Wheel pressure SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 338 of 1496

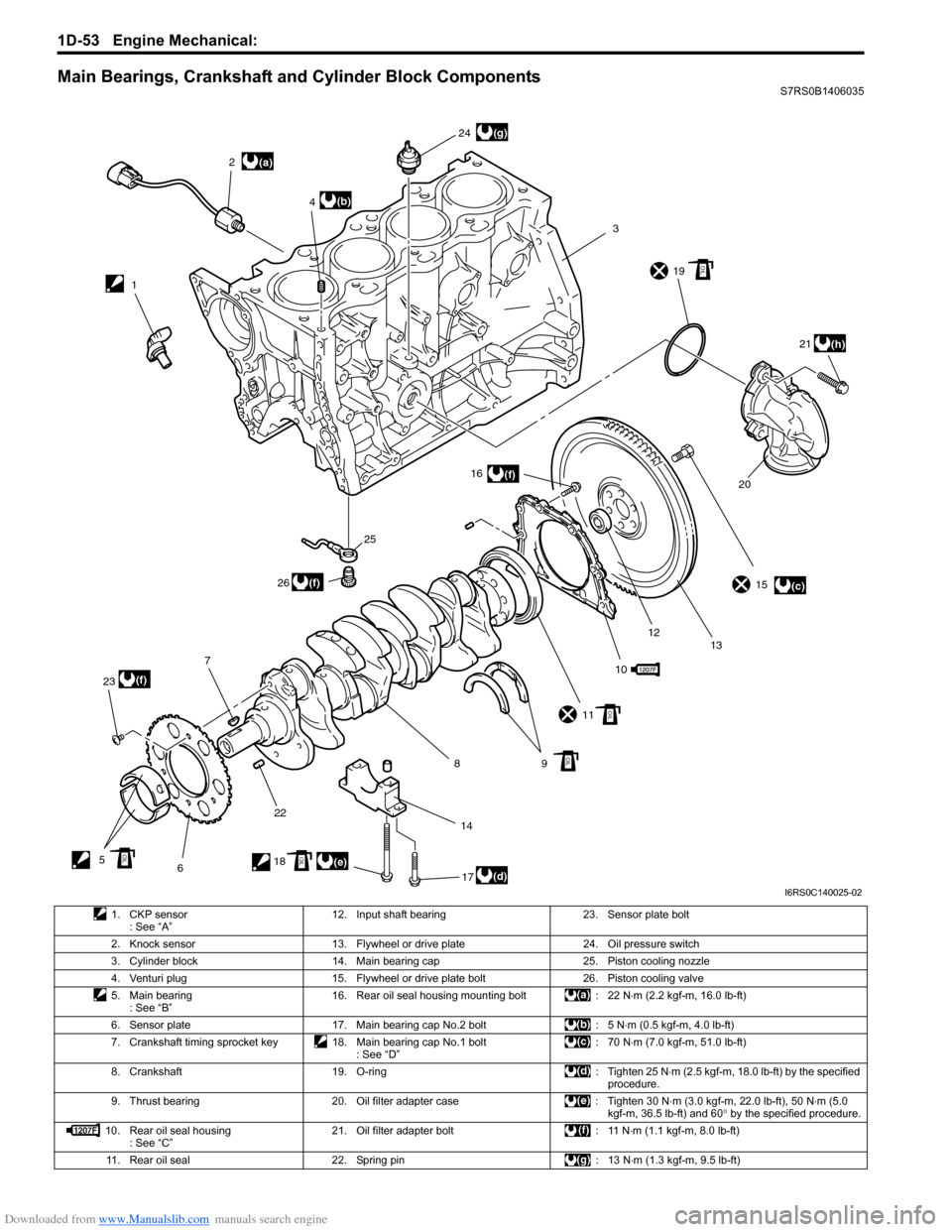

Downloaded from www.Manualslib.com manuals search engine 1D-53 Engine Mechanical:

Main Bearings, Crankshaft and Cylinder Block ComponentsS7RS0B1406035

(a)

(c)

(d)(e)

(b)

(f)

(f)

(f)

(g)

(h)

12

3

4

5 67

8910

11 15

12 13

14 16

17

18 19

2021

22

23 24

25

26

OIL

OIL

OIL

OILOIL

I6RS0C140025-02

1. CKP sensor : See “A” 12. Input shaft bearing 23. Sensor plate bolt

2. Knock sensor 13. Flywheel or drive plate 24. Oil pressure switch 3. Cylinder block 14. Main bearing cap 25. Piston cooling nozzle

4. Venturi plug 15. Flywheel or drive plate bolt 26. Piston cooling valve

5. Main bearing : See “B” 16. Rear oil seal housing mounting bolt : 22 N

⋅m (2.2 kgf-m, 16.0 lb-ft)

6. Sensor plate 17. Main bearing cap No.2 bolt : 5 N ⋅m (0.5 kgf-m, 4.0 lb-ft)

7. Crankshaft timing sprocket key 18. Main bearing cap No.1 bolt : See “D”:70 N

⋅m (7.0 kgf-m, 51.0 lb-ft)

8. Crankshaft 19. O-ring : Tighten 25 N ⋅m (2.5 kgf-m, 18.0 lb-ft) by the specified

procedure.

9. Thrust bearing 20. Oil filter adapter case : Tighten 30 N ⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N⋅m (5.0

kgf-m, 36.5 lb-ft) and 60 ° by the specified procedure.

10. Rear oil seal housing : See “C” 21. Oil filter adapter bolt : 11 N

⋅m (1.1 kgf-m, 8.0 lb-ft)

11. Rear oil seal 22. Spring pin : 13 N ⋅m (1.3 kgf-m, 9.5 lb-ft)

Page 355 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-3

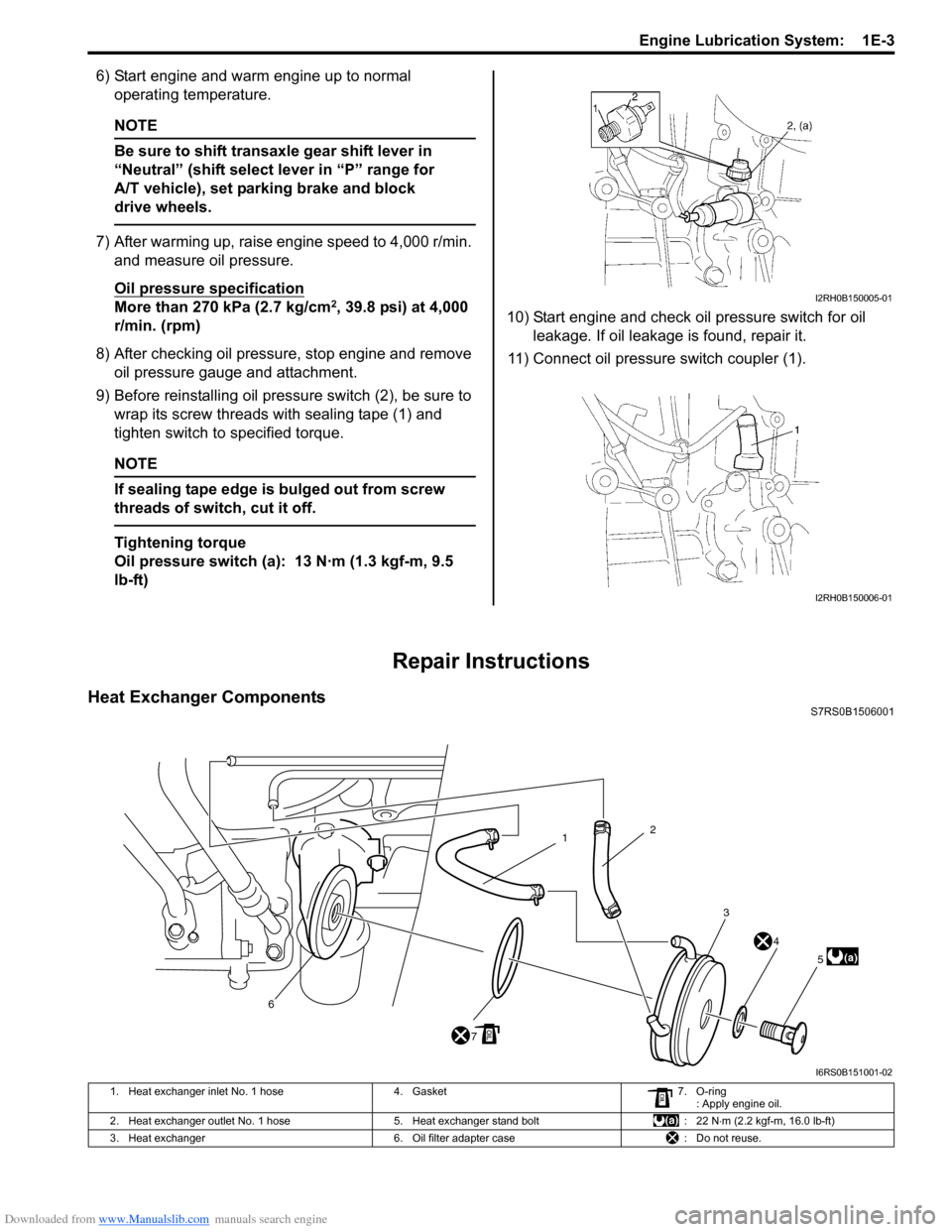

6) Start engine and warm engine up to normal operating temperature.

NOTE

Be sure to shift transaxle gear shift lever in

“Neutral” (shift select lever in “P” range for

A/T vehicle), set parking brake and block

drive wheels.

7) After warming up, raise engine speed to 4,000 r/min. and measure oil pressure.

Oil pressure specification

More than 270 kPa (2.7 kg/cm2, 39.8 psi) at 4,000

r/min. (rpm)

8) After checking oil pressure, stop engine and remove oil pressure gauge and attachment.

9) Before reinstalling oil pressure switch (2), be sure to

wrap its screw threads with sealing tape (1) and

tighten switch to specified torque.

NOTE

If sealing tape edge is bulged out from screw

threads of switch, cut it off.

Tightening torque

Oil pressure switch (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft) 10) Start engine and check oil pressure switch for oil

leakage. If oil leakage is found, repair it.

11) Connect oil pressure switch coupler (1).

Repair Instructions

Heat Exchanger ComponentsS7RS0B1506001

I2RH0B150005-01

I2RH0B150006-01

3

4

5

7

6

(a)

2

1

I6RS0B151001-02

1. Heat exchanger inlet No. 1 hose 4. Gasket7. O-ring

: Apply engine oil.

2. Heat exchanger outlet No. 1 hose 5. Heat exchanger stand bolt : 22 N⋅m (2.2 kgf-m, 16.0 lb-ft)

3. Heat exchanger 6. Oil filter adapter case : Do not reuse.

Page 382 of 1496

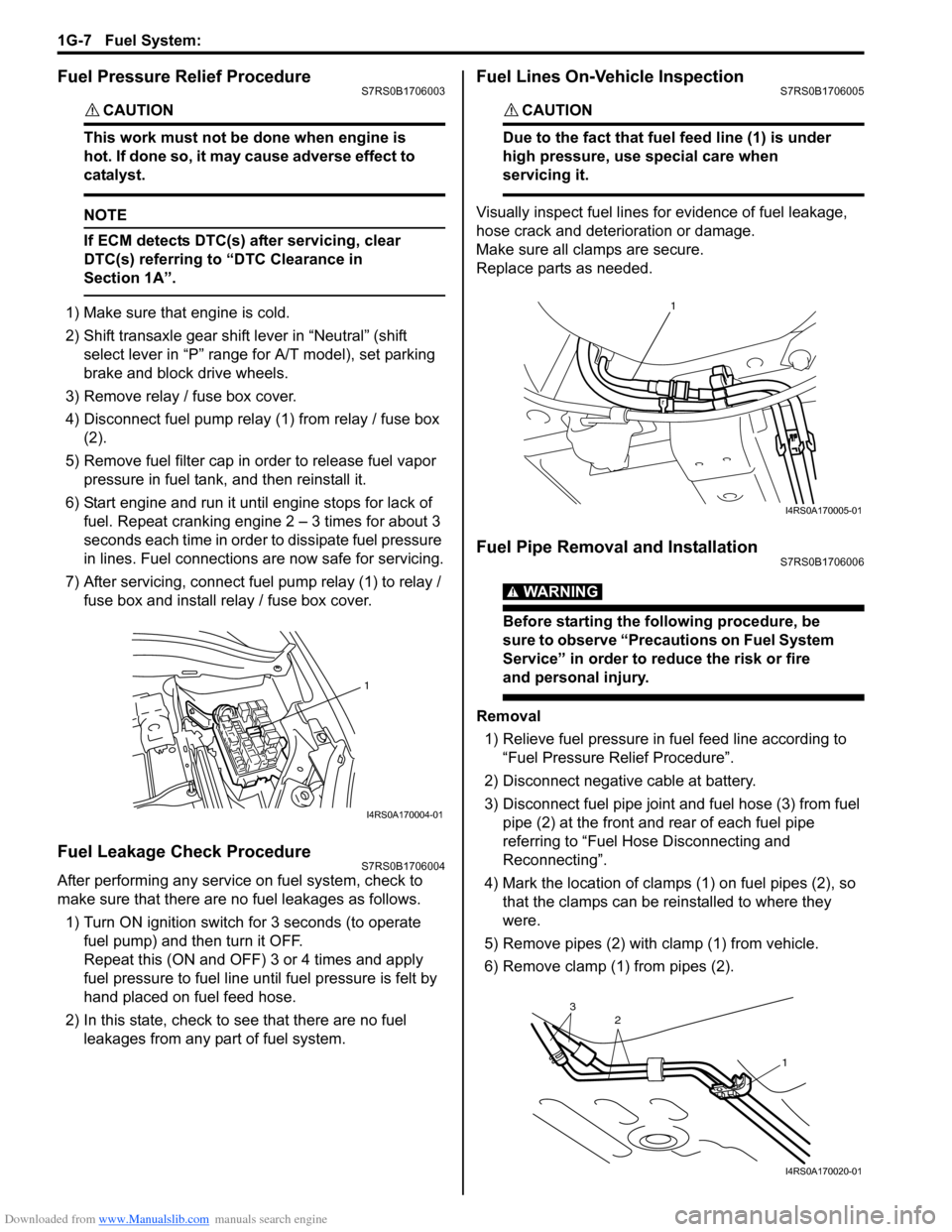

Downloaded from www.Manualslib.com manuals search engine 1G-7 Fuel System:

Fuel Pressure Relief ProcedureS7RS0B1706003

CAUTION!

This work must not be done when engine is

hot. If done so, it may cause adverse effect to

catalyst.

NOTE

If ECM detects DTC(s) after servicing, clear

DTC(s) referring to “DTC Clearance in

Section 1A”.

1) Make sure that engine is cold.

2) Shift transaxle gear shift lever in “Neutral” (shift select lever in “P” range for A/T model), set parking

brake and block drive wheels.

3) Remove relay / fuse box cover.

4) Disconnect fuel pump relay (1) from relay / fuse box (2).

5) Remove fuel filter cap in order to release fuel vapor pressure in fuel tank, and then reinstall it.

6) Start engine and run it until engine stops for lack of fuel. Repeat cranking engine 2 – 3 times for about 3

seconds each time in order to dissipate fuel pressure

in lines. Fuel connections are now safe for servicing.

7) After servicing, connect fuel pump relay (1) to relay / fuse box and install re lay / fuse box cover.

Fuel Leakage Check ProcedureS7RS0B1706004

After performing any service on fuel system, check to

make sure that there are no fuel leakages as follows.

1) Turn ON ignition switch for 3 seconds (to operate fuel pump) and then turn it OFF.

Repeat this (ON and OFF) 3 or 4 times and apply

fuel pressure to fuel line until fuel pressure is felt by

hand placed on fuel feed hose.

2) In this state, check to see that there are no fuel leakages from any part of fuel system.

Fuel Lines On-Vehicle InspectionS7RS0B1706005

CAUTION!

Due to the fact that fuel feed line (1) is under

high pressure, use special care when

servicing it.

Visually inspect fuel lines for evidence of fuel leakage,

hose crack and deterioration or damage.

Make sure all cl amps are secure.

Replace parts as needed.

Fuel Pipe Removal and InstallationS7RS0B1706006

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Relieve fuel pressure in fuel feed line according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect fuel pipe joint and fuel hose (3) from fuel pipe (2) at the front and rear of each fuel pipe

referring to “Fuel Hose Disconnecting and

Reconnecting”.

4) Mark the location of clamps (1) on fuel pipes (2), so that the clamps can be reinstalled to where they

were.

5) Remove pipes (2) with clamp (1) from vehicle.

6) Remove clamp (1) from pipes (2).

1

I4RS0A170004-01

1

I4RS0A170005-01

2

13

I4RS0A170020-01

Page 432 of 1496

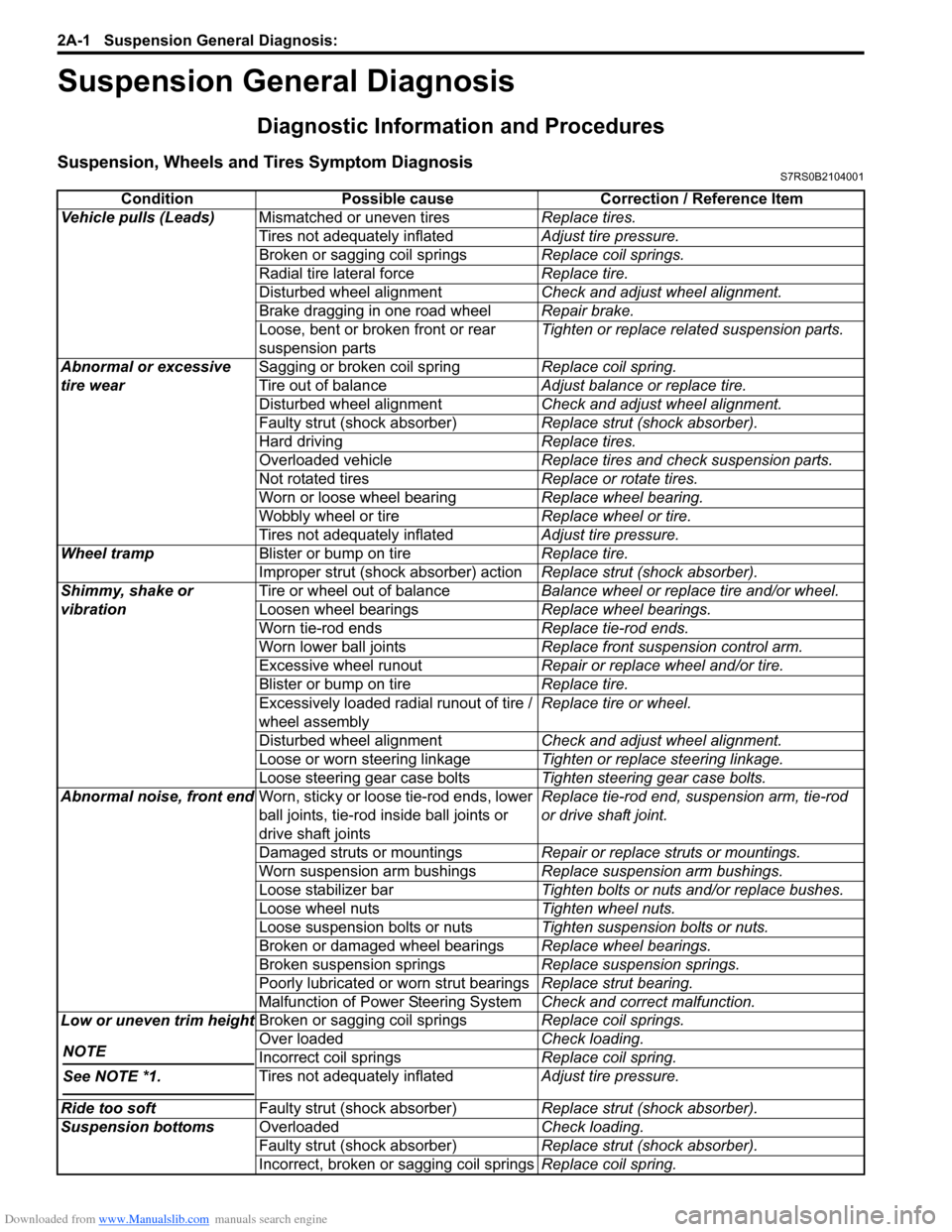

Downloaded from www.Manualslib.com manuals search engine 2A-1 Suspension General Diagnosis:

Suspension

Suspension General Diagnosis

Diagnostic Information and Procedures

Suspension, Wheels and Tires Symptom DiagnosisS7RS0B2104001

ConditionPossible cause Correction / Reference Item

Vehicle pulls (Leads) Mismatched or uneven tires Replace tires.

Tires not adequately inflated Adjust tire pressure.

Broken or sagging coil springs Replace coil springs.

Radial tire lateral force Replace tire.

Disturbed wheel alignment Check and adjust wheel alignment.

Brake dragging in one road wheel Repair brake.

Loose, bent or broken front or rear

suspension parts Tighten or replace related suspension parts.

Abnormal or excessive

tire wear Sagging or broken coil spring

Replace coil spring.

Tire out of balance Adjust balance or replace tire.

Disturbed wheel alignment Check and adjust wheel alignment.

Faulty strut (shock absorber) Replace strut (shock absorber).

Hard driving Replace tires.

Overloaded vehicle Replace tires and check suspension parts.

Not rotated tires Replace or rotate tires.

Worn or loose wheel bearing Replace wheel bearing.

Wobbly wheel or tire Replace wheel or tire.

Tires not adequately inflated Adjust tire pressure.

Wheel tramp Blister or bump on tire Replace tire.

Improper strut (shock absorber) action Replace strut (shock absorber).

Shimmy, shake or

vibration Tire or wheel out of balance

Balance wheel or replace tire and/or wheel.

Loosen wheel bearings Replace wheel bearings.

Worn tie-rod ends Replace tie-rod ends.

Worn lower ball joints Replace front suspension control arm.

Excessive wheel runout Repair or replace wheel and/or tire.

Blister or bump on tire Replace tire.

Excessively loaded radial runout of tire /

wheel assembly Replace tire or wheel.

Disturbed wheel alignment Check and adjust wheel alignment.

Loose or worn steering linkage Tighten or replace steering linkage.

Loose steering gear case bolts Tighten steering gear case bolts.

Abnormal noise, front end Worn, sticky or loose tie-rod ends, lower

ball joints, tie-rod in side ball joints or

drive shaft joints Replace tie-rod end, su

spension arm, tie-rod

or drive shaft joint.

Damaged struts or mountings Repair or replace struts or mountings.

Worn suspension arm bushings Replace suspension arm bushings.

Loose stabilizer bar Tighten bolts or nuts and/or replace bushes.

Loose wheel nuts Tighten wheel nuts.

Loose suspension bolts or nuts Tighten suspension bolts or nuts.

Broken or damaged wheel bearings Replace wheel bearings.

Broken suspension springs Replace suspension springs.

Poorly lubricated or worn strut bearings Replace strut bearing.

Malfunction of Power Steering System Check and correct malfunction.

Low or uneven trim height

NOTE

See NOTE *1.

Broken or sagging coil springs Replace coil springs.

Over loaded Check loading.

Incorrect coil springs Replace coil spring.

Tires not adequately inflated Adjust tire pressure.

Ride too soft Faulty strut (shock absorber) Replace strut (shock absorber).

Suspension bottoms Overloaded Check loading.

Faulty strut (shock absorber) Replace strut (shock absorber).

Incorrect, broken or sagging coil springs Replace coil spring.

Page 435 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-2

Front Wheel Alignment ConstructionS7RS0B2201002

Among factors for front wheel alignment, only toe setting

can be adjusted. Camber and caster are not adjustable.

Therefore, should camber or caster be out of

specification due to the damage caused by hazardous

road conditions or collision, whether the damage is in

body or in suspension should be determined and

damaged body should be repaired or damaged

suspension should be replaced.

Preliminary Checks Prior to Adjustment Front Wheel

Alignment

Steering and vibration complaints are not always the

result of improper wheel alignment. An additional item to

be checked is the possibility of tire lead due to worn or

improperly manufactured tires. “Lead” is the vehicle

deviation from a straight path on a level road without

hand pressure on the steering wheel. Refer to “Radial

Tire Lead / Pull Description in Section 2D” in order to

determine if the vehicle has a tire lead problem. Before

making any adjustment affecting wheel alignment, the

following checks and inspections should be made to

ensure correctness of alignment readings and alignment

adjustments:

• Check all tires for proper inflation pressures and approximately the same tread wear. • Check for loose of ball join

ts. Check tie-rod ends; if

excessive looseness is noted, it must be corrected

before adjusting.

• Check for run-out of wheels and tires.

• Check vehicle trim heights; if it is out of limit and a

correction is needed, it must be done before adjusting

toe.

• Check for loose of suspension control arms.

• Check for loose or missin g stabilizer bar attachments.

• Consideration must be given to excess loads, such as

tool boxes. If this excess load is normally carried in

vehicle, it should remain in vehicle during alignment

checks.

• Consider condition of equipment being used to check alignment and follow manufa cturer’s instructions.

• Regardless of equipment used to check alignment, vehicle must be placed on a level surface.

NOTE

To prevent possible incorrect reading of toe,

camber or caster, vehicle front and rear end

must be moved up and down a few times

before inspection.

Repair Instructions

Front Wheel Alignment Inspection and

Adjustment

S7RS0B2206001

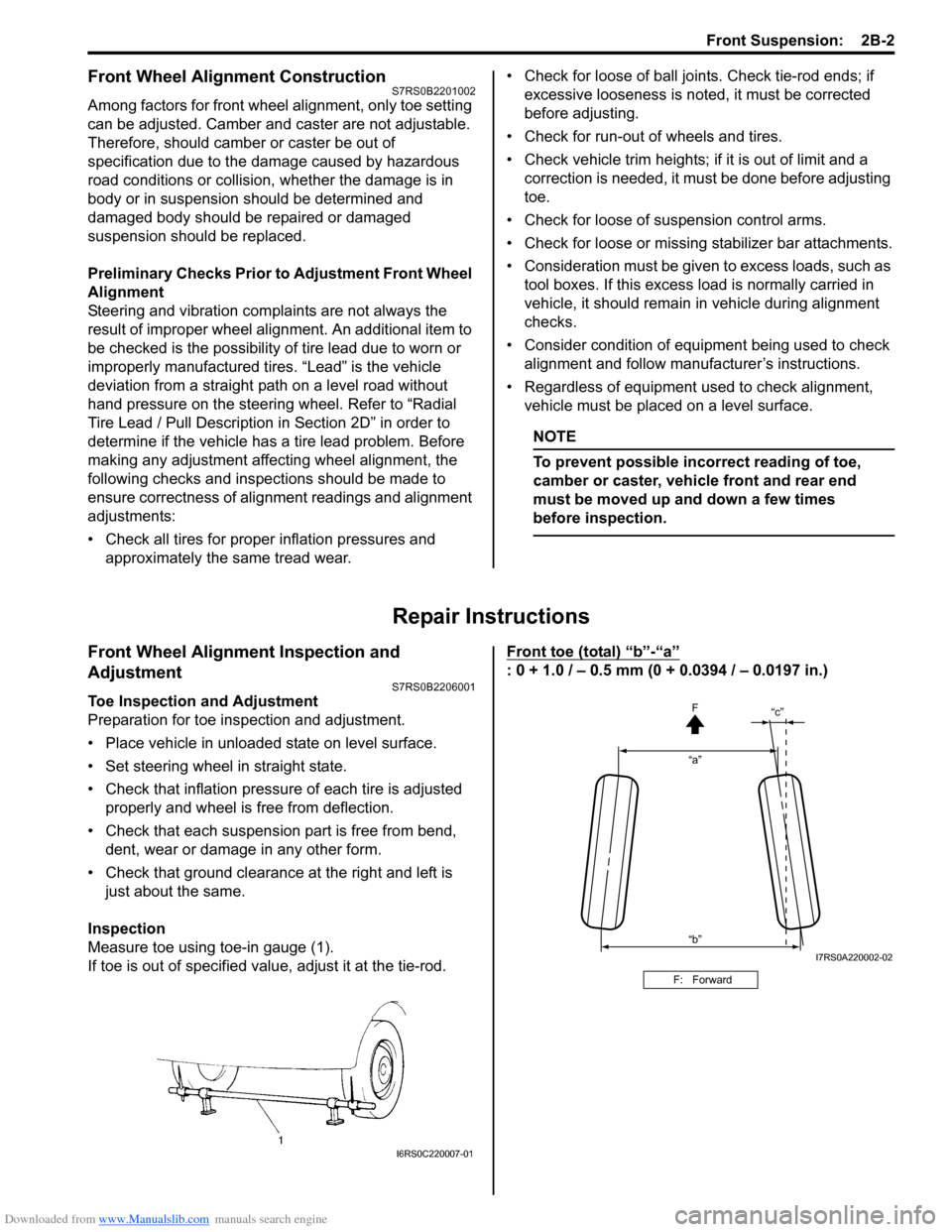

Toe Inspection and Adjustment

Preparation for toe inspection and adjustment.

• Place vehicle in unloaded state on level surface.

• Set steering wheel in straight state.

• Check that inflation pressure of each tire is adjusted properly and wheel is free from deflection.

• Check that each suspension part is free from bend, dent, wear or damage in any other form.

• Check that ground clearance at the right and left is just about the same.

Inspection

Measure toe using toe-in gauge (1).

If toe is out of specified value, adjust it at the tie-rod. Front toe (total) “b”-“a”

: 0 + 1.0 / – 0.5 mm (0 + 0.0394 / – 0.0197 in.)

I6RS0C220007-01

F: Forward

“a”

“c”

“b” F

I7RS0A220002-02

Page 457 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-3

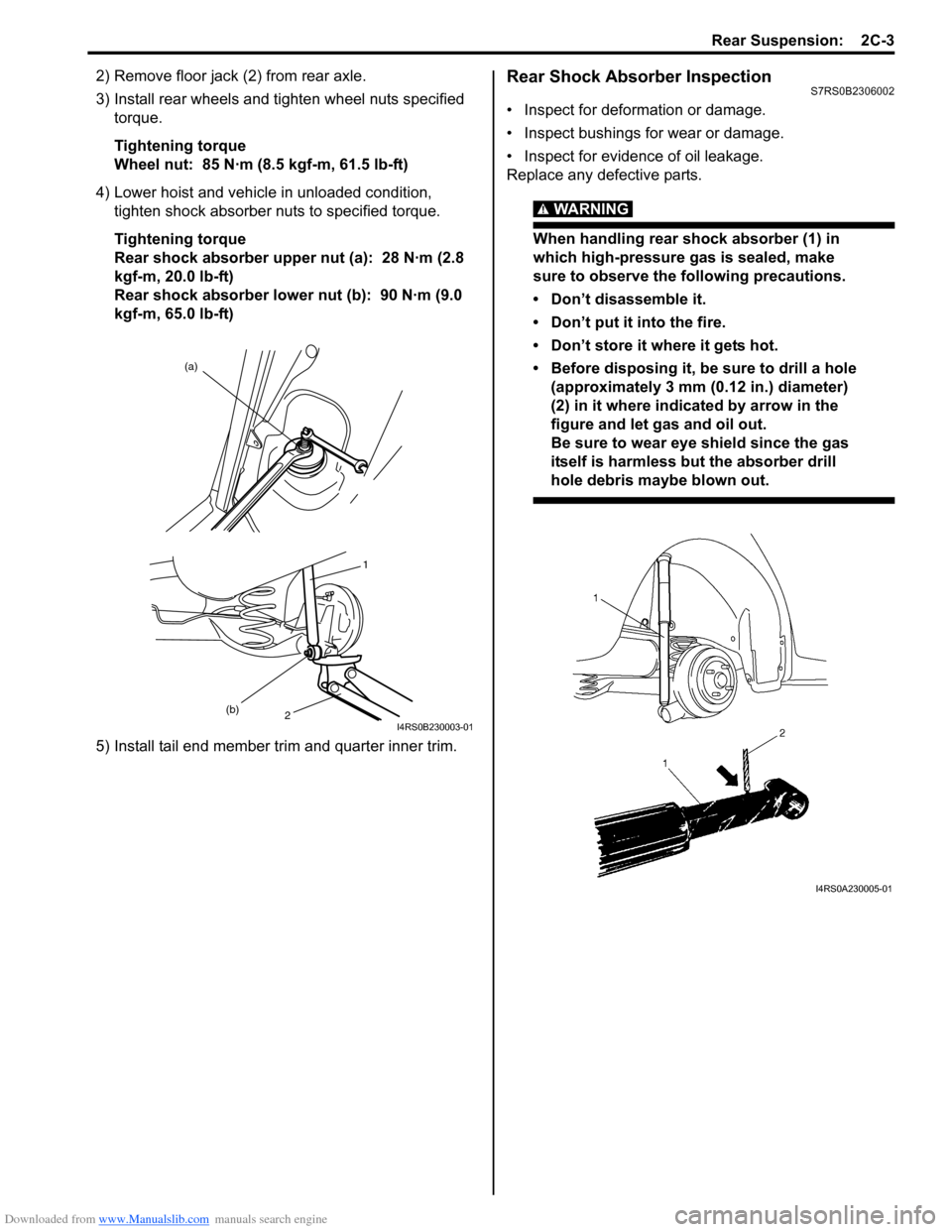

2) Remove floor jack (2) from rear axle.

3) Install rear wheels and tighten wheel nuts specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

4) Lower hoist and vehicle in unloaded condition, tighten shock absorber nuts to specified torque.

Tightening torque

Rear shock absorber upper nut (a): 28 N·m (2.8

kgf-m, 20.0 lb-ft)

Rear shock absorber lower nut (b): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

5) Install tail end member trim and quarter inner trim.Rear Shock Absorber InspectionS7RS0B2306002

• Inspect for deformation or damage.

• Inspect bushings for wear or damage.

• Inspect for evidence of oil leakage.

Replace any defective parts.

WARNING!

When handling rear shock absorber (1) in

which high-pressure gas is sealed, make

sure to observe the following precautions.

• Don’t disassemble it.

• Don’t put it into the fire.

• Don’t store it where it gets hot.

• Before disposing it, be sure to drill a hole (approximately 3 mm (0.12 in.) diameter)

(2) in it where indicated by arrow in the

figure and let gas and oil out.

Be sure to wear eye shield since the gas

itself is harmless but the absorber drill

hole debris maybe blown out.

(a)

1

(b) 2

I4RS0B230003-01

I4RS0A230005-01

Page 468 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-1 Wheels and Tires:

Suspension

Wheels and Tires

Precautions

Precaution for Emergency Flat Tire Repair KitS7RS0B2400001

WARNING!

Flat tire repair sealant including in kit is

harmful. Be sure to observe the following.

Otherwise, your health may be ruined.

• If swallowed, get medical attention immediately.

• Keep out of reach of children.

• Select place where there is good ventilation for this work.

• If it enters eye or contacts skin, wash thoroughly with water. If anything

abnormal still rema ins, get medical

attention immediately.

• Do not discard tire containing sealant as it is. Make sure to remove sealant from tire,

referring to “Tire Repair for Emergency

Repaired-Tire with Sealant”.

• Dispose of sealant as waste oil.

CAUTION!

• When tire repaired with Emergency Flat Tire Repair Kit is brought in, remove flat

tire repair sealant from tire and repair flat

tire referring to “Tire Repair for Emergency

Repaired-Tire with Sealant”.

• Sealant expiration date is printed on bottle label. if it expires, sealant should be

replaced with a new one to ensure

emergency flat tire repair.

General Description

Tires DescriptionS7RS0B2401001

The tire is of tubeless type. The tire is designed to

operate satisfactorily with loads up to the full rated load

capacity when inflated to the recommended inflation

pressures.

Correct tire pressures and driving habits have an

important influence on tire life. Heavy cornering,

excessively rapid acceleration, and unnecessary sharp

braking increase tire wear.

Tire Placard

The “Tire Placard” is located on the left or right door lock

pillar and should be referred to tire information.

The placard lists the maximum load, tire size and cold

tire pressure where applicable.

NOTE

Whether rim size and/or maximum load are

listed or not depends on regulations of each

country.

Inflation of Tires

The pressure recommended for any model is carefully

calculated to give a satisfacto ry ride, stability, steering,

tread wear, tire life and resistance to bruises.

Tire pressure, with tires cold, (after vehicle has set for 3

hours or more, or driven less than one mile) should be

checked monthly or before any extended trip. Set to the

specifications on the “Tire Placard” located on the left

door lock pillar.

It is normal for tire pressure to increase when the tires

become hot during driving.

Do not bleed or reduce tire pressure after driving.

Bleeding reduces the “Cold Inflation Pressure”.

Higher than recommended pressure can cause:

• Hard ride

• Tire bruising or carcass damage

• Rapid tread wear at center of tire

Unequal pressure on same axle can cause:

• Uneven braking

• Steering lead

• Reduced handling

• Swerve on acceleration

Page 469 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-2

Lower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

Replacement Tires

When replacement is necessary, the original equipment

type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load

range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride,

handling, speedometer / odometer calibration, vehicle

ground clearance and tire or snow chain clearance to the

body and chassis.

It is recommended that new tires be installed in pairs on

the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to

equalize braking traction.

WARNING!

Do not mix different types of tires on the

same vehicle such as radial, bias and bias-

belted tires except in emergencies, because

handling may be seriously affected and may

result in loss of control.

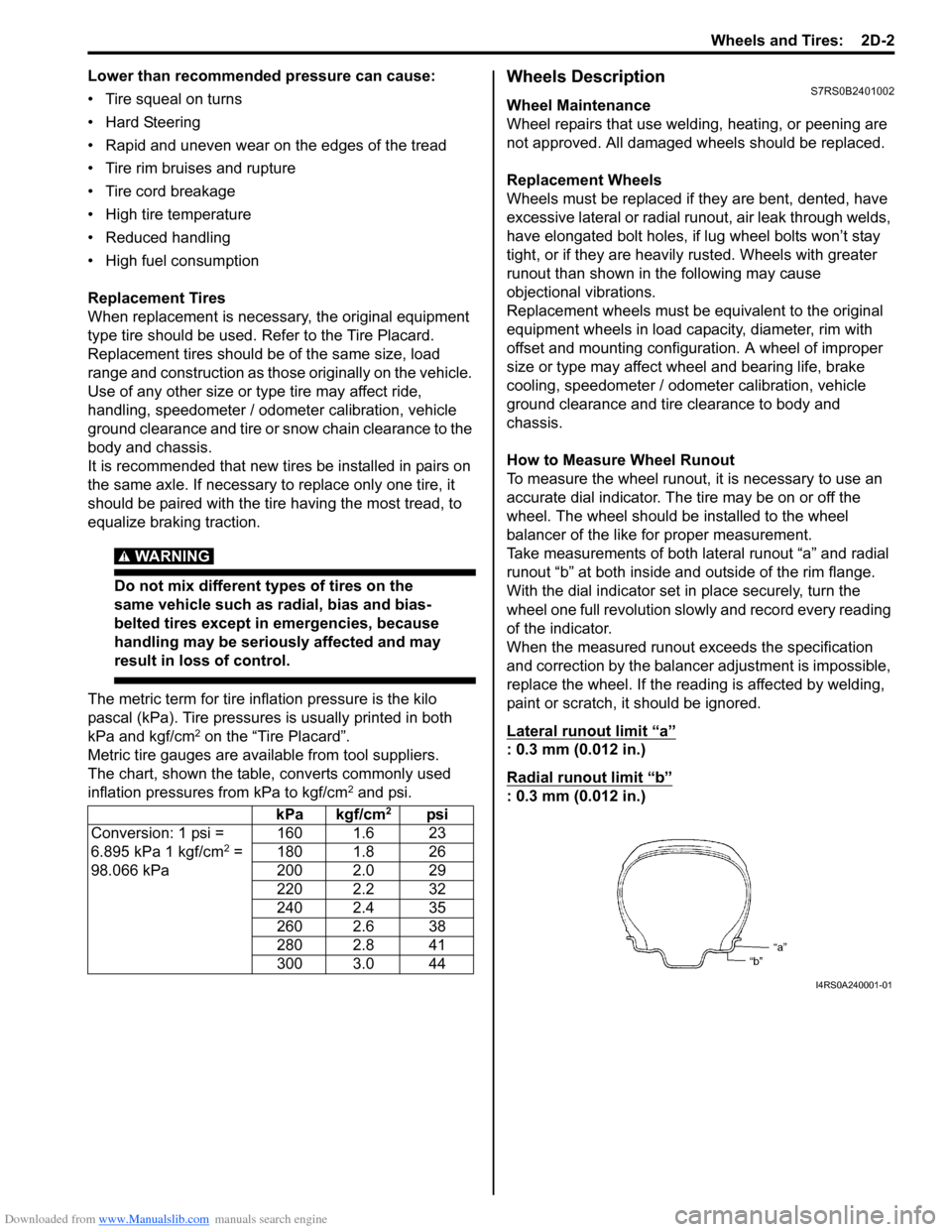

The metric term for tire infl ation pressure is the kilo

pascal (kPa). Tire pressures is usually printed in both

kPa and kgf/cm

2 on the “Tire Placard”.

Metric tire gauges are available from tool suppliers.

The chart, shown the table, converts commonly used

inflation pressures from kPa to kgf/cm

2 and psi.

Wheels DescriptionS7RS0B2401002

Wheel Maintenance

Wheel repairs that use welding, heating, or peening are

not approved. All damaged wheels should be replaced.

Replacement Wheels

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, air leak through welds,

have elongated bolt holes, if lug wheel bolts won’t stay

tight, or if they are heavily rusted. Wheels with greater

runout than shown in the following may cause

objectional vibrations.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim with

offset and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer / odometer calibration, vehicle

ground clearance and tire clearance to body and

chassis.

How to Measure Wheel Runout

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tire may be on or off the

wheel. The wheel should be installed to the wheel

balancer of the like for proper measurement.

Take measurements of both lateral runout “a” and radial

runout “b” at both inside an d outside of the rim flange.

With the dial indicator set in place securely, turn the

wheel one full revolution slowly and record every reading

of the indicator.

When the measured runout exceeds the specification

and correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratch, it should be ignored.

Lateral runout limit “a”

: 0.3 mm (0.012 in.)

Radial runout limit “b”

: 0.3 mm (0.012 in.)

kPa kgf/cm2psi

Conversion: 1 psi =

6.895 kPa 1 kgf/cm

2 =

98.066 kPa 160 1.6 23

180 1.8 26

200 2.0 29

220 2.2 32

240 2.4 35

260 2.6 38

280 2.8 41

300 3.0 44

I4RS0A240001-01

Page 470 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-3 Wheels and Tires:

Metric Lug Nuts and Wheel Studs

All models use metric lug nuts and wheel studs.

Metric lug nuts and wheel studs size

M12 x 1.25

If broken stud or nut are found, be sure to replace both

stud and nut with new one.

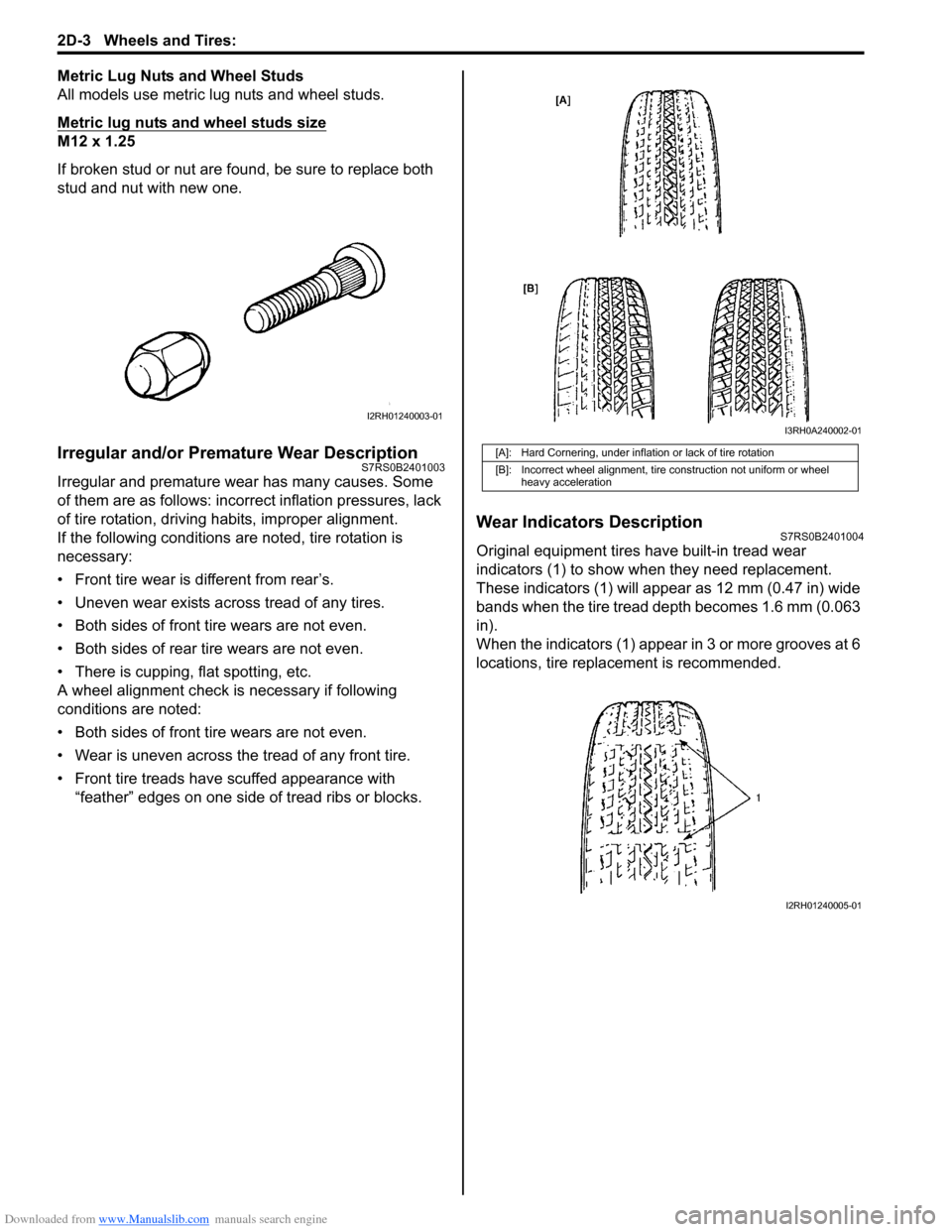

Irregular and/or Premature Wear DescriptionS7RS0B2401003

Irregular and premature wear has many causes. Some

of them are as follows: incorrect inflation pressures, lack

of tire rotation, driving habits, improper alignment.

If the following conditions are noted, tire rotation is

necessary:

• Front tire wear is different from rear’s.

• Uneven wear exists across tread of any tires.

• Both sides of front tire wears are not even.

• Both sides of rear tire wears are not even.

• There is cupping, flat spotting, etc.

A wheel alignment check is necessary if following

conditions are noted:

• Both sides of front tire wears are not even.

• Wear is uneven across the tread of any front tire.

• Front tire treads have scuffed appearance with “feather” edges on one side of tread ribs or blocks.

Wear Indicators DescriptionS7RS0B2401004

Original equipment tires have built-in tread wear

indicators (1) to show when they need replacement.

These indicators (1) will app ear as 12 mm (0.47 in) wide

bands when the tire tread depth becomes 1.6 mm (0.063

in).

When the indicators (1) appear in 3 or more grooves at 6

locations, tire replacement is recommended.

I2RH01240003-01

[A]: Hard Cornering, under inflation or lack of tire rotation

[B]: Incorrect wheel alignment, tire construction not uniform or wheel heavy acceleration

I3RH0A240002-01

I2RH01240005-01

Page 471 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-4

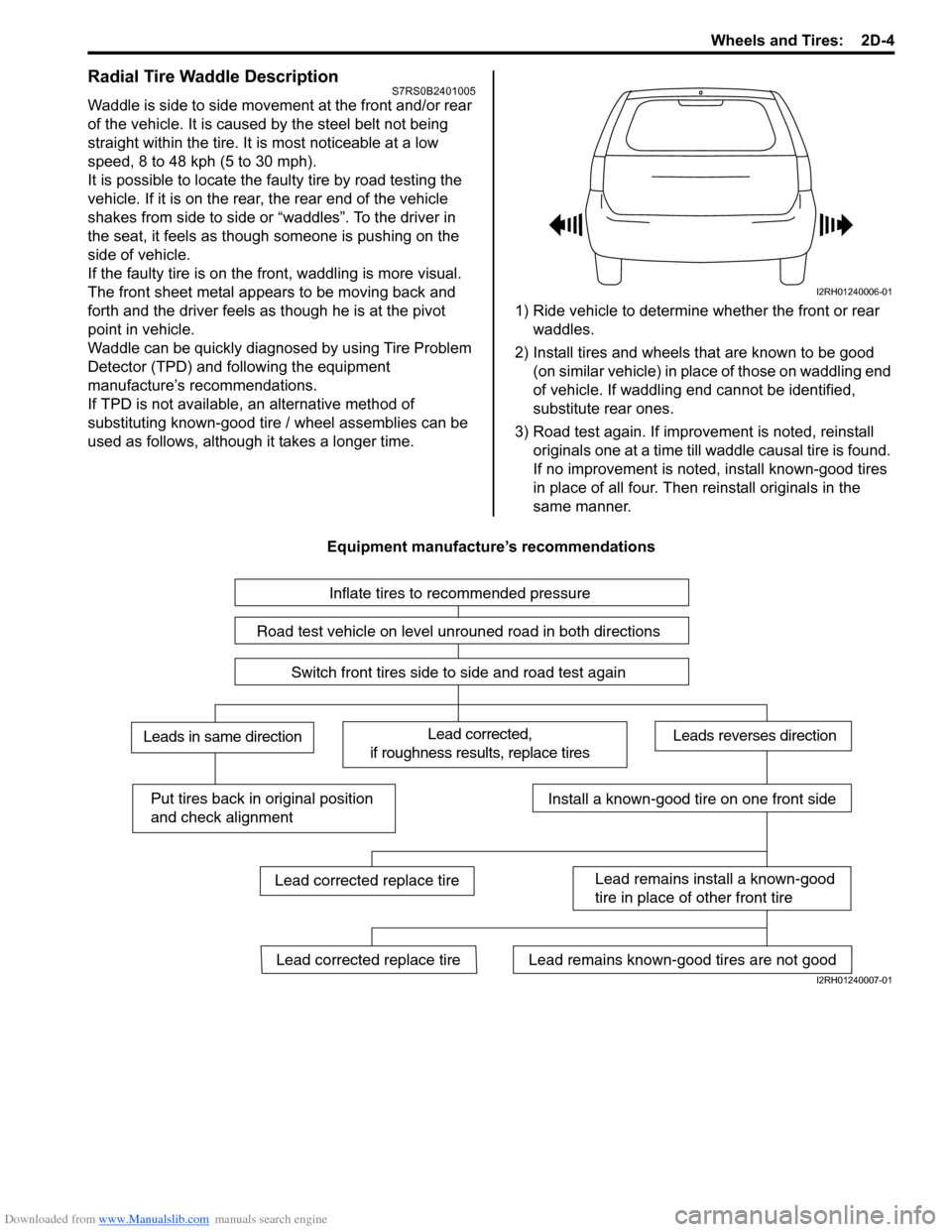

Radial Tire Waddle DescriptionS7RS0B2401005

Waddle is side to side movement at the front and/or rear

of the vehicle. It is caused by the steel belt not being

straight within the tire. It is most noticeable at a low

speed, 8 to 48 kph (5 to 30 mph).

It is possible to locate the f aulty tire by road testing the

vehicle. If it is on the rear , the rear end of the vehicle

shakes from side to side or “waddles”. To the driver in

the seat, it feels as though someone is pushing on the

side of vehicle.

If the faulty tire is on the front, waddling is more visual.

The front sheet metal appears to be moving back and

forth and the driver feels as though he is at the pivot

point in vehicle.

Waddle can be quickly diagnosed by using Tire Problem

Detector (TPD) and following the equipment

manufacture’s recommendations.

If TPD is not available, an alternative method of

substituting known-good tire / wheel assemblies can be

used as follows, although it takes a longer time. 1) Ride vehicle to determine whether the front or rear

waddles.

2) Install tires and wheels that are known to be good (on similar vehicle) in place of those on waddling end

of vehicle. If waddling end cannot be identified,

substitute rear ones.

3) Road test again. If improvement is noted, reinstall originals one at a time till w addle causal tire is found.

If no improvement is noted, install known-good tires

in place of all four. Then reinstall originals in the

same manner.

Equipment manufacture’s recommendations

I2RH01240006-01

Inflate tires to recommended pressure

Road test vehicle on level unrouned road in both directions

Switch front tires side to side and road test again

Lead corrected,

if roughness results, replace tiresLeads in same directionLeads reverses direction

Put tires back in original position

and check alignmentInstall a known-good tire on one front side

Lead remains install a known-good

tire in place of other front tire

Lead remains known-good tires are not goodLead corrected replace tire

Lead corrected replace tire

I2RH01240007-01