disabling air bag SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 946 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-10 Heater and Ventilation:

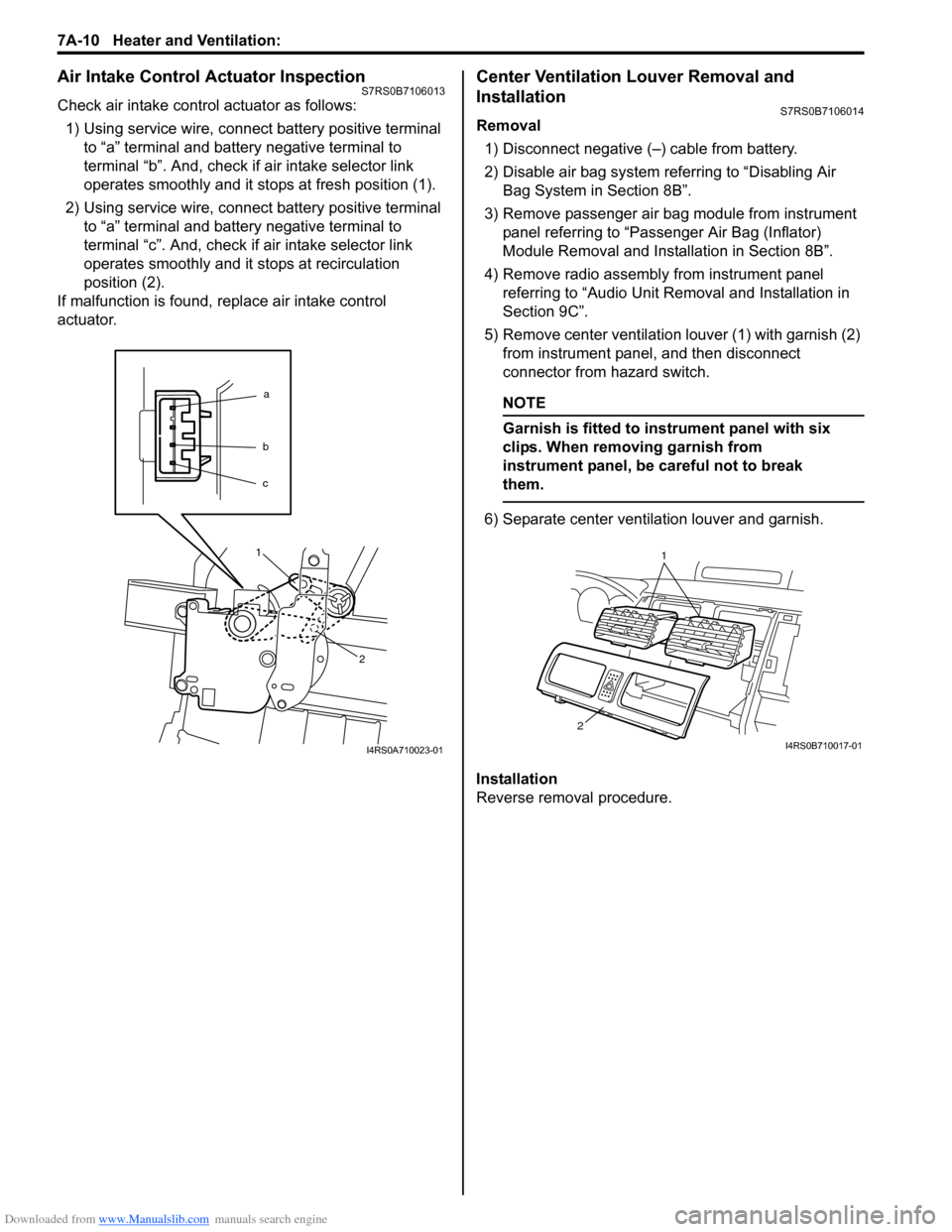

Air Intake Control Actuator InspectionS7RS0B7106013

Check air intake control actuator as follows:1) Using service wire, connect battery positive terminal to “a” terminal and battery negative terminal to

terminal “b”. And, check if air intake selector link

operates smoothly and it st ops at fresh position (1).

2) Using service wire, connect battery positive terminal to “a” terminal and battery negative terminal to

terminal “c”. And, check if air intake selector link

operates smoothly and it stops at recirculation

position (2).

If malfunction is found, replace air intake control

actuator.

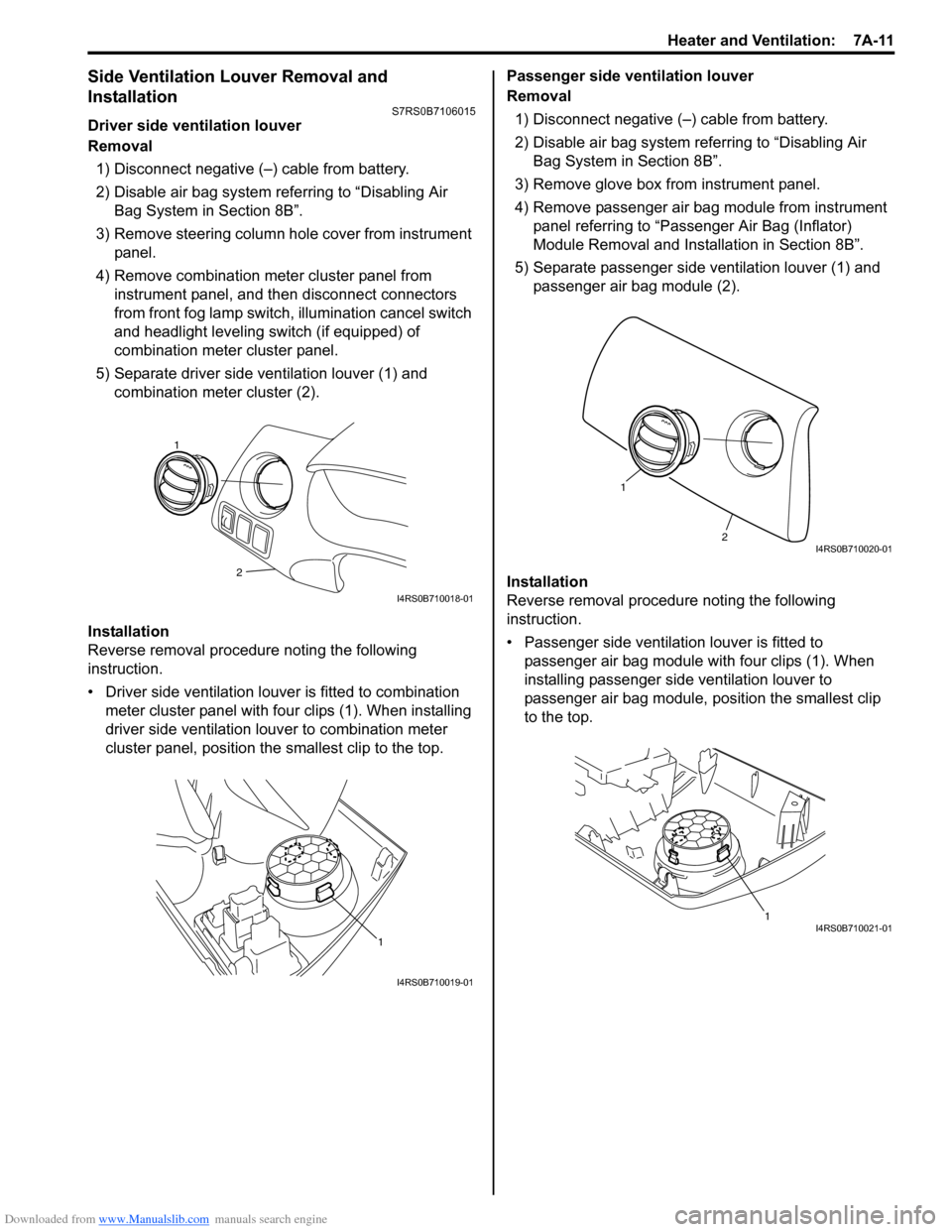

Center Ventilation Louver Removal and

Installation

S7RS0B7106014

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Audio Unit Re moval and Installation in

Section 9C”.

5) Remove center ventilation louver (1) with garnish (2) from instrument panel, and then disconnect

connector from hazard switch.

NOTE

Garnish is fitted to in strument panel with six

clips. When removing garnish from

instrument panel, be careful not to break

them.

6) Separate center ventilation louver and garnish.

Installation

Reverse removal procedure.

a

b

c

1

2

I4RS0A710023-01

1

2

I4RS0B710017-01

Page 947 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-11

Side Ventilation Louver Removal and

Installation

S7RS0B7106015

Driver side ventilation louver

Removal1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hol e cover from instrument

panel.

4) Remove combination meter cluster panel from instrument panel, and then disconnect connectors

from front fog lamp switch, illumination cancel switch

and headlight leveling switch (if equipped) of

combination meter cluster panel.

5) Separate driver side ventilation louver (1) and combination meter cluster (2).

Installation

Reverse removal procedure noting the following

instruction.

• Driver side ventilation louver is fitted to combination meter cluster panel with four clips (1). When installing

driver side ventilation louv er to combination meter

cluster panel, position the smallest clip to the top. Passenger side ventilation louver

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove glove box from instrument panel.

4) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

5) Separate passenger side ventilation louver (1) and passenger air bag module (2).

Installation

Reverse removal procedure noting the following

instruction.

• Passenger side ventilation louver is fitted to passenger air bag module with four clips (1). When

installing passenger side ventilation louver to

passenger air bag module, position the smallest clip

to the top.

2

1

I4RS0B710018-01

1

I4RS0B710019-01

2

1

I4RS0B710020-01

1I4RS0B710021-01

Page 972 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-24 Air Conditioning System: Manual Type

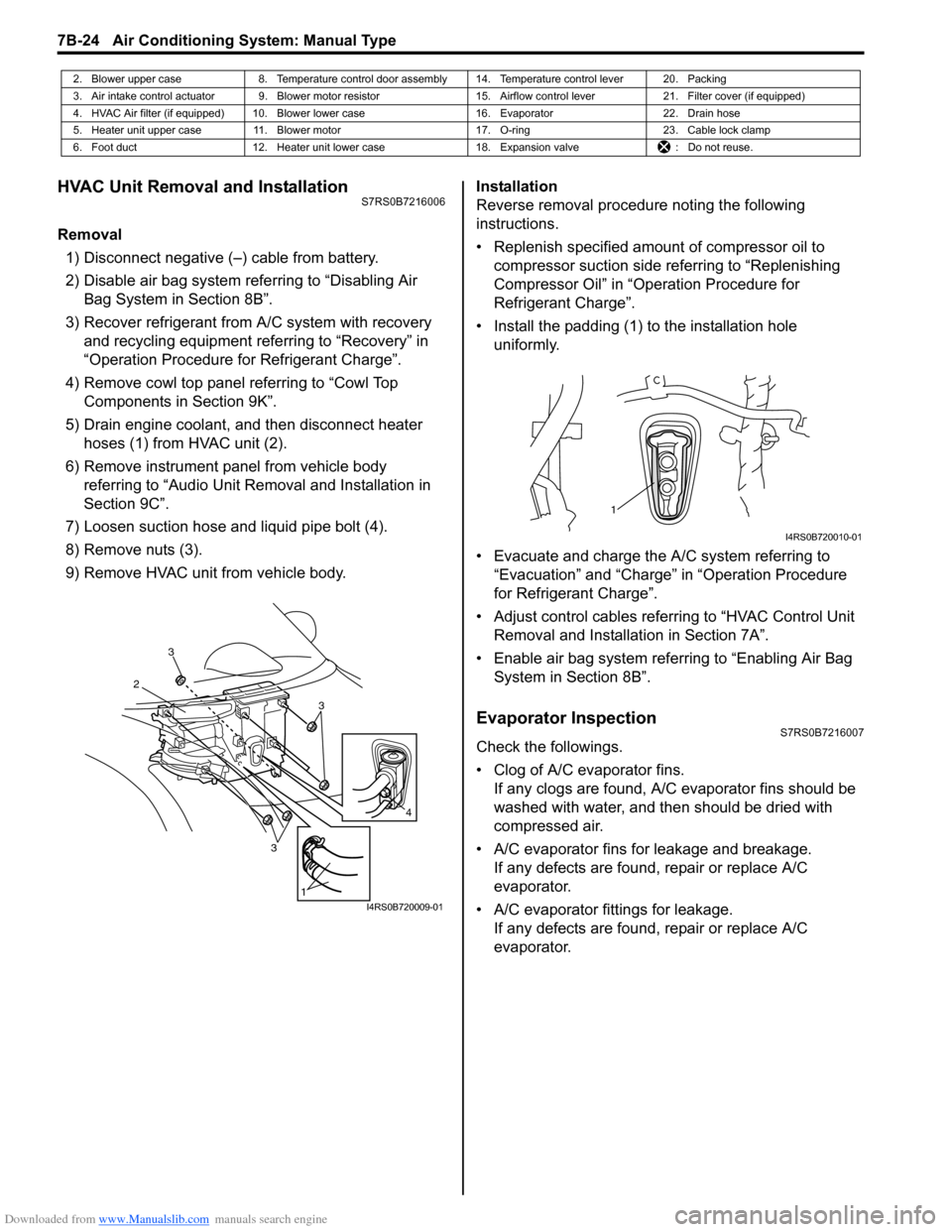

HVAC Unit Removal and InstallationS7RS0B7216006

Removal1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Recover refrigerant from A/C system with recovery and recycling equipment referring to “Recovery” in

“Operation Procedure for Refrigerant Charge”.

4) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

5) Drain engine coolant, and then disconnect heater hoses (1) from HVAC unit (2).

6) Remove instrument panel from vehicle body referring to “Audio Unit Re moval and Installation in

Section 9C”.

7) Loosen suction hose and liquid pipe bolt (4).

8) Remove nuts (3).

9) Remove HVAC unit from vehicle body. Installation

Reverse removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Install the padding (1) to the installation hole uniformly.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Adjust control cables referr ing to “HVAC Control Unit

Removal and Installati on in Section 7A”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Evaporator InspectionS7RS0B7216007

Check the followings.

• Clog of A/C evaporator fins.If any clogs are found, A/C evaporator fins should be

washed with water, and then should be dried with

compressed air.

• A/C evaporator fins for leakage and breakage. If any defects are found, repair or replace A/C

evaporator.

• A/C evaporator fittings for leakage. If any defects are found, repair or replace A/C

evaporator.

2. Blower upper case 8. Temperature control door assembly 14. Temperature control lever 20. Packing

3. Air intake control actuator 9. Blower motor resistor 15. Airflow control lever21. Filter cover (if equipped)

4. HVAC Air filter (if equipped) 10. Blower lower case 16. Evaporator22. Drain hose

5. Heater unit upper case 11. Blower motor 17. O-ring23. Cable lock clamp

6. Foot duct 12. Heater unit lower case 18. Expansion valve: Do not reuse.

3

2

3

3

1

4

I4RS0B720009-01

1

I4RS0B720010-01

Page 1025 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

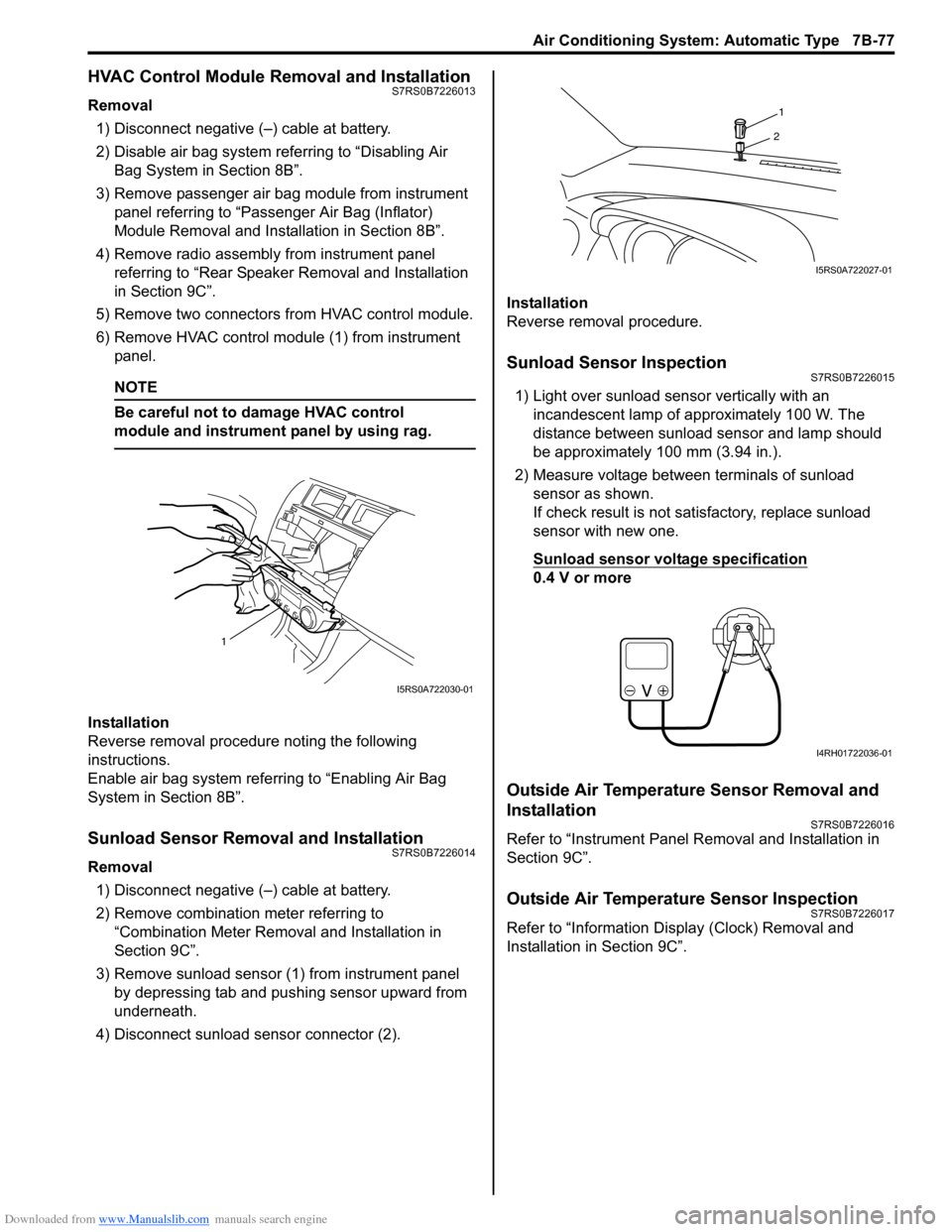

HVAC Control Module Removal and InstallationS7RS0B7226013

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Rear Speaker Removal and Installation

in Section 9C”.

5) Remove two connectors fr om HVAC control module.

6) Remove HVAC control modu le (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control

module and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Sunload Sensor Removal and InstallationS7RS0B7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter referring to “Combination Meter Removal and Installation in

Section 9C”.

3) Remove sunload sensor (1) from instrument panel by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2). Installation

Reverse removal procedure.

Sunload Sensor InspectionS7RS0B7226015

1) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W. The

distance between sunload sensor and lamp should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals of sunload sensor as shown.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

0.4 V or more

Outside Air Temperature Sensor Removal and

Installation

S7RS0B7226016

Refer to “Instrument Panel Re moval and Installation in

Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0B7226017

Refer to “Information Display (Clock) Removal and

Installation in Section 9C”.

1

I5RS0A722030-01

1

2

I5RS0A722027-01

I4RH01722036-01

Page 1030 of 1496

Downloaded from www.Manualslib.com manuals search engine 8-ii Table of Contents

DTC B1062 / B1066: Driver / Passenger Side-Air Bag Initiator Circuit Resistance Low .......... 8B-67

DTC B1063 / B1067: Driver / Passenger Side- Air Bag Initiator Circuit S hort to Ground .......... 8B-70

DTC B1064 / B1068: Driver / Passenger Side- Air Bag Initiator Circu it Short to Power

Circuit .............................................................. 8B-73

DTC B1071: Forward-Sensor Performance Problem ........................................................... 8B-76

DTC B1072: Forward-Sensor Communication Error ................................................................ 8B-76

DTC B1073: Forward-Sensor Circuit Short to Ground ............................................................ 8B-76

DTC B1074: Forward-Sensor Circuit Short to Power Circuit or Open ..................................... 8B-78

DTC B1081 / B1091: Driver / Passenger Side- Sensor Performance Probl em ......................... 8B-80

DTC B1082 / B1092: Driver / Passenger Side- Sensor Communication Erro r .......................... 8B-80

DTC B1083 / B1093: Driver / Passenger Side- Sensor Circuit Short to Ground ....................... 8B-80

DTC B1084 / B1094: Driver / Passenger Side- Sensor Circuit Short to Power Circuit or

Open ............................................................... 8B-81

DTC B1085 / B1095: Wrong Side-Sensor (Driver Side / Passenger) ID ........................... 8B-83

DTC B1361 / B1365: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

High ................................................................. 8B-84

DTC B1362 / B1366: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

Low ................................................................. 8B-86

DTC B1363 / B1367: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Ground ............................................................ 8B-88

DTC B1364 / B1368: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Power Circuit ................................................... 8B-90

Contact Coil Cable and Its Circuit Check .......... 8B-93 Inspection of Intermittent and Poor

Connections .................................................... 8B-95

Repair and Inspection Required after Accident .......................................................... 8B-96

Repair Instructions ............ ................................8B-98

Disabling Air Bag System.................................. 8B-98

Enabling Air Bag System .................................. 8B-99

SDM Removal and Installation ........................ 8B-100

SDM Inspection ............................................... 8B-101

Driver Air Bag (Inflato r) Module Removal and

Installation ..................................................... 8B-101

Driver Air Bag (Inflator) Module Inspection ..... 8B-103

Passenger Air Bag (Inflator) Module Removal and Installation .............................................. 8B-103

Passenger Air Bag (I nflator) Module

Inspection ...................................................... 8B-105

Side-Air Bag (Inflator) Module Removal and

Installation ..................................................... 8B-105

Side-Air Bag (Inflator) Inspection .................... 8B-107

Side Curtain-Air Bag (Inflator) Module Removal and Installation ............................... 8B-107

Side Curtain-Air Bag (Inflator) Module Inspection ...................................................... 8B-109

Forward-Sensor Removal and Installation ...... 8B-109

Forward-Sensor In spection ............................. 8B-110

Side-Sensor Removal and Installation ............ 8B-110

Side-Sensor Inspection ................................... 8B-111

Passenger Air Bag (Inflator) Module Repair

Harness Installation....................................... 8B-112

Air Bag (Inflator) Module and Seat Belt Pretensioner Disposal ................................... 8B-113

Deployed Air Bag (Inflator) Module and Activated Seat Belt Pretensioner Disposal.... 8B-124

Specifications .................. .................................8B-125

Tightening Torque Specifications .................... 8B-125

Special Tools and Equipmen t .........................8B-125

Use of Special Tools ....................................... 8B-125

Recommended Service Material ..................... 8B-127

Special Tool .................................................... 8B-127

Page 1035 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-4

Front Seat Belt Removal and InstallationS7RS0B8106002

WARNING!

• Never attempt to disassemble or repair the seat belt pretensioner (retractor

assembly). If any abnormality is found, be

sure to replace it with new one as an

assembly.

• Be sure to read “Precautions on Service and Diagnosis of Seat Belt” before starting

to work and observe every precaution

during work. Ne glecting them may result in

personal injury or una ctivation of the seat

belt pretensioner when necessary.

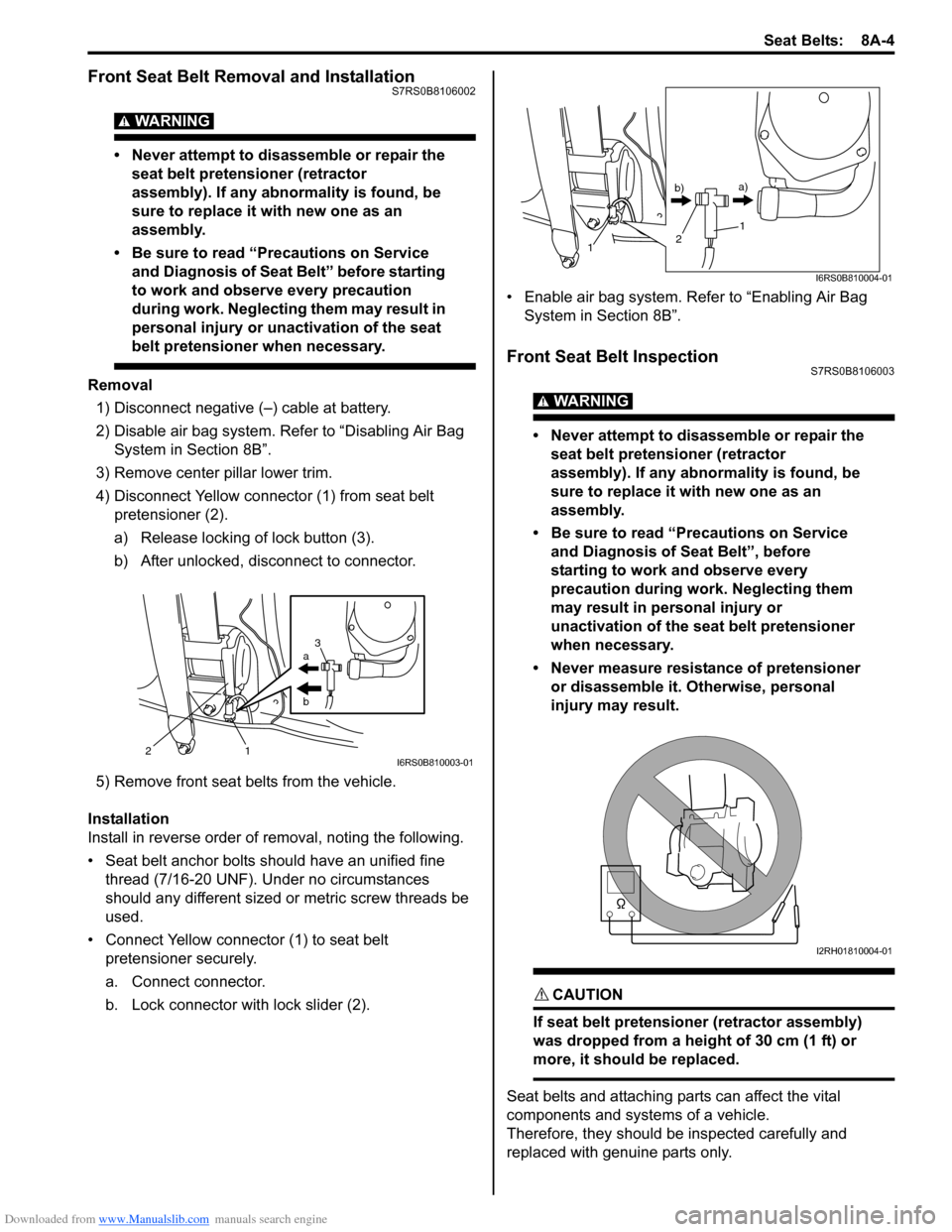

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag System in Section 8B”.

3) Remove center pillar lower trim.

4) Disconnect Yellow connector (1) from seat belt pretensioner (2).

a) Release locking of lock button (3).

b) After unlocked, disconnect to connector.

5) Remove front seat belts from the vehicle.

Installation

Install in reverse order of removal, noting the following.

• Seat belt anchor bolts should have an unified fine thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.

• Connect Yellow connector (1) to seat belt pretensioner securely.

a. Connect connector.

b. Lock connector with lock slider (2). • Enable air bag system. Refer to “Enabling Air Bag

System in Section 8B”.

Front Seat Belt InspectionS7RS0B8106003

WARNING!

• Never attempt to disassemble or repair the seat belt pretensioner (retractor

assembly). If any abnormality is found, be

sure to replace it with new one as an

assembly.

• Be sure to read “Precautions on Service and Diagnosis of Seat Belt”, before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

unactivation of the seat belt pretensioner

when necessary.

• Never measure resistance of pretensioner or disassemble it. Otherwise, personal

injury may result.

CAUTION!

If seat belt pretensioner (retractor assembly)

was dropped from a height of 30 cm (1 ft) or

more, it should be replaced.

Seat belts and attaching parts can affect the vital

components and systems of a vehicle.

Therefore, they should be inspected carefully and

replaced with genuine parts only.

a

b

21 3I6RS0B810003-01

1

1

2

b)

a)

I6RS0B810004-01

I2RH01810004-01

Page 1039 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-1

Restraint

Air Bag System

Precautions

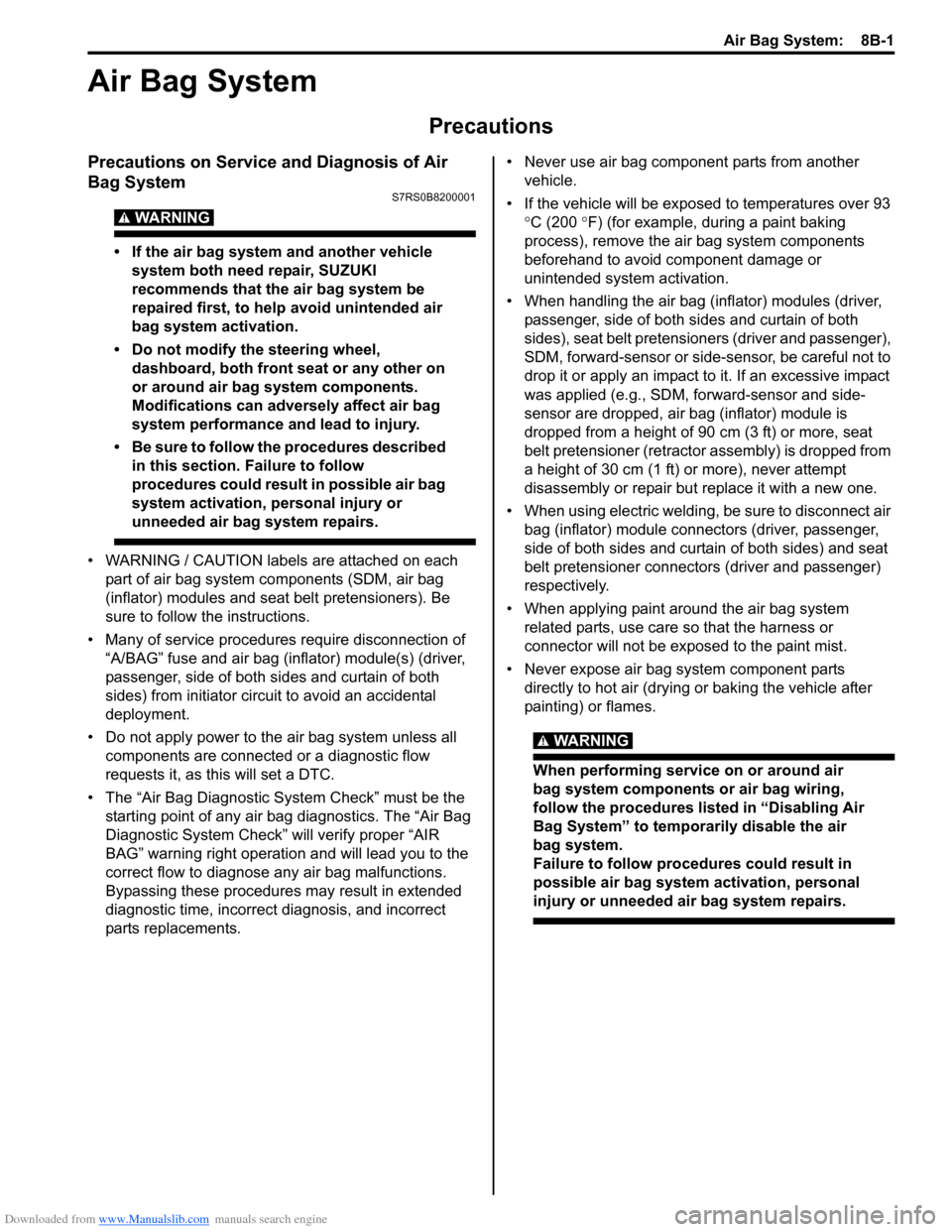

Precautions on Service and Diagnosis of Air

Bag System

S7RS0B8200001

WARNING!

• If the air bag system and another vehicle system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel, dashboard, both front seat or any other on

or around air bag system components.

Modifications can adversely affect air bag

system performance and lead to injury.

• Be sure to follow the procedures described in this section. Failure to follow

procedures could result in possible air bag

system activation, personal injury or

unneeded air bag system repairs.

• WARNING / CAUTION labels are attached on each

part of air bag system components (SDM, air bag

(inflator) modules and seat belt pretensioners). Be

sure to follow the instructions.

• Many of service procedures require disconnection of

“A/BAG” fuse and air bag (inflator) module(s) (driver,

passenger, side of both si des and curtain of both

sides) from initiator circuit to avoid an accidental

deployment.

• Do not apply power to the air bag system unless all components are connected or a diagnostic flow

requests it, as this will set a DTC.

• The “Air Bag Diagnostic S ystem Check” must be the

starting point of any air bag diagnostics. The “Air Bag

Diagnostic System Check” will verify proper “AIR

BAG” warning right operatio n and will lead you to the

correct flow to diagnose any air bag malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements. • Never use air bag component parts from another

vehicle.

• If the vehicle will be exposed to temperatures over 93

° C (200 °F) (for example, during a paint baking

process), remove the air bag system components

beforehand to avoid component damage or

unintended system activation.

• When handling the air bag (inflator) modules (driver, passenger, side of both si des and curtain of both

sides), seat belt pretensio ners (driver and passenger),

SDM, forward-sensor or side-sensor, be careful not to

drop it or apply an impact to it. If an excessive impact

was applied (e.g., SDM, forward-sensor and side-

sensor are dropped, air bag (inflator) module is

dropped from a height of 90 cm (3 ft) or more, seat

belt pretensioner (retractor assembly) is dropped from

a height of 30 cm (1 ft) or more), never attempt

disassembly or repair but replace it with a new one.

• When using electric welding, be sure to disconnect air bag (inflator) module connectors (driver, passenger,

side of both sides and curtain of both sides) and seat

belt pretensioner connectors (driver and passenger)

respectively.

• When applying paint around the air bag system related parts, use care so that the harness or

connector will not be expo sed to the paint mist.

• Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING!

When performing service on or around air

bag system components or air bag wiring,

follow the procedures listed in “Disabling Air

Bag System” to temporarily disable the air

bag system.

Failure to follow procedures could result in

possible air bag system activation, personal

injury or unneeded air bag system repairs.

Page 1136 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-98 Air Bag System:

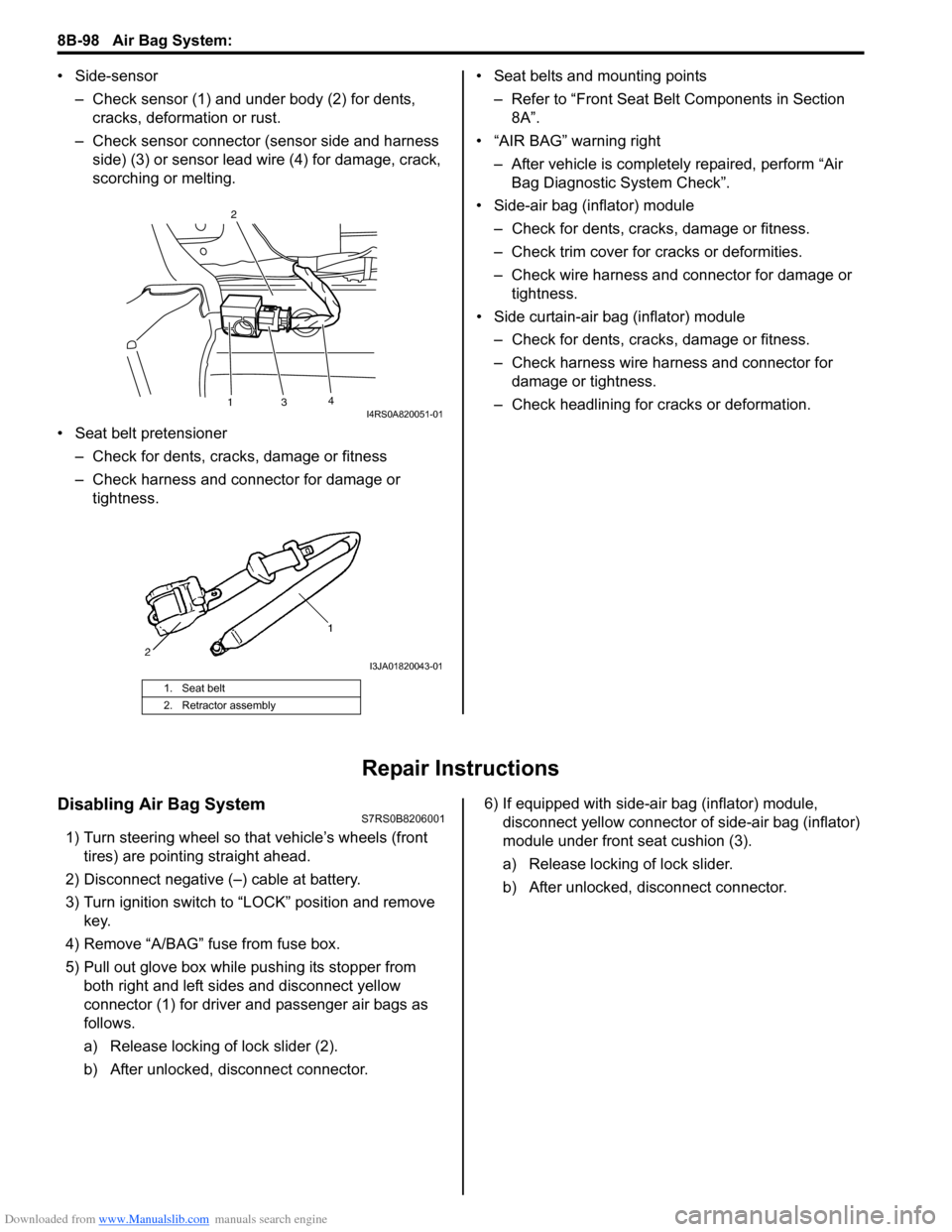

• Side-sensor– Check sensor (1) and under body (2) for dents, cracks, deformation or rust.

– Check sensor connector (sensor side and harness side) (3) or sensor lead wire (4) for damage, crack,

scorching or melting.

• Seat belt pretensioner – Check for dents, cracks , damage or fitness

– Check harness and connector for damage or tightness. • Seat belts and mounting points

– Refer to “Front Seat Belt Components in Section 8A”.

• “AIR BAG” warning right

– After vehicle is completely repaired, perform “Air Bag Diagnostic System Check”.

• Side-air bag (inflator) module – Check for dents, cra cks, damage or fitness.

– Check trim cover for cracks or deformities.

– Check wire harness and connector for damage or tightness.

• Side curtain-air bag (inflator) module – Check for dents, cra cks, damage or fitness.

– Check harness wire harness and connector for damage or tightness.

– Check headlining for cracks or deformation.

Repair Instructions

Disabling Air Bag SystemS7RS0B8206001

1) Turn steering wheel so that vehicle’s wheels (front tires) are pointing straight ahead.

2) Disconnect negative (–) cable at battery.

3) Turn ignition switch to “LOCK” position and remove key.

4) Remove “A/BAG” fu se from fuse box.

5) Pull out glove box while pushing its stopper from

both right and left sides and disconnect yellow

connector (1) for driver and passenger air bags as

follows.

a) Release locking of lock slider (2).

b) After unlocked, disconnect connector. 6) If equipped with side-air bag (inflator) module,

disconnect yellow connector of side-air bag (inflator)

module under front seat cushion (3).

a) Release locking of lock slider.

b) After unlocked, disconnect connector.

1. Seat belt

2. Retractor assembly

13 4

2I4RS0A820051-01

I3JA01820043-01

Page 1138 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-100 Air Bag System:

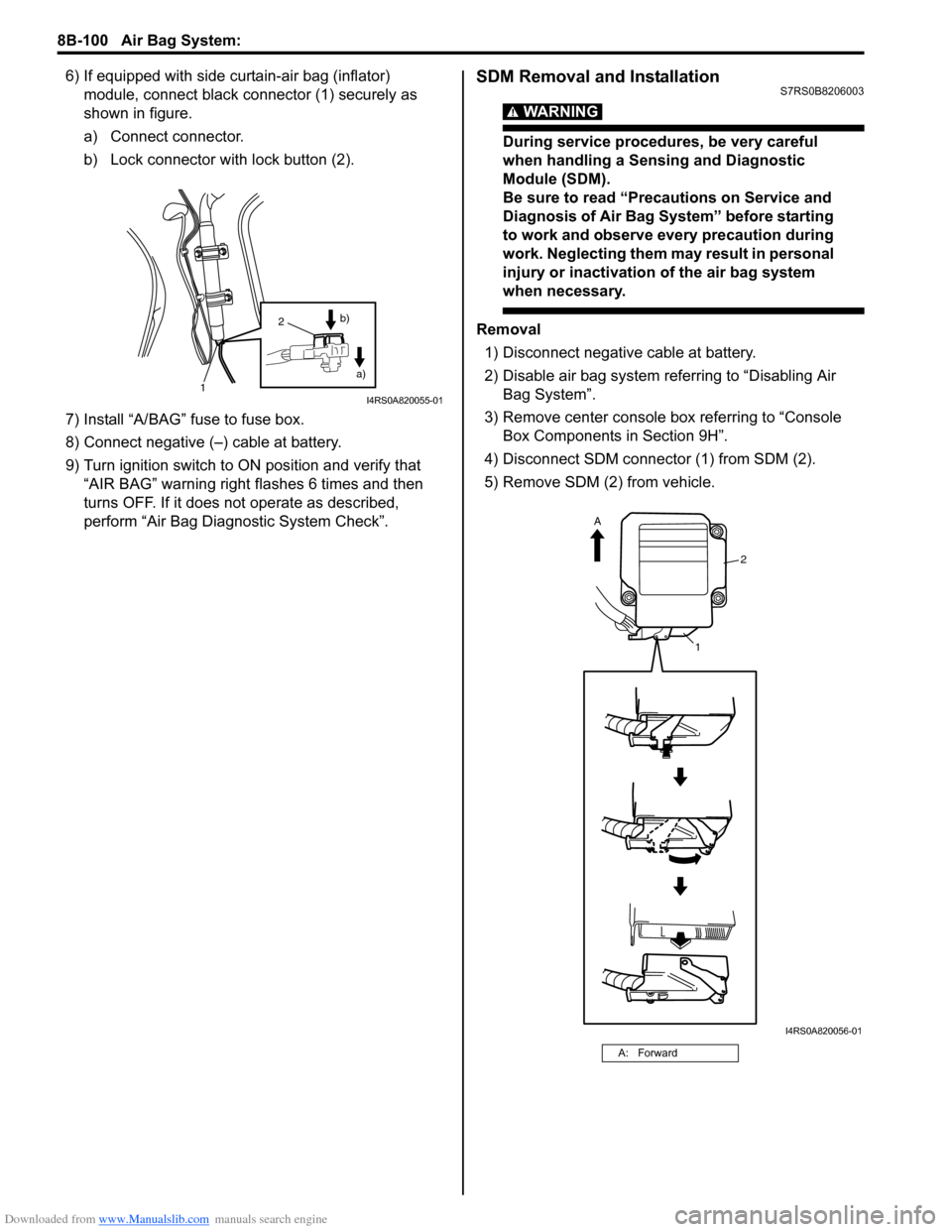

6) If equipped with side curtain-air bag (inflator) module, connect black connector (1) securely as

shown in figure.

a) Connect connector.

b) Lock connector with lock button (2).

7) Install “A/BAG” fuse to fuse box.

8) Connect negative (–) cable at battery.

9) Turn ignition switch to ON position and verify that “AIR BAG” warning right flashes 6 times and then

turns OFF. If it does not operate as described,

perform “Air Bag Diagn ostic System Check”.SDM Removal and InstallationS7RS0B8206003

WARNING!

During service procedures, be very careful

when handling a Sensing and Diagnostic

Module (SDM).

Be sure to read “Precautions on Service and

Diagnosis of Air Bag System” before starting

to work and observe every precaution during

work. Neglecting them ma y result in personal

injury or inactivation of the air bag system

when necessary.

Removal

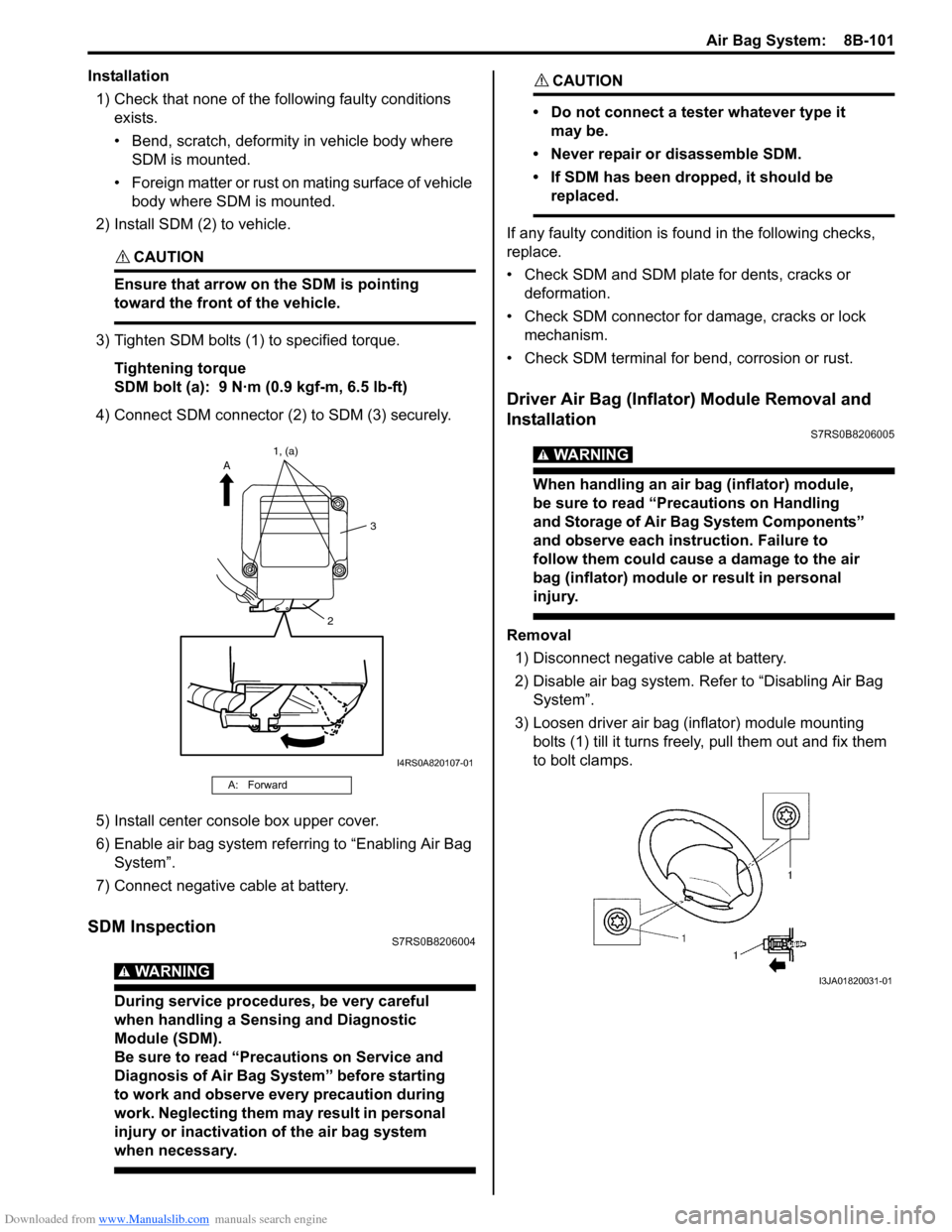

1) Disconnect negative cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System”.

3) Remove center console box referring to “Console Box Components in Section 9H”.

4) Disconnect SDM connector (1) from SDM (2).

5) Remove SDM (2) from vehicle.

1

2

a)

b)

I4RS0A820055-01

A: Forward

2

1

A

I4RS0A820056-01

Page 1139 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-101

Installation1) Check that none of the following faulty conditions exists.

• Bend, scratch, deformity in vehicle body where SDM is mounted.

• Foreign matter or rust on mating surface of vehicle body where SDM is mounted.

2) Install SDM (2) to vehicle.

CAUTION!

Ensure that arrow on the SDM is pointing

toward the front of the vehicle.

3) Tighten SDM bolts (1) to specified torque.

Tightening torque

SDM bolt (a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

4) Connect SDM connector (2) to SDM (3) securely.

5) Install center console box upper cover.

6) Enable air bag system referring to “Enabling Air Bag System”.

7) Connect negative cable at battery.

SDM InspectionS7RS0B8206004

WARNING!

During service procedures, be very careful

when handling a Sensing and Diagnostic

Module (SDM).

Be sure to read “Precautions on Service and

Diagnosis of Air Bag System” before starting

to work and observe every precaution during

work. Neglecting them ma y result in personal

injury or inactivation of the air bag system

when necessary.

CAUTION!

• Do not connect a tester whatever type it may be.

• Never repair or disassemble SDM.

• If SDM has been dropped, it should be replaced.

If any faulty condition is fo und in the following checks,

replace.

• Check SDM and SDM plate for dents, cracks or deformation.

• Check SDM connector for damage, cracks or lock mechanism.

• Check SDM terminal for bend, corrosion or rust.

Driver Air Bag (Inflator) Module Removal and

Installation

S7RS0B8206005

WARNING!

When handling an air bag (inflator) module,

be sure to read “Precautions on Handling

and Storage of Air Bag System Components”

and observe each instruction. Failure to

follow them could cause a damage to the air

bag (inflator) module or result in personal

injury.

Removal 1) Disconnect negative cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System”.

3) Loosen driver air bag (inflator) module mounting bolts (1) till it turns freely, pull them out and fix them

to bolt clamps.

A: Forward

2 3

A

1, (a)

I4RS0A820107-01

I3JA01820031-01