check engine SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 280 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-8 Engine Electrical Devices:

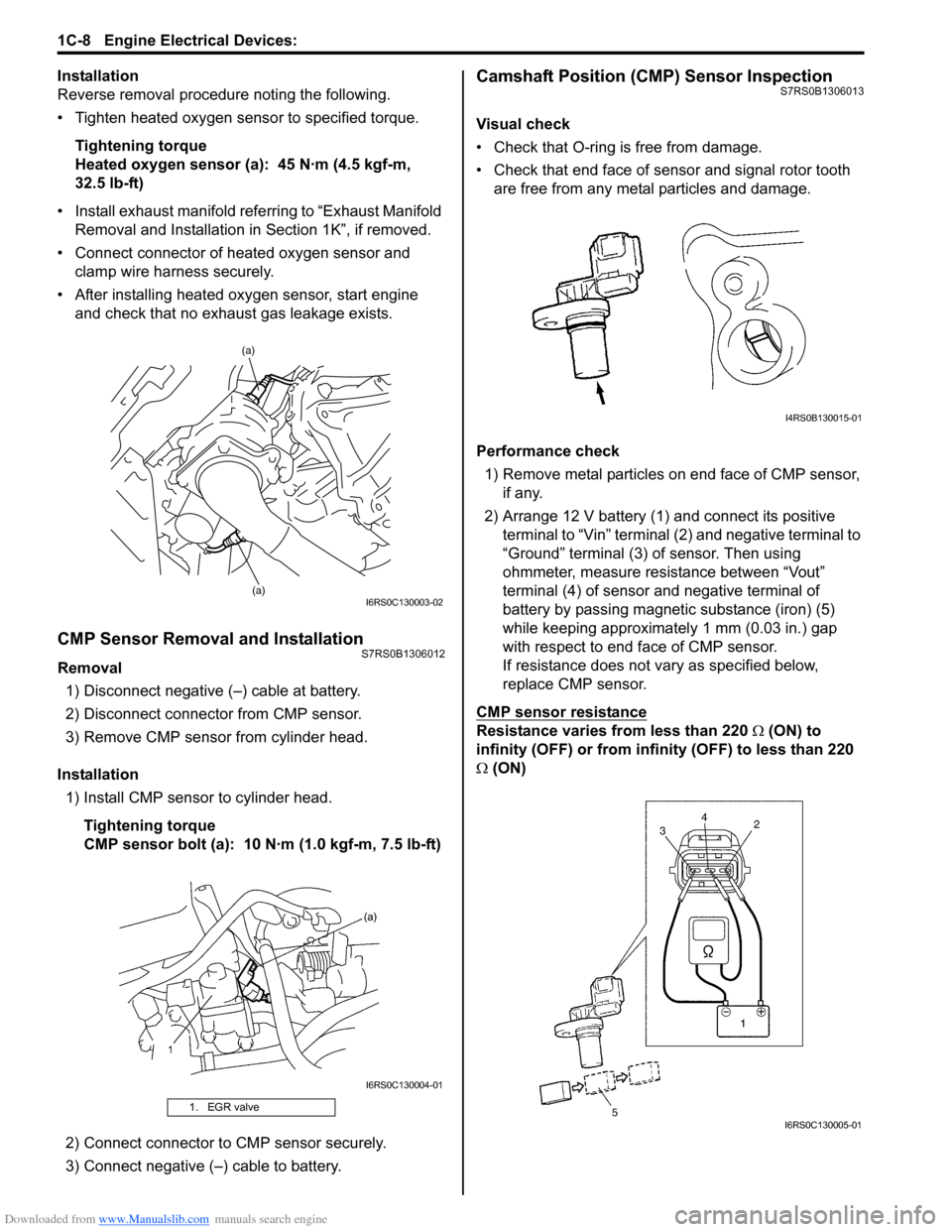

Installation

Reverse removal procedure noting the following.

• Tighten heated oxygen sensor to specified torque.Tightening torque

Heated oxygen sensor (a): 45 N·m (4.5 kgf-m,

32.5 lb-ft)

• Install exhaust manifold referring to “Exhaust Manifold Removal and Installation in Section 1K”, if removed.

• Connect connector of heated oxygen sensor and clamp wire harness securely.

• After installing heated oxygen sensor, start engine and check that no exhaust gas leakage exists.

CMP Sensor Removal and InstallationS7RS0B1306012

Removal

1) Disconnect negative (–) cable at battery.

2) Disconnect connector from CMP sensor.

3) Remove CMP sensor from cylinder head.

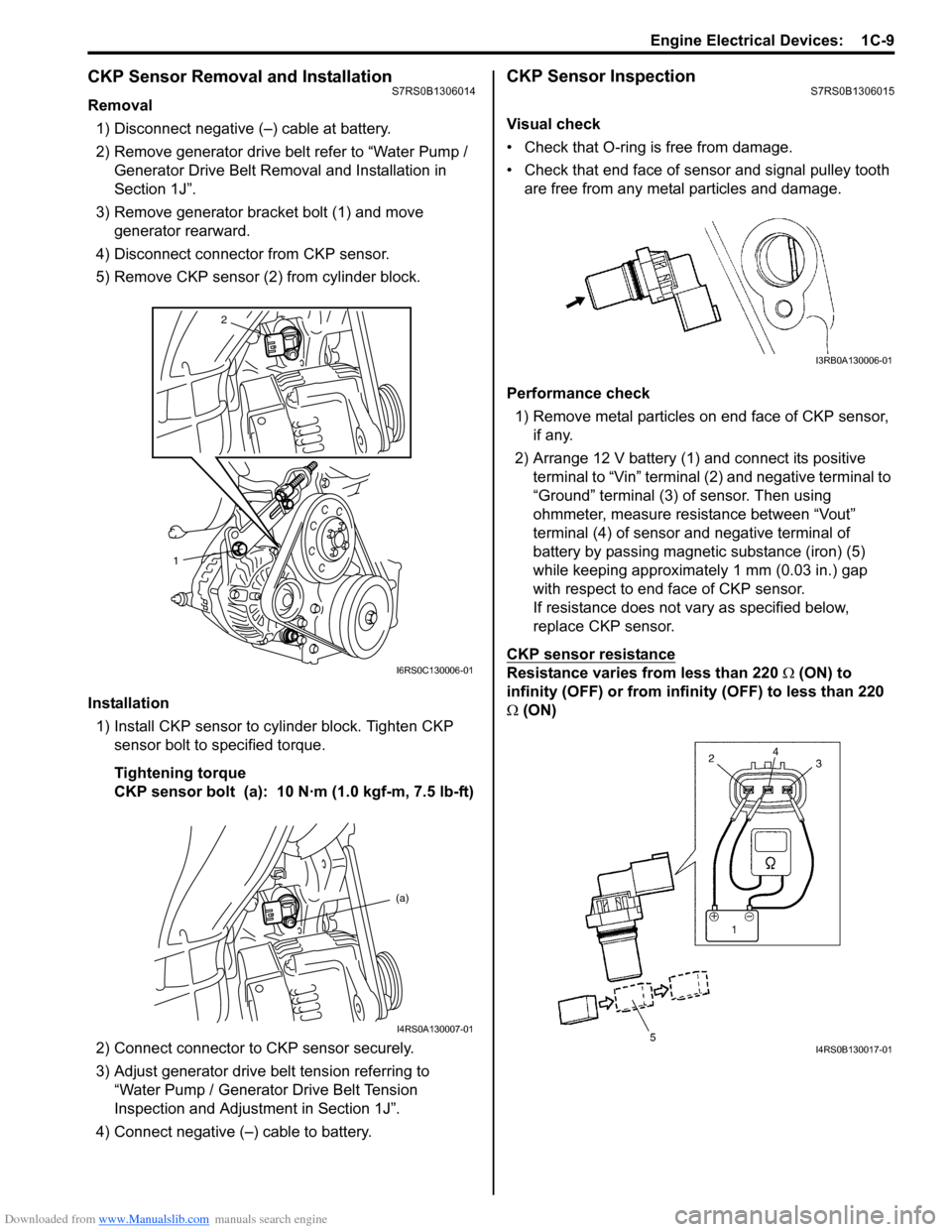

Installation 1) Install CMP sensor to cylinder head.

Tightening torque

CMP sensor bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

2) Connect connector to CMP sensor securely.

3) Connect negative (–) cable to battery.

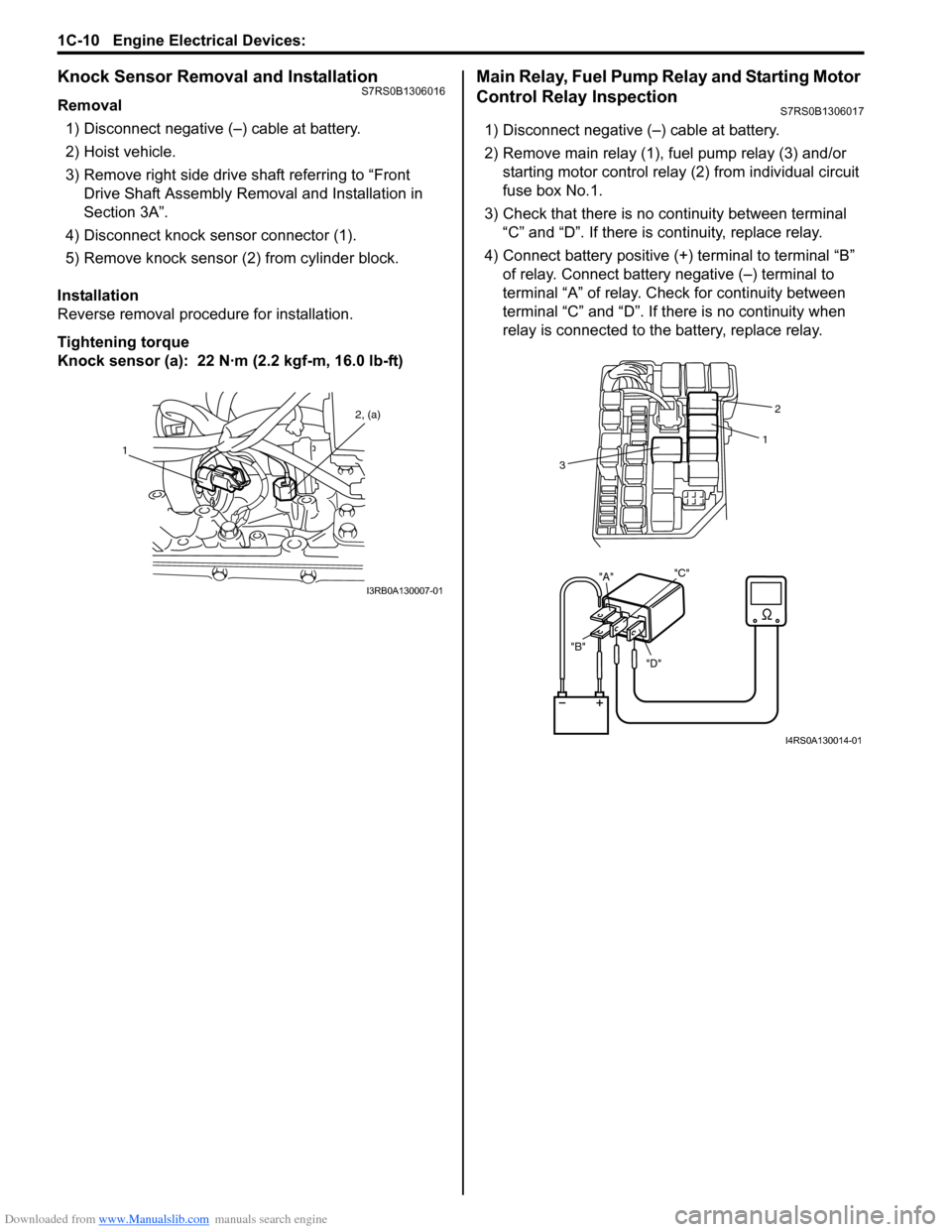

Camshaft Position (CMP) Sensor InspectionS7RS0B1306013

Visual check

• Check that O-ring is free from damage.

• Check that end face of sensor and signal rotor tooth are free from any metal particles and damage.

Performance check 1) Remove metal particles on end face of CMP sensor, if any.

2) Arrange 12 V battery (1) and connect its positive terminal to “Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

ohmmeter, measure resistance between “Vout”

terminal (4) of sensor and negative terminal of

battery by passing magnetic substance (iron) (5)

while keeping approximately 1 mm (0.03 in.) gap

with respect to end face of CMP sensor.

If resistance does not vary as specified below,

replace CMP sensor.

CMP sensor resistance

Resistance varies from less than 220 Ω (ON) to

infinity (OFF) or from infinity (OFF) to less than 220

Ω (ON)

1. EGR valve

(a)

(a)

I6RS0C130003-02

I6RS0C130004-01

I4RS0B130015-01

I6RS0C130005-01

Page 281 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-9

CKP Sensor Removal and InstallationS7RS0B1306014

Removal1) Disconnect negative (–) cable at battery.

2) Remove generator drive belt refer to “Water Pump / Generator Drive Belt Remo val and Installation in

Section 1J”.

3) Remove generator bracket bolt (1) and move generator rearward.

4) Disconnect connector from CKP sensor.

5) Remove CKP sensor (2) from cylinder block.

Installation 1) Install CKP sensor to cylinder block. Tighten CKP sensor bolt to specified torque.

Tightening torque

CKP sensor bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

2) Connect connector to CKP sensor securely.

3) Adjust generator drive belt tension referring to “Water Pump / Generator Drive Belt Tension

Inspection and Adjustment in Section 1J”.

4) Connect negative (–) cable to battery.

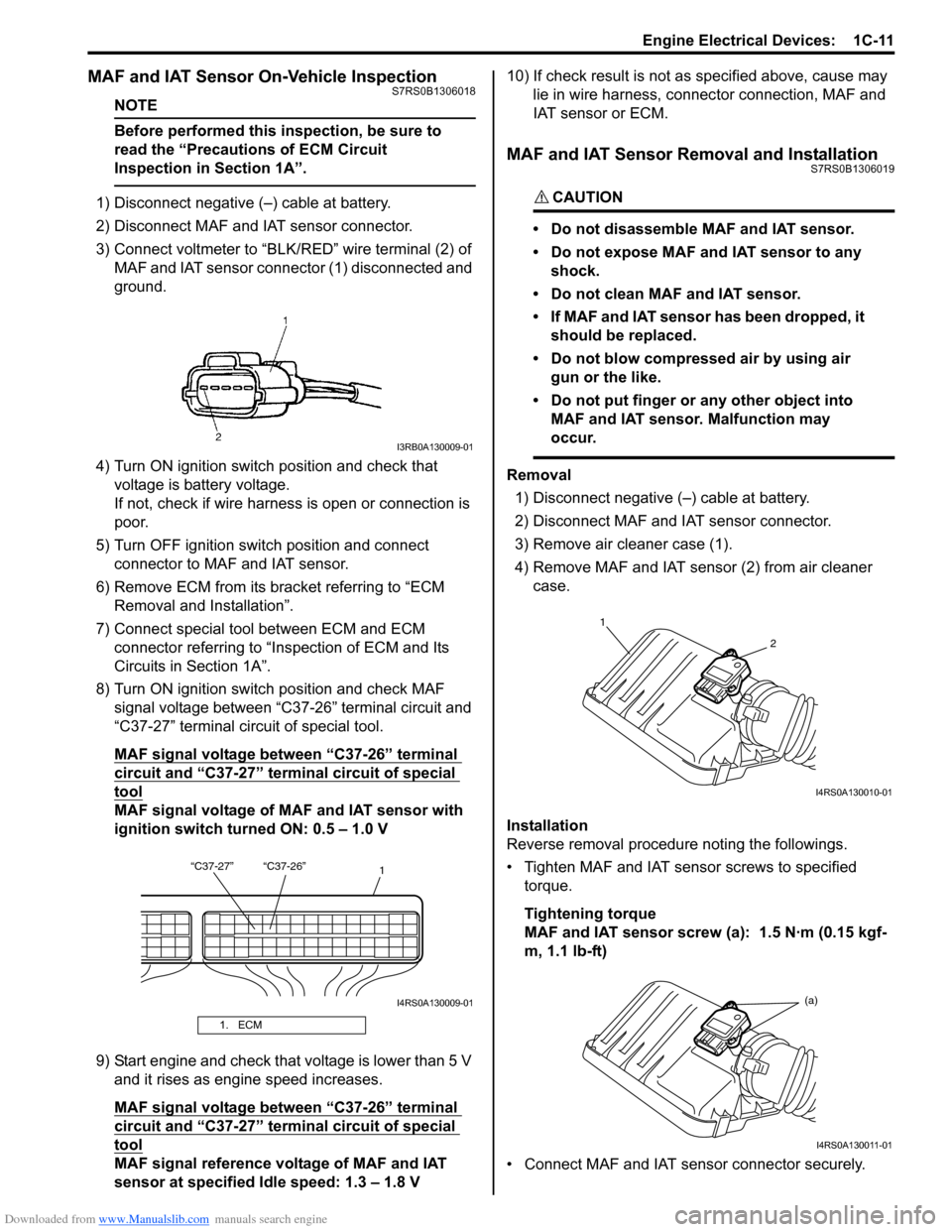

CKP Sensor InspectionS7RS0B1306015

Visual check

• Check that O-ring is free from damage.

• Check that end face of sensor and signal pulley tooth are free from any metal particles and damage.

Performance check 1) Remove metal particles on end face of CKP sensor, if any.

2) Arrange 12 V battery (1) and connect its positive terminal to “Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

ohmmeter, measure resistance between “Vout”

terminal (4) of sensor and negative terminal of

battery by passing magnetic substance (iron) (5)

while keeping approximately 1 mm (0.03 in.) gap

with respect to end face of CKP sensor.

If resistance does not vary as specified below,

replace CKP sensor.

CKP sensor resistance

Resistance varies from less than 220 Ω (ON) to

infinity (OFF) or from infinity (OFF) to less than 220

Ω (ON)

2

1

I6RS0C130006-01

(a)

I4RS0A130007-01

I3RB0A130006-01

I4RS0B130017-01

Page 282 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-10 Engine Electrical Devices:

Knock Sensor Removal and InstallationS7RS0B1306016

Removal1) Disconnect negative (–) cable at battery.

2) Hoist vehicle.

3) Remove right side drive shaft referring to “Front Drive Shaft Assembly Removal and Installation in

Section 3A”.

4) Disconnect knock sensor connector (1).

5) Remove knock sensor (2) from cylinder block.

Installation

Reverse removal procedure for installation.

Tightening torque

Knock sensor (a): 22 N· m (2.2 kgf-m, 16.0 lb-ft)

Main Relay, Fuel Pump Relay and Starting Motor

Control Relay Inspection

S7RS0B1306017

1) Disconnect negative (–) cable at battery.

2) Remove main relay (1), fuel pump relay (3) and/or

starting motor control relay (2) from individual circuit

fuse box No.1.

3) Check that there is no continuity between terminal “C” and “D”. If there is continuity, replace relay.

4) Connect battery positive (+ ) terminal to terminal “B”

of relay. Connect battery negative (–) terminal to

terminal “A” of relay. Ch eck for continuity between

terminal “C” and “D”. If t here is no continuity when

relay is connected to the battery, replace relay.

1 2, (a)

I3RB0A130007-01

"D"

"B" "A"

"C"

2

1

3

I4RS0A130014-01

Page 283 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-11

MAF and IAT Sensor On-Vehicle InspectionS7RS0B1306018

NOTE

Before performed this inspection, be sure to

read the “Precautions of ECM Circuit

Inspection in Section 1A”.

1) Disconnect negative (–) cable at battery.

2) Disconnect MAF and IAT sensor connector.

3) Connect voltmeter to “BLK/RED” wire terminal (2) of

MAF and IAT sensor connector (1) disconnected and

ground.

4) Turn ON ignition switch position and check that voltage is battery voltage.

If not, check if wire harness is open or connection is

poor.

5) Turn OFF ignition switch position and connect connector to MAF and IAT sensor.

6) Remove ECM from its bracket referring to “ECM Removal and Installation”.

7) Connect special tool between ECM and ECM connector referring to “Inspection of ECM and Its

Circuits in Section 1A”.

8) Turn ON ignition switch position and check MAF signal voltage between “C37-26” terminal circuit and

“C37-27” terminal circuit of special tool.

MAF signal voltage between “C37-26” terminal

circuit and “C37-27” termi nal circuit of special

tool

MAF signal voltage of MAF and IAT sensor with

ignition switch turned ON: 0.5 – 1.0 V

9) Start engine and check that voltage is lower than 5 V and it rises as engine speed increases.

MAF signal voltage between “C37-26” terminal

circuit and “C37-27” termi nal circuit of special

tool

MAF signal reference voltage of MAF and IAT

sensor at specified Idle speed: 1.3 – 1.8 V 10) If check result is not as

specified above, cause may

lie in wire harness, connec tor connection, MAF and

IAT sensor or ECM.

MAF and IAT Sensor Removal and InstallationS7RS0B1306019

CAUTION!

• Do not disassemble MAF and IAT sensor.

• Do not expose MAF and IAT sensor to any shock.

• Do not clean MAF and IAT sensor.

• If MAF and IAT sensor has been dropped, it should be replaced.

• Do not blow compressed air by using air gun or the like.

• Do not put finger or any other object into MAF and IAT sensor. Malfunction may

occur.

Removal

1) Disconnect negative (–) cable at battery.

2) Disconnect MAF and IAT sensor connector.

3) Remove air cleaner case (1).

4) Remove MAF and IAT sensor (2) from air cleaner case.

Installation

Reverse removal procedure noting the followings.

• Tighten MAF and IAT sensor screws to specified torque.

Tightening torque

MAF and IAT sensor screw (a): 1.5 N·m (0.15 kgf-

m, 1.1 lb-ft)

• Connect MAF and IAT sensor connector securely.

1. ECM

I3RB0A130009-01

“C37-27” “C37-26” 1

I4RS0A130009-01

1

2

I4RS0A130010-01

(a)

I4RS0A130011-01

Page 284 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-12 Engine Electrical Devices:

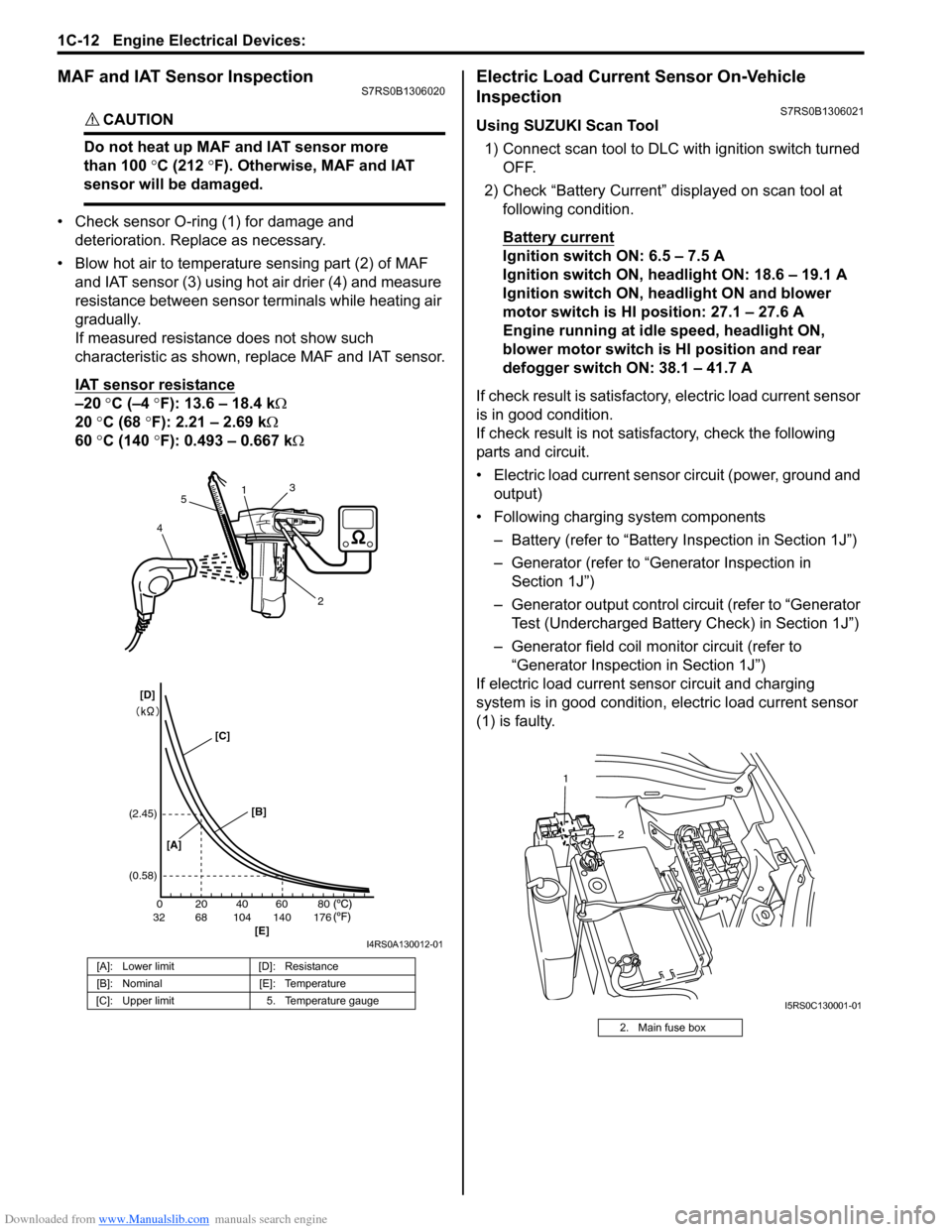

MAF and IAT Sensor InspectionS7RS0B1306020

CAUTION!

Do not heat up MAF and IAT sensor more

than 100 °C (212 °F). Otherwise, MAF and IAT

sensor will be damaged.

• Check sensor O-ring (1) for damage and deterioration. Replace as necessary.

• Blow hot air to temperature sensing part (2) of MAF and IAT sensor (3) using hot air drier (4) and measure

resistance between sensor terminals while heating air

gradually.

If measured resistance does not show such

characteristic as shown, replace MAF and IAT sensor.

IAT sensor resistance

–20 °C (–4 °F): 13.6 – 18.4 k Ω

20 °C (68 °F): 2.21 – 2.69 k Ω

60 °C (140 °F): 0.493 – 0.667 k Ω

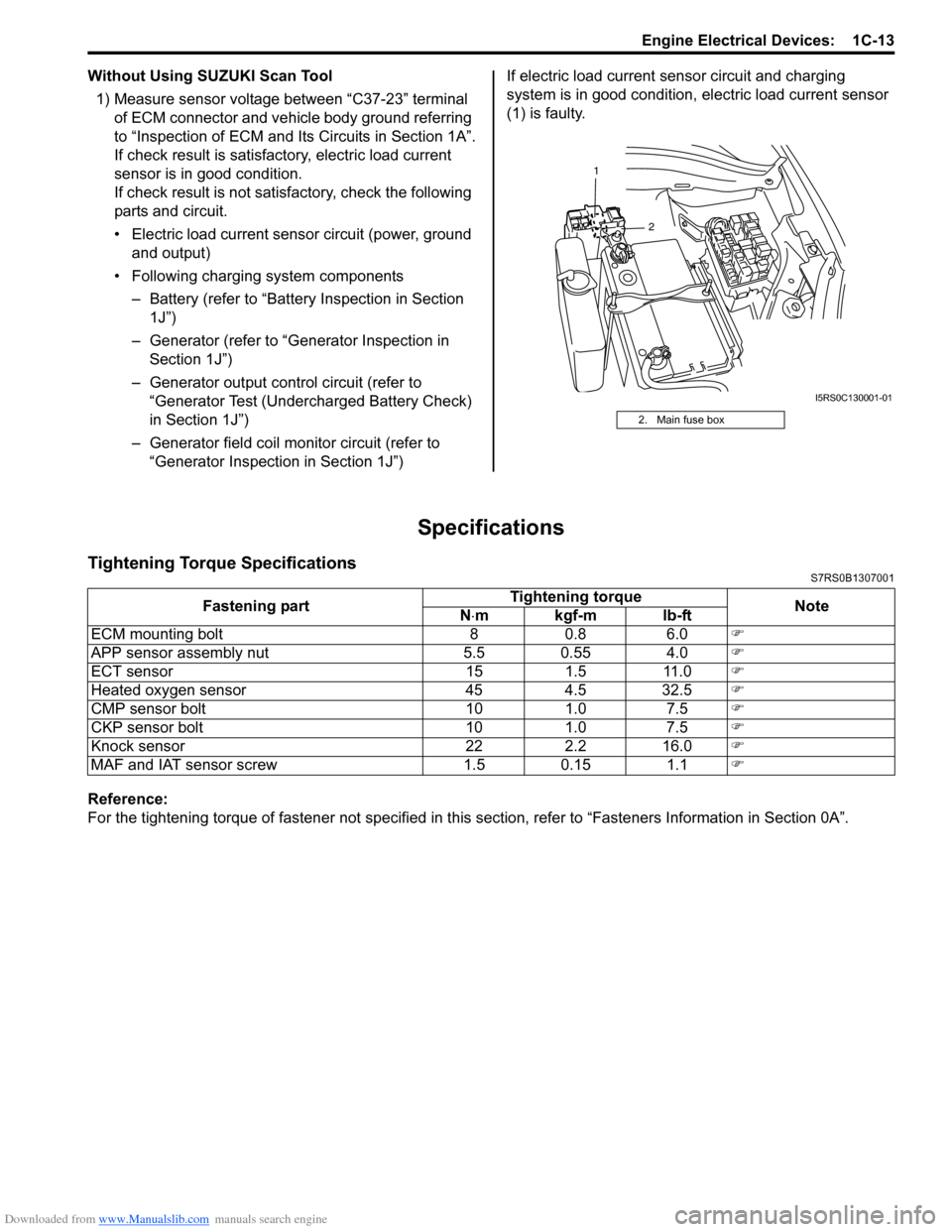

Electric Load Current Sensor On-Vehicle

Inspection

S7RS0B1306021

Using SUZUKI Scan Tool

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Check “Battery Current” displayed on scan tool at following condition.

Battery current

Ignition switch ON: 6.5 – 7.5 A

Ignition switch ON, headlight ON: 18.6 – 19.1 A

Ignition switch ON, headlight ON and blower

motor switch is HI position: 27.1 – 27.6 A

Engine running at idle speed, headlight ON,

blower motor switch is HI position and rear

defogger switch ON: 38.1 – 41.7 A

If check result is satisfactory, electric load current sensor

is in good condition.

If check result is not satisf actory, check the following

parts and circuit.

• Electric load current sensor circuit (power, ground and output)

• Following charging system components

– Battery (refer to “Battery Inspection in Section 1J”)

– Generator (refer to “Generator Inspection in Section 1J”)

– Generator output control ci rcuit (refer to “Generator

Test (Undercharged Battery Check) in Section 1J”)

– Generator field coil monitor circuit (refer to “Generator Inspection in Section 1J”)

If electric load current sensor circuit and charging

system is in good condition, electric load current sensor

(1) is faulty.

[A]: Lower limit [D]: Resistance

[B]: Nominal [E]: Temperature

[C]: Upper limit 5. Temperature gauge

200

6832104 140 17640 60 80

(2.45)

(0.58)

1

2

3

4 5

[A] [B]

[E]

[C]

[D]

I4RS0A130012-01

2. Main fuse box

2

1

I5RS0C130001-01

Page 285 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-13

Without Using SUZUKI Scan Tool1) Measure sensor voltage between “C37-23” terminal of ECM connector and vehicle body ground referring

to “Inspection of ECM and Its Circuits in Section 1A”.

If check result is satisfactory, electric load current

sensor is in good condition.

If check result is not satisfactory, check the following

parts and circuit.

• Electric load current sensor circuit (power, ground and output)

• Following charging system components – Battery (refer to “Battery Inspection in Section

1J”)

– Generator (refer to “Generator Inspection in Section 1J”)

– Generator output control circuit (refer to “Generator Test (Undercharged Battery Check)

in Section 1J”)

– Generator field coil monitor circuit (refer to “Generator Inspection in Section 1J”) If electric load current sensor circuit and charging

system is in good condition,

electric load current sensor

(1) is faulty.

Specifications

Tightening Torque SpecificationsS7RS0B1307001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

2. Main fuse box

2

1

I5RS0C130001-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

ECM mounting bolt 8 0.8 6.0 �)

APP sensor assembly nut 5.5 0.55 4.0 �)

ECT sensor 15 1.5 11.0 �)

Heated oxygen sensor 45 4.5 32.5 �)

CMP sensor bolt 10 1.0 7.5 �)

CKP sensor bolt 10 1.0 7.5 �)

Knock sensor 22 2.2 16.0 �)

MAF and IAT sensor screw 1.5 0.15 1.1 �)

Page 289 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-4

Targeted Timing Varying Operation

Diagnostic Information and Procedures

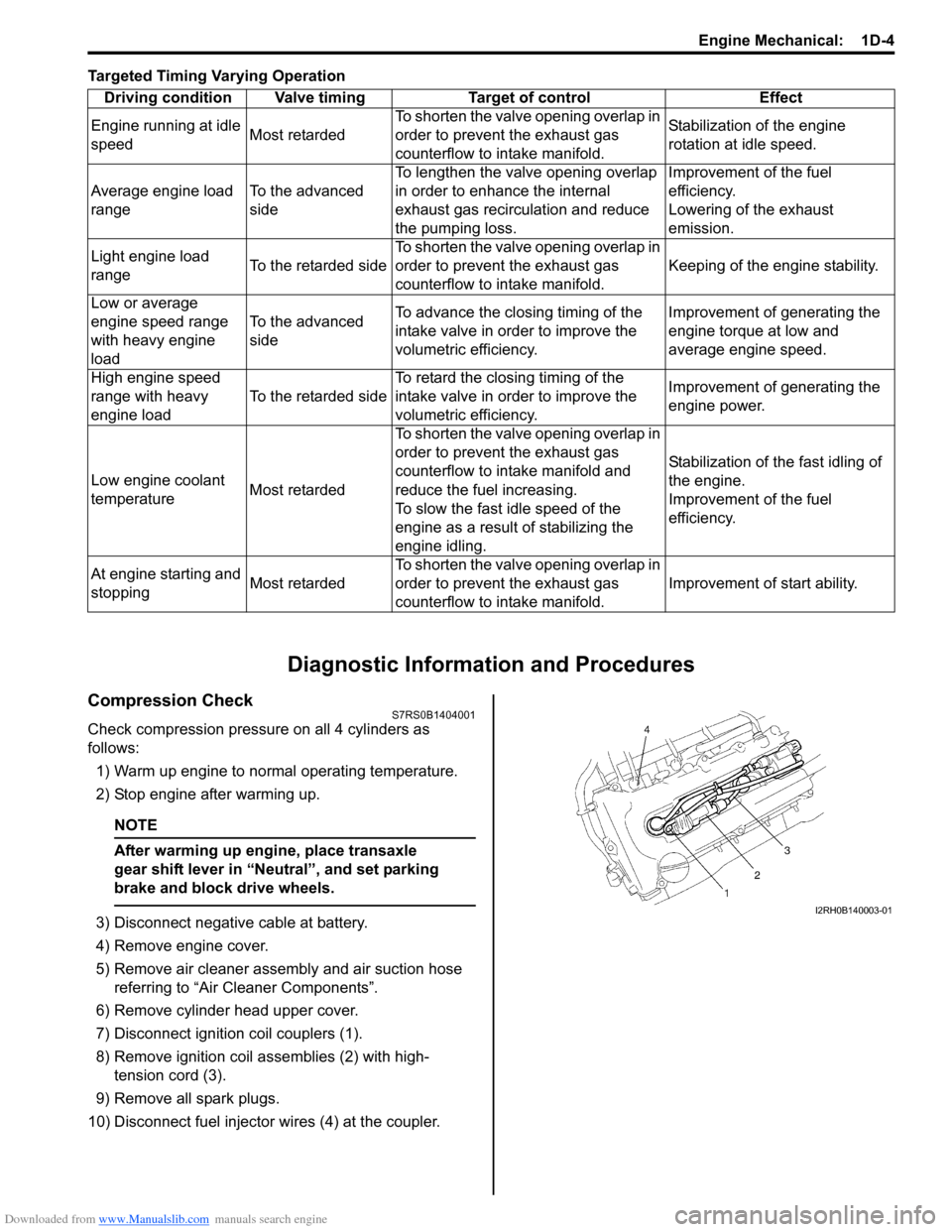

Compression CheckS7RS0B1404001

Check compression pressure on all 4 cylinders as

follows:

1) Warm up engine to normal operating temperature.

2) Stop engine after warming up.

NOTE

After warming up engine, place transaxle

gear shift lever in “Neutral”, and set parking

brake and block drive wheels.

3) Disconnect negative cable at battery.

4) Remove engine cover.

5) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

6) Remove cylinder head upper cover.

7) Disconnect ignition coil couplers (1).

8) Remove ignition coil assemblies (2) with high- tension cord (3).

9) Remove all spark plugs.

10) Disconnect fuel injector wires (4) at the coupler. Driving condition Valve timing Target of control Effect

Engine running at idle

speed Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Stabilization of the engine

rotation at idle speed.

Average engine load

range To the advanced

sideTo lengthen the valve opening overlap

in order to enhance the internal

exhaust gas recirculation and reduce

the pumping loss. Improvement of the fuel

efficiency.

Lowering of the exhaust

emission.

Light engine load

range To the retarded sideTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Keeping of the engine stability.

Low or average

engine speed range

with heavy engine

load To the advanced

side

To advance the closing timing of the

intake valve in order to improve the

volumetric efficiency. Improvement of generating the

engine torque at low and

average engine speed.

High engine speed

range with heavy

engine load To the retarded sideTo retard the closing timing of the

intake valve in order to improve the

volumetric efficiency. Improvement of generating the

engine power.

Low engine coolant

temperature Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold and

reduce the fuel increasing.

To slow the fast idle speed of the

engine as a result of stabilizing the

engine idling. Stabilization of the fast idling of

the engine.

Improvement of the fuel

efficiency.

At engine starting and

stopping Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Improvement of start ability.I2RH0B140003-01

Page 290 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-5 Engine Mechanical:

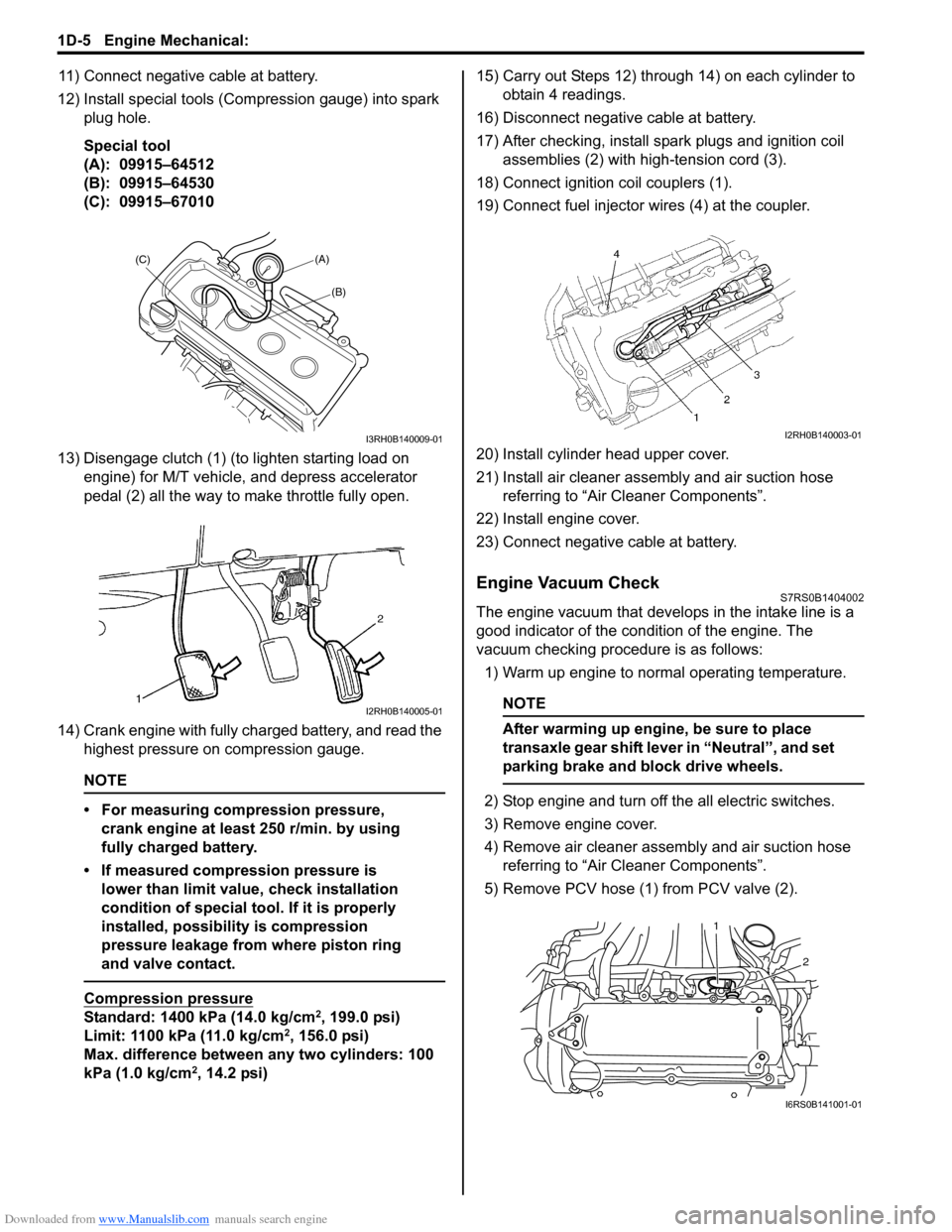

11) Connect negative cable at battery.

12) Install special tools (Compression gauge) into spark plug hole.

Special tool

(A): 09915–64512

(B): 09915–64530

(C): 09915–67010

13) Disengage clutch (1) (to lighten starting load on engine) for M/T vehicle, and depress accelerator

pedal (2) all the way to make throttle fully open.

14) Crank engine with fully charged battery, and read the highest pressure on compression gauge.

NOTE

• For measuring compression pressure, crank engine at least 250 r/min. by using

fully charged battery.

• If measured compression pressure is lower than limit value, check installation

condition of special tool. If it is properly

installed, possibility is compression

pressure leakage from where piston ring

and valve contact.

Compression pressure

Standard: 1400 kPa (14.0 kg/cm2, 199.0 psi)

Limit: 1100 kPa (11.0 kg/cm2, 156.0 psi)

Max. difference between any two cylinders: 100

kPa (1.0 kg/cm

2, 14.2 psi) 15) Carry out Steps 12) through 14) on each cylinder to

obtain 4 readings.

16) Disconnect negative cable at battery.

17) After checking, install spark plugs and ignition coil assemblies (2) with high-tension cord (3).

18) Connect ignition coil couplers (1).

19) Connect fuel injector wires (4) at the coupler.

20) Install cylinder head upper cover.

21) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

22) Install engine cover.

23) Connect negative cable at battery.

Engine Vacuum CheckS7RS0B1404002

The engine vacuum that develops in the intake line is a

good indicator of the condition of the engine. The

vacuum checking procedure is as follows:

1) Warm up engine to normal operating temperature.

NOTE

After warming up engine, be sure to place

transaxle gear shift lever in “Neutral”, and set

parking brake and block drive wheels.

2) Stop engine and turn off the all electric switches.

3) Remove engine cover.

4) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

5) Remove PCV hose (1) from PCV valve (2).

(A)

(C)

(B)

I3RH0B140009-01

I2RH0B140005-01

I2RH0B140003-01

2

1

I6RS0B141001-01

Page 291 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-6

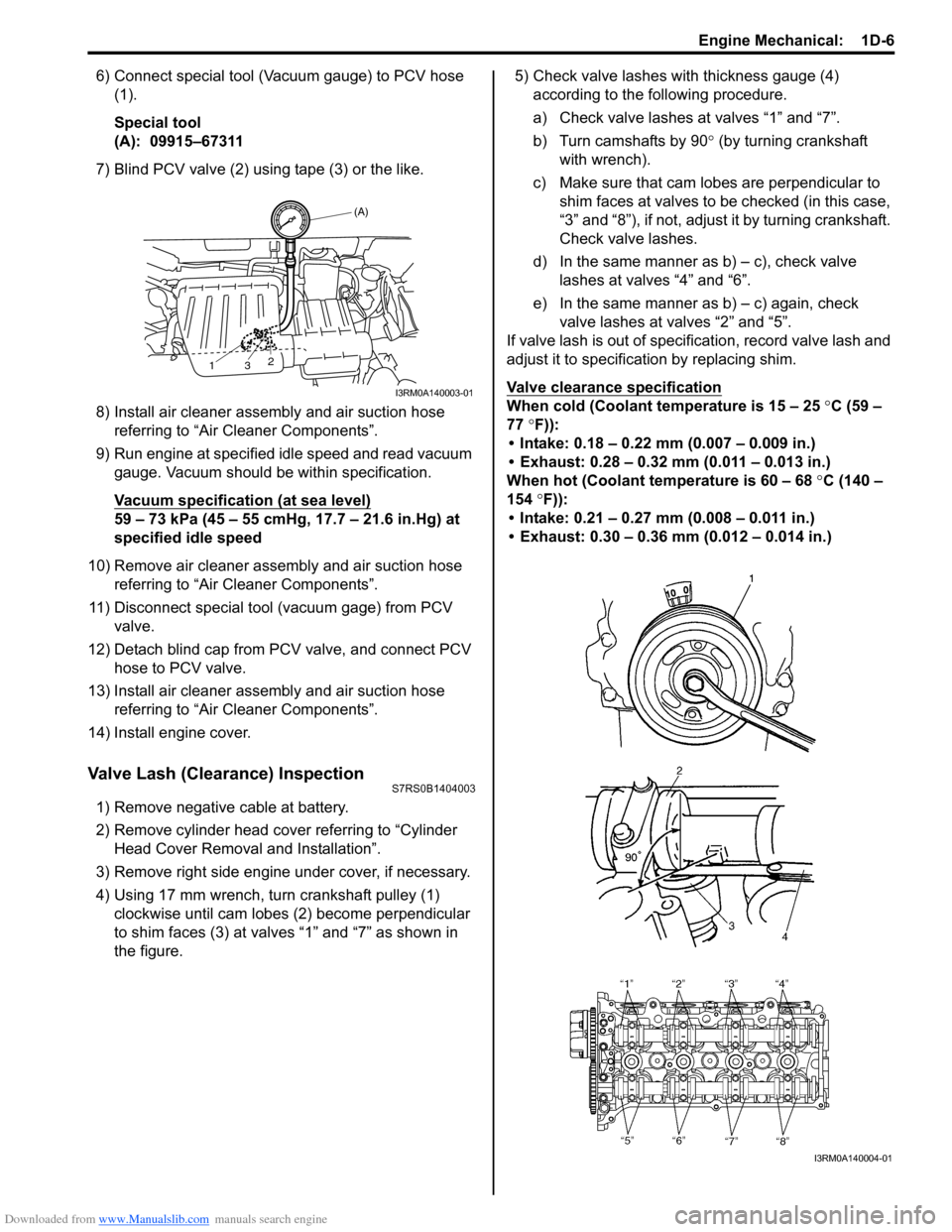

6) Connect special tool (Vacuum gauge) to PCV hose (1).

Special tool

(A): 09915–67311

7) Blind PCV valve (2) using tape (3) or the like.

8) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

9) Run engine at specified idle speed and read vacuum gauge. Vacuum should be within specification.

Vacuum specification (at sea level)

59 – 73 kPa (45 – 55 cmHg, 17.7 – 21.6 in.Hg) at

specified idle speed

10) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

11) Disconnect special tool (vacuum gage) from PCV valve.

12) Detach blind cap from PCV valve, and connect PCV hose to PCV valve.

13) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

14) Install engine cover.

Valve Lash (Clearance) InspectionS7RS0B1404003

1) Remove negative cable at battery.

2) Remove cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

3) Remove right side engine under cover, if necessary.

4) Using 17 mm wrench, turn crankshaft pulley (1) clockwise until cam lobes (2) become perpendicular

to shim faces (3) at valves “1” and “7” as shown in

the figure. 5) Check valve lashes with thickness gauge (4)

according to the following procedure.

a) Check valve lashes at valves “1” and “7”.

b) Turn camshafts by 90 ° (by turning crankshaft

with wrench).

c) Make sure that cam lobes are perpendicular to shim faces at valves to be checked (in this case,

“3” and “8”), if not, adjust it by turning crankshaft.

Check valve lashes.

d) In the same manner as b) – c), check valve

lashes at valves “4” and “6”.

e) In the same manner as b) – c) again, check valve lashes at valves “2” and “5”.

If valve lash is out of specification, record valve lash and

adjust it to specification by replacing shim.

Valve clearance specification

When cold (Coolant te mperature is 15 – 25 °C (59 –

77 °F)):

• Intake: 0.18 – 0.22 mm (0.007 – 0.009 in.)

• Exhaust: 0.28 – 0.32 mm (0.011 – 0.013 in.)

When hot (Coolant temperature is 60 – 68 °C (140 –

154 °F)):

• Intake: 0.21 – 0.27 mm (0.008 – 0.011 in.)

• Exhaust: 0.30 – 0.36 mm (0.012 – 0.014 in.)

(A)

13 2

I3RM0A140003-01

I3RM0A140004-01

Page 292 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-7 Engine Mechanical:

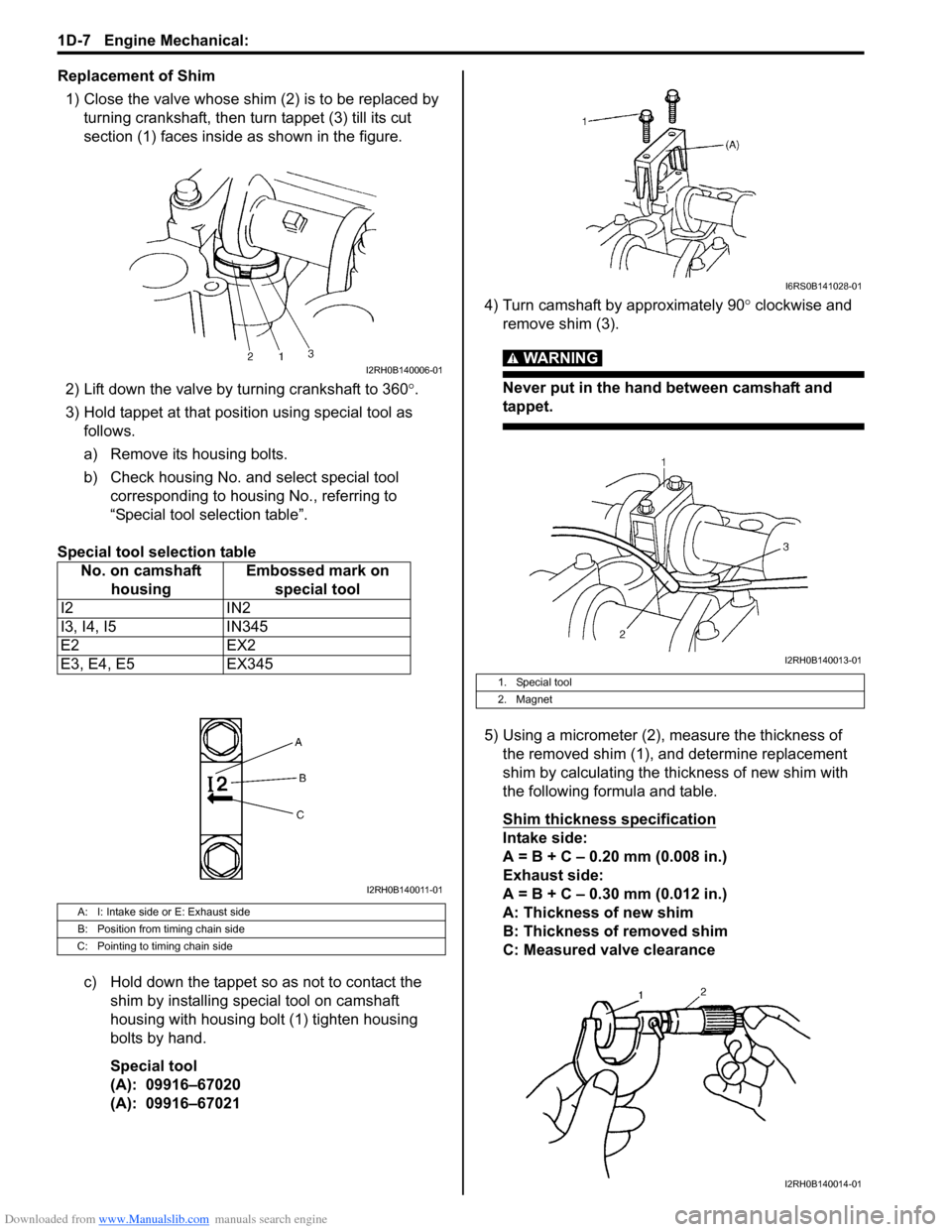

Replacement of Shim1) Close the valve whose shim (2) is to be replaced by turning crankshaft, then tu rn tappet (3) till its cut

section (1) faces inside as shown in the figure.

2) Lift down the valve by turning crankshaft to 360° .

3) Hold tappet at that position using special tool as follows.

a) Remove its housing bolts.

b) Check housing No. and select special tool corresponding to housing No., referring to

“Special tool selection table”.

Special tool selection table

c) Hold down the tappet so as not to contact the shim by installing special tool on camshaft

housing with housing bolt (1) tighten housing

bolts by hand.

Special tool

(A): 09916–67020

(A): 09916–67021 4) Turn camshaft by approximately 90

° clockwise and

remove shim (3).

WARNING!

Never put in the hand between camshaft and

tappet.

5) Using a micrometer (2), measure the thickness of the removed shim (1), and determine replacement

shim by calculating the thickness of new shim with

the following formula and table.

Shim thickness specification

Intake side:

A = B + C – 0.20 mm (0.008 in.)

Exhaust side:

A = B + C – 0.30 mm (0.012 in.)

A: Thickness of new shim

B: Thickness of removed shim

C: Measured valve clearance

No. on camshaft

housing Embossed mark on

special tool

I2 IN2

I3, I4, I5 IN345

E2 EX2

E3, E4, E5 EX345

A: I: Intake side or E: Exhaust side

B: Position from timing chain side

C: Pointing to timing chain side

I2RH0B140006-01

I2RH0B140011-01

1. Special tool

2. Magnet

I6RS0B141028-01

I2RH0B140013-01

I2RH0B140014-01