ground SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 982 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-34 Air Conditioning System: Automatic Type

Automatic Type

Precautions

A/C System CautionS7RS0B7220001

Refer to “A/C System Caution”.

Precautions in Diagnosing TroubleS7RS0B7220002

• Do not disconnect couplers from HVAC control module, battery cable from battery, HVAC control module ground

wire harness from body or main fuse before confirming diagnostic information (diagnostic trouble code) stored in

HVAC control module memory.

• Diagnostic information (diagnostic trouble code) stored in HVAC control module can be checked by display of HVAC

control module. Also, it can be checked by using SU ZUKI scan tool. Before checking diagnostic information

(diagnostic trouble code), read this manual and operator's manual for SUZUKI scan tool to know how to read

diagnostic information (diagnostic trouble code).

• When trouble is diagnosed using diagnostic information (diagnostic trouble code) on display of HVAC control

module, keep in your mind that each diagnostic inform ation (diagnostic trouble code) has priority, and only

diagnostic information (diagnostic troub le code) which has the highest priority is indicated. Therefore, after

troubleshooting the malfunction, make sure if there exists any other diagnostic information (diagnostic trouble

code).

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

Precautions on Servicing A/C SystemS7RS0B7220003

Refer to “Precautions on Servicing A/C System”.

General Description

Auto A/C System DescriptionS7RS0B7221001

The automatic type air conditioning system (auto A/C) is pr ovided with the function to automatically control the inside

air temperature, fan speed, air flow outl et direction and air intake position by HVAC control module in addition to

functions of the manual type air conditioning system (manua l A/C). Once the inside air temperature is set using the

temperature selector, HVAC control module automatically controls the inside air temperature at the constant level at all

times based on the inside air temperature, outside ai r temperature, amount of sunlight and engine coolant

temperature detected respectively by the inside air te mperature sensor, outside air temperature sensor, sunload

sensor and ECT sensor. At this time, “FULL AUTO A/ C” appears on the display of HVAC control module.

With the air intake selector pushed in the above state, it is possible to select any position of the air intake actuator.

Then, “FULL AUTO A/C” on the display changes to “AUTO A/C”.

Page 987 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-39

Diagnostic Information and Procedures

A/C System Symptom DiagnosisS7RS0B7224001

4. Rear defogger relay 15. Evaporator temperature sensor 26. Radiator cooling fan relay No.1 37. Rear defogger switch

5. Rear defogger 16. Sunload sensor 27. Radiator cooling fan relay No.2 38. To BCM

6. Blower motor relay 17. Junction block assembly 28. Radiator cooling fan relay No.3 39. To ECM

7. Blower motor 18. ECM 29. Information display 40. To main relay

8. Blower motor controller 19. ECT sensor 30. Lighting switch 41. To main fuse

9. DLC 20. Radiator cooling fan motor 31. A/C switch 42. Back-light

10. Air intake actuator 21. Compressor relay 32. MODE (air flow) selector 43. Defroster indicator 11. Air flow control actuator 22. Compressor 33. Air intake selector 44. Rear defogger indicator

Condition Possible cause Correction / Reference Item

No cool air comes out (A/

C system does not

operate) No refrigerant

Perform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blown Check related fuses, and then check for short

circuit to ground.

A/C switch faulty Check A/C switch referring to “Inspection of

HVAC Control Module and Its Circuit”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

A/C refrigerant pressure sensor faulty Check A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faulty Repair as necessary.

ECT sensor faulty Check ECT sensor referring to “ECT Sensor

Inspection in Section 1C”.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Compressor relay faulty Check compressor relay referring to

“Compressor Relay Inspection”.

Temperature selector, blower speed

selector, and/or air flow selector faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

BCM faulty Check BCM referring to “Inspection of BCM

and its Circuits in Section 10B”.

Page 988 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-40 Air Conditioning System: Automatic Type

No cool air comes out

(radiator cooling fan

motor does not operate)Fuse blown

Check related fuses, and then check for short

circuit to ground.

Wiring or grounding faulty Repair as necessary.

Radiator cooling fan motor relay faulty Check radiator cooling fan motor relay

referring to “Radiator Cooling Fan Relay

Inspection in Section 1F”.

Radiator cooling fan motor faulty Check radiator cooling fan motor referring to

“Radiator Cooling Fan Motor On-Vehicle

Inspection in Section 1F”.

ECM faulty Check ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

No cool air comes out

(blower motor does not

operate) Fuse blown

Check related fuses, and then check for short

circuit to ground.

Blower motor controller faulty Check blower motor controller referring to

“Blower Motor Controller Inspection”.

Blower speed selector faulty Check blower speed selector referring to

“Inspection of HVAC Control Module and Its

Circuit”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Wiring or grounding faulty Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Blower motor relay faulty Check blower motor relay referring to “Blower

Motor Relay Inspection in Section 7A”.

Condition Possible cause Correction / Reference Item

Page 990 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-42 Air Conditioning System: Automatic Type

Abnormal Noise Symptom Diagnosis of A/C

System

S7RS0B7224002

Refer to “Abnormal Noise Symptom Diagnosis of A/C

System”.

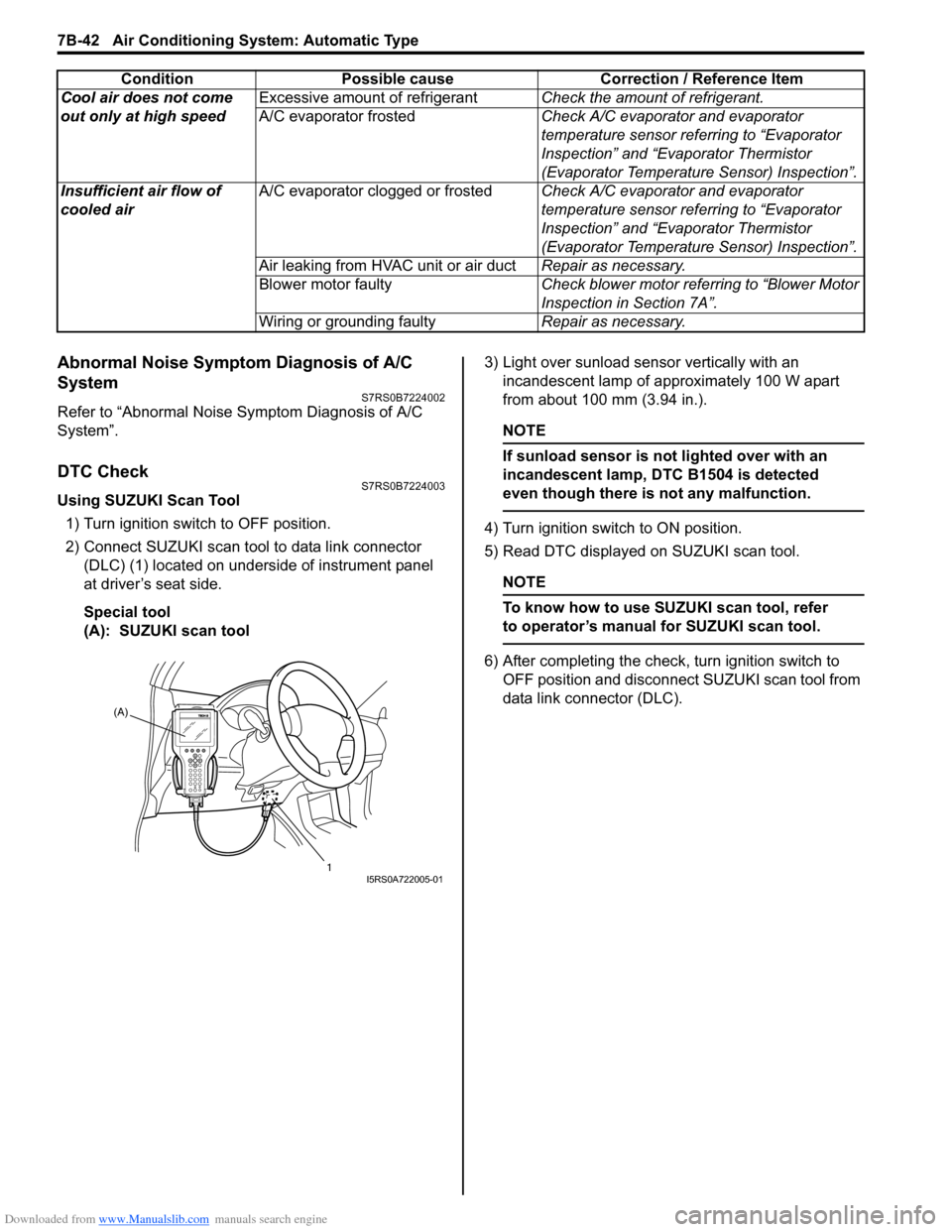

DTC CheckS7RS0B7224003

Using SUZUKI Scan Tool1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool 3) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W apart

from about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

even though there is not any malfunction.

4) Turn ignition switch to ON position.

5) Read DTC displayed on SUZUKI scan tool.

NOTE

To know how to use SUZUKI scan tool, refer

to operator’s manual for SUZUKI scan tool.

6) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

data link connector (DLC).

Cool air does not come

out only at high speed

Excessive amount of refrigerant

Check the amount of refrigerant.

A/C evaporator frosted Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Insufficient air flow of

cooled air A/C evaporator clogged or frosted

Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Air leaking from HVAC unit or air duct Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faulty Repair as necessary.

Condition Possible cause Correction / Reference Item

(A)

1

I5RS0A722005-01

Page 997 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-49

Step 7. Final confirmation test

Confirm if the problem symptom is troubleshoot and the A/C system is free from any abnormal conditions. If there

existed DTC, clear the DTC. Then , check if the DTC is still detected and if there is any other DTC.

Visual InspectionS7RS0B7224009

Check visually the following parts and systems.

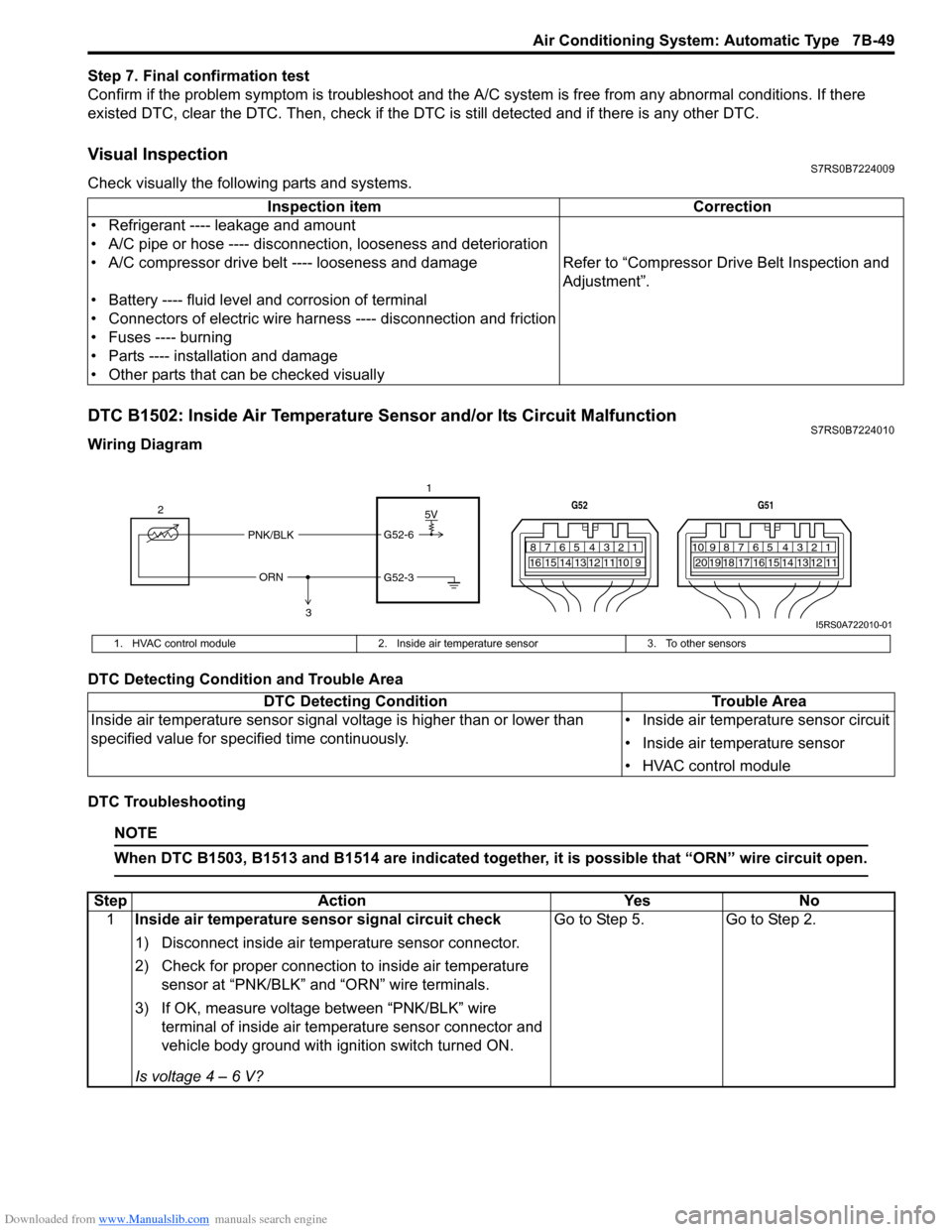

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224010

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1503, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

Inspection item Correction

• Refrigerant ---- leakage and amount

• A/C pipe or hose ---- disconnection, looseness and deterioration

• A/C compressor drive belt ---- looseness and damage Refer to “Compressor Drive Belt Inspection and

Adjustment”.

• Battery ---- fluid level and corrosion of terminal

• Connectors of electric wire harn ess ---- disconnection and friction

• Fuses ---- burning

• Parts ---- installation and damage

• Other parts that can be checked visually

5V

PNK/BLK

ORN G52-6

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722010-01

1. HVAC control module

2. Inside air temperature sensor 3. To other sensors

DTC Detecting Condition Trouble Area

Inside air temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Inside air temperature sensor circuit

• Inside air temperature sensor

• HVAC control module

Step

Action YesNo

1 Inside air temperature sensor signal circuit check

1) Disconnect inside air temperature sensor connector.

2) Check for proper connection to inside air temperature

sensor at “PNK/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

Page 998 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-50 Air Conditioning System: Automatic Type

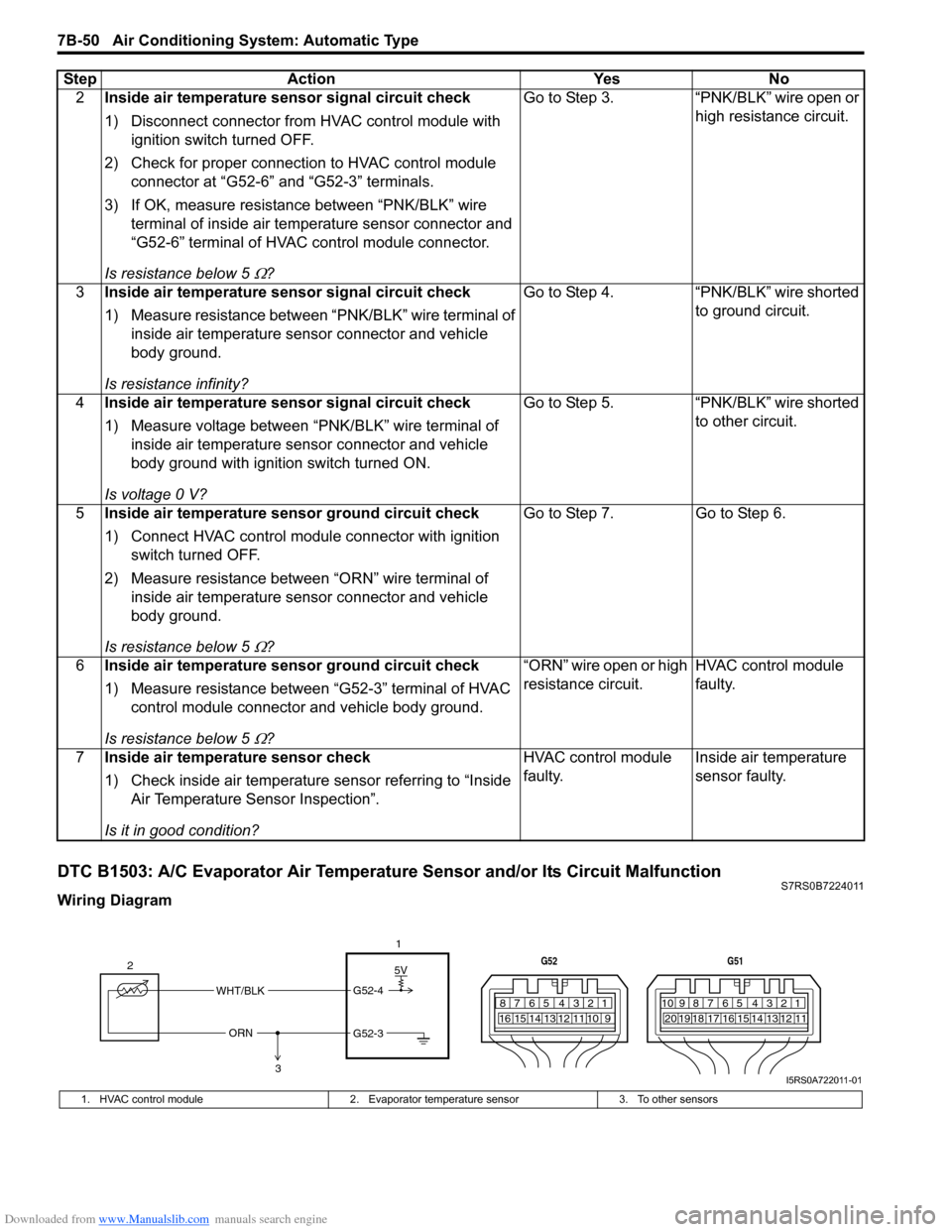

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224011

Wiring Diagram2

Inside air temperature sensor signal circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-6” and “G52-3” terminals.

3) If OK, measure resistance between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

“G52-6” terminal of HVAC control module connector.

Is resistance below 5

Ω? Go to Step 3. “PNK/BLK” wire open or

high resistance circuit.

3 Inside air temperature sensor signal circuit check

1) Measure resistance between “PNK/BLK” wire terminal of

inside air temperature sensor connector and vehicle

body ground.

Is resistance infinity? Go to Step 4.

“PNK/BLK” wire shorted

to ground circuit.

4 Inside air temperature sensor signal circuit check

1) Measure voltage between “PNK/BLK” wire terminal of

inside air temperature sensor connector and vehicle

body ground with ignition switch turned ON.

Is voltage 0 V? Go to Step 5.

“PNK/BLK” wire shorted

to other circuit.

5 Inside air temperature sensor ground circuit check

1) Connect HVAC control module connector with ignition

switch turned OFF.

2) Measure resistance between “ORN” wire terminal of inside air temperature sensor connector and vehicle

body ground.

Is resistance below 5

Ω? Go to Step 7. Go to Step 6.

6 Inside air temperature sensor ground circuit check

1) Measure resistance between “G52-3” terminal of HVAC

control module connector and vehicle body ground.

Is resistance below 5

Ω? “ORN” wire open or high

resistance circuit.

HVAC control module

faulty.

7 Inside air temperature sensor check

1) Check inside air temperature sensor referring to “Inside

Air Temperature Sensor Inspection”.

Is it in good condition? HVAC control module

faulty.

Inside air temperature

sensor faulty.

Step Action Yes No

5V

WHT/BLK

ORN G52-4

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722011-01

1. HVAC control module

2. Evaporator temperature sensor 3. To other sensors

Page 999 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-51

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1502, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

DTC Detecting ConditionTrouble Area

Evaporator temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Evaporator temperature sensor

circuit

• Evaporator temperature sensor

• HVAC control module

Step Action YesNo

1 Evaporator temperature sensor signal circuit check

1) Disconnect evaporator temperature sensor connector.

2) Check for proper connection to evaporator temperature

sensor at “WHT/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “WHT/BLK” wire terminal of evaporator te mperature sensor connector

and vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

2 Evaporator temperature sensor signal circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-4” and “G52-3” terminals.

3) If OK, measure resistance between “WHT/BLK” wire terminal of evaporator te mperature sensor connector

and “G52-4” terminal of HVAC control module connector.

Is resistance below 5

Ω? Go to Step 3. “WHT/BLK” wire open

or high resistance

circuit.

3 Evaporator temperature sensor signal circuit check

1) Measure resistance between “WHT/BLK” wire terminal

of evaporator temperature sensor connector and vehicle

body ground.

Is resistance infinity? Go to Step 4. “WHT/BLK” wire

shorted to ground

circuit.

4 Evaporator temperature sensor signal circuit check

1) Measure voltage between “WHT/BLK” wire terminal of

evaporator temperature sens or connector and vehicle

body ground with ignition switch turned ON.

Is voltage 0 V? Go to Step 5. “WHT/BLK” wire

shorted to other circuit.

5 Evaporator temperature sensor ground circuit check

1) Connect HVAC control module connector with ignition

switch turned OFF.

2) Measure resistance between “ORN” wire terminal of evaporator temperature sens or connector and vehicle

body ground.

Is resistance below 5

Ω? Go to Step 7. Go to Step 6.

6 Evaporator temperature sensor ground circuit check

1) Measure resistance between “G52-3” terminal of HVAC

control module connector and vehicle body ground.

Is resistance below 5

Ω? “ORN” wire open or high

resistance circuit.

HVAC control module

faulty.

Page 1000 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-52 Air Conditioning System: Automatic Type

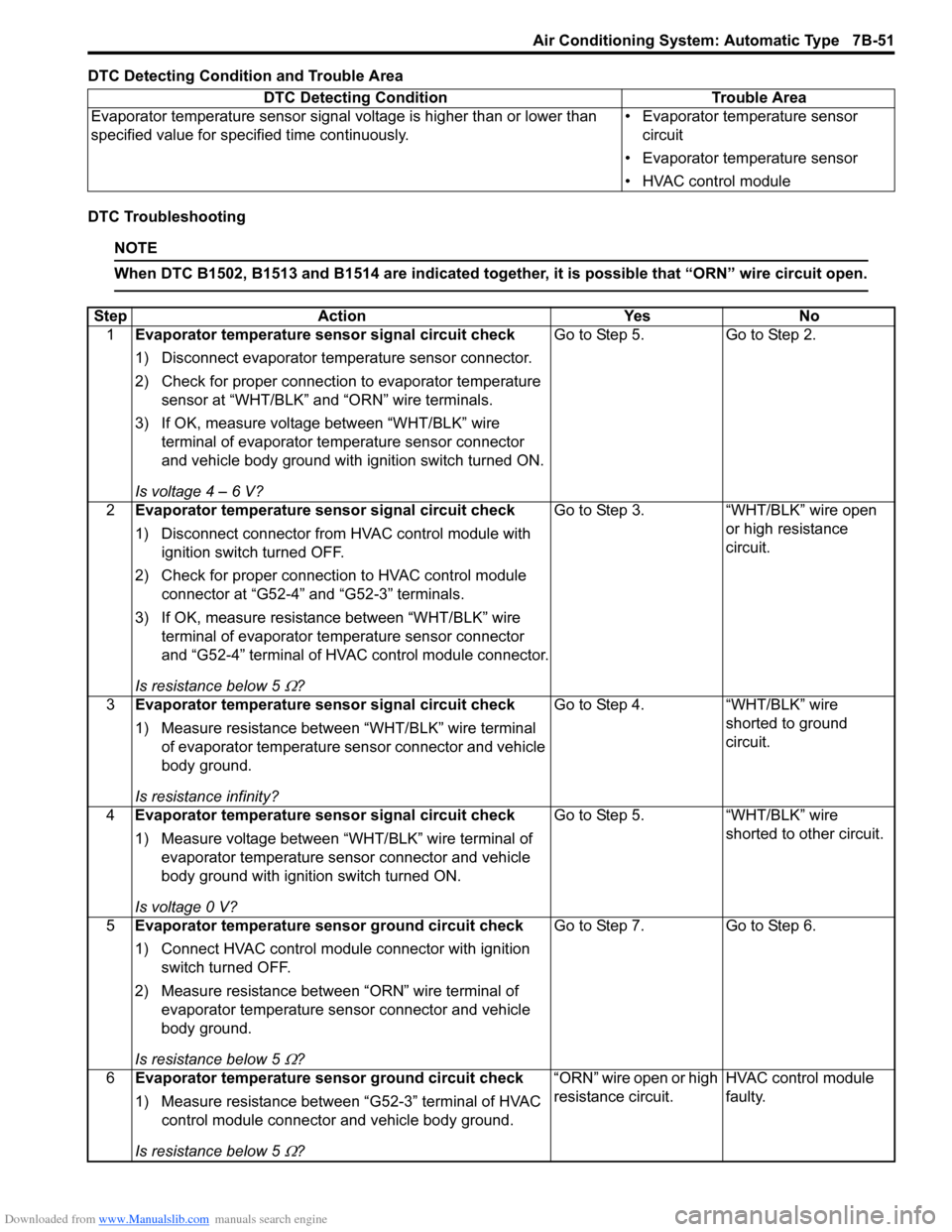

DTC B1504: Sunload Sensor and/or Its Circuit MalfunctionS7RS0B7224012

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting7

Evaporator temperature sensor check

1) Check evaporator temperature sensor referring to

“Evaporator Thermistor (Evaporator Temperature

Sensor) Inspection”.

Is it in good condition? HVAC control module

faulty.

Evaporator temperature

sensor faulty.

Step Action Yes No

5V

PNK G52-2

G52-5

YEL/BLK

2

1

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722012-01

1. HVAC control module

2. Sunload sensor

DTC Detecting Condition Trouble Area

Sunload sensor signal voltage is higher than or lower than specified value for

specified time continuously. • Sunload sensor circuit

• Sunload sensor

• HVAC control module

Step

Action YesNo

1 Sunload sensor power supply circuit check

1) Disconnect sunload sensor connector.

2) Check for proper connection to sunload sensor at “PNK”

and “YEL/BLK” wire terminals.

3) If OK, measure voltage between “PNK” wire terminal of sunload sensor connector and vehicle body ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

2 Sunload sensor power supply circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-2” and “G52-5” terminals.

3) If OK, measure resistance between “PNK” wire terminal of sunload sensor connector and “G52-2” terminal of

HVAC control module connector.

Is resistance below 5

Ω? Go to Step 3. “PNK” wire open or high

resistance circuit.

3 Sunload sensor power supply circuit check

1) Measure resistance between “PNK” wire terminal of

sunload sensor connector and vehicle body ground.

Is resistance infinity? Go to Step 4. “PNK” wire shorted to

ground circuit.

Page 1001 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-53

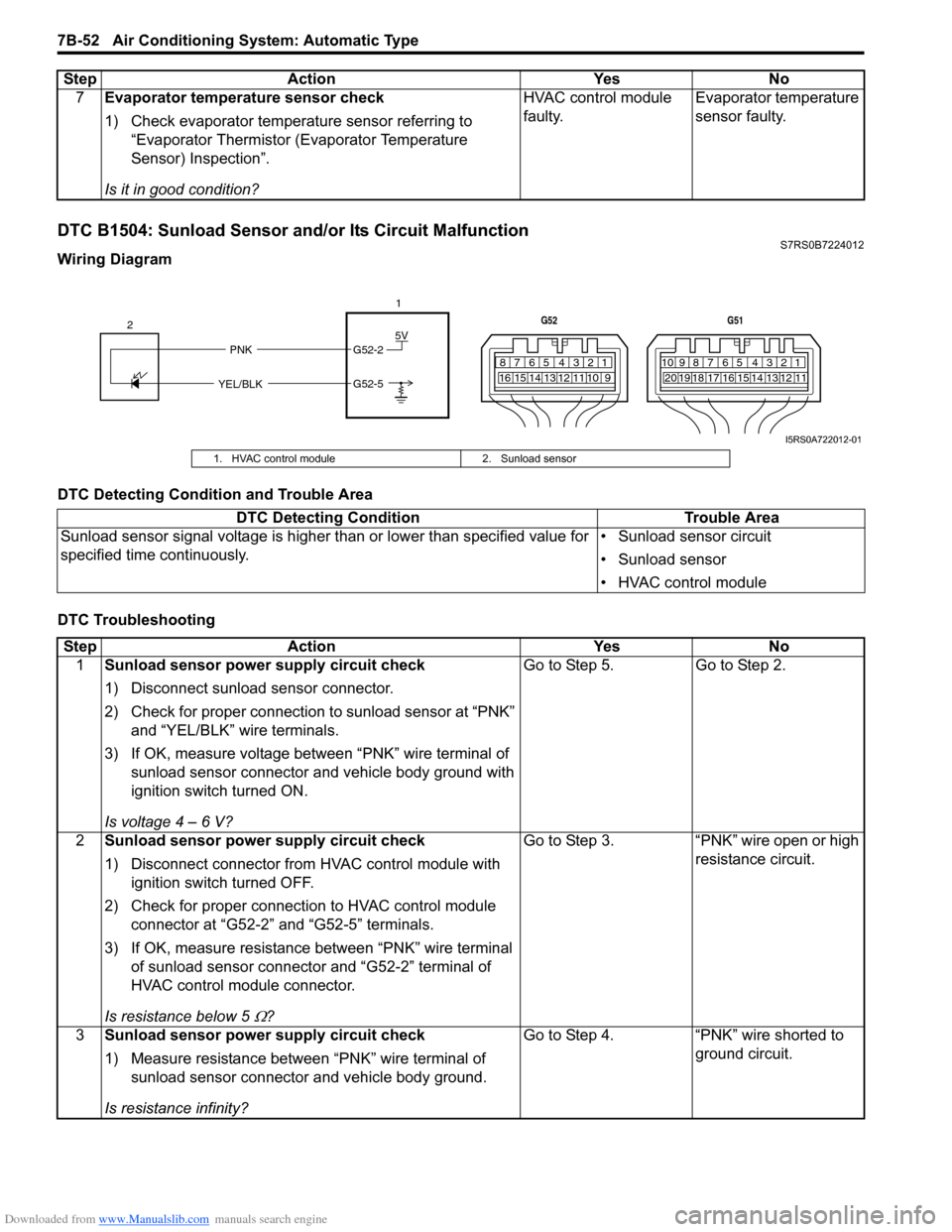

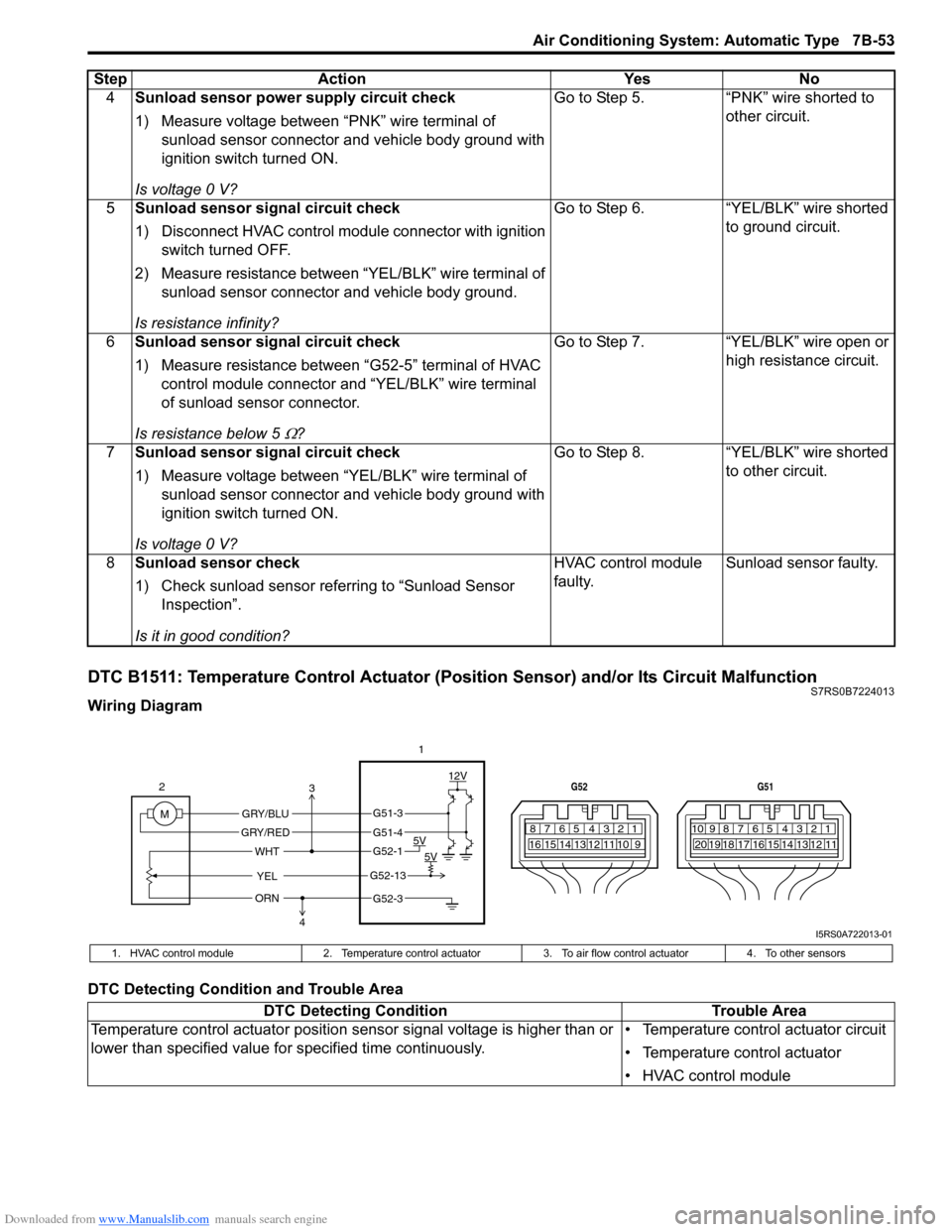

DTC B1511: Temperature Control Actuator (Position Sensor) and/or Its Circuit MalfunctionS7RS0B7224013

Wiring Diagram

DTC Detecting Condition and Trouble Area4

Sunload sensor power supply circuit check

1) Measure voltage between “PNK” wire terminal of

sunload sensor connector and vehicle body ground with

ignition switch turned ON.

Is voltage 0 V? Go to Step 5. “PNK” wire shorted to

other circuit.

5 Sunload sensor signal circuit check

1) Disconnect HVAC control modul e connector with ignition

switch turned OFF.

2) Measure resistance between “YEL/BLK” wire terminal of sunload sensor connector and vehicle body ground.

Is resistance infinity? Go to Step 6. “YEL/BLK” wire shorted

to ground circuit.

6 Sunload sensor signal circuit check

1) Measure resistance between “G52-5” terminal of HVAC

control module connector and “YEL/BLK” wire terminal

of sunload sensor connector.

Is resistance below 5

Ω? Go to Step 7. “YEL/BLK” wire open or

high resistance circuit.

7 Sunload sensor signal circuit check

1) Measure voltage between “YEL/BLK” wire terminal of

sunload sensor connector and vehicle body ground with

ignition switch turned ON.

Is voltage 0 V? Go to Step 8.

“YEL/BLK” wire shorted

to other circuit.

8 Sunload sensor check

1) Check sunload sensor referring to “Sunload Sensor

Inspection”.

Is it in good condition? HVAC control module

faulty.

Sunload sensor faulty.

Step

Action YesNo

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

M 12V

5V 5V

YEL

WHT

GRY/BLU

GRY/RED

2

1

ORN

G51-3

G51-4

G52-1

G52-13

G52-3

3

4

I5RS0A722013-01

1. HVAC control module 2. Temperature control actuator 3. To air flow control actuator4. To other sensors

DTC Detecting Condition Trouble Area

Temperature control actuator position sensor signal voltage is higher than or

lower than specified value for specified time continuously. • Temperature control actuator circuit

• Temperature control actuator

• HVAC control module

Page 1002 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-54 Air Conditioning System: Automatic Type

DTC TroubleshootingStep Action YesNo

1 Position sensor power supply circuit check

1) Disconnect temperature control actuator connector.

2) Check for proper connection to temperature control

actuator at “WHT”, “YEL” and “ORN” wire terminals.

3) If OK, measure voltage between “WHT” wire terminal of temperature control actuator connector and vehicle body

ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 2.

2 Position sensor power supply circuit check

1) Disconnect air flow control actuator connector with

ignition switch turned OFF.

2) Measure voltage between “WHT” wire terminal of temperature control actuator connector and vehicle body

ground with ignition switch turned ON.

Is voltage 4 – 6 V? Air flow control actuator

faulty.

Go to Step 3.

3 Position sensor power supply circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-1”, “G52-3” and “G52-13” terminals.

3) If OK, measure resistance between “WHT” wire terminal of temperature control actuator connector and “G52-1”

terminal of HVAC control module connector.

Is resistance below 5

Ω? Go to Step 4. “WHT” wire open or

high resistance circuit.

4 Position sensor power supply circuit check

1) Measure resistance between “WHT” wire terminal of

temperature control actuator connector and vehicle body

ground.

Is resistance infinity? Go to Step 5.

“WHT” wire shorted to

ground circuit.

5 Position sensor power supply circuit check

1) Measure voltage between “WHT” wire terminal of

temperature control actuator connector and vehicle body

ground with ignition switch turned ON.

Is voltage 0 V? Go to Step 6.

“WHT” wire shorted to

other circuit.

6 Position sensor signal circuit check

1) Connect HVAC control module connector with ignition

switch turned OFF.

2) Measure voltage between “YEL” wire terminal of temperature control actuator connector and vehicle body

ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 10. Go to Step 7.

7 Position sensor signal circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Measure resistance between “YEL” wire terminal of temperature control actuator connector and “G52-13”

terminal of HVAC control module connector.

Is resistance below 5

Ω? Go to Step 8. “YEL” wire open or high

resistance circuit.