reverse light SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 849 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-35

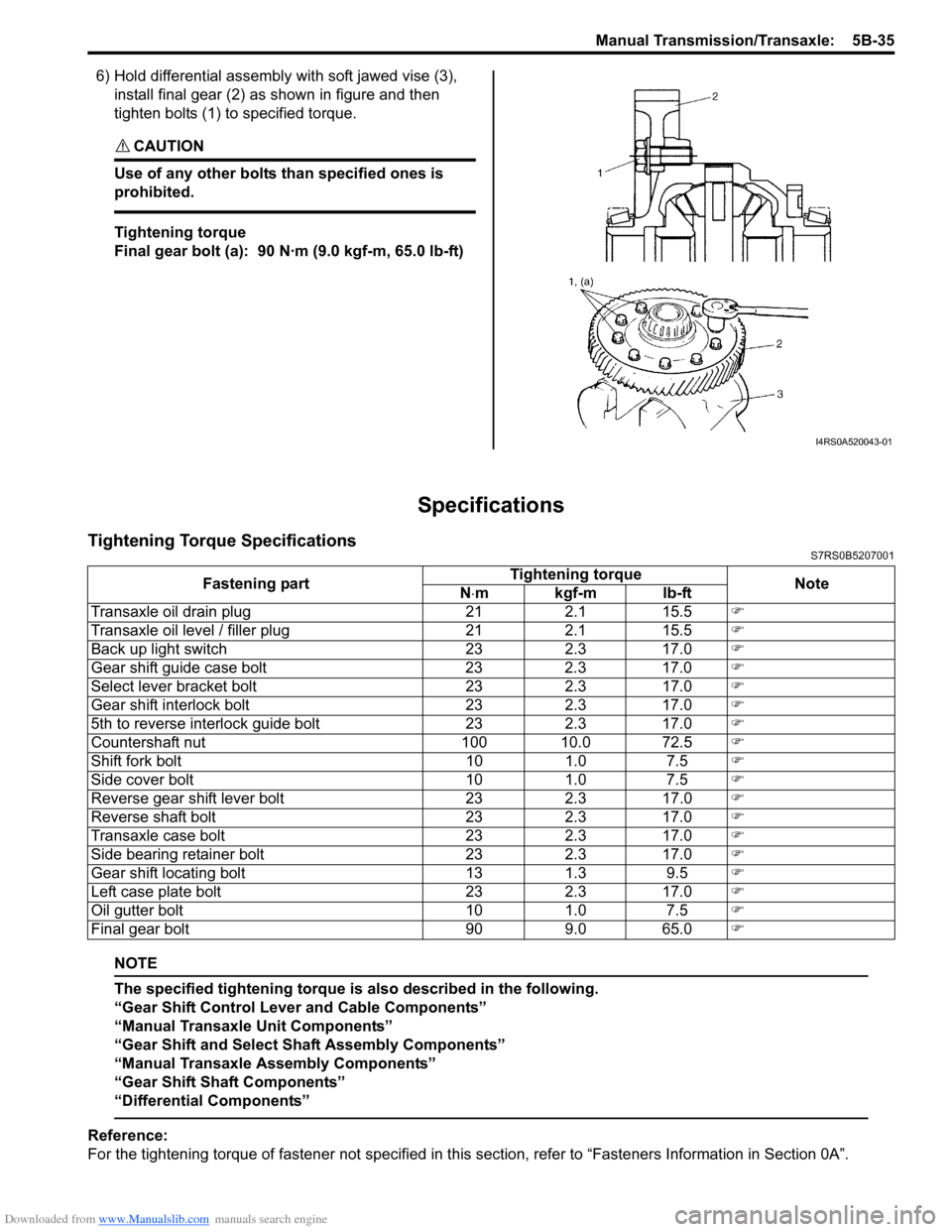

6) Hold differential assembly with soft jawed vise (3),

install final gear (2) as shown in figure and then

tighten bolts (1) to specified torque.

CAUTION!

Use of any other bolts than specified ones is

prohibited.

Tightening torque

Final gear bolt (a): 90 N·m (9.0 kgf-m, 65.0 lb-ft)

Specifications

Tightening Torque SpecificationsS7RS0B5207001

NOTE

The specified tightening torque is also described in the following.

“Gear Shift Control Leve r and Cable Components”

“Manual Transaxle Unit Components”

“Gear Shift and Select Shaft Assembly Components”

“Manual Transaxle Assembly Components”

“Gear Shift Shaft Components”

“Differential Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I4RS0A520043-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Transaxle oil drain plug 21 2.1 15.5 �)

Transaxle oil level / filler plug 21 2.1 15.5 �)

Back up light switch 23 2.3 17.0 �)

Gear shift guide case bolt 23 2.3 17.0 �)

Select lever bracket bolt 23 2.3 17.0 �)

Gear shift interlock bolt 23 2.3 17.0 �)

5th to reverse interlock guide bolt 23 2.3 17.0 �)

Countershaft nut 100 10.0 72.5 �)

Shift fork bolt 10 1.0 7.5 �)

Side cover bolt 10 1.0 7.5 �)

Reverse gear shift lever bolt 23 2.3 17.0 �)

Reverse shaft bolt 23 2.3 17.0 �)

Transaxle case bolt 23 2.3 17.0 �)

Side bearing retainer bolt 23 2.3 17.0 �)

Gear shift locating bolt 13 1.3 9.5 �)

Left case plate bolt 23 2.3 17.0 �)

Oil gutter bolt 10 1.0 7.5 �)

Final gear bolt 90 9.0 65.0 �)

Page 855 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-3

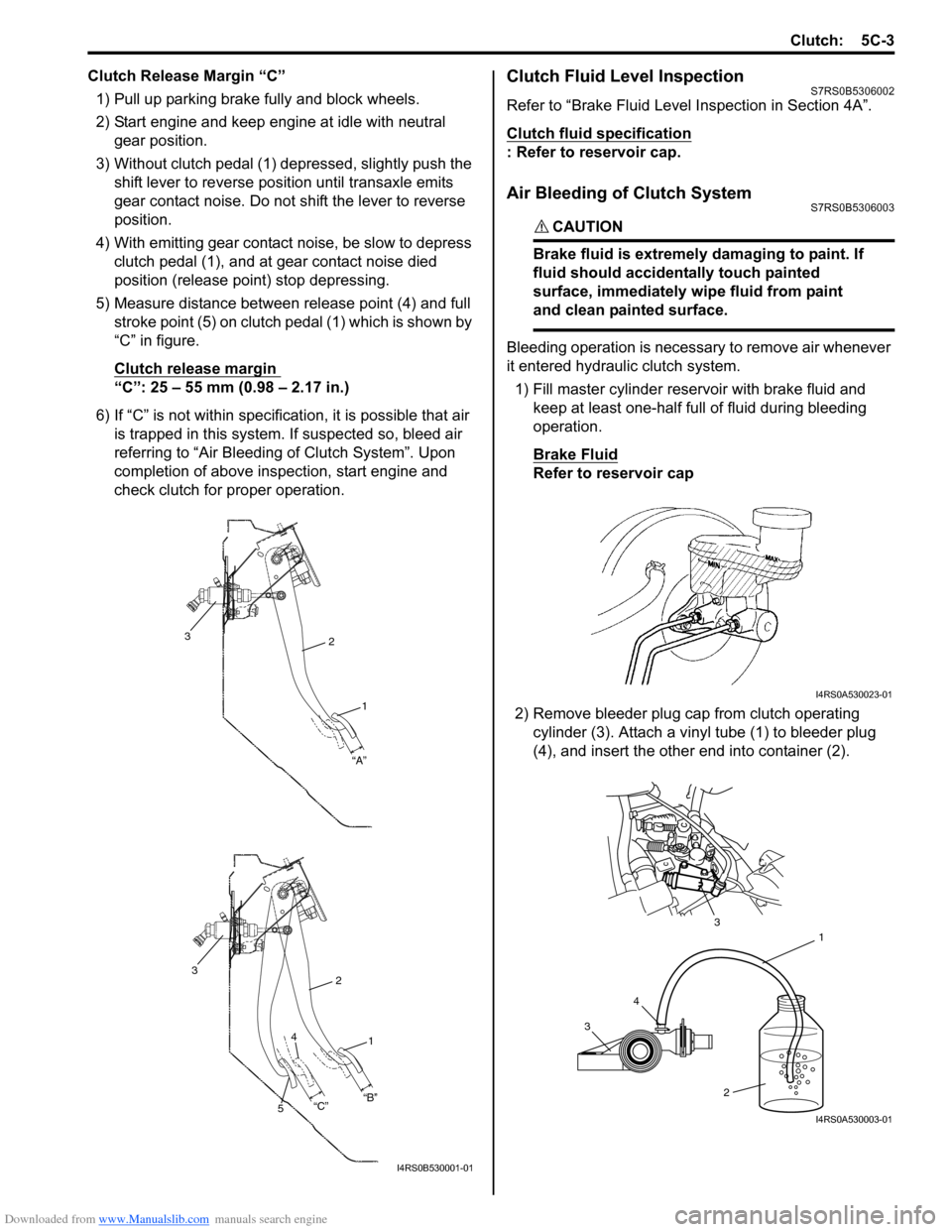

Clutch Release Margin “C”1) Pull up parking brake fully and block wheels.

2) Start engine and keep engine at idle with neutral gear position.

3) Without clutch pedal (1) dep ressed, slightly push the

shift lever to re verse position until transaxle emits

gear contact noise. Do not shift the lever to reverse

position.

4) With emitting gear contact noise, be slow to depress clutch pedal (1), and at gear contact noise died

position (release point) stop depressing.

5) Measure distance between release point (4) and full stroke point (5) on clutch pedal (1) which is shown by

“C” in figure.

Clutch release margin

“C”: 25 – 55 mm (0.98 – 2.17 in.)

6) If “C” is not within specificat ion, it is possible that air

is trapped in this system. If suspected so, bleed air

referring to “Air Bleeding of Clutch System”. Upon

completion of above inspection, start engine and

check clutch for proper operation.

Clutch Fluid Level InspectionS7RS0B5306002

Refer to “Brake Fluid Level Inspection in Section 4A”.

Clutch fluid specification

: Refer to reservoir cap.

Air Bleeding of Clutch SystemS7RS0B5306003

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic clutch system.

1) Fill master cylinder reservoir with brake fluid and keep at least one-half full of fluid during bleeding

operation.

Brake Fluid

Refer to reservoir cap

2) Remove bleeder plug cap from clutch operating cylinder (3). Attach a vinyl tube (1) to bleeder plug

(4), and insert the other end into container (2).

2

1

“A”

3

2

1

3

“B”

“C”

4

5

I4RS0B530001-01

I4RS0A530023-01

3 4 1

2

3

I4RS0A530003-01

Page 947 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-11

Side Ventilation Louver Removal and

Installation

S7RS0B7106015

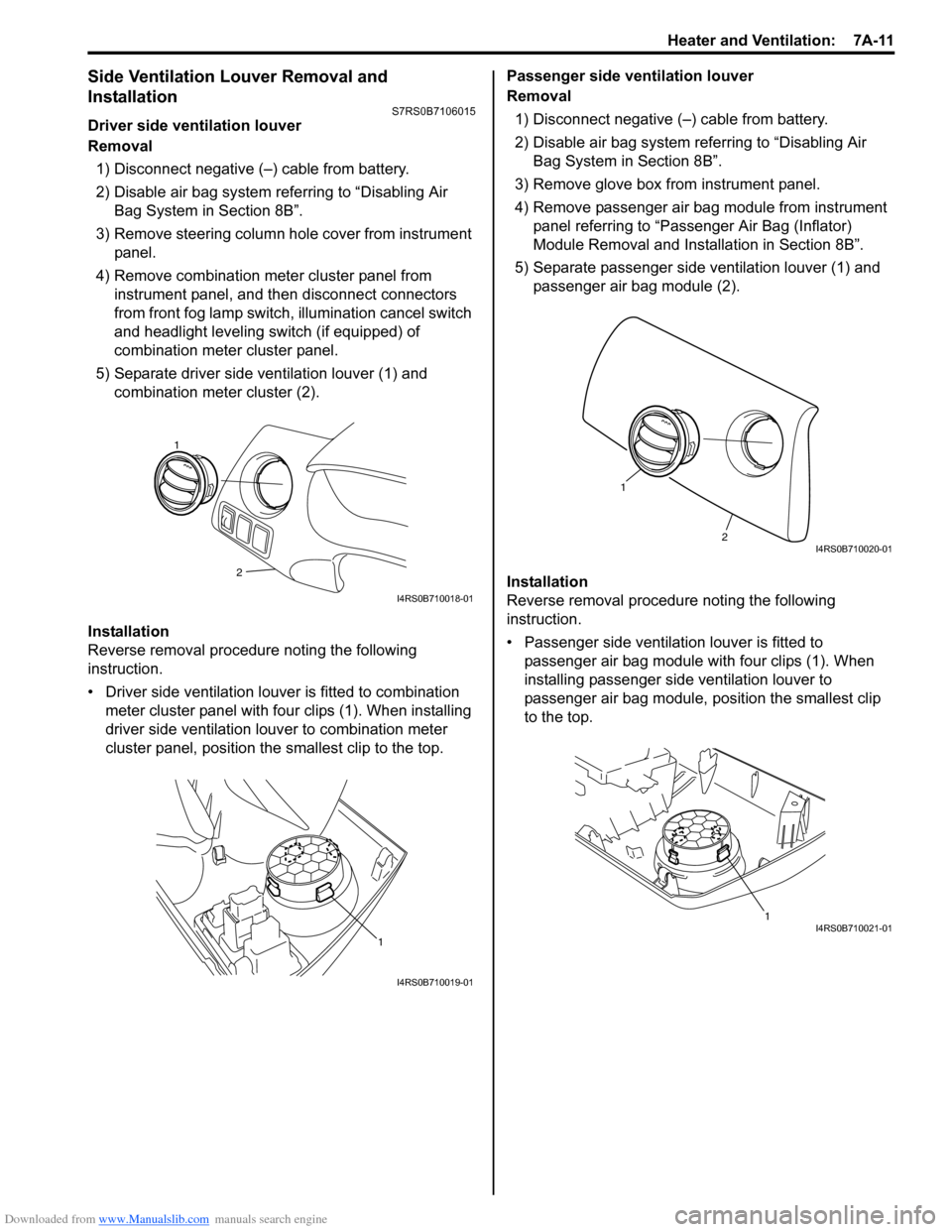

Driver side ventilation louver

Removal1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hol e cover from instrument

panel.

4) Remove combination meter cluster panel from instrument panel, and then disconnect connectors

from front fog lamp switch, illumination cancel switch

and headlight leveling switch (if equipped) of

combination meter cluster panel.

5) Separate driver side ventilation louver (1) and combination meter cluster (2).

Installation

Reverse removal procedure noting the following

instruction.

• Driver side ventilation louver is fitted to combination meter cluster panel with four clips (1). When installing

driver side ventilation louv er to combination meter

cluster panel, position the smallest clip to the top. Passenger side ventilation louver

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove glove box from instrument panel.

4) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

5) Separate passenger side ventilation louver (1) and passenger air bag module (2).

Installation

Reverse removal procedure noting the following

instruction.

• Passenger side ventilation louver is fitted to passenger air bag module with four clips (1). When

installing passenger side ventilation louver to

passenger air bag module, position the smallest clip

to the top.

2

1

I4RS0B710018-01

1

I4RS0B710019-01

2

1

I4RS0B710020-01

1I4RS0B710021-01

Page 958 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-10 Air Conditioning System: Manual Type

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower Motor

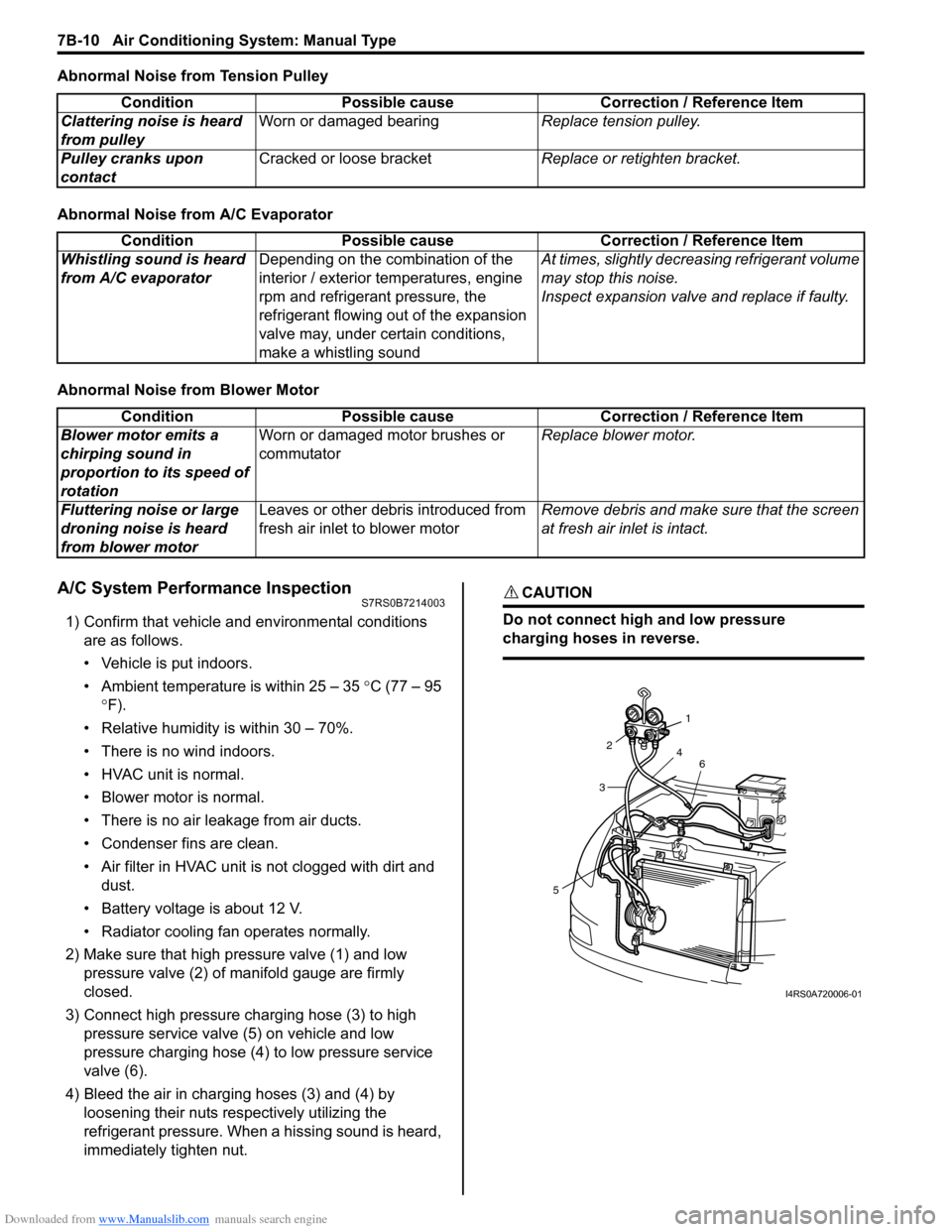

A/C System Performance InspectionS7RS0B7214003

1) Confirm that vehicle and environmental conditions are as follows.

• Vehicle is put indoors.

• Ambient temperature is within 25 – 35 °C (77 – 95

° F).

• Relative humidity is within 30 – 70%.

• There is no wind indoors.

• HVAC unit is normal.

• Blower motor is normal.

• There is no air leakage from air ducts.

• Condenser fins are clean.

• Air filter in HVAC unit is not clogged with dirt and

dust.

• Battery voltage is about 12 V.

• Radiator cooling fan operates normally.

2) Make sure that high pressure valve (1) and low pressure valve (2) of manifold gauge are firmly

closed.

3) Connect high pressure charging hose (3) to high pressure service valve (5) on vehicle and low

pressure charging hose (4) to low pressure service

valve (6).

4) Bleed the air in charging hoses (3) and (4) by loosening their nuts respectively utilizing the

refrigerant pressure. When a hissing sound is heard,

immediately tighten nut.

CAUTION!

Do not connect high and low pressure

charging hoses in reverse.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulley Worn or damaged bearing

Replace tension pulley.

Pulley cranks upon

contact Cracked or loose bracket

Replace or retighten bracket.

ConditionPossible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporator Depending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling sound At times, slightly decrea

sing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotation Worn or damaged motor brushes or

commutator

Replace blower motor.

Fluttering noise or large

droning noise is heard

from blower motor Leaves or other debris introduced from

fresh air inlet to blower motor

Remove debris and make sure that the screen

at fresh air inlet is intact.

53

2

1

4 6

I4RS0A720006-01

Page 1025 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

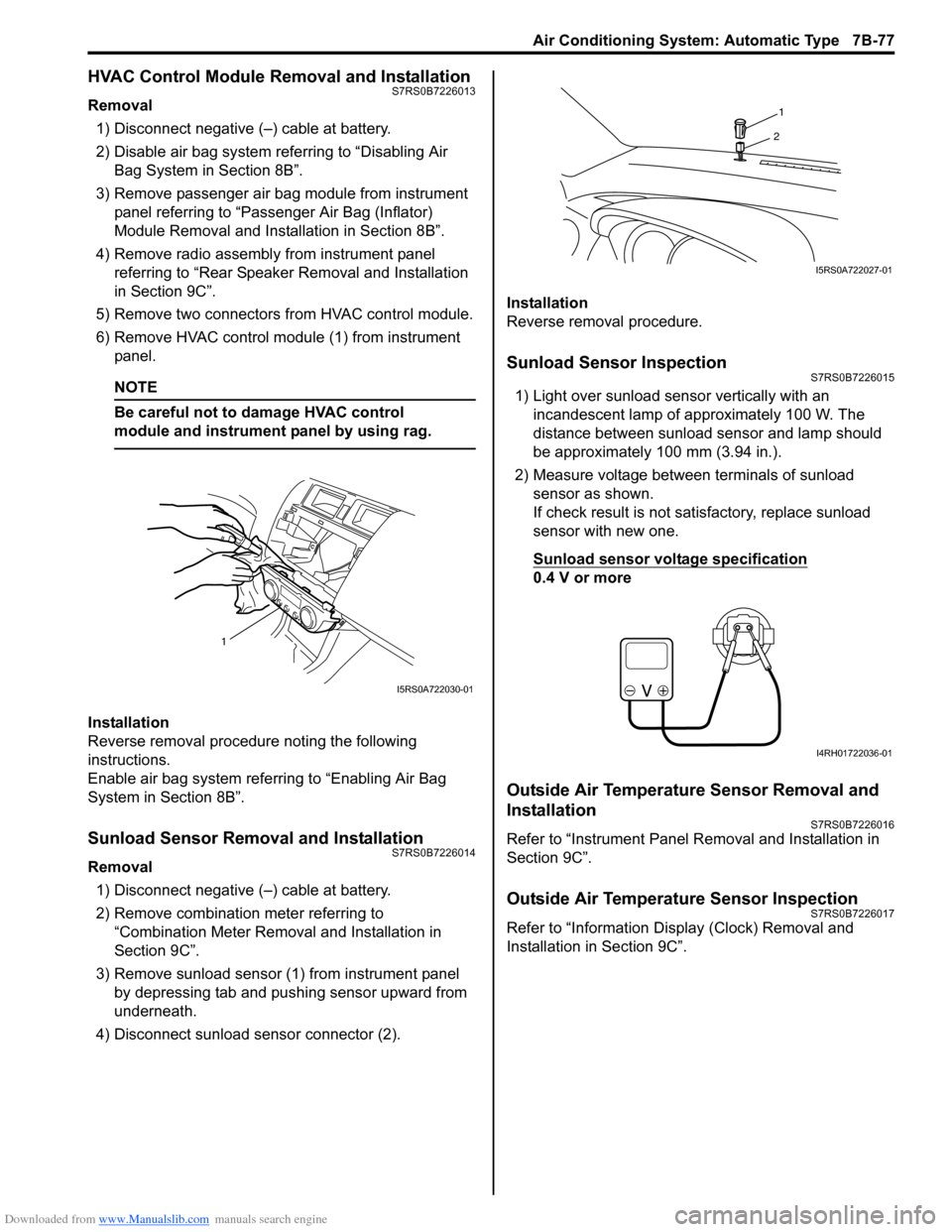

HVAC Control Module Removal and InstallationS7RS0B7226013

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Rear Speaker Removal and Installation

in Section 9C”.

5) Remove two connectors fr om HVAC control module.

6) Remove HVAC control modu le (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control

module and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Sunload Sensor Removal and InstallationS7RS0B7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter referring to “Combination Meter Removal and Installation in

Section 9C”.

3) Remove sunload sensor (1) from instrument panel by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2). Installation

Reverse removal procedure.

Sunload Sensor InspectionS7RS0B7226015

1) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W. The

distance between sunload sensor and lamp should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals of sunload sensor as shown.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

0.4 V or more

Outside Air Temperature Sensor Removal and

Installation

S7RS0B7226016

Refer to “Instrument Panel Re moval and Installation in

Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0B7226017

Refer to “Information Display (Clock) Removal and

Installation in Section 9C”.

1

I5RS0A722030-01

1

2

I5RS0A722027-01

I4RH01722036-01

Page 1257 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-86

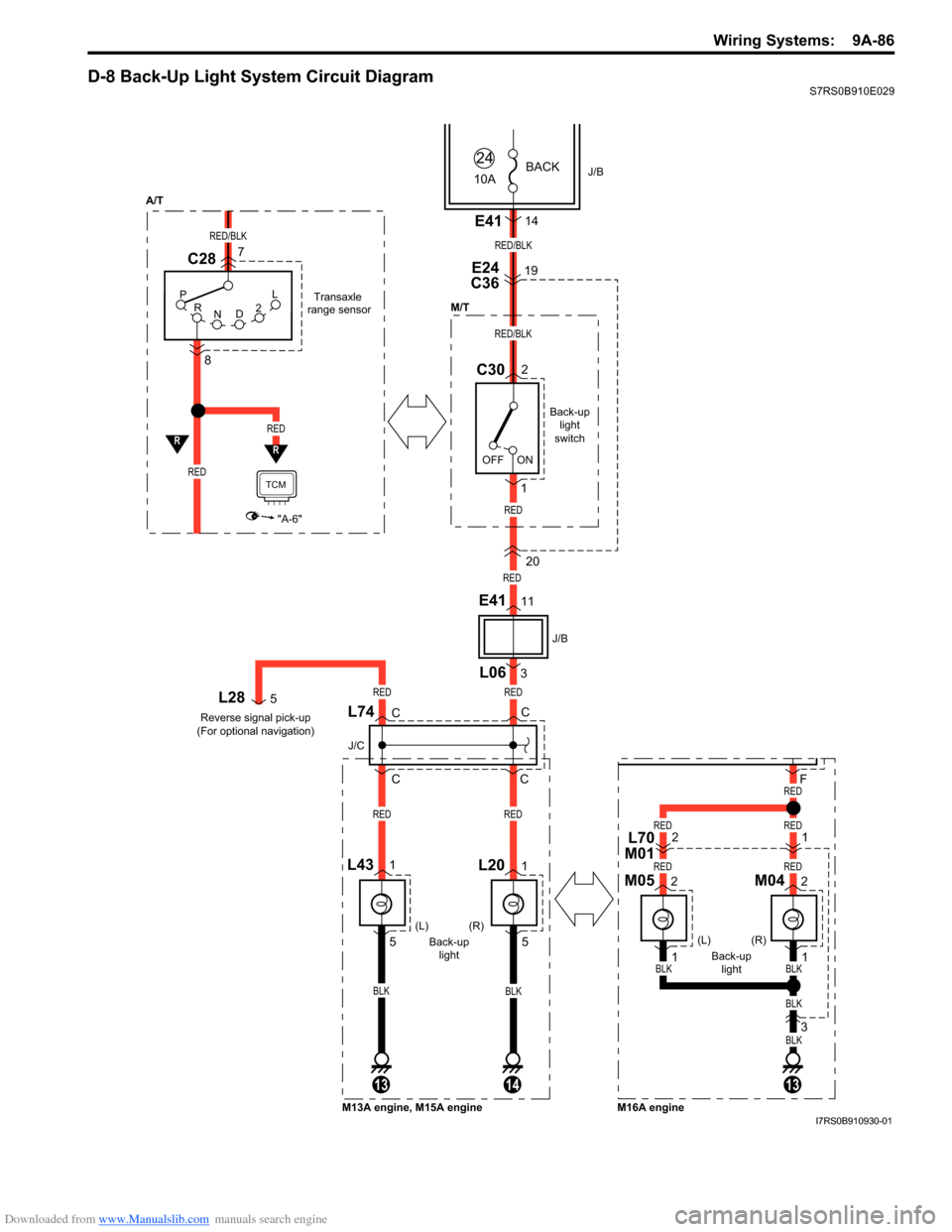

D-8 Back-Up Light System Circuit DiagramS7RS0B910E029

BLKBLK

141313

CC

C

J/C

L74CL28

Back-up light

switch

Back-up light (R)

RED

RED

RED/BLK

RED/BLK

ON

OFF J/B

10A

24BACK

E24

C3619

C302

1 20

L431L201

RED

RED

RED

M/T

L063

E4111

J/B

P R N D2LTransaxle

range sensor

RED/BLK

C28

R

RED

8

RED

"A-6"

TCM

R

E4114

7

5 5

Reverse signal pick-up

(For optional navigation)

5RED

(L)

Back-uplight (R)

(L)

M13A engine, M15A engine M16A engine

BLK

BLK

BLKBLK

F

M042

RED

REDRED

REDRED

1

M052

1

1L70

M012

3

A/T

I7RS0B910930-01

Page 1287 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-5

Interior Light Symptom DiagnosisS7RS0B9204008

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Repair Instructions

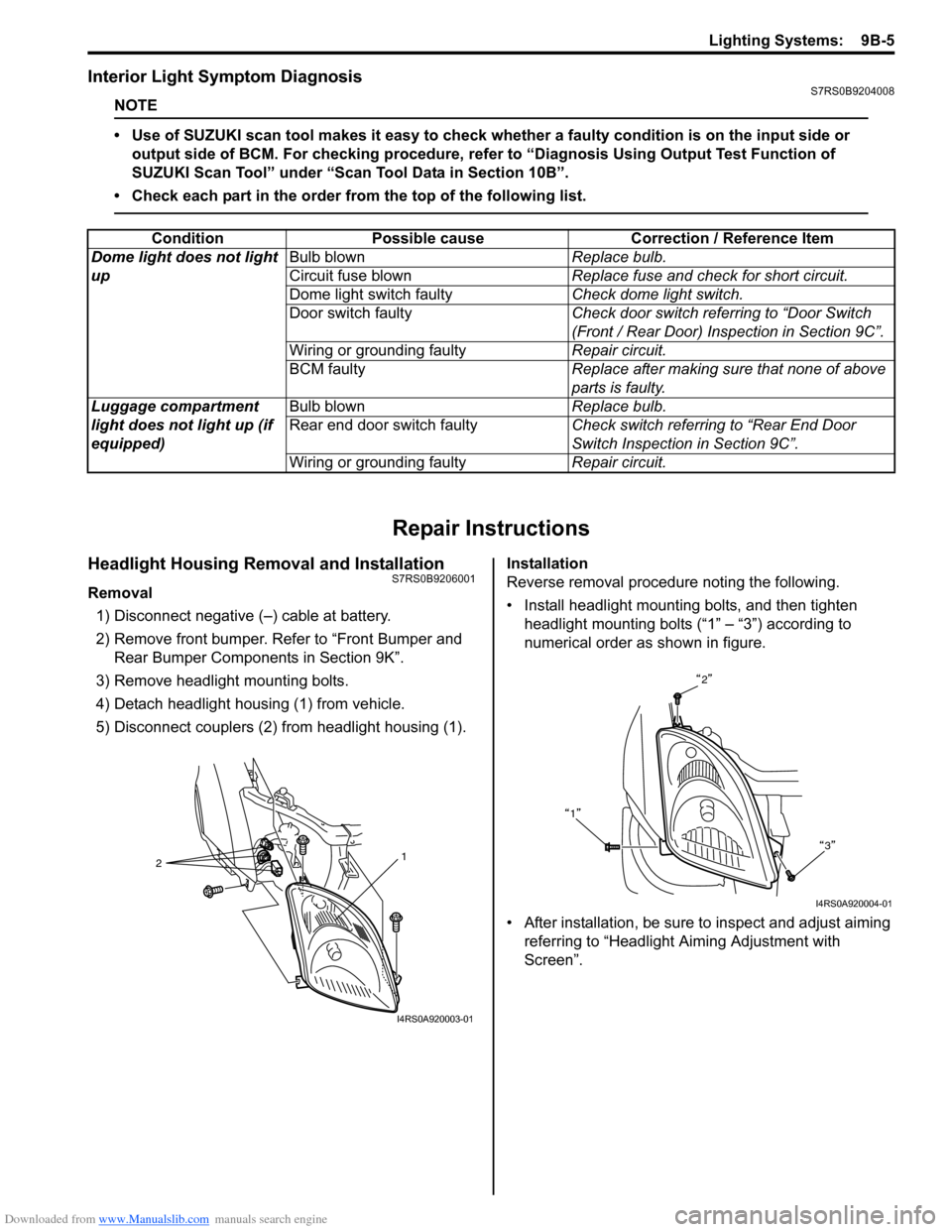

Headlight Housing Removal and InstallationS7RS0B9206001

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper. Refer to “Front Bumper and Rear Bumper Componen ts in Section 9K”.

3) Remove headlight mounting bolts.

4) Detach headlight housing (1) from vehicle.

5) Disconnect couplers (2) from headlight housing (1). Installation

Reverse removal procedure noting the following.

• Install headlight mounting bolts, and then tighten

headlight mounting bolts (“1” – “3”) according to

numerical order as shown in figure.

• After installation, be sure to inspect and adjust aiming referring to “Headlight Aiming Adjustment with

Screen”.

Condition Possible cause Correction / Reference Item

Dome light does not light

up Bulb blown

Replace bulb.

Circuit fuse blown Replace fuse and check for short circuit.

Dome light switch faulty Check dome light switch.

Door switch faulty Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Luggage compartment

light does not light up (if

equipped) Bulb blown

Replace bulb.

Rear end door switch faulty Check switch referring to “Rear End Door

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

2 1

I4RS0A920003-01

2

1 3

I4RS0A920004-01

Page 1290 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-8 Lighting Systems:

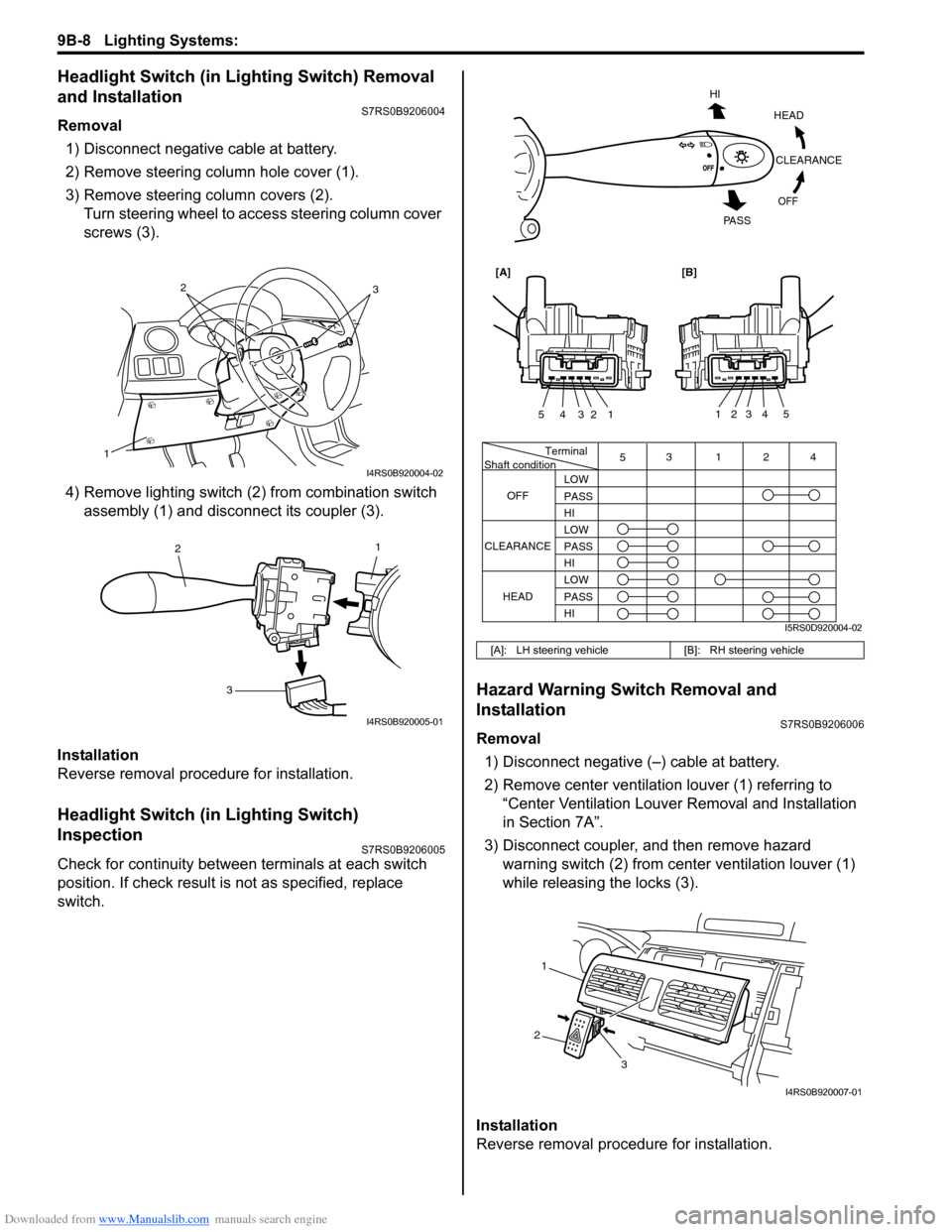

Headlight Switch (in Lighting Switch) Removal

and Installation

S7RS0B9206004

Removal1) Disconnect negative cable at battery.

2) Remove steering column hole cover (1).

3) Remove steering column covers (2). Turn steering wheel to acce ss steering column cover

screws (3).

4) Remove lighting switch (2 ) from combination switch

assembly (1) and disconnect its coupler (3).

Installation

Reverse removal procedure for installation.

Headlight Switch (in Lighting Switch)

Inspection

S7RS0B9206005

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Hazard Warning Switch Removal and

Installation

S7RS0B9206006

Removal 1) Disconnect negative (–) cable at battery.

2) Remove center ventilation louver (1) referring to

“Center Ventilation Louver Removal and Installation

in Section 7A”.

3) Disconnect coupler, and then remove hazard warning switch (2) from center ventilation louver (1)

while releasing the locks (3).

Installation

Reverse removal procedure for installation.

1

32

I4RS0B920004-02

1

2

3

I4RS0B920005-01

[A]: LH steering vehicle [B]: RH steering vehicle

Terminal

Shaft condition

OFF 5

3124

LOW

PASS

HI

LOW

PASS

HI LOW

PASS

HI

CLEARANCE

HEAD

HEADCLEARANCE

OFF

HI

PA S S

54321

54321

[A][B]

I5RS0D920004-02

1

2 3

I4RS0B920007-01

Page 1291 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-9

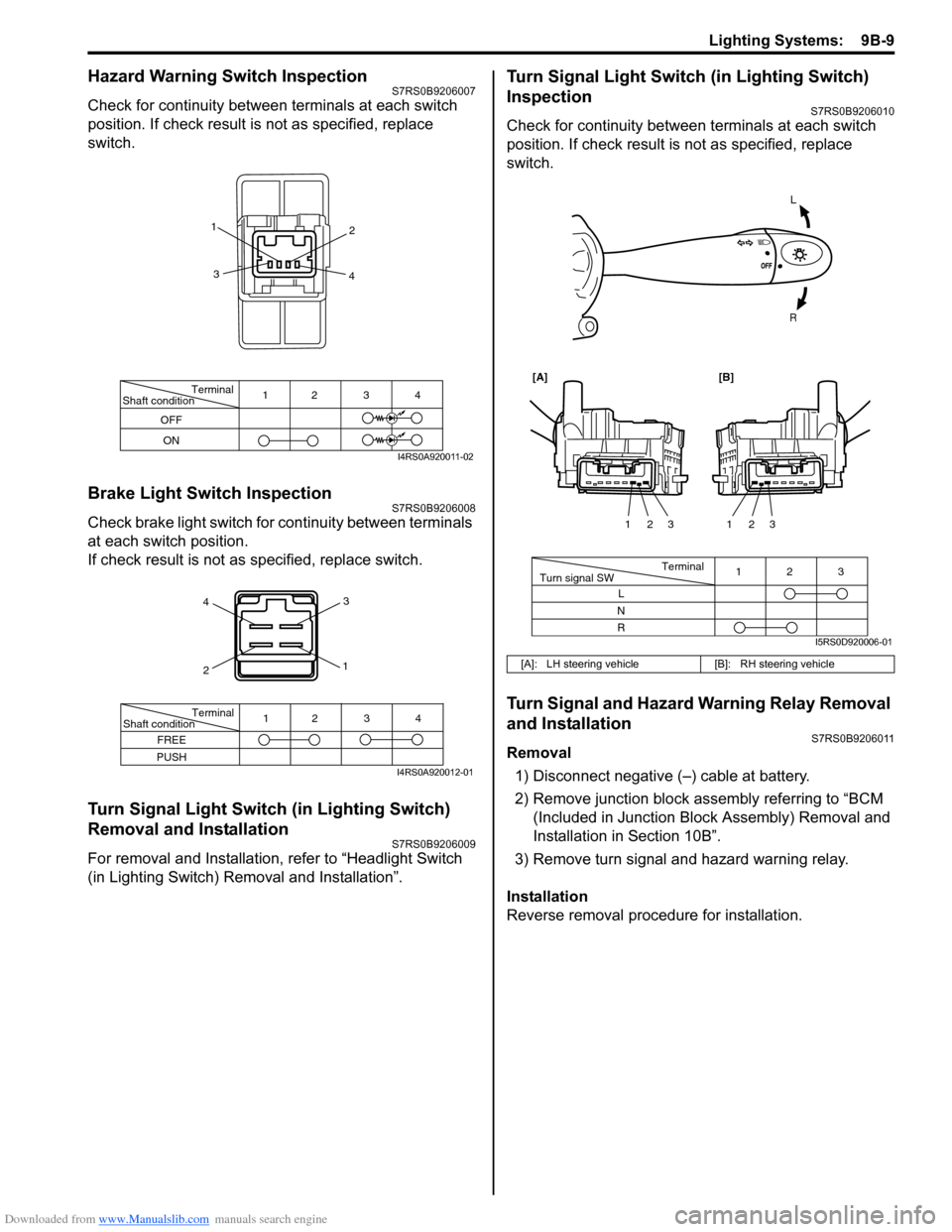

Hazard Warning Switch InspectionS7RS0B9206007

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Brake Light Switch InspectionS7RS0B9206008

Check brake light switch for continuity between terminals

at each switch position.

If check result is not as specified, replace switch.

Turn Signal Light Switch (in Lighting Switch)

Removal and Installation

S7RS0B9206009

For removal and Installation, refer to “Headlight Switch

(in Lighting Switch) Removal and Installation”.

Turn Signal Light Switch (in Lighting Switch)

Inspection

S7RS0B9206010

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Turn Signal and Hazard Warning Relay Removal

and Installation

S7RS0B9206011

Removal

1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Bl ock Assembly) Removal and

Installation in Section 10B”.

3) Remove turn signal and hazard warning relay.

Installation

Reverse removal procedure for installation.

Terminal

Shaft condition

OFF

ON 12 3 4

1

2

3 4

I4RS0A920011-02

4

2 3

1

Terminal

Shaft condition

FREE

PUSH 12 3 4

I4RS0A920012-01

[A]: LH steering vehicle

[B]: RH steering vehicle

L

R

Terminal

Turn signal SW 3

12

L

N

R 123

123

[A][B]

I5RS0D920006-01

Page 1292 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-10 Lighting Systems:

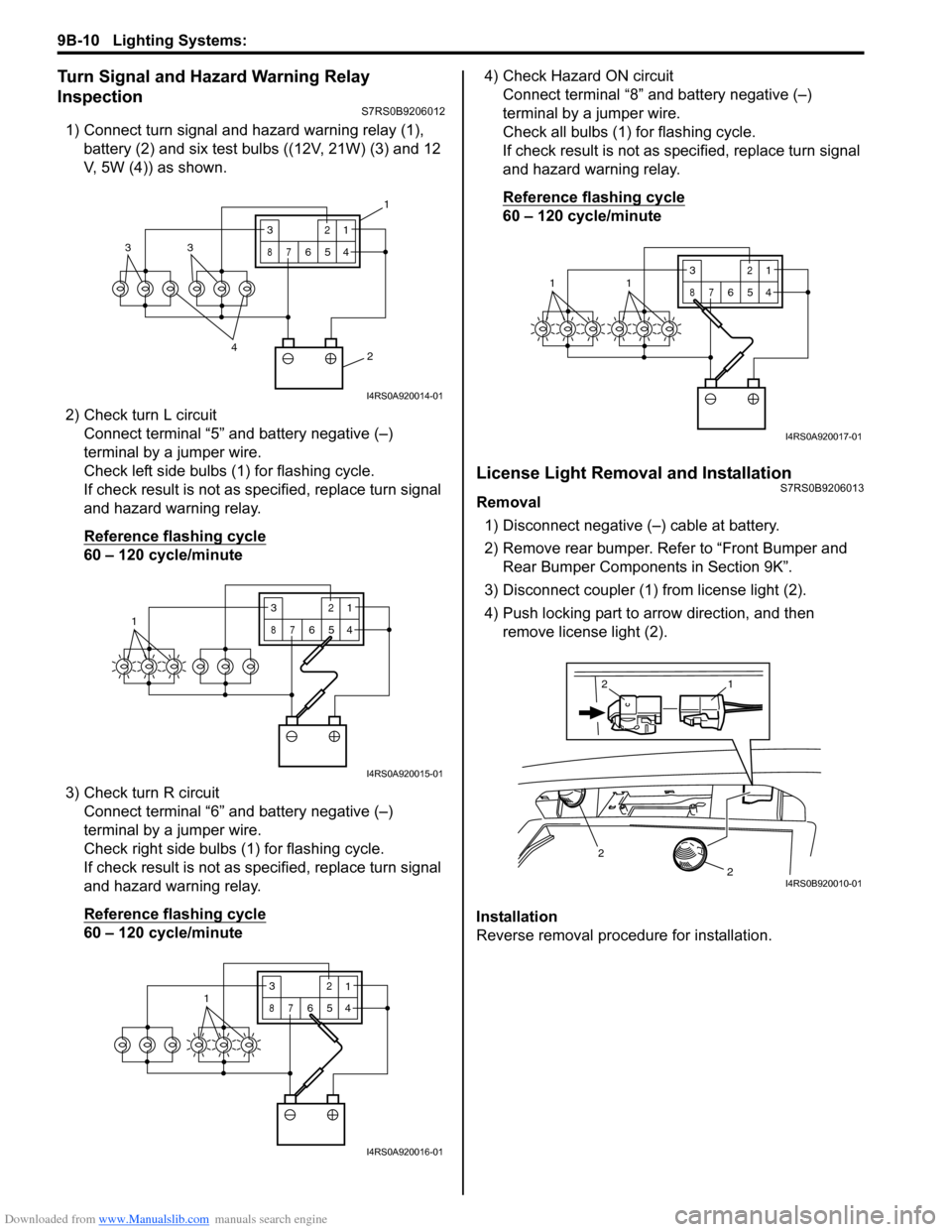

Turn Signal and Hazard Warning Relay

Inspection

S7RS0B9206012

1) Connect turn signal and hazard warning relay (1), battery (2) and six test bulbs ((12V, 21W) (3) and 12

V, 5W (4)) as shown.

2) Check turn L circuit Connect terminal “5” and battery negative (–)

terminal by a jumper wire.

Check left side bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute

3) Check turn R circuit Connect terminal “6” and battery negative (–)

terminal by a jumper wire.

Check right side bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute 4) Check Hazard ON circuit

Connect terminal “8” and battery negative (–)

terminal by a jumper wire.

Check all bulbs (1) for flashing cycle.

If check result is not as sp ecified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute

License Light Removal and InstallationS7RS0B9206013

Removal

1) Disconnect negative (–) cable at battery.

2) Remove rear bumper. Refe r to “Front Bumper and

Rear Bumper Components in Section 9K”.

3) Disconnect coupler (1) from license light (2).

4) Push locking part to arrow direction, and then remove license light (2).

Installation

Reverse removal procedure for installation.

2

4

33

3

87

12

654

1

I4RS0A920014-01

13

87

12

654

I4RS0A920015-01

3

87

12

6541

I4RS0A920016-01

3

87

12

6

5411

I4RS0A920017-01

2

2

1

2

I4RS0B920010-01