

WARNING!

To avoid danger of being burned, do not

touch exhaust system when system is hot.

Oxygen sensor removal should be performed

when system is cool.

1) Disconnect negative (–) cable at battery.

2) Disconnect connector of heated oxygen sensor and

release its wire harness from clamps.

3) Perform following items before removing heated oxygen sensor.

a) For HO2S-1, remove exhaust manifold referring to “Exhaust Manifold Remo val and Installation in

Section 1K”, if necessary.

b) For HO2S-2, hoist vehicle.

4) Remove heated oxygen sensor from exhaust pipe or exhaust manifold.

[A]: Lower limit [D]: Resistance

[B]: Normal [E]: Temperature

[C]: Upper limit

1,(a)

I2RH0B130009-01

20

0

68

32 104 140 176 40 60 80

[E]

2.29 - 2.62

0.309 - 0.331

[A]

[B]

[C][D]

I5JB0A130037-01

[A]: HO2S-1 [B]: HO2S-2

I4RS0A130006-01

Page 280 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-8 Engine Electrical Devices:

Installation

Reverse removal procedure noting the following.

• Tighten heated oxygen sensor to specified torque.Tightening torque

Heated oxygen sensor (a): 45 N·m (4.5 kgf-m,

32.5 lb-ft)

• Install exhaust manifold referring to “Exhaust Manifold Removal and Installation in Section 1K”, if removed.

• Connect connector of heated oxygen sensor and clamp wire harness securely.

• After installing heated oxygen sensor, start engine and check that no exhaust gas leakage exists.

CMP Sensor Removal and InstallationS7RS0B1306012

Removal

1) Disconnect negative (–) cable at battery.

2) Disconnect connector from CMP sensor.

3) Remove CMP sensor from cylinder head.

Installation 1) Install CMP sensor to cylinder head.

Tightening torque

CMP sensor bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

2) Connect connector to CMP sensor securely.

3) Connect negative (–) cable to battery.

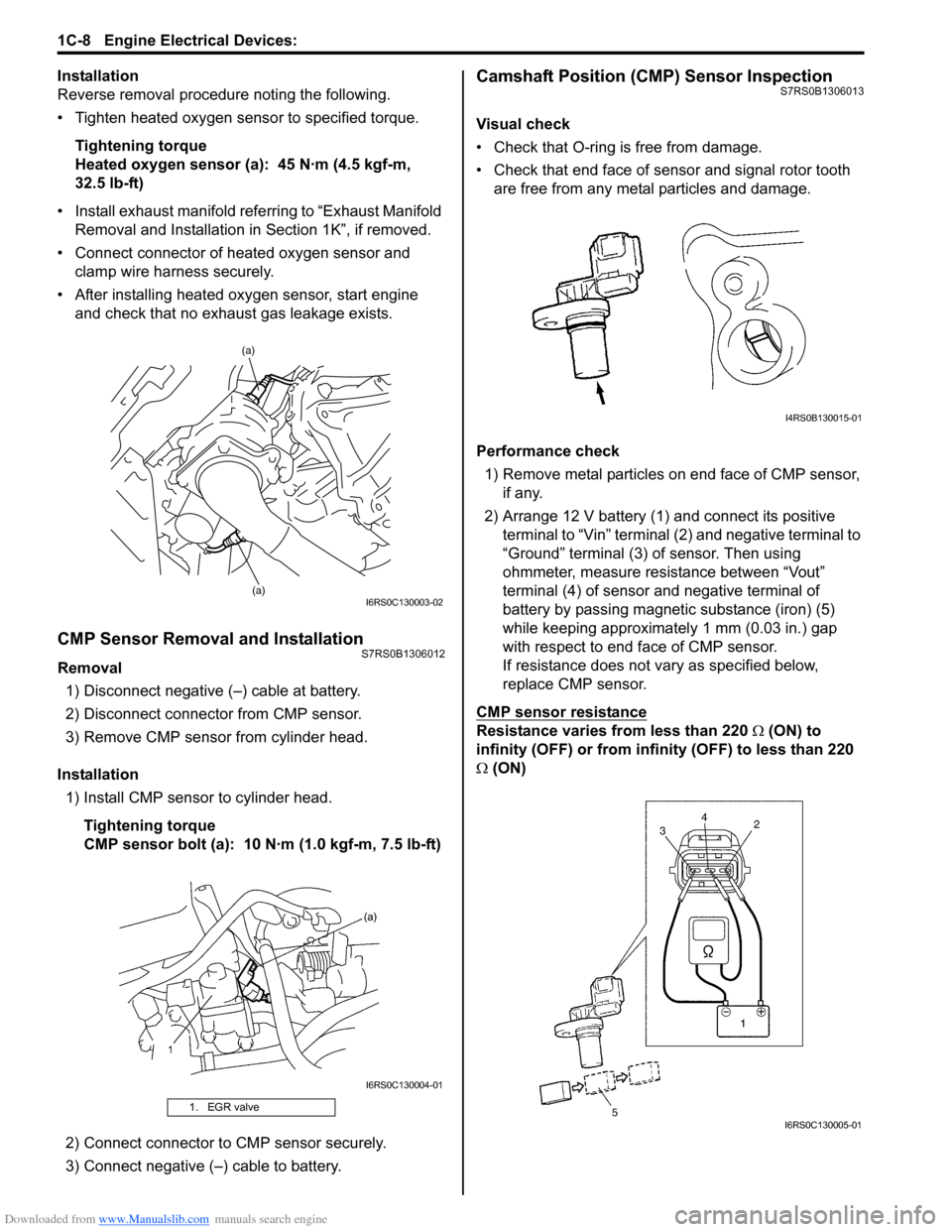

Camshaft Position (CMP) Sensor InspectionS7RS0B1306013

Visual check

• Check that O-ring is free from damage.

• Check that end face of sensor and signal rotor tooth are free from any metal particles and damage.

Performance check 1) Remove metal particles on end face of CMP sensor, if any.

2) Arrange 12 V battery (1) and connect its positive terminal to “Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

ohmmeter, measure resistance between “Vout”

terminal (4) of sensor and negative terminal of

battery by passing magnetic substance (iron) (5)

while keeping approximately 1 mm (0.03 in.) gap

with respect to end face of CMP sensor.

If resistance does not vary as specified below,

replace CMP sensor.

CMP sensor resistance

Resistance varies from less than 220 Ω (ON) to

infinity (OFF) or from infinity (OFF) to less than 220

Ω (ON)

1. EGR valve

(a)

(a)

I6RS0C130003-02

I6RS0C130004-01

I4RS0B130015-01

I6RS0C130005-01