camshaft torque SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 321 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-36

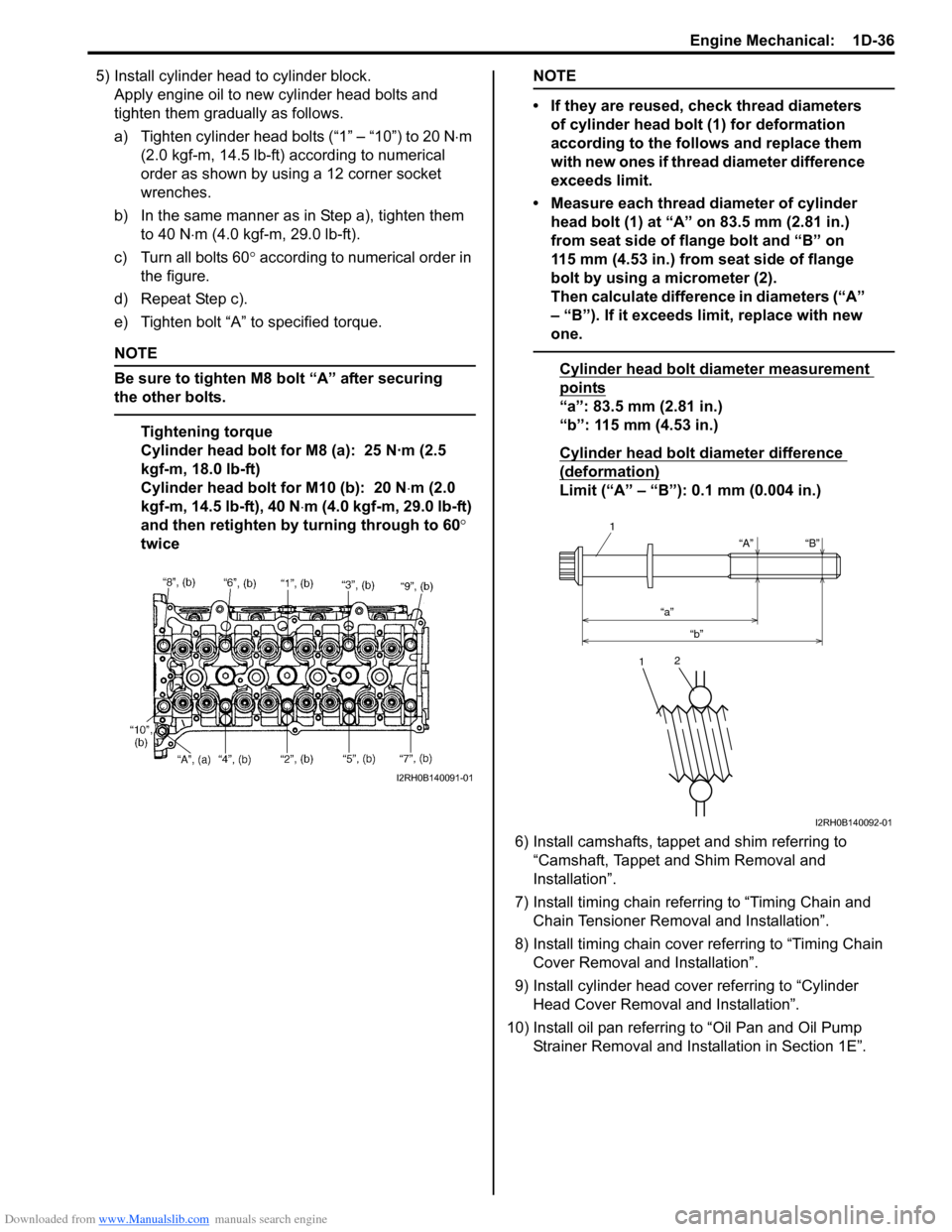

5) Install cylinder head to cylinder block.Apply engine oil to new cylinder head bolts and

tighten them gradually as follows.

a) Tighten cylinder head bolts (“1” – “10”) to 20 N ⋅m

(2.0 kgf-m, 14.5 lb-ft) according to numerical

order as shown by using a 12 corner socket

wrenches.

b) In the same manner as in Step a), tighten them to 40 N ⋅m (4.0 kgf-m, 29.0 lb-ft).

c) Turn all bolts 60 ° according to numerical order in

the figure.

d) Repeat Step c).

e) Tighten bolt “A” to specified torque.

NOTE

Be sure to tighten M8 bolt “A” after securing

the other bolts.

Tightening torque

Cylinder head bolt for M8 (a): 25 N·m (2.5

kgf-m, 18.0 lb-ft)

Cylinder head bolt for M10 (b): 20 N ⋅m (2.0

kgf-m, 14.5 lb-ft), 40 N ⋅m (4.0 kgf-m, 29.0 lb-ft)

and then retighten by turning through to 60 °

twice

NOTE

• If they are reused, check thread diameters of cylinder head bolt (1) for deformation

according to the follows and replace them

with new ones if thread diameter difference

exceeds limit.

• Measure each thread diameter of cylinder head bolt (1) at “A” on 83.5 mm (2.81 in.)

from seat side of flange bolt and “B” on

115 mm (4.53 in.) from seat side of flange

bolt by using a micrometer (2).

Then calculate difference in diameters (“A”

– “B”). If it exceeds limit, replace with new

one.

Cylinder head bolt diameter measurement

points

“a”: 83.5 mm (2.81 in.)

“b”: 115 mm (4.53 in.)

Cylinder head bolt diameter difference

(deformation)

Limit (“A” – “B”): 0.1 mm (0.004 in.)

6) Install camshafts, tappet and shim referring to “Camshaft, Tappet and Shim Removal and

Installation”.

7) Install timing chain referring to “Timing Chain and Chain Tensioner Remova l and Installation”.

8) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

9) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

10) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Inst allation in Section 1E”.

I2RH0B140091-01

“A”

“a” “b” “B”

1

1

2

I2RH0B140092-01

Page 342 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-57 Engine Mechanical:

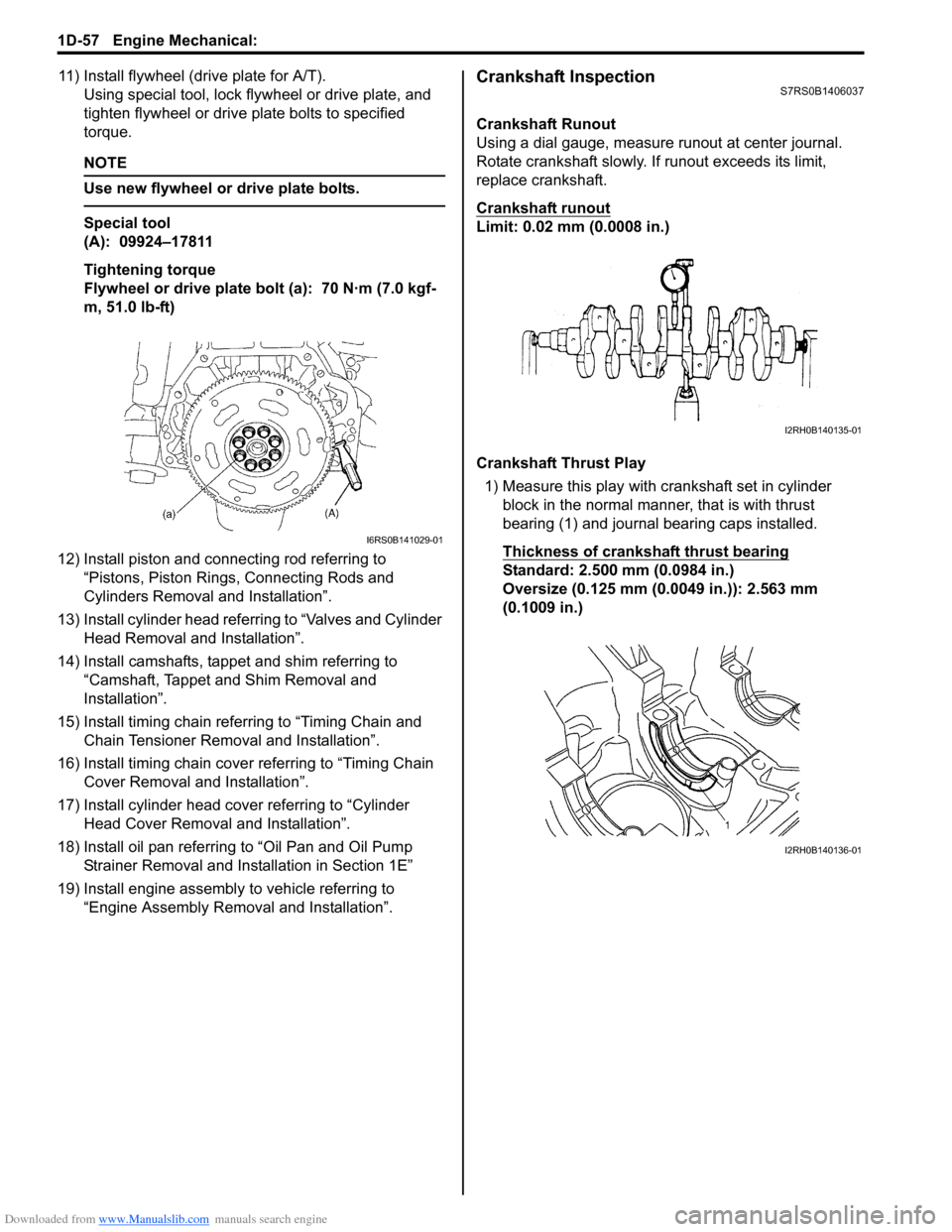

11) Install flywheel (drive plate for A/T).Using special tool, lock flyw heel or drive plate, and

tighten flywheel or drive plate bolts to specified

torque.

NOTE

Use new flywheel or drive plate bolts.

Special tool

(A): 09924–17811

Tightening torque

Flywheel or drive plate bolt (a): 70 N·m (7.0 kgf-

m, 51.0 lb-ft)

12) Install piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

13) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

14) Install camshafts, tappet and shim referring to “Camshaft, Tappet and Shim Removal and

Installation”.

15) Install timing chain referring to “Timing Chain and Chain Tensioner Removal and Installation”.

16) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

17) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

18) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”

19) Install engine assembly to vehicle referring to “Engine Assembly Removal and Installation”.

Crankshaft InspectionS7RS0B1406037

Crankshaft Runout

Using a dial gauge, measure runout at center journal.

Rotate crankshaft slowly. If runout exceeds its limit,

replace crankshaft.

Crankshaft runout

Limit: 0.02 mm (0.0008 in.)

Crankshaft Thrust Play

1) Measure this play with crankshaft set in cylinder block in the normal manner, that is with thrust

bearing (1) and journal bearing caps installed.

Thickness of crankshaft thrust bearing

Standard: 2.500 mm (0.0984 in.)

Oversize (0.125 mm (0.0049 in.)): 2.563 mm

(0.1009 in.)

I6RS0B141029-01

I2RH0B140135-01

I2RH0B140136-01

Page 349 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-64

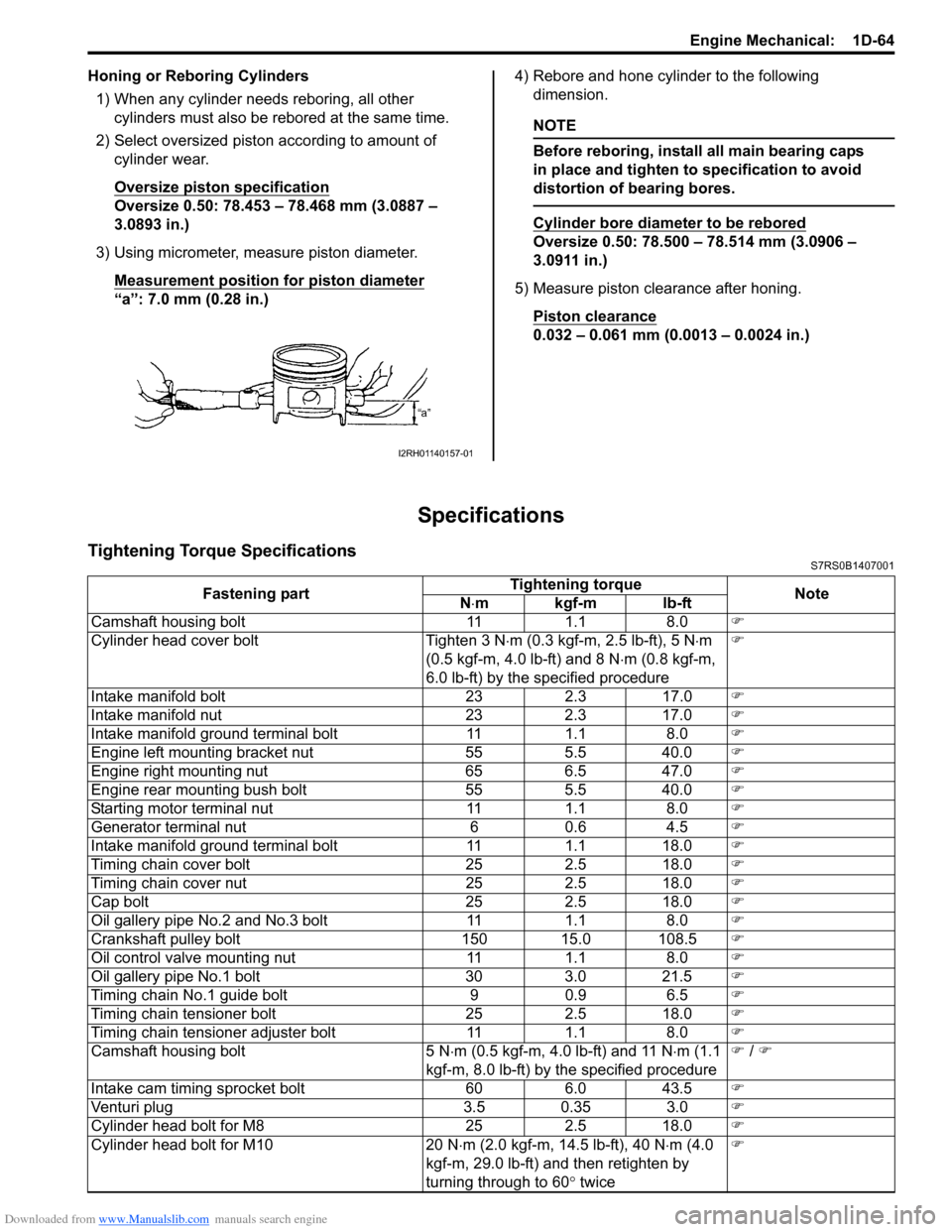

Honing or Reboring Cylinders1) When any cylinder needs reboring, all other cylinders must also be rebored at the same time.

2) Select oversized piston according to amount of cylinder wear.

Oversize piston specification

Oversize 0.50: 78.453 – 78.468 mm (3.0887 –

3.0893 in.)

3) Using micrometer, measure piston diameter. Measurement position for piston diameter

“a”: 7.0 mm (0.28 in.) 4) Rebore and hone cylinder to the following

dimension.

NOTE

Before reboring, install all main bearing caps

in place and tighten to specification to avoid

distortion of bearing bores.

Cylinder bore diameter to be rebored

Oversize 0.50: 78.500 – 78.514 mm (3.0906 –

3.0911 in.)

5) Measure piston clearance after honing. Piston clearance

0.032 – 0.061 mm (0.0013 – 0.0024 in.)

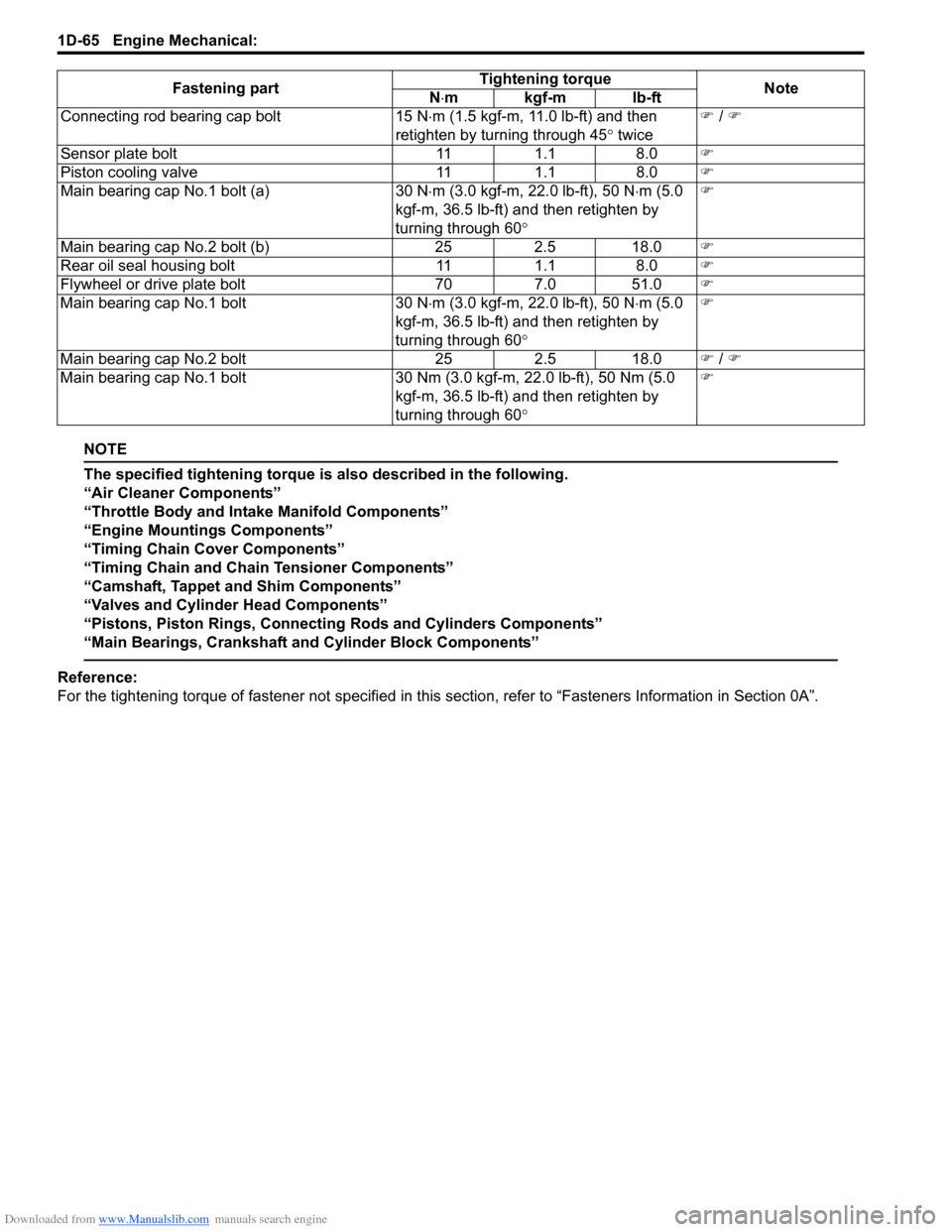

Specifications

Tightening Torque SpecificationsS7RS0B1407001

I2RH01140157-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Camshaft housing bolt 11 1.1 8.0 �)

Cylinder head cover bolt Tighten 3 N ⋅m (0.3 kgf-m, 2.5 lb-ft), 5 N ⋅m

(0.5 kgf-m, 4.0 lb-ft) and 8 N ⋅m (0.8 kgf-m,

6.0 lb-ft) by the specified procedure �)

Intake manifold bolt 23 2.3 17.0 �)

Intake manifold nut 23 2.3 17.0 �)

Intake manifold ground terminal bolt 11 1.1 8.0 �)

Engine left mounting bracket nut 55 5.5 40.0 �)

Engine right mounting nut 65 6.5 47.0 �)

Engine rear mounting bush bolt 55 5.5 40.0 �)

Starting motor terminal nut 11 1.1 8.0 �)

Generator terminal nut 6 0.6 4.5 �)

Intake manifold ground terminal bolt 11 1.1 18.0 �)

Timing chain cover bolt 25 2.5 18.0 �)

Timing chain cover nut 25 2.5 18.0 �)

Cap bolt 25 2.5 18.0 �)

Oil gallery pipe No.2 and No.3 bolt 11 1.1 8.0 �)

Crankshaft pulley bolt 150 15.0 108.5 �)

Oil control valve mounting nut 11 1.1 8.0 �)

Oil gallery pipe No.1 bolt 30 3.0 21.5 �)

Timing chain No.1 guide bolt 9 0.9 6.5 �)

Timing chain tensioner bolt 25 2.5 18.0 �)

Timing chain tensioner adjuster bolt 11 1.1 8.0 �)

Camshaft housing bolt 5 N ⋅m (0.5 kgf-m, 4.0 lb-ft) and 11 N ⋅m (1.1

kgf-m, 8.0 lb-ft) by the specified procedure �)

/ �)

Intake cam timing sprocket bolt 60 6.0 43.5 �)

Venturi plug 3.5 0.35 3.0 �)

Cylinder head bolt for M8 25 2.5 18.0 �)

Cylinder head bolt for M10 20 N ⋅m (2.0 kgf-m, 14.5 lb-ft), 40 N ⋅m (4.0

kgf-m, 29.0 lb-ft) and then retighten by

turning through to 60 ° twice �)

Page 350 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-65 Engine Mechanical:

NOTE

The specified tightening torque is also described in the following.

“Air Cleaner Components”

“Throttle Body and Intake Manifold Components”

“Engine Mountings Components”

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Connecting rod bearing cap bolt

15 N⋅m (1.5 kgf-m, 11.0 lb-ft) and then

retighten by turning through 45 ° twice �)

/ �)

Sensor plate bolt 111.1 8.0 �)

Piston cooling valve 111.1 8.0 �)

Main bearing cap No.1 bolt (a) 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt (b) 252.5 18.0 �)

Rear oil seal housing bolt 111.1 8.0 �)

Flywheel or drive plate bolt 707.0 51.0 �)

Main bearing cap No.1 bolt 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt 252.5 18.0 �) / �)

Main bearing cap No.1 bolt 30 Nm (3.0 kgf-m, 22.0 lb-ft), 50 Nm (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Page 401 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-9

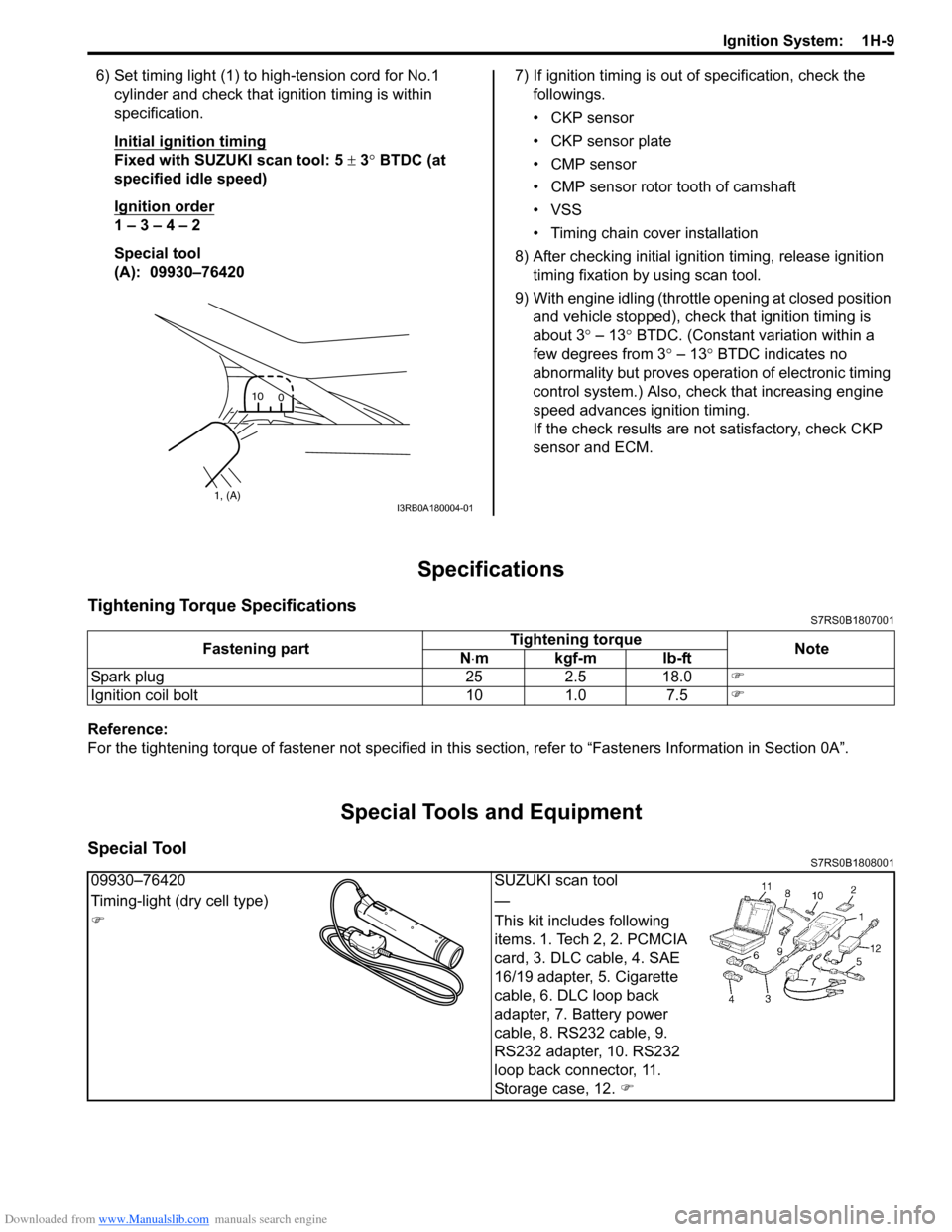

6) Set timing light (1) to high-tension cord for No.1 cylinder and check that ignition timing is within

specification.

Initial ignition timing

Fixed with SUZUKI scan tool: 5 ± 3° BTDC (at

specified idle speed)

Ignition order

1 – 3 – 4 – 2

Special tool

(A): 09930–76420 7) If ignition timing is out

of specification, check the

followings.

• CKP sensor

• CKP sensor plate

• CMP sensor

• CMP sensor rotor tooth of camshaft

• VSS

• Timing chain cover installation

8) After checking initial igniti on timing, release ignition

timing fixation by using scan tool.

9) With engine idling (throttl e opening at closed position

and vehicle stopped), check that ignition timing is

about 3 ° – 13° BTDC. (Constant variation within a

few degrees from 3 ° – 13° BTDC indicates no

abnormality but proves operation of electronic timing

control system.) Also, check that increasing engine

speed advances ignition timing.

If the check results are not satisfactory, check CKP

sensor and ECM.

Specifications

Tightening Torque SpecificationsS7RS0B1807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B1808001

1, (A)10

0I3RB0A180004-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Spark plug 25 2.5 18.0 �)

Ignition coil bolt 10 1.0 7.5 �)

09930–76420SUZUKI scan tool

Timing-light (dry cell type) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)